1. Introduction

1.1. Competitive rowing

Competitive rowing is an Olympic sport where the differences between the winner and the runners up are very small, usually less than 1 s over a 2000 m race while a race typically lasts 6 min. Since finishing times are so close, small improvements of the hydrodynamic propulsion can have a large impact on the outcome of a race. The optimisation of the propulsion requires a good understanding of the oar blade motion and the flow field around the oar blade, with its corresponding hydrodynamic forces. In this study, we capture the oar blade kinematics during actual on-water rowing and then reproduce the (scaled) motion in a laboratory, which enables the use of advanced flow field measurement techniques, such as particle image velocimetry (PIV), together with simultaneous force measurements.

After the athlete inserts the oar blade in the water and exerts a force on the handle, the oar is pivoting on the oar lock and moves through the water, generating propulsion; this is called the drive phase. Throughout the drive phase the oar blade remains in a vertical position and at a constant depth with its top edge at the height of the otherwise unperturbed free surface. In this study it is assumed that the rowing motion and generated forces are in the horizontal plane (![]() $x$,

$x$,![]() $y$-plane), because (i) the kinematics during the drive phase are exclusively in this plane, and (ii) it is known that, during on-water rowing, athletes do not need to exert any (significant) vertical force on the oar handle to keep the oar blade at constant depth below the surface. This implies that the resultant force on the rowing oar blade is also solely in the

$y$-plane), because (i) the kinematics during the drive phase are exclusively in this plane, and (ii) it is known that, during on-water rowing, athletes do not need to exert any (significant) vertical force on the oar handle to keep the oar blade at constant depth below the surface. This implies that the resultant force on the rowing oar blade is also solely in the ![]() $x$,

$x$,![]() $y$-plane.

$y$-plane.

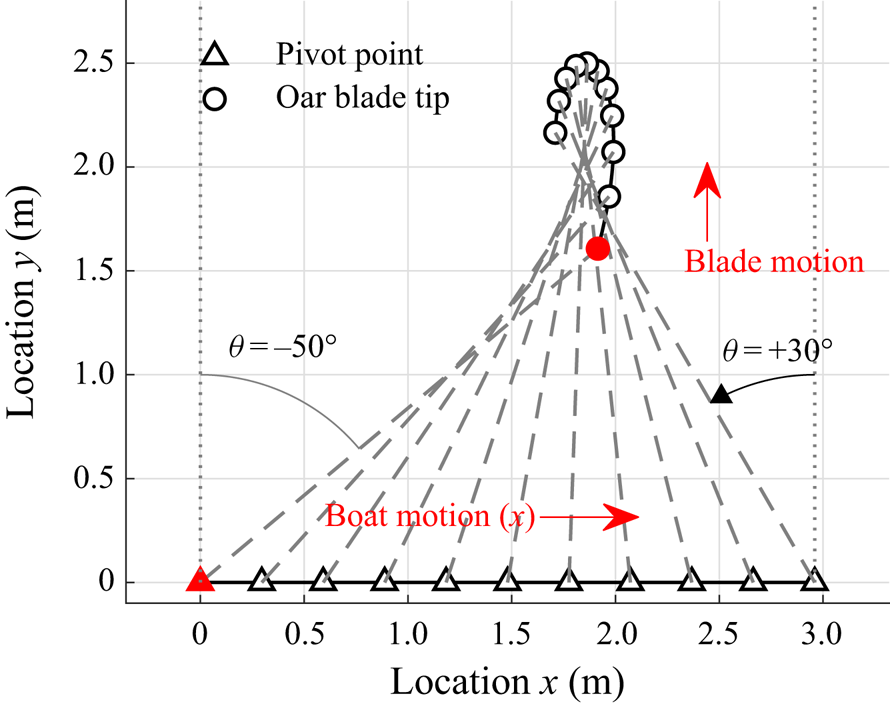

The oar blade path follows from the superposition of the pivoting motion of the oar on the motion of the pivot point, i.e. the boat motion, as illustrated in figure 1. In that figure, both the boat velocity and the angular velocity of the oar are taken constant, while in reality both vary in time. The positive ![]() $x$-direction is defined as the direction of the boat motion, the

$x$-direction is defined as the direction of the boat motion, the ![]() $y$-direction is perpendicular and outwards to that (away from the hull) in the horizontal plane, and the angle

$y$-direction is perpendicular and outwards to that (away from the hull) in the horizontal plane, and the angle ![]() $\theta$ defines the oar orientation, where

$\theta$ defines the oar orientation, where ![]() $\theta = 0^{\circ }$ is parallel to the

$\theta = 0^{\circ }$ is parallel to the ![]() $y$-direction. The oar angle

$y$-direction. The oar angle ![]() $\theta$ is defined positive in counter-clockwise direction, and thus increases from the catch, e.g.

$\theta$ is defined positive in counter-clockwise direction, and thus increases from the catch, e.g. ![]() $\theta = -50^{\circ }$, to the release, e.g.

$\theta = -50^{\circ }$, to the release, e.g. ![]() $\theta = 30^{\circ }$.

$\theta = 30^{\circ }$.

Figure 1. A generic oar blade path composed of the boat motion along a straight line (in the positive ![]() $x$-direction) and the rotation of the oar around a pivot point fixed to the boat (with

$x$-direction) and the rotation of the oar around a pivot point fixed to the boat (with ![]() $\theta = 0^{\circ }$ corresponding to a position of the oar perpendicular to the boat motion). For simplicity, both the angular velocity and the boat velocity are taken as constant for this generic path with

$\theta = 0^{\circ }$ corresponding to a position of the oar perpendicular to the boat motion). For simplicity, both the angular velocity and the boat velocity are taken as constant for this generic path with ![]() $V_{boat} = 3.7\ \textrm {m}\ \textrm {s}^{-1}$ and

$V_{boat} = 3.7\ \textrm {m}\ \textrm {s}^{-1}$ and ![]() $\dot {\theta } = 100^{\circ }\ \textrm {s}^{-1}$. The grey dashed lines represent the oar orientation, and the open spheres mark the oar blade tip. The oar blade tip moves in the positive

$\dot {\theta } = 100^{\circ }\ \textrm {s}^{-1}$. The grey dashed lines represent the oar orientation, and the open spheres mark the oar blade tip. The oar blade tip moves in the positive ![]() $y$-direction at the catch (red marker) and in the negative

$y$-direction at the catch (red marker) and in the negative ![]() $y$-direction during the last part of the stroke.

$y$-direction during the last part of the stroke.

1.2. Previous research on rowing

The hydrodynamics of a steady flow over an oar blade has been investigated both numerically and experimentally by Caplan & Gardner (Reference Caplan and Gardner2007) and Coppel et al. (Reference Coppel, Gardner, Caplan and Hargreaves2010), but neither account for the presence of a free surface, nor do they account for the accelerations and decelerations of the oar blade, or the strong curvature of the blade path. In the works of Sliasas & Tullis (Reference Sliasas and Tullis2009), Leroyer et al. (Reference Leroyer, Barré, Kobus and Visonneau2010) and Robert et al. (Reference Robert, Leroyer, Barré, Rongère, Queutey and Visonneau2014), the unsteady motion of the oar blade was incorporated in their numerical simulations using commercial software. They all found that the results for unsteady flow differed substantially from steady flow over an oar blade. In the work by Robert et al. (Reference Robert, Leroyer, Barré, Rongère, Queutey and Visonneau2014) the results are benchmarked against unsteady experimental work by Barré & Kobus (Reference Barré and Kobus2010) and were found to match reasonably well only when the free surface and unsteady motion of the oar blade were incorporated. Also, it should be noted that the rowing motion in the benchmark was strongly simplified, with the most important simplification being the absence of a catch and release, i.e. the rowing oar blade was kept submerged during both the drive and recovery phases such that consecutive strokes were no longer hydrodynamically independent. One of the most advanced measurement of the forces acting on a rowing blade was carried out by Hofmijster, Koning & Soest (Reference Hofmijster, De Koning and Van Soest2010) who carried out on-water force measurements. Due to technical limitations they were unable to validate their assumption regarding the point of application of the hydrodynamic forces acting on the blade, which was needed for the calculation of the efficiency of the rowing motion. Extensive field measurements have also been carried out by Kleshnev (Reference Kleshnev2016), with a strong focus on the biomechanics of rowing. Labbé et al. (Reference Labbé, Boucher, Clanet and Benzaquen2019) investigated the optimal oar characteristics, e.g. the optimal inboard and outboard length of the oar, by use of a theoretical model and a model rowing boat with four ‘robot rowers’, i.e. pulley–mass systems that provide a constant force during the propulsive phase. However, in none of these experimental studies was the actual flow around the oar blade investigated.

The accurate numerical simulation of the flow around a rowing oar blade is difficult because of the high Reynolds number, ![]() $Re \approx \mathcal {O}(10^5)\text {--}\mathcal {O}(10^6)$, the presence of a free surface, the complex path of the oar blade during the drive phase with large accelerations and decelerations (up to

$Re \approx \mathcal {O}(10^5)\text {--}\mathcal {O}(10^6)$, the presence of a free surface, the complex path of the oar blade during the drive phase with large accelerations and decelerations (up to ![]() $10\ \textrm {m}\ \textrm {s}^{-2}$) and the lack of a suitable turbulence model for the strongly anisotropic flow. Experimental work in a laboratory environment is difficult mainly because the oar blade moves fast along a complex path that is difficult to replicate, especially due to the large accelerations and decelerations. Although the oar blade force can be measured during actual on-water rowing, investigating the flow field outside a laboratory environment using advanced techniques, such as particle image velocimetry (PIV), is extremely challenging. Also, it is evident that the focus of most rowing research is on the measurement of forces and not on flow field phenomena that play a role in the propulsion in rowing, which is the subject of this study.

