1. Introduction

Compound particles are particles confined in a fluid drop. Suspensions of these complex and multiphase structures are encountered in petroleum, food and pharmaceutical processing industries (Bird, Armstrong & Hassager Reference Bird, Armstrong and Hassager1987; Barnes, Hutton & Walters Reference Barnes, Hutton and Walters1989; Tadros Reference Tadros2011; Jia, Wang & Fan Reference Jia, Wang and Fan2020) and in biological and soft matter systems (Wisdom et al. Reference Wisdom, Watson, Qu, Liu, Watson and Chen2013; Gasperini, Mano & Reis Reference Gasperini, Mano and Reis2014; Wen et al. Reference Wen, Yu, Zhu, Jiang and Qin2015; Reigh et al. Reference Reigh, Zhu, Gallaire and Lauga2017; Zhang et al. Reference Zhang, Wang, Zhou, Zhang, Gong, Gou, Xu and Ma2017; Choe et al. Reference Choe, Park, Park and Lee2018; Somerville et al. Reference Somerville, Law, Rey, Vogel, Archer and Buzza2020). While several classical and seminal works have focused on the rheological characterisation of a suspension of particles (Einstein Reference Einstein1906, Reference Einstein1911) or fluid droplets (Taylor Reference Taylor1932; Stone & Leal Reference Stone and Leal1990; Stone Reference Stone1994), relatively less attention has been given to study the stability and rheology of composite systems, namely multiphase structures consisting of solid particles and fluid droplets together, such as compound particles. Therefore, in this work, we theoretically investigate the fluid flow in and around a compound particle, the deformation dynamics of the confining drop and its stability against breakup in an imposed flow. Further, we characterise a dilute dispersion of compound particles by determining its rheology in terms of the effective viscosity, normal stress differences and complex modulus.

Several numerical (Kawano & Hashimoto Reference Kawano and Hashimoto1997; Smith, Ottino & Cruz Reference Smith, Ottino and Cruz2004; Chen, Liu & Shi Reference Chen, Liu and Shi2013; Hua, Shin & Kim Reference Hua, Shin and Kim2014; Chen et al. Reference Chen, Liu, Zhang and Zhao2015a; Chen, Liu & Zhao Reference Chen, Liu and Zhao2015b; Patlazhan, Vagner & Kravchenko Reference Patlazhan, Vagner and Kravchenko2015; Kim & Dabiri Reference Kim and Dabiri2017) and theoretical (Mori Reference Mori1978; Johnson Reference Johnson1981; Harper Reference Harper1982; Johnson & Sadhal Reference Johnson and Sadhal1985; Sadhal, Ayyaswamy & Chung Reference Sadhal, Ayyaswamy and Chung1997; Sagis & Öttinger Reference Sagis and Öttinger2013) studies have addressed the hydrodynamics and the deformation dynamics of composite systems in an imposed flow. Johnson (Reference Johnson1981) investigated the creeping flow past a rigid sphere coated with a thin film. Later, Sadhal & Johnson (Reference Sadhal and Johnson1983) and Johnson & Sadhal (Reference Johnson and Sadhal1983) extended this study to a fluid droplet coated with a thin film and calculated the modification to the drag force due to a thin coating. Rushton & Davies (Reference Rushton and Davies1983) theoretically investigated the translational dynamics of a compound droplet, a multiphase system where a droplet is confined in another droplet, either concentrically or eccentrically (Sadhal & Oguz Reference Sadhal and Oguz1985; Qu & Wang Reference Qu and Wang2012). The dynamics of a compound drop is also influenced by externally imposed flows. For example, Davis & Brenner (Reference Davis and Brenner1981) investigated the steady state deformation dynamics of a concentric compound particle in a shear flow. Stone & Leal (Reference Stone and Leal1990) generalised this study to understand compound droplets. They also performed boundary-integral-method-based numerical simulations and analysed the breakup of compound droplets in a linear flow. Kim & Dabiri (Reference Kim and Dabiri2017) numerically investigated the time evolution of eccentric compound droplets subjected to a simple shear flow. The effects of inertia (Bazhlekov, Shopov & Zapryanov Reference Bazhlekov, Shopov and Zapryanov1995), viscoelasticity (Zhou, Yue & Feng Reference Zhou, Yue and Feng2006), surfactant laden interfaces (Hamedi & Babadagli Reference Hamedi and Babadagli2010; Xu et al. Reference Xu, Liu, Zhao and Li2013; Srinivasan & Shah Reference Srinivasan and Shah2014; Zhang et al. Reference Zhang, Zhao, Li, Xu and Liu2015; Mandal, Ghosh & Chakraborty Reference Mandal, Ghosh and Chakraborty2016), confinement (Song, Xu & Yang Reference Song, Xu and Yang2010) and electric field (Soni, Thaokar & Juvekar Reference Soni, Thaokar and Juvekar2018; Santra, Das & Chakraborty Reference Santra, Das and Chakraborty2020a; Santra et al. Reference Santra, Panigrahi, Das and Chakraborty2020b) on compound drops have also been addressed and thus, the literature on compound drops is plentiful. However, the presence of three fluids and multiple deforming interfaces make the analysis of compound drops cumbersome. On the other hand, analytical calculations with compound particles though a subset of compound drops, (i) are tractable relatively easily and (ii) demonstrate the strong hydrodynamic response such as interface deformation that results from the interaction between the encapsulated solid particle and the confining fluid interface. Therefore, the analysis of compound particles provide useful physical insights into the deformation dynamics of the interface and rheological response of dispersions containing multiphase structures as we illustrate in this work. Table 1 summarises and distinguishes the present work from the previous theoretical studies which analysed the deformation dynamics of composite systems in an imposed flow. The bottom up approach of microstructure based rheology determination dates back to the classical calculation of effective viscosity of dilute suspensions of single phase constituents such as particles and droplets (Einstein Reference Einstein1906, Reference Einstein1911; Taylor Reference Taylor1932). Further modifications, for example, to analyse the effect of insoluble surfactants on the rheology of dilute emulsions, have been addressed numerically (Li & Pozrikidis Reference Li and Pozrikidis1997). Several works to incorporate such effects (Pal Reference Pal1996a; Zhao & Macosko Reference Zhao and Macosko2002; Vlahovska, Bławzdziewicz & Loewenberg Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Mandal, Das & Chakraborty Reference Mandal, Das and Chakraborty2017) and to relax the assumption of diluteness (Loewenberg & Hinch Reference Loewenberg and Hinch1996; Loewenberg Reference Loewenberg1998; Jansen, Agterof & Mellema Reference Jansen, Agterof and Mellema2001; Golemanov et al. Reference Golemanov, Tcholakova, Denkov, Ananthapadmanabhan and Lips2008) to predict the rheology of concentrated emulsions are available in the literature but attempts to understand the rheological behaviour of dispersions of compound particles or compound droplets are scarce (Johnson & Sadhal Reference Johnson and Sadhal1985; Stone & Leal Reference Stone and Leal1990; Pal Reference Pal1996b, Reference Pal2007, Reference Pal2011; Mandal et al. Reference Mandal, Ghosh and Chakraborty2016; Das, Mandal & Chakraborty Reference Das, Mandal and Chakraborty2020; Santra et al. Reference Santra, Panigrahi, Das and Chakraborty2020b).

Table 1. A summary of theoretical works in the past that analysed the deformation dynamics of composite systems in a background flow, and the rheology of their dilute dispersion.

In the present work, we analyse the deformation dynamics of a concentric compound particle in an imposed linear flow using an asymptotic expansion in capillary number, ![]() $Ca$. This is interesting because deformation dynamics is usually analysed only up to

$Ca$. This is interesting because deformation dynamics is usually analysed only up to ![]() ${O}(Ca)$ and it may be interesting to understand the deviations predicted by

${O}(Ca)$ and it may be interesting to understand the deviations predicted by ![]() ${O}(Ca^{2})$ calculations. The

${O}(Ca^{2})$ calculations. The ![]() $O(1)$ velocity field and

$O(1)$ velocity field and ![]() $O(Ca)$ deformation dynamics of a concentric compound particle in a linear flow is already reported in Chaithanya & Thampi (Reference Chaithanya and Thampi2019). In contrast, the present work investigates the

$O(Ca)$ deformation dynamics of a concentric compound particle in a linear flow is already reported in Chaithanya & Thampi (Reference Chaithanya and Thampi2019). In contrast, the present work investigates the ![]() $O(Ca)$ velocity field, and

$O(Ca)$ velocity field, and ![]() $O(Ca^2)$ deformation dynamics of a concentric compound particle. It has been found that the higher-order calculations are particularly relevant for compound particles, as they predict qualitatively different behaviour compared to the leading-order calculations as discussed in § 4. The present work is also able to analyse the effect of rotation of the deformed compound particle on the deformation dynamics, which is neglected in Chaithanya & Thampi (Reference Chaithanya and Thampi2019). Moreover, using these calculations we develop a constitutive equation for volume-averaged stress and characterise the rheological response of a dilute dispersion of compound particles. Both shear and extensional rheology are analysed in a single framework by quantifying the effective shear viscosity, extensional viscosity and normal stress differences. We also analyse, for the first time, the linear viscoelastic behaviour (of the dilute dispersion) in terms of complex modulus by subjecting the compound particle to a small-amplitude oscillatory shear (SAOS) flow. The approach followed in this paper is similar to the work by Leal (Reference Leal2007) and Ramachandran & Leal (Reference Ramachandran and Leal2012) in the context of a fluid droplet in a linear flow.

$O(Ca^2)$ deformation dynamics of a concentric compound particle. It has been found that the higher-order calculations are particularly relevant for compound particles, as they predict qualitatively different behaviour compared to the leading-order calculations as discussed in § 4. The present work is also able to analyse the effect of rotation of the deformed compound particle on the deformation dynamics, which is neglected in Chaithanya & Thampi (Reference Chaithanya and Thampi2019). Moreover, using these calculations we develop a constitutive equation for volume-averaged stress and characterise the rheological response of a dilute dispersion of compound particles. Both shear and extensional rheology are analysed in a single framework by quantifying the effective shear viscosity, extensional viscosity and normal stress differences. We also analyse, for the first time, the linear viscoelastic behaviour (of the dilute dispersion) in terms of complex modulus by subjecting the compound particle to a small-amplitude oscillatory shear (SAOS) flow. The approach followed in this paper is similar to the work by Leal (Reference Leal2007) and Ramachandran & Leal (Reference Ramachandran and Leal2012) in the context of a fluid droplet in a linear flow.

