1. Introduction

Nucleate boiling ranks among one of the most efficient heat-transfer processes. An underlying reason for this is the existence of strong temperature gradients in the close proximity of the heated surface, generated by the significant drop in temperature created between the solid wall itself and the liquid–vapour interface of the emerging bubble, which elevates the heat flux. It can be easily understood that, in the near-wall region, where the phasic interface (as perceived from the perspective of continuum fluid dynamics) comes into direct contact with the heated surface, heat fluxes of exceptional magnitude can be created. Thus, in order to precisely quantify the overall heat transfer, the near-wall morphology of growing bubbles needs to be characterised.

In the context of nucleate pool boiling, two modes of bubble growth are generally identified (Kim Reference Kim2009). The first one is the contact-line evaporation regime, in which relatively slow growth of near-spherical bubbles is observed (Fischer et al. Reference Fischer, Herbert, Slomski, Stephan and Oechsner2014; Huber et al. Reference Huber, Tanguy, Sagan and Colin2017; Bureš & Sato Reference Bureš and Sato2021c), and in which the phasic interface is terminated at the wall by a dry patch. Although this patch is sometimes assumed to be covered by an adsorbed liquid film of nanoscopic thickness (Morris Reference Morris2001; Schweikert, Sielaff & Stephan Reference Schweikert, Sielaff and Stephan2019), its presence appears not to affect the bubble-growth dynamics and, therefore, we can speak of a contact-line region, often termed the microregion (Stephan & Busse Reference Stephan and Busse1992; Janeček & Anderson Reference Janeček and Anderson2016). Here, vigorous heat- and mass-transfer processes occur; however, due to the small lateral extent of the microregion, this being O(100 nm), its importance to the overall heat-transfer mechanism is diminished (Morris Reference Morris2000; Huber et al. Reference Huber, Tanguy, Sagan and Colin2017). Nevertheless, the transfer processes within the microregion significantly alter the local liquid–vapour interface profile, giving rise to the existence of ‘apparent’ contact angles, even for perfectly wetting liquids: i.e. the angle of interfacial contact with the surface is observed to be generally non-zero for volatile liquids (Fourgeaud et al. Reference Fourgeaud, Ercolani, Duplat, Gully and Nikolayev2016; Schweikert et al. Reference Schweikert, Sielaff and Stephan2019).

The wetting conditions during bubble growth are considered to be instrumental in the appearance of the second growth regime, i.e. the microlayer evaporation regime (Afkhami et al. Reference Afkhami, Buongiorno, Guion, Popinet, Saade, Scardovelli and Zaleski2018; Guion et al. Reference Guion, Afkhami, Zaleski and Buongiorno2018; Urbano et al. Reference Urbano, Tanguy, Huber and Colin2018; Schweikert et al. Reference Schweikert, Sielaff and Stephan2019; Bureš & Sato Reference Bureš and Sato2021c). In this situation, a favourable interplay of bubble expansion and contact-line motion leads to the formation of the so-called microlayer, a thin layer of liquid adhering to the heated surface beneath the growing bubble. Owing to the minute thickness of the microlayer, very high heat fluxes can again be observed (Yabuki & Nakabeppu Reference Yabuki and Nakabeppu2014; Tanaka, Miyazaki & Yabuki Reference Tanaka, Miyazaki and Yabuki2021). In contrast to the microregion configuration, the large extent of the microlayer over the heated surface results in its evaporation being a significant contributor to the overall mass transfer of the evaporation process (Yabuki & Nakabeppu Reference Yabuki and Nakabeppu2014; Utaka et al. Reference Utaka, Hu, Chen and Morokuma2018; Tanaka et al. Reference Tanaka, Miyazaki and Yabuki2021). Indeed, in the microlayer evaporation regime, qualitatively different growth dynamics have been observed, with bubbles remaining almost hemispherical or oblate during a significant portion of the growth phase (Yabuki & Nakabeppu Reference Yabuki and Nakabeppu2014; Chen, Haginiwa & Utaka Reference Chen, Haginiwa and Utaka2017; Jung & Kim Reference Jung and Kim2018).

