1. Introduction

Many natural processes and technological applications rest on fluid–structure interactions to maintain their regular functionality. Of particular interest are the mutual interactions between slender elastic objects and a fluid medium that trigger elastohydrodynamic instabilities. Such instabilities are vital for the control, for example, of the passage of air through the lungs (Ishizaka & Flanagan Reference Ishizaka and Flanagan1972; Grotberg & Jensen Reference Grotberg and Jensen2004), the directionality of blood flow (Pedley, Brook & Seymour Reference Pedley, Brook and Seymour1996) and the blood pressure of tall animals (Pedley et al. Reference Pedley, Brook and Seymour1996). Moreover, bending deformations of slender objects in viscous or inertial fluids have been manipulated for applications in soft robotics (Kim, Laschi & Trimmer Reference Kim, Laschi and Trimmer2013; Matia & Gat Reference Matia and Gat2015; Rothemund et al. Reference Rothemund, Ainla, Belding, Preston, Kurihara, Suo and Whitesides2018), the fabrication of microfluidic soft actuators (Thorsen, Maerkl & Quake Reference Thorsen, Maerkl and Quake2002; Hosoi & Mahadevan Reference Hosoi and Mahadevan2004; Holmes et al. Reference Holmes, Tavakol, Froehlicher and Stone2013; Fargette, Neukirch & Antkowiak Reference Fargette, Neukirch and Antkowiak2014; Gomez, Moulton & Vella Reference Gomez, Moulton and Vella2017; Christov et al. Reference Christov, Cognet, Shidhore and Stone2018; Boyko et al. Reference Boyko, Eshel, Gommed, Gat and Bercovici2019; Jiao & Liu Reference Jiao and Liu2021), the manufacture of semiconductors (King Reference King1989) and the design of soft and active matter through catalytic reactions (Laskar et al. Reference Laskar, Manna, Shklyaev and Balazs2022; Manna et al. Reference Manna, Laskar, Shklyaev and Balazs2022) and dynamical wrinkles (Chopin, Dasgupta & Kudrolli Reference Chopin, Dasgupta and Kudrolli2017; Kodio, Griffiths & Vella Reference Kodio, Griffiths and Vella2017; Box et al. Reference Box, O'Kiely, Kodio, Inizan, Castrejón-Pita and Vella2019; Pocivavsek et al. Reference Pocivavsek, Ye, Pugar, Tzeng, Cerda, Velankar and Wagner2019; O'Kiely et al. Reference O'Kiely, Box, Kodio, Whiteley and Vella2020; Diamant Reference Diamant2021; Guan et al. Reference Guan, Sarma, Hamesh, Yang, Nguyen, Cerda, Pocivavsek and Velankar2022, Reference Guan, Nguyen, Pocivavsek, Cerda and Velankar2023).

Despite recent achievements, novel designs of small-scale devices still call for a deeper understanding of elastohydrodynamic couplings. One such design was recently introduced by Oshri (Reference Oshri2021). In that set-up, a thin sheet is compressed between the two sides of a closed chamber and divides it into two separate parts that are connected by a valve (figure 1). At time ![]() $t< 0$, the valve is closed, and each part of the chamber is filled with an incompressible fluid. In the absence of fluids, the sheet would have accommodated its minimum energetic state, i.e. the lowest mode of buckling, but in the presence of fluids, the sheet is forced to accommodate a higher energetic state. The additional energy can be exploited to displace the fluid from rest, if, for example, the valve is opened to allow the transfer of fluids between the two compartments of the chamber.

$t< 0$, the valve is closed, and each part of the chamber is filled with an incompressible fluid. In the absence of fluids, the sheet would have accommodated its minimum energetic state, i.e. the lowest mode of buckling, but in the presence of fluids, the sheet is forced to accommodate a higher energetic state. The additional energy can be exploited to displace the fluid from rest, if, for example, the valve is opened to allow the transfer of fluids between the two compartments of the chamber.

Figure 1. Schematic overview of the system. A thin sheet of total length ![]() $\tilde {L}$, bending modulus

$\tilde {L}$, bending modulus ![]() $\tilde {B}$, density

$\tilde {B}$, density ![]() $\tilde {\rho }_{sh}$ and thickness

$\tilde {\rho }_{sh}$ and thickness ![]() $\tilde {h}$ divides a closed rectangular chamber of dimensions

$\tilde {h}$ divides a closed rectangular chamber of dimensions ![]() $\tilde {L}_x\times \tilde {L}_y$ into two parts. The excess length of the sheet compared with the lateral dimension of the chamber is given by

$\tilde {L}_x\times \tilde {L}_y$ into two parts. The excess length of the sheet compared with the lateral dimension of the chamber is given by ![]() $\tilde {\varDelta }=\tilde {L}-\tilde {L}_x$ (not shown in the figure). The volumes of the chamber above and below the sheet,

$\tilde {\varDelta }=\tilde {L}-\tilde {L}_x$ (not shown in the figure). The volumes of the chamber above and below the sheet, ![]() $\tilde {v}_{i}(t)$ (

$\tilde {v}_{i}(t)$ (![]() $i=u,d$), are filled with an inviscid and irrotational fluid of density

$i=u,d$), are filled with an inviscid and irrotational fluid of density ![]() $\tilde {\rho }_{\ell }$. At

$\tilde {\rho }_{\ell }$. At ![]() $\tilde {t}\geq 0$, fluid is allowed to exchange freely between the two compartments of the chamber. In our formulation, the fluid exchange occurs through the upper and lower walls of the chamber (represented by dashed-dotted blue lines). To model this exchange, we apply periodic boundary conditions along these walls. One possible experimental set-up that corresponds to the above model involves a valve-controlled channel that connects the two compartments of the chamber.

$\tilde {t}\geq 0$, fluid is allowed to exchange freely between the two compartments of the chamber. In our formulation, the fluid exchange occurs through the upper and lower walls of the chamber (represented by dashed-dotted blue lines). To model this exchange, we apply periodic boundary conditions along these walls. One possible experimental set-up that corresponds to the above model involves a valve-controlled channel that connects the two compartments of the chamber.

In the above mentioned study, Oshri (Reference Oshri2021) analysed the quasi-static evolution of the system, wherein the volume of fluid exchanged between the two parts of the chamber is the control parameter. In contrast, the present work focuses on the dynamical evolution of the system, wherein the fluid is driven by the spontaneous relaxation of the sheet from higher to lower energetic states. We believe that the dynamic analysis of this set-up will open new avenues for designing advanced technological devices, such as micromechanical switches (Krylov et al. Reference Krylov, Ilic, Schreiber, Seretensky and Craighead2008; Zhang et al. Reference Zhang, Yan, Peng and Meng2014; Preston et al. Reference Preston, Jiang, Sanchez, Rothemund, Rawson, Nemitz, Lee, Suo, Walsh and Whitesides2019) and microfluidic mixing devices (Stroock et al. Reference Stroock, Dertinger, Ajdari, Mezić, Stone and Whitesides2002; Liu, Kim & Sung Reference Liu, Kim and Sung2004; Lee et al. Reference Lee, Chang, Wang and Fu2011). Indeed, the additional coupling between the sheet and the surrounding fluid confers increased flexibility in the design of such switches. Different fluids with different viscosities can be used to manipulate the time that is required for the sheet to release its stored energy, thereby increasing, for example, the time scales over which the switches operate. In addition, when the two parts of the chamber are filled with different fluids, the elastic energy released from the sheet can be exploited for mixing: the pressure field induced in the chamber can be utilized to inject the fluid from one side of the chamber into the fluid on the other side, thereby inducing mixing of the two fluids. Typically, such devices function in conditions of low Reynolds numbers, where the effects of viscosity are significant. However, our system can also be applied in the design of pneumatic time-delay switches and soft pneumatic actuators (Rothemund et al. Reference Rothemund, Ainla, Belding, Preston, Kurihara, Suo and Whitesides2018; Preston et al. Reference Preston, Jiang, Sanchez, Rothemund, Rawson, Nemitz, Lee, Suo, Walsh and Whitesides2019; Drotman et al. Reference Drotman, Jadhav, Sharp, Chan and Tolley2021), which typically operate in the opposing limit of high Reynolds numbers.

While successful implementation of these applications is in itself a challenging task (which we plan to pursue in future research), in this work, we aim to answer more fundamental questions related to the underlying physical behaviour of the system. For example, how much of the initial elastic energy is subsequently transferred from the sheet to the fluid? How is the velocity of the fluid that is induced in the chamber related to the elastic properties of the sheet? What is the maximum pressure difference that the sheet induces in the chamber?

As a first step to answering these questions, we derive an analytical model that encompasses the elasticity of thin sheets and the hydrodynamics of inviscid fluids. Our model reveals that the system depends on four dimensionless parameters: the normalized excess length of the sheet compared with the lateral dimension of the chamber, ![]() $\varDelta$, where the total length of the sheet is used to normalize all lengths; the normalized vertical dimension of the chamber,

$\varDelta$, where the total length of the sheet is used to normalize all lengths; the normalized vertical dimension of the chamber, ![]() $L_y$; the normalized initial volume difference in the chamber,

$L_y$; the normalized initial volume difference in the chamber, ![]() $v_{du}(0)$; and the structure-to-fluid mass ratio,

$v_{du}(0)$; and the structure-to-fluid mass ratio, ![]() $\lambda$. We show that for fixed dimensions of the chamber,

$\lambda$. We show that for fixed dimensions of the chamber, ![]() $L_y$ and

$L_y$ and ![]() $\varDelta$, the system exhibits two asymptotic solutions as a function of

$\varDelta$, the system exhibits two asymptotic solutions as a function of ![]() $\lambda$. The sheet's inertia dominates the dynamics when

$\lambda$. The sheet's inertia dominates the dynamics when ![]() $\lambda \gg 1$, and is therefore referred to below as the ‘solid-dominated’ region, while the dynamics is governed by the fluid's inertia when

$\lambda \gg 1$, and is therefore referred to below as the ‘solid-dominated’ region, while the dynamics is governed by the fluid's inertia when ![]() $\lambda \ll 1$, and is therefore referred to as the ‘fluid-dominated’ region.

$\lambda \ll 1$, and is therefore referred to as the ‘fluid-dominated’ region.