$10\ \textrm {m}\ \textrm {s}^{-2}$) and the lack of a suitable turbulence model for the strongly anisotropic flow. Experimental work in a laboratory environment is difficult mainly because the oar blade moves fast along a complex path that is difficult to replicate, especially due to the large accelerations and decelerations. Although the oar blade force can be measured during actual on-water rowing, investigating the flow field outside a laboratory environment using advanced techniques, such as particle image velocimetry (PIV), is extremely challenging. Also, it is evident that the focus of most rowing research is on the measurement of forces and not on flow field phenomena that play a role in the propulsion in rowing, which is the subject of this study.

The objective of this study is to provide insights into the flow field around a rowing oar blade that can be used to improve rowing performance. The flow field around a realistic oar blade and for realistic rowing motion is determined through PIV. With force measurements performed simultaneously with the PIV, the flow phenomena that generate propulsion during the drive phase are identified.

1.3. Hydrodynamic forces

The oar blade moving along its path can be considered as a plate-like geometry at a varying angle of attack ![]() $\alpha$, as defined in figure 2. For (quasi-) steady flow, the hydrodynamic force acting on the oar blade can be decomposed in a lift force component

$\alpha$, as defined in figure 2. For (quasi-) steady flow, the hydrodynamic force acting on the oar blade can be decomposed in a lift force component ![]() $F_L$ and the drag force component

$F_L$ and the drag force component ![]() $F_D$ defined as

$F_D$ defined as

where ![]() $\rho$ is the fluid density,

$\rho$ is the fluid density, ![]() $|V|$ is the velocity magnitude of the incoming flow,

$|V|$ is the velocity magnitude of the incoming flow, ![]() $A$ is the oar blade surface area based on its major length scales

$A$ is the oar blade surface area based on its major length scales ![]() $l_a$ and

$l_a$ and ![]() $l_b$ (see figure 6) and

$l_b$ (see figure 6) and ![]() $C_D$ and

$C_D$ and ![]() $C_L$ are the drag and lift coefficients, respectively. Under steady conditions for sufficiently high

$C_L$ are the drag and lift coefficients, respectively. Under steady conditions for sufficiently high ![]() $Re$, the drag coefficient is independent of

$Re$, the drag coefficient is independent of ![]() $Re$. Both the lift and drag coefficients vary with the angle of attack

$Re$. Both the lift and drag coefficients vary with the angle of attack ![]() $\alpha$. The lift coefficient

$\alpha$. The lift coefficient ![]() $C_L$ increases with angle of attack

$C_L$ increases with angle of attack ![]() $\alpha$ to a maximum. For still larger angles of attack the lift decreases due to massive flow separation, which is called stall (Anderson Reference Anderson1991).

$\alpha$ to a maximum. For still larger angles of attack the lift decreases due to massive flow separation, which is called stall (Anderson Reference Anderson1991).

Figure 2. The blade (solid black line) moving along the path (solid grey line) from ‘catch’ towards the ‘release’ in the direction illustrated by the path tangential line (dash-dotted grey) at an angle of attack ![]() $\alpha$, i.e. the angle between the path tangent and the oar blade that is at an orientation

$\alpha$, i.e. the angle between the path tangent and the oar blade that is at an orientation ![]() $\theta$. The blade normal vector

$\theta$. The blade normal vector ![]() $\boldsymbol {n}$ and blade tangential vector

$\boldsymbol {n}$ and blade tangential vector ![]() $\boldsymbol {t}$ are indicated in light grey. The hydrodynamic force on the oar blade

$\boldsymbol {t}$ are indicated in light grey. The hydrodynamic force on the oar blade ![]() $\boldsymbol {F}$ (magenta) is measured as a component tangential to the blade

$\boldsymbol {F}$ (magenta) is measured as a component tangential to the blade ![]() $F_t$ and normal to the blade

$F_t$ and normal to the blade ![]() $F_n$ (red). The measured force can also be decomposed into a propulsive component

$F_n$ (red). The measured force can also be decomposed into a propulsive component ![]() $F_x$ and a non-propulsive component

$F_x$ and a non-propulsive component ![]() $F_y$ (green) that are defined parallel to the

$F_y$ (green) that are defined parallel to the ![]() $x$-direction and

$x$-direction and ![]() $y$-direction, respectively. Alternatively, the hydrodynamic force can be decomposed in a lift component

$y$-direction, respectively. Alternatively, the hydrodynamic force can be decomposed in a lift component ![]() $F_L$ and a drag component

$F_L$ and a drag component ![]() $F_D$ (blue), defined perpendicular and opposed to the direction of motion, respectively.

$F_D$ (blue), defined perpendicular and opposed to the direction of motion, respectively.

Previous research by Caplan & Gardner (Reference Caplan and Gardner2007) and Coppel et al. (Reference Coppel, Gardner, Caplan and Hargreaves2010) showed that considering the flow around the oar blade as steady or quasi-steady does not produce realistic results. Studies on unsteady hydrodynamics indeed show that both the lift and drag can be strongly increased by an unsteady motion of the object in the flow. An acceleration of the object enhances the hydrodynamic drag through the mechanism of added mass, as described by Yu (Reference Yu1945) and Patton (Reference Patton1965) for flat plates. The increase in drag on the object is even larger for accelerations over longer durations due to the formation of trailing vortical structures, as described by e.g. Pullin & Wang (Reference Pullin and Wang2004), Ringuette, Milano & Gharib (Reference Ringuette, Milano and Gharib2007), Xu & Nitsche (Reference Xu and Nitsche2015) and Grift et al. (Reference Grift, Vijayaragavan, Tummers and Westerweel2019).

The increase of lift due to an acceleration of a plate-like geometry is described extensively in various studies, e.g. by Dickinson & Götz (Reference Dickinson and Götz1993) or Birch & Dickinson (Reference Birch and Dickinson2001), who both investigated insect flight, where the lift through unsteady wing beating is larger than the lift determined from steady flow analysis. A dominant mechanism in the observed lift increase is the occurrence of a leading-edge vortex (LEV). An excellent overview of the mechanics and modelling of LEVs is given by Eldredge & Jones (Reference Eldredge and Jones2019), where leading-edge vortices are investigated for a variety of plate kinematics at varying angles of attack, e.g. impulsively started plates, translational pitching plates and rotating plates.

It is interesting that the studies on unsteady drag and the studies on unsteady lift produce very similar force profiles for accelerating plates. Also, these studies adopt the same dimensionless time, which is effectively the number of characteristics lengths travelled by the object. Eldredge & Jones (Reference Eldredge and Jones2019) refer to this as the time measured in convective time units, while Gharib, Rambod & Shariff (Reference Gharib, Rambod and Shariff1998) and Grift et al. (Reference Grift, Vijayaragavan, Tummers and Westerweel2019) refer to it as the dimensionless formation time. The work by Eldredge & Jones (Reference Eldredge and Jones2019) on LEVs is limited to a maximum angle of attack of ![]() $45^{\circ }$, and the normal plates studied, e.g. by Gharib et al. (Reference Gharib, Rambod and Shariff1998) and Grift et al. (Reference Grift, Vijayaragavan, Tummers and Westerweel2019), are (obviously) limited to a

$45^{\circ }$, and the normal plates studied, e.g. by Gharib et al. (Reference Gharib, Rambod and Shariff1998) and Grift et al. (Reference Grift, Vijayaragavan, Tummers and Westerweel2019), are (obviously) limited to a ![]() $90^{\circ }$ angle of attack.

$90^{\circ }$ angle of attack.

1.4. Decomposition of the hydrodynamic force

Figure 2 illustrates the decompositions of the measured hydrodynamic force on the oar blade that are used throughout this study. The force on the oar blade is measured as the normal component ![]() $F_n$ and tangential component

$F_n$ and tangential component ![]() $F_t$ relative to the rowing oar blade. To investigate the propulsion we also define

$F_t$ relative to the rowing oar blade. To investigate the propulsion we also define ![]() $F_x$ as the propulsive component of the hydrodynamic force in the

$F_x$ as the propulsive component of the hydrodynamic force in the ![]() $x$-direction, i.e. the direction of the boat motion, and the non-propulsive component

$x$-direction, i.e. the direction of the boat motion, and the non-propulsive component ![]() $F_y$ that is perpendicular to

$F_y$ that is perpendicular to ![]() $F_x$ and directed in the positive

$F_x$ and directed in the positive ![]() $y$-direction. To decompose the hydrodynamic force in a lift component

$y$-direction. To decompose the hydrodynamic force in a lift component ![]() $F_L$ and a drag component

$F_L$ and a drag component ![]() $F_D$ it is necessary to define a proper reference velocity. This is not trivial, since the oar blade is not only translated in the

$F_D$ it is necessary to define a proper reference velocity. This is not trivial, since the oar blade is not only translated in the ![]() $x$,

$x$,![]() $y$-plane, but it is also rotated in this plane. Therefore, a single point on the blade is chosen to define a single flow velocity. We have chosen the blade tip as reference location, since, based on the kinematics, it is expected that a LEV will be formed at the blade tip during the first part of the drive phase when the blade moves sideways under quite a large angle of attack