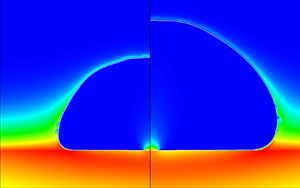

Figure 1 is a side-by-side schematic illustration of the characteristics of the two bubble-growth regimes; note that a microregion also appears in the microlayer evaporation regime, located at the inner edge of the microlayer.

Figure 1. Side-by-side illustrations of the two bubble-growth regimes: the contact-line evaporation regime (left) and the microlayer evaporation regime (right). The bottom right inset illustrates schematically the microlayer, and the left inset the microregion, where ![]() $\theta _0$ is the physical microscopic angle and

$\theta _0$ is the physical microscopic angle and ![]() $\theta _{mr}$ the apparent one (see § 3.6). Note that the microregion inset is inverted with respect to the bubble in the microlayer evaporation regime. The bottom left inset illustrates the so-called ‘hump-terminated microlayer’, a shape typical of film dewetting (Snoeijer et al. Reference Snoeijer, Andreotti, Delon and Fermigier2007; Delon et al. Reference Delon, Fermigier, Snoeijer and Andreotti2008).

$\theta _{mr}$ the apparent one (see § 3.6). Note that the microregion inset is inverted with respect to the bubble in the microlayer evaporation regime. The bottom left inset illustrates the so-called ‘hump-terminated microlayer’, a shape typical of film dewetting (Snoeijer et al. Reference Snoeijer, Andreotti, Delon and Fermigier2007; Delon et al. Reference Delon, Fermigier, Snoeijer and Andreotti2008).

The importance of the microlayer, and its possible link to the critical heat flux phenomenon (Zhao, Masuoka & Tsuruta Reference Zhao, Masuoka and Tsuruta2002; Theofanous & Dinh Reference Theofanous and Dinh2006), has motivated intense scientific investigation ever since its existence was first postulated by Moore & Mesler (Reference Moore and Mesler1961) on the basis of their measurements of local temperature variations over a heated surface, and subsequently experimentally confirmed by Sharp (Reference Sharp1964) and Jawurek (Reference Jawurek1969), who employed interferometry (an imaging technique based on observation of light interference patterns) to quantify the thickness of the microlayer. Both studies employed arc lamps as light sources. The accuracy of the interferometric approach was later substantially improved with the use of lasers, recently by Gao et al. (Reference Gao, Zhang, Cheng and Quan2013), Utaka et al. (Reference Utaka, Hu, Chen and Morokuma2018), Zou, Gupta & Maroo (Reference Zou, Gupta and Maroo2018), Liu et al. (Reference Liu, Gao, Zhang and Zhang2019) and Chen et al. (Reference Chen, Haginiwa and Utaka2017, Reference Chen, Hu, Hu, Utaka and Mori2020), to provide a detailed description of the evolution of the microlayer structure. Further methods of microlayer investigation include the laser extinction method, which can measure the thickness locally to very high precision, based on the attenuation of a laser beam when it passes through a liquid film (Utaka, Kashiwabara & Ozaki Reference Utaka, Kashiwabara and Ozaki2013; Utaka et al. Reference Utaka, Kashiwabara, Ozaki and Chen2014).

