1. Introduction

In the natural world, in industry and in laboratory experiments, there are always junctions between pipes of different diameters, i.e. contractions or expansions or constrictions. In this paper, we consider the two-dimensional planar versions, which are kinder numerically and easier to analyse theoretically. The junctions are normally abrupt with sharp corners. Sharp corners are particularly problematic for numerical studies of viscoelastic fluids, so sometimes the corners are rounded. We consider instead a slowly varying geometry, which is even kinder numerically, and which permits considerable theoretical progress.

The principal concern for viscoelastic fluids flowing through a contraction is the formation of long recirculating eddies upstream of the contraction; see Boger (Reference Boger1987). In these eddies, fluid might continue a chemical reaction or might change temperature. Should there then be a fluctuation in the driving pressure, fluid might be expelled from these eddies, producing an undesirable non-uniform output from the contraction. Due to our slowly varying geometry, we have not seen any recirculating eddies in all the cases that we have studied.

Instead of recirculating upstream eddies, our principal concern will be the pressure drop driving the fluid through the contraction. Because viscoelastic stresses can be slow to relax downstream of the contraction, it is necessary to consider an extended geometry of the contraction with sufficiently long entrance and exit sections. The effect of the contraction is then measured by a so-called ‘Couette correction’, which is the pressure drop over the extended geometry minus the pressure drop of a Newtonian viscous fluid over the entrance and exit sections, using a Newtonian fluid with the viscosity equal to that of the viscoelastic fluid at zero shear-rate, all suitably non-dimensionalised.

For the choice of viscoelastic fluid, we consider the Oldroyd-B model fluid. It is the simplest combination of a viscous stress and an elastic stress. There are many other possibilities. Before investigating those more complicated possibilities, it is useful to find the response of the simplest model. More than finding the response, we seek to understand why the model responds in the way that it does. One can then contemplate what is needed from the more complicated alternative models.

The pressure drop of a viscoelastic fluid flowing through a contraction has been studied before, in experiments with polymer solutions and in numerical solutions for the Oldroyd-B and other model fluids. Studying experimentally the flow of Boger and Newtonian fluids with the same shear viscosity through axisymmetric and planar orifices (large contractions with no exit channel), Binding & Walters (Reference Binding and Walters1988) found in their figure 16 that the pressure drop increased linearly with the flow rate up to a critical flow, beyond which the Boger fluid required higher pressures.

In a pair of experimental papers, Cartalos & Piau (Reference Cartalos and Piau1992a,Reference Cartalos and Piaub) studied the flow through an axisymmetric constriction of moderately dilute solutions of polyacrylamide and of polyethylene oxide dissolved in viscous solvents. Figure 6 of the first paper shows the pressure drop increasing linearly with the flow rate, then increasing more rapidly before increasing linearly again. In figures 7(b) and 8(b) of the second paper, the pressure drop divided by the value for a purely viscous fluid is shown to increase by an order of magnitude. There is an interesting discussion after equation (23) in Cartalos & Piau (Reference Cartalos and Piau1992a) of an advantage of the constriction geometry that, because the normal stresses relax downstream to their upstream values, there is no difference between the pressure difference and the difference of the full stress including pressure, viscous and elastic stresses. We shall return to this issue in § 3.5.

In another pair of experimental papers, Rothstein & McKinley (Reference Rothstein and McKinley1999, Reference Rothstein and McKinley2001) used a polystyrene Boger fluid in an axisymmetric 4 : 1 : 4 constriction. In figure 7 of the first paper, the pressure drop divided by the value for a purely viscous fluid is shown to increase by a factor of 3 by a Deborah number ![]() $De=6$, and then level off. A similar increase was found in figure 4 of the second paper for different constriction ratios of 2 and 8.

$De=6$, and then level off. A similar increase was found in figure 4 of the second paper for different constriction ratios of 2 and 8.

In finite-element simulations of an Oldroyd-B fluid with rather coarse meshes for an abrupt planar 4 : 1 contraction, Keunings & Crochet (Reference Keunings and Crochet1984) find in their figure 12 that the Couette correction decreases for ![]() $0\le De\le 0.5$. These simulations were extended to

$0\le De\le 0.5$. These simulations were extended to ![]() $De=20$ in figure 4 of Debbaut, Marchal & Crochet (Reference Debbaut, Marchal and Crochet1988), with a fairly linear decrease in the Couette correction. Before their figure 4, the authors note that a long downstream section of some 250 radii in length is required to calculate the Couette correction reliably to

$De=20$ in figure 4 of Debbaut, Marchal & Crochet (Reference Debbaut, Marchal and Crochet1988), with a fairly linear decrease in the Couette correction. Before their figure 4, the authors note that a long downstream section of some 250 radii in length is required to calculate the Couette correction reliably to ![]() $De=30$. We shall take up this problem in § 4 on the exit channel. Alves, Oliveira & Pinho (Reference Alves, Oliveira and Pinho2003) made some particularly accurate simulations of a planar 4 : 1 contraction with a clear linear decrease of the Couette correction in their figure 5 up to

$De=30$. We shall take up this problem in § 4 on the exit channel. Alves, Oliveira & Pinho (Reference Alves, Oliveira and Pinho2003) made some particularly accurate simulations of a planar 4 : 1 contraction with a clear linear decrease of the Couette correction in their figure 5 up to ![]() $De=5$. Finally, Binding, Phillips & Phillips (Reference Binding, Phillips and Phillips2006) found in their figure 7 that the normalised excess pressure drop decreased linearly for a contraction, decreased linearly although less for a constriction, and increased linearly just a little for an expansion, all with rounded corners and

$De=5$. Finally, Binding, Phillips & Phillips (Reference Binding, Phillips and Phillips2006) found in their figure 7 that the normalised excess pressure drop decreased linearly for a contraction, decreased linearly although less for a constriction, and increased linearly just a little for an expansion, all with rounded corners and ![]() $De<1$. There are many other numerical works, with planar and axisymmetric geometries, and for other rheological equations of state.

$De<1$. There are many other numerical works, with planar and axisymmetric geometries, and for other rheological equations of state.

Our own numerical and theoretical results in this paper find the same behaviour of a decrease in the pressure drop for an Oldroyd-B fluid flowing through a contraction. Thus the experiments with polymer solutions find an increase in the pressure drop, while numerical solutions for the Oldroyd-B fluid find a decrease. This contradiction has led to a good number of numerical studies with alternative model fluids, ones with more dissipation. We comment on this issue in our conclusions, in § 7. It is our theoretical results, particularly those for high Deborah numbers, that allow us to understand the cause of the behaviour, and so suggest suitable refinements of the Oldroyd-B model.

There have been many applications of lubrication theory to non-Newtonian flows. Tichy & Modest (Reference Tichy and Modest1980) studied a squeeze-film geometry using part of the constitutive equation for a second-order fluid. They also made an expansion in a small Deborah number ![]() $De\ll 1$, so that the tension in the streamlines appeared only as a correction. Ro & Homsy (Reference Ro and Homsy1996) studied Hele-Shaw and dip-coating flows using an Oldroyd-B fluid. They also made an expansion in a small Deborah number

$De\ll 1$, so that the tension in the streamlines appeared only as a correction. Ro & Homsy (Reference Ro and Homsy1996) studied Hele-Shaw and dip-coating flows using an Oldroyd-B fluid. They also made an expansion in a small Deborah number ![]() $We/Ca^{1/3}\ll 1$. Going to the first correction, they explored only the second-order fluid behaviour. Zhang, Matar & Craster (Reference Zhang, Matar and Craster2002) studied surfactant spreading on a thin film using an Oldroyd-B fluid. They solved their lubrication equations (24)–(32), again by an expansion in a small Deborah number

$We/Ca^{1/3}\ll 1$. Going to the first correction, they explored only the second-order fluid behaviour. Zhang, Matar & Craster (Reference Zhang, Matar and Craster2002) studied surfactant spreading on a thin film using an Oldroyd-B fluid. They solved their lubrication equations (24)–(32), again by an expansion in a small Deborah number ![]() $We\ll 1$, going to the first correction. Ahmed & Biancofiore (Reference Ahmed and Biancofiore2021) studied a slider bearing using an Oldroyd-B fluid. They solved their lubrication equations (3) numerically, and found the first correction in an expansion in a small Deborah number

$We\ll 1$, going to the first correction. Ahmed & Biancofiore (Reference Ahmed and Biancofiore2021) studied a slider bearing using an Oldroyd-B fluid. They solved their lubrication equations (3) numerically, and found the first correction in an expansion in a small Deborah number ![]() $\epsilon \,Wi\ll 1$. Boyko & Stone (Reference Boyko and Stone2022) studied a slowly varying contraction using an Oldroyd-B fluid. They solved numerically the full governing equations, before making the lubrication approximation, for two narrow geometries. They also made an expansion in a small Deborah number, finding the first and second corrections for the flow, and using a reciprocal theorem, the third correction for the pressure drop. In this paper, we shall solve numerically and asymptotically the lubrication equations for an Oldroyd-B fluid at large Deborah numbers, in a regime where the non-Newtonian behaviour is not a small correction. Large non-Newtonian effects within lubrication theory have been consider previously, by Sykes & Rallison (Reference Sykes and Rallison1997a,Reference Sykes and Rallisonb). They studied a suspension of fibres in a slowly varying channel and in a journal bearing.

$\epsilon \,Wi\ll 1$. Boyko & Stone (Reference Boyko and Stone2022) studied a slowly varying contraction using an Oldroyd-B fluid. They solved numerically the full governing equations, before making the lubrication approximation, for two narrow geometries. They also made an expansion in a small Deborah number, finding the first and second corrections for the flow, and using a reciprocal theorem, the third correction for the pressure drop. In this paper, we shall solve numerically and asymptotically the lubrication equations for an Oldroyd-B fluid at large Deborah numbers, in a regime where the non-Newtonian behaviour is not a small correction. Large non-Newtonian effects within lubrication theory have been consider previously, by Sykes & Rallison (Reference Sykes and Rallison1997a,Reference Sykes and Rallisonb). They studied a suspension of fibres in a slowly varying channel and in a journal bearing.

