1. Introduction

Thin falling films flowing down vertical heated walls are efficient in evaporation processes due to the large surface area to volume ratio of the film. Therefore, vertical falling film evaporators can operate at small temperature differences and are frequently used in, for example, the food and pulp and paper industries to evaporate water from the liquid product (Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023) or in desalination applications (Dai et al. Reference Dai, Zhang, Wang, Nawaz and Jacobi2022). In such evaporators, the liquid product typically flows inside or outside of a vertical steel tube that is heated on the other side by condensing steam (Schnabel Reference Schnabel2010). The evaporation takes place at the free surface of the product film and the heat transfer resistance is generally much higher in the liquid product than for the condensed steam film or the tube wall (Numrich Reference Numrich1995). Thus, the heat transfer resistance of the film should be minimised to design efficient evaporators. To achieve this, we need a thorough understanding of the heat transfer mechanisms between the wall and the film surface.

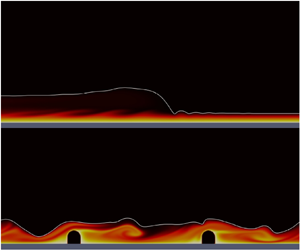

Usually, the heat exchange surface is smooth due to the relatively simple and cheap manufacturing process. The heat transfer in vertical falling films on smooth surfaces has been thoroughly studied before. Nusselt (Reference Nusselt1916) derived analytical solutions for the heat and mass transfer in smooth laminar falling films by disregarding the effects of interfacial waves and gas phase interactions. However, with increasing the flow rate, the flow transitions from a flat laminar film to a wavy one (characterised by the formation of solitary waves) and eventually becomes fully turbulent (Kapitza & Ter Haar Reference Kapitza and Ter Haar1948; Al-Sibai Reference Al-Sibai2006; Åkesjö et al. Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2017). The solitary wave should here be understood as a large-amplitude wave which propagates with a constant shape in the reference frame of the wave (Dietze, Leefken & Kneer Reference Dietze, Leefken and Kneer2008; Denner et al. Reference Denner, Pradas, Charogiannis, Markides, van Wachem and Kalliadasis2016). The flow conditions govern the hydrodynamics that has been shown to significantly influence the heat transport in the film. Miyara (Reference Miyara1999), Serifi, Malamataris & Bontozoglou (Reference Serifi, Malamataris and Bontozoglou2004) and Kunugi & Kino (Reference Kunugi and Kino2005) studied numerically the effects of solitary waves on the heat transfer in falling films. The findings showed that the solitary waves enhanced the heat transfer rate through the film above the conduction limit due to film thinning between the waves and convection effects (mixing) in the waves. Åkesjö et al. (Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2018) studied experimentally and numerically the effect of the hydrodynamics on the film heat transfer for smooth vertical pipes in laminar-to-turbulent flow regimes. The results showed a strong influence of the film thickness and mixing caused by backflow in streamwise waves on the heat transfer. Additionally, the same authors found that the transition from two- to three-dimensional waves did not have a significant effect on the heat transfer. Kalliadasis et al. (Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012) showed, using two-dimensional reduced-order models, that the recirculation in solitary waves increases with their amplitude and induces mixing of the temperature field that enhances the heat transport. Markides, Mathie & Charogiannis (Reference Markides, Mathie and Charogiannis2016) investigated experimentally the heat transfer in film flowing down an inclined foil and observed heat transfer rates up to three times higher than those predicted by the Nusselt theory. The authors suggest that unsteady flow phenomena associated with the interface waves contribute to the enhancement.

To further improve the heat transfer rate through the film, previous studies have suggested introducing surface modifications on the heated wall (Webb & Kim Reference Webb and Kim2005). There are two potential benefits of such modifications on the total heat transfer rate ![]() $Q = hA(T_{wall}-T_{sat})$, where

$Q = hA(T_{wall}-T_{sat})$, where ![]() $T_{wall}$ and

$T_{wall}$ and ![]() $T_{sat}$ are the wall and saturation temperatures, respectively. First, the modifications can alter the hydrodynamics (see Aksel & Schörner (Reference Aksel and Schörner2018) for an extensive review of the hydrodynamic effects) to increase the heat transfer coefficient

$T_{sat}$ are the wall and saturation temperatures, respectively. First, the modifications can alter the hydrodynamics (see Aksel & Schörner (Reference Aksel and Schörner2018) for an extensive review of the hydrodynamic effects) to increase the heat transfer coefficient ![]() $h$. Secondly, the modifications can increase the heat transfer area

$h$. Secondly, the modifications can increase the heat transfer area ![]() $A$. Still, it is generally preferred to increase

$A$. Still, it is generally preferred to increase ![]() $h$ without significant change of

$h$ without significant change of ![]() $A$ since increasing

$A$ since increasing ![]() $A$ typically requires more material, increased manufacturing complexity and thus higher costs (Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023). Here, we therefore focus on modified surfaces that primarily increase

$A$ typically requires more material, increased manufacturing complexity and thus higher costs (Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023). Here, we therefore focus on modified surfaces that primarily increase ![]() $h$.

$h$.

Because of the wide range of applications with disparate practical considerations (such as heat-sensitive fluids, sputtering, fouling, residence times, etc.) there exist no general design guidelines for surface modifications in vertical falling film evaporators (Lozano Avilés Reference Lozano Avilés2007). However, previous works have shown a potential for improving the heat or scalar transfer rate by more than ![]() $100\,\%$ using various designs of surface modifications in a wide range of applications. Here, we disregard studies focusing on surface modifications that induce nucleate boiling since the temperature difference is typically too low to initiate boiling in heat-sensitive fluids, and the associated (micro)structures, and vapour bubbles, may increase the risk of fouling in the evaporator (Tuoc Reference Tuoc2015; Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023). Surface modifications were observed to alter the film flow characteristics in, for example, Slade et al. (Reference Slade, Veremieiev, Lee and Gaskell2013) and Li et al. (Reference Li, Yi, Li, Pavlenko and Gao2018) and, in Yu et al. (Reference Yu, Loffler, Gambaryan-Roisman and Stephan2010), a grooved surface was shown to reduce the wall temperature during heating conditions. Najim et al. (Reference Najim, Feddaoui, Nait Alla and Charef2018) studied numerically a sinusoidal heat transfer surface and observed a heat transfer enhancement of up to 10 % depending on the amplitude and number of wall waves. Raach & Mitrovic (Reference Raach and Mitrovic2005) investigated numerically the effect of introducing turbulence wires in the film on the evaporation rate. The authors found that two wires in series (as opposed to a single wire) gave significant enhancement of turbulence and suggest an optimal spacing of 18 wire diameters between the wires. The study found a 100 % increase in evaporation rate but did not explain thoroughly the underlying mechanisms. Salvagnini & Taqueda (Reference Salvagnini and Taqueda2004) measured the evaporation rate of vertical falling film on a tube with a wire mesh. They observed enhancements of around 100 %–200 % depending on the film Reynolds number. Zheng & Worek (Reference Zheng and Worek1996) observed experimentally a heat transfer enhancement by adding rods in an inclined film. The authors suggested the enhancement is due to circulating zones generated by the rods and found that the optimal rod separation was 5 cm. Lozano Avilés (Reference Lozano Avilés2007) provided a detailed overview of studies using different types of structured surfaces and also investigated experimentally a vertically (longitudinal) grooved surface that enhanced the heat transfer by approximately 40 %. The latter study suggests that structures perpendicular to the flow are the most effective at disrupting the boundary layer and inducing mixing although such structures may induce stagnant liquid zones and are potentially problematic for liquids with solid particles. In this study, we focus on understanding the mechanisms that enhance the convective heat transfer and do not consider those potential issues in certain applications. For that purpose, we focus on perpendicular surface modifications that show the greatest potential for convective heat transfer enhancement.

$100\,\%$ using various designs of surface modifications in a wide range of applications. Here, we disregard studies focusing on surface modifications that induce nucleate boiling since the temperature difference is typically too low to initiate boiling in heat-sensitive fluids, and the associated (micro)structures, and vapour bubbles, may increase the risk of fouling in the evaporator (Tuoc Reference Tuoc2015; Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023). Surface modifications were observed to alter the film flow characteristics in, for example, Slade et al. (Reference Slade, Veremieiev, Lee and Gaskell2013) and Li et al. (Reference Li, Yi, Li, Pavlenko and Gao2018) and, in Yu et al. (Reference Yu, Loffler, Gambaryan-Roisman and Stephan2010), a grooved surface was shown to reduce the wall temperature during heating conditions. Najim et al. (Reference Najim, Feddaoui, Nait Alla and Charef2018) studied numerically a sinusoidal heat transfer surface and observed a heat transfer enhancement of up to 10 % depending on the amplitude and number of wall waves. Raach & Mitrovic (Reference Raach and Mitrovic2005) investigated numerically the effect of introducing turbulence wires in the film on the evaporation rate. The authors found that two wires in series (as opposed to a single wire) gave significant enhancement of turbulence and suggest an optimal spacing of 18 wire diameters between the wires. The study found a 100 % increase in evaporation rate but did not explain thoroughly the underlying mechanisms. Salvagnini & Taqueda (Reference Salvagnini and Taqueda2004) measured the evaporation rate of vertical falling film on a tube with a wire mesh. They observed enhancements of around 100 %–200 % depending on the film Reynolds number. Zheng & Worek (Reference Zheng and Worek1996) observed experimentally a heat transfer enhancement by adding rods in an inclined film. The authors suggested the enhancement is due to circulating zones generated by the rods and found that the optimal rod separation was 5 cm. Lozano Avilés (Reference Lozano Avilés2007) provided a detailed overview of studies using different types of structured surfaces and also investigated experimentally a vertically (longitudinal) grooved surface that enhanced the heat transfer by approximately 40 %. The latter study suggests that structures perpendicular to the flow are the most effective at disrupting the boundary layer and inducing mixing although such structures may induce stagnant liquid zones and are potentially problematic for liquids with solid particles. In this study, we focus on understanding the mechanisms that enhance the convective heat transfer and do not consider those potential issues in certain applications. For that purpose, we focus on perpendicular surface modifications that show the greatest potential for convective heat transfer enhancement.