Additionally, the heat-transfer characteristics of the microlayer have been measured both locally, using microsensors (Yabuki & Nakabeppu Reference Yabuki and Nakabeppu2014, Reference Yabuki and Nakabeppu2016; Yabuki et al. Reference Yabuki, Samaroo, Nakabeppu and Kawaji2015; Yabuki & Nakabeppu Reference Yabuki and Nakabeppu2017), and globally, using infrared (IR) cameras (Duan et al. Reference Duan, Phillips, McKrell and Buongiorno2013; Surtaev, Serdyukov & Chernyavskiy Reference Surtaev, Serdyukov and Chernyavskiy2017; Serdyukov et al. Reference Serdyukov, Surtaev, Pavlenko and Chernyavskiy2018; Kangude & Srivastava Reference Kangude and Srivastava2020; Tanaka et al. Reference Tanaka, Miyazaki and Yabuki2021). Such experiments have provided information on heat-flux conditions within the microlayer, and its significance in the overall boiling process. Finally, Jung & Kim (Reference Jung and Kim2014, Reference Jung and Kim2018, Reference Jung and Kim2019) and Giustini, Kim & Kim (Reference Giustini, Kim and Kim2020b) combined measurements of surface heat-transfer characteristics using IR thermometry with microlayer profile evaluation using laser interferometry, producing a comprehensive set of experimental data on nucleate boiling in the microlayer regime.

Although modern, high-resolution experimental techniques can provide detailed information on the actual microlayer dynamics, several limitations and deficiencies in the approach can be identified. Measurements of microlayer thickness are often indirect and/or rely either on assumptions, such as zero flow in the microlayer (Utaka et al. Reference Utaka, Kashiwabara and Ozaki2013; Yabuki & Nakabeppu Reference Yabuki and Nakabeppu2014), or on indirect numerical techniques (Bucci et al. Reference Bucci, Richenderfer, Su, McKrell and Buongiorno2016), the uncertainties of which need to be carefully evaluated (Kim et al. Reference Kim, Sergis, Kim and Hardalupas2020). Furthermore, an experimental set-up can accommodate only a limited number of diagnostic systems, reducing the amount of information that can be obtained in a synchronous way. The possibility of generalisation of the experimental results is also hindered by the limited combinations of test fluids that can be employed, the working conditions and the inability to independently vary the controlling parameters, such as the material properties, in a straightforward manner.

One possibility to alleviate these restrictions is offered by the use of direct numerical simulation (DNS) for modelling the bubble-growth process through the direct numerical solution of the governing equations of continuum fluid dynamics. The microlayer can then be explicitly resolved within the computations, and comprehensive information extracted. A validated DNS code can also be used in combination with an experiment, to complement the measured data, or on its own, to perform parametric studies outside the scope of the standard working fluids, and to study system sensitivity to the input parameters and applied boundary conditions (BCs).

In recent years, pioneering DNS studies on boiling with a resolved microlayer (DNS-BRM) have been conducted, thanks to the advent of high-performance computing, coupled with the continuous development of advanced numerical methods for multiphase computational fluid dynamics (MCFD). Note that all the numerical works referenced below have employed an axisymmetric cylindrical representation of the problem, since a full, three-dimensional (3-D) solution lies beyond the limits imposed by present-day computational resources, and the extremely high resolution demanded to perform a DNS-BRM study. Hänsch & Walker (Reference Hänsch and Walker2016) succeeded in simulating hydrodynamic microlayer formation with the time-dependent bubble-growth rate deduced from the analytical solution of Scriven (Reference Scriven1959). Similar work has been performed by Guion et al. (Reference Guion, Afkhami, Zaleski and Buongiorno2018) under the tenet that bubble growth takes place principally within the inertial regime (Faghri & Zhang Reference Faghri and Zhang2006), with the constant expansion rate given by the simplified formula of Mikic, Rohsenow & Griffith (Reference Mikic, Rohsenow and Griffith1970) for near-wall expansion. Heat transfer was first included in a DNS-BRM approach by Urbano et al. (Reference Urbano, Tanguy, Huber and Colin2018). A rigorous computational exercise was performed, utilising a computational mesh with submicrometre resolution, and a criterion proposed to distinguish between the contact-line and microlayer evaporation regimes, based on the results. However, the conjugate heat-transfer problem between the solid and the fluids (liquid and vapour) was not solved explicitly: rather, the wall was assumed to be uniformly superheated and isothermal. Furthermore, interfacial heat-transfer resistance (IHTR), a phenomenon also currently under investigation in the context of nucleate boiling (Giustini et al. Reference Giustini, Jung, Kim and Walker2016), was not considered.