2. Governing equations

2.1. Oldroyd-B

The Oldroyd-B model fluid is the simplest viscoelastic fluid, combining a simple viscous stress and a simple elastic stress:

where ![]() $\mu _0$ is a viscosity,

$\mu _0$ is a viscosity, ![]() $\boldsymbol {e}$ is the strain-rate of the flow,

$\boldsymbol {e}$ is the strain-rate of the flow, ![]() $G$ is an elastic modulus, and

$G$ is an elastic modulus, and ![]() $\boldsymbol {A}$ is the deformation of the microstructure. The viscosity

$\boldsymbol {A}$ is the deformation of the microstructure. The viscosity ![]() $\mu _0$ will be called the ‘solvent viscosity’, as it occurs in the bead-and-spring model of dilute polymer solutions. The microstructure deforms due to velocity differences in the flow as represented by the velocity gradient

$\mu _0$ will be called the ‘solvent viscosity’, as it occurs in the bead-and-spring model of dilute polymer solutions. The microstructure deforms due to velocity differences in the flow as represented by the velocity gradient ![]() ${\boldsymbol {\nabla }}\boldsymbol {u}$, and simultaneously relaxes to the isotropic state on a relaxation time

${\boldsymbol {\nabla }}\boldsymbol {u}$, and simultaneously relaxes to the isotropic state on a relaxation time ![]() $\tau$:

$\tau$:

The left-hand side and first two terms of the right-hand side are the so-called upper-convective time derivative ![]() $\mathop{\boldsymbol{A}}\limits^{\nabla}$ of the Oldroyd-B equation, appropriate for fibrous microstructures. A modified right-hand side

$\mathop{\boldsymbol{A}}\limits^{\nabla}$ of the Oldroyd-B equation, appropriate for fibrous microstructures. A modified right-hand side ![]() $-\boldsymbol {A}\boldsymbol {\cdot }{\boldsymbol {\nabla }}\boldsymbol {u}^{\rm T} - {\boldsymbol {\nabla }}\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {A}$ corresponds to the lower-convective time derivative

$-\boldsymbol {A}\boldsymbol {\cdot }{\boldsymbol {\nabla }}\boldsymbol {u}^{\rm T} - {\boldsymbol {\nabla }}\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {A}$ corresponds to the lower-convective time derivative ![]() $\mathop{\boldsymbol{A}}\limits^{\triangle}$, which produces the Oldroyd-A equation, appropriate to disk-like microstructures.

$\mathop{\boldsymbol{A}}\limits^{\triangle}$, which produces the Oldroyd-A equation, appropriate to disk-like microstructures.

The simple fluid model has just three parameters, ![]() $\mu _0$,

$\mu _0$, ![]() $G$ and

$G$ and ![]() $\tau$, to be fitted to experimental data. It represents fairly well many aspects, but not all, of the flow behaviour of some polymer solutions, such as Boger fluids. For these two reasons, the Oldroyd-B equation is a sensible choice for numerical calculations of flows. Finally, the elastic-dumbbell model of polymer solutions is governed by the Oldroyd-B equation.

$\tau$, to be fitted to experimental data. It represents fairly well many aspects, but not all, of the flow behaviour of some polymer solutions, such as Boger fluids. For these two reasons, the Oldroyd-B equation is a sensible choice for numerical calculations of flows. Finally, the elastic-dumbbell model of polymer solutions is governed by the Oldroyd-B equation.

In a uniform steady simple shear flow ![]() $\boldsymbol {u}=(\gamma y,0,0)$, the Oldroyd-B fluid has viscous-like shear stresses

$\boldsymbol {u}=(\gamma y,0,0)$, the Oldroyd-B fluid has viscous-like shear stresses

In the steady state, the microstructural deformation ![]() $A_{xy} = \gamma \tau$ should be thought of as the deformation-rate

$A_{xy} = \gamma \tau$ should be thought of as the deformation-rate ![]() $\gamma$ multiplied by the time

$\gamma$ multiplied by the time ![]() $\tau$ of how long the material can remember being deformed before it relaxes. With the steady deformation proportional to the shear-rate

$\tau$ of how long the material can remember being deformed before it relaxes. With the steady deformation proportional to the shear-rate ![]() $\gamma$, both the elastic and viscous shear stresses are proportional to

$\gamma$, both the elastic and viscous shear stresses are proportional to ![]() $\gamma$, with the combination described by an effective viscosity

$\gamma$, with the combination described by an effective viscosity ![]() $\mu _* = \mu _0 +G\tau$. We shall call this effective viscosity the steady shear viscosity of the Oldroyd-B fluid.

$\mu _* = \mu _0 +G\tau$. We shall call this effective viscosity the steady shear viscosity of the Oldroyd-B fluid.

In addition to shear stresses, there are so-called normal stresses

The difference ![]() $\sigma _{xx}-\sigma _{yy} = 2G(\gamma \tau )^2$ corresponds to an elastic tension in the streamlines. In order for this tension in the streamlines to play a role in the lubrication dynamics, it is necessary for the normal stresses to be much larger than the shear stresses. We see that this is possible if the Weissenberg number

$\sigma _{xx}-\sigma _{yy} = 2G(\gamma \tau )^2$ corresponds to an elastic tension in the streamlines. In order for this tension in the streamlines to play a role in the lubrication dynamics, it is necessary for the normal stresses to be much larger than the shear stresses. We see that this is possible if the Weissenberg number ![]() $We = \gamma \tau$ is very large. We shall need

$We = \gamma \tau$ is very large. We shall need ![]() $We$ to be as large as the ratio of the length to the width of the contraction. There is a question of whether the common experimental Boger fluids keep a quadratic variation in shear-rate of the normal stresses at the high shear-rates that we consider theoretically.

$We$ to be as large as the ratio of the length to the width of the contraction. There is a question of whether the common experimental Boger fluids keep a quadratic variation in shear-rate of the normal stresses at the high shear-rates that we consider theoretically.

To help us to understand the response of the Oldroyd-B fluid as it flows through a contraction, it is useful to consider the start up and shut down of a simple shear flow ![]() $\boldsymbol {u} = (\gamma (t)\,y,0,0)$, where

$\boldsymbol {u} = (\gamma (t)\,y,0,0)$, where

\begin{equation*} \gamma(t) = \begin{cases} 0 & \text{for}\ t<0,\\ \gamma_1 & \text{for}\ 0 \le t < t_1, \\ 0 & \text{for}\ t_1 \le t, \end{cases} \end{equation*}

\begin{equation*} \gamma(t) = \begin{cases} 0 & \text{for}\ t<0,\\ \gamma_1 & \text{for}\ 0 \le t < t_1, \\ 0 & \text{for}\ t_1 \le t, \end{cases} \end{equation*}

with the duration of the shear much longer than the relaxation time, ![]() $t_1\gg \tau$. The shear stress response is

$t_1\gg \tau$. The shear stress response is

\begin{equation*} \sigma_{xy}(t) = \begin{cases} 0 & \text{for}\ t<0,\\ \mu_0\gamma_1 + G\gamma_1\tau(1 - \exp({-t/\tau})) & \text{for}\ 0 \le t < t_1, \\ G\gamma_1\tau \exp({-(t-t_1)/\tau}) & \text{for}\ t_1 \le t. \end{cases} \end{equation*}

\begin{equation*} \sigma_{xy}(t) = \begin{cases} 0 & \text{for}\ t<0,\\ \mu_0\gamma_1 + G\gamma_1\tau(1 - \exp({-t/\tau})) & \text{for}\ 0 \le t < t_1, \\ G\gamma_1\tau \exp({-(t-t_1)/\tau}) & \text{for}\ t_1 \le t. \end{cases} \end{equation*}

We see that when the shearing is switched on, there is an immediate viscous stress ![]() $\mu _0\gamma _1$. As the microstructure begins to deform, an elastic component of the stress builds up. After a few relaxation times

$\mu _0\gamma _1$. As the microstructure begins to deform, an elastic component of the stress builds up. After a few relaxation times ![]() $t \gg \tau$, the deformation reaches the equilibrium value

$t \gg \tau$, the deformation reaches the equilibrium value ![]() $\gamma _1\tau$, which is the deformation-rate

$\gamma _1\tau$, which is the deformation-rate ![]() $\gamma _1$ times the memory time

$\gamma _1$ times the memory time ![]() $\tau$, and the shear stress takes a steady value

$\tau$, and the shear stress takes a steady value ![]() $(\mu _0+G\tau )\gamma _1$. When the shearing is switched off at

$(\mu _0+G\tau )\gamma _1$. When the shearing is switched off at ![]() $t_1$, the viscous component

$t_1$, the viscous component ![]() $\mu _0\gamma _1$ immediately drops out, while the elastic component relaxes over several relaxation times.

$\mu _0\gamma _1$ immediately drops out, while the elastic component relaxes over several relaxation times.

The system of stresses in a simple shear flow can be understood by considering the deformation of a microstructure composed of fibres that deform like material line-elements. A fibre parallel to the flow, ![]() $\boldsymbol {\delta \ell } = (\delta \ell,0,0)$, will move with the flow without change in size or orientation. A fibre perpendicular to the flow,

$\boldsymbol {\delta \ell } = (\delta \ell,0,0)$, will move with the flow without change in size or orientation. A fibre perpendicular to the flow, ![]() $\boldsymbol {\delta \ell } = (0,\delta \ell,0)$, will shear to

$\boldsymbol {\delta \ell } = (0,\delta \ell,0)$, will shear to ![]() $(\delta \ell \gamma t, \delta \ell, 0)$, i.e. the component perpendicular to the flow remains unchanged, while a component parallel to the flow grows linearly in time.