$y$-plane, but it is also rotated in this plane. Therefore, a single point on the blade is chosen to define a single flow velocity. We have chosen the blade tip as reference location, since, based on the kinematics, it is expected that a LEV will be formed at the blade tip during the first part of the drive phase when the blade moves sideways under quite a large angle of attack ![]() $\alpha$, as shown in figure 2. In this figure, the solid grey line represents the path of the blade tip. The drag

$\alpha$, as shown in figure 2. In this figure, the solid grey line represents the path of the blade tip. The drag ![]() $F_D$ is defined opposite to the motion of the blade tip and the lift

$F_D$ is defined opposite to the motion of the blade tip and the lift ![]() $F_L$ is perpendicular to

$F_L$ is perpendicular to ![]() $F_D$. The angle of attack

$F_D$. The angle of attack ![]() $\alpha$ is defined as the angle between the chord line of the blade and the tangent of the trajectory of the blade tip, as shown in figure 2. The mathematical relations describing the two decompositions then become

$\alpha$ is defined as the angle between the chord line of the blade and the tangent of the trajectory of the blade tip, as shown in figure 2. The mathematical relations describing the two decompositions then become

\begin{equation} \left.\begin{gathered} F_x = F_n \cos{\theta} - F_t \sin{\theta} \quad{\textrm{and}} \quad F_y = F_n \sin{\theta} + F_t \cos{\theta}\\ F_L = F_n\cos{\alpha} - F_t \sin{\alpha} \quad{\textrm{and}} \quad F_D = F_n \sin{\alpha} + F_t \cos{\alpha}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} F_x = F_n \cos{\theta} - F_t \sin{\theta} \quad{\textrm{and}} \quad F_y = F_n \sin{\theta} + F_t \cos{\theta}\\ F_L = F_n\cos{\alpha} - F_t \sin{\alpha} \quad{\textrm{and}} \quad F_D = F_n \sin{\alpha} + F_t \cos{\alpha}. \end{gathered}\right\} \end{equation}1.5. Definition of efficiency and effectiveness

Two aspects of the drive are considered to characterise the performance of the rowing motion: effectiveness and efficiency. The propulsion that is generated during the drive is the total change in momentum in the ![]() $x$-direction, i.e. the change in the

$x$-direction, i.e. the change in the ![]() $x$-component of the impulse vector

$x$-component of the impulse vector ![]() $\boldsymbol {J}$ that is defined as

$\boldsymbol {J}$ that is defined as

where ![]() $t_{catch}$ and

$t_{catch}$ and ![]() $t_{release}$ are the times when the oar blade enters and leaves the water, respectively, and

$t_{release}$ are the times when the oar blade enters and leaves the water, respectively, and ![]() $\boldsymbol {F}$ is the hydrodynamic force vector that can be decomposed into a propulsive component

$\boldsymbol {F}$ is the hydrodynamic force vector that can be decomposed into a propulsive component ![]() $F_x$ and a non-propulsive component

$F_x$ and a non-propulsive component ![]() $F_y$. The effectiveness of the propulsion is defined as

$F_y$. The effectiveness of the propulsion is defined as ![]() $J_x$, i.e. the component of the impulse in the

$J_x$, i.e. the component of the impulse in the ![]() $x$-direction.

$x$-direction.

For the athlete the cost of generating propulsion is the total energy spent (work performed) during the drive phase. Therefore, it is interesting to define an efficiency in terms of propulsion per unit energy. Since both the kinematics of the oar blade (translation ![]() $\boldsymbol {V}$ and rotation

$\boldsymbol {V}$ and rotation ![]() $\dot {\boldsymbol {\theta }}$) as well as the hydrodynamic force

$\dot {\boldsymbol {\theta }}$) as well as the hydrodynamic force ![]() $\boldsymbol {F}$ and moment

$\boldsymbol {F}$ and moment ![]() $\boldsymbol {M}$ are known from the measurements, the instantaneous power

$\boldsymbol {M}$ are known from the measurements, the instantaneous power ![]() $P$ can be defined as

$P$ can be defined as

and the total energy spent (work performed) ![]() $E$ during the drive then becomes

$E$ during the drive then becomes

The energetic efficiency can now be defined as the ratio of the effectiveness ![]() $J_x$ and the energy

$J_x$ and the energy ![]() $E$ as in

$E$ as in

Note that this quantity is not dimensionless and has the dimension of ![]() $\textrm {s}\ \textrm {m}^{-1}$, i.e. a reciprocal of velocity. Multiplication of

$\textrm {s}\ \textrm {m}^{-1}$, i.e. a reciprocal of velocity. Multiplication of ![]() $\eta _E$ by a reference velocity would yield a dimensionless quantity. However, within the scope of this study we did not find a meaningful reference velocity that led to a dimensionless energetic efficiency that provides more insight than the dimensional energetic efficiency defined in (1.6). When discussing various configurations to optimise the rowing performance, the energetic efficiency is non-dimensionalised with the energetic efficiency of a ‘base case’, as defined in § 4.6.2.

$\eta _E$ by a reference velocity would yield a dimensionless quantity. However, within the scope of this study we did not find a meaningful reference velocity that led to a dimensionless energetic efficiency that provides more insight than the dimensional energetic efficiency defined in (1.6). When discussing various configurations to optimise the rowing performance, the energetic efficiency is non-dimensionalised with the energetic efficiency of a ‘base case’, as defined in § 4.6.2.

Another approach to quantifying the efficiency of rowing is to determine the degree to which the impulse ![]() $\boldsymbol {J}$ is in the desired direction for propulsion, i.e. in the

$\boldsymbol {J}$ is in the desired direction for propulsion, i.e. in the ![]() $x$-direction. The impulse efficiency

$x$-direction. The impulse efficiency ![]() $\eta _J$ is defined as the alignment of the impulse vector with the

$\eta _J$ is defined as the alignment of the impulse vector with the ![]() $x$-direction

$x$-direction

with ![]() $0 < \eta _J < 1$, where

$0 < \eta _J < 1$, where ![]() $\eta _J = 1$ indicates that the impulse vector is directed in the propulsive direction, and

$\eta _J = 1$ indicates that the impulse vector is directed in the propulsive direction, and ![]() $\eta _J = 0$ indicates that the impulse vector is directed perpendicular to that, i.e. not contributing to propulsion at all. Alternatively, one could use the angle

$\eta _J = 0$ indicates that the impulse vector is directed perpendicular to that, i.e. not contributing to propulsion at all. Alternatively, one could use the angle ![]() $\phi _J$ between the impulse vector

$\phi _J$ between the impulse vector ![]() $\boldsymbol {J}$ and the propulsive direction

$\boldsymbol {J}$ and the propulsive direction ![]() $x$ as a measure of efficiency

$x$ as a measure of efficiency

2. Oar blade kinematics

2.1. Kinematics by image analysis of on-water rowing

To determine the oar blade kinematics, a rowing boat passing underneath a bridge is filmed from atop of the bridge. The camera (GoPro Hero 5 black) is aimed downwards, perpendicular to the water surface, and ![]() $1920 \times 1080$ pixel images are recorded at a rate of 120 frames per second (f.p.s.). The oar blade kinematics are obtained by tracking markers on the oar using a correlation-based algorithm. The markers on the oar also serve as a calibration target to transform the recorded kinematics from the image domain (pixels) to the physical domain (metres).

$1920 \times 1080$ pixel images are recorded at a rate of 120 frames per second (f.p.s.). The oar blade kinematics are obtained by tracking markers on the oar using a correlation-based algorithm. The markers on the oar also serve as a calibration target to transform the recorded kinematics from the image domain (pixels) to the physical domain (metres).

The lens distortion is removed from the captured images by using the commercial software MATLAB 2018B, which has a built-in chequerboard calibration and fish-eye model based on the model proposed by Urban, Leitloff & Hinz (Reference Urban, Leitloff and Hinz2015). The oar blade kinematics are then obtained by using a template-based image correlation similar to that proposed by van Houwelingen et al. (Reference van Houwelingen, Antwerpen, Holten, Grift, Westerweel and Clercx2018). The oar blade path is captured with a resolution of 4.2 mm in the physical plane, while the algorithm uses sub-pixel accurate correlation through peak fitting (Adrian & Westerweel Reference Adrian and Westerweel2011). The oar blade path is determined as a function of time based on the marker locations in each captured frame. A typical result is shown in figure 3. The start and end of the drive phase are determined by visual inspection of the captured images.

Figure 3. The path of the oar blade tip (solid blue line) during the drive of a men's coxless four (M4![]() $-$) from catch to release at equidistant times. Images were acquired by filming from a fixed position on a bridge viewing vertically downward.

$-$) from catch to release at equidistant times. Images were acquired by filming from a fixed position on a bridge viewing vertically downward.