Heat transfer improvements of up to ![]() $100\,\%$ have also been observed in our previous experimental studies on a pilot-scale evaporator using perpendicular surface modifications under industrially relevant conditions (Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023). Although the results in the aforementioned studies with surface modifications are promising, it is not yet clear how and why the surface modifications enhance the heat transfer rate (Lozano Avilés Reference Lozano Avilés2007; Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023) and the underlying mechanisms for the heat transport in such cases have so far received relatively little attention (to the best of the authors’ knowledge). It is, therefore, important to understand the governing mechanisms behind the enhancement to facilitate optimal design of the modifications under various flow conditions and fluids. The present work thus aims at closing this knowledge gap by providing a general methodology and explanation of such mechanisms. For this purpose, we define a model problem consisting of a relatively simple representation of perpendicular surface modifications (see figure 1a), analogous to those used in Åkesjö et al. (Reference Åkesjö, Gourdon, Jongsma and Sasic2023). These modifications have been shown to provide similar heat transfer enhancements as the other types of perpendicular structures used in the literature, and we thus believe that they are suitable for the purpose of this work. It should also be noted that although we choose here a specific model problem, the general formulation of the methodology developed in this work can be used to study the heat transfer mechanisms for any type of surface modifications.

$100\,\%$ have also been observed in our previous experimental studies on a pilot-scale evaporator using perpendicular surface modifications under industrially relevant conditions (Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023). Although the results in the aforementioned studies with surface modifications are promising, it is not yet clear how and why the surface modifications enhance the heat transfer rate (Lozano Avilés Reference Lozano Avilés2007; Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023) and the underlying mechanisms for the heat transport in such cases have so far received relatively little attention (to the best of the authors’ knowledge). It is, therefore, important to understand the governing mechanisms behind the enhancement to facilitate optimal design of the modifications under various flow conditions and fluids. The present work thus aims at closing this knowledge gap by providing a general methodology and explanation of such mechanisms. For this purpose, we define a model problem consisting of a relatively simple representation of perpendicular surface modifications (see figure 1a), analogous to those used in Åkesjö et al. (Reference Åkesjö, Gourdon, Jongsma and Sasic2023). These modifications have been shown to provide similar heat transfer enhancements as the other types of perpendicular structures used in the literature, and we thus believe that they are suitable for the purpose of this work. It should also be noted that although we choose here a specific model problem, the general formulation of the methodology developed in this work can be used to study the heat transfer mechanisms for any type of surface modifications.

Figure 1. (a) Illustration of the surface modifications and the considered topological parameters pitch ![]() $\hat {p}$, height

$\hat {p}$, height ![]() $\hat {h}$ and length

$\hat {h}$ and length ![]() $\hat {l}$. (b) Schematic view of the problem. The liquid film flows along the modified wall in the gravitational direction

$\hat {l}$. (b) Schematic view of the problem. The liquid film flows along the modified wall in the gravitational direction ![]() $\boldsymbol {g}$. The wall temperature

$\boldsymbol {g}$. The wall temperature ![]() $T_{wall}$ is kept constant above the saturation temperature

$T_{wall}$ is kept constant above the saturation temperature ![]() $T_{sat}$ that is maintained at the gas–liquid interface and gas phase. The temperature difference induces a heat flux

$T_{sat}$ that is maintained at the gas–liquid interface and gas phase. The temperature difference induces a heat flux ![]() $q_{wall}$ from the wall towards the interface where the applied heat is absorbed by the heat flux

$q_{wall}$ from the wall towards the interface where the applied heat is absorbed by the heat flux ![]() $q_{evap}$ required for evaporation.

$q_{evap}$ required for evaporation.

At the industrial scale, evaporators may consist of a series of evaporator units, each comprising hundreds, or even thousands, of steel tubes, more than 10 m long. At such scales, it is also beneficial if the surface modifications are simple to manufacture, but yet effective, to be economically feasible. Bump-shaped corrugations, similar to our representation, were also found to improve interfacial scalar transfer in vertical falling films by more than 30 % (slightly more than the evaluated sinusoidal corrugations) in Dietze (Reference Dietze2019).

In this study, we aim to elucidate the heat transfer mechanisms behind the improved heat transport in the film, due to the surface modifications. To achieve this, we perform fully resolved direct numerical simulations (DNS) of evaporative falling films. We formulate in § 2.2 a heat flux decomposition that allows us to quantify and analyse the spatial distribution of mean and fluctuating advective and diffusive wall-normal heat fluxes through the film. The heat flux analyses are used to quantify and determine how the heat transfer is altered by the modifications. Based on the results, we propose a hypothesis of four synergistic mechanisms behind the heat transfer improvement in § 3.2. Additionally, we investigate the influence of flow conditions (§ 3.1), surface topology parameters (§§ 3.3.1 and 3.3.2) and material parameters (§ 3.3.3) on the heat fluxes and the overall heat transfer rate. Finally, we summarise our findings by analysing how key dimensionless parameters can explain and predict the overall heat transfer rate on both smooth and modified surfaces in § 3.4.

2. Methodology

We study the heat transfer in vertical falling films during evaporation conditions using multiphase DNS. Surface modifications are introduced at the wall to improve the heat transfer. The general design of the modifications is adopted from promising results in previous experimental studies at industrially relevant conditions (Sanches Romeiro Reference Sanches Romeiro2009; Åkesjö Reference Åkesjö2018; Åkesjö et al. Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2019, Reference Åkesjö, Gourdon, Jongsma and Sasic2023). These modifications are parameterised using the pitch ![]() $\hat {p}$ (vertical distance between modifications), height

$\hat {p}$ (vertical distance between modifications), height ![]() $\hat {h}$ (height of modification in wall-normal direction) and length

$\hat {h}$ (height of modification in wall-normal direction) and length ![]() $\hat {l}$ (length of modification in vertical direction). These parameters are non-dimensionalised using the viscous length scale

$\hat {l}$ (length of modification in vertical direction). These parameters are non-dimensionalised using the viscous length scale ![]() $(\nu _l^2/g)^{1/3}$ as further described in § 2.1. We avoid too-sharp edges on the modifications (that may cause numerical problems and excessive sputtering in real applications) by adopting a radius of

$(\nu _l^2/g)^{1/3}$ as further described in § 2.1. We avoid too-sharp edges on the modifications (that may cause numerical problems and excessive sputtering in real applications) by adopting a radius of ![]() $\hat {l}/2$ on the outer edges of the modifications. An illustration of the modifications is shown in figure 1(a).

$\hat {l}/2$ on the outer edges of the modifications. An illustration of the modifications is shown in figure 1(a).

In our analysis, we assume a constant wall temperature above saturation conditions ![]() $T_{wall}>T_{sat}$ on the product side. A constant wall temperature is reasonable if the wall Biot number satisfies

$T_{wall}>T_{sat}$ on the product side. A constant wall temperature is reasonable if the wall Biot number satisfies ![]() ${Bi} = ht_w/k_w \ll 1$ (where

${Bi} = ht_w/k_w \ll 1$ (where ![]() $h$ is the heat transfer coefficient on the product side of the wall,

$h$ is the heat transfer coefficient on the product side of the wall, ![]() $t_w$ is the wall thickness and

$t_w$ is the wall thickness and ![]() $k_w$ is the wall thermal conductivity) and the condensing steam maintains the steam side of the wall at the steam saturation temperature. The

$k_w$ is the wall thermal conductivity) and the condensing steam maintains the steam side of the wall at the steam saturation temperature. The ![]() ${Bi}\ll 1$ implies that the heat conduction in the wall dominates the heat transfer rate in the film, thus homogenising the wall temperature in the vertical direction. We further assume that the gas phase on the product side is pure vapour and that the gas–liquid interface (and the gas phase) is at saturation conditions (Schnabel Reference Schnabel2010; Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023).

${Bi}\ll 1$ implies that the heat conduction in the wall dominates the heat transfer rate in the film, thus homogenising the wall temperature in the vertical direction. We further assume that the gas phase on the product side is pure vapour and that the gas–liquid interface (and the gas phase) is at saturation conditions (Schnabel Reference Schnabel2010; Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023).