We investigate the system's behaviour both in the early stages of its evolution and at moderate times during which nonlinear effects control the dynamics. For the early stages, we employ linear stability analysis around the (unstable) second buckling mode and the (stable) first buckling mode. We obtain the highest growth rate, ![]() $\sigma$, and the lowest frequency of vibration,

$\sigma$, and the lowest frequency of vibration, ![]() $\omega$, around these initial states. The two solutions exhibit similar behaviour as a function of

$\omega$, around these initial states. The two solutions exhibit similar behaviour as a function of ![]() $\lambda$, namely they converge to a constant in the solid-dominated region, while they exhibit the scaling

$\lambda$, namely they converge to a constant in the solid-dominated region, while they exhibit the scaling ![]() $\lambda ^{1/2}$ in the fluid-dominated region. Furthermore, we show that in the solid-dominated region only one mode of the sheet is essentially excited at the instability, while an infinite number of modes are excited in the fluid-dominated region. Analytical approximations are derived for each of these cases under the assumption that the amplitude of the sheet remains small, i.e.

$\lambda ^{1/2}$ in the fluid-dominated region. Furthermore, we show that in the solid-dominated region only one mode of the sheet is essentially excited at the instability, while an infinite number of modes are excited in the fluid-dominated region. Analytical approximations are derived for each of these cases under the assumption that the amplitude of the sheet remains small, i.e. ![]() $\varDelta \ll 1$ (Landau & Lifshitz Reference Landau and Lifshitz1986).

$\varDelta \ll 1$ (Landau & Lifshitz Reference Landau and Lifshitz1986).

At moderate times, a weakly nonlinear analysis is performed around the second buckling mode. Given a small initial volume difference between the upper and lower parts of the chamber, we analyse the dynamic evolution of the system up to the peak time ![]() $t_{p}$, at which the sheet releases most of its initial potential energy. We show that, after some initial delay, the sheet rapidly escapes from the unstable state. We derive the approximation

$t_{p}$, at which the sheet releases most of its initial potential energy. We show that, after some initial delay, the sheet rapidly escapes from the unstable state. We derive the approximation ![]() $\sigma t_{p}\simeq \ln [c\varDelta ^{1/2}/v_{du}(0)]$, where

$\sigma t_{p}\simeq \ln [c\varDelta ^{1/2}/v_{du}(0)]$, where ![]() $\sigma$ is the growth rate of the linear instability and

$\sigma$ is the growth rate of the linear instability and ![]() $c$ is a constant, and show that it agrees well with the numerical results. At

$c$ is a constant, and show that it agrees well with the numerical results. At ![]() $t_{p}$, most of the initial potential energy is converted into kinetic energy of the sheet if

$t_{p}$, most of the initial potential energy is converted into kinetic energy of the sheet if ![]() $\lambda \gg 1$ and into hydrodynamic energy if

$\lambda \gg 1$ and into hydrodynamic energy if ![]() $\lambda \ll 1$. We show that at

$\lambda \ll 1$. We show that at ![]() $t=t_{p}$ a relatively large spike of pressure drop is applied on the sheet.

$t=t_{p}$ a relatively large spike of pressure drop is applied on the sheet.

The paper is organized as follows. In § 2, we first formulate the problem for finite excess lengths. Then, we reduce this formulation to the small-amplitude approximation and introduce the modal expansion of the solution. In § 3, we investigate the early stages of the evolution. After recalling the static solution, we employ a linear stability analysis around the second and the first modes of buckling. In § 4, we investigate the system's evolution at moderate times. In particular, we examine the energetic interplay between the sheet and the fluid, derive the scaling for the peak time, ![]() $t_{p}$, and explore the relation between the volume difference and the pressure drop on the sheet. Finally, in § 5, we discuss a possible experimental realization of the system and, in § 6, we draw conclusions, and propose a direction for future study.

$t_{p}$, and explore the relation between the volume difference and the pressure drop on the sheet. Finally, in § 5, we discuss a possible experimental realization of the system and, in § 6, we draw conclusions, and propose a direction for future study.

2. Formulation of the problem

We consider an inextensible thin sheet of total length ![]() $\tilde {L}$, bending modulus

$\tilde {L}$, bending modulus ![]() $\tilde {B}$, thickness

$\tilde {B}$, thickness ![]() $\tilde {h}$ and density

$\tilde {h}$ and density ![]() $\tilde {\rho }_{sh}$. The sheet divides a rectangular closed chamber into two parts, which are connected by a valve (figure 1). The lateral, the vertical and the width dimensions of the chamber are denoted by

$\tilde {\rho }_{sh}$. The sheet divides a rectangular closed chamber into two parts, which are connected by a valve (figure 1). The lateral, the vertical and the width dimensions of the chamber are denoted by ![]() $\tilde {L}_x$,

$\tilde {L}_x$, ![]() $\tilde {L}_y$ and

$\tilde {L}_y$ and ![]() $\tilde {W}$, respectively. A Cartesian coordinate system is located on the left edge of the sheet. A cross-section of the chamber on the

$\tilde {W}$, respectively. A Cartesian coordinate system is located on the left edge of the sheet. A cross-section of the chamber on the ![]() $\tilde {x}\tilde {y}$ plane is placed at

$\tilde {x}\tilde {y}$ plane is placed at ![]() $0\leq \tilde {x}\leq \tilde {L}_x$ and

$0\leq \tilde {x}\leq \tilde {L}_x$ and ![]() $-\tilde {L}_y/2 \leq \tilde {y}\leq \tilde {L}_y/2$. When

$-\tilde {L}_y/2 \leq \tilde {y}\leq \tilde {L}_y/2$. When ![]() $\tilde {t}<0$, the valve connecting the two parts of the chamber is closed, and the volumes above and below the sheet,

$\tilde {t}<0$, the valve connecting the two parts of the chamber is closed, and the volumes above and below the sheet, ![]() $\tilde {v}_{u}(\tilde {t})$ and

$\tilde {v}_{u}(\tilde {t})$ and ![]() $\tilde {v}_{d}(\tilde {t})$, are filled with an incompressible, inviscid fluid of density

$\tilde {v}_{d}(\tilde {t})$, are filled with an incompressible, inviscid fluid of density ![]() $\tilde {\rho }_{\ell }$. Hereafter, we denote quantities related to the upper and lower parts of the chamber by the subscripts ‘

$\tilde {\rho }_{\ell }$. Hereafter, we denote quantities related to the upper and lower parts of the chamber by the subscripts ‘![]() $u$’ and ‘

$u$’ and ‘![]() $d$’, respectively. At

$d$’, respectively. At ![]() $\tilde {t}\geq 0$, the valve is opened, and free exchange of fluid is allowed in the chamber.

$\tilde {t}\geq 0$, the valve is opened, and free exchange of fluid is allowed in the chamber.

In the analysis that follows, we normalize all lengths by the total length of the sheet, ![]() $\tilde {L}$, and we normalize time by the inertial time scale of the sheet

$\tilde {L}$, and we normalize time by the inertial time scale of the sheet ![]() $\tilde {t}_{\star }=\tilde {L}^2(\tilde {\rho }_{sh} \tilde {h}/\tilde {B})^{1/2}$, i.e.

$\tilde {t}_{\star }=\tilde {L}^2(\tilde {\rho }_{sh} \tilde {h}/\tilde {B})^{1/2}$, i.e.

We choose this normalization because we anticipate that the wavelengths on the sheet will scale with the sheet's total length. In addition, since the dynamics in the system is driven by the sheet's motion, we chose the sheet's inertial time scale for the normalization. Note that our normalization with respect to lengths and time implies the normalization of the hydrodynamic fields and of the elastic fields, as will be emphasized further during the formulation. Hereafter, we denote all dimensional quantities with tildes over the symbols, and the corresponding non-dimensional quantities without a tilde.

Our model is based on the following six assumptions. Firstly, we assume that the system remains uniform along the width dimension of the chamber. Therefore, we set ![]() $W=1$ and consider a two-dimensional system. Secondly, we assume that the volume occupied by the elastic sheet is negligible compared with the total volume of the chamber, i.e.

$W=1$ and consider a two-dimensional system. Secondly, we assume that the volume occupied by the elastic sheet is negligible compared with the total volume of the chamber, i.e. ![]() $\tilde {h}\tilde {L}/(\tilde {L}_x \tilde {L}_y) \ll 1$, and as a result

$\tilde {h}\tilde {L}/(\tilde {L}_x \tilde {L}_y) \ll 1$, and as a result ![]() $v_{u}(t)+v_{d}(t)=L_x L_y$. Thirdly, we assume that the fluid exchange between the two parts of the chamber occurs through the upper and lower walls, i.e. the walls located at

$v_{u}(t)+v_{d}(t)=L_x L_y$. Thirdly, we assume that the fluid exchange between the two parts of the chamber occurs through the upper and lower walls, i.e. the walls located at ![]() $y=\pm L_y/2$. Fourthly, we assume that the vertical dimension of the chamber,

$y=\pm L_y/2$. Fourthly, we assume that the vertical dimension of the chamber, ![]() $L_y$, is larger than the typical length scale,

$L_y$, is larger than the typical length scale, ![]() $\ell$, over which the disturbances in the flow caused by the sheet's motion decay to zero. In addition, we assume that there is no contact between the sheet and the sidewalls of the chamber, or of the sheet with itself, at any time during the system's evolution. Lastly, we assume that at

$\ell$, over which the disturbances in the flow caused by the sheet's motion decay to zero. In addition, we assume that there is no contact between the sheet and the sidewalls of the chamber, or of the sheet with itself, at any time during the system's evolution. Lastly, we assume that at ![]() $t=0$ the system is at rest and that the sheet accommodates a configuration that is dictated by the volume difference

$t=0$ the system is at rest and that the sheet accommodates a configuration that is dictated by the volume difference ![]() $v_{du}(0)=v_{d}(0)-v_{u}(0)$.

$v_{du}(0)=v_{d}(0)-v_{u}(0)$.