The kinematics of an oar blade are determined for three scenarios: a men's coxless four (M4![]() $-$) at race pace (36 strokes per minute) and at ‘standard’ pace (20 strokes per minute), i.e. the pace that can be maintained for a long time without getting exhausted, under neutral weather conditions, and a men's coxed four (M4

$-$) at race pace (36 strokes per minute) and at ‘standard’ pace (20 strokes per minute), i.e. the pace that can be maintained for a long time without getting exhausted, under neutral weather conditions, and a men's coxed four (M4![]() $+$) at standard pace with strong head wind (4–5 Bft). Both the M4

$+$) at standard pace with strong head wind (4–5 Bft). Both the M4![]() $+$ and M4

$+$ and M4![]() $-$ have an athlete set-up from bow to stroke (the athlete closest to the stern): port, starboard, port, starboard. Also, currents were not observed, i.e. duckweed on the water was practically stationary. The kinematics of the athlete on port closest to stern were captured. Typical boat velocities are 4, 4.5 and

$-$ have an athlete set-up from bow to stroke (the athlete closest to the stern): port, starboard, port, starboard. Also, currents were not observed, i.e. duckweed on the water was practically stationary. The kinematics of the athlete on port closest to stern were captured. Typical boat velocities are 4, 4.5 and ![]() $5\ \textrm {m}\ \textrm {s}^{-1}$ for the M4

$5\ \textrm {m}\ \textrm {s}^{-1}$ for the M4![]() $+$, M4

$+$, M4![]() $-$ at standard pace, and the M4

$-$ at standard pace, and the M4![]() $-$ at race pace, respectively. All participants are considered experienced elite rowers and the resulting oar blade paths are shown in figure 4. In all three scenarios the blade enters the water with its tip at the location

$-$ at race pace, respectively. All participants are considered experienced elite rowers and the resulting oar blade paths are shown in figure 4. In all three scenarios the blade enters the water with its tip at the location ![]() $x = 0$,

$x = 0$, ![]() $y = 0$, after which the blade moves along the path and rotates counter-clockwise. The obtained path data are dependent on many factors such as weather conditions, boat type, currents, athlete skill level, team composition, etc. Path data are also presented by Kleshnev (Reference Kleshnev1999). Those results are subject to differences due to the factors mentioned above and in addition are also measured differently than in the current study. Instead of a visual method (video), Kleshnev (Reference Kleshnev1999) reconstructs the blade path based on the oar angle and boat velocity. Also, the way that the catch and release are determined by Kleshnev (Reference Kleshnev1999) differs from the current study as the reversal of the oar direction is used as indicator and not the actual entering and exiting the water of the blade. This results in the catch being estimated to early during the stroke cycle and the release too late in the stroke cycle, so that Kleshnev (Reference Kleshnev1999) overestimates the actual blade path, resulting in a longer blade path than in this study. The results from Kleshnev (Reference Kleshnev1999) and this study are compared in figure 4(a). Taking the leading edge of the blade as point of reference, both the obtained data and data from Kleshnev (Reference Kleshnev1999) show that the oar blade path spans approximately

$y = 0$, after which the blade moves along the path and rotates counter-clockwise. The obtained path data are dependent on many factors such as weather conditions, boat type, currents, athlete skill level, team composition, etc. Path data are also presented by Kleshnev (Reference Kleshnev1999). Those results are subject to differences due to the factors mentioned above and in addition are also measured differently than in the current study. Instead of a visual method (video), Kleshnev (Reference Kleshnev1999) reconstructs the blade path based on the oar angle and boat velocity. Also, the way that the catch and release are determined by Kleshnev (Reference Kleshnev1999) differs from the current study as the reversal of the oar direction is used as indicator and not the actual entering and exiting the water of the blade. This results in the catch being estimated to early during the stroke cycle and the release too late in the stroke cycle, so that Kleshnev (Reference Kleshnev1999) overestimates the actual blade path, resulting in a longer blade path than in this study. The results from Kleshnev (Reference Kleshnev1999) and this study are compared in figure 4(a). Taking the leading edge of the blade as point of reference, both the obtained data and data from Kleshnev (Reference Kleshnev1999) show that the oar blade path spans approximately ![]() $1\ \textrm {m}^2$ and show that a typical slip, i.e. the distance the oar blade travels through the water in the negative

$1\ \textrm {m}^2$ and show that a typical slip, i.e. the distance the oar blade travels through the water in the negative ![]() $x$-direction (opposed to the boat motion), is approximately one blade width (0.5 m). Figure 4(b) shows that, for all scenarios, the catch occurs at

$x$-direction (opposed to the boat motion), is approximately one blade width (0.5 m). Figure 4(b) shows that, for all scenarios, the catch occurs at ![]() $\theta \approx -50^{\circ }$ and the oar angle increases approximately linear over time. The release angle varies in the range

$\theta \approx -50^{\circ }$ and the oar angle increases approximately linear over time. The release angle varies in the range ![]() $\theta \approx 25^{\circ }$ for the slowest boat (M4

$\theta \approx 25^{\circ }$ for the slowest boat (M4![]() $+$, head wind) and

$+$, head wind) and ![]() $\theta \approx 30^{\circ }$ for the fastest boat (M4

$\theta \approx 30^{\circ }$ for the fastest boat (M4![]() $-$, race). Also a clear difference in slip is observed. The slip is largest for the slowest scenario, the M4

$-$, race). Also a clear difference in slip is observed. The slip is largest for the slowest scenario, the M4![]() $+$ with head wind (3–4 Bft), and smallest for the fastest scenario, the M4

$+$ with head wind (3–4 Bft), and smallest for the fastest scenario, the M4![]() $-$ at race pace, see figure 4(a).

$-$ at race pace, see figure 4(a).

Figure 4. (a) The oar blade paths for a men's coxed four (M4![]() $+$) with head wind (dashed line), and for a men's coxless four (M4

$+$) with head wind (dashed line), and for a men's coxless four (M4![]() $-$) at race pace (dotted line) and standard pace (solid line). For comparison, the blade path reported by Kleshnev (Reference Kleshnev1999) is shown (grey dashed line). It overestimates the actual path length due to the used method, i.e. reconstruction via the oar angle and boat velocity. (b) The oar angle

$-$) at race pace (dotted line) and standard pace (solid line). For comparison, the blade path reported by Kleshnev (Reference Kleshnev1999) is shown (grey dashed line). It overestimates the actual path length due to the used method, i.e. reconstruction via the oar angle and boat velocity. (b) The oar angle ![]() $\theta$ as a function of time

$\theta$ as a function of time ![]() $t$ during the drive phase. The release angle decreases for faster boats (dashed grey line).

$t$ during the drive phase. The release angle decreases for faster boats (dashed grey line).

The kinematics of the M4![]() $-$ at standard pace were chosen for further analysis, since its velocity and acceleration, scaled down for use in the laboratory, as discussed in § 3.2, are within the operating range of our experimental set-up, see § 3 for details. The chosen kinematics lay in between the kinematics of the other two more extreme scenarios and are thought to be representative of a variety of rowing strokes.

$-$ at standard pace were chosen for further analysis, since its velocity and acceleration, scaled down for use in the laboratory, as discussed in § 3.2, are within the operating range of our experimental set-up, see § 3 for details. The chosen kinematics lay in between the kinematics of the other two more extreme scenarios and are thought to be representative of a variety of rowing strokes.

3. Experimental set-up

The experimental set-up used in this study is essentially the same set-up used by Grift et al. (Reference Grift, Vijayaragavan, Tummers and Westerweel2019) with some minor adaptations. The oar blade kinematics are reproduced in the experimental set-up (see figure 5) using a 1 : 2 scale model of the oar blade attached to a force/torque transducer (ATI 6-DOF with a sample rate of 10 kHz) via a cylindrical strut (with a circular cross-section). The strut pierces the free surface and the top of the oar blade coincides with the free surface when the latter is unperturbed. The robot arm (Reis Robitics RL50), which holds the blade via the strut at its trailing edge, moves the blade along the path with its four degrees of freedom: translation in ![]() $x$-,

$x$-, ![]() $y$- and

$y$- and ![]() $z$-direction, and rotation

$z$-direction, and rotation ![]() $\theta$ around the

$\theta$ around the ![]() $z$-axis. The motion is the

$z$-axis. The motion is the ![]() $z$-direction is used to realise the catch and release of the oar blade. The strut holds the blade at the same point as that the oar shaft holds the blade during actual on-water rowing, with the cylindrical strut centre coinciding with the vertical dashed line indicated in figure 6. The cylindrical strut can hinge around its axis and can be fixed at various oar blade angles

$z$-direction is used to realise the catch and release of the oar blade. The strut holds the blade at the same point as that the oar shaft holds the blade during actual on-water rowing, with the cylindrical strut centre coinciding with the vertical dashed line indicated in figure 6. The cylindrical strut can hinge around its axis and can be fixed at various oar blade angles ![]() $\beta$ by tightening a bolt at the top of the cylinder. The robot position is sampled at a default rate of 92 Hz with a resolution of

$\beta$ by tightening a bolt at the top of the cylinder. The robot position is sampled at a default rate of 92 Hz with a resolution of ![]() $1\ \mathrm {\mu }\textrm {m}$ and is repeatable within 0.1 mm, which is small with respect to the typical dimensions of the oar blade and its path. It is assumed that the hydrodynamic force on the strut is negligible (based on a much smaller strut frontal area

$1\ \mathrm {\mu }\textrm {m}$ and is repeatable within 0.1 mm, which is small with respect to the typical dimensions of the oar blade and its path. It is assumed that the hydrodynamic force on the strut is negligible (based on a much smaller strut frontal area ![]() ${\approx }10^{-4}\ \textrm {m}^2$ compared with the blade area

${\approx }10^{-4}\ \textrm {m}^2$ compared with the blade area ![]() ${\approx }0.02\ \textrm {m}^2$, while the drag coefficients are of the same order of magnitude). The force due to the inertia of the strut and blade are not negligible. To isolate the force due to the fluid flow from the measured force, each experiment was performed in both water and air and the measured force in air was subsequently subtracted from the measured force in water.