The evaporation rate is typically insignificant compared with the rate of the liquid product flow (p. 1290 in Schnabel (Reference Schnabel2010)). To justify this assumption, we consider a representative case of an evaporative falling film defined by ![]() $\mathit {Re}=100$ and

$\mathit {Re}=100$ and ![]() $\mathit {Nu}=0.5$ over a length of

$\mathit {Nu}=0.5$ over a length of ![]() $1000\delta _N$ Nusselt film thicknesses (these parameters are defined later). Taking liquid properties from the industrial fluid used in the experiments of Åkesjö et al. (Reference Åkesjö, Gourdon, Jongsma and Sasic2023) and using the latent heat of water as 2320 kJ kg

$1000\delta _N$ Nusselt film thicknesses (these parameters are defined later). Taking liquid properties from the industrial fluid used in the experiments of Åkesjö et al. (Reference Åkesjö, Gourdon, Jongsma and Sasic2023) and using the latent heat of water as 2320 kJ kg![]() $^{-1}$, we get a reduction of the liquid mass flow rate of

$^{-1}$, we get a reduction of the liquid mass flow rate of ![]() $4\,\%$ at the end of the section. For the cases considered in the present study, the film thickness is therefore practically constant. We assume the gas phase dynamics does not significantly influence the heat transfer in the liquid phase. This is partly due to the typical density

$4\,\%$ at the end of the section. For the cases considered in the present study, the film thickness is therefore practically constant. We assume the gas phase dynamics does not significantly influence the heat transfer in the liquid phase. This is partly due to the typical density ![]() $\rho _r = \rho _l / \rho _g = O(1000)$ and viscosity

$\rho _r = \rho _l / \rho _g = O(1000)$ and viscosity ![]() $\mu _r = \mu _l / \mu _g = O(100)$ ratios that indicate that relatively low pressure and viscous forces act on the interface by the gas at moderate relative velocities. As a rough estimate of when the gas phase velocity becomes significant, we consider a laminar vertical falling film with a no-slip wall and continuous shear stress at the gas–liquid interface. Here, the wall-normal shear stress distribution in the liquid is given by

$\mu _r = \mu _l / \mu _g = O(100)$ ratios that indicate that relatively low pressure and viscous forces act on the interface by the gas at moderate relative velocities. As a rough estimate of when the gas phase velocity becomes significant, we consider a laminar vertical falling film with a no-slip wall and continuous shear stress at the gas–liquid interface. Here, the wall-normal shear stress distribution in the liquid is given by

where ![]() $v$ is the vertical velocity,

$v$ is the vertical velocity, ![]() $x$ the wall-normal coordinate,

$x$ the wall-normal coordinate, ![]() $g$ the gravitational acceleration and

$g$ the gravitational acceleration and ![]() $\delta _l$ the film thickness. Clearly, the interfacial shear stress

$\delta _l$ the film thickness. Clearly, the interfacial shear stress ![]() $\tau _i$ (the second term on the right-hand side of (2.1)) must be

$\tau _i$ (the second term on the right-hand side of (2.1)) must be ![]() $\tau _i \sim \rho _l g \delta _l$ to significantly alter the hydrodynamics. The

$\tau _i \sim \rho _l g \delta _l$ to significantly alter the hydrodynamics. The ![]() $\tau _i$ in vertical annular flows has been studied experimentally in, for example, Belt, Van't Westende & Portela (Reference Belt, Van't Westende and Portela2009) and Mura & Gourdon (Reference Mura and Gourdon2017) and is typically modelled in the form

$\tau _i$ in vertical annular flows has been studied experimentally in, for example, Belt, Van't Westende & Portela (Reference Belt, Van't Westende and Portela2009) and Mura & Gourdon (Reference Mura and Gourdon2017) and is typically modelled in the form ![]() $\tau _i = C_f \rho _g V_g^2$ where

$\tau _i = C_f \rho _g V_g^2$ where ![]() $C_f$ is a friction factor and

$C_f$ is a friction factor and ![]() $V_g$ is the bulk gas velocity. Considering typical (in SI units) order of magnitudes

$V_g$ is the bulk gas velocity. Considering typical (in SI units) order of magnitudes ![]() $\rho _l=O(10^3)$,

$\rho _l=O(10^3)$, ![]() $g=O(10)$,

$g=O(10)$, ![]() $\delta _l = O(10^{-3})$,

$\delta _l = O(10^{-3})$, ![]() $\rho _g=O(1)$ and a relatively high estimate of

$\rho _g=O(1)$ and a relatively high estimate of ![]() $C_f=O(0.1)$ (observed for highly viscous fluids (Mura & Gourdon Reference Mura and Gourdon2017) but

$C_f=O(0.1)$ (observed for highly viscous fluids (Mura & Gourdon Reference Mura and Gourdon2017) but ![]() $C_f=O(0.01)$ for water), the

$C_f=O(0.01)$ for water), the ![]() $V_g = O(10)$ is required for

$V_g = O(10)$ is required for ![]() $\tau _i \sim \rho _l g \delta _l$. Here, we thus assume

$\tau _i \sim \rho _l g \delta _l$. Here, we thus assume ![]() $V_g$ sufficiently below such an estimate.

$V_g$ sufficiently below such an estimate.

We further assume any wall-normal heat transfer due to the flow in the circumferential direction of the tube negligible as compared with that caused by the flow in the wall-normal and vertical directions. In Åkesjö et al. (Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2018) the authors observed experimentally that the circumferential flow was much lower compared with the vertical one under relevant conditions and that it does not, therefore, significantly influence the liquid heat transfer.

The above-mentioned assumptions allow us to consider the problem as two-dimensional and to neglect the transport of mass across the interface due to evaporation. Still, we take into account the absorption of heat at the interface due to the latent heat of phase change that gives saturation conditions at the interface. A schematic illustration of the considered problem is shown in figure 1(b).

To compute average evaporative heat transfer rates, we consider statistically steady conditions (sufficiently far from the inlet) where all relevant statistics regarding the hydro- and thermodynamics of the film, such as the time-averaged temperature profile, film thickness ![]() $\delta _l$ and evaporation rate, are constant in the streamwise direction (Åkesjö et al. Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2018, Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2019). The streamwise position at which the statistics becomes constant generally depends on the governing parameters. Consequently, we compute our statistics on a number of uniformly distributed streamwise locations (typically 20–50) in the simulation domain. During postprocessing we can then assess if, and where, the statistics becomes constant. The presented data is only computed from the steady region of the domain (where we also remove the initial transient time series). For cases with a periodic domain, the statistics is by definition constant in the streamwise direction (at least when considering averages over at least one pitch length) although it takes a certain time to reach the statistically steady conditions. Here, we evaluate at what time the statistics becomes constant and remove the initial transient from the averaging data.

$\delta _l$ and evaporation rate, are constant in the streamwise direction (Åkesjö et al. Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2018, Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2019). The streamwise position at which the statistics becomes constant generally depends on the governing parameters. Consequently, we compute our statistics on a number of uniformly distributed streamwise locations (typically 20–50) in the simulation domain. During postprocessing we can then assess if, and where, the statistics becomes constant. The presented data is only computed from the steady region of the domain (where we also remove the initial transient time series). For cases with a periodic domain, the statistics is by definition constant in the streamwise direction (at least when considering averages over at least one pitch length) although it takes a certain time to reach the statistically steady conditions. Here, we evaluate at what time the statistics becomes constant and remove the initial transient from the averaging data.

At statistically steady conditions, the average wall heat flux ![]() $\bar {q}_{wall}$ is absorbed by the average evaporative heat flux

$\bar {q}_{wall}$ is absorbed by the average evaporative heat flux ![]() $\bar {q}_{evap}$ at the gas–liquid interface. The average heat transfer coefficient for evaporation

$\bar {q}_{evap}$ at the gas–liquid interface. The average heat transfer coefficient for evaporation ![]() $h_e$ can thus be defined as

$h_e$ can thus be defined as

For cases with surface modifications in an inlet–outlet domain, the evaporative heat flux ![]() $\bar {q}_{evap}$ is averaged over one pitch length

$\bar {q}_{evap}$ is averaged over one pitch length ![]() $\hat {p}$ to account for local variations around the modifications. In periodic domains,

$\hat {p}$ to account for local variations around the modifications. In periodic domains, ![]() $\bar {q}_{evap}$ is averaged over the entire domain. In this study, the

$\bar {q}_{evap}$ is averaged over the entire domain. In this study, the ![]() $h_e$ is always obtained at statistically steady conditions. The corresponding Nusselt number is commonly (and in this study) defined using a viscous length scale as (Schnabel Reference Schnabel2010)

$h_e$ is always obtained at statistically steady conditions. The corresponding Nusselt number is commonly (and in this study) defined using a viscous length scale as (Schnabel Reference Schnabel2010)

\begin{equation} \mathit{Nu} = \frac{h_e}{k_l} \left(\frac{\nu_l^2}{g}\right)^{1/3},\end{equation}

\begin{equation} \mathit{Nu} = \frac{h_e}{k_l} \left(\frac{\nu_l^2}{g}\right)^{1/3},\end{equation}

where ![]() $\nu _l$ is the kinematic viscosity of the liquid and

$\nu _l$ is the kinematic viscosity of the liquid and ![]() $k_l$ is the thermal conductivity of the liquid.

$k_l$ is the thermal conductivity of the liquid.

2.1. Numerical framework

We use a multiphase DNS framework based on the volume of fluid (VOF) method which has been used extensively to resolve the complex hydro- and interfacial dynamics of falling films in other numerical works (Dietze et al. Reference Dietze, Leefken and Kneer2008; Doro & Aidun Reference Doro and Aidun2013; Albert, Marschall & Bothe Reference Albert, Marschall and Bothe2014; Åkesjö et al. Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2019).

