1. Introduction and literature review

Natural convection over ribbed/finned surfaces is widely encountered in engineering applications, such as cooling of electronics and telecommunication devices, air solar collectors and gas-cooled nuclear reactors. Compared with forced convection, a system that depends on the natural-convection heat transfer regime has lower initial and running costs, less noise and vibrations, higher reliability, almost maintenance-free operations and better ability for use in hostile environments under dust, moist air, etc. On the other hand, the main problem facing designers is the low heat transfer coefficient of these systems. Due to the ever-growing trend of miniaturization of electronic components and the increase in power supply, higher heat generation rates per unit volume are encountered (Joshi, Willson & Hazard Reference Joshi, Willson and Hazard1989). This trend has stimulated many investigations to enhance natural-convection cooling systems so that they can be effective at handling operation requirements. One intuitively appealing solution to enhance the heat transfer performance of these systems is to apply some sort of alteration or disturbance on the heated surface(s) in analogy to the well-established concept of heat transfer promotion by adding ribs/fins to surfaces exposed to forced convection (Bunker & Donnellan Reference Bunker and Donnellan2003; Chyu, Oluyede & Moon Reference Chyu, Oluyede and Moon2007; Han, Dutta & Ekkad Reference Han, Dutta and Ekkad2012). However, studies on the effectiveness of adding surface alterations (ribs, interrupted fins, dimples, etc.) to vertical plates exposed to natural convection have not led yet to convincing guidelines, with some researchers reporting an improvement of up to 200![]() $\%$ compared with the performance of plane vertical plates, and others who have found them useless or even of negative influence on the local and averaged heat transfer parameters (Bhavnani & Bergles Reference Bhavnani and Bergles1990).

$\%$ compared with the performance of plane vertical plates, and others who have found them useless or even of negative influence on the local and averaged heat transfer parameters (Bhavnani & Bergles Reference Bhavnani and Bergles1990).

The need to better understand the interaction between the surface microstructure and the buoyancy-driven flow has motivated many experimental and numerical investigations to assess the usefulness and the feasibility of adding different types of protrusions to the heated surfaces in terms of their effects on the flow regime, the heat transfer characteristics and the mass of the cooling modules. Examples of some surface alterations/extensions, considered in previous investigations, are displayed in figure 1, including periodic (wavy, rounded, zigzag) corrugations (Kishinami et al. Reference Kishinami, Saito and Tokura1990; Bhavnani & Bergles Reference Bhavnani and Bergles1991; Yao Reference Yao2006; Hærvig & Sørensen Reference Hærvig and Sørensen2020), steps (Bhavnani & Bergles Reference Bhavnani and Bergles1990), two-dimensional ribs (Tanda Reference Tanda1997; Cavazzuti & Corticelli Reference Cavazzuti and Corticelli2008) and different arrangements of fins (Guglielmini et al. Reference Guglielmini, Nannei and Tanda1987; Ahmadi et al. Reference Ahmadi, Mostafavi and Bahrami2014; El Ghandouri et al. Reference El Ghandouri, El Maakoul, Saadeddine and Meziane2020). Various experimental techniques have been adopted for mapping the thermal field to assess the detailed heat transfer performance. Two-dimensional and three-dimensional feature-resolving numerical simulations have also demonstrated to be powerful tools for the acquisition of large amounts of data on thermal fields and flow regimes, particularly for complex configurations (Yao Reference Yao2006; Cavazzuti & Corticelli Reference Cavazzuti and Corticelli2008; Ahmadi et al. Reference Ahmadi, Mostafavi and Bahrami2014; Hærvig & Sørensen Reference Hærvig and Sørensen2020).

Figure 1. Schematic drawings of some surface alterations examined in the literature. The indicated geometries are (from top left to bottom right): sinusoidal waves (Bhavnani & Bergles Reference Bhavnani and Bergles1991), complex waves (Yao Reference Yao2006), convex–concave semi-circles (Kishinami, Saito & Tokura Reference Kishinami, Saito and Tokura1990), zigzag shaping (Hærvig & Sørensen Reference Hærvig and Sørensen2020), steps (Bhavnani & Bergles Reference Bhavnani and Bergles1990); transverse square ribs (Tanda Reference Tanda1997), transverse trapezoidal ribs (Cavazzuti & Corticelli Reference Cavazzuti and Corticelli2008), rippled vertical fins (El Ghandouri et al. Reference El Ghandouri, El Maakoul, Saadeddine and Meziane2020), staggered arrangement of interrupted fins (Guglielmini, Nannei & Tanda Reference Guglielmini, Nannei and Tanda1987), in-line arrangement of interrupted fins (Ahmadi, Mostafavi & Bahrami Reference Ahmadi, Mostafavi and Bahrami2014).

Numerical work on flows over surfaces with complicated small-scale details including irregularities, roughness, porosity, etc. has been a challenge due to the high computational resources required to numerically discretize flow and temperature fields in the vicinity of the surface microstructures. In the present work, the multiscale homogenization approach is proposed to simplify the modelling of buoyancy-driven flows over periodically roughened vertical surfaces, while maintaining an acceptable level of accuracy. Asymptotic homogenization is an approach which targets the study of the macroscale behaviour of a medium which contains microscopic details, by replacing the rapidly varying properties related to the heterogeneity of the medium by equivalent homogeneous macroscopic properties (Babuška Reference Babuška1976). This technique can play a pivotal role when handling differential equations that govern physical problems with microscale fluctuations (Engquist & Souganidis Reference Engquist and Souganidis2008) which are characterized by some sort of periodicity or pseudo-periodicity. These problems can be computationally simplified by first solving ad hoc auxiliary systems of equations in a microscopic domain to evaluate the necessary upscaled conditions by means of averaging. The approach relies on the asymptotic expansion of the dependent variables in terms of a wisely chosen small parameter whose existence is related to the presence of well-separated scales, for instance a microscopic length scale (![]() $\ell$) and a macroscopic length scale (

$\ell$) and a macroscopic length scale (![]() $L \gg \ell$), so that the parameter

$L \gg \ell$), so that the parameter ![]() $\epsilon = {\ell }/{L} \ll 1$ can be defined, and the solution of the problem can be sought up to different orders of accuracy in terms of

$\epsilon = {\ell }/{L} \ll 1$ can be defined, and the solution of the problem can be sought up to different orders of accuracy in terms of ![]() $\epsilon$.

$\epsilon$.

Flow over micro-textured surfaces represents a typical homogenization problem. Jiménez Bolaños & Vernescu (Reference Jiménez Bolaños and Vernescu2017) have derived the Navier-slip effective condition for the Stokes flow over a rough surface via homogenization theory as a first-order corrector term to the no-slip condition of a smooth surface. Zampogna, Magnaudet & Bottaro (Reference Zampogna, Magnaudet and Bottaro2019a) have pursued a generalization of the classical first-order Navier-slip condition (Navier Reference Navier1823) over a rough surface by means of a third-order Navier-slip tensor. The homogenized model was pushed to second order by Lācis et al. (Reference Lācis, Sudhakar, Pasche and Bagheri2020) with the introduction of a transpiration velocity, the normal velocity component at the fictitious interface, thus enhancing model predictions for a turbulent boundary layer over a rough surface. A further improvement has been added by Bottaro & Naqvi (Reference Bottaro and Naqvi2020), who sought a solution up to third-order accuracy. The range of applications subtended by homogenization theory is being continuously widened and enhancements to the basic formulation are ongoing. Zampogna et al. (Reference Zampogna, Naqvi, Magnaudet and Bottaro2019b) have extended the theory to the study of the turbulent flow over compliant riblets, seeking reduction of the skin friction drag. Adjoint homogenization has been introduced by Bottaro (Reference Bottaro2019) as a method to take into account nonlinear effects within the microscopic region.

The work presented in this paper is a novel implementation of the multiscale homogenization technique to study natural-convection heat transfer over rough surfaces. The only previous contribution in this aspect was the work by Introïni, Quintard & Duval (Reference Introïni, Quintard and Duval2011), who applied the volume-averaging upscaling method to the study of the steady laminar buoyancy-driven flow over rough surfaces. However, their model suffered from some deficiencies that limit its applicability range. A critical assumption adopted by Introïni and collaborators was the neglect of buoyancy effects within the microscopic region, so that the momentum and energy conservation equations are decoupled. This assumption, despite being mathematically advantageous, limits the model applicability to cases in which the Rayleigh number characterizing the microscopic problem (based on the microscopic length scale and the temperature difference across the microscopic region) is sufficiently small. To satisfy this condition, the bulk Rayleigh number must be lower than some threshold value, and the roughness elements must be confined within the thermal boundary layer. In practical situations, high values of the Rayleigh number are often encountered. Moreover, the model developed by Introïni et al. (Reference Introïni, Quintard and Duval2011) is only accurate to first order in ![]() $\epsilon$.

$\epsilon$.

In this paper, asymptotic homogenization is used to formulate expressions for the macroscopic velocity and temperature effective conditions at a virtual interface separating the microscopic and the macroscopic sub-domains. Unlike Introïni et al. (Reference Introïni, Quintard and Duval2011), the Boussinesq approximation is employed for the buoyancy term in the microscopic momentum equation to be linearly coupled with the energy equation. The dependent parameters are expanded asymptotically in powers of the small parameter ![]() $\epsilon ={\text {pattern periodicity }(\ell )}/{\text {plate length }(L)}$. The effective conditions for velocity and temperature are all sought up to second-order accuracy. In the next section, the governing equations and the boundary conditions of the problem are outlined, and domain decomposition is explained. In § 3, the microscopic region is considered where the asymptotic expansion of the dependent variables is defined, and the problem is reconstructed at different orders of

$\epsilon ={\text {pattern periodicity }(\ell )}/{\text {plate length }(L)}$. The effective conditions for velocity and temperature are all sought up to second-order accuracy. In the next section, the governing equations and the boundary conditions of the problem are outlined, and domain decomposition is explained. In § 3, the microscopic region is considered where the asymptotic expansion of the dependent variables is defined, and the problem is reconstructed at different orders of ![]() $\epsilon$. For each order, generic forms of the solutions are assumed and auxiliary differential systems are formulated. Then, the case of transverse square ribs is discussed in § 4. The parameters of interest are determined via numerical solution of the auxiliary systems, and the effect of the matching surface location is considered. In § 5, a parametric study seeking the effect of varying the rib size to the pitch distance ratio on the different coefficients is presented. In § 6, the macroscale problem is considered by imposing the upscaled boundary conditions at a virtual vertical interface passing through the outer rims of the ribs; full feature-resolving simulations are also conducted to validate the predictions of the model. In § 7, the accuracy deterioration of the homogenized model is monitored with the increase of

$\epsilon$. For each order, generic forms of the solutions are assumed and auxiliary differential systems are formulated. Then, the case of transverse square ribs is discussed in § 4. The parameters of interest are determined via numerical solution of the auxiliary systems, and the effect of the matching surface location is considered. In § 5, a parametric study seeking the effect of varying the rib size to the pitch distance ratio on the different coefficients is presented. In § 6, the macroscale problem is considered by imposing the upscaled boundary conditions at a virtual vertical interface passing through the outer rims of the ribs; full feature-resolving simulations are also conducted to validate the predictions of the model. In § 7, the accuracy deterioration of the homogenized model is monitored with the increase of ![]() $\epsilon$ and/or the Grashof number, and the limit of validity of the approach is ascertained. Furthermore, the accuracy of the method is confirmed for different shapes of the roughness elements. In the concluding section, the main findings of the study are highlighted.