This paper is organised as follows. In § 2, we present the mathematical formulation and present the analytical solutions using a domain perturbation technique with capillary number, ![]() $Ca$ as the small parameter. We thus calculate the velocity and pressure fields up to

$Ca$ as the small parameter. We thus calculate the velocity and pressure fields up to ![]() ${O}(Ca)$ using the standard technique of superposition of vector harmonics and then determine the consequence of this flow field, namely the shape of the confining drop corrected up to

${O}(Ca)$ using the standard technique of superposition of vector harmonics and then determine the consequence of this flow field, namely the shape of the confining drop corrected up to ![]() ${O}(Ca^2)$. In § 4, we analyse the deformation of the confining drop, and contrast the dynamics obtained by the

${O}(Ca^2)$. In § 4, we analyse the deformation of the confining drop, and contrast the dynamics obtained by the ![]() ${O}(Ca)$ and

${O}(Ca)$ and ![]() ${O}(Ca^2)$ calculations. Then in § 5, we determine the rheology of a dilute dispersion of compound particles in terms of shear and extensional viscosities, normal stress differences and the complex modulus.

${O}(Ca^2)$ calculations. Then in § 5, we determine the rheology of a dilute dispersion of compound particles in terms of shear and extensional viscosities, normal stress differences and the complex modulus.

2. Mathematical formulation

We consider a drop of radius ![]() $b$ that concentrically encapsulates a solid particle of radius

$b$ that concentrically encapsulates a solid particle of radius ![]() $a = b/\alpha$ as shown in figure 1, and

$a = b/\alpha$ as shown in figure 1, and ![]() $\alpha$ is referred to as the size ratio. The inner and outer fluids are assumed to be Newtonian having viscosities

$\alpha$ is referred to as the size ratio. The inner and outer fluids are assumed to be Newtonian having viscosities ![]() $\hat {\mu }$ and

$\hat {\mu }$ and ![]() $\mu = \lambda \hat {\mu }$ respectively, and

$\mu = \lambda \hat {\mu }$ respectively, and ![]() $\lambda$ is referred to as the viscosity ratio. The typical applications in which the compound particles are encountered are associated with small length and velocity scales, thus the viscous effects are dominant compared to the inertial effects. Hence, we assume that the Reynolds number is small and solve for the Stokes’ equations in the inner and outer fluids (Russel, Saville & Schowalter Reference Russel, Saville and Schowalter1989),

$\lambda$ is referred to as the viscosity ratio. The typical applications in which the compound particles are encountered are associated with small length and velocity scales, thus the viscous effects are dominant compared to the inertial effects. Hence, we assume that the Reynolds number is small and solve for the Stokes’ equations in the inner and outer fluids (Russel, Saville & Schowalter Reference Russel, Saville and Schowalter1989),

where, ![]() $\boldsymbol{\hat {u}}$ and

$\boldsymbol{\hat {u}}$ and ![]() $\boldsymbol{u}$ are the velocity fields in the inner and outer fluids respectively. The corresponding pressure fields are

$\boldsymbol{u}$ are the velocity fields in the inner and outer fluids respectively. The corresponding pressure fields are ![]() $\hat {p}$ and

$\hat {p}$ and ![]() $p$. The variables are non-dimensionalised by using the confining drop size

$p$. The variables are non-dimensionalised by using the confining drop size ![]() $b$ as the characteristic length. Let

$b$ as the characteristic length. Let ![]() $\mathcal {G}$ be the characteristic strain rate associated with the compound particle and therefore,

$\mathcal {G}$ be the characteristic strain rate associated with the compound particle and therefore, ![]() $b\mathcal {G}$ and

$b\mathcal {G}$ and ![]() $\mu \mathcal {G}$ are chosen as the characteristic velocity and pressure respectively for obtaining non-dimensional quantities.

$\mu \mathcal {G}$ are chosen as the characteristic velocity and pressure respectively for obtaining non-dimensional quantities.

Figure 1. A schematic of the compound particle consisting of a solid sphere of radius ![]() $a$ encapsulated in a drop of radius

$a$ encapsulated in a drop of radius ![]() $b = a \alpha$. The confining interface deforms when subjected to an imposed flow

$b = a \alpha$. The confining interface deforms when subjected to an imposed flow ![]() $\boldsymbol{u}^{imp}$. The longest and shortest dimensions of the deformed interface are respectively indicated by

$\boldsymbol{u}^{imp}$. The longest and shortest dimensions of the deformed interface are respectively indicated by ![]() $r_{max}$ and

$r_{max}$ and ![]() $r_{min}$. If the imposed flow is a simple shear flow, the alignment angle

$r_{min}$. If the imposed flow is a simple shear flow, the alignment angle ![]() $\varphi$ is defined as the angle between the elongated direction of the confining drop and the direction of the imposed flow.

$\varphi$ is defined as the angle between the elongated direction of the confining drop and the direction of the imposed flow.

Equations (2.1a,b) and (2.2a,b) are solved using the standard technique of superposition of vector harmonics subjected to the following boundary conditions:

(i) In the far field, the velocity of the outer fluid approaches the imposed velocity field, i.e.

(2.3)We consider the ambient flow to be linear, of the form, \begin{equation} \boldsymbol{u} \rightarrow {\boldsymbol{u}}^{\textit{imp}} \text{ as } \boldsymbol{x} \rightarrow \infty. \end{equation}(2.4)where,

\begin{equation} \boldsymbol{u} \rightarrow {\boldsymbol{u}}^{\textit{imp}} \text{ as } \boldsymbol{x} \rightarrow \infty. \end{equation}(2.4)where, \begin{equation} {\boldsymbol{u}}^{\textit{imp}}=(\boldsymbol{\mathsf{E}}+\boldsymbol{\varOmega}) \boldsymbol{\cdot} \boldsymbol{x}, \end{equation}

\begin{equation} {\boldsymbol{u}}^{\textit{imp}}=(\boldsymbol{\mathsf{E}}+\boldsymbol{\varOmega}) \boldsymbol{\cdot} \boldsymbol{x}, \end{equation} $\boldsymbol{x}$ is the position vector,

$\boldsymbol{x}$ is the position vector,  $\boldsymbol{\mathsf{E}}$ and

$\boldsymbol{\mathsf{E}}$ and  $\boldsymbol{\varOmega }$ are respectively the symmetric and anti-symmetric parts of the velocity gradient tensor,

$\boldsymbol{\varOmega }$ are respectively the symmetric and anti-symmetric parts of the velocity gradient tensor,  $\boldsymbol {\nabla } {\boldsymbol{u}}^{\textit{imp}}$.

$\boldsymbol {\nabla } {\boldsymbol{u}}^{\textit{imp}}$.(ii) No-slip boundary condition is imposed on the surface of the encapsulated particle,

(2.5) \begin{equation} \boldsymbol{\hat{u}}=\boldsymbol{\varOmega} \boldsymbol{\cdot} \boldsymbol{x} \text{ at }|\boldsymbol{x}| = 1/\alpha. \end{equation}

\begin{equation} \boldsymbol{\hat{u}}=\boldsymbol{\varOmega} \boldsymbol{\cdot} \boldsymbol{x} \text{ at }|\boldsymbol{x}| = 1/\alpha. \end{equation}(iii) Continuity in velocity and stresses are maintained on the confining interface,

(2.6) \begin{gather} \boldsymbol{u}-\boldsymbol{\hat{u}}=\boldsymbol{0}, \end{gather}(2.7)where

\begin{gather} \boldsymbol{u}-\boldsymbol{\hat{u}}=\boldsymbol{0}, \end{gather}(2.7)where \begin{gather}\left(\boldsymbol{\sigma}-\frac{1}{\lambda}\boldsymbol{\hat{\sigma}}\right)\boldsymbol{\cdot} \boldsymbol{n} = \frac{1}{Ca}(\boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{n})\boldsymbol{n}, \end{gather}

\begin{gather}\left(\boldsymbol{\sigma}-\frac{1}{\lambda}\boldsymbol{\hat{\sigma}}\right)\boldsymbol{\cdot} \boldsymbol{n} = \frac{1}{Ca}(\boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{n})\boldsymbol{n}, \end{gather} $Ca=\mu \mathcal {G} b/\gamma$ is the capillary number,

$Ca=\mu \mathcal {G} b/\gamma$ is the capillary number,  $\boldsymbol{n}$ is the unit normal vector to the confining interface and

$\boldsymbol{n}$ is the unit normal vector to the confining interface and  $\boldsymbol{\sigma }=-p \boldsymbol{\mathsf{I}}+ (\boldsymbol {\nabla } \boldsymbol{u}+\boldsymbol {\nabla } \boldsymbol{u}^{T})$ and

$\boldsymbol{\sigma }=-p \boldsymbol{\mathsf{I}}+ (\boldsymbol {\nabla } \boldsymbol{u}+\boldsymbol {\nabla } \boldsymbol{u}^{T})$ and  $(1/\lambda )\boldsymbol{\hat {\sigma }}=-\hat {p} \boldsymbol{\mathsf{I}}+(1/\lambda )(\boldsymbol {\nabla } \boldsymbol{\hat {u}}+\boldsymbol {\nabla } \boldsymbol{\hat {u}}^{T})$ are the stress tensors in the outer and inner fluids, respectively.