We start by non-dimensionalising all variables using ![]() $\nu _l$,

$\nu _l$, ![]() $\rho _l$ and

$\rho _l$ and ![]() $g$. The non-dimensional variables are the spatial coordinates

$g$. The non-dimensional variables are the spatial coordinates ![]() $x^*_i = x_i/(\nu _l^2/g)^{1/3}$, velocity

$x^*_i = x_i/(\nu _l^2/g)^{1/3}$, velocity ![]() $u^*_i = u_i / (\nu _l g)^{1/3}$, time

$u^*_i = u_i / (\nu _l g)^{1/3}$, time ![]() $t^*= t/(\nu _l / g^2)^{1/3}$, density

$t^*= t/(\nu _l / g^2)^{1/3}$, density ![]() $\rho ^* = \rho /\rho _l$, dynamic viscosity

$\rho ^* = \rho /\rho _l$, dynamic viscosity ![]() $\mu ^* = \mu /(\nu _l \rho _l)$, pressure

$\mu ^* = \mu /(\nu _l \rho _l)$, pressure ![]() $p^* = p/(\rho _l (\nu _l^2/g)^{1/3} g )$, gravitational acceleration

$p^* = p/(\rho _l (\nu _l^2/g)^{1/3} g )$, gravitational acceleration ![]() $g_i^* = g_i/g$, interface curvature

$g_i^* = g_i/g$, interface curvature ![]() $\kappa ^* = \kappa / (g/\nu _l^2)^{1/3}$ and temperature

$\kappa ^* = \kappa / (g/\nu _l^2)^{1/3}$ and temperature ![]() $T^* = (T-T_{sat})/(T_{wall}-T_{sat})$. In the remainder of this paper, all variables are non-dimensionalised accordingly and the asterisk notation is hereafter omitted. The non-dimensional governing equations read

$T^* = (T-T_{sat})/(T_{wall}-T_{sat})$. In the remainder of this paper, all variables are non-dimensionalised accordingly and the asterisk notation is hereafter omitted. The non-dimensional governing equations read

where the term ![]() $1/\rho _r$ is only added in cases with a periodic domain to prevent the gas from accelerating in the gravitational direction,

$1/\rho _r$ is only added in cases with a periodic domain to prevent the gas from accelerating in the gravitational direction, ![]() $\boldsymbol{\mathsf{S}}=(\boldsymbol {\nabla }\boldsymbol {u} + \boldsymbol {\nabla }\boldsymbol {u}^{\rm T})/2$ is the rate of deformation tensor,

$\boldsymbol{\mathsf{S}}=(\boldsymbol {\nabla }\boldsymbol {u} + \boldsymbol {\nabla }\boldsymbol {u}^{\rm T})/2$ is the rate of deformation tensor, ![]() $\hat {\boldsymbol {n}}$ is the interface normal,

$\hat {\boldsymbol {n}}$ is the interface normal, ![]() $\delta _S$ is the Dirac distribution function that is only non-zero at the interface,

$\delta _S$ is the Dirac distribution function that is only non-zero at the interface, ![]() $\mathit {Ka} = \sigma / (g^{1/3}\nu _l^{4/3}\rho _l)$ is the Kapitza number (where

$\mathit {Ka} = \sigma / (g^{1/3}\nu _l^{4/3}\rho _l)$ is the Kapitza number (where ![]() $\sigma$ is the surface tension that we assume constant since the interfacial temperature is maintained at saturation conditions),

$\sigma$ is the surface tension that we assume constant since the interfacial temperature is maintained at saturation conditions), ![]() $f$ is the volume fraction field that is

$f$ is the volume fraction field that is ![]() $1$ in the liquid phase and

$1$ in the liquid phase and ![]() $0$ is the gas and

$0$ is the gas and ![]() $q_\mathit {evap}$ is the evaporative cooling term due to latent heat of phase change at the interface. The density is defined as

$q_\mathit {evap}$ is the evaporative cooling term due to latent heat of phase change at the interface. The density is defined as ![]() $\rho (f)=f+(1-f)(1/\rho _r)$, while the viscosity

$\rho (f)=f+(1-f)(1/\rho _r)$, while the viscosity ![]() $\mu (f)=(f+(1-f)\mu _r)^{-1}$ and thermal diffusivity

$\mu (f)=(f+(1-f)\mu _r)^{-1}$ and thermal diffusivity ![]() $D(f)=(f \mathit {Pr}_l+(1-f)\mathit {Pr}_g \mu _r/\rho _r)^{-1}$ are the harmonic means that are suitable approximations for gas–liquid interfaces (Tryggvason, Scardovelli & Zaleski Reference Tryggvason, Scardovelli and Zaleski2011). The liquid and gas Prandtl numbers are defined as

$D(f)=(f \mathit {Pr}_l+(1-f)\mathit {Pr}_g \mu _r/\rho _r)^{-1}$ are the harmonic means that are suitable approximations for gas–liquid interfaces (Tryggvason, Scardovelli & Zaleski Reference Tryggvason, Scardovelli and Zaleski2011). The liquid and gas Prandtl numbers are defined as ![]() $\mathit {Pr}_l = \nu _l/D_l$ and

$\mathit {Pr}_l = \nu _l/D_l$ and ![]() $\mathit {Pr}_g = \nu _g/D_g$, respectively, and the thermal diffusivities are

$\mathit {Pr}_g = \nu _g/D_g$, respectively, and the thermal diffusivities are ![]() $D_l=k_l/(\rho _l c_{p,l})$ and

$D_l=k_l/(\rho _l c_{p,l})$ and ![]() $D_g=k_g/(\rho _g c_{p,g})$.

$D_g=k_g/(\rho _g c_{p,g})$.

The total thermal resistance of the evaporating falling film can be considered as two resistances in series. The first one is the thermal resistance of the liquid film and the second one is the thermal resistance of the gas–liquid interface during evaporation due to molecular (kinetic) effects. By assuming saturation conditions in the gas and at the gas–liquid interface (the interface overheating is negligible as has been observed in our previous experiments (Åkesjö et al. Reference Åkesjö, Gourdon, Jongsma and Sasic2023) and used in Schnabel (Reference Schnabel2010) and Kharangate, Lee & Mudawar (Reference Kharangate, Lee and Mudawar2015)), we implicitly assume that the thermal resistance of the liquid film dominates the total thermal resistance and that the evaporation rate, therefore, is limited by the rate at which heat is transported to the interface by the liquid. Consequently, the evaporation rate is not limited by kinetic effects at the interface.

In general, there exist neither a universally accepted evaporation model nor an implementation approach in two-phase flow problems involving phase change (Kharangate & Mudawar Reference Kharangate and Mudawar2017). A common model is the Rankine–Hugoniot jump conditions that neglects molecular (kinetic) effects and is generally used by assuming continuous interface saturation conditions (![]() $T_{l,{int}}=T_{g,{int}}=T_{sat}$) (thus assuming no interface resistance) (Gibou et al. Reference Gibou, Chen, Nguyen and Banerjee2007). The model is based on evaluating the net energy transfer across the interface as

$T_{l,{int}}=T_{g,{int}}=T_{sat}$) (thus assuming no interface resistance) (Gibou et al. Reference Gibou, Chen, Nguyen and Banerjee2007). The model is based on evaluating the net energy transfer across the interface as

where ![]() $k_l$ and

$k_l$ and ![]() $k_g$ are the thermal conductivity of the liquid and gas, respectively, and

$k_g$ are the thermal conductivity of the liquid and gas, respectively, and ![]() $\boldsymbol {\nabla } T$ is evaluated on either side of the interface. Since typically

$\boldsymbol {\nabla } T$ is evaluated on either side of the interface. Since typically ![]() $k_g \ll k_l$, this relation simplifies to

$k_g \ll k_l$, this relation simplifies to

suggesting that the evaporation rate is determined by the rate at which the liquid transports heat to the interface.

The evaporation rate can also be estimated using the model by Schrage (Reference Schrage1953) (based on the kinetic theory of gases) or the simplified and popular model of Tanasawa (Reference Tanasawa1991). These models take into account the additional thermal resistance at the interface, due to the kinetic effects. However, as long as this interface resistance is much smaller than the thermal resistance of the film, the specific model or model parameters do not significantly influence the results. The model by Tanasawa has the relatively simple functional form

where both phases are assumed at saturation conditions, but allows for a jump in temperature and pressure across the interface. The correct temperature boundary condition (BC) at the interface is still an unresolved issue (Juric & Tryggvason Reference Juric and Tryggvason1998) and neither (2.9) nor (2.10) are appropriate for all evaporative conditions. However, in the limit of small interfacial temperature jumps and small deviations from saturation conditions (thermal resistance of the interface is small), both models (2.9) and (2.10) predict the same evaporation rate since the rate predicted by both models is limited by the ability of the liquid to transport heat to the interface. In our DNS, we fully resolve this heat transport.

Since the Tanasawa model is more straightforward to implement into the VOF framework (as described in, for example, Hardt & Wondra (Reference Hardt and Wondra2008) and Kunkelmann (Reference Kunkelmann2011)), and has been successfully used to study evaporating films before (for example in the VOF methodology of Kharangate et al. (Reference Kharangate, Lee and Mudawar2015) and in the modelling framework of Sultan, Boudaoud & Amar (Reference Sultan, Boudaoud and Amar2005) that used the Hertz–Knudsen relation, which the Tanasawa model is based upon) we have chosen this model in our work.