For an inviscid and irrotational fluid, the state of the flow is determined by four fields. Two of these are the fluid's potential functions ![]() $\phi _i(x,y,t)$, where

$\phi _i(x,y,t)$, where ![]() $i=u,d$, from which we can determine the velocity profile of the fluid as

$i=u,d$, from which we can determine the velocity profile of the fluid as ![]() ${\boldsymbol {v}}_i=\boldsymbol {\nabla } \phi _i$, where

${\boldsymbol {v}}_i=\boldsymbol {\nabla } \phi _i$, where ![]() $\boldsymbol {\nabla }$ is the two-dimensional gradient operator. The other two fields that characterize the flow are the pressures

$\boldsymbol {\nabla }$ is the two-dimensional gradient operator. The other two fields that characterize the flow are the pressures ![]() $p_i(x,y,t)$ in each side of the chamber. Using our normalization convention, we find that the potential functions are normalized by

$p_i(x,y,t)$ in each side of the chamber. Using our normalization convention, we find that the potential functions are normalized by ![]() $\phi _i=\tilde {\phi }_i(\tilde {\rho }_{sh} \tilde {h}/\tilde {B})^{1/2}$ and the pressures by

$\phi _i=\tilde {\phi }_i(\tilde {\rho }_{sh} \tilde {h}/\tilde {B})^{1/2}$ and the pressures by ![]() $p_i=\tilde {p}_i\tilde {L}^3/\tilde {B}$. The evolution of these hydrodynamic fields, in space and over time, is determined by the continuity equation and Bernoulli's equation:

$p_i=\tilde {p}_i\tilde {L}^3/\tilde {B}$. The evolution of these hydrodynamic fields, in space and over time, is determined by the continuity equation and Bernoulli's equation:

where ![]() $c_i(t)$ are arbitrary functions that depend on time. Throughout the system's development, these functions are employed to maintain a constant pressure at a point within each part of the chamber (Lamb Reference Lamb1945). In addition, in (2.2b) and (2.5), we define the dimensionless parameters:

$c_i(t)$ are arbitrary functions that depend on time. Throughout the system's development, these functions are employed to maintain a constant pressure at a point within each part of the chamber (Lamb Reference Lamb1945). In addition, in (2.2b) and (2.5), we define the dimensionless parameters:

\begin{equation} \lambda=\frac{\tilde{\rho}_{sh}\tilde{h}}{\tilde{\rho}_{\ell}\tilde{L}},\quad \varDelta=1-L_x. \end{equation}

\begin{equation} \lambda=\frac{\tilde{\rho}_{sh}\tilde{h}}{\tilde{\rho}_{\ell}\tilde{L}},\quad \varDelta=1-L_x. \end{equation}

The structure-to-fluid mass ratio, ![]() $\lambda$, accounts for the ratio between the densities of the sheet and the fluid and the slenderness of the sheet. This dimensionless parameter plays a role, for example, in the problem of a flag flapping under a uniform axial flow (Argentina & Mahadevan Reference Argentina and Mahadevan2005; Connel & Yue Reference Connel and Yue2007; Alben Reference Alben2008; Alben & Shelley Reference Alben and Shelley2008). The parameter

$\lambda$, accounts for the ratio between the densities of the sheet and the fluid and the slenderness of the sheet. This dimensionless parameter plays a role, for example, in the problem of a flag flapping under a uniform axial flow (Argentina & Mahadevan Reference Argentina and Mahadevan2005; Connel & Yue Reference Connel and Yue2007; Alben Reference Alben2008; Alben & Shelley Reference Alben and Shelley2008). The parameter ![]() $\varDelta$ accounts for the difference between the total length of the sheet and the lateral dimension of the chamber. In dimensional form, it may be expressed as

$\varDelta$ accounts for the difference between the total length of the sheet and the lateral dimension of the chamber. In dimensional form, it may be expressed as ![]() $\tilde {\varDelta }=\tilde {L}-\tilde {L}_x$. For a given system, the parameters

$\tilde {\varDelta }=\tilde {L}-\tilde {L}_x$. For a given system, the parameters ![]() $\lambda$ and

$\lambda$ and ![]() $\varDelta$ remain constant throughout the dynamic evolution.

$\varDelta$ remain constant throughout the dynamic evolution.

To solve the continuity equation (2.2a), we must first specify the boundary conditions on the chamber's walls and the fluid–sheet interfaces. Since the fluid that exits the upper wall of the chamber enters through the lower wall, we set periodic boundary conditions through ![]() $y=\pm L_y/2$. Thereafter, we ensure that there is no penetration of fluid through the sidewalls of the chamber. These restrictions give the boundary conditions:

$y=\pm L_y/2$. Thereafter, we ensure that there is no penetration of fluid through the sidewalls of the chamber. These restrictions give the boundary conditions:

In addition to the periodic boundary conditions at ![]() $y=\pm L_y/2$, it is necessary to ensure that

$y=\pm L_y/2$, it is necessary to ensure that ![]() $p_{u}(x,L_y/2,t)=p_{d}(x,-L_y/2,t)$ along these walls. By utilizing Bernoulli's equation (2.2a), and the periodic boundary conditions, it becomes apparent that this requirement is satisfied when

$p_{u}(x,L_y/2,t)=p_{d}(x,-L_y/2,t)$ along these walls. By utilizing Bernoulli's equation (2.2a), and the periodic boundary conditions, it becomes apparent that this requirement is satisfied when ![]() $c_{d}(t)=c_{u}(t)\equiv c(t)$. Consequently, we can determine the function

$c_{d}(t)=c_{u}(t)\equiv c(t)$. Consequently, we can determine the function ![]() $c(t)$ by fixing the pressure at a specific point in the lower part of the chamber. In the following analysis we choose

$c(t)$ by fixing the pressure at a specific point in the lower part of the chamber. In the following analysis we choose

Two sets of equations model the contact between the sheet and the fluid. The first set corresponds to the kinematic boundary conditions that ensure continuous contact between the sheet and the fluid. The second set corresponds to the force balance equations on the sheet that ensure proper transfer of the momentum between the solid and the fluid. To obtain these two sets of equations, we first define the elastic fields that describe the position of the sheet on the ![]() $xy$ plane. It is important to note that, as we assumed the sheet to be inextensible, the elastic model accounts only for bending deformations and does not include stretching deformations. In contrast to the Eulerian description of the fluid, it is convenient to adopt a Lagrangian description for the sheet and to define the elastic fields as functions of the normalized arclength parameter on the sheet,

$xy$ plane. It is important to note that, as we assumed the sheet to be inextensible, the elastic model accounts only for bending deformations and does not include stretching deformations. In contrast to the Eulerian description of the fluid, it is convenient to adopt a Lagrangian description for the sheet and to define the elastic fields as functions of the normalized arclength parameter on the sheet, ![]() $s\in [0,1]$. With this change of reference frame, we define the position vector to a point on the sheet as

$s\in [0,1]$. With this change of reference frame, we define the position vector to a point on the sheet as ![]() ${\boldsymbol {x}}_{sh}(s,t)=(x_{sh}(s,t),y_{sh}(s,t))$ and the angle between the tangent to the sheet and the

${\boldsymbol {x}}_{sh}(s,t)=(x_{sh}(s,t),y_{sh}(s,t))$ and the angle between the tangent to the sheet and the ![]() $x$ axis as

$x$ axis as ![]() $\theta (s,t)$ (see figure 1). These three elastic fields, i.e.

$\theta (s,t)$ (see figure 1). These three elastic fields, i.e. ![]() $x_{sh}(s,t)$,

$x_{sh}(s,t)$, ![]() $y_{sh}(s,t)$ and

$y_{sh}(s,t)$ and ![]() $\theta (s,t)$, are not independent, since they are related by the geometric constraints

$\theta (s,t)$, are not independent, since they are related by the geometric constraints

By using these definitions, the kinematic boundary conditions on the sheet–fluid interfaces are given by

where ![]() ${\rm D}/{\rm D}t=\partial /\partial t +{\boldsymbol {v}}_i \boldsymbol {\cdot } \boldsymbol {\nabla }$ is the two-dimensional convective derivative. The balance of moments and forces on the sheet is given by

${\rm D}/{\rm D}t=\partial /\partial t +{\boldsymbol {v}}_i \boldsymbol {\cdot } \boldsymbol {\nabla }$ is the two-dimensional convective derivative. The balance of moments and forces on the sheet is given by

where ![]() ${\boldsymbol {F}}=(F_x(s,t),F_y(s,t))$ is the vector of reaction forces per unit length at a cross-section of the sheet and our normalization implies that

${\boldsymbol {F}}=(F_x(s,t),F_y(s,t))$ is the vector of reaction forces per unit length at a cross-section of the sheet and our normalization implies that ![]() ${\boldsymbol {F}}=\tilde {{\boldsymbol {F}}}\tilde {L}^2/\tilde {B}$. In addition,

${\boldsymbol {F}}=\tilde {{\boldsymbol {F}}}\tilde {L}^2/\tilde {B}$. In addition, ![]() ${\hat {\boldsymbol {n}}}_{d}=(-\sin \theta,\cos \theta )$ is a unit normal vector on the sheet that points outwards from the lower part of the chamber, and the hydrodynamic pressures in (2.8b) are calculated on their respective sides of the sheet–fluid interfaces. Note that in (2.8a) we neglect the rotational inertia term. This is justified in the limit of a thin and inextensible sheet, as assumed in this analysis (Neukirch et al. Reference Neukirch, Frelat, Goriely and Maurini2012; Goriely Reference Goriely2017; Kodio, Goriely & Vella Reference Kodio, Goriely and Vella2020). Equations (2.8) are supplemented by the following boundary conditions on the sheet's edges:

${\hat {\boldsymbol {n}}}_{d}=(-\sin \theta,\cos \theta )$ is a unit normal vector on the sheet that points outwards from the lower part of the chamber, and the hydrodynamic pressures in (2.8b) are calculated on their respective sides of the sheet–fluid interfaces. Note that in (2.8a) we neglect the rotational inertia term. This is justified in the limit of a thin and inextensible sheet, as assumed in this analysis (Neukirch et al. Reference Neukirch, Frelat, Goriely and Maurini2012; Goriely Reference Goriely2017; Kodio, Goriely & Vella Reference Kodio, Goriely and Vella2020). Equations (2.8) are supplemented by the following boundary conditions on the sheet's edges:

where we assume hinged boundary conditions in (2.9c).