$\epsilon$ and/or the Grashof number, and the limit of validity of the approach is ascertained. Furthermore, the accuracy of the method is confirmed for different shapes of the roughness elements. In the concluding section, the main findings of the study are highlighted.

2. Governing equations and domain decomposition

2.1. The dimensional equations

As a major assumption, the changes in the density of the fluid are considered to only affect the buoyancy term in the momentum conservation equation. Under the Boussinesq approximation, the conservation equations in terms of the dimensional variables, space coordinates ![]() $\hat {x}_{i}$, time

$\hat {x}_{i}$, time ![]() $\hat {t}$, pressure

$\hat {t}$, pressure ![]() $\hat {P}$, velocity

$\hat {P}$, velocity ![]() $\hat {u}_{i}$ and temperature

$\hat {u}_{i}$ and temperature ![]() $\hat {T}$, are expressed as follows:

$\hat {T}$, are expressed as follows:

\begin{gather}\hat{\rho}_{\infty}\left(\frac{\partial \hat{u}_{i}}{\partial \hat{t}}+\hat{u}_{j} \frac{\partial{\hat{u}_{i}}}{\partial {\hat x_{j}}}\right)={-}\frac{\partial({\hat{P}-\hat{P}_{\infty}})}{\partial{\hat{x}_{i}}}+\mu \frac{\partial^2 \hat{u}_{i}}{\partial {\hat{x}_{j}}^2} -\hat{\rho}_{\infty}\beta(\hat{T}-\hat{T}_{\infty})g_{i}, \end{gather}

\begin{gather}\hat{\rho}_{\infty}\left(\frac{\partial \hat{u}_{i}}{\partial \hat{t}}+\hat{u}_{j} \frac{\partial{\hat{u}_{i}}}{\partial {\hat x_{j}}}\right)={-}\frac{\partial({\hat{P}-\hat{P}_{\infty}})}{\partial{\hat{x}_{i}}}+\mu \frac{\partial^2 \hat{u}_{i}}{\partial {\hat{x}_{j}}^2} -\hat{\rho}_{\infty}\beta(\hat{T}-\hat{T}_{\infty})g_{i}, \end{gather} \begin{gather}\frac{\partial \hat{T}}{\partial \hat{t}}+\hat{u}_{j} \frac{\partial{\hat T}}{\partial {\hat x_{j}}}= \alpha\frac{\partial^2 \hat{T}}{\partial {\hat{x}_{j}}^2}, \end{gather}

\begin{gather}\frac{\partial \hat{T}}{\partial \hat{t}}+\hat{u}_{j} \frac{\partial{\hat T}}{\partial {\hat x_{j}}}= \alpha\frac{\partial^2 \hat{T}}{\partial {\hat{x}_{j}}^2}, \end{gather}

with ![]() $\hat \rho _\infty$,

$\hat \rho _\infty$, ![]() $\hat P_\infty$ and

$\hat P_\infty$ and ![]() $\hat T_\infty$ the density, pressure and temperature in the stagnant flow region, sufficiently far away from the vertical wall. The parameters assumed constant in the equations above are the volumetric thermal expansion coefficient,

$\hat T_\infty$ the density, pressure and temperature in the stagnant flow region, sufficiently far away from the vertical wall. The parameters assumed constant in the equations above are the volumetric thermal expansion coefficient, ![]() $\beta$, the dynamic viscosity,

$\beta$, the dynamic viscosity, ![]() $\mu =\hat \rho _\infty \nu$, with

$\mu =\hat \rho _\infty \nu$, with ![]() $\nu$ the kinematic viscosity, and the thermal diffusivity,

$\nu$ the kinematic viscosity, and the thermal diffusivity, ![]() $\alpha$. With the axes as in figure 2, the volume force per unit mass has components

$\alpha$. With the axes as in figure 2, the volume force per unit mass has components ![]() $g_i=-g \delta _{i1}$ with

$g_i=-g \delta _{i1}$ with ![]() $g$ the gravitational acceleration and

$g$ the gravitational acceleration and ![]() $\delta _{ij}$ the Kronecker index. The parameter controlling the thermal convection flow is the Rayleigh number

$\delta _{ij}$ the Kronecker index. The parameter controlling the thermal convection flow is the Rayleigh number ![]() $Ra$, defined as

$Ra$, defined as

where the temperature of the wall, ![]() $\hat T_w$, is maintained constant, and the plate height,

$\hat T_w$, is maintained constant, and the plate height, ![]() $L$, is the macroscopic length scale of the problem. We also define the Grashof number,

$L$, is the macroscopic length scale of the problem. We also define the Grashof number, ![]() $Gr=Ra/Pr$, with

$Gr=Ra/Pr$, with ![]() $Pr=\nu /\alpha$ the Prandtl number, a property of the fluid. Given the presence of two characteristic length scales, a macroscopic and a microscopic one, the latter related to the periodicity

$Pr=\nu /\alpha$ the Prandtl number, a property of the fluid. Given the presence of two characteristic length scales, a macroscopic and a microscopic one, the latter related to the periodicity ![]() $l$ of the microstructures present on the vertical surface, two problems will be set up. These two problems will be coupled at some distance from the wall, a distance that is asymptotically large when seen from the microscopic point of view and asymptotically small when seen from the macroscopic viewpoint.

$l$ of the microstructures present on the vertical surface, two problems will be set up. These two problems will be coupled at some distance from the wall, a distance that is asymptotically large when seen from the microscopic point of view and asymptotically small when seen from the macroscopic viewpoint.

Figure 2. Sketch of a general vertical rough surface, periodically micro-patterned, with notations and indication of microscopic and macroscopic domains.

2.2. The macroscale problem

To set the proper scales of the macroscopic problem we consider the fact that the motion of the fluid is generated by the buoyancy force; if ![]() $\mathcal {U}$ is the characteristic velocity of the fluid, we can write

$\mathcal {U}$ is the characteristic velocity of the fluid, we can write

We thus define the velocity scale ![]() $\mathcal {U}=\sqrt {\beta (\hat T_w-\hat T_\infty ) g L} = Gr^{1/2} \frac {\nu }{L}$ and normalize the velocity vector as

$\mathcal {U}=\sqrt {\beta (\hat T_w-\hat T_\infty ) g L} = Gr^{1/2} \frac {\nu }{L}$ and normalize the velocity vector as

The other dimensionless variables are defined as follows:

for the balance equations to become

These equations depend on only the macroscopic independent variables, ![]() $t$ and

$t$ and ![]() $X_i$, and must be solved subject to matching conditions at

$X_i$, and must be solved subject to matching conditions at ![]() $X_2 \to 0$, together with

$X_2 \to 0$, together with ![]() $\varTheta =U_1=0$ and

$\varTheta =U_1=0$ and ![]() ${\partial U_2}/{\partial X_2}=0$ for

${\partial U_2}/{\partial X_2}=0$ for ![]() $X_2 \to \infty$.

$X_2 \to \infty$.

2.3. The microscale problem

The near-wall problem differs from the previous one in that the microscopic velocity scale is taken to be ![]() $\epsilon \, \mathcal {U}$, with

$\epsilon \, \mathcal {U}$, with ![]() $\epsilon =\ell /L\ll 1$. Also, the pressure scale for the near-wall flow is the viscous pressure, i.e.

$\epsilon =\ell /L\ll 1$. Also, the pressure scale for the near-wall flow is the viscous pressure, i.e. ![]() $\mu (\epsilon \,{\mathcal {U}})/l$. Dimensionless variables in the microscopic domain are introduced as follows:

$\mu (\epsilon \,{\mathcal {U}})/l$. Dimensionless variables in the microscopic domain are introduced as follows:

The microscopic dimensionless equations are

with the reduced Grashof number ![]() $\mathcal {R}_G$, defined by

$\mathcal {R}_G$, defined by ![]() $\mathcal {R}_G= \epsilon \sqrt {Gr}$, assumed of order one. The microscale problem is bounded by the microstructured wall on one side; therefore, the following condition is imposed at this location:

$\mathcal {R}_G= \epsilon \sqrt {Gr}$, assumed of order one. The microscale problem is bounded by the microstructured wall on one side; therefore, the following condition is imposed at this location:

with ![]() $y_{w}=y_{w}(x_1,x_3)$ the micro-patterned wall. A representative volume element must be chosen, of unit length along

$y_{w}=y_{w}(x_1,x_3)$ the micro-patterned wall. A representative volume element must be chosen, of unit length along ![]() $x_1$ and

$x_1$ and ![]() $x_3$ (cf. figure 2), and periodic conditions are enforced for all dependent variables along these directions. On account of the scalings adopted for inner (i.e. near-wall) and outer problems, the conditions for

$x_3$ (cf. figure 2), and periodic conditions are enforced for all dependent variables along these directions. On account of the scalings adopted for inner (i.e. near-wall) and outer problems, the conditions for ![]() $x_2\to \infty$ are

$x_2\to \infty$ are

these amount to matching the components of the traction vector and of the heat flux between the two regions. For ease of notation, in the equations above we have introduced the following definitions for the macroscopic dimensionless stresses in the streamwise, normal and spanwise directions (respectively ![]() $S_{12}, S_{22}, S_{32}$) as well as the macroscopic dimensionless normal temperature gradient (

$S_{12}, S_{22}, S_{32}$) as well as the macroscopic dimensionless normal temperature gradient (![]() $\eta$):

$\eta$):

Notice that both ![]() $S_{i2}$ and

$S_{i2}$ and ![]() $\eta$ depend on only macroscopic variables; they represent the forcing of the outer flow on the near-wall state.