To find a suitable model parameter ![]() $\alpha$ that gives negligible interfacial thermal resistance (introduced by the Tanasawa model), we consider the case of steady heat conduction in an evaporating laminar liquid film on a flat wall where

$\alpha$ that gives negligible interfacial thermal resistance (introduced by the Tanasawa model), we consider the case of steady heat conduction in an evaporating laminar liquid film on a flat wall where

Adding ![]() $(T_{int} - T_{sat})$ on both sides of (2.11) and rearranging we get

$(T_{int} - T_{sat})$ on both sides of (2.11) and rearranging we get

Using the non-dimensional formalism of the present paper this can be reformulated into

With typical values of ![]() $\delta ^*=O(10)$ and

$\delta ^*=O(10)$ and ![]() $Pr_l=O(10)$ in our cases, we obtain

$Pr_l=O(10)$ in our cases, we obtain

Here, we want ![]() $T^*_{int} \ll 1$ meaning that the temperature drop across the entire film

$T^*_{int} \ll 1$ meaning that the temperature drop across the entire film ![]() $(T_{wall}-T_{sat})$ is much larger than the temperature drop at the interface

$(T_{wall}-T_{sat})$ is much larger than the temperature drop at the interface ![]() $(T_{int}-T_{sat})$. Fulfilling these conditions thus implies that the interface resistance is indeed negligible. To maintain

$(T_{int}-T_{sat})$. Fulfilling these conditions thus implies that the interface resistance is indeed negligible. To maintain ![]() $T^*_{int} \ll 1$, (2.14) shows that

$T^*_{int} \ll 1$, (2.14) shows that ![]() $\alpha > 1$ is appropriate to obtain an interface temperature close to saturation conditions. For example, using

$\alpha > 1$ is appropriate to obtain an interface temperature close to saturation conditions. For example, using ![]() $\alpha = 100$ gives an interface temperature that deviates approximately

$\alpha = 100$ gives an interface temperature that deviates approximately ![]() $0.0001(T_{wall}-T_{sat})$ from the saturation temperature. In the present problem, the exact value of

$0.0001(T_{wall}-T_{sat})$ from the saturation temperature. In the present problem, the exact value of ![]() $\alpha$ is thus not important, it should just be large enough to achieve

$\alpha$ is thus not important, it should just be large enough to achieve ![]() $T_{int}\approx T_{sat}$ without causing numerical instabilities.

$T_{int}\approx T_{sat}$ without causing numerical instabilities.

To estimate an appropriate magnitude of ![]() $\alpha$, we use the idea that the local rate of heating at the interface should equal the local rate of cooling. Thus, an incremental increase of the interface temperature from

$\alpha$, we use the idea that the local rate of heating at the interface should equal the local rate of cooling. Thus, an incremental increase of the interface temperature from ![]() $T_{sat}$ to

$T_{sat}$ to ![]() $T_{int}$ gives

$T_{int}$ gives

where ![]() $n$ is the current computational time step and

$n$ is the current computational time step and ![]() $\Delta t$ is the time step size. We are aware of the fact that one could implement here a higher-order representation, but, we choose this simple form since it maintains

$\Delta t$ is the time step size. We are aware of the fact that one could implement here a higher-order representation, but, we choose this simple form since it maintains ![]() $T_{int} \approx T_{sat}$ in all our simulation cases without the need for parameter tuning or computing liquid temperature gradients normal to the interface. The representation (2.15) is therefore used in all our simulation cases.

$T_{int} \approx T_{sat}$ in all our simulation cases without the need for parameter tuning or computing liquid temperature gradients normal to the interface. The representation (2.15) is therefore used in all our simulation cases.

The time step ![]() $\Delta t$ is determined with the Courant–Friedrichs–Lewy (Courant number of 0.5) and the capillary time step criteria (Denner & van Wachem Reference Denner and van Wachem2015), where the latter criterion typically limits

$\Delta t$ is determined with the Courant–Friedrichs–Lewy (Courant number of 0.5) and the capillary time step criteria (Denner & van Wachem Reference Denner and van Wachem2015), where the latter criterion typically limits ![]() $\Delta t$ in our simulations to be within the range of

$\Delta t$ in our simulations to be within the range of ![]() $O(10^{-3}) - O(10^{-2})$. This gives a corresponding

$O(10^{-3}) - O(10^{-2})$. This gives a corresponding ![]() $\alpha =1/\Delta t$ in the range of approximately 100–1000. Additional simulations were also performed with a constant

$\alpha =1/\Delta t$ in the range of approximately 100–1000. Additional simulations were also performed with a constant ![]() $\alpha =500$, with practically no difference observed on the average heat transfer rates or interface temperature.

$\alpha =500$, with practically no difference observed on the average heat transfer rates or interface temperature.

Kharangate et al. (Reference Kharangate, Lee and Mudawar2015) also used the Tanasawa model to study turbulent evaporating falling films with the VOF method. To find a suitable ![]() $\alpha$ that maintains

$\alpha$ that maintains ![]() $T_{int} \approx T_{sat}$, the authors gradually increased the accommodation coefficient (included in

$T_{int} \approx T_{sat}$, the authors gradually increased the accommodation coefficient (included in ![]() $\alpha$) until

$\alpha$) until ![]() $(T_{int}-T_{sat})$ is minimised to an acceptable level. The end result is practically the same as ours.

$(T_{int}-T_{sat})$ is minimised to an acceptable level. The end result is practically the same as ours.

The falling film operating condition (here interpreted as the non-dimensional flow rate) is defined using the Reynolds number as

where ![]() $\varGamma$ is the mass flow rate of liquid per unit length of circumference,

$\varGamma$ is the mass flow rate of liquid per unit length of circumference, ![]() $\delta _l$ is the average film height and

$\delta _l$ is the average film height and ![]() $V_l$ is the average vertical velocity of the film. We fix the ratios

$V_l$ is the average vertical velocity of the film. We fix the ratios ![]() $\rho _r=1000$ and

$\rho _r=1000$ and ![]() $\mu _r =100$ that are relevant for industrial applications. The effects of these ratios are essentially negligible since their magnitudes indicate that the forces acting on the interface by the gas are small compared with the liquid (Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012). We also specify

$\mu _r =100$ that are relevant for industrial applications. The effects of these ratios are essentially negligible since their magnitudes indicate that the forces acting on the interface by the gas are small compared with the liquid (Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012). We also specify ![]() $\mathit {Pr}_g=0.7$ that is typical for gases. The effect of the latter parameter is also negligible since heat is only transported through the liquid film (from the wall and absorbed due to evaporation at the interface) whereas the gas phase is at uniform saturation conditions.

$\mathit {Pr}_g=0.7$ that is typical for gases. The effect of the latter parameter is also negligible since heat is only transported through the liquid film (from the wall and absorbed due to evaporation at the interface) whereas the gas phase is at uniform saturation conditions.

By fixing ![]() $\rho _r=1000$,

$\rho _r=1000$, ![]() $\mu _r =100$ and

$\mu _r =100$ and ![]() $\mathit {Pr}_g = 0.7$, we have the three governing fluid parameters

$\mathit {Pr}_g = 0.7$, we have the three governing fluid parameters ![]() $(\mathit {Ka},\mathit {Re},\mathit {Pr}_l)$ that, together with the surface topology parameters

$(\mathit {Ka},\mathit {Re},\mathit {Pr}_l)$ that, together with the surface topology parameters ![]() $(\hat {p},\hat {h},\hat {l})$, completely describe the hydro- and thermodynamics of the film. We thus consider the average heat transfer rate through the film as given by

$(\hat {p},\hat {h},\hat {l})$, completely describe the hydro- and thermodynamics of the film. We thus consider the average heat transfer rate through the film as given by ![]() $\mathit {Nu}_{smooth}(\mathit {Ka},\mathit {Re},\mathit {Pr}_l)$ on a smooth surface and

$\mathit {Nu}_{smooth}(\mathit {Ka},\mathit {Re},\mathit {Pr}_l)$ on a smooth surface and ![]() $\mathit {Nu}_{mod}(\mathit {Ka},\mathit {Re},\mathit {Pr}_l,\hat {p},\hat {h},\hat {l})$ on a modified surface.

$\mathit {Nu}_{mod}(\mathit {Ka},\mathit {Re},\mathit {Pr}_l,\hat {p},\hat {h},\hat {l})$ on a modified surface.