${\approx }0.02\ \textrm {m}^2$, while the drag coefficients are of the same order of magnitude). The force due to the inertia of the strut and blade are not negligible. To isolate the force due to the fluid flow from the measured force, each experiment was performed in both water and air and the measured force in air was subsequently subtracted from the measured force in water.

Figure 5. (a) Experimental set-up with the robot arm holding the oar blade just below the free surface via a force/torque (![]() $F/T$) transducer and a strut. (b) Light sheets from opposite sides illuminate the tracer particles in the field of view to avoid shadows due to the opaque oar blade. The PIV camera is positioned underneath the tank and captures images via a

$F/T$) transducer and a strut. (b) Light sheets from opposite sides illuminate the tracer particles in the field of view to avoid shadows due to the opaque oar blade. The PIV camera is positioned underneath the tank and captures images via a ![]() $45^{\circ }$ mirror. The robot arm, which holds the blade via the strut at its trailing edge, moves the blade along the path with its four degrees of freedom: translation in

$45^{\circ }$ mirror. The robot arm, which holds the blade via the strut at its trailing edge, moves the blade along the path with its four degrees of freedom: translation in ![]() $x$-,

$x$-, ![]() $y$- and

$y$- and ![]() $z$-direction, and rotation

$z$-direction, and rotation ![]() $\theta$ around the

$\theta$ around the ![]() $z$-axis.

$z$-axis.

Figure 6. (a) Front view of the oar blade model with blade width ![]() $l_a = 275\ \textrm {mm}$, and blade height

$l_a = 275\ \textrm {mm}$, and blade height ![]() $l_b = 125\ \textrm {mm}$. The light sheet for the PIV measurements is located at blade half-height. The angle at which the oar is attached to the blade can be adjusted through the blade angle

$l_b = 125\ \textrm {mm}$. The light sheet for the PIV measurements is located at blade half-height. The angle at which the oar is attached to the blade can be adjusted through the blade angle ![]() $\beta$. The axis of rotation, which is also where the strut holds the oar blade, is perpendicular to the

$\beta$. The axis of rotation, which is also where the strut holds the oar blade, is perpendicular to the ![]() $x$,

$x$,![]() $y$ plane and

$y$ plane and ![]() $\beta = 0^{\circ }$ is the standard orientation of the blade, i.e. the blade is mounted as a direct extension of the oar. (b) Side view of the oar blade model giving an impression of the camber of the blade, with a maximum camber of

$\beta = 0^{\circ }$ is the standard orientation of the blade, i.e. the blade is mounted as a direct extension of the oar. (b) Side view of the oar blade model giving an impression of the camber of the blade, with a maximum camber of ![]() $l_c = 18\ \textrm {mm}$. (c) A top view of the oar blade that shows the oar blade at two configurations:

$l_c = 18\ \textrm {mm}$. (c) A top view of the oar blade that shows the oar blade at two configurations: ![]() $\beta = 0^{\circ }$ and

$\beta = 0^{\circ }$ and ![]() $\beta = 15^{\circ }$. The pivot point of the oar blade (

$\beta = 15^{\circ }$. The pivot point of the oar blade (![]() $\beta$) is located at the strut that holds the blade. In the experiment the actual oar (shaft) does not (physically) exist; instead, the oar blade is moved along the path while held via the strut.

$\beta$) is located at the strut that holds the blade. In the experiment the actual oar (shaft) does not (physically) exist; instead, the oar blade is moved along the path while held via the strut.

The robot arm is placed above an open-top glass tank having a horizontal cross-section of ![]() $2\ \textrm {m} \times 2\ \textrm {m}$ and a height of 0.6 m filled with water up to 0.5 m. The size of the tank is chosen to be as large as practically feasible. To estimate the effect of the finite size of the tank on the hydrodynamics, a surface blockage is defined as the ratio of the surface area of the blade

$2\ \textrm {m} \times 2\ \textrm {m}$ and a height of 0.6 m filled with water up to 0.5 m. The size of the tank is chosen to be as large as practically feasible. To estimate the effect of the finite size of the tank on the hydrodynamics, a surface blockage is defined as the ratio of the surface area of the blade ![]() $A_{blade} \approx l_a\times l_b$ (see figure 6a) and the tank cross-section in the vertical plane

$A_{blade} \approx l_a\times l_b$ (see figure 6a) and the tank cross-section in the vertical plane ![]() $A_{tank}=2\ \textrm {m}\times 0.5\ \textrm {m}$. This results in a blockage ratio of 0.034, which according to West & Apelt (Reference West and Apelt1982) is sufficiently small to assume that the walls of the tank do not have a significant effect on the hydrodynamic force on the blade. During the experimental runs surface waves are generated, but measuring a single stroke in the set-up is completed before waves are reflected from the tank wall to the oar blade. A water level of 0.5 m is deemed sufficient as PIV measurements in the horizontal plane at various depths below the oar blade show that flow features only extend two blade heights (0.25 m) below the surface. Also, force measurements performed with a water level of 0.35 m did not yield results different from measurements with a water level of 0.5 m. The water in the tank is kept at a temperature of

$A_{tank}=2\ \textrm {m}\times 0.5\ \textrm {m}$. This results in a blockage ratio of 0.034, which according to West & Apelt (Reference West and Apelt1982) is sufficiently small to assume that the walls of the tank do not have a significant effect on the hydrodynamic force on the blade. During the experimental runs surface waves are generated, but measuring a single stroke in the set-up is completed before waves are reflected from the tank wall to the oar blade. A water level of 0.5 m is deemed sufficient as PIV measurements in the horizontal plane at various depths below the oar blade show that flow features only extend two blade heights (0.25 m) below the surface. Also, force measurements performed with a water level of 0.35 m did not yield results different from measurements with a water level of 0.5 m. The water in the tank is kept at a temperature of ![]() $20\,^{\circ }\textrm {C}$, to keep the water density

$20\,^{\circ }\textrm {C}$, to keep the water density ![]() $\rho$ and water viscosity

$\rho$ and water viscosity ![]() $\mu$ constant at

$\mu$ constant at ![]() $\rho = 1.0\times 10^{3}\ \textrm {kg}\ \textrm {m}^{-3}$ and

$\rho = 1.0\times 10^{3}\ \textrm {kg}\ \textrm {m}^{-3}$ and ![]() $\mu = 1.0 \times 10^{-3}\ \textrm {Pa}\ \textrm {s}$, respectively. Each measurement is performed in water that is considered completely stagnant, which in practice requires at least 15 min between experimental runs.

$\mu = 1.0 \times 10^{-3}\ \textrm {Pa}\ \textrm {s}$, respectively. Each measurement is performed in water that is considered completely stagnant, which in practice requires at least 15 min between experimental runs.

3.1. Particle image velocimetry

The vorticity in a selected horizontal plane is obtained through PIV (Adrian & Westerweel Reference Adrian and Westerweel2011) to capture the intricacies of the flow around the oar blade. The plane is at the centre of the blade, as indicated in figure 6(a). The tank provides full optical access, i.e. the sidewalls and bottom of the tank are all made of glass. A PIV camera (Phantom VEO 640L) is positioned underneath the tank and parallel to the water surface, imaging frames of ![]() $2560\times 1600$ pixels at 500 f.p.s. via a

$2560\times 1600$ pixels at 500 f.p.s. via a ![]() $45^{\circ }$ mirror, as indicated in figure 5(a). The field of view is

$45^{\circ }$ mirror, as indicated in figure 5(a). The field of view is ![]() $0.6\ \textrm {m}\times 1.0\ \textrm {m}$. Ten grams of neutrally buoyant fluorescent spherical tracer particles (Cospheric UVPMS-BR-0.995,

$0.6\ \textrm {m}\times 1.0\ \textrm {m}$. Ten grams of neutrally buoyant fluorescent spherical tracer particles (Cospheric UVPMS-BR-0.995, ![]() $53\text {-}63\ \mathrm {\mu }\textrm {m}$ diameter) are added to the water. These particles are illuminated using two overlapping light sheets from opposing sides to avoid shadows from the opaque oar blade model that is positioned in the light sheet. The light sheets are generated using a single dual-cavity Nd:YAG laser (Litron 150 W LDY303-HE PIV) followed by a beam splitter.

$53\text {-}63\ \mathrm {\mu }\textrm {m}$ diameter) are added to the water. These particles are illuminated using two overlapping light sheets from opposing sides to avoid shadows from the opaque oar blade model that is positioned in the light sheet. The light sheets are generated using a single dual-cavity Nd:YAG laser (Litron 150 W LDY303-HE PIV) followed by a beam splitter.

The acquired images are processed using commercial software (LaVision DaVis 8.4). To create image pairs from the sequential images every frame (![]() $n$) is paired with the next frame (

$n$) is paired with the next frame (![]() $n+1$). The exposure time delay

$n+1$). The exposure time delay ![]() $\Delta t$ between the pair of images at 500 f.p.s. is then 2 ms. A multi-pass correlation based PIV algorithm is used to obtain the velocity field from the image pairs. The interrogation windows are set at

$\Delta t$ between the pair of images at 500 f.p.s. is then 2 ms. A multi-pass correlation based PIV algorithm is used to obtain the velocity field from the image pairs. The interrogation windows are set at ![]() $64\times 64$ pixels for the first pass and at

$64\times 64$ pixels for the first pass and at ![]() $32\times 32$ pixels for the two subsequent passes. A 50 % overlap between adjacent interrogation windows is used. This results in velocity fields with a vector spacing of 6.1 mm and a typical cumulative first and second vector choice larger than 98 % in the part of the flow perturbed by the blade.