$(\delta \ell \gamma t, \delta \ell, 0)$, i.e. the component perpendicular to the flow remains unchanged, while a component parallel to the flow grows linearly in time.

The microstructure in an Oldroyd-B fluid is described by a second-order tensor ![]() $\boldsymbol {A}$. We think of this tensor as the tensor product of two vector fibres. Thus

$\boldsymbol {A}$. We think of this tensor as the tensor product of two vector fibres. Thus ![]() $A_{xx}=1$ corresponds to two fibres of unit length parallel to the flow, which are unchanged in the simple shear flow, so

$A_{xx}=1$ corresponds to two fibres of unit length parallel to the flow, which are unchanged in the simple shear flow, so ![]() $A_{xx}=1$ remains constant. On the other hand,

$A_{xx}=1$ remains constant. On the other hand, ![]() $A_{yy}=1$ corresponds to two fibres perpendicular to the flow, each of which will develop in the simple shear components parallel to the flow,

$A_{yy}=1$ corresponds to two fibres perpendicular to the flow, each of which will develop in the simple shear components parallel to the flow, ![]() $A_{xy}=A_{yx} = \gamma t$, while leaving the component perpendicular to the flow,

$A_{xy}=A_{yx} = \gamma t$, while leaving the component perpendicular to the flow, ![]() $A_{yy}=1$, unchanged. Finally, these shear components

$A_{yy}=1$, unchanged. Finally, these shear components ![]() $A_{xy}$ and

$A_{xy}$ and ![]() $A_{yx}$ correspond to one fibre parallel and one fibre perpendicular. Through the shear, the perpendicular fibres develop components parallel to the flow, so producing

$A_{yx}$ correspond to one fibre parallel and one fibre perpendicular. Through the shear, the perpendicular fibres develop components parallel to the flow, so producing ![]() $A_{xx} = 1 + 2(\gamma t)^2$.

$A_{xx} = 1 + 2(\gamma t)^2$.

The above discussion is for a uniform steady simple shear. While the flow through a contraction flow is a shearing flow with one layer of fluid sliding over another, it is not steady in the Lagrangian view moving with the fluid. As the flow accelerates, a fibre in the direction of the flow will stretch proportional to the increase in velocity. (In a steady flow, a material line-element evolves according to ![]() $\boldsymbol {u}\boldsymbol {\cdot }{\boldsymbol {\nabla }}\delta {\boldsymbol {\ell }} = \delta {\boldsymbol {\ell }}\boldsymbol {\cdot }{\boldsymbol {\nabla }}\boldsymbol {u}$. If the fibre

$\boldsymbol {u}\boldsymbol {\cdot }{\boldsymbol {\nabla }}\delta {\boldsymbol {\ell }} = \delta {\boldsymbol {\ell }}\boldsymbol {\cdot }{\boldsymbol {\nabla }}\boldsymbol {u}$. If the fibre ![]() $\delta {\boldsymbol {\ell }}$ starts parallel to

$\delta {\boldsymbol {\ell }}$ starts parallel to ![]() $\boldsymbol {u}$, then the solution is

$\boldsymbol {u}$, then the solution is ![]() $\delta {\boldsymbol {\ell }}\propto \boldsymbol {u}$.) Thus we can expect the component of

$\delta {\boldsymbol {\ell }}\propto \boldsymbol {u}$.) Thus we can expect the component of ![]() $\boldsymbol {A}$ in the direction of the flow, corresponding to two fibres parallel to the flow, to increase in proportion to the square of the velocity. As fibres parallel to the flow stretch, fibres perpendicular to the flow must compress by the same proportion in order to conserve mass in a planar flow. (Axisymmetric flows would differ at this point.) Thus we can expect the component of

$\boldsymbol {A}$ in the direction of the flow, corresponding to two fibres parallel to the flow, to increase in proportion to the square of the velocity. As fibres parallel to the flow stretch, fibres perpendicular to the flow must compress by the same proportion in order to conserve mass in a planar flow. (Axisymmetric flows would differ at this point.) Thus we can expect the component of ![]() $\boldsymbol {A}$ perpendicular to the flow to decrease proportional to the square of the velocity, while the shearing components of

$\boldsymbol {A}$ perpendicular to the flow to decrease proportional to the square of the velocity, while the shearing components of ![]() $\boldsymbol {A}$, corresponding to one fibre parallel and one fibre perpendicular, should be unchanged as the flow accelerates. Note that this discussion of the deformation of the microstructure has ignored its relaxation.

$\boldsymbol {A}$, corresponding to one fibre parallel and one fibre perpendicular, should be unchanged as the flow accelerates. Note that this discussion of the deformation of the microstructure has ignored its relaxation.

The previous paragraph gives the basis of the high-![]() $De$ analysis in § 3.4.

$De$ analysis in § 3.4.

The idea that the microstructure stretches like a material line-element in regions where the relaxation is negligible was suggested by Rallison & Hinch (Reference Rallison and Hinch1988) in § 5.2 when considering how dumbbells behave in rapid sink flows. This stretching was expressed by Hinch (Reference Hinch1993) at the beginning of § 3 as ![]() $\boldsymbol {A} = f(\psi )\,\boldsymbol {u}\boldsymbol {u}$, where

$\boldsymbol {A} = f(\psi )\,\boldsymbol {u}\boldsymbol {u}$, where ![]() $f$ is constant along a streamline, when considering flow around a sharp corner. Keiller (Reference Keiller1993a) added in his equation (18) the shear components, when improving a numerical method for entry flows. Finally, Renardy (Reference Renardy1994) in his equation (3) gave a decomposition of the deformation for steady planar flows into three components, parallel, shear and perpendicular to the flow. We shall return to this decomposition much later, in § 6.3.

$f$ is constant along a streamline, when considering flow around a sharp corner. Keiller (Reference Keiller1993a) added in his equation (18) the shear components, when improving a numerical method for entry flows. Finally, Renardy (Reference Renardy1994) in his equation (3) gave a decomposition of the deformation for steady planar flows into three components, parallel, shear and perpendicular to the flow. We shall return to this decomposition much later, in § 6.3.

2.2. Lubrication equations

We consider a flow in the ![]() $x$-direction through a planar contraction starting at

$x$-direction through a planar contraction starting at ![]() $x=0$ and finishing at

$x=0$ and finishing at ![]() $x=\ell$. The width of the channel is

$x=\ell$. The width of the channel is ![]() $2h(x)$, with a straight centreline

$2h(x)$, with a straight centreline ![]() $y=0$ and rigid boundaries at

$y=0$ and rigid boundaries at ![]() $y = \pm h(x)$. There is a short inlet section in

$y = \pm h(x)$. There is a short inlet section in ![]() $x<0$ with a constant width

$x<0$ with a constant width ![]() $2h(0)$, and a long outlet section in

$2h(0)$, and a long outlet section in ![]() $x>\ell$ with a constant width

$x>\ell$ with a constant width ![]() $2h(\ell )$. For the channel to be slowly varying, the width is taken to be much smaller than the length:

$2h(\ell )$. For the channel to be slowly varying, the width is taken to be much smaller than the length:

We shall work only to leading order in ![]() $\epsilon$, and not exhibit where any correction terms can occur. A second non-dimensional parameter of the geometry is the contraction ratio

$\epsilon$, and not exhibit where any correction terms can occur. A second non-dimensional parameter of the geometry is the contraction ratio

In our numerical studies, we shall take ![]() $H = 2^{1/2}$,

$H = 2^{1/2}$, ![]() $2$,

$2$, ![]() $2^{3/2}$ and

$2^{3/2}$ and ![]() $4$. Between each case in this sequence, the shear-rate doubles and the normal stresses quadruple.

$4$. Between each case in this sequence, the shear-rate doubles and the normal stresses quadruple.

In the standard lubrication scalings, we non-dimensionalise the distance ![]() $x$ along the channel by the length

$x$ along the channel by the length ![]() $\ell$ of the contraction, and the distance

$\ell$ of the contraction, and the distance ![]() $y$ across the channel as well as the width

$y$ across the channel as well as the width ![]() $h(x)$ by the width of the inlet

$h(x)$ by the width of the inlet ![]() $h_0= h(0)$. With a volume flux

$h_0= h(0)$. With a volume flux ![]() $2Q$, we non-dimensionalise the component

$2Q$, we non-dimensionalise the component ![]() $u$ of the flow along the channel by

$u$ of the flow along the channel by ![]() $Q/h_0$, and the much smaller component of the flow across the channel by

$Q/h_0$, and the much smaller component of the flow across the channel by ![]() $Q/\ell$. Time

$Q/\ell$. Time ![]() $t$ is non-dimensionalised by the residence time in the contraction

$t$ is non-dimensionalised by the residence time in the contraction ![]() $\ell h_0/Q$, and pressure

$\ell h_0/Q$, and pressure ![]() $p$ by the pressure drop of a Newtonian viscous fluid with the solvent viscosity

$p$ by the pressure drop of a Newtonian viscous fluid with the solvent viscosity ![]() $\mu _0$ by

$\mu _0$ by ![]() $\mu _0 Q \ell /h_0^3$.

$\mu _0 Q \ell /h_0^3$.

With these scalings, a non-dimensional parameter arises that measures the elasticity:

In the bead-and-spring model of dilute polymer solutions, this ![]() $c$ would be the concentration of the polymers. For most of the numerical studies, we shall take

$c$ would be the concentration of the polymers. For most of the numerical studies, we shall take ![]() $c=1$, which would not qualify as dilute.