In their more recent work, Hänsch & Walker (Reference Hänsch and Walker2019) coupled their hydrodynamic solver with a prescribed Scriven-type growth rate to their own microlayer depletion model, represented by the solution of the steady-state one-dimensional (1-D) heat conduction equation, while the wall temperature distribution was obtained by solving the unsteady conduction problem within the solid substrate. The depletion model itself took into account IHTR, with a value of the resistance based on the experiments of Jung & Kim (Reference Jung and Kim2014). Only limited comparison of the microlayer evolution with experimental data was performed, with the growth rate of the simulated bubble prescribed a priori to match the experimental measurements. A purely hydrodynamic DNS-BRM investigation with a Scriven-type fixed growth-rate model was also undertaken by Giustini et al. (Reference Giustini, Kim, Issa and Bluck2020a); similar comparisons with the experiments of Jung & Kim (Reference Jung and Kim2018) as by Hänsch & Walker (Reference Hänsch and Walker2019) were made. Using a Mikic-type fixed growth rate, Giustini et al. (Reference Giustini, Kim, Issa and Bluck2020a) also simulated microlayer formation during the boiling of liquid sodium, whose material properties differ significantly from those of the typically studied fluids, i.e. water and ethanol under atmospheric conditions.

In spite of the undeniable progress being made in the field of DNS-BRM in recent years, a survey of the above-referenced works reveals that several issues still need to be resolved:

(i) No actual validation of the numerical approaches employed has so far been performed, thereby reducing the confidence level of the predictions.

(ii) Heat transfer has been included only in the fluid domain (Urbano et al. Reference Urbano, Tanguy, Huber and Colin2018), through reduced-order modelling (Hänsch & Walker Reference Hänsch and Walker2019), or in many cases not at all (Hänsch & Walker Reference Hänsch and Walker2016; Guion et al. Reference Guion, Afkhami, Zaleski and Buongiorno2018; Giustini et al. Reference Giustini, Kim, Issa and Bluck2020a). The role of IHTR in the heat-transfer mechanism in particular is still an open issue.

(iii) The role of wetting conditions in microlayer dynamics has also not been addressed adequately: i.e. only static contact angles have been considered so far, an exception being the work of Giustini et al. (Reference Giustini, Kim, Issa and Bluck2020a), who preferred to employ a vanishing contact angle BC. Urbano et al. (Reference Urbano, Tanguy, Huber and Colin2018) attributed dewetting to be the principal driving mechanism for microlayer destruction. In our recent work (Bureš & Sato Reference Bureš and Sato2021c), we have highlighted the role of numerical slip (Afkhami et al. Reference Afkhami, Buongiorno, Guion, Popinet, Saade, Scardovelli and Zaleski2018) in simulations of microlayer dynamics, and proposed that this could artificially promote dewetting in DNS-BRM, and stressed the need for the careful implementation in the code of the actual wetting phenomenon. Furthermore, the value of the contact angle to be imposed in the simulation is often unclear, since dynamic wetting conditions of volatile liquids can significantly differ from static, adiabatic conditions (Raj et al. Reference Raj, Kunkelmann, Stephan, Plawsky and Kim2012; Janeček & Nikolayev Reference Janeček and Nikolayev2013; Fourgeaud et al. Reference Fourgeaud, Ercolani, Duplat, Gully and Nikolayev2016; Schweikert et al. Reference Schweikert, Sielaff and Stephan2019).