$32\times 32$ pixels for the two subsequent passes. A 50 % overlap between adjacent interrogation windows is used. This results in velocity fields with a vector spacing of 6.1 mm and a typical cumulative first and second vector choice larger than 98 % in the part of the flow perturbed by the blade.

3.2. Scaling of the kinematics and oar blade

Due to the limitations of the experimental set-up (primarily the maximum velocity and maximum acceleration of the robot) the oar blade kinematics (both geometry and velocity) were reproduced at a 1 : 2 scale of the actual kinematics. The resulting oar blade model has a width of ![]() $l_a = 275\ \textrm {mm}$ and a height of

$l_a = 275\ \textrm {mm}$ and a height of ![]() $l_b = 125\ \textrm {mm}$, see figure 6. To investigate the scaling behaviour the velocity is varied through a velocity scaling factor

$l_b = 125\ \textrm {mm}$, see figure 6. To investigate the scaling behaviour the velocity is varied through a velocity scaling factor ![]() $\kappa$, as shown in table 1, where

$\kappa$, as shown in table 1, where ![]() $\kappa = 1.00$ corresponds to the maximum velocity setting in the laboratory environment, which is 0.5 times the actual velocity in real rowing.

$\kappa = 1.00$ corresponds to the maximum velocity setting in the laboratory environment, which is 0.5 times the actual velocity in real rowing.

Table 1. The effect of different scaling options on the Reynolds number ![]() $Re$, Froude number

$Re$, Froude number ![]() $Fr$ and characteristic time scale

$Fr$ and characteristic time scale ![]() $T_{ref}$. During the experiment different velocity scaling factors

$T_{ref}$. During the experiment different velocity scaling factors ![]() $\kappa$ are investigated. Based on the Reynolds number

$\kappa$ are investigated. Based on the Reynolds number ![]() $Re$, all configurations appear to be in the turbulent regime. Based on the Froude number

$Re$, all configurations appear to be in the turbulent regime. Based on the Froude number ![]() $Fr$, all configurations appear to be in the so-called subcritical flow regime. The characteristic time scale

$Fr$, all configurations appear to be in the so-called subcritical flow regime. The characteristic time scale ![]() $T_{ref}$ and the mean rate of change of angle of attack

$T_{ref}$ and the mean rate of change of angle of attack ![]() $\dot {\alpha }$ are identical for real on-water rowing and the experiments at

$\dot {\alpha }$ are identical for real on-water rowing and the experiments at ![]() $\kappa = 1.00$.

$\kappa = 1.00$.

As will be discussed in detail in § 4.2.3, the ratio of momentum transferred in the ![]() $x$-direction,

$x$-direction, ![]() $J_x$, and in the

$J_x$, and in the ![]() $y$-direction,

$y$-direction, ![]() $J_y$, is constant for

$J_y$, is constant for ![]() $\kappa \geqslant 0.50$ and the magnitude of the hydrodynamic force scales with

$\kappa \geqslant 0.50$ and the magnitude of the hydrodynamic force scales with ![]() $V_{ref}^2 \sim \kappa ^2$. This implies that the general flow pattern does not vary with

$V_{ref}^2 \sim \kappa ^2$. This implies that the general flow pattern does not vary with ![]() $\kappa$ for sufficiently large velocities, which suggests that the flow has reached the turbulent regime for

$\kappa$ for sufficiently large velocities, which suggests that the flow has reached the turbulent regime for ![]() $\kappa \geqslant 0.50$. The Reynolds number

$\kappa \geqslant 0.50$. The Reynolds number ![]() $Re$ is defined as

$Re$ is defined as

where the characteristic length ![]() $L_{ref}$ is based on the plate dimensions

$L_{ref}$ is based on the plate dimensions ![]() $L_{ref} = \sqrt {l_a\times l_b}$, and the characteristic velocity

$L_{ref} = \sqrt {l_a\times l_b}$, and the characteristic velocity ![]() $V_{ref}$ is the mean velocity of the blade tip during the drive phase. The resulting Reynolds numbers for the different configurations are shown in table 1. The velocity scaling factor

$V_{ref}$ is the mean velocity of the blade tip during the drive phase. The resulting Reynolds numbers for the different configurations are shown in table 1. The velocity scaling factor ![]() $\kappa = 0.50$ corresponds to a Reynolds number of

$\kappa = 0.50$ corresponds to a Reynolds number of ![]() $Re=0.82\times 10^{5}$, which is deemed sufficiently high to be in the turbulent regime.

$Re=0.82\times 10^{5}$, which is deemed sufficiently high to be in the turbulent regime.

Due to the presence of a free surface one might expect that wave-making resistance could be of importance and this is expressed through the Froude number

where ![]() $g = 9.81\ \textrm {m}\ \textrm {s}^{-2}$ is the gravitational acceleration. We defined the length scale

$g = 9.81\ \textrm {m}\ \textrm {s}^{-2}$ is the gravitational acceleration. We defined the length scale ![]() $L_{ref}$ on the major dimensions of the plate, although it is difficult to determine a characteristic length scale for a plate-like geometry located just below the surface (see Grift et al. Reference Grift, Vijayaragavan, Tummers and Westerweel2019), and even more so for a rowing oar blade, since its orientation and direction of motion vary strongly in time. At the start of the drive the blade moves through the water sideways, barely disturbing the surface, while half-way through the drive phase the blade moves approximately perpendicular to its surface. With the defined length scale we obtain

$L_{ref}$ on the major dimensions of the plate, although it is difficult to determine a characteristic length scale for a plate-like geometry located just below the surface (see Grift et al. Reference Grift, Vijayaragavan, Tummers and Westerweel2019), and even more so for a rowing oar blade, since its orientation and direction of motion vary strongly in time. At the start of the drive the blade moves through the water sideways, barely disturbing the surface, while half-way through the drive phase the blade moves approximately perpendicular to its surface. With the defined length scale we obtain ![]() $Fr < 1$, indicating subcritical flow for on-water rowing and for all experimental configurations, see table 1. As during the experiments large surface waves are not observed and scaling with any

$Fr < 1$, indicating subcritical flow for on-water rowing and for all experimental configurations, see table 1. As during the experiments large surface waves are not observed and scaling with any ![]() $\kappa \geqslant 0.5$ yields the same ratio of impulse generated in the

$\kappa \geqslant 0.5$ yields the same ratio of impulse generated in the ![]() $x$ and

$x$ and ![]() $y$-directions, it is concluded that Froude number scaling is not required in this study. The characteristic time scale

$y$-directions, it is concluded that Froude number scaling is not required in this study. The characteristic time scale ![]() $T_{ref} = L_{ref}/V_{ref}$ and the mean rate of change of the angle of attack

$T_{ref} = L_{ref}/V_{ref}$ and the mean rate of change of the angle of attack ![]() $\dot {\alpha }$ are only the same for actual on-water rowing and the experiments performed for

$\dot {\alpha }$ are only the same for actual on-water rowing and the experiments performed for ![]() $\kappa = 1$.

$\kappa = 1$.

3.3. Validation of the oar blade path in the experimental set-up

The industrial robot reproduces the oar blade path very well, as shown in figure 7(a), with a maximum deviation of less than 0.01 m, which is small (1 %) relative to the total path length of 0.96 m. Also, the blade tip coordinates ![]() $x$ and

$x$ and ![]() $y$ as a function of time

$y$ as a function of time ![]() $t$ are very well reproduced, as shown in figure 7(b). At any moment in time the blade tip is within a distance of 0.03 m from the measured kinematics, which again is a small deviation (3 %) relative to the total path length of 0.96 m.

$t$ are very well reproduced, as shown in figure 7(b). At any moment in time the blade tip is within a distance of 0.03 m from the measured kinematics, which again is a small deviation (3 %) relative to the total path length of 0.96 m.

Figure 7. Comparison of the measured (and scaled) path of the oar blade tip (dashed grey line) and the path of the oar blade tip reproduced by the robot (solid black line). (a) The path of the blade tip in the ![]() $x$,

$x$,![]() $y$ plane. (b) The coordinates

$y$ plane. (b) The coordinates ![]() $x$ and

$x$ and ![]() $y$ of the blade tip as a function of time

$y$ of the blade tip as a function of time ![]() $t$.

$t$.

3.4. Overview of the reproduced kinematics

The detailed kinematics as reproduced by the robot are shown in figure 8. The kinematics shown in figure 8(b) to 8(f) are plotted against dimensionless time ![]() $t^*$ which is defined as

$t^*$ which is defined as

such that the catch is at ![]() $t^* = 0$ and the release at

$t^* = 0$ and the release at ![]() $t^* = 1$. The kinematics as a function of

$t^* = 1$. The kinematics as a function of ![]() $t^*$ are identical for all

$t^*$ are identical for all ![]() $\kappa$. In the figure the kinematics for a standard oar blade geometry (

$\kappa$. In the figure the kinematics for a standard oar blade geometry (![]() $\beta = 0^{\circ }$) are shown in black. The kinematics for an adapted blade geometry where the oar blade angle is increased to

$\beta = 0^{\circ }$) are shown in black. The kinematics for an adapted blade geometry where the oar blade angle is increased to ![]() $\beta = 15^{\circ }$ are shown in grey. At that angle rowing propulsion is found to be optimal, which is further discussed in § 4.6.