This completes the formulation of the problem. In summary, given the excess length ![]() $\varDelta$, the vertical dimension of the chamber

$\varDelta$, the vertical dimension of the chamber ![]() $L_y$, the parameter

$L_y$, the parameter ![]() $\lambda$ and the initial volume difference in the chamber

$\lambda$ and the initial volume difference in the chamber ![]() $v_{du}(0)$, the dynamic evolution of the system is determined from the solution of the coupled equations (2.2)–(2.9). In the analysis that follows, we always assume that the sheet and the fluid are initially at rest, i.e.

$v_{du}(0)$, the dynamic evolution of the system is determined from the solution of the coupled equations (2.2)–(2.9). In the analysis that follows, we always assume that the sheet and the fluid are initially at rest, i.e. ![]() $({\partial {\boldsymbol {x}}_{sh}}/{\partial t}) (s,0)=0$ and

$({\partial {\boldsymbol {x}}_{sh}}/{\partial t}) (s,0)=0$ and ![]() $\phi _i(x,y,0)=0$.

$\phi _i(x,y,0)=0$.

While solutions to our set of nonlinear equations can, in practice, be sought only numerically, some analytical progress that sheds light on the underlying physics of the system can be achieved under the assumption that the excess length remains small, i.e. ![]() $\varDelta \ll 1$. For this reason, in the next section, we reduce our model to this so-called small-amplitude approximation (Landau & Lifshitz Reference Landau and Lifshitz1986) and exploit this formulation to study the time-dependent behaviour of the system.

$\varDelta \ll 1$. For this reason, in the next section, we reduce our model to this so-called small-amplitude approximation (Landau & Lifshitz Reference Landau and Lifshitz1986) and exploit this formulation to study the time-dependent behaviour of the system.

However, before we proceed to the next section, we should add a comment regarding the system's energy. Since we assumed an ideal fluid, i.e. one without viscous dissipation, and since we consider an elastic model, our equations have a conserved first integral that corresponds to the system's total energy. In accordance with Appendix A, it can be shown that the total energy of the system is given by the sum of the energies of the sheet and the fluid, ![]() $E=E_{sh}(t)+E_{f}(t)$, where

$E=E_{sh}(t)+E_{f}(t)$, where ![]() $E_{sh}(t)$ accounts for the sum of the kinetic and the potential energies of the sheet, which are designated

$E_{sh}(t)$ accounts for the sum of the kinetic and the potential energies of the sheet, which are designated ![]() $E_{sh}^{p}(t)$ and

$E_{sh}^{p}(t)$ and ![]() $E_{sh}^{k}(t)$, respectively, and

$E_{sh}^{k}(t)$, respectively, and ![]() $E_{f}(t)$ accounts for the kinetic energy of the fluid. Therefore, the total energy is given by

$E_{f}(t)$ accounts for the kinetic energy of the fluid. Therefore, the total energy is given by

\begin{equation} E=\frac{1}{2}\int_0^1 \left[\left|\frac{\partial{\boldsymbol{x}}_{sh}}{\partial t}\right|^2+ \left(\frac{\partial \theta}{\partial s}\right)^2\right]{\rm d}s+ \sum_{i={u,d}}\frac{1}{2\lambda}\iint_{v_i(t)}|\boldsymbol{\nabla}\phi_i|^2\,{\rm d}\kern0.7pt x\,{{\rm d}y}, \end{equation}

\begin{equation} E=\frac{1}{2}\int_0^1 \left[\left|\frac{\partial{\boldsymbol{x}}_{sh}}{\partial t}\right|^2+ \left(\frac{\partial \theta}{\partial s}\right)^2\right]{\rm d}s+ \sum_{i={u,d}}\frac{1}{2\lambda}\iint_{v_i(t)}|\boldsymbol{\nabla}\phi_i|^2\,{\rm d}\kern0.7pt x\,{{\rm d}y}, \end{equation}

where ![]() $|\cdot |$ corresponds to the norm of the enclosed vector and our normalization implies that

$|\cdot |$ corresponds to the norm of the enclosed vector and our normalization implies that ![]() $E=\tilde {E}\tilde {L}/\tilde {B}$. Since our system starts from rest, the total energy of the system equals the initial potential energy of the sheet,

$E=\tilde {E}\tilde {L}/\tilde {B}$. Since our system starts from rest, the total energy of the system equals the initial potential energy of the sheet, ![]() $E=E_{sh}^{p}(0)$, and this energy is conserved throughout the system's evolution.

$E=E_{sh}^{p}(0)$, and this energy is conserved throughout the system's evolution.

2.1. The small-amplitude approximation

The assumption that the amplitude of the sheet remains small, or equivalently that ![]() $\varDelta \ll 1$, implies that the geometric relations (2.6) reduce to

$\varDelta \ll 1$, implies that the geometric relations (2.6) reduce to ![]() $\partial y_{sh}/\partial s\simeq \theta$ and

$\partial y_{sh}/\partial s\simeq \theta$ and ![]() $\partial x_{sh}/\partial s\simeq 1-\frac {1}{2}(\partial y_{sh}/\partial s)^2$. The nonlinearity in the derivative of

$\partial x_{sh}/\partial s\simeq 1-\frac {1}{2}(\partial y_{sh}/\partial s)^2$. The nonlinearity in the derivative of ![]() $x_{sh}(s,t)$ is retained in the leading order of the theory so as to satisfy the constraint on the excess length (2.9a). Indeed, in the small-amplitude approximation, this constraint is given by

$x_{sh}(s,t)$ is retained in the leading order of the theory so as to satisfy the constraint on the excess length (2.9a). Indeed, in the small-amplitude approximation, this constraint is given by

Here, we replace the arclength coordinate of the sheet with the Eulerian coordinate of the fluid, ![]() $s\simeq x$, according to our level of approximation. Correspondingly, the balance of forces and moments on the sheet (2.8) reduces to

$s\simeq x$, according to our level of approximation. Correspondingly, the balance of forces and moments on the sheet (2.8) reduces to

where the lateral compression, ![]() $F_x(t)$, is a function that depends solely of time. In addition, the pressure difference that the fluid exerts on the sheet, i.e. the last term in (2.12), is calculated at the sheet–fluid interface,

$F_x(t)$, is a function that depends solely of time. In addition, the pressure difference that the fluid exerts on the sheet, i.e. the last term in (2.12), is calculated at the sheet–fluid interface, ![]() $y=0$.

$y=0$.

Thus far, we have approximated only the elastic part of the model. To further simplify the hydrodynamic part, we need to estimate the order of its corresponding fields. Given that the initial energy of the sheet scales linearly with the excess length, ![]() $E_{sh}(0)\propto \varDelta$, and that the total energy of the system is conserved, the energy of the fluid is, at most, proportional to

$E_{sh}(0)\propto \varDelta$, and that the total energy of the system is conserved, the energy of the fluid is, at most, proportional to ![]() $E_{f}\sim \varDelta$. Therefore, if we approximate the energy of the fluid by

$E_{f}\sim \varDelta$. Therefore, if we approximate the energy of the fluid by ![]() $E_{f}\sim |{\boldsymbol {v}}|^2 \ell$, where

$E_{f}\sim |{\boldsymbol {v}}|^2 \ell$, where ![]() $|{\boldsymbol {v}}|$ is the typical velocity in the chamber and

$|{\boldsymbol {v}}|$ is the typical velocity in the chamber and ![]() $\ell$ is the decay length of the disturbances in the flow, we obtain

$\ell$ is the decay length of the disturbances in the flow, we obtain ![]() $|{\boldsymbol {v}}|\sim \sqrt {\varDelta /\ell }$. Furthermore, if we assume that the order of approximation of a derivative over the potential function, with respect to either a spatial dimension or time, does not change, then we can approximate Bernoulli's equation (2.2b), and the kinematic boundary conditions by

$|{\boldsymbol {v}}|\sim \sqrt {\varDelta /\ell }$. Furthermore, if we assume that the order of approximation of a derivative over the potential function, with respect to either a spatial dimension or time, does not change, then we can approximate Bernoulli's equation (2.2b), and the kinematic boundary conditions by

These approximations will further be verified a posteriori in § 4, where we analyse the nonlinear dynamics of the system. In particular, we compare the results of this approximation with the numerical solution of the nonlinear model (2.2)–(2.9). Note that since the continuity equations (2.2a) are already linear in the potential functions, they remain unchanged in our approximated model.

This completes the reduction of our model to the small-amplitude limit. In summary, (2.2a) and (2.11)–(2.13), supplemented by the linearized form of the boundary conditions (2.5), (2.4), (2.9b) and (2.9c), form a closure and describe the coupled dynamics of the sheet and the fluid in the small-amplitude approximation. A comment is necessary regarding this simplified formulation. In accordance with the derivation in Appendix B, it can be shown that the reduced model emanates from the minimization of the action ![]() $\mathcal {S}=\int _0^{\rm T}\mathcal {L}\,{\rm d}t$, where

$\mathcal {S}=\int _0^{\rm T}\mathcal {L}\,{\rm d}t$, where

\begin{align} \mathcal{L} &= \int_0^1\left[\frac{1}{2}\left(\frac{\partial y_{sh}}{\partial t}\right)^2-\frac{1}{2} \left(\frac{\partial^2y_{sh}}{\partial x^2}\right)^2+F_x(t) \left(\frac{1}{2}\left(\frac{\partial y_{sh}}{\partial x}\right)^2-\varDelta\right)\right. \nonumber\\ &\quad \left.\vphantom{\left(\frac{\partial y_{sh}}{\partial t}\right)^2} +\frac{1}{\lambda}\left[\phi_{d}(x,0,t)-\phi_{u}(x,0,t)\right] \frac{\partial y_{sh}}{\partial t}\right]{{\rm d}\kern0.7pt x} \nonumber\\ &\quad -\frac{1}{2\lambda}\int_{0}^{{L_y}/{2}} \int_0^1|\boldsymbol{\nabla}\phi_{u}|^2\,{\rm d}\kern0.7pt x\,{\rm d}y- \frac{1}{2\lambda}\int_{-{L_y}/{2}}^0 \int_0^1|\boldsymbol{\nabla}\phi_{d}|^2\,{\rm d}\kern0.7pt x\,{\rm d}y, \end{align}

\begin{align} \mathcal{L} &= \int_0^1\left[\frac{1}{2}\left(\frac{\partial y_{sh}}{\partial t}\right)^2-\frac{1}{2} \left(\frac{\partial^2y_{sh}}{\partial x^2}\right)^2+F_x(t) \left(\frac{1}{2}\left(\frac{\partial y_{sh}}{\partial x}\right)^2-\varDelta\right)\right. \nonumber\\ &\quad \left.\vphantom{\left(\frac{\partial y_{sh}}{\partial t}\right)^2} +\frac{1}{\lambda}\left[\phi_{d}(x,0,t)-\phi_{u}(x,0,t)\right] \frac{\partial y_{sh}}{\partial t}\right]{{\rm d}\kern0.7pt x} \nonumber\\ &\quad -\frac{1}{2\lambda}\int_{0}^{{L_y}/{2}} \int_0^1|\boldsymbol{\nabla}\phi_{u}|^2\,{\rm d}\kern0.7pt x\,{\rm d}y- \frac{1}{2\lambda}\int_{-{L_y}/{2}}^0 \int_0^1|\boldsymbol{\nabla}\phi_{d}|^2\,{\rm d}\kern0.7pt x\,{\rm d}y, \end{align}

with respect to the elastic fields ![]() $y_{sh}(x,t)$ and

$y_{sh}(x,t)$ and ![]() $F_x(t)$ and the hydrodynamic fields

$F_x(t)$ and the hydrodynamic fields ![]() $\phi _{i}(x,y,t)$. In the next section, we employ a modal expansion of these fields and combine it with the Lagrangian formulation to derive a simplified set of equations that are dependent solely on time.