$\eta$ depend on only macroscopic variables; they represent the forcing of the outer flow on the near-wall state.

We still need to specify the asymptotic matching conditions which will eventually result in effective boundary conditions for the macroscopic problem, to be applied some distance from the microstructured wall. They are:

3. Asymptotic analysis of the microscale problem

3.1. Expansion of the inner variables

Asymptotic expansions in terms of the small parameter ![]() $\epsilon$ are introduced, and like-order terms are collected, leading to a hierarchy of problems. We impose

$\epsilon$ are introduced, and like-order terms are collected, leading to a hierarchy of problems. We impose

and likewise for ![]() $p$ and

$p$ and ![]() $\theta$. Furthermore, using the chain rule, we replace in the microscopic equations the term

$\theta$. Furthermore, using the chain rule, we replace in the microscopic equations the term ![]() ${\partial }/{\partial x_i}$ by

${\partial }/{\partial x_i}$ by ![]() ${\partial }/{\partial x_i}+\epsilon \,({\partial }/{\partial X_i})$. The asymptotic expressions are plugged into (2.8a) to (2.8f) governing the microscale problem.

${\partial }/{\partial x_i}+\epsilon \,({\partial }/{\partial X_i})$. The asymptotic expressions are plugged into (2.8a) to (2.8f) governing the microscale problem.

3.2. Reconstruction of the problem at different orders

The problems at the asymptotic orders of interest are given below.

3.2.1. The  ${O}(\epsilon ^0)$ problem

${O}(\epsilon ^0)$ problem

We have

\begin{gather}-\frac{\partial p^{(0)}}{\partial x_i}+ \frac{\partial^2 u_i^{(0)}}{\partial x_j^2}+\mathcal{R}_G \theta^{(0)} \delta_{i1}=0, \end{gather}

\begin{gather}-\frac{\partial p^{(0)}}{\partial x_i}+ \frac{\partial^2 u_i^{(0)}}{\partial x_j^2}+\mathcal{R}_G \theta^{(0)} \delta_{i1}=0, \end{gather} \begin{gather}\frac{\partial^2 \theta^{(0)}}{\partial x_j^2}=0, \end{gather}

\begin{gather}\frac{\partial^2 \theta^{(0)}}{\partial x_j^2}=0, \end{gather}with boundary conditions

\begin{gather}-p^{(0)}\delta_{i2}+\left(\frac{\partial u_i^{(0)}}{\partial x_2}+\frac{\partial u_2^{(0)}}{\partial x_i}\right)=S_{i2}, \quad \frac{\partial \theta^{(0)}}{\partial x_2}=0 \quad {\rm for} \ x_2\to\infty. \end{gather}

\begin{gather}-p^{(0)}\delta_{i2}+\left(\frac{\partial u_i^{(0)}}{\partial x_2}+\frac{\partial u_2^{(0)}}{\partial x_i}\right)=S_{i2}, \quad \frac{\partial \theta^{(0)}}{\partial x_2}=0 \quad {\rm for} \ x_2\to\infty. \end{gather}A solution of this problem can be sought by separation of variables, on account of the linearity of the system, for the solution to take the form

with ![]() $\breve u_{ik}$,

$\breve u_{ik}$, ![]() $u_i^{\dagger}$,

$u_i^{\dagger}$, ![]() $\breve {p}_{k}$ and

$\breve {p}_{k}$ and ![]() $p^{\dagger}$ tensors which depend on microscopic variables only, and

$p^{\dagger}$ tensors which depend on microscopic variables only, and ![]() $P_0$ an integration constant function only of

$P_0$ an integration constant function only of ![]() $X_j$. After plugging the ansatz for the order-zero solution into the balance equations, it becomes clear that uniqueness conditions are needed for

$X_j$. After plugging the ansatz for the order-zero solution into the balance equations, it becomes clear that uniqueness conditions are needed for ![]() $\breve p_k$ and

$\breve p_k$ and ![]() $p^{\dagger}$, which appear in the system only through their gradients. We enforce the vanishing of the integrals of

$p^{\dagger}$, which appear in the system only through their gradients. We enforce the vanishing of the integrals of ![]() $\breve p_k$ and

$\breve p_k$ and ![]() $p^{\dagger}$ over a cubic cell of unit side length positioned sufficiently far from the wall (nominally for

$p^{\dagger}$ over a cubic cell of unit side length positioned sufficiently far from the wall (nominally for ![]() $x_2\to \infty$); this leads to the vanishing of

$x_2\to \infty$); this leads to the vanishing of ![]() $P_0$. It is also clear that we cannot stop the solution at this order, since the leading-order temperature solution is simply

$P_0$. It is also clear that we cannot stop the solution at this order, since the leading-order temperature solution is simply ![]() $\theta ^{(0)}=1$, i.e. the effect of the microstructure appears in the temperature at the next

$\theta ^{(0)}=1$, i.e. the effect of the microstructure appears in the temperature at the next ![]() $\epsilon$ order.

$\epsilon$ order.

The dynamic problem at ![]() ${O}(\epsilon ^0)$ yields the same equations for

${O}(\epsilon ^0)$ yields the same equations for ![]() $\breve u_{ik}$ and

$\breve u_{ik}$ and ![]() $\breve p_k$ already given for the isothermal case by Bottaro & Naqvi (Reference Bottaro and Naqvi2020), so that we can anticipate that the first correction to the no-slip condition for the velocity will be a Navier-slip term. Such a leading-order problem reads

$\breve p_k$ already given for the isothermal case by Bottaro & Naqvi (Reference Bottaro and Naqvi2020), so that we can anticipate that the first correction to the no-slip condition for the velocity will be a Navier-slip term. Such a leading-order problem reads

with

The ![]() ${\dagger}$ variables, which describe the effect of buoyancy on velocity and pressure fields, satisfy the steady system

${\dagger}$ variables, which describe the effect of buoyancy on velocity and pressure fields, satisfy the steady system

\begin{gather}-\frac{\partial p^{\dagger}}{\partial x_i}+\frac{\partial^2 u_{i}^{\dagger}}{\partial x_j^2}={-}\delta_{i1}, \end{gather}

\begin{gather}-\frac{\partial p^{\dagger}}{\partial x_i}+\frac{\partial^2 u_{i}^{\dagger}}{\partial x_j^2}={-}\delta_{i1}, \end{gather}with

\begin{gather}- p^{\dagger} \delta_{i2}+\left(\frac{\partial u_{i}^{\dagger}}{\partial x_2}+\frac{\partial u_{2}^{\dagger}}{\partial x_i}\right)=0 \quad {\rm at} \ x_2 \to \infty. \end{gather}

\begin{gather}- p^{\dagger} \delta_{i2}+\left(\frac{\partial u_{i}^{\dagger}}{\partial x_2}+\frac{\partial u_{2}^{\dagger}}{\partial x_i}\right)=0 \quad {\rm at} \ x_2 \to \infty. \end{gather}

As it will be shown later on, the problems can be further simplified when ![]() $x_3$-elongated wall ribs are examined, as in the case of riblets (Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989; Luchini, Manzo & Pozzi Reference Luchini, Manzo and Pozzi1991).

$x_3$-elongated wall ribs are examined, as in the case of riblets (Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989; Luchini, Manzo & Pozzi Reference Luchini, Manzo and Pozzi1991).

3.2.2. The  ${O}(\epsilon ^1)$ problem

${O}(\epsilon ^1)$ problem

The equations at order ![]() $\epsilon$ are forced by the order-one state, i.e.

$\epsilon$ are forced by the order-one state, i.e.

\begin{gather}-\frac{\partial p^{(1)}}{\partial x_i}+ \frac{\partial^2 u_i^{(1)}}{\partial x_j^2}+\mathcal{R}_G \theta^{(1)} \delta_{i1}= \frac{\partial p^{(0)}}{\partial X_i}-2 \frac{\partial^2 u_i^{(0)}}{\partial x_j \partial X_j}+\mathcal{R}_G \left(\frac{\partial u_i^{(0)}}{\partial t}+u_j^{(0)}\frac{\partial u_i^{(0)}}{\partial x_j}\right), \end{gather}

\begin{gather}-\frac{\partial p^{(1)}}{\partial x_i}+ \frac{\partial^2 u_i^{(1)}}{\partial x_j^2}+\mathcal{R}_G \theta^{(1)} \delta_{i1}= \frac{\partial p^{(0)}}{\partial X_i}-2 \frac{\partial^2 u_i^{(0)}}{\partial x_j \partial X_j}+\mathcal{R}_G \left(\frac{\partial u_i^{(0)}}{\partial t}+u_j^{(0)}\frac{\partial u_i^{(0)}}{\partial x_j}\right), \end{gather} \begin{gather}\frac{\partial^2 \theta^{(1)}}{\partial x_j^2}={-}2\frac{\partial^2 \theta^{(0)}}{\partial x_j \partial X_j}+\mathcal{R}_G\, Pr\left(\frac{\partial \theta^{(0)}}{\partial t}+u_j^{(0)}\frac{\partial \theta^{(0)}}{\partial x_j}\right), \end{gather}

\begin{gather}\frac{\partial^2 \theta^{(1)}}{\partial x_j^2}={-}2\frac{\partial^2 \theta^{(0)}}{\partial x_j \partial X_j}+\mathcal{R}_G\, Pr\left(\frac{\partial \theta^{(0)}}{\partial t}+u_j^{(0)}\frac{\partial \theta^{(0)}}{\partial x_j}\right), \end{gather}with boundary conditions

\begin{gather}-p^{(1)}\delta_{i2}+\left(\frac{\partial u_i^{(1)}}{\partial x_2}+\frac{\partial u_2^{(1)}}{\partial x_i}\right)={-}\left(\frac{\partial u_i^{(0)}}{\partial X_2}+\frac{\partial u_2^{(0)}}{\partial X_i}\right)\quad {\rm at} \ x_2\to\infty, \end{gather}

\begin{gather}-p^{(1)}\delta_{i2}+\left(\frac{\partial u_i^{(1)}}{\partial x_2}+\frac{\partial u_2^{(1)}}{\partial x_i}\right)={-}\left(\frac{\partial u_i^{(0)}}{\partial X_2}+\frac{\partial u_2^{(0)}}{\partial X_i}\right)\quad {\rm at} \ x_2\to\infty, \end{gather}