$c=1$, which would not qualify as dilute.

We shall ignore inertia. This means taking the appropriate reduced Reynolds number to be negligibly small:

where ![]() $\rho$ is the density of the fluid.

$\rho$ is the density of the fluid.

A final non-dimensional parameter is needed to measure the relaxation time ![]() $\tau$ in the constitutive equation. In most flows, there is no difference between a Weissenberg number and a Deborah number. An exception is in lubrication flows. The Weissenberg number

$\tau$ in the constitutive equation. In most flows, there is no difference between a Weissenberg number and a Deborah number. An exception is in lubrication flows. The Weissenberg number ![]() $We = Q\tau /h_0^2$ measures the relaxation time compared with the local shear-rate, which we shall not use. As discussed in the previous section § 2.1, we need the Weissenberg number to be as large as

$We = Q\tau /h_0^2$ measures the relaxation time compared with the local shear-rate, which we shall not use. As discussed in the previous section § 2.1, we need the Weissenberg number to be as large as ![]() $\epsilon ^{-1}$, in order to bring the tension in the streamlines into the leading-order dynamics. For this reason, we use the Deborah number

$\epsilon ^{-1}$, in order to bring the tension in the streamlines into the leading-order dynamics. For this reason, we use the Deborah number

This Deborah number is the ratio of the relaxation time to the residence time in the contraction.

In order to promote the non-Newtonian tension in the streamlines to a leading-order role, we scale differently the different components of the deformation of the microstructure: ![]() $A_{yy}$ by

$A_{yy}$ by ![]() $\epsilon ^0$,

$\epsilon ^0$, ![]() $A_{xy}$ by

$A_{xy}$ by ![]() $\epsilon ^{-1}$, and

$\epsilon ^{-1}$, and ![]() $A_{xx}$ by

$A_{xx}$ by ![]() $\epsilon ^{-2}$.

$\epsilon ^{-2}$.

With these non-dimensionalisations, the governing equations become the following. The conservation of mass is

As in all thin-film flows, the ![]() $y$-component of the momentum equation gives at leading order that the pressure is constant across the flow, i.e.

$y$-component of the momentum equation gives at leading order that the pressure is constant across the flow, i.e. ![]() $p=p(x,t)$. The conservation of momentum in the

$p=p(x,t)$. The conservation of momentum in the ![]() $x$-direction is then

$x$-direction is then

Finally, the Oldroyd-B equations are

\begin{equation*} \begin{aligned}

&\left({\frac{\partial }{\partial t}} + u\,{\frac{\partial

}{\partial x}} + v\,{\frac{\partial }{\partial y}}\right)

A_{xx} -2eA_{xx} - 2\gamma_1A_{xy} =-\frac{1}{De}\,A_{xx}, \notag\\

&\left({\frac{\partial }{\partial t}} +

u\,{\frac{\partial }{\partial x}} + v\,{\frac{\partial

}{\partial y}}\right) A_{xy} -\gamma_2A_{xx}\ \ -

\gamma_1A_{yy} =-\frac{1}{De}\,A_{xy}, \notag\\

&\left({\frac{\partial }{\partial t}} + u\,{\frac{\partial

}{\partial x}} + v\,{\frac{\partial }{\partial y}}\right)

A_{yy} -2\gamma_2A_{xy} +2eA_{yy}

=-\frac{1}{De}\,(A_{yy}-1), \end{aligned}

\end{equation*}

\begin{equation*} \begin{aligned}

&\left({\frac{\partial }{\partial t}} + u\,{\frac{\partial

}{\partial x}} + v\,{\frac{\partial }{\partial y}}\right)

A_{xx} -2eA_{xx} - 2\gamma_1A_{xy} =-\frac{1}{De}\,A_{xx}, \notag\\

&\left({\frac{\partial }{\partial t}} +

u\,{\frac{\partial }{\partial x}} + v\,{\frac{\partial

}{\partial y}}\right) A_{xy} -\gamma_2A_{xx}\ \ -

\gamma_1A_{yy} =-\frac{1}{De}\,A_{xy}, \notag\\

&\left({\frac{\partial }{\partial t}} + u\,{\frac{\partial

}{\partial x}} + v\,{\frac{\partial }{\partial y}}\right)

A_{yy} -2\gamma_2A_{xy} +2eA_{yy}

=-\frac{1}{De}\,(A_{yy}-1), \end{aligned}

\end{equation*}where the shear-rates and extension-rate are

These governing equations are equivalent to those written down before in the papers cited at the end of § 1. Compared with those earlier works, we have not included negligibly small terms in the small ![]() $\epsilon$, and have used a microstructural representation of the Oldroyd-B rheology. Note that the scaled

$\epsilon$, and have used a microstructural representation of the Oldroyd-B rheology. Note that the scaled ![]() $A_{xx}$ relaxes to

$A_{xx}$ relaxes to ![]() $\epsilon ^2$, which is neglected in the first of the Oldroyd-B equations. Note that in lubrication approximations, the hoop-stress is neglected, so there can be no purely elastic instability due to curved streamlines.

$\epsilon ^2$, which is neglected in the first of the Oldroyd-B equations. Note that in lubrication approximations, the hoop-stress is neglected, so there can be no purely elastic instability due to curved streamlines.

2.3. Curvilinear coordinates

For numerical calculations, it is convenient to map the geometry of the contraction onto a unit square

The coordinate lines ![]() $x=\rm {const.}$ and

$x=\rm {const.}$ and ![]() $\eta =\rm {const.}$ are not orthogonal in the

$\eta =\rm {const.}$ are not orthogonal in the ![]() $xy$-plane, due to the slope

$xy$-plane, due to the slope ![]() $h'(x)$. Transforming partial differential equations is much easier with orthogonal curvilinear coordinates. Because the slope of the boundary is

$h'(x)$. Transforming partial differential equations is much easier with orthogonal curvilinear coordinates. Because the slope of the boundary is ![]() $O(\epsilon )$ small in the slowly varying geometry, only a small displacement in the

$O(\epsilon )$ small in the slowly varying geometry, only a small displacement in the ![]() $x$-direction is necessary to create an orthogonal system

$x$-direction is necessary to create an orthogonal system

In the previous subsection, we used ![]() $u$ for the downstream

$u$ for the downstream ![]() $x$-component of velocity, and

$x$-component of velocity, and ![]() $v$ for the cross-stream

$v$ for the cross-stream ![]() $y$-component. Henceforth, we change to use

$y$-component. Henceforth, we change to use ![]() $u$ for the velocity in the downstream

$u$ for the velocity in the downstream ![]() $\xi$-direction, and

$\xi$-direction, and ![]() $v$ for the flow in the cross-stream

$v$ for the flow in the cross-stream ![]() $\eta$-direction. There is a negligible

$\eta$-direction. There is a negligible ![]() $O(\epsilon ^2)$ difference between the flow

$O(\epsilon ^2)$ difference between the flow ![]() $u$ in the

$u$ in the ![]() $\xi$- and

$\xi$- and ![]() $x$-directions. However, the flow in the

$x$-directions. However, the flow in the ![]() $y$-direction is greater by

$y$-direction is greater by ![]() $uh'$ than the flow

$uh'$ than the flow ![]() $v$ in the

$v$ in the ![]() $\eta$-direction, because the small slope

$\eta$-direction, because the small slope ![]() $h'$ is multiplied by a large downstream velocity

$h'$ is multiplied by a large downstream velocity ![]() $u$. In a similar way, we shall use

$u$. In a similar way, we shall use ![]() $A_{11}$,

$A_{11}$, ![]() $A_{12}$ and

$A_{12}$ and ![]() $A_{22}$ for the components of the microstructure in the

$A_{22}$ for the components of the microstructure in the ![]() $\xi \xi$-,

$\xi \xi$-, ![]() $\xi \eta$- and

$\xi \eta$- and ![]() $\eta \eta$-directions. As with the velocity, there is a negligible

$\eta \eta$-directions. As with the velocity, there is a negligible ![]() $O(\epsilon ^2)$ difference between

$O(\epsilon ^2)$ difference between ![]() $A_{11}$ and

$A_{11}$ and ![]() $A_{xx}$, and

$A_{xx}$, and ![]() $O(1)$ differences between the other curvilinear and Cartesian components.

$O(1)$ differences between the other curvilinear and Cartesian components.

In these curvilinear coordinates, the governing equations become for mass and momentum

and for Oldroyd-B

with shear-rates and extension-rate

There are boundary and inlet conditions. On the velocity, we impose no-slip on the upper rigid boundary,

and symmetry across the centreline,

The constitutive equation is hyperbolic and requires knowledge of the microstructural state at the entry. We assume a Poiseuille flow in the straight entry channel, and the microstructure is in the steady state of the simple shear there:

with ![]() $h=1$ at the entry. The factor

$h=1$ at the entry. The factor ![]() $3/2$ in the velocity ensures that the volume flux is

$3/2$ in the velocity ensures that the volume flux is ![]() $1$ in the half-width of the channel

$1$ in the half-width of the channel ![]() $0\le \eta \le 1$.

$0\le \eta \le 1$.

The vanishing of the cross-stream velocity ![]() $v$ on the centreline and upper boundary means that the downstream volume flux is constant along the contraction, and we have chosen to normalise this flux to be unity:

$v$ on the centreline and upper boundary means that the downstream volume flux is constant along the contraction, and we have chosen to normalise this flux to be unity:

Maintaining the flux to be constant sets the local value of the pressure gradient. The last expression can be twice integrated by parts. Using the boundary conditions (2.5) and (2.6), we have

Substituting the expression for ![]() $\partial ^2u/\partial \eta ^2$ from the momentum equation (2.2) and performing a couple of integrals, we find an expression for the pressure gradient:

$\partial ^2u/\partial \eta ^2$ from the momentum equation (2.2) and performing a couple of integrals, we find an expression for the pressure gradient:

An important advantage of the lubrication approximation is that the pressure is determined locally with no need to solve a numerically expensive Poisson problem.