The governing equations (2.4)–(2.7) are solved in the open-source code Basilisk (Popinet Reference Popinet2015) that is widely used for DNS of gas–liquid interfacial flows (Dietze Reference Dietze2019; Lavalle et al. Reference Lavalle, Mergui, Grenier and Dietze2021; Boyd, Becker & Ling Reference Boyd, Becker and Ling2024). Here, the computational domain is always a square in two-dimensional. We specify the side length ![]() $L/\delta _N=O(100\unicode{x2013}1000)$ for our cases, where the Nusselt film thickness

$L/\delta _N=O(100\unicode{x2013}1000)$ for our cases, where the Nusselt film thickness ![]() $\delta _N$ is defined in (2.17). We adopt a cell-centred Cartesian tree-structured grid (square cells) and use an adaptive refinement technique that maintains a uniform resolution in the entire liquid film corresponding to the maximum specified refinement level. This gives a typical resolution of approximately 20–50 grid points per

$\delta _N$ is defined in (2.17). We adopt a cell-centred Cartesian tree-structured grid (square cells) and use an adaptive refinement technique that maintains a uniform resolution in the entire liquid film corresponding to the maximum specified refinement level. This gives a typical resolution of approximately 20–50 grid points per ![]() $\delta _N$ in our simulations, depending on the governing parameters. In the gas phase, the resolution gradually decreases to the minimum refinement level corresponding to 64 grid points per

$\delta _N$ in our simulations, depending on the governing parameters. In the gas phase, the resolution gradually decreases to the minimum refinement level corresponding to 64 grid points per ![]() $L$. With this grid configuration, a typical simulation requires

$L$. With this grid configuration, a typical simulation requires ![]() $O(10^5\unicode{x2013}10^6)$ grid points and runs on 32 cores for a few days. Statistically steady conditions are typically obtained after approximately 200 non-dimensional time units. The surface modifications are introduced on the left-hand wall of the domain using the embedded boundary methodology of Basilisk that follows the procedure in Johansen & Colella (Reference Johansen and Colella1998).

$O(10^5\unicode{x2013}10^6)$ grid points and runs on 32 cores for a few days. Statistically steady conditions are typically obtained after approximately 200 non-dimensional time units. The surface modifications are introduced on the left-hand wall of the domain using the embedded boundary methodology of Basilisk that follows the procedure in Johansen & Colella (Reference Johansen and Colella1998).

The system of equations is solved with a time-splitting projection method. The spatial gradients are discretised with standard second-order numerical schemes, and the velocity advection term with the Bell–Colella–Glaz second-order upwind scheme (Popinet Reference Popinet2003). The velocity and scalar fields are evolved in time with a staggered second-order method. The gas–liquid interface is reconstructed from the volume fraction field as a line in each computational cell containing the interface using the piecewise linear interface reconstruction method (Scardovelli & Zaleski Reference Scardovelli and Zaleski1999). This ensures that the interface is sharp and maintained within a single cell. The volume fraction field is then advected using geometric fluxes based on the reconstructed interface. Surface tension is accounted for using a well-balanced discretisation and an accurate height-function method is used to compute the interface curvature (Popinet Reference Popinet2018).

We use two different types of streamwise BCs in the computational domain. The first is termed an inlet–outlet domain and uses the laminar solution by Nusselt (Reference Nusselt1916) where the non-dimensional film thickness and mean velocity are given by

\begin{gather}v_N = \left(\frac{\mathit{Re}^2}{3}\right)^{1/3}, \end{gather}

\begin{gather}v_N = \left(\frac{\mathit{Re}^2}{3}\right)^{1/3}, \end{gather}

respectively. At the top of the domain, we impose the inlet volume fraction ![]() $f(0{\leq } x {\leq } \delta _N)=1$ and

$f(0{\leq } x {\leq } \delta _N)=1$ and ![]() $f(\delta _N {<} x {\leq } L)=0$ and the velocity profile

$f(\delta _N {<} x {\leq } L)=0$ and the velocity profile

\begin{gather} v(0{\leq} x {\leq} \delta_N) ={-}\frac{3}{2} v_N \left[2 \left(\frac{x}{\delta_N}\right) - \left(\frac{x}{\delta_N} \right)^2 \right ] [ 1+ \varepsilon \sin{(2{\rm \pi} f t)} ], \end{gather}

\begin{gather} v(0{\leq} x {\leq} \delta_N) ={-}\frac{3}{2} v_N \left[2 \left(\frac{x}{\delta_N}\right) - \left(\frac{x}{\delta_N} \right)^2 \right ] [ 1+ \varepsilon \sin{(2{\rm \pi} f t)} ], \end{gather}

where ![]() $\varepsilon =0.05$ is the perturbation amplitude and

$\varepsilon =0.05$ is the perturbation amplitude and ![]() $f=0.0261$ is the non-dimensional perturbation frequency. The perturbations are used to expedite fully developed conditions in the finite domain (Dietze et al. Reference Dietze, Leefken and Kneer2008; Denner et al. Reference Denner, Pradas, Charogiannis, Markides, van Wachem and Kalliadasis2016; Åkesjö et al. Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2017). The specific value of the perturbation frequency is not expected to significantly influence our results since, for similar flow conditions on smooth surfaces, Åkesjö et al. (Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2017) showed that the developed wave dynamics converges for all the tested frequencies after sufficient length from the inlet (

$f=0.0261$ is the non-dimensional perturbation frequency. The perturbations are used to expedite fully developed conditions in the finite domain (Dietze et al. Reference Dietze, Leefken and Kneer2008; Denner et al. Reference Denner, Pradas, Charogiannis, Markides, van Wachem and Kalliadasis2016; Åkesjö et al. Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2017). The specific value of the perturbation frequency is not expected to significantly influence our results since, for similar flow conditions on smooth surfaces, Åkesjö et al. (Reference Åkesjö, Gourdon, Vamling, Innings and Sasic2017) showed that the developed wave dynamics converges for all the tested frequencies after sufficient length from the inlet (![]() ${\approx }1000\delta _N$). In addition, on modified surfaces, (Åkesjö (Reference Åkesjö2018), figures 6–17) showed that the heat transfer from the wall to the film, at statistically steady conditions, is not related to the inlet perturbation frequency, but is instead dominated by the hydrodynamic fluctuations introduced by the surface modifications.

${\approx }1000\delta _N$). In addition, on modified surfaces, (Åkesjö (Reference Åkesjö2018), figures 6–17) showed that the heat transfer from the wall to the film, at statistically steady conditions, is not related to the inlet perturbation frequency, but is instead dominated by the hydrodynamic fluctuations introduced by the surface modifications.

The temperature BCs are ![]() $T=1$ at the wall,

$T=1$ at the wall, ![]() $T=0$ at the inlet and far-field, and symmetry at the outlet. The outlet is further specified as an open boundary with

$T=0$ at the inlet and far-field, and symmetry at the outlet. The outlet is further specified as an open boundary with ![]() $\partial u_i / \partial y = \partial p / \partial y = 0$ to allow the flow to exit with minimal reflections (Denner et al. Reference Denner, Pradas, Charogiannis, Markides, van Wachem and Kalliadasis2016). The inlet BCs are used to initialise all fields in the domain. The inlet–outlet domain is used for all validation cases and comparisons with experiments (§§ 2.4 and 3.1) to allow the hydro- and thermodynamics of the film to develop over long streamwise distances.

$\partial u_i / \partial y = \partial p / \partial y = 0$ to allow the flow to exit with minimal reflections (Denner et al. Reference Denner, Pradas, Charogiannis, Markides, van Wachem and Kalliadasis2016). The inlet BCs are used to initialise all fields in the domain. The inlet–outlet domain is used for all validation cases and comparisons with experiments (§§ 2.4 and 3.1) to allow the hydro- and thermodynamics of the film to develop over long streamwise distances.

In the second type of domain, we use periodic boundaries in the streamwise direction to compute and study average liquid heat fluxes at statistically steady conditions (in § 3.2) and to investigate the influence of important parameters on the total heat transfer rate (in § 3.3). The main advantage of the periodic domain is that the statistics is by definition constant in the entire domain (considering averages over at least one pitch length) although it takes a certain time to reach the statistically steady conditions. The periodic domains are also significantly smaller and thus computationally cheaper. This is opposed to the inlet–outlet domains where the domains are long and the statistics converges only after a sufficient length from the inlet that is not known a priori. For cases in a periodic domain, we evaluate at what time the statistics becomes constant and remove the initial transient from the averaging data. It should be noted that a periodic domain is only suitable for cases without solitary waves or where the wavelength of such waves is known and the domain length is selected appropriately. This is verified in our cases. The initial conditions in the periodic domain are the same as for the inlet–outlet domain except for the initial film thickness that is tuned to obtain the desired ![]() $\mathit {Re}$ number at statistically steady conditions. The inlet perturbations are here imposed at the top of the domain for an initial non-dimensional time

$\mathit {Re}$ number at statistically steady conditions. The inlet perturbations are here imposed at the top of the domain for an initial non-dimensional time ![]() $0\leq t\leq 40$ (approximately one flow-through time) and then stopped to again expedite fully developed conditions. Table 1 shows the domain type, non-dimensional parameters and results for all our simulation cases.

$0\leq t\leq 40$ (approximately one flow-through time) and then stopped to again expedite fully developed conditions. Table 1 shows the domain type, non-dimensional parameters and results for all our simulation cases.