We must now substitute the results for ![]() $u_i^{(0)}$,

$u_i^{(0)}$, ![]() $p^{(0)}$ and

$p^{(0)}$ and ![]() $\theta ^{(0)}$ into (3.6a) to (3.6f). As a first step, a solution for

$\theta ^{(0)}$ into (3.6a) to (3.6f). As a first step, a solution for ![]() $\theta ^{(1)}$ is to be sought from the energy equation and the corresponding boundary conditions. Specifically, these equations read

$\theta ^{(1)}$ is to be sought from the energy equation and the corresponding boundary conditions. Specifically, these equations read

Owing to linearity, the solution can be written as

The new microscopic field ![]() $\tilde \theta$ solves the system

$\tilde \theta$ solves the system

The equations governing the behaviour of ![]() $u_i^{(1)}$ and

$u_i^{(1)}$ and ![]() $p^{(1)}$ can be recast as follows:

$p^{(1)}$ can be recast as follows:

\begin{gather} \frac{\partial u_i^{(1)}}{\partial x_i}={-}\breve u_{jk} \frac{\partial S_{k2}}{\partial X_j}\end{gather}

\begin{gather} \frac{\partial u_i^{(1)}}{\partial x_i}={-}\breve u_{jk} \frac{\partial S_{k2}}{\partial X_j}\end{gather} \begin{gather} -\frac{\partial p^{(1)}}{\partial x_i}+\frac{\partial^2 u_i^{(1)}}{\partial x_j^2}=\mathcal{R}_G^3 u_j^{\dagger} \frac{\partial u_i^{\dagger}}{\partial x_j}+\mathcal{R}_G^2 \left[\breve u_{jk} \frac{\partial u_i^{\dagger}}{\partial x_j}+ u_j^{\dagger} \frac{\partial \breve u_{ik}}{\partial x_j}\right]S_{k2}\nonumber\\ \hspace{6pc} +\mathcal{R}_G\left[\breve u_{jk} \frac{\partial u_{i \ell}}{\partial x_j}\right]S_{k2} S_{\ell 2}+ \mathcal{R}_G \breve u_{ik} \frac{\partial S_{k2}}{\partial t}\nonumber\\ \hspace{7pc} -\mathcal{R}_G \eta \tilde \theta \delta_{i1} + \breve p_k \frac{\partial S_{k2}}{\partial X_i} -2 \frac{\partial \breve u_{ik}}{\partial x_j} \frac{\partial S_{k2}}{\partial X_j}, \end{gather}

\begin{gather} -\frac{\partial p^{(1)}}{\partial x_i}+\frac{\partial^2 u_i^{(1)}}{\partial x_j^2}=\mathcal{R}_G^3 u_j^{\dagger} \frac{\partial u_i^{\dagger}}{\partial x_j}+\mathcal{R}_G^2 \left[\breve u_{jk} \frac{\partial u_i^{\dagger}}{\partial x_j}+ u_j^{\dagger} \frac{\partial \breve u_{ik}}{\partial x_j}\right]S_{k2}\nonumber\\ \hspace{6pc} +\mathcal{R}_G\left[\breve u_{jk} \frac{\partial u_{i \ell}}{\partial x_j}\right]S_{k2} S_{\ell 2}+ \mathcal{R}_G \breve u_{ik} \frac{\partial S_{k2}}{\partial t}\nonumber\\ \hspace{7pc} -\mathcal{R}_G \eta \tilde \theta \delta_{i1} + \breve p_k \frac{\partial S_{k2}}{\partial X_i} -2 \frac{\partial \breve u_{ik}}{\partial x_j} \frac{\partial S_{k2}}{\partial X_j}, \end{gather}with boundary conditions

\begin{gather}\left.\begin{array}{c@{}} \dfrac{\partial u_1^{(1)}}{\partial x_2}+\dfrac{\partial u_2^{(1)}}{\partial x_1}={-}\breve u_{1k} \dfrac{\partial S_{k2}}{\partial X_2} -\breve u_{2k} \dfrac{\partial S_{k2}}{\partial X_1}, \\ - p^{(1)}+2\dfrac{\partial u_2^{(1)}}{\partial x_2}={-}2 \breve u_{2k}\dfrac{\partial S_{k2}}{\partial X_2}, \\ \dfrac{\partial u_3^{(1)}}{\partial x_2}+\dfrac{\partial u_2^{(1)}}{\partial x_3}={-}\breve u_{3k} \dfrac{\partial S_{k2}}{\partial X_2} -\breve u_{2k} \dfrac{\partial S_{k2}}{\partial X_3} \quad {\rm at} \ x_2\to\infty. \end{array}\right\} \end{gather}

\begin{gather}\left.\begin{array}{c@{}} \dfrac{\partial u_1^{(1)}}{\partial x_2}+\dfrac{\partial u_2^{(1)}}{\partial x_1}={-}\breve u_{1k} \dfrac{\partial S_{k2}}{\partial X_2} -\breve u_{2k} \dfrac{\partial S_{k2}}{\partial X_1}, \\ - p^{(1)}+2\dfrac{\partial u_2^{(1)}}{\partial x_2}={-}2 \breve u_{2k}\dfrac{\partial S_{k2}}{\partial X_2}, \\ \dfrac{\partial u_3^{(1)}}{\partial x_2}+\dfrac{\partial u_2^{(1)}}{\partial x_3}={-}\breve u_{3k} \dfrac{\partial S_{k2}}{\partial X_2} -\breve u_{2k} \dfrac{\partial S_{k2}}{\partial X_3} \quad {\rm at} \ x_2\to\infty. \end{array}\right\} \end{gather}Again, a generic form of the solution can be sought, i.e.

\begin{gather}

u_i^{(1)}=\dot u_{ijk} \left[\frac{\partial

S_{k2}}{\partial X_j}\right] + \ddot u_{ik} [\mathcal{R}_G

(S_{k2})^2]+ \ddot u_{i12} [\mathcal{R}_G

S_{12}S_{22}]+\ddot u_{i13} [\mathcal{R}_G

S_{12}S_{32}]\nonumber\\

\hspace{5pc} +\ddot u_{i23}

[\mathcal{R}_G S_{22}S_{32}]+u_i' [\mathcal{R}_G

\eta]+\bar{u}_{ik} [\mathcal{R}_G^2 S_{k2}] + u_i^ \ddagger

[\mathcal{R}_G^3] +u^t_{ik}

\left[\mathcal{R}_G \frac{\partial S_{k2}}{\partial

t}\right],

\end{gather}

\begin{gather}

u_i^{(1)}=\dot u_{ijk} \left[\frac{\partial

S_{k2}}{\partial X_j}\right] + \ddot u_{ik} [\mathcal{R}_G

(S_{k2})^2]+ \ddot u_{i12} [\mathcal{R}_G

S_{12}S_{22}]+\ddot u_{i13} [\mathcal{R}_G

S_{12}S_{32}]\nonumber\\

\hspace{5pc} +\ddot u_{i23}

[\mathcal{R}_G S_{22}S_{32}]+u_i' [\mathcal{R}_G

\eta]+\bar{u}_{ik} [\mathcal{R}_G^2 S_{k2}] + u_i^ \ddagger

[\mathcal{R}_G^3] +u^t_{ik}

\left[\mathcal{R}_G \frac{\partial S_{k2}}{\partial

t}\right],

\end{gather} \begin{gather} p^{(1)}=\dot p_{jk}

\left[\frac{\partial S_{k2}}{\partial X_j}\right] + \ddot

p_{k} [\mathcal{R}_G (S_{k2})^2]+ \ddot p_{12}

[\mathcal{R}_G S_{12}S_{22}]+\ddot p_{13} [\mathcal{R}_G

S_{12}S_{32}]\nonumber\\

\hspace{5pc} +\ddot p_{23} [\mathcal{R}_G S_{22}S_{32}]+p{'} [\mathcal{R}_G \eta]+\overline p_{k} [\mathcal{R}_G^2 S_{k2}] + p^ \ddagger [\mathcal{R}_G^3]+p^t_k\left[\mathcal{R}_G \frac{\partial S_{k2}}{\partial t}\right]. \end{gather}

\begin{gather} p^{(1)}=\dot p_{jk}

\left[\frac{\partial S_{k2}}{\partial X_j}\right] + \ddot

p_{k} [\mathcal{R}_G (S_{k2})^2]+ \ddot p_{12}

[\mathcal{R}_G S_{12}S_{22}]+\ddot p_{13} [\mathcal{R}_G

S_{12}S_{32}]\nonumber\\

\hspace{5pc} +\ddot p_{23} [\mathcal{R}_G S_{22}S_{32}]+p{'} [\mathcal{R}_G \eta]+\overline p_{k} [\mathcal{R}_G^2 S_{k2}] + p^ \ddagger [\mathcal{R}_G^3]+p^t_k\left[\mathcal{R}_G \frac{\partial S_{k2}}{\partial t}\right]. \end{gather}Twenty-three decoupled systems of equations arise from substituting the preceding forms into (3.10a) to (3.10d). They are given in Appendix A.

3.2.3. Taking the temperature condition to higher order

Given that the macroscopic velocity at the matching surface is now available up to order ![]() $\epsilon ^2$ (cf. (2.11a)), it is advisable to do the same with the temperature. Employing the values of the dependent variables at the earlier orders, the microscopic energy equation at

$\epsilon ^2$ (cf. (2.11a)), it is advisable to do the same with the temperature. Employing the values of the dependent variables at the earlier orders, the microscopic energy equation at ![]() ${O}(\epsilon ^2)$ now reads

${O}(\epsilon ^2)$ now reads

\begin{equation} \frac{\partial^2 \theta^{(2)}}{\partial x_i^2}= Pr \mathcal{R}_G \left[\tilde \theta \frac{\partial \eta}{\partial t}+ \breve u_{jk} \frac{\partial \tilde \theta}{\partial x_j} \eta S_{k2}+ u^{\dagger}_j \frac{\partial \tilde \theta}{\partial x_j} \eta \mathcal{R}_G\right] -2 \frac{\partial \tilde \theta}{\partial x_j}\, \frac{\partial \eta}{\partial X_j}. \end{equation}

\begin{equation} \frac{\partial^2 \theta^{(2)}}{\partial x_i^2}= Pr \mathcal{R}_G \left[\tilde \theta \frac{\partial \eta}{\partial t}+ \breve u_{jk} \frac{\partial \tilde \theta}{\partial x_j} \eta S_{k2}+ u^{\dagger}_j \frac{\partial \tilde \theta}{\partial x_j} \eta \mathcal{R}_G\right] -2 \frac{\partial \tilde \theta}{\partial x_j}\, \frac{\partial \eta}{\partial X_j}. \end{equation}The boundary conditions are:

The following general form for the solution of ![]() $\theta ^{(2)}$ may be assumed:

$\theta ^{(2)}$ may be assumed:

Eight decoupled systems of equations stem from substituting the latter form into (3.12a) and (3.12b); they are provided in Appendix B.