$(1/\lambda )\boldsymbol{\hat {\sigma }}=-\hat {p} \boldsymbol{\mathsf{I}}+(1/\lambda )(\boldsymbol {\nabla } \boldsymbol{\hat {u}}+\boldsymbol {\nabla } \boldsymbol{\hat {u}}^{T})$ are the stress tensors in the outer and inner fluids, respectively.(iv) Under the action of the imposed flow, the confining interface of the compound particle deforms and does not remain spherical. With the intention of using domain perturbation technique as a method to solve the problem which can be done by considering

$Ca$ as a small parameter, it is convenient to describe the shape of the confining interface using a scalar function,

$Ca$ as a small parameter, it is convenient to describe the shape of the confining interface using a scalar function,  $F(\boldsymbol{x}_{s},t)=r-(1+Ca f (\boldsymbol{x}_{s},t ))=0$, where

$F(\boldsymbol{x}_{s},t)=r-(1+Ca f (\boldsymbol{x}_{s},t ))=0$, where  $r = |\boldsymbol{x}|$ and

$r = |\boldsymbol{x}|$ and  $\boldsymbol{x}_{s}$ is the position of the interface. In terms of this scalar function, the kinematic boundary condition on the interface is given by (Leal Reference Leal2007; Ramachandran & Leal Reference Ramachandran and Leal2012)

(2.8)where

$\boldsymbol{x}_{s}$ is the position of the interface. In terms of this scalar function, the kinematic boundary condition on the interface is given by (Leal Reference Leal2007; Ramachandran & Leal Reference Ramachandran and Leal2012)

(2.8)where \begin{equation} \frac{1}{| \boldsymbol{\nabla} F |} \frac{\partial F}{\partial t }+ Ca (\boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n})=0, \end{equation}

\begin{equation} \frac{1}{| \boldsymbol{\nabla} F |} \frac{\partial F}{\partial t }+ Ca (\boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n})=0, \end{equation} $\boldsymbol{u}$ is the fluid velocity evaluated at the interface, either approached from the inner or the outer fluid and

$\boldsymbol{u}$ is the fluid velocity evaluated at the interface, either approached from the inner or the outer fluid and  $t$ is non-dimensionalised by the interface relaxation time scale

$t$ is non-dimensionalised by the interface relaxation time scale  $Ca \mathcal {G}^{-1}$. The normal vector

$Ca \mathcal {G}^{-1}$. The normal vector  $\boldsymbol{n}$ on the interface and the curvature

$\boldsymbol{n}$ on the interface and the curvature  $\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol{n}$ of the interface may be obtained as

(2.9)and

$\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol{n}$ of the interface may be obtained as

(2.9)and \begin{equation} \boldsymbol{n}=\frac{\boldsymbol{\nabla} F}{| \boldsymbol{\nabla} F |}=\frac{1}{| \boldsymbol{\nabla} F |} \left( \frac{\boldsymbol{x}}{r} -Ca \boldsymbol{\nabla} f \right), \end{equation}(2.10)respectively. Here,

\begin{equation} \boldsymbol{n}=\frac{\boldsymbol{\nabla} F}{| \boldsymbol{\nabla} F |}=\frac{1}{| \boldsymbol{\nabla} F |} \left( \frac{\boldsymbol{x}}{r} -Ca \boldsymbol{\nabla} f \right), \end{equation}(2.10)respectively. Here, \begin{equation} \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{n}= \frac{1}{| \boldsymbol{\nabla} F |} \left( \frac{2}{r} - Ca \boldsymbol{\nabla}^2 f \right)- Ca^2 \frac{1}{| \boldsymbol{\nabla} F |^3} \left( \frac{\boldsymbol{x}}{r} - Ca \boldsymbol{\nabla} f \right) \boldsymbol{\cdot} (\boldsymbol{\nabla}(\boldsymbol{\nabla} f) \boldsymbol{\cdot} \boldsymbol{\nabla} f), \end{equation}

\begin{equation} \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{n}= \frac{1}{| \boldsymbol{\nabla} F |} \left( \frac{2}{r} - Ca \boldsymbol{\nabla}^2 f \right)- Ca^2 \frac{1}{| \boldsymbol{\nabla} F |^3} \left( \frac{\boldsymbol{x}}{r} - Ca \boldsymbol{\nabla} f \right) \boldsymbol{\cdot} (\boldsymbol{\nabla}(\boldsymbol{\nabla} f) \boldsymbol{\cdot} \boldsymbol{\nabla} f), \end{equation} $| \boldsymbol {\nabla } F |=\sqrt {1+Ca^2 |\boldsymbol {\nabla } f|^2}$. Further, the kinematic boundary condition (2.8) may be simplified as,

(2.11)

$| \boldsymbol {\nabla } F |=\sqrt {1+Ca^2 |\boldsymbol {\nabla } f|^2}$. Further, the kinematic boundary condition (2.8) may be simplified as,

(2.11) \begin{equation} \frac{\partial f}{\partial t}=( \boldsymbol{u}|_{r=(1+Ca f)} \boldsymbol{\cdot} \boldsymbol{n}) \sqrt{1+ Ca^{2} |\boldsymbol{\nabla} f|^2}. \end{equation}

\begin{equation} \frac{\partial f}{\partial t}=( \boldsymbol{u}|_{r=(1+Ca f)} \boldsymbol{\cdot} \boldsymbol{n}) \sqrt{1+ Ca^{2} |\boldsymbol{\nabla} f|^2}. \end{equation}

Even though the governing equations are linear, the problem is nonlinear because of the coupling between the unknown confining drop shape (![]() $f$) and the flow field. However, the problem can be solved analytically, by assuming that the droplet deformations are small, i.e.

$f$) and the flow field. However, the problem can be solved analytically, by assuming that the droplet deformations are small, i.e. ![]() $Ca\ll 1$. We solve the governing equations by expanding all the variables via domain perturbation approach in terms of capillary number,

$Ca\ll 1$. We solve the governing equations by expanding all the variables via domain perturbation approach in terms of capillary number, ![]() $Ca$, (Stone & Leal Reference Stone and Leal1990) as,

$Ca$, (Stone & Leal Reference Stone and Leal1990) as,

\begin{equation} \left.\begin{array}{c} f(\boldsymbol{x},t)=f^{(0)}(\boldsymbol{x},t)+Ca f^{(1)}(\boldsymbol{x},t)+Ca^{2} f^{(2)}(\boldsymbol{x},t)+\cdots, \\ p(\boldsymbol{x},t)=p^{(0)}(\boldsymbol{x},t)+Ca p^{(1)}(\boldsymbol{x},t)+Ca^{2} p^{(2)}(\boldsymbol{x},t)+\cdots, \\ \boldsymbol{u}(\boldsymbol{x},t)=\boldsymbol{u}^{(0)}(\boldsymbol{x},t)+Ca \boldsymbol{u}^{(1)}(\boldsymbol{x},t)+Ca^{2} \boldsymbol{u}^{(2)}(\boldsymbol{x},t)+\cdots, \\ \hat{p}(\boldsymbol{x},t)=\hat{p}^{(0)}(\boldsymbol{x},t)+Ca \hat{p}^{(1)}(\boldsymbol{x},t)+Ca^{2} \hat{p}^{(2)}(\boldsymbol{x},t)+\cdots, \\ \boldsymbol{\hat{u}}(\boldsymbol{x},t)=\boldsymbol{\hat{u}}^{(0)}(\boldsymbol{x},t)+Ca \boldsymbol{\hat{u}}^{(1)}(\boldsymbol{x},t)+Ca^{2} \boldsymbol{\hat{u}}^{(2)}(\boldsymbol{x},t)+\cdots. \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c} f(\boldsymbol{x},t)=f^{(0)}(\boldsymbol{x},t)+Ca f^{(1)}(\boldsymbol{x},t)+Ca^{2} f^{(2)}(\boldsymbol{x},t)+\cdots, \\ p(\boldsymbol{x},t)=p^{(0)}(\boldsymbol{x},t)+Ca p^{(1)}(\boldsymbol{x},t)+Ca^{2} p^{(2)}(\boldsymbol{x},t)+\cdots, \\ \boldsymbol{u}(\boldsymbol{x},t)=\boldsymbol{u}^{(0)}(\boldsymbol{x},t)+Ca \boldsymbol{u}^{(1)}(\boldsymbol{x},t)+Ca^{2} \boldsymbol{u}^{(2)}(\boldsymbol{x},t)+\cdots, \\ \hat{p}(\boldsymbol{x},t)=\hat{p}^{(0)}(\boldsymbol{x},t)+Ca \hat{p}^{(1)}(\boldsymbol{x},t)+Ca^{2} \hat{p}^{(2)}(\boldsymbol{x},t)+\cdots, \\ \boldsymbol{\hat{u}}(\boldsymbol{x},t)=\boldsymbol{\hat{u}}^{(0)}(\boldsymbol{x},t)+Ca \boldsymbol{\hat{u}}^{(1)}(\boldsymbol{x},t)+Ca^{2} \boldsymbol{\hat{u}}^{(2)}(\boldsymbol{x},t)+\cdots. \end{array}\right\} \end{equation}

This asymptotic expansion assumes that the capillary number calculated based on either of the fluids is small, i.e. ![]() $Ca \ll 1$ and

$Ca \ll 1$ and ![]() $Ca/\lambda \ll 1$. In the domain perturbation approach, the interfacial quantities at

$Ca/\lambda \ll 1$. In the domain perturbation approach, the interfacial quantities at ![]() $r= (1 +Ca f)$ can be obtained by using Taylor's series expansion in terms of quantities calculated at the droplet surface

$r= (1 +Ca f)$ can be obtained by using Taylor's series expansion in terms of quantities calculated at the droplet surface ![]() $r=1$. For e.g. the velocity at the confining (deformed) interface can be obtained as

$r=1$. For e.g. the velocity at the confining (deformed) interface can be obtained as

Using this approach, we solve for the velocity and pressure fields up to ![]() ${O}(Ca)$ and simultaneously determine the

${O}(Ca)$ and simultaneously determine the ![]() ${O}(Ca)$ and

${O}(Ca)$ and ![]() ${O}(Ca^2)$ correction to the confining spherical drop shape.

${O}(Ca^2)$ correction to the confining spherical drop shape.

3. Hydrodynamics of the compound particle in a linear flow

In this section, we determine the velocity and pressure fields by solving (2.1a,b) and (2.2a,b) along with the boundary conditions (2.3)–(2.8) using domain perturbation technique explained above and the standard solution methodology of superposition of vector harmonics to solve Stokes’ equations.

3.1. Leading-order solution  ${O}(1)$

${O}(1)$

By substituting (2.12) in (2.1a,b) and (2.2a,b), the ![]() ${O}(1)$ governing equations and the corresponding boundary conditions can be obtained. The leading-order solution is reported and analysed in Chaithanya & Thampi (Reference Chaithanya and Thampi2019), so below we just provide the final expressions.

${O}(1)$ governing equations and the corresponding boundary conditions can be obtained. The leading-order solution is reported and analysed in Chaithanya & Thampi (Reference Chaithanya and Thampi2019), so below we just provide the final expressions.