$\beta = 15^{\circ }$ are shown in grey. At that angle rowing propulsion is found to be optimal, which is further discussed in § 4.6.

Figure 8. (black) Reproduced kinematics for the standard oar blade geometry, i.e. ![]() $\beta = 0^{\circ }$, (grey) reproduced kinematics for the optimised oar blade geometry, i.e.

$\beta = 0^{\circ }$, (grey) reproduced kinematics for the optimised oar blade geometry, i.e. ![]() $\beta = 15^{\circ }$. (a) The oar blade tip path, (b) the oar blade tip position as a function of dimensionless time

$\beta = 15^{\circ }$. (a) The oar blade tip path, (b) the oar blade tip position as a function of dimensionless time ![]() $t^*$, (c) the oar angle

$t^*$, (c) the oar angle ![]() $\theta$ as a function of dimensionless time

$\theta$ as a function of dimensionless time ![]() $t^*$, (d) the oar blade tip velocity components

$t^*$, (d) the oar blade tip velocity components ![]() $V_x$ and

$V_x$ and ![]() $V_y$ as functions of dimensionless time

$V_y$ as functions of dimensionless time ![]() $t^*$ and (e,f) the angle of attack

$t^*$ and (e,f) the angle of attack ![]() $\alpha$ as a function of dimensionless time

$\alpha$ as a function of dimensionless time ![]() $t^*$.

$t^*$.

4. Results

In this section, force measurements obtained using the ![]() $F/T$ transducer, oar blade kinematics obtained from the robot position data system and flow fields obtained from the PIV measurements are presented and interpreted to provide insight into the hydrodynamics of rowing propulsion. Results are presented on the force on, and the flow field around, a rowing oar blade moving along the path shown in figure 7(a). To compare the results for drives with different durations due to different velocity scaling factors

$F/T$ transducer, oar blade kinematics obtained from the robot position data system and flow fields obtained from the PIV measurements are presented and interpreted to provide insight into the hydrodynamics of rowing propulsion. Results are presented on the force on, and the flow field around, a rowing oar blade moving along the path shown in figure 7(a). To compare the results for drives with different durations due to different velocity scaling factors ![]() $\kappa$ results are shown as a function of dimensionless time

$\kappa$ results are shown as a function of dimensionless time ![]() $t^*$. Since the catch and release take a finite amount of time (just as in reality), some hydrodynamic force (and impulse) associated with the catch and release is generated outside the time interval

$t^*$. Since the catch and release take a finite amount of time (just as in reality), some hydrodynamic force (and impulse) associated with the catch and release is generated outside the time interval ![]() $0 \leqslant t^* \leqslant 1$, see figure 9. Of the total generated impulse (the surface between the force signal and the

$0 \leqslant t^* \leqslant 1$, see figure 9. Of the total generated impulse (the surface between the force signal and the ![]() $x$-axis), 95 % is generated during the drive phase (

$x$-axis), 95 % is generated during the drive phase (![]() $0 \leqslant t^* \leqslant 1$). As it was found that excluding effects of the catch and release has no effect on any of the conclusions or outcomes, the current study focusses on the drive phase defined as

$0 \leqslant t^* \leqslant 1$). As it was found that excluding effects of the catch and release has no effect on any of the conclusions or outcomes, the current study focusses on the drive phase defined as ![]() $0 \leqslant t^* \leqslant 1$.

$0 \leqslant t^* \leqslant 1$.

Figure 9. (a) Measured force components ![]() $F_n$ and

$F_n$ and ![]() $F_t$ as a function of

$F_t$ as a function of ![]() $t^*$ for three realisations at a velocity scaling factor

$t^*$ for three realisations at a velocity scaling factor ![]() $\kappa = 1.00$. The three different realisations are indicated by different line styles, but these lines are overlapping almost perfectly. (b) Measured force components

$\kappa = 1.00$. The three different realisations are indicated by different line styles, but these lines are overlapping almost perfectly. (b) Measured force components ![]() $F_n$ and

$F_n$ and ![]() $F_t$ as a function of

$F_t$ as a function of ![]() $t^*$ for different velocity scaling factors, i.e.

$t^*$ for different velocity scaling factors, i.e. ![]() $\kappa = 0.50$ (—), 0.75 (- - -), 1.00 (

$\kappa = 0.50$ (—), 0.75 (- - -), 1.00 (![]() $\cdot \,\cdot \,\cdot$). (c) The small fluctuations in the blade velocity (marked with red arrows) match the fluctuations in the force signal shown in figure 9(a). (d) The measured force components

$\cdot \,\cdot \,\cdot$). (c) The small fluctuations in the blade velocity (marked with red arrows) match the fluctuations in the force signal shown in figure 9(a). (d) The measured force components ![]() $F_n$ and

$F_n$ and ![]() $F_t$ as a function of

$F_t$ as a function of ![]() $t^*$ for

$t^*$ for ![]() $\kappa = 0.50$ (—), 0.75 (- - -) and 1.00 (

$\kappa = 0.50$ (—), 0.75 (- - -) and 1.00 (![]() $\cdot \,\cdot \,\cdot$) scaled with

$\cdot \,\cdot \,\cdot$) scaled with ![]() $\kappa ^2$ reasonably match, and thus scale similar to (1.1a,b).

$\kappa ^2$ reasonably match, and thus scale similar to (1.1a,b).

4.1. Repeatability of force measurements

To check the repeatability of the robot motion and the force measurements all measurements were performed multiple times for different values of ![]() $\kappa$. Three realisations for

$\kappa$. Three realisations for ![]() $\kappa =1.00$ at the standard blade angle

$\kappa =1.00$ at the standard blade angle ![]() $\beta = 0^{\circ }$ are presented in figure 9(a). It is seen that the three realisations of the measured force components

$\beta = 0^{\circ }$ are presented in figure 9(a). It is seen that the three realisations of the measured force components ![]() $F_n$ and

$F_n$ and ![]() $F_t$ overlap almost perfectly. Also, the blade path, i.e. the location of the oar blade tip in time, is reproduced accurately with a maximum deviation of 0.2 mm, which is close to the 0.1 mm repeatability specified by the manufacturer of the robot and very small (0.1 %) relative to the total path length of 0.96 m. The minor fluctuations that appear in the force signal in figure 9(a) are consistent with the fluctuations in the velocity of the blade that is shown in figure 9(c). For clarity, this is indicated by the dashed red arrows that show that the local maxima in

$F_t$ overlap almost perfectly. Also, the blade path, i.e. the location of the oar blade tip in time, is reproduced accurately with a maximum deviation of 0.2 mm, which is close to the 0.1 mm repeatability specified by the manufacturer of the robot and very small (0.1 %) relative to the total path length of 0.96 m. The minor fluctuations that appear in the force signal in figure 9(a) are consistent with the fluctuations in the velocity of the blade that is shown in figure 9(c). For clarity, this is indicated by the dashed red arrows that show that the local maxima in ![]() $F_t$ and local minima in

$F_t$ and local minima in ![]() $F_n$ correspond to the local maxima in the tip velocity. The velocity fluctuations match the prescribed path and similar velocity fluctuations are found in the recorded path as well.

$F_n$ correspond to the local maxima in the tip velocity. The velocity fluctuations match the prescribed path and similar velocity fluctuations are found in the recorded path as well.

4.1.1. Effects of velocity scaling

It is seen in figure 9(b) that the force signals are qualitatively very similar for different values of ![]() $\kappa$. Based on figure 9(d), where the measured force is divided by

$\kappa$. Based on figure 9(d), where the measured force is divided by ![]() $\kappa ^2$, the force indeed appears to scale well with

$\kappa ^2$, the force indeed appears to scale well with ![]() $\kappa ^2$ (and thus with

$\kappa ^2$ (and thus with ![]() $|V|^2$), as might be expected from (1.1a,b), except around the release at

$|V|^2$), as might be expected from (1.1a,b), except around the release at ![]() $t^*\approx 1$. During the release the wake that followed the oar blade during the drive phase impinges on the blade, which is further discussed in § 4.3, and apparently this process somewhat varies with the velocity scaling factor. However, we argue that for the largest part of the drive phase they are in excellent agreement, as is further illustrated by the integrated quantities presented in § 4.2.3.

$t^*\approx 1$. During the release the wake that followed the oar blade during the drive phase impinges on the blade, which is further discussed in § 4.3, and apparently this process somewhat varies with the velocity scaling factor. However, we argue that for the largest part of the drive phase they are in excellent agreement, as is further illustrated by the integrated quantities presented in § 4.2.3.

4.2. Decomposition of a typical force measurement

Figure 10 shows the various components of the measured hydrodynamic force according to the three decompositions described in § 1.4, see figure 2. The results in figure 10 pertain to a standard blade angle ![]() $\beta = 0^{\circ }$ and a velocity scaling factor

$\beta = 0^{\circ }$ and a velocity scaling factor ![]() $\kappa = 1.00$. Note that

$\kappa = 1.00$. Note that ![]() $\kappa = 1.00$ can be seen as representative for all

$\kappa = 1.00$ can be seen as representative for all ![]() $\kappa \geqslant 0.5$.