4. The case of transverse square ribs

As an example of the implementation of the theory, the case of transverse square ribs is considered so that the auxiliary systems can be significantly simplified. In particular, because of invariance along ![]() $x_3$, all auxiliary problems simplify considerably (with derivatives

$x_3$, all auxiliary problems simplify considerably (with derivatives ![]() $\partial /\partial x_3$ set to zero), and only two-dimensional Stokes-like (or Laplace-like or Poisson-like) problems remain to be solved in the

$\partial /\partial x_3$ set to zero), and only two-dimensional Stokes-like (or Laplace-like or Poisson-like) problems remain to be solved in the ![]() $(x_1, x_2)$ plane, subject to periodic conditions along

$(x_1, x_2)$ plane, subject to periodic conditions along ![]() $x_1$. A sketch of the microscopic representative volume element is provided in figure 3. Some of the microscopic problems admit trivial solutions. For instance, it is easy to find that in the elementary cell it is

$x_1$. A sketch of the microscopic representative volume element is provided in figure 3. Some of the microscopic problems admit trivial solutions. For instance, it is easy to find that in the elementary cell it is ![]() $\breve u_{12}=\breve u_{22}=\breve u_{13}=\breve u_{23}=\breve u_{31}=\breve u_{32}=u_3^{\dagger} =0$, plus

$\breve u_{12}=\breve u_{22}=\breve u_{13}=\breve u_{23}=\breve u_{31}=\breve u_{32}=u_3^{\dagger} =0$, plus ![]() $\breve p_2 = -1$ and

$\breve p_2 = -1$ and ![]() $\breve p_3=0$. The systems which do not have a simple solution have been solved numerically by using the STAR-CCM+ multi-physics software (version 15.06.007-R8), by successfully refining the grid until fully grid-converged states are found, for varying dimensions of the cell along

$\breve p_3=0$. The systems which do not have a simple solution have been solved numerically by using the STAR-CCM+ multi-physics software (version 15.06.007-R8), by successfully refining the grid until fully grid-converged states are found, for varying dimensions of the cell along ![]() $x_2$. Detailed numerical results of the reduced auxiliary systems relative to the

$x_2$. Detailed numerical results of the reduced auxiliary systems relative to the ![]() ${O} (\epsilon ^0)$,

${O} (\epsilon ^0)$, ![]() ${O} (\epsilon ^1)$ and

${O} (\epsilon ^1)$ and ![]() ${O} (\epsilon ^2)$ problems are presented as supplementary material available at https://doi.org/10.1017/jfm.2022.320, for a rib size to periodicity ratio,

${O} (\epsilon ^2)$ problems are presented as supplementary material available at https://doi.org/10.1017/jfm.2022.320, for a rib size to periodicity ratio, ![]() $e/l$, equal to

$e/l$, equal to ![]() $0.25$, and matching interface location positioned at

$0.25$, and matching interface location positioned at ![]() $x_2=y_\infty = 5$.

$x_2=y_\infty = 5$.

Figure 3. Sketch of a unit cell in the microscopic domain, indicating coordinates and geometric parameters.

4.1. A synthesis of the microscopic results

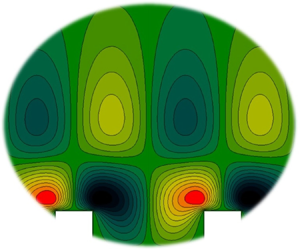

The behaviours of the parameters of interest, those which contribute to the effective boundary conditions, are presented in figure 4, separating them into two groups according to their gradients in the ![]() $x_2$-direction (either positive or negative). At the matching interface (

$x_2$-direction (either positive or negative). At the matching interface (![]() $x_2=y_\infty =5$), the variables contributing to the effective boundary conditions become independent of

$x_2=y_\infty =5$), the variables contributing to the effective boundary conditions become independent of ![]() $x_1$ and take the following uniform values:

$x_1$ and take the following uniform values:

Figure 4. Behaviour of the parameters of interest along a line in the ![]() $x_2$-direction which goes through the middle of the rib (

$x_2$-direction which goes through the middle of the rib (![]() $x_1=0$ with reference to figure 3). The displayed numerical results are for the case

$x_1=0$ with reference to figure 3). The displayed numerical results are for the case ![]() $e/\ell =0.25$ and

$e/\ell =0.25$ and ![]() $y_\infty =5$.

$y_\infty =5$.

4.2. Effects of varying the matching interface location

The effect of changing the matching surface distance, ![]() $y_\infty$, on the values of the seven independent groups of effective parameters has been analysed with the aid of successive numerical simulations, varying

$y_\infty$, on the values of the seven independent groups of effective parameters has been analysed with the aid of successive numerical simulations, varying ![]() $y_\infty$ from 2 to 6, as listed in table 1. An in-depth look into the table reveals that we have three categories of relations between the values of the microscopic parameters at the matching interface vs the location of the interface itself; specifically, linear, quadratic and cubic relations. Fitting the results, we propose the following expressions for the closure variables evaluated at

$y_\infty$ from 2 to 6, as listed in table 1. An in-depth look into the table reveals that we have three categories of relations between the values of the microscopic parameters at the matching interface vs the location of the interface itself; specifically, linear, quadratic and cubic relations. Fitting the results, we propose the following expressions for the closure variables evaluated at ![]() $y_\infty$:

$y_\infty$:

\begin{gather}\left.\begin{array}{c@{}} u_{1}^{\dagger}= \dot u_{112} ={-} \dot u_{211} = \dfrac{y_\infty^2}{2} + \lambda_x y_\infty + m_{12},\\[8pt] \dot u_{332} ={-} \dot u_{233} = \dfrac{y_\infty^2}{2} + \lambda_z y_\infty +m_{32}, \end{array}\right\} \end{gather}

\begin{gather}\left.\begin{array}{c@{}} u_{1}^{\dagger}= \dot u_{112} ={-} \dot u_{211} = \dfrac{y_\infty^2}{2} + \lambda_x y_\infty + m_{12},\\[8pt] \dot u_{332} ={-} \dot u_{233} = \dfrac{y_\infty^2}{2} + \lambda_z y_\infty +m_{32}, \end{array}\right\} \end{gather} \begin{gather} \left.\begin{array}{c@{}} u_{1}^\prime\approx 2\left[\dfrac{y_\infty^3}{6} + m_{32} y_\infty^2 + \lambda_x y_\infty \right] + \mathcal{B}, \\ u_{11}^t\approx{-}2\left[\dfrac{y_\infty^3}{6} + m_{12} y_\infty^2 + \lambda_x y_\infty \right] +\mathcal{B}_{1t},\\ u_{33}^t\approx\theta^t={-}2\left[\frac{y_\infty^3}{6} + \lambda_z \frac{y_\infty^2}{2} + m_{32} y_\infty \right] +\mathcal{B}_{3t}.\end{array}\right\} \end{gather}

\begin{gather} \left.\begin{array}{c@{}} u_{1}^\prime\approx 2\left[\dfrac{y_\infty^3}{6} + m_{32} y_\infty^2 + \lambda_x y_\infty \right] + \mathcal{B}, \\ u_{11}^t\approx{-}2\left[\dfrac{y_\infty^3}{6} + m_{12} y_\infty^2 + \lambda_x y_\infty \right] +\mathcal{B}_{1t},\\ u_{33}^t\approx\theta^t={-}2\left[\frac{y_\infty^3}{6} + \lambda_z \frac{y_\infty^2}{2} + m_{32} y_\infty \right] +\mathcal{B}_{3t}.\end{array}\right\} \end{gather}

The dimensionless Navier-slip coefficients (![]() $\lambda _x,\lambda _z$), surface permeability coefficients (

$\lambda _x,\lambda _z$), surface permeability coefficients (![]() $m_{12}, m_{32}$), velocity-flux sensitivity (

$m_{12}, m_{32}$), velocity-flux sensitivity (![]() $\mathcal {B}$) and time-fluctuation coefficients (

$\mathcal {B}$) and time-fluctuation coefficients (![]() $\mathcal {B}_{1t}, \mathcal {B}_{3t}$) are only dependent of the geometric parameters of the ribbed surface,

$\mathcal {B}_{1t}, \mathcal {B}_{3t}$) are only dependent of the geometric parameters of the ribbed surface, ![]() $e/\ell$ in the case of square ribs. These coefficients can be calculated for any geometry of transverse ribs, once the microscopic numerical simulations are conducted with suitable values of

$e/\ell$ in the case of square ribs. These coefficients can be calculated for any geometry of transverse ribs, once the microscopic numerical simulations are conducted with suitable values of ![]() $y_\infty$, and the results of the microscopic parameters at the matching interface are substituted in accurate fitting equations, or are extrapolated to

$y_\infty$, and the results of the microscopic parameters at the matching interface are substituted in accurate fitting equations, or are extrapolated to ![]() $y_\infty = 0$.

$y_\infty = 0$.

Table 1. Microscopic results found at different values of ![]() $y_\infty$ for square ribs with

$y_\infty$ for square ribs with ![]() $e/\ell =0.25$.

$e/\ell =0.25$.

Simpler, accurate methods for the estimation of the coefficients of interest are proposed within the present framework. The Navier-slip coefficients can be calculated by running the simulations of the leading-order systems, forced by ![]() $S_{12}$ and

$S_{12}$ and ![]() $S_{32}$, with a suitable value of

$S_{32}$, with a suitable value of ![]() $y_\infty$ to get, respectively, the fields of

$y_\infty$ to get, respectively, the fields of ![]() $\breve u_{11}$ and

$\breve u_{11}$ and ![]() $\breve u_{33}$; thereafter, the values of

$\breve u_{33}$; thereafter, the values of ![]() $\lambda _x$ and

$\lambda _x$ and ![]() $\lambda _z$ can be found by averaging the corresponding field on the plane

$\lambda _z$ can be found by averaging the corresponding field on the plane ![]() $x_2=0$. It is interesting that these same fields can then be employed to estimate the values of

$x_2=0$. It is interesting that these same fields can then be employed to estimate the values of ![]() $m_{12}$ and

$m_{12}$ and ![]() $m_{32}$, making use of the numerical result pointed out by Bottaro & Naqvi (Reference Bottaro and Naqvi2020), i.e.