2.4. Numerical method

The contraction runs from ![]() $x=0$ to

$x=0$ to ![]() $x=1$ in the non-dimensionalisation. A short entry channel and a long exit channel, both of constant width, are added to the contraction. There is no upstream influence in the governing physics (2.1) to (2.3), so theoretically no entry channel is required. However, it is convenient for coding the numerical method and for controlling the effects of a small numerical diffusion to have a short entry. On the other hand, the exit channel must be long to allow the elastic stresses to relax to their steady values. We shall discuss in § 4.1 how long the exit channel must be, but typical values range from

$x=1$ in the non-dimensionalisation. A short entry channel and a long exit channel, both of constant width, are added to the contraction. There is no upstream influence in the governing physics (2.1) to (2.3), so theoretically no entry channel is required. However, it is convenient for coding the numerical method and for controlling the effects of a small numerical diffusion to have a short entry. On the other hand, the exit channel must be long to allow the elastic stresses to relax to their steady values. We shall discuss in § 4.1 how long the exit channel must be, but typical values range from ![]() $x_\infty =5$ to

$x_\infty =5$ to ![]() $x_\infty =20$. A single simple shape is used for the contraction. To allow second-order numerical accuracy, a smooth shape is used with vanishing slope at the start and end:

$x_\infty =20$. A single simple shape is used for the contraction. To allow second-order numerical accuracy, a smooth shape is used with vanishing slope at the start and end:

\begin{equation} h(x) = \begin{cases} 1 & \text{for }{-0.5} < x < 0, \\ 1- (1-H^{-1})x^2(2 - x)^2 & \text{for }0< x < 1,\\ H^{-1} & \text{for }1 < x < x_\infty. \end{cases} \end{equation}

\begin{equation} h(x) = \begin{cases} 1 & \text{for }{-0.5} < x < 0, \\ 1- (1-H^{-1})x^2(2 - x)^2 & \text{for }0< x < 1,\\ H^{-1} & \text{for }1 < x < x_\infty. \end{cases} \end{equation}

Here, ![]() $H$ is the contraction ratio, the ratio of the entry to exit widths. This shape is shown in figure 3 for

$H$ is the contraction ratio, the ratio of the entry to exit widths. This shape is shown in figure 3 for ![]() $H=2$.

$H=2$.

The numerical approach is at each instant to solve for the flow ![]() $(u,v)$ given the instantaneous values of the elastic stress

$(u,v)$ given the instantaneous values of the elastic stress ![]() $A_{11}$,

$A_{11}$, ![]() $A_{12}$ and

$A_{12}$ and ![]() $A_{22}$, and then to use this flow to time step the elastic stresses until they reach a steady state.

$A_{22}$, and then to use this flow to time step the elastic stresses until they reach a steady state.

Given the elastic stresses and the pressure gradient from (2.8), the momentum equation (2.2) is integrated with respect to ![]() $\eta$, starting at the centreline

$\eta$, starting at the centreline ![]() $\eta =0$ where

$\eta =0$ where ![]() $\partial u/\partial \eta = 0$, to find the shear-rate

$\partial u/\partial \eta = 0$, to find the shear-rate ![]() $\partial u/\partial \eta$. This shear-rate is then integrated with respect to

$\partial u/\partial \eta$. This shear-rate is then integrated with respect to ![]() $\eta$, starting at the upper boundary

$\eta$, starting at the upper boundary ![]() $\eta =1$ where

$\eta =1$ where ![]() $u=0$, to find the velocity

$u=0$, to find the velocity ![]() $u$. Note that these integrations at each downstream section are independent of one another. Finally, with

$u$. Note that these integrations at each downstream section are independent of one another. Finally, with ![]() $u(x,\eta )$ known, the cross-stream velocity

$u(x,\eta )$ known, the cross-stream velocity ![]() $v$ is found by integrating the mass conservation (2.1) with respect to

$v$ is found by integrating the mass conservation (2.1) with respect to ![]() $\eta$, starting at the centreline where

$\eta$, starting at the centreline where ![]() $v=0$.

$v=0$.

Given the flow ![]() $u(x,\eta )$ and

$u(x,\eta )$ and ![]() $v(x,\eta )$, the Oldroyd equations (2.3) are time-stepped to find the microstructure

$v(x,\eta )$, the Oldroyd equations (2.3) are time-stepped to find the microstructure ![]() $A_{11}$,

$A_{11}$, ![]() $A_{12}$ and

$A_{12}$ and ![]() $A_{22}$ at the next time step. For initial conditions of the microstructure, we take the expressions in (2.7) corresponding to a steady uniform Poiseuille flow in a channel of width

$A_{22}$ at the next time step. For initial conditions of the microstructure, we take the expressions in (2.7) corresponding to a steady uniform Poiseuille flow in a channel of width ![]() $h(x)$.

$h(x)$.

Equispaced finite differences are used. Second-order spatial central differencing is used, except for the ![]() $u$ advection, which is first-order upwinded because downstream advection is important at high Deborah numbers. Upwinding is not used for the small

$u$ advection, which is first-order upwinded because downstream advection is important at high Deborah numbers. Upwinding is not used for the small ![]() $v$ advection. When calculating some fluxes, a second-order correction is applied to produce a fourth-order result for the flux. The time stepping is made by first-order forward differencing. Typical values of the grid size and time step are

$v$ advection. When calculating some fluxes, a second-order correction is applied to produce a fourth-order result for the flux. The time stepping is made by first-order forward differencing. Typical values of the grid size and time step are ![]() $\delta x=0.0208$,

$\delta x=0.0208$, ![]() $\delta \eta = 0.0333$ and

$\delta \eta = 0.0333$ and ![]() $\delta t = 10^{-3}$. Random spot checks are made to confirm an accuracy of around three figures. Run times are around 15 seconds on a laptop, considerably faster than solving the full non-lubrication equations by finite elements. At high Deborah numbers, a numerical instability occurred, which could be delayed by decreasing

$\delta t = 10^{-3}$. Random spot checks are made to confirm an accuracy of around three figures. Run times are around 15 seconds on a laptop, considerably faster than solving the full non-lubrication equations by finite elements. At high Deborah numbers, a numerical instability occurred, which could be delayed by decreasing ![]() $\delta \eta$ while keeping

$\delta \eta$ while keeping ![]() $\delta x$ fixed, as suggested by Keiller (Reference Keiller1992b). Also, for stability, a smaller

$\delta x$ fixed, as suggested by Keiller (Reference Keiller1992b). Also, for stability, a smaller ![]() $\delta t$ was needed at very small Deborah numbers

$\delta t$ was needed at very small Deborah numbers ![]() $De$. The time to come to a steady state was typically

$De$. The time to come to a steady state was typically ![]() $t=5$, shorter for small Deborah numbers, and longer for high Deborah numbers with long exit channels.

$t=5$, shorter for small Deborah numbers, and longer for high Deborah numbers with long exit channels.

3. Results for contraction

3.1. Pressure drop

First, we study the pressure drop across the contraction, from ![]() $x=0$ to

$x=0$ to ![]() ${x=1}$. Recall that the pressure drop has been non-dimensionalised by

${x=1}$. Recall that the pressure drop has been non-dimensionalised by ![]() $\mu _0 Q\ell /h_0^3$. In the next section, we shall consider the important pressure drop in the exit channel after the contraction. In subsequent sections we shall study an expansion and a constriction.

$\mu _0 Q\ell /h_0^3$. In the next section, we shall consider the important pressure drop in the exit channel after the contraction. In subsequent sections we shall study an expansion and a constriction.

In lubrication theory, the pressure is constant at leading order across the flow. Hence the pressure drop across the contraction is simply

In our theoretical and numerical calculations, the pressure drop is therefore unambiguous. It is less clear, however, what experiments measure. One can use flush-mounted wall pressure transducers, which would measure the above pressure drop. In a flow between two large baths, one might think that the pressure drop between the two baths is the difference between the stress averaged across the section:

\begin{equation*} \left[-p + \frac{c}{De}\int_0^1 A_{11} \,{\rm d}\eta\right]_{x=0}^{x=1}.\end{equation*}

\begin{equation*} \left[-p + \frac{c}{De}\int_0^1 A_{11} \,{\rm d}\eta\right]_{x=0}^{x=1}.\end{equation*}Alternatively, one might note the greater out-flux of elastic energy, and then subtract this to obtain the dissipative part of the pressure drop:

\begin{equation*} \left[- p - \frac{c}{De}\int_0^1 \frac32\,(1-\eta^2)\,\frac12\,A_{11} \,{\rm d}\eta\right]_{x=0}^{x=1}. \end{equation*}

\begin{equation*} \left[- p - \frac{c}{De}\int_0^1 \frac32\,(1-\eta^2)\,\frac12\,A_{11} \,{\rm d}\eta\right]_{x=0}^{x=1}. \end{equation*}We shall return to the question of which pressure drop in § 3.5.

The pressure drop across the contraction for a Newtonian fluid with unit viscosity is

Table 1 gives the numerical values for ![]() $\Delta p_1$ for the four contraction ratios

$\Delta p_1$ for the four contraction ratios ![]() $H$ and the geometry (2.9) used in this paper. At

$H$ and the geometry (2.9) used in this paper. At ![]() $H=1$,

$H=1$, ![]() $\Delta p_1 = 3$. At high contraction ratios,

$\Delta p_1 = 3$. At high contraction ratios, ![]() $\Delta p_1 \sim (9{\rm \pi} \sqrt {2}/32)H^{5/2}$. For

$\Delta p_1 \sim (9{\rm \pi} \sqrt {2}/32)H^{5/2}$. For ![]() $H=4$, this expression gives 40.0 in place of the 48.2 in the table.