$\kappa \geqslant 0.5$.

Figure 10. The decomposition of measured forces ![]() $F_n$ and

$F_n$ and ![]() $F_t$ in propulsive force

$F_t$ in propulsive force ![]() $F_x$ and non-propulsive force

$F_x$ and non-propulsive force ![]() $F_y$ as well as the decomposition in drag force

$F_y$ as well as the decomposition in drag force ![]() $F_D$ and lift force

$F_D$ and lift force ![]() $F_L$, see figure 2 and (1.2), for

$F_L$, see figure 2 and (1.2), for ![]() $\kappa = 1.00$. (a) The decomposed forces as a function of

$\kappa = 1.00$. (a) The decomposed forces as a function of ![]() $t^*$ and (b) as a function of oar angle

$t^*$ and (b) as a function of oar angle ![]() $\theta$. In (a) the vertical dashed line shows the time instance when the oar is perpendicular to the boat motion, i.e.

$\theta$. In (a) the vertical dashed line shows the time instance when the oar is perpendicular to the boat motion, i.e. ![]() $\theta = 0^{\circ }$. It is evident that the first part of the drive, i.e. when

$\theta = 0^{\circ }$. It is evident that the first part of the drive, i.e. when ![]() $\theta <0^{\circ }$, contributes most to the momentum transfer. (b) The maximum in propulsive force

$\theta <0^{\circ }$, contributes most to the momentum transfer. (b) The maximum in propulsive force ![]() $F_x$ occurs just before the perpendicular position of the oar at

$F_x$ occurs just before the perpendicular position of the oar at ![]() $\theta = -10^{\circ }$ or

$\theta = -10^{\circ }$ or ![]() $t^* = 0.60$.

$t^* = 0.60$.

4.2.1. Decomposition into normal component  $F_n$ and tangential component

$F_n$ and tangential component  $F_t$

$F_t$

In figure 10 the hydrodynamic force on the blade is decomposed into a normal component ![]() $F_n$ and a tangential component

$F_n$ and a tangential component ![]() $F_t$. The normal component

$F_t$. The normal component ![]() $F_n$ first decreases to a minimum at

$F_n$ first decreases to a minimum at ![]() $\theta = -10^{\circ }$ and then increases again towards a peak around the release at

$\theta = -10^{\circ }$ and then increases again towards a peak around the release at ![]() $t^* = 1$. The normal component

$t^* = 1$. The normal component ![]() $F_n$ acts in the direction of the convex side of the oar blade during the drive phase and reverses only for a short period in time around the release when the wake flow impinges on the decelerating blade.

$F_n$ acts in the direction of the convex side of the oar blade during the drive phase and reverses only for a short period in time around the release when the wake flow impinges on the decelerating blade.

The tangential component ![]() $F_t$ follows a very similar profile, but it has the opposite sign and the magnitude is approximately 20 % of that of the normal component

$F_t$ follows a very similar profile, but it has the opposite sign and the magnitude is approximately 20 % of that of the normal component ![]() $F_n$. Throughout the drive, the tangential component

$F_n$. Throughout the drive, the tangential component ![]() $F_t$ is directed towards the pivot point of the oar and it only reverses for a short period of time around the release. This means that the tangential component is opposing the boat motion for an oar orientation of

$F_t$ is directed towards the pivot point of the oar and it only reverses for a short period of time around the release. This means that the tangential component is opposing the boat motion for an oar orientation of ![]() $\theta < 0^\circ$, and is therefore only contributing positively to propulsion for

$\theta < 0^\circ$, and is therefore only contributing positively to propulsion for ![]() $\theta > 0^{\circ }$, i.e. during the last part of the drive. Since in actual on-water rowing the oar is mechanically constrained only in its motion in the negative tangential direction, the athlete has to apply a counter-force in negative tangential direction, i.e. push the oar outwards, to keep the oar in place.

$\theta > 0^{\circ }$, i.e. during the last part of the drive. Since in actual on-water rowing the oar is mechanically constrained only in its motion in the negative tangential direction, the athlete has to apply a counter-force in negative tangential direction, i.e. push the oar outwards, to keep the oar in place.

4.2.2. Decomposition into propulsive and non-propulsive components  $F_x$ and

$F_x$ and  $F_y$

$F_y$

Very useful is the decomposition of the hydrodynamic force into a propulsive component ![]() $F_x$ and non-propulsive component

$F_x$ and non-propulsive component ![]() $F_y$, as shown in figure 10. During most of the drive phase the propulsive component

$F_y$, as shown in figure 10. During most of the drive phase the propulsive component ![]() $F_x$ positively contributes to propulsion, i.e.

$F_x$ positively contributes to propulsion, i.e. ![]() $F_x> 0$. Only around the release does the sign of the propulsive component briefly reverse. This is due to the aforementioned wake flow impinging on the decelerating oar blade. Directly after the catch the propulsive component

$F_x> 0$. Only around the release does the sign of the propulsive component briefly reverse. This is due to the aforementioned wake flow impinging on the decelerating oar blade. Directly after the catch the propulsive component ![]() $F_x$ is small and it then steadily increases to a maximum at

$F_x$ is small and it then steadily increases to a maximum at ![]() $\theta \approx -10^{\circ }$, which is in agreement with the value reported by Soper & Hume (Reference Soper and Hume2004). However, a direct comparison between force profiles is difficult since the reported forces in this study, the hydrodynamic forces (isolated from the forces exerted by the athlete and forces due to inertia of the oar blade/shaft), are fundamentally different from the forces generally reported in the literature. The reported forces in the literature are the sum of hydrodynamic forces, forces applied by the athlete and forces due to inertia of the oar blade/shaft (Soper & Hume Reference Soper and Hume2004). The non-propulsive component

$\theta \approx -10^{\circ }$, which is in agreement with the value reported by Soper & Hume (Reference Soper and Hume2004). However, a direct comparison between force profiles is difficult since the reported forces in this study, the hydrodynamic forces (isolated from the forces exerted by the athlete and forces due to inertia of the oar blade/shaft), are fundamentally different from the forces generally reported in the literature. The reported forces in the literature are the sum of hydrodynamic forces, forces applied by the athlete and forces due to inertia of the oar blade/shaft (Soper & Hume Reference Soper and Hume2004). The non-propulsive component ![]() $F_y$ is applying a compressive force perpendicular to the boat motion (

$F_y$ is applying a compressive force perpendicular to the boat motion (![]() $F_y < 0$) throughout most of the drive.

$F_y < 0$) throughout most of the drive.

4.2.3. Effectiveness and efficiency

The effectiveness ![]() $J_x$ and the efficiencies

$J_x$ and the efficiencies ![]() $\eta _J$ and

$\eta _J$ and ![]() $\eta _E$ are calculated from the propulsive and non-propulsive components

$\eta _E$ are calculated from the propulsive and non-propulsive components ![]() $F_x$ and

$F_x$ and ![]() $F_y$ as described in § 1.5. The effectiveness,

$F_y$ as described in § 1.5. The effectiveness, ![]() $J_x$ and efficiencies,

$J_x$ and efficiencies, ![]() $\eta _J$ and

$\eta _J$ and ![]() $\eta _E$, as a function of the velocity scaling factor

$\eta _E$, as a function of the velocity scaling factor ![]() $\kappa$ are shown in figures 11(a) and 11(b), respectively, for 57 measurements. The effectiveness

$\kappa$ are shown in figures 11(a) and 11(b), respectively, for 57 measurements. The effectiveness ![]() $J_x$ appears to be linear in

$J_x$ appears to be linear in ![]() $\kappa$. This is explained by the use of a scaling argument. Let

$\kappa$. This is explained by the use of a scaling argument. Let ![]() $F_x \sim V^2 \sim \kappa ^2$, and for the integration interval

$F_x \sim V^2 \sim \kappa ^2$, and for the integration interval ![]() $\tau$, i.e. the duration of the drive phase,

$\tau$, i.e. the duration of the drive phase, ![]() $\tau$,

$\tau$, ![]() $\tau \sim 1/V \sim \kappa ^{-1}$, then

$\tau \sim 1/V \sim \kappa ^{-1}$, then ![]() $J_x \sim F_x \tau \sim \kappa$. The same argument holds for

$J_x \sim F_x \tau \sim \kappa$. The same argument holds for ![]() $J_y$, which implies that the ratio of these components

$J_y$, which implies that the ratio of these components ![]() $\eta _J = J_x / J_y$ is a constant. Indeed, the impulse efficiency is constant at

$\eta _J = J_x / J_y$ is a constant. Indeed, the impulse efficiency is constant at ![]() $\eta _J = 0.84$ for

$\eta _J = 0.84$ for ![]() $\kappa \geqslant 0.50$, see figure 11(b). This implies that the flows around the oar blade are qualitatively the same for

$\kappa \geqslant 0.50$, see figure 11(b). This implies that the flows around the oar blade are qualitatively the same for ![]() $\kappa \geqslant 0.50$. Throughout the remainder of this study only results for

$\kappa \geqslant 0.50$. Throughout the remainder of this study only results for ![]() $\kappa \geqslant 0.50$ are presented, as we deem the flow at lower values of

$\kappa \geqslant 0.50$ are presented, as we deem the flow at lower values of ![]() $\kappa$ not representative for actual on-water rowing.

$\kappa$ not representative for actual on-water rowing.

Figure 11. Effectiveness ![]() $J_x$ and efficiencies