$\phi _{i}(x,y,t)$. In the next section, we employ a modal expansion of these fields and combine it with the Lagrangian formulation to derive a simplified set of equations that are dependent solely on time.

2.1.1. Modal expansion

The continuity equations (2.2a), and their corresponding boundary conditions on the fluid–chamber interfaces (2.4), are satisfied when the potential functions are given by

\begin{align} \phi_i(x,y,t) &= a_0(t)\left(y\pm \frac{L_y}{2}\right)+\sum_{m=1}^{\infty}\cos ({\rm \pi} m x)\left[a_m(t)\exp\left({{\rm \pi} m\left(y\pm \frac{L_y}{2}\right)}\right) \right. \nonumber\\ &\quad \left.+\,c_m(t)\exp\left({-{\rm \pi} m \left(y\pm\frac{L_y}{2}\right)}\right)\right], \end{align}

\begin{align} \phi_i(x,y,t) &= a_0(t)\left(y\pm \frac{L_y}{2}\right)+\sum_{m=1}^{\infty}\cos ({\rm \pi} m x)\left[a_m(t)\exp\left({{\rm \pi} m\left(y\pm \frac{L_y}{2}\right)}\right) \right. \nonumber\\ &\quad \left.+\,c_m(t)\exp\left({-{\rm \pi} m \left(y\pm\frac{L_y}{2}\right)}\right)\right], \end{align}

where ![]() $a_m(t)$ (

$a_m(t)$ (![]() $m=0,1,2,\ldots$) and

$m=0,1,2,\ldots$) and ![]() $c_m(t)$ (

$c_m(t)$ (![]() $m=1,2,3,\ldots$) are unknown time-dependent coefficients and the

$m=1,2,3,\ldots$) are unknown time-dependent coefficients and the ![]() $\pm$ signs correspond to the solutions of the potential functions in the lower and the upper parts of the chamber, respectively. Similarly, we expand the solution of the sheet's height function in the following normal modes:

$\pm$ signs correspond to the solutions of the potential functions in the lower and the upper parts of the chamber, respectively. Similarly, we expand the solution of the sheet's height function in the following normal modes:

\begin{equation} y_{sh}(x,t)=\sum_{n=1}^{\infty}A_n(t)\sin({\rm \pi} n x), \end{equation}

\begin{equation} y_{sh}(x,t)=\sum_{n=1}^{\infty}A_n(t)\sin({\rm \pi} n x), \end{equation}

where the functions ![]() $\sin ({\rm \pi} n x)$ automatically satisfy the boundary conditions on the sheet edges (2.9b) and (2.9c), and

$\sin ({\rm \pi} n x)$ automatically satisfy the boundary conditions on the sheet edges (2.9b) and (2.9c), and ![]() $A_n(t)$ are as-yet unknown coefficients.

$A_n(t)$ are as-yet unknown coefficients.

With these expansions, the solution to our problem reduces to finding the unknown coefficients, ![]() $a_m(t)$,

$a_m(t)$, ![]() $c_m(t)$ and

$c_m(t)$ and ![]() $A_n(t)$, and the compression force

$A_n(t)$, and the compression force ![]() $F_x(t)$, from the solution of the force balance equation (2.12), Bernoulli's equation (2.13a), the kinematic boundary conditions (2.13b) and the geometric constraint (2.11). Equation (2.16) involves infinite summation over the modes of the height function, but, in practice, we will truncate this series at

$F_x(t)$, from the solution of the force balance equation (2.12), Bernoulli's equation (2.13a), the kinematic boundary conditions (2.13b) and the geometric constraint (2.11). Equation (2.16) involves infinite summation over the modes of the height function, but, in practice, we will truncate this series at ![]() $n=N$. A closed system of equations is then obtained when the coefficients of

$n=N$. A closed system of equations is then obtained when the coefficients of ![]() $a_m(t)$ and

$a_m(t)$ and ![]() $c_m(t)$ are truncated at

$c_m(t)$ are truncated at ![]() $N-1$.

$N-1$.

However, instead of directly using these equations, we take a different – yet equivalent – approach, by utilizing the Lagrangian formulation (2.14). To this end, we follow the analysis in Appendix C and substitute the potential functions (2.15), and the height function (2.16), into the Lagrangian (2.14). We then integrate over the spatial coordinates. Thereafter, we minimize the Lagrangian with respect to ![]() $a_m(t)$ and

$a_m(t)$ and ![]() $c_m(t)$ and express these coefficients in terms of

$c_m(t)$ and express these coefficients in terms of ![]() $A_n(t)$. Substituting

$A_n(t)$. Substituting ![]() $a_m(t)$ and

$a_m(t)$ and ![]() $c_m(t)$ back into the Lagrangian gives

$c_m(t)$ back into the Lagrangian gives

where Einstein's summation rule is implied for repeated indices, and we define the following symmetric matrices:

\begin{gather} T_{nk}=\frac{1}{4}\delta_{nk}+\frac{L_y}{2\lambda}W(n,0)W(k,0)+\sum_{m=1}^{N-1} \frac{2}{{\rm \pi} m \lambda}\tanh\left(\frac{{\rm \pi} m L_y}{2}\right)W(k,m)W(n,m), \end{gather}

\begin{gather} T_{nk}=\frac{1}{4}\delta_{nk}+\frac{L_y}{2\lambda}W(n,0)W(k,0)+\sum_{m=1}^{N-1} \frac{2}{{\rm \pi} m \lambda}\tanh\left(\frac{{\rm \pi} m L_y}{2}\right)W(k,m)W(n,m), \end{gather}

where ![]() $\delta _{nk}$ is the Kronecker delta, and

$\delta _{nk}$ is the Kronecker delta, and ![]() $W(n,m)= ({n}/{{\rm \pi} })({(1-(-1)^{n+m})}/{(n^2-m^2)})$ for

$W(n,m)= ({n}/{{\rm \pi} })({(1-(-1)^{n+m})}/{(n^2-m^2)})$ for ![]() $n\neq m$ and zero otherwise.

$n\neq m$ and zero otherwise.

Two comments are in order regarding this Lagrangian. First, since the matrix ![]() $T_{nk}$ is coupled to the kinetic terms in the Lagrangian, it takes on the role of a mass matrix in this formulation. This mass matrix has contributions from both the inertia of the sheet, i.e. the first term in

$T_{nk}$ is coupled to the kinetic terms in the Lagrangian, it takes on the role of a mass matrix in this formulation. This mass matrix has contributions from both the inertia of the sheet, i.e. the first term in ![]() $T_{nk}$, and the hydrodynamics of the fluid, i.e. the terms proportional to

$T_{nk}$, and the hydrodynamics of the fluid, i.e. the terms proportional to ![]() $1/\lambda$. The latter hydrodynamic terms are frequently referred to as added mass or virtual mass, since they describe an additional mass that the sheet appears to acquire when it accelerates in the fluid (Munk Reference Munk1924; Lighthill Reference Lighthill1960; Coene Reference Coene1992).

$1/\lambda$. The latter hydrodynamic terms are frequently referred to as added mass or virtual mass, since they describe an additional mass that the sheet appears to acquire when it accelerates in the fluid (Munk Reference Munk1924; Lighthill Reference Lighthill1960; Coene Reference Coene1992).

The second comment is related to the potential functions ![]() $\phi _i(x,y,t)$ that result from the minimization. Using (C2b), we substitute

$\phi _i(x,y,t)$ that result from the minimization. Using (C2b), we substitute ![]() $c_m(t)=-a_m(t)$ in the potential functions (2.15) to obtain

$c_m(t)=-a_m(t)$ in the potential functions (2.15) to obtain

\begin{equation} \phi_i(x,y,t)=a_0(t)\left(y\pm \frac{L_y}{2}\right)+2\sum_{m=1}^{N-1}a_m(t)\cos({\rm \pi} m x)\sinh\left[{\rm \pi} m\left(y\pm \frac{L_y}{2}\right)\right]. \end{equation}

\begin{equation} \phi_i(x,y,t)=a_0(t)\left(y\pm \frac{L_y}{2}\right)+2\sum_{m=1}^{N-1}a_m(t)\cos({\rm \pi} m x)\sinh\left[{\rm \pi} m\left(y\pm \frac{L_y}{2}\right)\right]. \end{equation}

This solution implies that at ![]() $y=\pm L_y/2$ the velocity of the fluid is oriented only in the

$y=\pm L_y/2$ the velocity of the fluid is oriented only in the ![]() $y$ direction, i.e.