Using the standard technique of superposition of vector harmonics (Leal Reference Leal2007; Chaithanya & Thampi Reference Chaithanya and Thampi2019), we may write the velocity and pressure fields in the outer fluid as a linear combination of ![]() $\boldsymbol{\mathsf{E}}$ and

$\boldsymbol{\mathsf{E}}$ and ![]() $\boldsymbol{\varOmega }$ as

$\boldsymbol{\varOmega }$ as

where ![]() $\boldsymbol{\mathsf{D}}_{(n)}$ represents the decaying spherical harmonics of order

$\boldsymbol{\mathsf{D}}_{(n)}$ represents the decaying spherical harmonics of order ![]() $n$, defined as

$n$, defined as ![]() $n$th-order gradients of fundamental solution of Laplace's equation,

$n$th-order gradients of fundamental solution of Laplace's equation, ![]() $1/r$. Similarly, the pressure and velocity fields in the inner fluid are

$1/r$. Similarly, the pressure and velocity fields in the inner fluid are

where, ![]() $\boldsymbol{\mathsf{G}}_{(n)}$ represents the growing spherical harmonics of order

$\boldsymbol{\mathsf{G}}_{(n)}$ represents the growing spherical harmonics of order ![]() $n$ and it is related to the decaying harmonics as,

$n$ and it is related to the decaying harmonics as, ![]() $\boldsymbol{\mathsf{G}}_{(n)}=r^{2n+1}\boldsymbol{\mathsf{D}}_{(n)}$. Here,

$\boldsymbol{\mathsf{G}}_{(n)}=r^{2n+1}\boldsymbol{\mathsf{D}}_{(n)}$. Here, ![]() $c_i$,

$c_i$, ![]() $d_i$ and

$d_i$ and ![]() $e_i$ are the constants that are linear function of shape parameter

$e_i$ are the constants that are linear function of shape parameter ![]() $b_1$, which is related to the leading-order shape function as,

$b_1$, which is related to the leading-order shape function as,

The expressions for the constants ![]() $c_i$,

$c_i$, ![]() $d_i$ and

$d_i$ and ![]() $e_i$ are given in Appendix A. Using (3.5) and leading-order form of (2.11), we obtain the temporal evolution of the shape parameter,

$e_i$ are given in Appendix A. Using (3.5) and leading-order form of (2.11), we obtain the temporal evolution of the shape parameter,

indicating that the relaxation process of the confining interface is exponential with ![]() $b_1^{*}$ as the steady state shape parameter and

$b_1^{*}$ as the steady state shape parameter and ![]() $t_{c}$ as the relaxation time scale.

$t_{c}$ as the relaxation time scale.

3.2. First-order solution  ${O}(Ca)$

${O}(Ca)$

In this section, we solve for the ![]() ${O}(Ca)$ pressure and velocity fields. The governing equations at

${O}(Ca)$ pressure and velocity fields. The governing equations at ![]() ${O}(Ca)$ are given by

${O}(Ca)$ are given by

The corresponding boundary conditions are,

the no-slip boundary condition on the interface of the encapsulated particle,

the continuity of normal and tangential velocities on the confining interface,

\begin{equation} \left. \begin{array}{c} ( (\boldsymbol{u}-\boldsymbol{\hat{u}}) \boldsymbol{\cdot} \boldsymbol{n} )^{(1)}_{r= ( 1+Ca f^{(0)})} =0, \\ (( \boldsymbol{\mathsf{I}}-\boldsymbol{n} \boldsymbol{n}) \boldsymbol{\cdot} (\boldsymbol{u} -\boldsymbol{\hat{u}} ))^{(1)}_{r= ( 1+Ca f^{(0)})} =0, \end{array} \right\} \end{equation}

\begin{equation} \left. \begin{array}{c} ( (\boldsymbol{u}-\boldsymbol{\hat{u}}) \boldsymbol{\cdot} \boldsymbol{n} )^{(1)}_{r= ( 1+Ca f^{(0)})} =0, \\ (( \boldsymbol{\mathsf{I}}-\boldsymbol{n} \boldsymbol{n}) \boldsymbol{\cdot} (\boldsymbol{u} -\boldsymbol{\hat{u}} ))^{(1)}_{r= ( 1+Ca f^{(0)})} =0, \end{array} \right\} \end{equation}and the stress balance at the interface,

\begin{gather} \left(\left(\boldsymbol{\sigma} -\frac{1}{\lambda}\boldsymbol{\hat{\sigma}} \right) \boldsymbol{\colon} \boldsymbol{n n} \right)^{(1)}_{r= ( 1+Ca f^{(0)})} = (\boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{n})^{(2)}, \end{gather}

\begin{gather} \left(\left(\boldsymbol{\sigma} -\frac{1}{\lambda}\boldsymbol{\hat{\sigma}} \right) \boldsymbol{\colon} \boldsymbol{n n} \right)^{(1)}_{r= ( 1+Ca f^{(0)})} = (\boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{n})^{(2)}, \end{gather} \begin{gather}\left( \left( ( \boldsymbol{\mathsf{I}}-\boldsymbol{n} \boldsymbol{n} ) \boldsymbol{\cdot} \left( \boldsymbol{\sigma}-\frac{1}{\lambda} \boldsymbol{\hat{\sigma}} \right) \right) \boldsymbol{\cdot} \boldsymbol{n} \right)^{(1)}_{r= ( 1+Ca f^{(0)})}=0. \end{gather}

\begin{gather}\left( \left( ( \boldsymbol{\mathsf{I}}-\boldsymbol{n} \boldsymbol{n} ) \boldsymbol{\cdot} \left( \boldsymbol{\sigma}-\frac{1}{\lambda} \boldsymbol{\hat{\sigma}} \right) \right) \boldsymbol{\cdot} \boldsymbol{n} \right)^{(1)}_{r= ( 1+Ca f^{(0)})}=0. \end{gather}

Similar to the previous section, (3.7) are solved using the technique of superposition of vector harmonics. The pressure and velocity fields in the outer fluid are at most quadratically dependent on ![]() $\boldsymbol{\mathsf{E}}$ and

$\boldsymbol{\mathsf{E}}$ and ![]() $\boldsymbol{\varOmega }$. Thus,

$\boldsymbol{\varOmega }$. Thus,

\begin{align}

p^{(1)}&=c_{4}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}

\boldsymbol{\mathsf{E}}+\,c_{5}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:} (\boldsymbol{\mathsf{E}}

\boldsymbol{\cdot}

\boldsymbol{\mathsf{E}})+c_{6}(\boldsymbol{\mathsf{D}}_{(4)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\boldsymbol{:}\boldsymbol{\mathsf{E}}

+\,c_{7}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}}) \nonumber\\ &\quad

+c_{8}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}

(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})+c_{9}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}

\boldsymbol{\varOmega})+c_{10}(\boldsymbol{\varOmega:

\varOmega}),\end{align}

\begin{align}

p^{(1)}&=c_{4}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}

\boldsymbol{\mathsf{E}}+\,c_{5}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:} (\boldsymbol{\mathsf{E}}

\boldsymbol{\cdot}

\boldsymbol{\mathsf{E}})+c_{6}(\boldsymbol{\mathsf{D}}_{(4)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\boldsymbol{:}\boldsymbol{\mathsf{E}}

+\,c_{7}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}}) \nonumber\\ &\quad

+c_{8}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}

(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})+c_{9}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}

\boldsymbol{\varOmega})+c_{10}(\boldsymbol{\varOmega:

\varOmega}),\end{align} \begin{align}

\boldsymbol{u}^{(1)}&=\tfrac{1}{2}\boldsymbol{x}p^{(1)}+c_{11}\boldsymbol{\mathsf{D}}_{(1)} \boldsymbol{\,\cdot\,\, \boldsymbol{\mathsf{E}}}+\, c_{12}\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{:}\boldsymbol{\mathsf{E}}\,+\,c_{13}( \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}}) \boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+c_{14}\boldsymbol{\mathsf{E}}\boldsymbol{\,\cdot}(\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}}) \nonumber\\ &\quad +c_{15}\boldsymbol{\mathsf{D}}_{(1)}(\boldsymbol{\mathsf{E}} \boldsymbol{:} \boldsymbol{\mathsf{E}})+c_{16}\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}}) +c_{17}\boldsymbol{\varOmega \cdot}\boldsymbol{\mathsf{D}}_{(1)}+c_{18}(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}) \boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)} \nonumber\\ &\quad +c_{19} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\varOmega}) \boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+\,c_{20}\boldsymbol{\varOmega \,\cdot}( \boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}})+c_{21}(\boldsymbol{\varOmega \cdot \varOmega})\boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+\,c_{22}(\boldsymbol{\varOmega : \varOmega} )\boldsymbol{\mathsf{D}}_{(1)}\nonumber\\

&\quad +c_{23}\boldsymbol{\mathsf{E}} \boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{D}}_{(5)})+c_{24} (\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{\,\cdot\, \varOmega} )\boldsymbol{: \varOmega}+\,c_{25} (\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{\,\cdot\, \varOmega} )\boldsymbol{:}\boldsymbol{\mathsf{E}}\!. \end{align}

\begin{align}

\boldsymbol{u}^{(1)}&=\tfrac{1}{2}\boldsymbol{x}p^{(1)}+c_{11}\boldsymbol{\mathsf{D}}_{(1)} \boldsymbol{\,\cdot\,\, \boldsymbol{\mathsf{E}}}+\, c_{12}\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{:}\boldsymbol{\mathsf{E}}\,+\,c_{13}( \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}}) \boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+c_{14}\boldsymbol{\mathsf{E}}\boldsymbol{\,\cdot}(\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}}) \nonumber\\ &\quad +c_{15}\boldsymbol{\mathsf{D}}_{(1)}(\boldsymbol{\mathsf{E}} \boldsymbol{:} \boldsymbol{\mathsf{E}})+c_{16}\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}}) +c_{17}\boldsymbol{\varOmega \cdot}\boldsymbol{\mathsf{D}}_{(1)}+c_{18}(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}) \boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)} \nonumber\\ &\quad +c_{19} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\varOmega}) \boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+\,c_{20}\boldsymbol{\varOmega \,\cdot}( \boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}})+c_{21}(\boldsymbol{\varOmega \cdot \varOmega})\boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+\,c_{22}(\boldsymbol{\varOmega : \varOmega} )\boldsymbol{\mathsf{D}}_{(1)}\nonumber\\

&\quad +c_{23}\boldsymbol{\mathsf{E}} \boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{D}}_{(5)})+c_{24} (\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{\,\cdot\, \varOmega} )\boldsymbol{: \varOmega}+\,c_{25} (\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{\,\cdot\, \varOmega} )\boldsymbol{:}\boldsymbol{\mathsf{E}}\!. \end{align}Similarly, the pressure and velocity fields in the inner fluid are,

\begin{align}

\hat{p}^{(1)}&=d_{4}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,d_{5}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})+d_{6}(\boldsymbol{\mathsf{G}}_{(4)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,d_{7}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})+d_{8}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:}

(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+d_{9}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{\cdot} \boldsymbol{\varOmega})+d_{10}(\boldsymbol{\varOmega:

\varOmega})+e_{4}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,e_{5}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:} (\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+e_{6}(\boldsymbol{\mathsf{D}}_{(4)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\boldsymbol{:}\boldsymbol{\mathsf{E}}

+\,e_{7}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})+e_{8}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}

(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+e_{9}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{\cdot} \boldsymbol{\varOmega})+e_{10}(\boldsymbol{\varOmega: \varOmega}),