$m_{32}$, making use of the numerical result pointed out by Bottaro & Naqvi (Reference Bottaro and Naqvi2020), i.e.

with ![]() $S_{cell}$ the surface of the representative near-wall cell. The following values of the coefficients eventually arise when

$S_{cell}$ the surface of the representative near-wall cell. The following values of the coefficients eventually arise when ![]() $e/\ell =0.25$:

$e/\ell =0.25$:

4.3. The formal expressions of the effective boundary conditions

The expressions of the microscopic dimensionless velocity components are now available up to ![]() ${O} (\epsilon ^1)$, while the microscopic dimensionless temperature (

${O} (\epsilon ^1)$, while the microscopic dimensionless temperature (![]() $\theta$) is known up to

$\theta$) is known up to ![]() ${O} (\epsilon ^2)$. The values of the preceding quantities can be linked to the corresponding dimensionless macroscopic parameters at the matching interface, based on the concept of continuity of velocity (2.11a) and temperature (2.11b). In particular, it is convenient to enforce the conditions on the outer rim of the ribs, which amounts to specifying

${O} (\epsilon ^2)$. The values of the preceding quantities can be linked to the corresponding dimensionless macroscopic parameters at the matching interface, based on the concept of continuity of velocity (2.11a) and temperature (2.11b). In particular, it is convenient to enforce the conditions on the outer rim of the ribs, which amounts to specifying ![]() $x_2 = \epsilon X_2 = 0$ in the matching relations ((2.11a), (2.11b)), along with setting

$x_2 = \epsilon X_2 = 0$ in the matching relations ((2.11a), (2.11b)), along with setting ![]() $y_\infty =0$ in the fits of the microscopic parameters (given in § 4.2) entering the effective boundary conditions. Eventually, we obtain

$y_\infty =0$ in the fits of the microscopic parameters (given in § 4.2) entering the effective boundary conditions. Eventually, we obtain

\begin{align} U_1|_{X_2=0} &= \epsilon [\lambda_x S_{12}+ m_{12} \mathcal{R}_G ]_{X_2=0} \nonumber\\ &\quad + \epsilon^2 \left[m_{12}\frac{\partial S_{22}}{\partial X_1}+ \mathcal{B} \mathcal{R}_G \frac{\partial \varTheta}{\partial X_2} + \mathcal{B}_{1t} \mathcal{R}_G \frac{\partial S_{12}}{\partial t} \right]_{X_2=0} + {O}(\epsilon^3), \end{align}

\begin{align} U_1|_{X_2=0} &= \epsilon [\lambda_x S_{12}+ m_{12} \mathcal{R}_G ]_{X_2=0} \nonumber\\ &\quad + \epsilon^2 \left[m_{12}\frac{\partial S_{22}}{\partial X_1}+ \mathcal{B} \mathcal{R}_G \frac{\partial \varTheta}{\partial X_2} + \mathcal{B}_{1t} \mathcal{R}_G \frac{\partial S_{12}}{\partial t} \right]_{X_2=0} + {O}(\epsilon^3), \end{align} The no-slip conditions of the smooth surface are identically retrieved at ![]() ${O} (\epsilon ^0)$. The effective conditions for velocity are similar to those given by Lācis et al. (Reference Lācis, Sudhakar, Pasche and Bagheri2020) and Bottaro & Naqvi (Reference Bottaro and Naqvi2020) for flow over rough surfaces without heat transfer. Nevertheless, the presence of the buoyancy terms, proportional to

${O} (\epsilon ^0)$. The effective conditions for velocity are similar to those given by Lācis et al. (Reference Lācis, Sudhakar, Pasche and Bagheri2020) and Bottaro & Naqvi (Reference Bottaro and Naqvi2020) for flow over rough surfaces without heat transfer. Nevertheless, the presence of the buoyancy terms, proportional to ![]() $\mathcal {R}_G$ and

$\mathcal {R}_G$ and ![]() $\mathcal {R}_G ({\partial \varTheta }/{\partial X_2})$ in the equation of the velocity component

$\mathcal {R}_G ({\partial \varTheta }/{\partial X_2})$ in the equation of the velocity component ![]() $U_1$, and of the time-fluctuation terms in the equations of (

$U_1$, and of the time-fluctuation terms in the equations of (![]() $U_1, U_3, \varTheta$) should be highlighted. We emphasize that the presence of the buoyancy-related term is a first-order contribution to the effective condition for the streamwise velocity,

$U_1, U_3, \varTheta$) should be highlighted. We emphasize that the presence of the buoyancy-related term is a first-order contribution to the effective condition for the streamwise velocity, ![]() $\hat U_1$, and is directly attributed to the assumption that the Grashof number is sufficiently large, i.e.

$\hat U_1$, and is directly attributed to the assumption that the Grashof number is sufficiently large, i.e. ![]() $\epsilon \mathcal {R}_G = \epsilon ^2 \sqrt {Gr}$ is of

$\epsilon \mathcal {R}_G = \epsilon ^2 \sqrt {Gr}$ is of ![]() ${O} (\epsilon ^1)$, and not

${O} (\epsilon ^1)$, and not ![]() ${O} (\epsilon ^2)$.

${O} (\epsilon ^2)$.

In dimensional terms, the conditions on the plane ![]() $\hat x_2 = 0$ read

$\hat x_2 = 0$ read

\begin{align} \hat

u_1|_{\hat x_2 = 0} &\approx \underbrace{ \hat \lambda_{x}

\left[\frac{\partial \hat u_1}{\partial \hat

x_2}+\frac{\partial \hat u_2}{\partial \hat

x_1}\right]_{\hat x_2 = 0} + \hat m_{12}\frac{\beta g (\hat

T_w- \hat

T_\infty)}{\nu}}_{\text{First

order}} \nonumber\\ &\quad + \underbrace{\hat m_{12}

\left[ \frac{\partial}{\partial \hat x_1}\left( -

\frac{(\hat p - \hat p_\infty)}{\mu}+2\frac{\partial \hat

u_2}{\partial \hat x_2}\right)\right]_{\hat x_2 = 0}+

\hat{\mathcal{B}} \frac{g \beta}{\nu} \left.\frac{\partial

\hat T}{\partial \hat x_2}\right|_{\hat x_2 =

0}}_{\text{Second

order}}\nonumber\\ &\quad + \underbrace

{\hat{\mathcal{B}}_{1t} \frac{1}{\nu}

\frac{\partial}{\partial \hat t}\left[\frac{\partial \hat

u_1}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial

\hat x_1}\right]_{\hat x_2 =

0}}_{\text{Second

order}},

\end{align}

\begin{align} \hat

u_1|_{\hat x_2 = 0} &\approx \underbrace{ \hat \lambda_{x}

\left[\frac{\partial \hat u_1}{\partial \hat

x_2}+\frac{\partial \hat u_2}{\partial \hat

x_1}\right]_{\hat x_2 = 0} + \hat m_{12}\frac{\beta g (\hat

T_w- \hat

T_\infty)}{\nu}}_{\text{First

order}} \nonumber\\ &\quad + \underbrace{\hat m_{12}

\left[ \frac{\partial}{\partial \hat x_1}\left( -

\frac{(\hat p - \hat p_\infty)}{\mu}+2\frac{\partial \hat

u_2}{\partial \hat x_2}\right)\right]_{\hat x_2 = 0}+

\hat{\mathcal{B}} \frac{g \beta}{\nu} \left.\frac{\partial

\hat T}{\partial \hat x_2}\right|_{\hat x_2 =

0}}_{\text{Second

order}}\nonumber\\ &\quad + \underbrace

{\hat{\mathcal{B}}_{1t} \frac{1}{\nu}

\frac{\partial}{\partial \hat t}\left[\frac{\partial \hat

u_1}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial

\hat x_1}\right]_{\hat x_2 =

0}}_{\text{Second

order}},

\end{align} \begin{align} \hat

u_2|_{\hat x_2 = 0} & \approx \underbrace{ -\hat m_{12}

\frac{\partial}{\partial \hat x_1}\left[\frac{\partial \hat

u_1}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial

\hat x_1}\right]_{\hat x_2 = 0}-\hat m_{32}

\frac{\partial}{\partial \hat x_3}\left[\frac{\partial \hat

u_3}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial

\hat x_3}\right]_{\hat x_2 =

0}}_{\text{Second

order}},

\end{align}

\begin{align} \hat

u_2|_{\hat x_2 = 0} & \approx \underbrace{ -\hat m_{12}

\frac{\partial}{\partial \hat x_1}\left[\frac{\partial \hat

u_1}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial

\hat x_1}\right]_{\hat x_2 = 0}-\hat m_{32}

\frac{\partial}{\partial \hat x_3}\left[\frac{\partial \hat

u_3}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial

\hat x_3}\right]_{\hat x_2 =

0}}_{\text{Second

order}},

\end{align} \begin{align} \hat u_3|_{\hat x_2 = 0} &\approx \underbrace{\hat \lambda_{z} \left[\frac{\partial \hat u_3}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial \hat x_3}\right]_{\hat x_2 = 0}}_{\text{First order}}+ \underbrace{\hat m_{32} \,\frac{\partial}{\partial \hat x_3}\left[ - \frac{(\hat p - \hat p_\infty)}{\mu}+2\frac{\partial \hat u_2}{\partial \hat x_2}\right]_{\hat x_2 = 0}}_{\text{Second order}} \nonumber\\ &\quad +\underbrace{\hat{\mathcal{B}}_{3t} \frac{1}{\nu} \frac{\partial}{\partial \hat t}\left[\frac{\partial \hat u_3}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial \hat x_3}\right]_{\hat x_2 = 0}}_{\text{Second order}}, \end{align}

\begin{align} \hat u_3|_{\hat x_2 = 0} &\approx \underbrace{\hat \lambda_{z} \left[\frac{\partial \hat u_3}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial \hat x_3}\right]_{\hat x_2 = 0}}_{\text{First order}}+ \underbrace{\hat m_{32} \,\frac{\partial}{\partial \hat x_3}\left[ - \frac{(\hat p - \hat p_\infty)}{\mu}+2\frac{\partial \hat u_2}{\partial \hat x_2}\right]_{\hat x_2 = 0}}_{\text{Second order}} \nonumber\\ &\quad +\underbrace{\hat{\mathcal{B}}_{3t} \frac{1}{\nu} \frac{\partial}{\partial \hat t}\left[\frac{\partial \hat u_3}{\partial \hat x_2}+\frac{\partial \hat u_2}{\partial \hat x_3}\right]_{\hat x_2 = 0}}_{\text{Second order}}, \end{align} \begin{align} \hat T|_{\hat x_2 = 0} &\approx \underbrace{\hat T_w}_{\text{Zero order}} + \underbrace{\hat \lambda_z \left.\frac{\partial \hat T}{\partial \hat x_2}\right|_{\hat x_2 = 0}}_{\text{First order}} + \underbrace{\hat{\mathcal{B}}_{3t} \left.\frac{1}{\alpha} \frac{\partial^2 \hat T}{\partial \hat x_2 \partial \hat t}\right|_{\hat x_2 = 0}}_{\text{Second order}}. \end{align}

\begin{align} \hat T|_{\hat x_2 = 0} &\approx \underbrace{\hat T_w}_{\text{Zero order}} + \underbrace{\hat \lambda_z \left.\frac{\partial \hat T}{\partial \hat x_2}\right|_{\hat x_2 = 0}}_{\text{First order}} + \underbrace{\hat{\mathcal{B}}_{3t} \left.\frac{1}{\alpha} \frac{\partial^2 \hat T}{\partial \hat x_2 \partial \hat t}\right|_{\hat x_2 = 0}}_{\text{Second order}}. \end{align}