$y$ direction, i.e. ![]() $\partial \phi _i/\partial x(x,\pm L_y/2,t)=0$. It also implies that

$\partial \phi _i/\partial x(x,\pm L_y/2,t)=0$. It also implies that ![]() $\phi _i(x,\pm L_y/2,t)=0$, which, given (2.5) and (2.13a), yields a constant zero pressure along the inlet and the outlet walls of the chamber,

$\phi _i(x,\pm L_y/2,t)=0$, which, given (2.5) and (2.13a), yields a constant zero pressure along the inlet and the outlet walls of the chamber, ![]() $p_i(x,\pm L_y/2,t)=0$. We anticipate that these conditions will occur only when the disturbances that the sheet induces in the flow decay to zero. Therefore, the small-amplitude model holds strictly when

$p_i(x,\pm L_y/2,t)=0$. We anticipate that these conditions will occur only when the disturbances that the sheet induces in the flow decay to zero. Therefore, the small-amplitude model holds strictly when ![]() $L_y\gg \ell$, where

$L_y\gg \ell$, where ![]() $\ell \simeq 1/({\rm \pi} m)$, for the smallest non-zero mode, is now explicitly identified as the decay length of the hydrodynamic disturbances.

$\ell \simeq 1/({\rm \pi} m)$, for the smallest non-zero mode, is now explicitly identified as the decay length of the hydrodynamic disturbances.

Keeping in mind these limitations of the small-amplitude model, we go back to derive the equations for the coefficients ![]() $A_n(t)$. Given an initial volume difference, which, in turn, corresponds to an initial configuration of the sheet, i.e. a set of initial conditions for the coefficients

$A_n(t)$. Given an initial volume difference, which, in turn, corresponds to an initial configuration of the sheet, i.e. a set of initial conditions for the coefficients ![]() $A_n(0)$, and keeping in mind that the system starts from rest, i.e.

$A_n(0)$, and keeping in mind that the system starts from rest, i.e. ![]() $({\rm d}A_n/{\rm d}t)(0)=0$, we can determine the dynamic evolution of the system from the minimization of (2.17) with respect to

$({\rm d}A_n/{\rm d}t)(0)=0$, we can determine the dynamic evolution of the system from the minimization of (2.17) with respect to ![]() $A_n(t)$ and

$A_n(t)$ and ![]() $F_x(t)$. This minimization yields

$F_x(t)$. This minimization yields ![]() $N+1$ algebraic differential equations that, in our matrix notation, read

$N+1$ algebraic differential equations that, in our matrix notation, read

Once ![]() $A_n(t)$ are determined from the solution of (2.20), the position of the sheet in time and in space is given by (2.16), and the hydrodynamic potentials and the pressure fields are determined from (2.15), (C2) and (2.13a). In the next section, we utilize this formulation to investigate the early time evolution. Then, in § 4 we use it to analyse the dynamics at later times.

$A_n(t)$ are determined from the solution of (2.20), the position of the sheet in time and in space is given by (2.16), and the hydrodynamic potentials and the pressure fields are determined from (2.15), (C2) and (2.13a). In the next section, we utilize this formulation to investigate the early time evolution. Then, in § 4 we use it to analyse the dynamics at later times.

3. The early time evolution

In this section, we investigate the system's stability close to an initial equilibrium state. The section is divided into two parts. In the first, we recall the static solutions of the system in the small-amplitude approximation. In the second, we employ a linear stability analysis around the first two buckling modes to extract the growth rates and the flow fields of the perturbation around these modes.

3.1. Recap of the quasi-static solution

Following the analysis in the study of Oshri (Reference Oshri2021), the quasi-static evolution of the system is governed by two different branches of solutions, which we call ‘asymmetric’ and ‘symmetric’. Here, we recall the height functions in these branches.

On the one hand, when the initial volume difference is set as ![]() $0\leq v_{du}(0)\leq v_{du}^{cr}$, where

$0\leq v_{du}(0)\leq v_{du}^{cr}$, where ![]() $v_{du}^{cr}= ({2(3+{\rm \pi} ^2)}/{{\rm \pi} \sqrt {3(15+2{\rm \pi} ^2)}})\varDelta ^{1/2}$, the system is governed by the asymmetric branch. In this branch, the lateral compression is constant,

$v_{du}^{cr}= ({2(3+{\rm \pi} ^2)}/{{\rm \pi} \sqrt {3(15+2{\rm \pi} ^2)}})\varDelta ^{1/2}$, the system is governed by the asymmetric branch. In this branch, the lateral compression is constant, ![]() $F_x(0)=4{\rm \pi} ^2$, and the height functions are given by

$F_x(0)=4{\rm \pi} ^2$, and the height functions are given by

\begin{align} y_{sh}(x,0) &= \frac{p_{ud}(x,y,0)}{16{\rm \pi}^4}\left[2{\rm \pi}^2(1-x)x+1-\cos\left(2{\rm \pi} x\right)\right] \nonumber\\ &\quad +\frac{1}{\rm \pi}\sqrt{\varDelta-\frac{15+2{\rm \pi}^2}{768{\rm \pi}^6}p_{ud}(x,y,0)^2}\sin\left(2{\rm \pi} x\right), \end{align}

\begin{align} y_{sh}(x,0) &= \frac{p_{ud}(x,y,0)}{16{\rm \pi}^4}\left[2{\rm \pi}^2(1-x)x+1-\cos\left(2{\rm \pi} x\right)\right] \nonumber\\ &\quad +\frac{1}{\rm \pi}\sqrt{\varDelta-\frac{15+2{\rm \pi}^2}{768{\rm \pi}^6}p_{ud}(x,y,0)^2}\sin\left(2{\rm \pi} x\right), \end{align}

where ![]() $p_{ud}(x,y,0)=p_{u}(x,y,0)-p_{d}(x,y,0)$ is the pressure difference between the upper and lower parts of the chamber. The potential energy of the sheet in this branch is given by

$p_{ud}(x,y,0)=p_{u}(x,y,0)-p_{d}(x,y,0)$ is the pressure difference between the upper and lower parts of the chamber. The potential energy of the sheet in this branch is given by

Note that when ![]() $v_{du}(0)\rightarrow 0$ we know from (3.1b) that the pressure difference vanishes,

$v_{du}(0)\rightarrow 0$ we know from (3.1b) that the pressure difference vanishes, ![]() $p_{ud}(x,y,0)\rightarrow 0$, and the elastic configuration converges to the second, asymmetric, mode of buckling,

$p_{ud}(x,y,0)\rightarrow 0$, and the elastic configuration converges to the second, asymmetric, mode of buckling, ![]() $y_{sh}(x,0)\rightarrow \sqrt {\varDelta /{\rm \pi} ^2}\sin (2{\rm \pi} x)$. The total energy of the system in this configuration is given by

$y_{sh}(x,0)\rightarrow \sqrt {\varDelta /{\rm \pi} ^2}\sin (2{\rm \pi} x)$. The total energy of the system in this configuration is given by ![]() $E_{as}=4{\rm \pi} ^2\varDelta$. Note also that we considered solutions with an initial volume difference that is greater than zero. This is because the static solution has mirror symmetry around the

$E_{as}=4{\rm \pi} ^2\varDelta$. Note also that we considered solutions with an initial volume difference that is greater than zero. This is because the static solution has mirror symmetry around the ![]() $x$ axis. Solutions with

$x$ axis. Solutions with ![]() $v_{du}(0)<0$ (and

$v_{du}(0)<0$ (and ![]() $p_{ud}(x,y,t)<0$) are obtained by a reflection of the height functions (3.1) around the horizontal axis.

$p_{ud}(x,y,t)<0$) are obtained by a reflection of the height functions (3.1) around the horizontal axis.

On the other hand, when the volume difference is set as ![]() $v_{du}^{cr}\leq v_{du}(0)< \sqrt {2\varDelta /3}$, the system is governed by the symmetric branch. In this case, the inextensibility of the sheet implies an upper limit on the volume difference. In the case of a hinged sheet, this limit is given by

$v_{du}^{cr}\leq v_{du}(0)< \sqrt {2\varDelta /3}$, the system is governed by the symmetric branch. In this case, the inextensibility of the sheet implies an upper limit on the volume difference. In the case of a hinged sheet, this limit is given by ![]() $\sqrt {2\varDelta /3}$. The height functions in this branch are given by the parametric solution:

$\sqrt {2\varDelta /3}$. The height functions in this branch are given by the parametric solution:

\begin{gather}p_{ud}(x,y,0)={-}\frac{16\sqrt{6}u^{7/2}\cos u}{\sqrt{6u+4u(6+u^2)\cos^2 u-15\sin (2u)}}\varDelta^{1/2}, \end{gather}

\begin{gather}p_{ud}(x,y,0)={-}\frac{16\sqrt{6}u^{7/2}\cos u}{\sqrt{6u+4u(6+u^2)\cos^2 u-15\sin (2u)}}\varDelta^{1/2}, \end{gather} \begin{gather}v_{du}(0)={-}\frac{2\sqrt{2}\left[u(3+u^2)-3\tan u\right] \cos u}{\sqrt{3}u^{3/2}\sqrt{6u+4u(6+u^2)\cos^2 u-15\sin(2u)}}\varDelta^{1/2}, \end{gather}

\begin{gather}v_{du}(0)={-}\frac{2\sqrt{2}\left[u(3+u^2)-3\tan u\right] \cos u}{\sqrt{3}u^{3/2}\sqrt{6u+4u(6+u^2)\cos^2 u-15\sin(2u)}}\varDelta^{1/2}, \end{gather}

where ![]() $u=\sqrt {F_x(0)}/2$ is a function of the lateral compression. Given the initial volume difference,

$u=\sqrt {F_x(0)}/2$ is a function of the lateral compression. Given the initial volume difference, ![]() $v_{du}(0)$, and the excess length,

$v_{du}(0)$, and the excess length, ![]() $\varDelta$, we can determine the lateral compression,

$\varDelta$, we can determine the lateral compression, ![]() $F_x(0)$, from (3.3c), and then substitute this solution into (3.3a) and (3.3b) to obtain the height profile. When

$F_x(0)$, from (3.3c), and then substitute this solution into (3.3a) and (3.3b) to obtain the height profile. When ![]() $p_{ud}(x,y,0)\rightarrow 0$, the height function converges to the first, symmetric, mode of buckling, which is given by

$p_{ud}(x,y,0)\rightarrow 0$, the height function converges to the first, symmetric, mode of buckling, which is given by ![]() $y_{sh}(x,0)\rightarrow \sqrt {4\varDelta /{\rm \pi} ^2}\sin ({\rm \pi} x)$ and

$y_{sh}(x,0)\rightarrow \sqrt {4\varDelta /{\rm \pi} ^2}\sin ({\rm \pi} x)$ and ![]() $v_{du}(0)=8\varDelta ^{1/2}/{\rm \pi} ^2$. The total elastic energy of this shape is given by

$v_{du}(0)=8\varDelta ^{1/2}/{\rm \pi} ^2$. The total elastic energy of this shape is given by ![]() $E_{s}={\rm \pi} ^2\varDelta$. An example of the evolution of the sheet and the

$E_{s}={\rm \pi} ^2\varDelta$. An example of the evolution of the sheet and the ![]() $p_{ud}(x,y,0)$–

$p_{ud}(x,y,0)$–![]() $v_{du}(0)$ relation in this static solution, where

$v_{du}(0)$ relation in this static solution, where ![]() $0\leq v_{du}(0)< \sqrt {2\varDelta /3}$, is plotted in figure 2. In the following sections, we use these height functions (3.1a) and (3.3a) as the base solutions for our perturbative time-dependent expansion.