Table 1. Non-dimensional parameters of the DNS. Cases starting with ‘S’ indicate a smooth heat transfer surface, ‘M’ is a modified surface and the ‘P’ refers to periodic BCs in the streamwise direction. Cases with in/outlet BCs have the Nusselt solution for velocity and volume fraction at the inlet and an open boundary at the outlet. All lengths are non-dimensionalised with the viscous length scale ![]() $(\nu _l^2/g)^{1/3}$ (or, if specified, related to the Nusselt film thickness

$(\nu _l^2/g)^{1/3}$ (or, if specified, related to the Nusselt film thickness ![]() $\delta _N$) and velocities with

$\delta _N$) and velocities with ![]() $(\nu _l g)^{1/3}$. The

$(\nu _l g)^{1/3}$. The ![]() $\mathit {Re}$,

$\mathit {Re}$, ![]() $\mathit {Ka}$ and

$\mathit {Ka}$ and ![]() $\mathit {Pr}_l$ (and the topology parameters for a modified surface; pitch

$\mathit {Pr}_l$ (and the topology parameters for a modified surface; pitch ![]() $\hat {p}$, height

$\hat {p}$, height ![]() $\hat {h}$ and length

$\hat {h}$ and length ![]() $\hat {l}$) determine the hydro- and thermodynamics of the falling film. The length of the computational domain

$\hat {l}$) determine the hydro- and thermodynamics of the falling film. The length of the computational domain ![]() $L$ is given in terms of

$L$ is given in terms of ![]() $\delta _N$ and the liquid grid resolution as the number of grid spacings

$\delta _N$ and the liquid grid resolution as the number of grid spacings ![]() $\varDelta$ per

$\varDelta$ per ![]() $\delta _N$. Here

$\delta _N$. Here ![]() $V_l$ is the average vertical (streamwise) film velocity,

$V_l$ is the average vertical (streamwise) film velocity, ![]() $\delta _l$ is the actual average film thickness and

$\delta _l$ is the actual average film thickness and ![]() $u_{l,{std}}$ is the standard deviation of the wall-normal liquid velocity fluctuations used in the definition of

$u_{l,{std}}$ is the standard deviation of the wall-normal liquid velocity fluctuations used in the definition of ![]() $\mathit {Pe}_l = u_{l,{std}} \delta _N / D_l$. The superscript

$\mathit {Pe}_l = u_{l,{std}} \delta _N / D_l$. The superscript ![]() $l$ represent values for the liquid phase.

$l$ represent values for the liquid phase.

2.2. Heat flux decomposition

To understand the mechanisms behind the improved heat transfer (due to surface modifications), we first analyse instantaneous temperature fields to get a qualitative understanding of the influence of the surface modifications on the heat transfer through the film. Then, we compute average wall-normal heat fluxes in the film at statistically steady conditions to quantify the relative importance of the identified heat flux contributions and their spatial distribution. The heat fluxes in the film are decomposed into mean and fluctuating components to assess the influence of the altered mean flow and the hydrodynamic disturbances generated by the surface modifications. The averaging procedure is based on the methodology proposed in Loisy (Reference Loisy2016).

We start by defining the phase indicator function ![]() $H$ as

$H$ as

where ![]() $\varOmega _l$ is the liquid region and

$\varOmega _l$ is the liquid region and ![]() $\varOmega _g$ is the gas region of the domain.

$\varOmega _g$ is the gas region of the domain.

We are here interested in the heat transport through the liquid phase. For this purpose, we condition the general temperature transport equation (one-fluid formulation that is valid in both phases) with ![]() $H$ and use the relations

$H$ and use the relations ![]() $\partial H / \partial t + \boldsymbol {u} \boldsymbol {\cdot } \boldsymbol {\nabla } H = 0$,

$\partial H / \partial t + \boldsymbol {u} \boldsymbol {\cdot } \boldsymbol {\nabla } H = 0$, ![]() $\boldsymbol {\nabla } H = \delta _S\hat {\boldsymbol {n}}$ and the interface BC

$\boldsymbol {\nabla } H = \delta _S\hat {\boldsymbol {n}}$ and the interface BC ![]() $D_l\boldsymbol {\nabla } T \boldsymbol {\cdot } \hat {\boldsymbol {n}} \delta _S = q_{evap}\delta _S = q_{{evap},S}$ to obtain

$D_l\boldsymbol {\nabla } T \boldsymbol {\cdot } \hat {\boldsymbol {n}} \delta _S = q_{evap}\delta _S = q_{{evap},S}$ to obtain

that is still valid in both phases but non-zero only in the liquid phase. We define the ensemble average operator ![]() $\langle \ \rangle$ as

$\langle \ \rangle$ as ![]() $\langle G \rangle (\boldsymbol {x},t) = \int G(\boldsymbol {x},t:C)p(C)\,{\rm d} C$, where

$\langle G \rangle (\boldsymbol {x},t) = \int G(\boldsymbol {x},t:C)p(C)\,{\rm d} C$, where ![]() $G$ is a generic observable in configuration

$G$ is a generic observable in configuration ![]() $C$ and

$C$ and ![]() $p(C)$ is the probability density of configuration

$p(C)$ is the probability density of configuration ![]() $C$. The liquid ensemble averages are defined as

$C$. The liquid ensemble averages are defined as ![]() $\langle \boldsymbol {u}_l \rangle = \langle H\boldsymbol {u} \rangle (\boldsymbol {x},t)$ and

$\langle \boldsymbol {u}_l \rangle = \langle H\boldsymbol {u} \rangle (\boldsymbol {x},t)$ and ![]() $\langle T_l \rangle = \langle T \rangle (\boldsymbol {x},t)$, where we note that the non-dimensional temperature is non-zero only in the liquid phase (

$\langle T_l \rangle = \langle T \rangle (\boldsymbol {x},t)$, where we note that the non-dimensional temperature is non-zero only in the liquid phase (![]() $\langle T \rangle = \langle HT \rangle$). The liquid temperature and velocity fields are decomposed into fluctuating and mean values as

$\langle T \rangle = \langle HT \rangle$). The liquid temperature and velocity fields are decomposed into fluctuating and mean values as ![]() $T_l = T_l' + \langle T_l \rangle$ and

$T_l = T_l' + \langle T_l \rangle$ and ![]() $\boldsymbol {u}_l = \boldsymbol {u}_l' + \langle \boldsymbol {u}_l \rangle$. These relations are substituted into (2.23), which is then ensemble averaged. At fully developed (statistically steady) conditions

$\boldsymbol {u}_l = \boldsymbol {u}_l' + \langle \boldsymbol {u}_l \rangle$. These relations are substituted into (2.23), which is then ensemble averaged. At fully developed (statistically steady) conditions ![]() $\partial \langle HT \rangle / \partial t = 0$ and the resulting relation reads

$\partial \langle HT \rangle / \partial t = 0$ and the resulting relation reads

Using the definitions ![]() $\langle \boldsymbol {q'} \rangle _{l,{adv}}(\boldsymbol {x}) = \langle \boldsymbol {u}_l' T_l' \rangle$,

$\langle \boldsymbol {q'} \rangle _{l,{adv}}(\boldsymbol {x}) = \langle \boldsymbol {u}_l' T_l' \rangle$, ![]() $\langle \boldsymbol {q}\rangle _{l,{adv}}(\boldsymbol {x}) = \langle \boldsymbol {u}_l\rangle \langle T_l\rangle$,

$\langle \boldsymbol {q}\rangle _{l,{adv}}(\boldsymbol {x}) = \langle \boldsymbol {u}_l\rangle \langle T_l\rangle$, ![]() $\langle \boldsymbol {q'} \rangle _{l,{diff}}(\boldsymbol {x}) = -\langle H D_l \boldsymbol {\nabla } T_l' \rangle$ and

$\langle \boldsymbol {q'} \rangle _{l,{diff}}(\boldsymbol {x}) = -\langle H D_l \boldsymbol {\nabla } T_l' \rangle$ and ![]() $\langle \boldsymbol {q}\rangle _{l,{diff}}(\boldsymbol {x}) = -\langle H D_l \boldsymbol {\nabla } \langle T_l \rangle \rangle$, we get the relation

$\langle \boldsymbol {q}\rangle _{l,{diff}}(\boldsymbol {x}) = -\langle H D_l \boldsymbol {\nabla } \langle T_l \rangle \rangle$, we get the relation

where the heat flux contributions on the left-hand side represent, respectively: (i) advection of the temperature fluctuations by the liquid velocity fluctuations; (ii) advection of the mean temperature field by the mean velocity field; (iii) diffusive flux due to the temperature fluctuations; and (iv) diffusion of the mean temperature field.

At fully developed conditions, heat is only transported on average in the wall-normal direction, from the wall to the gas–liquid interface. To analyse the average contribution from each wall-normal heat flux through the film, we can thus average the wall-normal heat fluxes of (2.25) over the streamwise ![]() $y$-direction (the averaging is performed only in the fluid domain and not in the solid regions occupied by the surface modifications) as

$y$-direction (the averaging is performed only in the fluid domain and not in the solid regions occupied by the surface modifications) as ![]() $\langle {q} \rangle ^y_{l}(x) = 1/L_f \int _0^{L_f} \langle {q}\rangle _{l}(x,y)\,{{\rm d}y}$, where

$\langle {q} \rangle ^y_{l}(x) = 1/L_f \int _0^{L_f} \langle {q}\rangle _{l}(x,y)\,{{\rm d}y}$, where ![]() $L_f(x)$ is the streamwise length of the fluid domain (defined below) and where we denote the quantities averaged in the streamwise

$L_f(x)$ is the streamwise length of the fluid domain (defined below) and where we denote the quantities averaged in the streamwise ![]() $y$-direction with the superscript

$y$-direction with the superscript ![]() $y$. As discussed in § 2.1, the location of the fully developed region is not known a priori, and we use instead a periodic computational domain (which after an initial transient is inherently fully developed in the entire domain) to compute the average heat fluxes of (2.25).