$H=4$, this expression gives 40.0 in place of the 48.2 in the table.

Table 1. The pressure drops (non-dimensionalised by ![]() $\mu _0Q\ell /h^3_0$)

$\mu _0Q\ell /h^3_0$) ![]() $\Delta p_1$ and

$\Delta p_1$ and ![]() $\Delta p_2$ defined by (3.2) and (3.6) across the contraction section for various contraction ratios

$\Delta p_2$ defined by (3.2) and (3.6) across the contraction section for various contraction ratios ![]() $H>1$, and across an expansion with expansion ratios

$H>1$, and across an expansion with expansion ratios ![]() $1/H>1$. The pressure drop

$1/H>1$. The pressure drop ![]() $\Delta p_3$ defined by (6.2) is across a constriction.

$\Delta p_3$ defined by (6.2) is across a constriction.

At low Deborah numbers, the Oldroyd-B fluid has a Newtonian behaviour with a viscosity ![]() $(1+c)$, and hence will have a pressure drop at

$(1+c)$, and hence will have a pressure drop at ![]() $De=0$ of

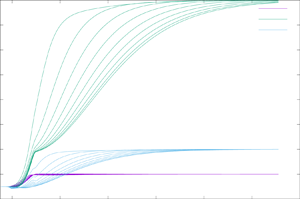

$De=0$ of ![]() $(1+c)\,\Delta p_1$. In figure 1, we plot

$(1+c)\,\Delta p_1$. In figure 1, we plot ![]() $\Delta p$, the pressure drop (3.1), relative to this value at

$\Delta p$, the pressure drop (3.1), relative to this value at ![]() $De=0$. The numerical results of the lubrication theory of this paper have been tested in figure 1 against full two-dimensional finite-element calculations using the code of Boyko & Stone (Reference Boyko and Stone2022) for contraction ratios

$De=0$. The numerical results of the lubrication theory of this paper have been tested in figure 1 against full two-dimensional finite-element calculations using the code of Boyko & Stone (Reference Boyko and Stone2022) for contraction ratios ![]() $2$ and

$2$ and ![]() $2^{3/2}$, and a small value

$2^{3/2}$, and a small value ![]() $\epsilon =0.02$ of the parameter measuring the slow variation of the geometry. We note that the pressure drop is typically 30 % less for the Oldroyd-B fluid.

$\epsilon =0.02$ of the parameter measuring the slow variation of the geometry. We note that the pressure drop is typically 30 % less for the Oldroyd-B fluid.

Figure 1. Pressure drop ![]() $\Delta p$ across the contraction section divided by its Newtonian value

$\Delta p$ across the contraction section divided by its Newtonian value ![]() $(1+c)\,\Delta p_1$, as a function of the Deborah number

$(1+c)\,\Delta p_1$, as a function of the Deborah number ![]() $De$, for

$De$, for ![]() $c=1.0$. The four curves are for different contraction ratios,

$c=1.0$. The four curves are for different contraction ratios, ![]() $H= 2^{1/2}$,

$H= 2^{1/2}$, ![]() $2$,

$2$, ![]() $2^{3/2}$ and

$2^{3/2}$ and ![]() $4$. The points are results from two-dimensional finite-element calculations for

$4$. The points are results from two-dimensional finite-element calculations for ![]() $H=2$ and

$H=2$ and ![]() $2^{3/2}$ with

$2^{3/2}$ with ![]() $\epsilon =0.02$.

$\epsilon =0.02$.

3.2. Low Deborah numbers

Boyko & Stone (Reference Boyko and Stone2022) have given an asymptotic analysis for small ![]() $De$. At

$De$. At ![]() $O(De)$, the Oldroyd-B fluid has a second-order fluid behaviour, so the flow remains unchanged by the theorem of Tanner & Pipkin (Reference Tanner and Pipkin1969):

$O(De)$, the Oldroyd-B fluid has a second-order fluid behaviour, so the flow remains unchanged by the theorem of Tanner & Pipkin (Reference Tanner and Pipkin1969):

Solving the microstructure equations (2.3) iteratively for ![]() $De\ll 1$, we have

$De\ll 1$, we have

\begin{align*}

A_{22} &\sim 1 - De\,2e, \\

A_{12} &\sim De\,\gamma_1 + De^2\,(-2e\gamma_1 - u\gamma_1'), \\

A_{11} &\sim De^2\,2\gamma_1^2,

\end{align*}

\begin{align*}

A_{22} &\sim 1 - De\,2e, \\

A_{12} &\sim De\,\gamma_1 + De^2\,(-2e\gamma_1 - u\gamma_1'), \\

A_{11} &\sim De^2\,2\gamma_1^2,

\end{align*}with the shear-rates and extension-rate (2.4a–c) becoming

Evaluating the momentum equation (2.2),

Note that there is no variation in ![]() $\eta$ in this expression for the pressure gradient, as required by the theorem of Tanner & Pipkin (Reference Tanner and Pipkin1969). Integrating, we obtain the estimate of the pressure drop at low Deborah numbers:

$\eta$ in this expression for the pressure gradient, as required by the theorem of Tanner & Pipkin (Reference Tanner and Pipkin1969). Integrating, we obtain the estimate of the pressure drop at low Deborah numbers:

In figure 2, we replot the data in figure 1 now as the reduction in the pressure drop divided by the geometric factor ![]() $(H^4-1)$ in order to test this asymptotic result (3.3). We see good agreement for

$(H^4-1)$ in order to test this asymptotic result (3.3). We see good agreement for ![]() $De<0.1$, and significant deviation by

$De<0.1$, and significant deviation by ![]() $De=0.2$. There is some hint of a linear decrease at

$De=0.2$. There is some hint of a linear decrease at ![]() $De>0.4$. Boyko & Stone (Reference Boyko and Stone2022) give in their (4.11) and (4.14) two further terms in the asymptotic expansion for the pressure drop. These two extra terms double the range of good agreement, but offer no suggestion of the important linear regime at higher

$De>0.4$. Boyko & Stone (Reference Boyko and Stone2022) give in their (4.11) and (4.14) two further terms in the asymptotic expansion for the pressure drop. These two extra terms double the range of good agreement, but offer no suggestion of the important linear regime at higher ![]() $De$. We gain confidence in the numerical code for the lubrication approach from this agreement with the low-Deborah-number asymptotics, along with the early agreement with results from full two-dimensional finite-element calculations in figure 1.

$De$. We gain confidence in the numerical code for the lubrication approach from this agreement with the low-Deborah-number asymptotics, along with the early agreement with results from full two-dimensional finite-element calculations in figure 1.

Figure 2. The difference between the pressure drop ![]() $\Delta p$ and its Newtonian value

$\Delta p$ and its Newtonian value ![]() $(1+c)\,\Delta p_1$, divided by

$(1+c)\,\Delta p_1$, divided by ![]() $(H^4-1)$, as a function of the Deborah number

$(H^4-1)$, as a function of the Deborah number ![]() $De$, for

$De$, for ![]() $c=1.0$. The four curves are for the contraction ratios

$c=1.0$. The four curves are for the contraction ratios ![]() $H = 2^{1/2}$, 2,

$H = 2^{1/2}$, 2, ![]() $2^{3/2}$ and

$2^{3/2}$ and ![]() $4$. The black line is the low-

$4$. The black line is the low-![]() $De$ asymptotic result

$De$ asymptotic result ![]() $-\frac {9}{2}c\,De$.

$-\frac {9}{2}c\,De$.

3.3. Streamwise development

To probe deeper what lies behind the changes in pressure drop, we first look at the velocity profiles along the channel. In figure 3, the velocity ![]() $u(x,\eta )$ is plotted horizontally as a function of

$u(x,\eta )$ is plotted horizontally as a function of ![]() $y=h(x)\,\eta$ vertically, at a series of downstream positions

$y=h(x)\,\eta$ vertically, at a series of downstream positions ![]() $x$ in the extended range

$x$ in the extended range ![]() $-0.1667< x<2.0$, with the contraction in

$-0.1667< x<2.0$, with the contraction in ![]() $0< x<1$. For comparison, the parabolic profiles with the same flux are also plotted. In the entrance section,

$0< x<1$. For comparison, the parabolic profiles with the same flux are also plotted. In the entrance section, ![]() $x<0$, the velocity is exactly parabolic. In the exit section,

$x<0$, the velocity is exactly parabolic. In the exit section, ![]() $x>1$, the velocity rapidly becomes parabolic, being only 0.5 % different at

$x>1$, the velocity rapidly becomes parabolic, being only 0.5 % different at ![]() $x=1$, for the contraction ratio

$x=1$, for the contraction ratio ![]() $H=2$. In the contraction section, the velocity deviates from parabolic by at most 5.7 %. While the theorem of Tanner & Pipkin (Reference Tanner and Pipkin1969) gives no change in the velocity profile at

$H=2$. In the contraction section, the velocity deviates from parabolic by at most 5.7 %. While the theorem of Tanner & Pipkin (Reference Tanner and Pipkin1969) gives no change in the velocity profile at ![]() $O(De)$, the Deborah number of figure 3 is

$O(De)$, the Deborah number of figure 3 is ![]() $De=0.5$, which is some way beyond the linear regime

$De=0.5$, which is some way beyond the linear regime ![]() $De<0.1$.

$De<0.1$.

Figure 3. Velocity profiles along the flow, for ![]() $c=1.0$,

$c=1.0$, ![]() $De=0.5$ and

$De=0.5$ and ![]() $H= 2$. Recall that

$H= 2$. Recall that ![]() $x$ and

$x$ and ![]() $y$ were non-dimensionalised differently, by

$y$ were non-dimensionalised differently, by ![]() $\ell$ and

$\ell$ and ![]() $h(0)$, respectively.