\end{align}

\begin{align}

\hat{p}^{(1)}&=d_{4}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,d_{5}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})+d_{6}(\boldsymbol{\mathsf{G}}_{(4)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,d_{7}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})+d_{8}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:}

(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+d_{9}\boldsymbol{\mathsf{G}}_{(2)}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{\cdot} \boldsymbol{\varOmega})+d_{10}(\boldsymbol{\varOmega:

\varOmega})+e_{4}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,e_{5}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:} (\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+e_{6}(\boldsymbol{\mathsf{D}}_{(4)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\boldsymbol{:}\boldsymbol{\mathsf{E}}

+\,e_{7}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})+e_{8}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}

(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+e_{9}\boldsymbol{\mathsf{D}}_{(2)}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{\cdot} \boldsymbol{\varOmega})+e_{10}(\boldsymbol{\varOmega: \varOmega}),

\end{align} \begin{align}

\boldsymbol{\hat{u}}^{(1)}&=\frac{\lambda}{2}\boldsymbol{x}\hat{p}^{(1)}+d_{11}\boldsymbol{\mathsf{G}}_{(1)}

\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}+ d_{12}\boldsymbol{\mathsf{G}}_{(3)}

\boldsymbol{:}\boldsymbol{\mathsf{E}}+d_{13}( \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})

\boldsymbol{\cdot} \boldsymbol{\mathsf{G}}_{(1)}+d_{14}\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}(\boldsymbol{\mathsf{G}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\nonumber\\

&\quad +d_{15}\boldsymbol{\mathsf{G}}_{(1)}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})+d_{16}\boldsymbol{\mathsf{G}}_{(3)}\boldsymbol{:}(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})+d_{17}\boldsymbol{\varOmega

\cdot}\boldsymbol{\mathsf{G}}_{(1)}+d_{18}(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}) \boldsymbol{\cdot} \boldsymbol{\mathsf{G}}_{(1)}\nonumber\\ &\quad

+d_{19} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\varOmega}) \boldsymbol{\cdot}

\boldsymbol{\mathsf{G}}_{(1)}+\,d_{20}\boldsymbol{\varOmega \cdot}(

\boldsymbol{\mathsf{G}}_{(3)}\boldsymbol{:} \boldsymbol{\mathsf{E}})+d_{21}(\boldsymbol{\varOmega \cdot \varOmega}

)\boldsymbol{\cdot} \boldsymbol{\mathsf{G}}_{(1)}+\,c_{22}(\boldsymbol{\varOmega :

\varOmega} )\boldsymbol{\mathsf{G}}_{(1)}\nonumber\\ &\quad

+d_{23}\boldsymbol{\mathsf{E}}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{:} \boldsymbol{\mathsf{G}}_{(5)})+d_{24}

(\boldsymbol{\mathsf{G}}_{(3)} \boldsymbol{\,\cdot \,\varOmega}

)\boldsymbol{: \varOmega}+\,d_{25} (\boldsymbol{\mathsf{G}}_{(3)}

\boldsymbol{\,\cdot \,\varOmega} )\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,e_{11}\boldsymbol{\mathsf{D}}_{(1)} \boldsymbol{\cdot}\boldsymbol{\mathsf{E}}\nonumber\\ &\quad +e_{12}\boldsymbol{\mathsf{D}}_{(3)}

\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,e_{13}( \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})

\boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+e_{14}\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}(\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}})+e_{15}\boldsymbol{\mathsf{D}}_{(1)}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+e_{16}\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})+e_{17}\boldsymbol{\varOmega

\cdot}\boldsymbol{\mathsf{D}}_{(1)}+e_{18}(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}) \boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)}+\,e_{19} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\varOmega}) \boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)}\nonumber\\

&\quad +e_{20}\boldsymbol{\varOmega \cdot}(

\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:} \boldsymbol{\mathsf{E}})+e_{21}(\boldsymbol{\varOmega \cdot \varOmega}

)\boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)}+\,e_{22}(\boldsymbol{\varOmega :

\varOmega} )\boldsymbol{\mathsf{D}}_{(1)}+e_{23}\boldsymbol{\mathsf{E}}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{D}}_{(5)})\nonumber\\

&\quad

+e_{24} (\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{\,\cdot \, \varOmega}

)\boldsymbol{: \varOmega}+\,e_{25} (\boldsymbol{\mathsf{D}}_{(3)}

\boldsymbol{\,\cdot\, \varOmega} )\boldsymbol{:}\boldsymbol{\mathsf{E}},

\end{align}

\begin{align}

\boldsymbol{\hat{u}}^{(1)}&=\frac{\lambda}{2}\boldsymbol{x}\hat{p}^{(1)}+d_{11}\boldsymbol{\mathsf{G}}_{(1)}

\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}+ d_{12}\boldsymbol{\mathsf{G}}_{(3)}

\boldsymbol{:}\boldsymbol{\mathsf{E}}+d_{13}( \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})

\boldsymbol{\cdot} \boldsymbol{\mathsf{G}}_{(1)}+d_{14}\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}(\boldsymbol{\mathsf{G}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}})\nonumber\\

&\quad +d_{15}\boldsymbol{\mathsf{G}}_{(1)}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})+d_{16}\boldsymbol{\mathsf{G}}_{(3)}\boldsymbol{:}(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})+d_{17}\boldsymbol{\varOmega

\cdot}\boldsymbol{\mathsf{G}}_{(1)}+d_{18}(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}) \boldsymbol{\cdot} \boldsymbol{\mathsf{G}}_{(1)}\nonumber\\ &\quad

+d_{19} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\varOmega}) \boldsymbol{\cdot}

\boldsymbol{\mathsf{G}}_{(1)}+\,d_{20}\boldsymbol{\varOmega \cdot}(

\boldsymbol{\mathsf{G}}_{(3)}\boldsymbol{:} \boldsymbol{\mathsf{E}})+d_{21}(\boldsymbol{\varOmega \cdot \varOmega}

)\boldsymbol{\cdot} \boldsymbol{\mathsf{G}}_{(1)}+\,c_{22}(\boldsymbol{\varOmega :

\varOmega} )\boldsymbol{\mathsf{G}}_{(1)}\nonumber\\ &\quad

+d_{23}\boldsymbol{\mathsf{E}}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{:} \boldsymbol{\mathsf{G}}_{(5)})+d_{24}

(\boldsymbol{\mathsf{G}}_{(3)} \boldsymbol{\,\cdot \,\varOmega}

)\boldsymbol{: \varOmega}+\,d_{25} (\boldsymbol{\mathsf{G}}_{(3)}

\boldsymbol{\,\cdot \,\varOmega} )\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,e_{11}\boldsymbol{\mathsf{D}}_{(1)} \boldsymbol{\cdot}\boldsymbol{\mathsf{E}}\nonumber\\ &\quad +e_{12}\boldsymbol{\mathsf{D}}_{(3)}

\boldsymbol{:}\boldsymbol{\mathsf{E}}+\,e_{13}( \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})

\boldsymbol{\cdot} \boldsymbol{\mathsf{D}}_{(1)}+e_{14}\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}(\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}\boldsymbol{\mathsf{E}})+e_{15}\boldsymbol{\mathsf{D}}_{(1)}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}})\nonumber\\ &\quad

+e_{16}\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:}(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})+e_{17}\boldsymbol{\varOmega

\cdot}\boldsymbol{\mathsf{D}}_{(1)}+e_{18}(\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}}) \boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)}+\,e_{19} (\boldsymbol{\mathsf{E}}\boldsymbol{\cdot}\boldsymbol{\varOmega}) \boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)}\nonumber\\

&\quad +e_{20}\boldsymbol{\varOmega \cdot}(

\boldsymbol{\mathsf{D}}_{(3)}\boldsymbol{:} \boldsymbol{\mathsf{E}})+e_{21}(\boldsymbol{\varOmega \cdot \varOmega}

)\boldsymbol{\cdot}\boldsymbol{\mathsf{D}}_{(1)}+\,e_{22}(\boldsymbol{\varOmega :

\varOmega} )\boldsymbol{\mathsf{D}}_{(1)}+e_{23}\boldsymbol{\mathsf{E}}\boldsymbol{:}(\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{D}}_{(5)})\nonumber\\

&\quad

+e_{24} (\boldsymbol{\mathsf{D}}_{(3)} \boldsymbol{\,\cdot \, \varOmega}

)\boldsymbol{: \varOmega}+\,e_{25} (\boldsymbol{\mathsf{D}}_{(3)}

\boldsymbol{\,\cdot\, \varOmega} )\boldsymbol{:}\boldsymbol{\mathsf{E}},

\end{align}

where ![]() $c_{i}$,

$c_{i}$, ![]() $d_{i}$ and

$d_{i}$ and ![]() $e_{i}$ for

$e_{i}$ for ![]() $i=4 \text { to } 25$ are the constants determined from the boundary conditions as follows. As earlier, the shape function

$i=4 \text { to } 25$ are the constants determined from the boundary conditions as follows. As earlier, the shape function ![]() $f^{(1)}$ may be expressed as quadratic combinations of

$f^{(1)}$ may be expressed as quadratic combinations of ![]() $\boldsymbol{\mathsf{E}}$ and

$\boldsymbol{\mathsf{E}}$ and ![]() $\boldsymbol{\varOmega }$ as,

$\boldsymbol{\varOmega }$ as,

\begin{align}

f^{(1)}&=b_{2}\frac{\boldsymbol{x} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot}

\boldsymbol{x}}{r^2}+b_{3}\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}}+b_{4}\frac{\boldsymbol{x}

\boldsymbol{\cdot} (\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}}) \boldsymbol{\cdot} \boldsymbol{x}}{r^2}+b_{5}\frac{(\boldsymbol{x}

\boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot}

\boldsymbol{x})^{2}}{r^{4}} \nonumber\\ & \quad +b_{6}

\frac{\boldsymbol{x \cdot (\varOmega \cdot \boldsymbol{\mathsf{E}})

\cdot x}}{r^2} +b_{7} \boldsymbol{\varOmega :

\varOmega}+b_{8}\frac{\boldsymbol{x \cdot (\varOmega \cdot

\varOmega) \cdot x}}{r^2},

\end{align}

\begin{align}

f^{(1)}&=b_{2}\frac{\boldsymbol{x} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot}

\boldsymbol{x}}{r^2}+b_{3}\boldsymbol{\mathsf{E}}\boldsymbol{:}\boldsymbol{\mathsf{E}}+b_{4}\frac{\boldsymbol{x}

\boldsymbol{\cdot} (\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}}) \boldsymbol{\cdot} \boldsymbol{x}}{r^2}+b_{5}\frac{(\boldsymbol{x}

\boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot}

\boldsymbol{x})^{2}}{r^{4}} \nonumber\\ & \quad +b_{6}

\frac{\boldsymbol{x \cdot (\varOmega \cdot \boldsymbol{\mathsf{E}})

\cdot x}}{r^2} +b_{7} \boldsymbol{\varOmega :

\varOmega}+b_{8}\frac{\boldsymbol{x \cdot (\varOmega \cdot

\varOmega) \cdot x}}{r^2},

\end{align}

where ![]() $b_{j}$,

$b_{j}$, ![]() $j=2 \text { to } 8$ are unknown constants. In other words, we have seven additional constants along with

$j=2 \text { to } 8$ are unknown constants. In other words, we have seven additional constants along with ![]() $b_{1}$ discussed in the previous section to describe the deformed drop shape. As the volume of the inner fluid in the compound particle should remain constant,

$b_{1}$ discussed in the previous section to describe the deformed drop shape. As the volume of the inner fluid in the compound particle should remain constant,

where ![]() $S_{D}$ and

$S_{D}$ and ![]() $S_{P}$ are the surfaces of the confining drop and the encapsulated particle, respectively. Simplifying (3.17), we get

$S_{P}$ are the surfaces of the confining drop and the encapsulated particle, respectively. Simplifying (3.17), we get

and this gives the following relations between the constants describing the interface

Enforcing the equation of continuity on the velocity field results additional relations between the unknown constants,

\begin{align} \left. \begin{aligned} c_{6}={-}c_{14},\enspace c_{7}=0,\enspace c_{10}=0, \enspace c_{11}=0, \enspace c_{13}=0, \enspace c_{18}=c_{19},\enspace c_{21}=0,\\ \displaystyle\lambda d_{4}={-}\dfrac{126 d_{12}}{5},\enspace \lambda d_{6}={-}\dfrac{110 d_{23}}{7},\enspace \lambda d_{9}={-}\dfrac{42d_{24}}{5}, \enspace -\dfrac{5\lambda d_{5}}{2}+6d_{14}+21d_{16}=0,\\ \displaystyle\dfrac{3 \lambda d_{7}}{2}+d_{13}+3d_{15}=0, \enspace \dfrac{3 \lambda d_{10}}{2}+3d_{22}-d_{21}=0, \enspace \dfrac{5 \lambda d_{8}}{2}+14d_{20}+21d_{25}=0,\\ \lambda e_{6}={-}e_{14},\enspace e_{7}=0, \enspace e_{10}=0, \enspace e_{11}=0, \enspace e_{13}=0, \enspace e_{18}=e_{19},\enspace e_{21}=0. \end{aligned} \right\} \end{align}

\begin{align} \left. \begin{aligned} c_{6}={-}c_{14},\enspace c_{7}=0,\enspace c_{10}=0, \enspace c_{11}=0, \enspace c_{13}=0, \enspace c_{18}=c_{19},\enspace c_{21}=0,\\ \displaystyle\lambda d_{4}={-}\dfrac{126 d_{12}}{5},\enspace \lambda d_{6}={-}\dfrac{110 d_{23}}{7},\enspace \lambda d_{9}={-}\dfrac{42d_{24}}{5}, \enspace -\dfrac{5\lambda d_{5}}{2}+6d_{14}+21d_{16}=0,\\ \displaystyle\dfrac{3 \lambda d_{7}}{2}+d_{13}+3d_{15}=0, \enspace \dfrac{3 \lambda d_{10}}{2}+3d_{22}-d_{21}=0, \enspace \dfrac{5 \lambda d_{8}}{2}+14d_{20}+21d_{25}=0,\\ \lambda e_{6}={-}e_{14},\enspace e_{7}=0, \enspace e_{10}=0, \enspace e_{11}=0, \enspace e_{13}=0, \enspace e_{18}=e_{19},\enspace e_{21}=0. \end{aligned} \right\} \end{align}

In order to impose the continuity in velocity and stress boundary conditions on the deformed interface, we evaluate those quantities at ![]() $r = (1+Ca f^{(0)})$ as,

$r = (1+Ca f^{(0)})$ as,

\begin{align} \left. \begin{aligned} (\boldsymbol{u}|_{r= (1+Ca f^{(0)})})^{(1)}=\boldsymbol{u}^{(1)}|_{r=1}+ f^{(0)} \boldsymbol{\nabla} \boldsymbol{u}^{(0)} \boldsymbol{\cdot} \boldsymbol{x}|_{r=1} ,\\ (\boldsymbol{\sigma} \boldsymbol{\cdot} \boldsymbol{n} )^{(1)}_{r= (1+Ca f^{(0)})} =\boldsymbol{\sigma}^{(1)}|_{r=1} \boldsymbol{\cdot} \boldsymbol{n}^{(0)}+\boldsymbol{\sigma}^{(0)}|_{r=1} \boldsymbol{\cdot} \boldsymbol{n}^{(1)} + f^{(0)}( \boldsymbol{\nabla} \boldsymbol{\sigma}^{(0)} \boldsymbol{\cdot} \boldsymbol{x}|_{r=1} ) \boldsymbol{\cdot} \boldsymbol{n}^{(0)}. \end{aligned} \right\} \end{align}

\begin{align} \left. \begin{aligned} (\boldsymbol{u}|_{r= (1+Ca f^{(0)})})^{(1)}=\boldsymbol{u}^{(1)}|_{r=1}+ f^{(0)} \boldsymbol{\nabla} \boldsymbol{u}^{(0)} \boldsymbol{\cdot} \boldsymbol{x}|_{r=1} ,\\ (\boldsymbol{\sigma} \boldsymbol{\cdot} \boldsymbol{n} )^{(1)}_{r= (1+Ca f^{(0)})} =\boldsymbol{\sigma}^{(1)}|_{r=1} \boldsymbol{\cdot} \boldsymbol{n}^{(0)}+\boldsymbol{\sigma}^{(0)}|_{r=1} \boldsymbol{\cdot} \boldsymbol{n}^{(1)} + f^{(0)}( \boldsymbol{\nabla} \boldsymbol{\sigma}^{(0)} \boldsymbol{\cdot} \boldsymbol{x}|_{r=1} ) \boldsymbol{\cdot} \boldsymbol{n}^{(0)}. \end{aligned} \right\} \end{align}

From (2.9), (2.10) and (3.16), we obtain the normal vector ![]() $\boldsymbol{n}^{(1)}$ and the curvature of the interface

$\boldsymbol{n}^{(1)}$ and the curvature of the interface ![]() $(\boldsymbol {\nabla } \boldsymbol{\,\cdot\, n})^{(2)}$ at

$(\boldsymbol {\nabla } \boldsymbol{\,\cdot\, n})^{(2)}$ at ![]() ${O}(Ca)$ as

${O}(Ca)$ as

and

\begin{align} (\boldsymbol{\nabla}

\boldsymbol{\,\cdot\, n})^{(2)}&= 2((f^{(0)})^{2}-f^{(1)})-(

\nabla^{2} f)^{(1)}-(\boldsymbol{\nabla} f^{(0)} )^{2}

-\boldsymbol{x \,\cdot\,}( \boldsymbol{\nabla} f^{(0)}

\boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{\nabla}

f^{(0)} ) \nonumber\\ &=({-}10b_{1}^{2}+18b_{5})(

\boldsymbol{x} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{x} )^{2}+4b_{2} \boldsymbol{x}

\boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{x} -(2b_3+2b_4) \boldsymbol{\mathsf{E}} \boldsymbol{:}\boldsymbol{\mathsf{E}}

\nonumber\\ &\quad + (4b_{4}-8b_{5}) \boldsymbol{x \,\cdot }

(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})\boldsymbol{ \cdot\, x}+\,4b_{6}

\boldsymbol{x \,\cdot } (\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})\boldsymbol{ \cdot\,

x}\,-(2b_{7}+2b_{8})\boldsymbol{\varOmega : \varOmega}

\nonumber\\ &\quad +4b_{8} \boldsymbol{x \,\cdot }

(\boldsymbol{\varOmega \cdot \varOmega})\boldsymbol{ \,\cdot \,

x}, \end{align}

\begin{align} (\boldsymbol{\nabla}

\boldsymbol{\,\cdot\, n})^{(2)}&= 2((f^{(0)})^{2}-f^{(1)})-(

\nabla^{2} f)^{(1)}-(\boldsymbol{\nabla} f^{(0)} )^{2}

-\boldsymbol{x \,\cdot\,}( \boldsymbol{\nabla} f^{(0)}

\boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{\nabla}

f^{(0)} ) \nonumber\\ &=({-}10b_{1}^{2}+18b_{5})(

\boldsymbol{x} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{x} )^{2}+4b_{2} \boldsymbol{x}

\boldsymbol{\cdot} \boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{x} -(2b_3+2b_4) \boldsymbol{\mathsf{E}} \boldsymbol{:}\boldsymbol{\mathsf{E}}

\nonumber\\ &\quad + (4b_{4}-8b_{5}) \boldsymbol{x \,\cdot }

(\boldsymbol{\mathsf{E}} \boldsymbol{\cdot} \boldsymbol{\mathsf{E}})\boldsymbol{ \cdot\, x}+\,4b_{6}

\boldsymbol{x \,\cdot } (\boldsymbol{\varOmega}\boldsymbol{\cdot}\boldsymbol{\mathsf{E}})\boldsymbol{ \cdot\,

x}\,-(2b_{7}+2b_{8})\boldsymbol{\varOmega : \varOmega}

\nonumber\\ &\quad +4b_{8} \boldsymbol{x \,\cdot }

(\boldsymbol{\varOmega \cdot \varOmega})\boldsymbol{ \,\cdot \,

x}, \end{align}

respectively. The system of equations obtained by imposing the boundary conditions are given in Appendix B. In the limit ![]() $\alpha \to \infty$, the expressions for the constants (refer (B16)–(B30) in Appendix B) are consistent with the

$\alpha \to \infty$, the expressions for the constants (refer (B16)–(B30) in Appendix B) are consistent with the ![]() ${O}(Ca)$ calculations for a drop (Ramachandran & Leal Reference Ramachandran and Leal2012). As done earlier, the kinematic boundary condition may be used to evaluate the shape function,

${O}(Ca)$ calculations for a drop (Ramachandran & Leal Reference Ramachandran and Leal2012). As done earlier, the kinematic boundary condition may be used to evaluate the shape function, ![]() $f^{(1)}$ as,

$f^{(1)}$ as,

which further reduces to the description of temporal evolution of the deformed interface as,

Here, the variables ![]() $c_i$ are linear functions of

$c_i$ are linear functions of ![]() $b_j$ where

$b_j$ where ![]() $j$ varies from

$j$ varies from ![]() $2$ to

$2$ to ![]() $8$. We solve the above set of (3.25a)–(3.25e) along with (3.19a,b) to obtain the shape parameters

$8$. We solve the above set of (3.25a)–(3.25e) along with (3.19a,b) to obtain the shape parameters ![]() $b_{j}$. The temporal evolution of the shape is illustrated using plots in the next section and the steady state shape values of

$b_{j}$. The temporal evolution of the shape is illustrated using plots in the next section and the steady state shape values of ![]() $b_{j}$ are given in Appendix C. The expressions for the shape functions in the limit

$b_{j}$ are given in Appendix C. The expressions for the shape functions in the limit ![]() $\alpha \to \infty$ are also given in Appendix C (refer (C2)–(C7)), they are consistent with the calculations for a drop (Ramachandran & Leal Reference Ramachandran and Leal2012).