For these reasons, we have decided to validate a computational method for DNS-BRM studies with a focus on the microscopic physics of the problem; to this end, we have adapted the open-source code PSI-BOIL for such application. (The code is available at https://github.com/PSI-NES-LSM-CFD/PSI-Boil.) We have introduced the axisymmetric cylindrical geometric volume-of-fluid (GVOF) method for interface tracking (Bureš, Sato & Pautz Reference Bureš, Sato and Pautz2021), and coupled it with the existing sharp-interface heat- and mass-transfer model within PSI-BOIL, and with the phasic velocity extrapolation algorithm of Malan et al. (Reference Malan, Malan, Zaleski and Rousseau2021), but with several modifications (Bureš & Sato Reference Bureš and Sato2021b). As reference data for validation, we have acquired comprehensive measurements of first-bubble growth in a microlayer evaporation regime taken at the Massachusetts Institute of Technology by Bucci (Reference Bucci2020), partially presented in Bucci, Buongiorno & Bucci (Reference Bucci, Buongiorno and Bucci2021). In the present study, we have used the data for which the experimentalists had the highest confidence in the fidelity of the reported results, corresponding to a situation with an applied heat flux of ![]() $425~{\rm kW}~{\rm m}^{-2}$.

$425~{\rm kW}~{\rm m}^{-2}$.

The present paper is a continuation of our previous work (Bureš & Sato Reference Bureš and Sato2021c), in which we were concerned with deriving a theoretical description of the conditions leading to microlayer formation. Here, we focus on the development and validation of a computational method for DNS-BRM studies, and the application of this method to the analysis of the distribution of the microlayer thickness following its initial formation. In § 2, we present specific details of the method, while in § 3 the topic of IHTR is discussed, with the values of the resistance for use in the simulations determined from appropriate experimental data. Expressions adopted for the dynamic contact angle, in lieu of a definitive experimental value, are also discussed. The validation of the overall method against the measurements of Bucci (Reference Bucci2020) is given in § 4; good agreement with the experimental data is demonstrated, and points of concern highlighted. In § 5, we review sensitivities to particular simulation settings and assumptions. In § 6, we perform a sensitivity study of the microlayer thickness following its formation, recovering a semi-empirical relation describing its distribution. Finally, overall conclusions are drawn in § 7. Furthermore, in Appendix B, a first demonstration of DNS of boiling with an explicitly resolved microlayer in 3-D Cartesian coordinates is also presented.

(The reader should note that, in this paper, the work of Professor M. Bucci (Bucci et al. Reference Bucci, Richenderfer, Su, McKrell and Buongiorno2016) and the work of Mr M. Bucci (Bucci Reference Bucci2020), as well as their joint publication (Bucci et al. Reference Bucci, Buongiorno and Bucci2021), are referenced. We bring this to the reader's attention to avoid possible confusion of these two researchers.)

2. Governing equations

PSI-BOIL is an open-source MCFD code developed at the Paul Scherrer Institute in Switzerland. The primary mission of its eleven-year-long development is to promote basic computational research of volatile multiphase flows in the framework of continuum theory. To this end, the governing equations for incompressible flows with phase change are solved, including phase, momentum, mass and energy exchanges. The solution algorithm is described in detail by Bureš et al. (Reference Bureš, Sato and Pautz2021) and Bureš & Sato (Reference Bureš and Sato2021b). Below, a brief summary is given, special attention being paid to the numerical treatment of the solid substrate in nucleate boiling, a topic not covered in our previous papers. In the present context, all the governing equations are solved in a two-dimensional (2-D), axisymmetric cylindrical geometry, though a full 3-D option is available in the code. The verification and validation for two-phase flows with and without phase change are reported in Bureš et al. (Reference Bureš, Sato and Pautz2021) and Bureš & Sato (Reference Bureš and Sato2021b), and they are not repeated in this paper.