The dimensional groups of coefficients ![]() $(\hat \lambda _x, \hat \lambda _z)$,

$(\hat \lambda _x, \hat \lambda _z)$, ![]() $(\hat m_{12}, \hat m_{32})$ and (

$(\hat m_{12}, \hat m_{32})$ and (![]() $\hat {\mathcal {B}}, \hat {\mathcal {B}}_{1t}, \hat {\mathcal {B}}_{3t}$) are homogeneous to, respectively, a length, a surface area and a volume, and correspond to the product of their dimensionless counterparts times, respectively,

$\hat {\mathcal {B}}, \hat {\mathcal {B}}_{1t}, \hat {\mathcal {B}}_{3t}$) are homogeneous to, respectively, a length, a surface area and a volume, and correspond to the product of their dimensionless counterparts times, respectively, ![]() $l$,

$l$, ![]() $l^2$ and

$l^2$ and ![]() $l^3$. The conditions above represent the most important contribution of the present paper.

$l^3$. The conditions above represent the most important contribution of the present paper.

5. The role of rib height to pitch distance ratio: parametric study

From a practical point of view, it is advantageous to generate a database of the values of the seven dimensionless, geometry-dependent coefficients of interest, to cover a wide range of rib height to pitch distance ratios, ![]() $e/l$, in order to enable the direct use of the effective boundary conditions for the macroscopic problems. In this study, the ratio was varied within the range

$e/l$, in order to enable the direct use of the effective boundary conditions for the macroscopic problems. In this study, the ratio was varied within the range ![]() $0.025 \leq e/l \leq 0.8$. For each value of

$0.025 \leq e/l \leq 0.8$. For each value of ![]() $e/l$, the procedure described in § 4.2 for the accurate estimation of the coefficients was followed. The resulting database is presented in tabular form (table 2) and graphically in figure 5. It is clear that all model coefficients peak, in magnitude, within the range

$e/l$, the procedure described in § 4.2 for the accurate estimation of the coefficients was followed. The resulting database is presented in tabular form (table 2) and graphically in figure 5. It is clear that all model coefficients peak, in magnitude, within the range ![]() $e/\ell =0.1$ to

$e/\ell =0.1$ to ![]() $0.3$, which implies significant velocity and thermal slip. All coefficients tend to zero as

$0.3$, which implies significant velocity and thermal slip. All coefficients tend to zero as ![]() $e$ tends to zero or approaches

$e$ tends to zero or approaches ![]() $\ell$, for the effective boundary conditions at

$\ell$, for the effective boundary conditions at ![]() $x_2=0$ to become no slip and isothermal wall.

$x_2=0$ to become no slip and isothermal wall.

Figure 5. The behaviour of the upscaled coefficients of interest with the change of rib height to pitch distance ratio. The curves are fitted on the basis of kriging interpolation.

Table 2. The upscaled coefficients of interest for different rib height to pitch distance ratios.

6. Macroscale behaviour of the flow

In this section, attention is given to validation of the effective conditions obtained in § 4, with the upscaled coefficients calculated for the case of square ribs. The macroscale problem is considered, with the governing equations given in § 2. Since the ribs are elongated in the transverse direction, and since only the case of laminar flow is considered, there is no need to resolve the spanwise direction; the problem can be simplified to its two-dimensional form in the (![]() $X_1,X_2$) plane. In addition, steady-state solutions are targeted for validation purposes. Three types of simulations have been carried out: (i) natural convection over a vertical smooth surface; (ii) full feature-resolving natural convection over a vertical ribbed surface; (iii) homogenized problem with effective boundary conditions at a virtual wall. For each simulation, the computational domain, the boundary conditions and the grid structure are explained in detail later in this section. As for the case of the microscopic problems, we have found it convenient to carry out the simulations with STAR-CCM+. The second-order upwind formulation has been adopted for the spatial discretization of all fields, with the calculation of the gradients based on a hybrid Gauss–least squares method. The SIMPLE scheme has been employed for the pressure–velocity coupling.

$X_1,X_2$) plane. In addition, steady-state solutions are targeted for validation purposes. Three types of simulations have been carried out: (i) natural convection over a vertical smooth surface; (ii) full feature-resolving natural convection over a vertical ribbed surface; (iii) homogenized problem with effective boundary conditions at a virtual wall. For each simulation, the computational domain, the boundary conditions and the grid structure are explained in detail later in this section. As for the case of the microscopic problems, we have found it convenient to carry out the simulations with STAR-CCM+. The second-order upwind formulation has been adopted for the spatial discretization of all fields, with the calculation of the gradients based on a hybrid Gauss–least squares method. The SIMPLE scheme has been employed for the pressure–velocity coupling.

6.1. Isothermal vertical smooth surface case

A numerical calculation is first performed for a smooth isothermal surface at a plate Grashof number ![]() $Gr= 5.563 \times 10^8$ and a Prandtl number

$Gr= 5.563 \times 10^8$ and a Prandtl number ![]() $Pr= 0.712$; this corresponds, for instance, to a buoyancy-driven air flow with

$Pr= 0.712$; this corresponds, for instance, to a buoyancy-driven air flow with ![]() $\hat T_\infty =18 \,^\circ \textrm {C}$,

$\hat T_\infty =18 \,^\circ \textrm {C}$, ![]() $\hat T_w=58 \,^\circ \textrm {C}$,

$\hat T_w=58 \,^\circ \textrm {C}$, ![]() $L= 0.5$ m and the fluid properties calculated at standard pressure and based on the film temperature

$L= 0.5$ m and the fluid properties calculated at standard pressure and based on the film temperature ![]() $\hat T_f={(\hat T_w+\hat T_\infty )}/{2}$. Different purposes are targeted from this step: (i) estimation of the adequacy of the computational domain; (ii) validation of the CFD numerical scheme and of the inlet/outlet boundary conditions by comparing the results with available databases through the literature; (iii) the no-slip smooth surface case is equivalent to a homogenized simulation of the rough surface with zero-order effective conditions, so the results will help to monitor the accuracy enhancement when progressively higher-order approximations are used.

$\hat T_f={(\hat T_w+\hat T_\infty )}/{2}$. Different purposes are targeted from this step: (i) estimation of the adequacy of the computational domain; (ii) validation of the CFD numerical scheme and of the inlet/outlet boundary conditions by comparing the results with available databases through the literature; (iii) the no-slip smooth surface case is equivalent to a homogenized simulation of the rough surface with zero-order effective conditions, so the results will help to monitor the accuracy enhancement when progressively higher-order approximations are used.

The computational domain and the boundary conditions are illustrated in figure 6. No-slip and constant temperature conditions are defined on the vertical wall; uniform pressure boundary conditions are imposed at the upper and the lower boundaries such that an equilibrium with the hydrostatic pressure head is satisfied. The width of the domain should be selected in such a way that the streamwise velocity smoothly vanishes at the far boundary at ![]() $X_2=S$, with the normal gradients of horizontal velocity and temperature smoothly decreasing to zero. This was checked by running the simulation with different values of the domain width,

$X_2=S$, with the normal gradients of horizontal velocity and temperature smoothly decreasing to zero. This was checked by running the simulation with different values of the domain width, ![]() $S$, and monitoring a result of interest (the surface-averaged Nusselt number) until convergence was attained. The local Nusselt number (

$S$, and monitoring a result of interest (the surface-averaged Nusselt number) until convergence was attained. The local Nusselt number (![]() $Nu$) and its surface-averaged counterpart (

$Nu$) and its surface-averaged counterpart (![]() $\overline {Nu}$) are defined for the smooth surface by

$\overline {Nu}$) are defined for the smooth surface by

\begin{gather} Nu= \frac{-L}{\hat T_w-\hat T_\infty} \left.\frac{\partial \hat T}{\partial \hat x_2}\right|_{X_2=0}={-}\left.\frac{\partial \varTheta}{\partial X_2}\right|_{X_2=0}, \end{gather}

\begin{gather} Nu= \frac{-L}{\hat T_w-\hat T_\infty} \left.\frac{\partial \hat T}{\partial \hat x_2}\right|_{X_2=0}={-}\left.\frac{\partial \varTheta}{\partial X_2}\right|_{X_2=0}, \end{gather} \begin{gather}\overline{Nu} =\int_0^1 -\left.\frac{\partial \varTheta}{\partial X_2}\right|_{X_2=0}\,{\rm d}X_1 . \end{gather}

\begin{gather}\overline{Nu} =\int_0^1 -\left.\frac{\partial \varTheta}{\partial X_2}\right|_{X_2=0}\,{\rm d}X_1 . \end{gather}

As can be realized from figure 6(b), a domain width ![]() $S= 0.8$ appears to be sufficient; however, a value of

$S= 0.8$ appears to be sufficient; however, a value of ![]() $S= 2$ was used throughout the work to ensure the absence of spurious reflections from the outer boundary when testing microstructured walls and/or larger values of

$S= 2$ was used throughout the work to ensure the absence of spurious reflections from the outer boundary when testing microstructured walls and/or larger values of ![]() $Gr$. The two-dimensional grid is described in detail in Appendix C; eventually, the extrapolated value of the average Nusselt number is estimated to be 75.055 based on the conducted mesh-dependency study, also illustrated in the Appendix.