$h(0)$, respectively.

The velocity is slightly faster near the upper boundary, and slightly slower near the centreline. The speed up near the boundary is caused by the tension in the streamlines. The tension vanishes on the centreline and increases towards the boundary. The tension also increases as the channel narrows. It is the larger tension at the end of the contraction that pulls the fluid to be faster next to the boundary. With the flux fixed, the velocity near the centreline has to be slower to compensate.

A consequence of the velocity profiles being nearly parabolic is that the lines ![]() $\eta = \textrm {const.}$ are nearly the streamlines. In figure 4, we plot the variations along lines of constant

$\eta = \textrm {const.}$ are nearly the streamlines. In figure 4, we plot the variations along lines of constant ![]() $\eta$, which should be a good approximation to variations along a streamline. The exit channel has been extended to

$\eta$, which should be a good approximation to variations along a streamline. The exit channel has been extended to ![]() $x=11$. In purple, we plot as a function of downstream position

$x=11$. In purple, we plot as a function of downstream position ![]() $x$ the velocity relative to its value at the entrance, i.e.

$x$ the velocity relative to its value at the entrance, i.e. ![]() $u(x,\eta )/u(0,\eta )$. This ratio starts at

$u(x,\eta )/u(0,\eta )$. This ratio starts at ![]() $1$ at the entrance, increases in the contraction section

$1$ at the entrance, increases in the contraction section ![]() $0< x<1$, and takes the value

$0< x<1$, and takes the value ![]() $2$ in the exit channel. Because the velocity profiles are very nearly parabolic, there is little variation between the lines of constant

$2$ in the exit channel. Because the velocity profiles are very nearly parabolic, there is little variation between the lines of constant ![]() $\eta$.

$\eta$.

Figure 4. Streamwise variations on constant ![]() $\eta = 0.1\ \text{in steps of}\ 0.1\ \text{to}\ 0.9$ of velocity

$\eta = 0.1\ \text{in steps of}\ 0.1\ \text{to}\ 0.9$ of velocity ![]() $u$, elastic normal stress

$u$, elastic normal stress ![]() $NS$, and elastic contribution to the shear stress

$NS$, and elastic contribution to the shear stress ![]() $SS$; all scaled by their entry values, for

$SS$; all scaled by their entry values, for ![]() $H= 2$,

$H= 2$, ![]() $De=0.5$,

$De=0.5$, ![]() $c=1.0$.

$c=1.0$.

In green and in blue, we plot in the same way the elastic normal stress ![]() $A_{11}$ and the elastic shear stress

$A_{11}$ and the elastic shear stress ![]() $A_{12}$ relative to their values at the entrance, i.e. we plot

$A_{12}$ relative to their values at the entrance, i.e. we plot ![]() $A_{**}(x,\eta )/A_{**}(0,\eta )$. For the contraction ratio

$A_{**}(x,\eta )/A_{**}(0,\eta )$. For the contraction ratio ![]() $H=2$, the velocity should double, the shear stress quadruple, and the normal stress increase by a factor of 16, when they relax to the steady state downstream in the exit channel. The highest curves in the figure correspond to streamlines near to the upper boundary, the lowest curves near to the centreline. Near to the boundary, the flow is slow, so that fluid travels a shorter distance during the relaxation time. Near the centreline, the fluid needs to travel a distance of approximately

$H=2$, the velocity should double, the shear stress quadruple, and the normal stress increase by a factor of 16, when they relax to the steady state downstream in the exit channel. The highest curves in the figure correspond to streamlines near to the upper boundary, the lowest curves near to the centreline. Near to the boundary, the flow is slow, so that fluid travels a shorter distance during the relaxation time. Near the centreline, the fluid needs to travel a distance of approximately ![]() $\Delta x =8$ in the exit channel before attaining 95 % of the steady state.

$\Delta x =8$ in the exit channel before attaining 95 % of the steady state.

The need for a long exit channel for stress relaxation means that there is little relaxation in the contraction section for this Deborah number ![]() $De=0.5$. This observation is the key to the high

$De=0.5$. This observation is the key to the high ![]() $De$ asymptotics below.

$De$ asymptotics below.

By the end of the contraction at ![]() $x=1$, the velocity has doubled, the shear stress has not changed from its entry value (at least away from the boundary), and the normal stress has quadrupled. Much of the increase in the stresses to their eventual steady values occurs in the long exit channel. We need to examine the stresses at the end of the contraction, at

$x=1$, the velocity has doubled, the shear stress has not changed from its entry value (at least away from the boundary), and the normal stress has quadrupled. Much of the increase in the stresses to their eventual steady values occurs in the long exit channel. We need to examine the stresses at the end of the contraction, at ![]() $x=1$, and the extent to which they are suppressed relative to their eventual relaxed values far downstream, (2.7) with

$x=1$, and the extent to which they are suppressed relative to their eventual relaxed values far downstream, (2.7) with ![]() $h=1/H$.

$h=1/H$.

We plot in figure 5(a) the normal stress ![]() $A_{11}$ at

$A_{11}$ at ![]() $x=1$ divided by its value given by (2.7), with

$x=1$ divided by its value given by (2.7), with ![]() $h=1/H$ as a function of

$h=1/H$ as a function of ![]() $y$ across the flow for five different Deborah numbers. In the centre of the flow,

$y$ across the flow for five different Deborah numbers. In the centre of the flow, ![]() $0\le y <0.35$, the normal stresses are a quarter of their eventual values, independent of the Deborah number for

$0\le y <0.35$, the normal stresses are a quarter of their eventual values, independent of the Deborah number for ![]() $De>0.3$. For the contraction ratio considered,

$De>0.3$. For the contraction ratio considered, ![]() $H=2$, the normal stresses eventually increase by a factor of 16 from their value at the start of the contraction. Being suppressed by a quarter means that they have increased by a factor of 4 from the start. Four is the square of the contraction ratio

$H=2$, the normal stresses eventually increase by a factor of 16 from their value at the start of the contraction. Being suppressed by a quarter means that they have increased by a factor of 4 from the start. Four is the square of the contraction ratio ![]() $H=2$. Similar figures, not shown, for contraction ratios

$H=2$. Similar figures, not shown, for contraction ratios ![]() $H=2^{1/2}$ and

$H=2^{1/2}$ and ![]() $2^{3/2}$ find that the normal stresses increase by factors of 2 and 8, respectively, within the contraction, i.e. by a factor of

$2^{3/2}$ find that the normal stresses increase by factors of 2 and 8, respectively, within the contraction, i.e. by a factor of ![]() $H^2$ in all cases.

$H^2$ in all cases.

Figure 5. Cross-stream variations of normal stress at end of the contraction at ![]() $x=1$. Normal stresses at the end of the contraction, divided by eventual relaxed value far downstream in exit channel, (a) for the full width as a function of

$x=1$. Normal stresses at the end of the contraction, divided by eventual relaxed value far downstream in exit channel, (a) for the full width as a function of ![]() $y$, and (b) for the boundary layer as a function of

$y$, and (b) for the boundary layer as a function of ![]() $(y-0.5)\,De$, for

$(y-0.5)\,De$, for ![]() $De = 0.1 \ \text{in steps of}\ 0.1\ \text{to}\ 0.5$, contraction ratio

$De = 0.1 \ \text{in steps of}\ 0.1\ \text{to}\ 0.5$, contraction ratio ![]() $H= 2$, and

$H= 2$, and ![]() $c=1.0$. The solid black lines are

$c=1.0$. The solid black lines are ![]() $H^{-2}=0.25$.

$H^{-2}=0.25$.

Near the upper boundary, the flow is slow, so that the normal stresses have longer during their transit through the contraction to approach their fully relaxed values. They are therefore less suppressed compared with the core of the flow, and not suppressed at all on the boundary where the velocity vanishes. Figure 5(b) replots the data multiplying the distance from the boundary by the Deborah number. We see a universal boundary layer once ![]() $De>0.1$. The thickness of the boundary layer is

$De>0.1$. The thickness of the boundary layer is ![]() $\delta y=0.04/De$. The boundary layer will give small corrections to our estimate of the pressure drop.

$\delta y=0.04/De$. The boundary layer will give small corrections to our estimate of the pressure drop.

Returning to the increase of the normal stresses by the factor of only ![]() $H^2$ by the end of the contraction, we recall the discussion at the end of § 2.1, which suggested that the tension in the streamlines should increase with the square of an accelerating velocity if relaxation was ignored. We test this in figure 6 by plotting

$H^2$ by the end of the contraction, we recall the discussion at the end of § 2.1, which suggested that the tension in the streamlines should increase with the square of an accelerating velocity if relaxation was ignored. We test this in figure 6 by plotting ![]() $A_{11}(x,\eta )/u^2(x,\eta )$ divided by its value at the entrance

$A_{11}(x,\eta )/u^2(x,\eta )$ divided by its value at the entrance ![]() $A_{11}(0,\eta )/u^2(0,\eta )$ as a function of

$A_{11}(0,\eta )/u^2(0,\eta )$ as a function of ![]() $x$, the distance along the flow, for the central half of the flow,

$x$, the distance along the flow, for the central half of the flow, ![]() $0<\eta <0.5$. To a good approximation, we see

$0<\eta <0.5$. To a good approximation, we see ![]() $A_{11}\propto u^2$. The slight drop in the curves in figure 6 of the normal stress divided by

$A_{11}\propto u^2$. The slight drop in the curves in figure 6 of the normal stress divided by ![]() $u^2$ is because

$u^2$ is because ![]() $\eta = \textrm {const.}$ is only approximately the streamline.

$\eta = \textrm {const.}$ is only approximately the streamline.