2.1. Phase conservation and interface tracking

Two phases, liquid and vapour, are included in PSI-BOIL. Their mass densities are considered to be constant, ![]() $\rho _l$ and

$\rho _l$ and ![]() $\rho _v$ (

$\rho _v$ (![]() ${\rm kg}~{\rm m}^{-3}$); thus, to track the phasic distribution, it is sufficient to solve the transport equation for the liquid volume fraction,

${\rm kg}~{\rm m}^{-3}$); thus, to track the phasic distribution, it is sufficient to solve the transport equation for the liquid volume fraction, ![]() $\phi$, defined for a computational cell with volume

$\phi$, defined for a computational cell with volume ![]() $\Delta V$ (m

$\Delta V$ (m![]() $^3$) as

$^3$) as

where ![]() $V_l$ is the volume of the cell occupied by liquid. The vapour volume fraction is then

$V_l$ is the volume of the cell occupied by liquid. The vapour volume fraction is then ![]() $(1-\phi )$.

$(1-\phi )$.

The transport equation for ![]() $\phi$ can be derived from general two-phase integral balance considerations and reads (Bureš & Sato Reference Bureš and Sato2021b)

$\phi$ can be derived from general two-phase integral balance considerations and reads (Bureš & Sato Reference Bureš and Sato2021b)

Here, ![]() $\boldsymbol {u}_l$ (

$\boldsymbol {u}_l$ (![]() ${\rm m}~{\rm s}^{-1}$) is the (divergence-free) liquid velocity field, satisfying the incompressibility condition, and computed from a modified version of the extrapolation algorithm of Malan et al. (Reference Malan, Malan, Zaleski and Rousseau2021), without which consistent advection of

${\rm m}~{\rm s}^{-1}$) is the (divergence-free) liquid velocity field, satisfying the incompressibility condition, and computed from a modified version of the extrapolation algorithm of Malan et al. (Reference Malan, Malan, Zaleski and Rousseau2021), without which consistent advection of ![]() $\phi$ in the presence of phase change would not be possible. Furthermore,

$\phi$ in the presence of phase change would not be possible. Furthermore, ![]() $\dot {m}'''$ is the evaporative mass source density

$\dot {m}'''$ is the evaporative mass source density ![]() $({\rm kg}~({\rm m}^{3}~{\rm s})^{-1})$. The advection term is treated using the GVOF method of Weymouth & Yue (Reference Weymouth and Yue2010), expressed in terms of the liquid surface flows

$({\rm kg}~({\rm m}^{3}~{\rm s})^{-1})$. The advection term is treated using the GVOF method of Weymouth & Yue (Reference Weymouth and Yue2010), expressed in terms of the liquid surface flows ![]() $F_{l,i}$

$F_{l,i}$ ![]() $({\rm m}^3~{\rm s}^{-1})$ defined for each bounding surface

$({\rm m}^3~{\rm s}^{-1})$ defined for each bounding surface ![]() $i$ of the computational cell. Equation (2.2) is discretised in explicit form as follows:

$i$ of the computational cell. Equation (2.2) is discretised in explicit form as follows:

\begin{gather}\frac{\phi^{n+1}-\phi^\star}{\Delta t} ={-} \frac{1}{\Delta V}\sum_i F_{l,i}, \end{gather}

\begin{gather}\frac{\phi^{n+1}-\phi^\star}{\Delta t} ={-} \frac{1}{\Delta V}\sum_i F_{l,i}, \end{gather}

where ![]() $\Delta t$ (s) is the discrete time step,

$\Delta t$ (s) is the discrete time step, ![]() $\phi ^\star$ is an intermediate value of the volume fraction, while

$\phi ^\star$ is an intermediate value of the volume fraction, while ![]() $n$ and

$n$ and ![]() $n+1$ indicate the previous and new time steps, respectively. The evaporative mass source density needed for the phase-change step (2.3) is calculated according to

$n+1$ indicate the previous and new time steps, respectively. The evaporative mass source density needed for the phase-change step (2.3) is calculated according to

Here, ![]() $a_\gamma$ (m

$a_\gamma$ (m![]() $^2$ m

$^2$ m![]() $^{-3}$) is the interfacial area density, computed by means of the marching cubes algorithm (Lorensen & Cline Reference Lorensen and Cline1987), and based on the local

