Article contents

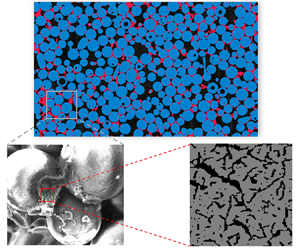

Image-based modelling of coke combustion in a multiscale porous medium using a micro-continuum framework

Published online by Cambridge University Press: 15 December 2021

Abstract

Non-isothermal reactive transport in complicated porous media is diverse in nature and industrial applications. There are challenges in the modelling of multiple physicochemical processes in multiscale pore structures with various length scales ranging from nanometres to micrometres. This study focuses on coke combustion during in situ crude oil combustion techniques. A micro-continuum model was developed to perform an image-based simulation of coke combustion through a multiscale porous medium. The simulation coupled weakly compressible gas flow, species transport, conjugate heat transfer, heterogeneous coke oxidation kinetics and structural evolution. The unresolved nanoporous coke region was treated as a continuum, for which the random pore model, permeability model and species diffusivity model were integrated as sub-grid models to account for the sub-resolution reactive surface area, Darcy flow and Knudsen diffusion, respectively. A Pe–Da diagram was provided to present five characteristic combustion regimes covering the ignition temperature and air flux in realistic field operations and laboratory measurements. The present model proved to achieve more accurate predictions of the feasible ignition temperature than previous models. Compared with the air flux of  $\phi \sim O\textrm{(1) s}{\textrm{m}^\textrm{3}}(\textrm{air})\;{({\textrm{m}^\textrm{2}}\ \textrm{h})^{ - 1}}$ in the field, the increasing air flux in the laboratory transformed the combustion regime from diffusion-limited to convection-limited, which led to an overpredicted burning temperature. Reactive fingering combustion was analysed to understand the potential risks in some experimental measurements. The findings provide a better understanding of coke combustion and can help engineers design sustainable combustion methods. The developed image-based model allows other types of multiscale and nonlinear reactive transport to be simulated.

$\phi \sim O\textrm{(1) s}{\textrm{m}^\textrm{3}}(\textrm{air})\;{({\textrm{m}^\textrm{2}}\ \textrm{h})^{ - 1}}$ in the field, the increasing air flux in the laboratory transformed the combustion regime from diffusion-limited to convection-limited, which led to an overpredicted burning temperature. Reactive fingering combustion was analysed to understand the potential risks in some experimental measurements. The findings provide a better understanding of coke combustion and can help engineers design sustainable combustion methods. The developed image-based model allows other types of multiscale and nonlinear reactive transport to be simulated.

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2021. Published by Cambridge University Press

References

- 11

- Cited by