$\alpha \to \infty$ are also given in Appendix C (refer (C2)–(C7)), they are consistent with the calculations for a drop (Ramachandran & Leal Reference Ramachandran and Leal2012).

Hence, using a domain perturbation approach and standard technique of superposition of vector harmonics, we calculated the pressure and velocity fields up to ![]() ${O}(Ca)$ in both inner and outer fluids for a compound particle when subjected to an imposed linear flow. Along with these, we determined the time evolution of the deforming interface of the confining drop up to

${O}(Ca)$ in both inner and outer fluids for a compound particle when subjected to an imposed linear flow. Along with these, we determined the time evolution of the deforming interface of the confining drop up to ![]() ${O}(Ca^2)$. These solutions are illustrated in the next section for various linear flows.

${O}(Ca^2)$. These solutions are illustrated in the next section for various linear flows.

4. Deformation dynamics of a compound particle in a general linear flow

In the previous section, we described the ![]() ${O}(1)$ flow field (Chaithanya & Thampi Reference Chaithanya and Thampi2019), and then derived the

${O}(1)$ flow field (Chaithanya & Thampi Reference Chaithanya and Thampi2019), and then derived the ![]() ${O}(Ca)$ flow field generated by a compound particle and the corresponding consequences, namely the

${O}(Ca)$ flow field generated by a compound particle and the corresponding consequences, namely the ![]() ${O}(Ca)$ and

${O}(Ca)$ and ![]() ${O}(Ca^2)$ corrections to the confining drop shape. We now analyse these results for different linear flows (i) a simple shear flow, and (ii) extensional (both uniaxial and biaxial) flows. We then expand the discussion on interface deformation dynamics for generalised shear and generalised extensional flows in this section.

${O}(Ca^2)$ corrections to the confining drop shape. We now analyse these results for different linear flows (i) a simple shear flow, and (ii) extensional (both uniaxial and biaxial) flows. We then expand the discussion on interface deformation dynamics for generalised shear and generalised extensional flows in this section.

4.1. Simple shear flow

Consider a simple shear flow of the form ![]() $\boldsymbol{u}= x_{2} \boldsymbol {i}_{1}$, where

$\boldsymbol{u}= x_{2} \boldsymbol {i}_{1}$, where ![]() $x_{2}$ is the component of position vector

$x_{2}$ is the component of position vector ![]() $\boldsymbol{x}$ and

$\boldsymbol{x}$ and ![]() $i_{1}$ is the unit normal vector associated with

$i_{1}$ is the unit normal vector associated with ![]() $x_{1}$ in the chosen coordinate system. The symmetric and anti-symmetric parts of the velocity gradient tensor of the imposed flow are,

$x_{1}$ in the chosen coordinate system. The symmetric and anti-symmetric parts of the velocity gradient tensor of the imposed flow are,

\begin{equation} \boldsymbol{\mathsf{E}}^{S}=\frac{1}{2}\begin{bmatrix} 0 & 1 & 0 \\ 1 & 0 & 0\\ 0 & 0 & 0 \end{bmatrix}, \quad \boldsymbol{\varOmega}^{S}=\frac{1}{2}\begin{bmatrix} 0 & 1 & 0 \\ -1 & 0 & 0\\ 0 & 0 & 0 \end{bmatrix}. \end{equation}

\begin{equation} \boldsymbol{\mathsf{E}}^{S}=\frac{1}{2}\begin{bmatrix} 0 & 1 & 0 \\ 1 & 0 & 0\\ 0 & 0 & 0 \end{bmatrix}, \quad \boldsymbol{\varOmega}^{S}=\frac{1}{2}\begin{bmatrix} 0 & 1 & 0 \\ -1 & 0 & 0\\ 0 & 0 & 0 \end{bmatrix}. \end{equation}Using (4.1a,b), the shape of the confining drop may be obtained as,

\begin{align} r(\theta, \phi)&=\left(1+ b_{1} Ca\left(\frac{x_{1}x_{2}}{r^{2}} \right)+Ca^{2}\left(b_{2}\frac{x_{1}x_{2}}{r^{2}}+\frac{b_{3}-b_{7}}{2} +\frac{b_{4}-b_{8}}{4}\left(\frac{x_{1}^{2}+x_{2}^{2}}{r^{2}}\right) \right.\right.\nonumber\\ & \quad \left.\left.+b_{5}\frac{x_{1}^{2}x_{2}^{2}}{r^{4}}+\frac{b_{6}}{4} \left(\frac{x_{1}^{2}-x_{2}^{2}}{r^{2}}\right)\right)+O(Ca^3)\right), \end{align}

\begin{align} r(\theta, \phi)&=\left(1+ b_{1} Ca\left(\frac{x_{1}x_{2}}{r^{2}} \right)+Ca^{2}\left(b_{2}\frac{x_{1}x_{2}}{r^{2}}+\frac{b_{3}-b_{7}}{2} +\frac{b_{4}-b_{8}}{4}\left(\frac{x_{1}^{2}+x_{2}^{2}}{r^{2}}\right) \right.\right.\nonumber\\ & \quad \left.\left.+b_{5}\frac{x_{1}^{2}x_{2}^{2}}{r^{4}}+\frac{b_{6}}{4} \left(\frac{x_{1}^{2}-x_{2}^{2}}{r^{2}}\right)\right)+O(Ca^3)\right), \end{align}

where ![]() $x_{1}=r\sin {\theta }\cos {\phi }$,

$x_{1}=r\sin {\theta }\cos {\phi }$, ![]() $x_{2}=r\sin {\theta }\sin {\phi }$ and

$x_{2}=r\sin {\theta }\sin {\phi }$ and ![]() $x_{3}=r\cos {\theta }$,

$x_{3}=r\cos {\theta }$, ![]() $r$ is the magnitude of the position vector

$r$ is the magnitude of the position vector ![]() $\boldsymbol{x}$,

$\boldsymbol{x}$, ![]() $\theta$ is the polar angle measured from the

$\theta$ is the polar angle measured from the ![]() $x_{3}$ axis (

$x_{3}$ axis (![]() $0\leq \theta \leq {\rm \pi}$) and

$0\leq \theta \leq {\rm \pi}$) and ![]() $\phi$ is the azimuthal angle measured around the

$\phi$ is the azimuthal angle measured around the ![]() $x_3$ axis (

$x_3$ axis (![]() $0 \leq \phi \leq 2{\rm \pi}$).

$0 \leq \phi \leq 2{\rm \pi}$).

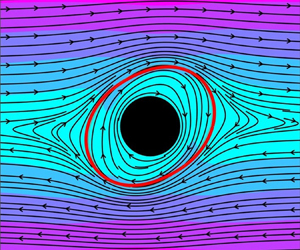

The steady state flow fields in and around a deformed compound particle are illustrated in figure 2(a). Equations (A2), (A4), (B2), (B4) and (C1) have been used to calculate the velocity field and the corresponding confining drop shape. For comparison, ![]() ${O}(1)$ velocity field is shown in figure 2(b) (Chaithanya & Thampi Reference Chaithanya and Thampi2019). In the imposed simple shear flow, the encapsulated rigid particle rotates with an angular velocity

${O}(1)$ velocity field is shown in figure 2(b) (Chaithanya & Thampi Reference Chaithanya and Thampi2019). In the imposed simple shear flow, the encapsulated rigid particle rotates with an angular velocity ![]() $\mathcal {G}/2$, and the curved streamlines inside the confining drop illustrate the recirculating fluid flow around this rotating rigid particle. Similarly, the outer fluid close to the interface also has curved streamlines. However, compared to that of a spherical compound particle (figure 2b) or a particle without a confining drop (Sadhal et al. Reference Sadhal, Ayyaswamy and Chung1997; Leal Reference Leal2007), the streamlines around the compound particle show distortions corresponding to the deformed interface.

$\mathcal {G}/2$, and the curved streamlines inside the confining drop illustrate the recirculating fluid flow around this rotating rigid particle. Similarly, the outer fluid close to the interface also has curved streamlines. However, compared to that of a spherical compound particle (figure 2b) or a particle without a confining drop (Sadhal et al. Reference Sadhal, Ayyaswamy and Chung1997; Leal Reference Leal2007), the streamlines around the compound particle show distortions corresponding to the deformed interface.

Figure 2. (a) Velocity field, represented as streamlines, in and around a compound particle in an imposed shear flow in the flow–gradient (![]() $x_{1}$–

$x_{1}$–![]() $x_{2}$) plane, for

$x_{2}$) plane, for ![]() $\alpha =2$,

$\alpha =2$, ![]() $Ca=0.1$ and

$Ca=0.1$ and ![]() $\lambda =1$. The

$\lambda =1$. The ![]() ${O}(1)$ flow field is shown in (b) for comparison. The colour field shows the magnitude of velocity. The filled circle is the encapsulated solid particle and the solid red line shows the confining drop interface.

${O}(1)$ flow field is shown in (b) for comparison. The colour field shows the magnitude of velocity. The filled circle is the encapsulated solid particle and the solid red line shows the confining drop interface.

Now we proceed to analyse the confining drop shape and its evolution. The time evolution of the confining drop shape (up to ![]() ${O}(Ca^{2})$) in a simple shear flow for

${O}(Ca^{2})$) in a simple shear flow for ![]() $\alpha =2$,

$\alpha =2$, ![]() $\lambda =1$ and

$\lambda =1$ and ![]() $Ca=0.2$ is depicted in figure 3(a). At

$Ca=0.2$ is depicted in figure 3(a). At ![]() $t=0$, the confining drop is spherical, but the imposed flow deforms the interface with time. Finally, the confining drop attains a steady shape that is elongated in a direction close to the extensional axis of the imposed flow and compressed in the orthogonal direction.

