Article contents

Controlling secondary flows in Taylor–Couette flow using stress-free boundary conditions

Published online by Cambridge University Press: 09 July 2021

Abstract

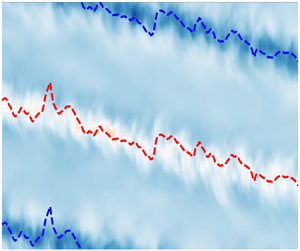

Taylor–Couette (TC) flow, the flow between two independently rotating and co-axial cylinders, is commonly used as a canonical model for shear flows. Unlike plane Couette flow, pinned secondary flows can be found in TC flow. These are known as Taylor rolls and drastically affect the flow behaviour. We study the possibility of modifying these secondary structures using patterns of stress-free and no-slip boundary conditions on the inner cylinder. For this, we perform direct numerical simulations of narrow-gap TC flow with pure inner-cylinder rotation at four different shear Reynolds numbers up to  $Re_s=3\times 10^4$. We find that one-dimensional azimuthal patterns do not have a significant effect on the flow topology, and that the resulting torque is a large fraction (

$Re_s=3\times 10^4$. We find that one-dimensional azimuthal patterns do not have a significant effect on the flow topology, and that the resulting torque is a large fraction ( $\sim$80 %–90 %) of torque in the fully no-slip case. One-dimensional axial patterns decrease the torque more, and for certain pattern frequency disrupt the rolls by interfering with the existing Reynolds stresses that generate secondary structures. For

$\sim$80 %–90 %) of torque in the fully no-slip case. One-dimensional axial patterns decrease the torque more, and for certain pattern frequency disrupt the rolls by interfering with the existing Reynolds stresses that generate secondary structures. For  $Re\geq 10^4$, this disruption leads to a smaller torque than what would be expected from simple boundary layer effects and the resulting effective slip length and slip velocity. We find that two-dimensional checkerboard patterns have similar behaviour to azimuthal patterns and do not affect the flow or the torque substantially, but two-dimensional spiral inhomogeneities can move around the pinned secondary flows as they induce persistent axial velocities. We quantify the roll's movement for various angles and the widths of the spiral pattern, and find a non-monotonic behaviour as a function of pattern angle and pattern frequency.

$Re\geq 10^4$, this disruption leads to a smaller torque than what would be expected from simple boundary layer effects and the resulting effective slip length and slip velocity. We find that two-dimensional checkerboard patterns have similar behaviour to azimuthal patterns and do not affect the flow or the torque substantially, but two-dimensional spiral inhomogeneities can move around the pinned secondary flows as they induce persistent axial velocities. We quantify the roll's movement for various angles and the widths of the spiral pattern, and find a non-monotonic behaviour as a function of pattern angle and pattern frequency.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2021. Published by Cambridge University Press

References

REFERENCES

- 3

- Cited by