$0\leq v_{du}(0)< \sqrt {2\varDelta /3}$, is plotted in figure 2. In the following sections, we use these height functions (3.1a) and (3.3a) as the base solutions for our perturbative time-dependent expansion.

Figure 2. Evolution of the static solution in the small-amplitude approximation, where ![]() $\varDelta =0.01$. (a) The volume difference,

$\varDelta =0.01$. (a) The volume difference, ![]() $v_{du}(0)$, as a function of the pressure difference,

$v_{du}(0)$, as a function of the pressure difference, ![]() $p_{ud}(x,y,0)$. In the asymmetric branch the

$p_{ud}(x,y,0)$. In the asymmetric branch the ![]() $p_{ud}(x,y,0)$–

$p_{ud}(x,y,0)$–![]() $v_{du}(0)$ relation is given by (3.1b), while in the symmetric branch it is given by (3.3b) and (3.3c). The volume difference at the asymmetric-to-symmetric transition,

$v_{du}(0)$ relation is given by (3.1b), while in the symmetric branch it is given by (3.3b) and (3.3c). The volume difference at the asymmetric-to-symmetric transition, ![]() $v_{du}(0)=v_{du}^{cr}$, is labelled by ③. The pressure difference in the chamber vanishes when the sheet accommodates either the second or the first mode of buckling, labels ① and ④. As the volume difference approaches its limiting value

$v_{du}(0)=v_{du}^{cr}$, is labelled by ③. The pressure difference in the chamber vanishes when the sheet accommodates either the second or the first mode of buckling, labels ① and ④. As the volume difference approaches its limiting value ![]() $v_{du}(0)\rightarrow (2\varDelta /3)^{1/2}$, the pressure difference diverges. (b) Evolution of the sheet's profile as the volume difference increases; see the corresponding labelled numbers in (a). Note, that despite the relatively large change in the pressure difference in the symmetric branch, the elastic configurations remain almost unchanged.

$v_{du}(0)\rightarrow (2\varDelta /3)^{1/2}$, the pressure difference diverges. (b) Evolution of the sheet's profile as the volume difference increases; see the corresponding labelled numbers in (a). Note, that despite the relatively large change in the pressure difference in the symmetric branch, the elastic configurations remain almost unchanged.

Before we proceed, we emphasize that while the sheet's configuration evolves continuously from the moment that we open the valve, the static pressure difference, given in (3.1b) and (3.3b), changes instantaneously at ![]() $t=0$. This is because we assumed an incompressible fluid, in which the speed of sound is infinite. Nonetheless, the asymmetric and the symmetric modes of buckling, obtained respectively from (3.1a) and (3.3a) in the limit

$t=0$. This is because we assumed an incompressible fluid, in which the speed of sound is infinite. Nonetheless, the asymmetric and the symmetric modes of buckling, obtained respectively from (3.1a) and (3.3a) in the limit ![]() $p_{ud}(x,y,0)\rightarrow 0$, are exceptions. These configurations remain in static equilibrium, which can nevertheless be unstable, when the valve is opened. For this reason, in the next section, we investigate the linear stability of the system around these two limiting initial states.

$p_{ud}(x,y,0)\rightarrow 0$, are exceptions. These configurations remain in static equilibrium, which can nevertheless be unstable, when the valve is opened. For this reason, in the next section, we investigate the linear stability of the system around these two limiting initial states.

3.2. Linear stability

To derive the linear stability around the two limiting scenarios, i.e. the second and first buckling modes, we assume that the sheet's height function is given by the static solution, up to a small perturbation that grows exponentially with time. Correspondingly, we first perturb the amplitudes of the normal modes and the lateral compression around the base solutions, i.e. ![]() $A_n(t)=A_n(0)+\epsilon \bar {A}_n\,{\rm e}^{\sigma t}$ and

$A_n(t)=A_n(0)+\epsilon \bar {A}_n\,{\rm e}^{\sigma t}$ and ![]() $F_x(t)=F_x(0)+\epsilon \bar {F}_x\,{\rm e}^{\sigma t}$, where

$F_x(t)=F_x(0)+\epsilon \bar {F}_x\,{\rm e}^{\sigma t}$, where ![]() $\bar {A}_n$ and

$\bar {A}_n$ and ![]() $\bar {F}_x$ are unknown constants,

$\bar {F}_x$ are unknown constants, ![]() $\sigma$ is the growth rate and

$\sigma$ is the growth rate and ![]() $\epsilon \ll 1$ is an arbitrarily small parameter. Then, we substitute these perturbed functions into the equations of motion (2.20), and expand them up to linear order in

$\epsilon \ll 1$ is an arbitrarily small parameter. Then, we substitute these perturbed functions into the equations of motion (2.20), and expand them up to linear order in ![]() $\epsilon$. The leading order of this expansion, order

$\epsilon$. The leading order of this expansion, order ![]() $\epsilon ^0$, is given by

$\epsilon ^0$, is given by

and the subleading order, order ![]() $\epsilon$, is given by

$\epsilon$, is given by

The above equations in the subleading order always have the trivial solution ![]() $\bar {A}_n=0$ and

$\bar {A}_n=0$ and ![]() $\bar {F}_x=0$, unless their corresponding determinant vanishes. This condition gives the growth rate,

$\bar {F}_x=0$, unless their corresponding determinant vanishes. This condition gives the growth rate, ![]() $\sigma$. Once

$\sigma$. Once ![]() $\sigma$ is determined, its corresponding eigenfunction is obtained from the solution of (3.5). The hydrodynamic fields related to this eigenfunction are determined from (2.15) and (C2).

$\sigma$ is determined, its corresponding eigenfunction is obtained from the solution of (3.5). The hydrodynamic fields related to this eigenfunction are determined from (2.15) and (C2).

3.2.1. Linear stability around the second mode of buckling

When the initial configuration of the sheet is given by the second mode of buckling, the base solution is derived from (3.1a) in the limit ![]() $p_{ud}(x,y,0)\rightarrow 0$. This solution reads

$p_{ud}(x,y,0)\rightarrow 0$. This solution reads ![]() $y_{sh}(x,0)=\sqrt {\varDelta /{\rm \pi} ^2}\sin (2{\rm \pi} x)$ and

$y_{sh}(x,0)=\sqrt {\varDelta /{\rm \pi} ^2}\sin (2{\rm \pi} x)$ and ![]() $F_x(0)=4{\rm \pi} ^2$. A projection of this configuration on the normal mode expansion (2.16) gives

$F_x(0)=4{\rm \pi} ^2$. A projection of this configuration on the normal mode expansion (2.16) gives ![]() $A_n(0)=\sqrt {\varDelta /{\rm \pi} ^2}\delta _{2n}$. As expected, this initial state exactly satisfies the equilibrium equations at order

$A_n(0)=\sqrt {\varDelta /{\rm \pi} ^2}\delta _{2n}$. As expected, this initial state exactly satisfies the equilibrium equations at order ![]() $\epsilon ^0$ (3.4). At the next order, i.e. order

$\epsilon ^0$ (3.4). At the next order, i.e. order ![]() $\epsilon$, we find that

$\epsilon$, we find that ![]() $\bar {F}_x=0$ and

$\bar {F}_x=0$ and ![]() $\bar {A}_n=0$ for all the even perturbations, i.e.

$\bar {A}_n=0$ for all the even perturbations, i.e. ![]() $n=2,4,6,\dots$. Consequently, (3.5) yields linear and homogeneous equations that involve only the odd perturbations. These equations always have the trivial solution

$n=2,4,6,\dots$. Consequently, (3.5) yields linear and homogeneous equations that involve only the odd perturbations. These equations always have the trivial solution ![]() $\bar {A}_n=0$, except when the corresponding determinant vanishes. A tractable solution to this condition, which also gives a good approximation to the highest growth rate, is obtained at the lowest order when

$\bar {A}_n=0$, except when the corresponding determinant vanishes. A tractable solution to this condition, which also gives a good approximation to the highest growth rate, is obtained at the lowest order when ![]() $N=2$. This solution reads

$N=2$. This solution reads

\begin{equation} \sigma=\frac{\sqrt{3}{\rm \pi}^2}{\sqrt{1+\dfrac{8 L_y}{{\rm \pi}^2\lambda}}}. \end{equation}

\begin{equation} \sigma=\frac{\sqrt{3}{\rm \pi}^2}{\sqrt{1+\dfrac{8 L_y}{{\rm \pi}^2\lambda}}}. \end{equation}

In figure 3, we plot this analytical approximation for the growth rate as a function of ![]() $\lambda$, and compare it with the numerical solution of (3.5) for the case where

$\lambda$, and compare it with the numerical solution of (3.5) for the case where ![]() $N=8$. In addition, we compare this analytical solution with the growth rate obtained from the linearization of (2.2)–(2.9), i.e. where

$N=8$. In addition, we compare this analytical solution with the growth rate obtained from the linearization of (2.2)–(2.9), i.e. where ![]() $\varDelta$ is assumed to be finite. See Appendix D for the details of this solution.

$\varDelta$ is assumed to be finite. See Appendix D for the details of this solution.