$t=0$, the confining drop is spherical, but the imposed flow deforms the interface with time. Finally, the confining drop attains a steady shape that is elongated in a direction close to the extensional axis of the imposed flow and compressed in the orthogonal direction.

Figure 3. The time evolution of (a) the confining drop shape in a simple shear flow for ![]() $\lambda =1$,

$\lambda =1$, ![]() $\alpha =2$ and

$\alpha =2$ and ![]() $Ca=0.2$ (equations (3.6), (3.25) along with (3.19a,b)). The black patch at the centre indicates the encapsulated solid particle. (b) The deformation parameter

$Ca=0.2$ (equations (3.6), (3.25) along with (3.19a,b)). The black patch at the centre indicates the encapsulated solid particle. (b) The deformation parameter ![]() $\mathcal {D}$ determined by (4.3), and (c) the alignment angle

$\mathcal {D}$ determined by (4.3), and (c) the alignment angle ![]() $\varphi$, for various size ratios

$\varphi$, for various size ratios ![]() $\alpha$ and viscosity ratios

$\alpha$ and viscosity ratios ![]() $\lambda$. The solid lines correspond to

$\lambda$. The solid lines correspond to ![]() $\mathcal {D}$ (and

$\mathcal {D}$ (and ![]() $\varphi$) obtained for various

$\varphi$) obtained for various ![]() $\alpha$ and the dotted lines correspond to those obtained for various

$\alpha$ and the dotted lines correspond to those obtained for various ![]() $\lambda$.

$\lambda$.

Similar to the deformation parameter defined by Taylor (Reference Taylor1932) to analyse the shape of drops, we define a deformation parameter ![]() $\mathcal {D}$ as

$\mathcal {D}$ as

that quantifies the extent of deformation of the compound particle as done in Chaithanya & Thampi (Reference Chaithanya and Thampi2019). Here, ![]() $r_{max}$ and

$r_{max}$ and ![]() $r_{min}$ are the longest and shortest dimensions of the deformed interface as shown in figure 1. The limits,

$r_{min}$ are the longest and shortest dimensions of the deformed interface as shown in figure 1. The limits, ![]() $\mathcal {D}=0$ and

$\mathcal {D}=0$ and ![]() $\mathcal {D}=1$ respectively correspond to the case of an undeformed spherical interface and the case where the confining interface touches the encapsulated solid particle. The latter case can be regarded as the onset of break-up of the confining drop since the interface comes into contact with the encapsulated solid particle. Therefore, unlike that of a simple drop, large values of deformation parameter do not necessarily mean a large deformation of the confining drop. This is especially the case in the limit

$\mathcal {D}=1$ respectively correspond to the case of an undeformed spherical interface and the case where the confining interface touches the encapsulated solid particle. The latter case can be regarded as the onset of break-up of the confining drop since the interface comes into contact with the encapsulated solid particle. Therefore, unlike that of a simple drop, large values of deformation parameter do not necessarily mean a large deformation of the confining drop. This is especially the case in the limit ![]() $\alpha \to 1$. In other words, in the limit

$\alpha \to 1$. In other words, in the limit ![]() $\alpha \to 1$, breakup (

$\alpha \to 1$, breakup (![]() $\mathcal {D} = 1$) may occur even with a weak deformation of the confining drop, and therefore the perturbation approach used in this work remains valid all the way up to the confining drop breakup.

$\mathcal {D} = 1$) may occur even with a weak deformation of the confining drop, and therefore the perturbation approach used in this work remains valid all the way up to the confining drop breakup.

The time evolution of deformation parameter ![]() $\mathcal {D}$ for

$\mathcal {D}$ for ![]() $Ca=0.2$ but for various values of

$Ca=0.2$ but for various values of ![]() $\alpha$ and

$\alpha$ and ![]() $\lambda$ are plotted in figure 3(b). In all cases,

$\lambda$ are plotted in figure 3(b). In all cases, ![]() $\mathcal {D}$ increases with time indicating the progression of deformation. Finally

$\mathcal {D}$ increases with time indicating the progression of deformation. Finally ![]() $\mathcal {D}$ reaches a plateau corresponding to the steady state shape of the confining drop. In some cases,

$\mathcal {D}$ reaches a plateau corresponding to the steady state shape of the confining drop. In some cases, ![]() $\mathcal {D}$ reaches

$\mathcal {D}$ reaches ![]() $1$ representing the break up of the confining interface. Of course the progression of deformation and the final value of

$1$ representing the break up of the confining interface. Of course the progression of deformation and the final value of ![]() $\mathcal {D}$ depend upon the particular values of

$\mathcal {D}$ depend upon the particular values of ![]() $\alpha$ and

$\alpha$ and ![]() $\lambda$, and this dependence is discussed later in this section.

$\lambda$, and this dependence is discussed later in this section.

Another consequence of calculations at ![]() ${O}(Ca^2)$ is its ability to predict the orientation of the elongated interface in a simple shear flow. The

${O}(Ca^2)$ is its ability to predict the orientation of the elongated interface in a simple shear flow. The ![]() ${O}(Ca)$ correction to the confining drop shape shows that the elongated direction of the confining drop aligns with the extensional axis of the flow, i.e.

${O}(Ca)$ correction to the confining drop shape shows that the elongated direction of the confining drop aligns with the extensional axis of the flow, i.e. ![]() $45^\circ$ with the flow direction in the flow–gradient plane as reported in Chaithanya & Thampi (Reference Chaithanya and Thampi2019). However,

$45^\circ$ with the flow direction in the flow–gradient plane as reported in Chaithanya & Thampi (Reference Chaithanya and Thampi2019). However, ![]() ${O}(Ca^2)$ calculation takes into account the effect of vorticity of the imposed flow, which then predicts that the elongated interface does not orient along the extensional axis of the imposed flow. We define an alignment angle

${O}(Ca^2)$ calculation takes into account the effect of vorticity of the imposed flow, which then predicts that the elongated interface does not orient along the extensional axis of the imposed flow. We define an alignment angle ![]() $\varphi$, as shown in figure 1, as the angle between the elongated direction of the confining drop and the flow direction (

$\varphi$, as shown in figure 1, as the angle between the elongated direction of the confining drop and the flow direction (![]() $x_1$) in a simple shear flow.

$x_1$) in a simple shear flow.

The time evolution of alignment angle ![]() $\varphi$ at

$\varphi$ at ![]() $Ca=0.2$ for various values of

$Ca=0.2$ for various values of ![]() $\alpha$ and

$\alpha$ and ![]() $\lambda$ is plotted in figure 3(c). The alignment angle

$\lambda$ is plotted in figure 3(c). The alignment angle ![]() $\varphi$ decreases with time before reaching a steady value, indicating that the deformed drop rotates towards the flow direction as dictated by the imposed vorticity, finally attaining an orientation that is in between the flow direction and the extensional axis of the imposed shear flow.

$\varphi$ decreases with time before reaching a steady value, indicating that the deformed drop rotates towards the flow direction as dictated by the imposed vorticity, finally attaining an orientation that is in between the flow direction and the extensional axis of the imposed shear flow.

The extent of deformation of the confining interface of the compound particle that resulted from the imposed shear flow is different in different directions. The steady state shape of the confining drop (see (4.2)), when viewed in three different planes, namely the flow–gradient (![]() $x_{1}$–

$x_{1}$–![]() $x_{2}$), flow–vorticity (

$x_{2}$), flow–vorticity (![]() $x_{1}$–

$x_{1}$–![]() $x_{3}$) and gradient–vorticity (

$x_{3}$) and gradient–vorticity (![]() $x_{2}$–

$x_{2}$–![]() $x_{3}$) planes are shown in figures 4(a)–4(c). The interface deformation is largest in the flow–gradient plane with the confining drop elongated in a direction described by

$x_{3}$) planes are shown in figures 4(a)–4(c). The interface deformation is largest in the flow–gradient plane with the confining drop elongated in a direction described by ![]() $\varphi$. Confining drop is lesser deformed in the flow–vorticity plane and the gradient–vorticity plane, with the interface elongated in the flow direction in the former and compressed along the vorticity direction in the latter.

$\varphi$. Confining drop is lesser deformed in the flow–vorticity plane and the gradient–vorticity plane, with the interface elongated in the flow direction in the former and compressed along the vorticity direction in the latter.

Figure 4. The deformed shape (see (4.2)) of the confining drop viewed from various planes: (a) in flow–gradient (![]() $x_{1}$–

$x_{1}$–![]() $x_{2}$) plane, (b) in flow–vorticity (

$x_{2}$) plane, (b) in flow–vorticity (![]() $x_{1}$–

$x_{1}$–![]() $x_{3}$) plane and (c) in gradient–vorticity (

$x_{3}$) plane and (c) in gradient–vorticity (![]() $x_{2}$–

$x_{2}$–![]() $x_{3}$) plane for different capillary numbers. The dashed line represents the initial, undeformed shape of the confining drop and the filled circle is the encapsulated solid particle.

$x_{3}$) plane for different capillary numbers. The dashed line represents the initial, undeformed shape of the confining drop and the filled circle is the encapsulated solid particle.

Figures 4(a)–4(c) also illustrate the deformed shape of the confining drop for various capillary numbers. Increase in ![]() $Ca$ signifies increasingly dominant shear force over the resisting interfacial tension and, therefore, the extent of deformation of the confining interface increases with increase in

$Ca$ signifies increasingly dominant shear force over the resisting interfacial tension and, therefore, the extent of deformation of the confining interface increases with increase in ![]() $Ca$. This is evident from the confining drop shapes shown in various planes (figures 4(a)–4(c)). For the largest capillary number

$Ca$. This is evident from the confining drop shapes shown in various planes (figures 4(a)–4(c)). For the largest capillary number ![]() $Ca = 0.3$ considered in this figure, dimples form on the interface, as evident in the flow–gradient plane (figure 4a). The extent of compression of the interface is not same in all directions, with the maximum compression observed along the vorticity direction. Incidentally, in this particular case, the deformed interface comes in contact with the encapsulated solid particle (figure 4c) and marks the break up of the confining drop.

$Ca = 0.3$ considered in this figure, dimples form on the interface, as evident in the flow–gradient plane (figure 4a). The extent of compression of the interface is not same in all directions, with the maximum compression observed along the vorticity direction. Incidentally, in this particular case, the deformed interface comes in contact with the encapsulated solid particle (figure 4c) and marks the break up of the confining drop.

The extent of deformation of the confining drop is mainly dependent upon the three non-dimensional numbers, namely the capillary number ![]() $Ca$, the size ratio

$Ca$, the size ratio ![]() $\alpha$ and the viscosity ratio