$Gr$. The two-dimensional grid is described in detail in Appendix C; eventually, the extrapolated value of the average Nusselt number is estimated to be 75.055 based on the conducted mesh-dependency study, also illustrated in the Appendix.

Figure 6. Computational domain with boundary conditions used for the numerical simulation of the natural convection over the isothermal vertical smooth plate (![]() $X_2=0$). Panel (b) shows a graphical representation of the sensitivity of the solution to variations in the domain width. Here,

$X_2=0$). Panel (b) shows a graphical representation of the sensitivity of the solution to variations in the domain width. Here, ![]() $Gr= 5.563 \times 10^8$,

$Gr= 5.563 \times 10^8$, ![]() $Pr= 0.712$.

$Pr= 0.712$.

The dimensionless temperature and streamwise velocity profiles are plotted across chosen normal sections distributed along the plate, as displayed in figure 7. The velocity and the temperature contours in the vicinity of the smooth wall are also shown, to highlight the development of the boundary layers. The peak of the velocity profile shifts away from the wall as ![]() $X_1$ increases, in qualitative agreement with the estimate of the classical Squire–Eckert theory (Lienhard & Lienhard Reference Lienhard IV and Lienhard V2019) according to which the velocity peaks at almost

$X_1$ increases, in qualitative agreement with the estimate of the classical Squire–Eckert theory (Lienhard & Lienhard Reference Lienhard IV and Lienhard V2019) according to which the velocity peaks at almost ![]() $\frac {1}{3}$ of the boundary layer thickness. At the same time, the temperature gradient at the wall is reduced with

$\frac {1}{3}$ of the boundary layer thickness. At the same time, the temperature gradient at the wall is reduced with ![]() $X_1$. The latter effect is responsible for the decrease of the local Nusselt number (

$X_1$. The latter effect is responsible for the decrease of the local Nusselt number (![]() $Nu$) along the plate, plotted in figure 8. The distribution of the local Nusselt number is in perfect agreement with the corresponding reference results by Ostrach (Reference Ostrach1953). An analysis of Ostrach's results reveals that the Nusselt number (

$Nu$) along the plate, plotted in figure 8. The distribution of the local Nusselt number is in perfect agreement with the corresponding reference results by Ostrach (Reference Ostrach1953). An analysis of Ostrach's results reveals that the Nusselt number (![]() $Nu$) is related to the vertical position (

$Nu$) is related to the vertical position (![]() $X_1$) via the expression

$X_1$) via the expression

\begin{equation} \frac{X_1 Nu}{\left(\dfrac{Gr}{4} X_1^3\right)^{0.25}} = f_n(Pr). \end{equation}

\begin{equation} \frac{X_1 Nu}{\left(\dfrac{Gr}{4} X_1^3\right)^{0.25}} = f_n(Pr). \end{equation}

At a Prandtl number of 0.712, the function ![]() $f_n(Pr)$ was estimated to be almost 0.504. Therefore, (6.2) can be recast as an explicit relation between

$f_n(Pr)$ was estimated to be almost 0.504. Therefore, (6.2) can be recast as an explicit relation between ![]() $Nu$ and

$Nu$ and ![]() $X_1$ at any fixed value of the Grashof number.

$X_1$ at any fixed value of the Grashof number.

Figure 7. Smooth surface case: dimensionless velocity and temperature profiles across different normal sections distributed along the vertical plate. Contours representing the velocity and the thermal fields are also provided. Here, ![]() $Gr= 5.563 \times 10^8$,

$Gr= 5.563 \times 10^8$, ![]() $Pr= 0.712$.

$Pr= 0.712$.

Figure 8. Smooth surface case: numerical prediction of the local Nusselt number distribution along the vertical plate, compared with the expected behaviour based on the similarity solution by Ostrach (Reference Ostrach1953).

6.2. The case of isothermal ribbed surface

A typical validation case is now considered. The developed asymptotic wall model is assumed to be reasonably accurate provided that ![]() $\epsilon$ is sufficiently small. In addition, limitations are imposed on the magnitude of the coefficient of the convective term in the normalized microscopic governing equations,

$\epsilon$ is sufficiently small. In addition, limitations are imposed on the magnitude of the coefficient of the convective term in the normalized microscopic governing equations, ![]() $C= \epsilon ^2\, \sqrt {Gr}= \epsilon \, \mathcal {R}_G$, for convective effects to be absent in the leading-order problem but present at next order. For the basic validation case, we consider natural convection over an isothermal vertical plate with 168 transverse square ribs

$C= \epsilon ^2\, \sqrt {Gr}= \epsilon \, \mathcal {R}_G$, for convective effects to be absent in the leading-order problem but present at next order. For the basic validation case, we consider natural convection over an isothermal vertical plate with 168 transverse square ribs ![]() $(\epsilon = \frac {1}{168})$ with a pitch distance to rib height ratio

$(\epsilon = \frac {1}{168})$ with a pitch distance to rib height ratio ![]() ${l}/{e}=3.75$. The problem is characterized by a plate Grashof number

${l}/{e}=3.75$. The problem is characterized by a plate Grashof number ![]() $Gr= 5.563 \times 10^8$ and a Prandtl number

$Gr= 5.563 \times 10^8$ and a Prandtl number ![]() $Pr= 0.712$. With these parameters, the value of the coefficient

$Pr= 0.712$. With these parameters, the value of the coefficient ![]() $C$ is 0.836. Results of the feature-resolving simulation and the homogenization-based calculations of the basic ribbed surface case are presented and compared.

$C$ is 0.836. Results of the feature-resolving simulation and the homogenization-based calculations of the basic ribbed surface case are presented and compared.

6.2.1. Feature-resolving simulation of the ribbed surface case

The two-dimensional feature-resolving numerical simulation, where the details of the ribbed surface are captured by the grid, represents a necessary step for the validation of the homogenized model.

The computational domain is illustrated in figure 9, including the geometric details of the ribbed surface. The applied boundary conditions are the same as in the smooth surface case, taking into account that the no-slip velocity and temperature conditions are now imposed on a patterned surface, not on a plain one. The two-dimensional grid near the ribs is also shown, and the different grid refinement levels are stated. A near-wall region of thickness ![]() $5e$ is defined where a high mesh density is employed to capture the flow dynamics in the vicinity of the perturbed surface; however, the gradual growth of the mesh guarantees that the whole field is fairly well resolved. The number of two-dimensional cells given in the figure illustrates clearly the high computational cost of the fully featured simulation of the ribbed surface compared with requirements of the smooth surface case, described in Appendix C. The Nusselt number at any point on the ribbed surface is given by

$5e$ is defined where a high mesh density is employed to capture the flow dynamics in the vicinity of the perturbed surface; however, the gradual growth of the mesh guarantees that the whole field is fairly well resolved. The number of two-dimensional cells given in the figure illustrates clearly the high computational cost of the fully featured simulation of the ribbed surface compared with requirements of the smooth surface case, described in Appendix C. The Nusselt number at any point on the ribbed surface is given by

\begin{equation} Nu= \frac{-L}{\hat T_w-\hat T_\infty}\times \left.\frac{\partial \hat T}{\partial \hat n}\right|_{wall}={-}\left.\frac{\partial \varTheta}{\partial n}\right|_{wall}, \end{equation}

\begin{equation} Nu= \frac{-L}{\hat T_w-\hat T_\infty}\times \left.\frac{\partial \hat T}{\partial \hat n}\right|_{wall}={-}\left.\frac{\partial \varTheta}{\partial n}\right|_{wall}, \end{equation}

where ![]() $\hat n$ denotes the dimensional distance in the surface-normal direction and

$\hat n$ denotes the dimensional distance in the surface-normal direction and ![]() $n={\hat n}/{L}$. A dimensional surface distance

$n={\hat n}/{L}$. A dimensional surface distance ![]() $\hat s$ is defined in such a way that it goes along the ribbed surface capturing its details, i.e.

$\hat s$ is defined in such a way that it goes along the ribbed surface capturing its details, i.e. ![]() $\hat s$ goes from 0 to

$\hat s$ goes from 0 to ![]() $L+ (2e \times N_{ribs})$ with

$L+ (2e \times N_{ribs})$ with ![]() $N_{ribs}={1}/{\epsilon }= {L}/{\ell }$ the number of ribs. Accordingly, the surface-averaged Nusselt number based on the projected area of the two-dimensional ribbed plate is defined as

$N_{ribs}={1}/{\epsilon }= {L}/{\ell }$ the number of ribs. Accordingly, the surface-averaged Nusselt number based on the projected area of the two-dimensional ribbed plate is defined as

\begin{equation} \overline{Nu} = \frac{1}{L}\int_0^{L+{2e}/{\epsilon}}-\left.\frac{\partial \varTheta}{\partial n}\right|_{wall}\,{\rm d} \hat s = \int_0^{1+{2e}/{\ell}}-\left.\frac{\partial \varTheta}{\partial n}\right|_{wall}\,{\rm d}s , \end{equation}

\begin{equation} \overline{Nu} = \frac{1}{L}\int_0^{L+{2e}/{\epsilon}}-\left.\frac{\partial \varTheta}{\partial n}\right|_{wall}\,{\rm d} \hat s = \int_0^{1+{2e}/{\ell}}-\left.\frac{\partial \varTheta}{\partial n}\right|_{wall}\,{\rm d}s , \end{equation}

where ![]() $s={\hat s}/{L}$, and the value of

$s={\hat s}/{L}$, and the value of ![]() ${e}/{\ell }$ represents the rib height to the pitch distance ratio. The given expression for

${e}/{\ell }$ represents the rib height to the pitch distance ratio. The given expression for ![]() $\overline {Nu}$ takes into account the surface area increase, with respect to the baseplate area, due to the presence of ribs. For the considered values of parameters (

$\overline {Nu}$ takes into account the surface area increase, with respect to the baseplate area, due to the presence of ribs. For the considered values of parameters (![]() $Gr= 5.563 \times 10^8$,

$Gr= 5.563 \times 10^8$, ![]() $Pr= 0.712$,

$Pr= 0.712$, ![]() $\epsilon = \frac {1}{168}$,

$\epsilon = \frac {1}{168}$, ![]() ${l}/{e}=3.75$), the reported value of

${l}/{e}=3.75$), the reported value of ![]() $\overline {Nu}$ was estimated based on Richardson's extrapolation of results for successively refined grids, and finally found to be 73.200 (compared with a value of