Figure 6. Streamwise variations on constant ![]() $\eta = 0.1\ \text{in steps of}\ 0.1\ \text{to}\ 0.5$ of velocity

$\eta = 0.1\ \text{in steps of}\ 0.1\ \text{to}\ 0.5$ of velocity ![]() $u$, elastic normal stress

$u$, elastic normal stress ![]() $NS$, and normal stress divided by the square of the velocity

$NS$, and normal stress divided by the square of the velocity ![]() $NS/u^2$; all scaled by their entry values, for

$NS/u^2$; all scaled by their entry values, for ![]() $H= 2$,

$H= 2$, ![]() $De=0.5$ and

$De=0.5$ and ![]() $c=1.0$.

$c=1.0$.

3.4. High Deborah numbers

Figure 4 showed that at ![]() $De=0.5$ the stress mostly relaxed in the exit channel, i.e. there was little relaxation in the contraction itself. Moreover, with no relaxation, the elastic shear stress

$De=0.5$ the stress mostly relaxed in the exit channel, i.e. there was little relaxation in the contraction itself. Moreover, with no relaxation, the elastic shear stress ![]() $A_{12}(x,\eta )$ remained equal on the streamlines to its value at the entrance,

$A_{12}(x,\eta )$ remained equal on the streamlines to its value at the entrance, ![]() $-3\,De\,\eta$. Figure 6 showed that at

$-3\,De\,\eta$. Figure 6 showed that at ![]() $De=0.5$ the elastic normal stress

$De=0.5$ the elastic normal stress ![]() $A_{11}(x,\eta )$ increases along the streamlines from its value at the entrance

$A_{11}(x,\eta )$ increases along the streamlines from its value at the entrance ![]() $18\,De^2\,\eta ^2$ in proportion to the square of the increase in the velocity, i.e.

$18\,De^2\,\eta ^2$ in proportion to the square of the increase in the velocity, i.e. ![]() $\propto h^{-2}(x)$, at least away from the boundary. These results were anticipated at the end of § 2.1. We thus have for sufficiently high Deborah numbers, such as

$\propto h^{-2}(x)$, at least away from the boundary. These results were anticipated at the end of § 2.1. We thus have for sufficiently high Deborah numbers, such as ![]() $De>0.3$,

$De>0.3$,

Substituting these into the expression (2.8) for the pressure gradient gives

The three terms on the right-hand side come, respectively, from the solvent viscosity, the elastic shear stresses and the elastic normal stresses. Integrating gives

Here ![]() $\Delta p_1$ was defined in (3.2) and tabulated in table 1. The second term is

$\Delta p_1$ was defined in (3.2) and tabulated in table 1. The second term is

also tabulated in table 1. At ![]() $H=1$,

$H=1$, ![]() $\Delta p_2 = 3$. At high contraction ratios,

$\Delta p_2 = 3$. At high contraction ratios, ![]() $\Delta p_2 \sim (3{\rm \pi} \sqrt {2}/4)H^{1/2}$. For

$\Delta p_2 \sim (3{\rm \pi} \sqrt {2}/4)H^{1/2}$. For ![]() $H=4$, this expression gives 6.664 in place of the 6.249 in the table.

$H=4$, this expression gives 6.664 in place of the 6.249 in the table.

At low Deborah number, the elastic shear stresses make a contribution ![]() $c\,\Delta p_1$. At high Deborah number, their contribution is reduced to

$c\,\Delta p_1$. At high Deborah number, their contribution is reduced to ![]() $c\,\Delta p_2$, because the residence time in the contraction is insufficient for the stress to attain its eventual steady state. The final term from the normal stresses gives a decrease in the pressure drop, which is linear in the Deborah number. The stronger tension in the streamlines at the end of the contraction pulls the flow through the contraction, so reducing the need for pressure to push the flow through.

$c\,\Delta p_2$, because the residence time in the contraction is insufficient for the stress to attain its eventual steady state. The final term from the normal stresses gives a decrease in the pressure drop, which is linear in the Deborah number. The stronger tension in the streamlines at the end of the contraction pulls the flow through the contraction, so reducing the need for pressure to push the flow through.

The expressions for the elastic stresses (3.4a,b) are applicable in the central fast part of the flow and not near the boundary. In a boundary layer, the stresses are larger, ![]() $A_{11}=O(De^2\,H^4)$ and

$A_{11}=O(De^2\,H^4)$ and ![]() $A_{12}=O(De\,H^2)$. The thickness of the boundary layer was found in figure 5(b) to be

$A_{12}=O(De\,H^2)$. The thickness of the boundary layer was found in figure 5(b) to be ![]() $O(1/De)$. The contributions of the two stresses to the integral (2.8) will therefore be

$O(1/De)$. The contributions of the two stresses to the integral (2.8) will therefore be ![]() $O(H^4/De)$ and

$O(H^4/De)$ and ![]() $O(H^2/De)$, which are both small compared with terms in (3.5).

$O(H^2/De)$, which are both small compared with terms in (3.5).

We test the prediction (3.5) for the pressure drop at high Deborah number by plotting in figure 7 the pressure drop ![]() $\Delta p$ minus the contributions

$\Delta p$ minus the contributions ![]() $\Delta p_1 + c\,\Delta p_2$, all divided by the geometry factor

$\Delta p_1 + c\,\Delta p_2$, all divided by the geometry factor ![]() $(H^2-1)$, as a function of the Deborah number

$(H^2-1)$, as a function of the Deborah number ![]() $De$. Results for the different contraction ratios collapse onto the same curve, decreasing linearly for high Deborah numbers

$De$. Results for the different contraction ratios collapse onto the same curve, decreasing linearly for high Deborah numbers ![]() $De>0.5$. The slope of the line is not quite the

$De>0.5$. The slope of the line is not quite the ![]() $-\frac 95 c$ predicted. The cause of the discrepancy has been identified as due to the small change in the flow from the parabolic profile that occurs when

$-\frac 95 c$ predicted. The cause of the discrepancy has been identified as due to the small change in the flow from the parabolic profile that occurs when ![]() $c=1.0$. Figure 8 shows that as the concentration

$c=1.0$. Figure 8 shows that as the concentration ![]() $c$ is decreased from 1.0 the asymptote approaches

$c$ is decreased from 1.0 the asymptote approaches ![]() $-\frac 95\,De$.

$-\frac 95\,De$.

Figure 7. A test of the high-![]() $De$ asymptotic result (3.5). The pressure drop

$De$ asymptotic result (3.5). The pressure drop ![]() $\Delta p$ minus

$\Delta p$ minus ![]() $\Delta p_1 + c\,\Delta p_2$ divided by

$\Delta p_1 + c\,\Delta p_2$ divided by ![]() $(H^2-1)$, for

$(H^2-1)$, for ![]() $c=1.0$ and

$c=1.0$ and ![]() $H = 2^{1/2}$,

$H = 2^{1/2}$, ![]() $2$,

$2$, ![]() $2^{3/2}$ and

$2^{3/2}$ and ![]() $4$. The solid black line is

$4$. The solid black line is ![]() $-\frac {9}{5}c\,De$.

$-\frac {9}{5}c\,De$.

Figure 8. The effect of concentration. Plotted as a function of the Deborah number is ![]() $(\Delta p - \Delta p_1 - c\,\Delta p_2)/(c(H^2-1))$, for

$(\Delta p - \Delta p_1 - c\,\Delta p_2)/(c(H^2-1))$, for ![]() $c=4,2,1,0.5,0.25,0.05$ and for

$c=4,2,1,0.5,0.25,0.05$ and for ![]() $H=2$. The solid black line is

$H=2$. The solid black line is ![]() $-\frac {9}{5}\,De$.

$-\frac {9}{5}\,De$.

3.5. Energy fluxes and dissipation

We postponed discussion of which pressure drop might be measured in different experiments. There is also a paradox to be resolved that the work done by the reduced pressure drop produces an efflux of elastic energy while the viscous dissipation would seem to remain unchanged if the velocity profile continued to be parabolic.

We form the mechanical energy equation by multiplying the lubrication approximation of the momentum equation (2.2) by the velocity ![]() $u$, and integrating over a control volume of the contraction,

$u$, and integrating over a control volume of the contraction, ![]() $0\le x\le 1$ and

$0\le x\le 1$ and ![]() $0\le \eta \le 1$. After integrating some terms by parts, we obtain

$0\le \eta \le 1$. After integrating some terms by parts, we obtain

\begin{gather*} 0 = p(0) - p(1)- \int_0^1\int_0^1 \left(\frac{1}{h}\,{\frac{\partial u}{\partial \eta}}\right)^2h\,{\rm d}\eta \,{{\rm d}\kern0.06em x} \\ +\frac{c}{De}\left(\left[\int_0^1 uA_{11}h\,{\rm d}\eta\right]_{x=0}^1 - \int_0^1\int_0^1\left({\frac{\partial u}{\partial x}}\,A_{11} +\frac{1}{h}\,{\frac{\partial u}{\partial \eta}}\,A_{12}\right)h \,{\rm d}\eta\,{{\rm d}\kern0.06em x}\right)\!. \end{gather*}

\begin{gather*} 0 = p(0) - p(1)- \int_0^1\int_0^1 \left(\frac{1}{h}\,{\frac{\partial u}{\partial \eta}}\right)^2h\,{\rm d}\eta \,{{\rm d}\kern0.06em x} \\ +\frac{c}{De}\left(\left[\int_0^1 uA_{11}h\,{\rm d}\eta\right]_{x=0}^1 - \int_0^1\int_0^1\left({\frac{\partial u}{\partial x}}\,A_{11} +\frac{1}{h}\,{\frac{\partial u}{\partial \eta}}\,A_{12}\right)h \,{\rm d}\eta\,{{\rm d}\kern0.06em x}\right)\!. \end{gather*}