Figure 3. Log–log plot of the highest growth rate as a function of ![]() $\lambda$ where

$\lambda$ where ![]() $L_y=2$. Symbols correspond to the linear stability analysis of (2.2)–(2.9), and solid and dashed lines correspond to the growth rates obtained from the small-amplitude approximation. When

$L_y=2$. Symbols correspond to the linear stability analysis of (2.2)–(2.9), and solid and dashed lines correspond to the growth rates obtained from the small-amplitude approximation. When ![]() $\lambda \gg 1$, the growth rate converges to the constant

$\lambda \gg 1$, the growth rate converges to the constant ![]() $\sigma \simeq \sqrt {3}{\rm \pi} ^2$, whereas when

$\sigma \simeq \sqrt {3}{\rm \pi} ^2$, whereas when ![]() $\lambda \ll 1$ the growth rate is given by

$\lambda \ll 1$ the growth rate is given by ![]() $\sigma \simeq \sqrt {3{\rm \pi} ^6/8}(\lambda /L_y)^{1/2}$. Note that the differences between the solid (

$\sigma \simeq \sqrt {3{\rm \pi} ^6/8}(\lambda /L_y)^{1/2}$. Note that the differences between the solid (![]() $N=2$) and dashed (

$N=2$) and dashed (![]() $N=8$) lines are almost not visible in the figure. While the growth rate is independent of the excess length in the small-amplitude approximation, the more general solution (symbols) shows that the growth rate increases with

$N=8$) lines are almost not visible in the figure. While the growth rate is independent of the excess length in the small-amplitude approximation, the more general solution (symbols) shows that the growth rate increases with ![]() $\varDelta$.

$\varDelta$.

Equation (3.6) is one of the central results in this paper. Several comments are in order regarding this solution. Firstly, note that the highest growth rate is always real and positive, i.e. the second mode of buckling is always an unstable state of the system.

Secondly, while (3.6) depends on the parameter ![]() $\lambda /L_y=\tilde {\rho }_{sh} \tilde {h}/(\tilde {\rho }_{\ell }\tilde {L}_y)$, this result is not general but depends on the order of approximation. Had we solved (3.5) with

$\lambda /L_y=\tilde {\rho }_{sh} \tilde {h}/(\tilde {\rho }_{\ell }\tilde {L}_y)$, this result is not general but depends on the order of approximation. Had we solved (3.5) with ![]() $N\geq 3$, the two parameters

$N\geq 3$, the two parameters ![]() $\lambda$ and

$\lambda$ and ![]() $L_y$ would have appeared independently in the solution. Nonetheless, comparing the lowest order solution, i.e. the solution with

$L_y$ would have appeared independently in the solution. Nonetheless, comparing the lowest order solution, i.e. the solution with ![]() $N=2$, with that of, say,

$N=2$, with that of, say, ![]() $N=8$, we find that the growth rate remains almost unchanged (compare the solid and dashed lines in figure 3). For this reason, we conclude that (3.6) well describes the growth rate in the limit

$N=8$, we find that the growth rate remains almost unchanged (compare the solid and dashed lines in figure 3). For this reason, we conclude that (3.6) well describes the growth rate in the limit ![]() $\varDelta \ll 1$.

$\varDelta \ll 1$.

Thirdly, while the solution of the small-amplitude approximation is independent of the excess length, ![]() $\varDelta$, the more general solution for finite values of

$\varDelta$, the more general solution for finite values of ![]() $\varDelta$ does depend on this parameter. See figure 3 for a comparison. In particular, for a fixed value of

$\varDelta$ does depend on this parameter. See figure 3 for a comparison. In particular, for a fixed value of ![]() $\lambda$, the growth rate increases with an increase in

$\lambda$, the growth rate increases with an increase in ![]() $\varDelta$.

$\varDelta$.

Fourthly, the analytical solution of the growth rate (3.6), exhibits two different regions as a function of ![]() $\lambda$. When

$\lambda$. When ![]() $\lambda /L_y\gg 1$, the growth rate is a constant,

$\lambda /L_y\gg 1$, the growth rate is a constant, ![]() $\sigma \simeq \sqrt {3}{\rm \pi} ^2$, that coincides with the growth rate of a sheet that is uncoupled from an external fluid. However, when

$\sigma \simeq \sqrt {3}{\rm \pi} ^2$, that coincides with the growth rate of a sheet that is uncoupled from an external fluid. However, when ![]() $\lambda /L_y\ll 1$, the growth rate exhibits the scaling

$\lambda /L_y\ll 1$, the growth rate exhibits the scaling ![]() $\sigma \simeq \sqrt {3{\rm \pi} ^6/8}(\lambda /L_y)^{1/2}$. These asymptotic solutions define two limiting behaviours of the system. The former scenario represents a ‘solid-dominated’ region, in which the pressure difference exerted by the fluid on the sheet is negligible compared with the inertia of the sheet. The latter scenario, where

$\sigma \simeq \sqrt {3{\rm \pi} ^6/8}(\lambda /L_y)^{1/2}$. These asymptotic solutions define two limiting behaviours of the system. The former scenario represents a ‘solid-dominated’ region, in which the pressure difference exerted by the fluid on the sheet is negligible compared with the inertia of the sheet. The latter scenario, where ![]() $\sigma \propto (\lambda /L_y)^{1/2}$, represents the opposite limit of a ‘fluid-dominated’ region, in which the inertia of the sheet is negligible compared with the pressure difference exerted by the fluid on the sheet. Similarly, these two regions are also reflected in the added mass term,

$\sigma \propto (\lambda /L_y)^{1/2}$, represents the opposite limit of a ‘fluid-dominated’ region, in which the inertia of the sheet is negligible compared with the pressure difference exerted by the fluid on the sheet. Similarly, these two regions are also reflected in the added mass term, ![]() $8L_y/({\rm \pi} ^2\lambda )$, in the denominator of the growth rate. When

$8L_y/({\rm \pi} ^2\lambda )$, in the denominator of the growth rate. When ![]() $\lambda$ is large, the added mass approaches zero and the sheet's inertia is not affected by the fluid's motion. In contrast, when

$\lambda$ is large, the added mass approaches zero and the sheet's inertia is not affected by the fluid's motion. In contrast, when ![]() $\lambda$ is small, the effective mass of the sheet increases, resulting in slower dynamics. It is worth noting that since the dynamics of the system becomes very slow in the fluid-dominated region, we would expect some aspects of this solution to align with our earlier, quasi-static solution in the asymmetric branch, as shown in (3.1). This is because the quasi-static solution describes a slow spontaneous relaxation of the system, where the inertia of the sheet is negligible. This convergence to the quasi-static solution is further demonstrated in the following analysis.

$\lambda$ is small, the effective mass of the sheet increases, resulting in slower dynamics. It is worth noting that since the dynamics of the system becomes very slow in the fluid-dominated region, we would expect some aspects of this solution to align with our earlier, quasi-static solution in the asymmetric branch, as shown in (3.1). This is because the quasi-static solution describes a slow spontaneous relaxation of the system, where the inertia of the sheet is negligible. This convergence to the quasi-static solution is further demonstrated in the following analysis.

Fifthly, note that if we fix ![]() $L_y$, the matrices in (3.5) and (2.18) become diagonal in the solid-dominated region. Therefore, up to small corrections of the order

$L_y$, the matrices in (3.5) and (2.18) become diagonal in the solid-dominated region. Therefore, up to small corrections of the order ![]() $1/\lambda$,

$1/\lambda$, ![]() $\bar {A}_1$ alone is excited at the instability. Indeed, in figure 4(a), in which we plot the eigenfunction for the case where

$\bar {A}_1$ alone is excited at the instability. Indeed, in figure 4(a), in which we plot the eigenfunction for the case where ![]() $\lambda =100$ for both

$\lambda =100$ for both ![]() $N=2$ and

$N=2$ and ![]() $N=8$, we find that the two solutions are almost identical. In contrast, in the fluid-dominated region,

$N=8$, we find that the two solutions are almost identical. In contrast, in the fluid-dominated region, ![]() $\lambda \ll 1$ and the matrices in (3.5) have non-zero off-diagonal terms. Therefore, all the odd modes become coupled and are excited at the instability. Nonetheless, our numerical investigation indicates that

$\lambda \ll 1$ and the matrices in (3.5) have non-zero off-diagonal terms. Therefore, all the odd modes become coupled and are excited at the instability. Nonetheless, our numerical investigation indicates that ![]() $\bar {A}_n/\bar {A}_1\ll 1$ for all

$\bar {A}_n/\bar {A}_1\ll 1$ for all ![]() $n\geq 3$. Therefore, while we would expect the leading-order solution, i.e.

$n\geq 3$. Therefore, while we would expect the leading-order solution, i.e. ![]() $N=2$, to approximate the eigenfunction well, it will not coincide with the higher-order solution. Indeed, in figure 4(b), we compare the eigenfunctions obtained from the lowest order and the high orders of approximations and find finite differences between them. We note that the eigenfunction in the fluid-dominated region emerges from the quasi-static configuration (3.1a), when we expand (3.1a) in powers of

$N=2$, to approximate the eigenfunction well, it will not coincide with the higher-order solution. Indeed, in figure 4(b), we compare the eigenfunctions obtained from the lowest order and the high orders of approximations and find finite differences between them. We note that the eigenfunction in the fluid-dominated region emerges from the quasi-static configuration (3.1a), when we expand (3.1a) in powers of ![]() $p_{ud}(x,y,0)$, extract the linear order of this expansion and normalize it in accordance with our convention. The agreement between this quasi-static profile and the eigenfunction obtained from the linear stability analysis is shown in figure 4(b) (open squares).

$p_{ud}(x,y,0)$, extract the linear order of this expansion and normalize it in accordance with our convention. The agreement between this quasi-static profile and the eigenfunction obtained from the linear stability analysis is shown in figure 4(b) (open squares).

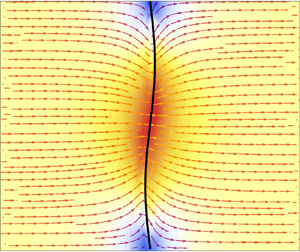

Figure 4. Eigenfunctions of the sheet's height function in both the solid- and fluid-dominated regions. In both panels, ![]() $L_y=2$ and open blue circles correspond to the linear stability analysis at finite

$L_y=2$ and open blue circles correspond to the linear stability analysis at finite ![]() $\varDelta$, i.e. derived from (2.2)–(2.9). The eigenfunctions are normalized such that