$y$. As discussed in § 2.1, the location of the fully developed region is not known a priori, and we use instead a periodic computational domain (which after an initial transient is inherently fully developed in the entire domain) to compute the average heat fluxes of (2.25).

Equation (2.25) can now be rewritten in terms of the streamwise averaged quantities as

Integrating (2.26) from the wall (with the BC ![]() $\langle {q}\rangle ^y_{wall}$) to a location

$\langle {q}\rangle ^y_{wall}$) to a location ![]() $x$ gives the steady-state balance of heat fluxes into and out of the fluid domain as

$x$ gives the steady-state balance of heat fluxes into and out of the fluid domain as

where ![]() $\langle {q}\rangle ^y_{wall}(x)=Q_{wall}(x)/L_f(x)$ is the average wall heat flux into the fluid domain. Figure 2 illustrates the average heat flux balance at the position

$\langle {q}\rangle ^y_{wall}(x)=Q_{wall}(x)/L_f(x)$ is the average wall heat flux into the fluid domain. Figure 2 illustrates the average heat flux balance at the position ![]() $x$ in the fluid domain that is coloured in blue. The absorption of heat due to evaporative cooling occurs between the two wavy lines that represent the region in which the gas–liquid interface fluctuates (

$x$ in the fluid domain that is coloured in blue. The absorption of heat due to evaporative cooling occurs between the two wavy lines that represent the region in which the gas–liquid interface fluctuates (![]() $\langle q_{{evap},S} \rangle ^y$ is non-zero here). As the position

$\langle q_{{evap},S} \rangle ^y$ is non-zero here). As the position ![]() $x$ moves outwards into the latter region,

$x$ moves outwards into the latter region, ![]() $\langle q \rangle ^y_l (x)$ decreases and, beyond that region,

$\langle q \rangle ^y_l (x)$ decreases and, beyond that region, ![]() $\langle q \rangle ^y_l (x) = 0$ (all heat applied by the wall is absorbed by evaporation). The

$\langle q \rangle ^y_l (x) = 0$ (all heat applied by the wall is absorbed by evaporation). The ![]() $Q_{wall}(x)$ is the total heat flow rate applied to the fluid by the wall up to

$Q_{wall}(x)$ is the total heat flow rate applied to the fluid by the wall up to ![]() $x$ (along the red dashed line in figure 2) and

$x$ (along the red dashed line in figure 2) and ![]() $L_f(x)$ is the streamwise length of the fluid domain at

$L_f(x)$ is the streamwise length of the fluid domain at ![]() $x$ (length of the black dashed line where

$x$ (length of the black dashed line where ![]() $L_f(x{<}h) < L$ but

$L_f(x{<}h) < L$ but ![]() $L_f(x{>}h) = L$ due to the solid surface modifications that extend to

$L_f(x{>}h) = L$ due to the solid surface modifications that extend to ![]() $x=h$). The

$x=h$). The ![]() $\langle {q}\rangle ^y_{wall}(x)$ thereby varies for

$\langle {q}\rangle ^y_{wall}(x)$ thereby varies for ![]() $x \leq h$ because of the surface modifications (that contribute to

$x \leq h$ because of the surface modifications (that contribute to ![]() $Q_{wall}(x)$ and alter

$Q_{wall}(x)$ and alter ![]() $L_f(x)$). At

$L_f(x)$). At ![]() $x>h$,

$x>h$, ![]() $\langle {q}\rangle ^y_{wall}(x)$ is positive and constant. The term

$\langle {q}\rangle ^y_{wall}(x)$ is positive and constant. The term ![]() $\langle {q}\rangle ^y_{evap}(x)=Q_{evap}(x)/L_f(x)$ represents the average heat flux out of the fluid domain due to evaporation until location

$\langle {q}\rangle ^y_{evap}(x)=Q_{evap}(x)/L_f(x)$ represents the average heat flux out of the fluid domain due to evaporation until location ![]() $x$ where

$x$ where ![]() $Q_{evap}(x)=\int _0^x \langle q_{{evap},S} \rangle ^y \,{{\rm d}{\kern0.8pt}x}'$. The left-hand side of (2.27) represents the contributions to the total heat flux

$Q_{evap}(x)=\int _0^x \langle q_{{evap},S} \rangle ^y \,{{\rm d}{\kern0.8pt}x}'$. The left-hand side of (2.27) represents the contributions to the total heat flux ![]() $\langle q \rangle ^y_l (x)$ (the sum of the left-hand side) through the liquid at position

$\langle q \rangle ^y_l (x)$ (the sum of the left-hand side) through the liquid at position ![]() $x$.

$x$.

Figure 2. Schematic illustration of the average heat fluxes through the liquid film. The blue region represents the fluid domain up to position ![]() $x$ and the two blue wavy lines indicate the interface region in which the evaporative cooling takes place. The latter region is thus where the gas–liquid interface fluctuates. The red dashed line represents the total wall length

$x$ and the two blue wavy lines indicate the interface region in which the evaporative cooling takes place. The latter region is thus where the gas–liquid interface fluctuates. The red dashed line represents the total wall length ![]() $L_{wall}(x)$ up to position

$L_{wall}(x)$ up to position ![]() $x$ and the black dashed line is the length of the fluid domain

$x$ and the black dashed line is the length of the fluid domain ![]() $L_f(x)$ at

$L_f(x)$ at ![]() $x$. The red arrows represent heat flux from the wall to the fluid, the blue arrows are the heat flux through the fluid domain at

$x$. The red arrows represent heat flux from the wall to the fluid, the blue arrows are the heat flux through the fluid domain at ![]() $x$ and the green arrows represent heat flux out of the fluid domain due to evaporation. According to (2.27), the total average heat flux

$x$ and the green arrows represent heat flux out of the fluid domain due to evaporation. According to (2.27), the total average heat flux ![]() $\langle q \rangle ^y_l(x)$ through the fluid domain at a position

$\langle q \rangle ^y_l(x)$ through the fluid domain at a position ![]() $x$ (black dashed line) equals the difference between the wall heat flux up to

$x$ (black dashed line) equals the difference between the wall heat flux up to ![]() $x$ (

$x$ (![]() $\langle {q}\rangle ^y_{wall}(x) = Q_{wall}(x)/L_f(x)$ representing the wall heat flow rate along the red dashed line) and the average evaporative heat flux out of the domain (

$\langle {q}\rangle ^y_{wall}(x) = Q_{wall}(x)/L_f(x)$ representing the wall heat flow rate along the red dashed line) and the average evaporative heat flux out of the domain (![]() $\langle {q}\rangle ^y_{evap}(x)=\int _0^x \langle q_{{evap},S} \rangle ^y \,{{\rm d}{\kern0.8pt}x}' / L_f(x)$).

$\langle {q}\rangle ^y_{evap}(x)=\int _0^x \langle q_{{evap},S} \rangle ^y \,{{\rm d}{\kern0.8pt}x}' / L_f(x)$).

Using (2.25) and (2.27), we quantify the different modes of heat transfer within the liquid film and determine the governing mechanisms behind the heat transfer improvement due to surface modifications. First, however, we start by validating our numerical framework.

2.3. Grid independence study

To capture the governing hydro- and thermodynamics of the problem, all relevant scales must be resolved. Because of the relatively high ![]() $\mathit {Pr}_l=O(10)$ in the present problem, we expect the smallest thermal scales to dictate the required grid resolution. To determine the necessary resolution in the liquid film, we define a test case with a modified surface and a high

$\mathit {Pr}_l=O(10)$ in the present problem, we expect the smallest thermal scales to dictate the required grid resolution. To determine the necessary resolution in the liquid film, we define a test case with a modified surface and a high ![]() $\mathit {Pr}_l=20$ where we expect the thermal scales to be minimal (of the cases considered in this study). The fluid parameters are

$\mathit {Pr}_l=20$ where we expect the thermal scales to be minimal (of the cases considered in this study). The fluid parameters are ![]() $\mathit {Ka}=488$ and

$\mathit {Ka}=488$ and ![]() $\mathit {Re}=100$ and the surface topology parameters (illustrated in figure 1a) are

$\mathit {Re}=100$ and the surface topology parameters (illustrated in figure 1a) are ![]() $\hat {p}=10\delta _N$ and

$\hat {p}=10\delta _N$ and ![]() $\hat {h}=\hat {l}=\delta _N$ with the Nusselt film thickness

$\hat {h}=\hat {l}=\delta _N$ with the Nusselt film thickness ![]() $\delta _N$ defined in (2.17).

$\delta _N$ defined in (2.17).

We use a periodic square domain of side length ![]() $L=80\delta _N$,

$L=80\delta _N$, ![]() $T_{wall}=1$ and we initialise the temperature field with

$T_{wall}=1$ and we initialise the temperature field with ![]() $T=0$. Once the average temperature and the

$T=0$. Once the average temperature and the ![]() $\mathit {Re}$ number of the film have reached statistically steady values we compute the average

$\mathit {Re}$ number of the film have reached statistically steady values we compute the average ![]() $\mathit {Nu}$-value and wall-normal temperature profile over the domain. This is done for grid resolutions from

$\mathit {Nu}$-value and wall-normal temperature profile over the domain. This is done for grid resolutions from ![]() $6$ to