$^{-3}$) is the interfacial area density, computed by means of the marching cubes algorithm (Lorensen & Cline Reference Lorensen and Cline1987), and based on the local ![]() $\phi$ stencil, adapted for use in axisymmetric geometry;

$\phi$ stencil, adapted for use in axisymmetric geometry; ![]() $L$ (J kg

$L$ (J kg![]() $^{-1}$) is the latent heat of vaporisation; and

$^{-1}$) is the latent heat of vaporisation; and ![]() $\lambda _l$ and

$\lambda _l$ and ![]() $\lambda _v$ are the liquid and vapour thermal conductivities

$\lambda _v$ are the liquid and vapour thermal conductivities ![]() $({\rm W}~({\rm m}~{\rm K})^{-1})$, respectively. Furthermore,

$({\rm W}~({\rm m}~{\rm K})^{-1})$, respectively. Furthermore, ![]() $\boldsymbol {\nabla } T|_{\gamma,l}$ and

$\boldsymbol {\nabla } T|_{\gamma,l}$ and ![]() $\boldsymbol {\nabla } T|_{\gamma,v}$ are the temperature gradients on the liquid and vapour sides of the interface

$\boldsymbol {\nabla } T|_{\gamma,v}$ are the temperature gradients on the liquid and vapour sides of the interface ![]() $({\rm K}~{\rm m}^{-1})$. They are calculated using fourth-order-accurate upwind differences for non-uniform grids, evaluated at the interface; details appear in Bureš & Sato (Reference Bureš and Sato2021b). The unit normal vector to the interface pointing from the vapour phase to the liquid phase,

$({\rm K}~{\rm m}^{-1})$. They are calculated using fourth-order-accurate upwind differences for non-uniform grids, evaluated at the interface; details appear in Bureš & Sato (Reference Bureš and Sato2021b). The unit normal vector to the interface pointing from the vapour phase to the liquid phase, ![]() $\boldsymbol {n}$, is evaluated using the ELVIRA algorithm of Pilliod & Puckett (Reference Pilliod and Puckett2004). Note that the interfacial jump in kinetic energy is neglected, being in general small in comparison to the latent heat of phase transition, as can be deduced from a scaling analysis.

$\boldsymbol {n}$, is evaluated using the ELVIRA algorithm of Pilliod & Puckett (Reference Pilliod and Puckett2004). Note that the interfacial jump in kinetic energy is neglected, being in general small in comparison to the latent heat of phase transition, as can be deduced from a scaling analysis.

The second step in the solution of the transport equation (2.4) is performed using the directional-split, bounded-conservative GVOF algorithm of Weymouth & Yue (Reference Weymouth and Yue2010), also adapted for use in axisymmetric geometry.

2.2. Momentum conservation

The two-phase momentum conservation equations, written in the single-fluid approximation, read as follows:

Note that the recoil pressure due to phase change has not been considered, since it is generally negligible within the present application area, as we concluded using a scaling analysis. In this equation, ![]() $\boldsymbol {u}$ is the single-fluid mechanical velocity,

$\boldsymbol {u}$ is the single-fluid mechanical velocity, ![]() $p$ is the pressure (Pa),

$p$ is the pressure (Pa), ![]() $\boldsymbol {g}$ is the gravitational acceleration (

$\boldsymbol {g}$ is the gravitational acceleration (![]() ${\rm m}~{\rm s}^{-2}$),

${\rm m}~{\rm s}^{-2}$), ![]() $\,\boldsymbol {f}_\sigma$ is the surface-tension force density

$\,\boldsymbol {f}_\sigma$ is the surface-tension force density ![]() $({\rm N}~{\rm m}^{-3})$ and

$({\rm N}~{\rm m}^{-3})$ and ![]() $\rho$ is the mixture density, given by

$\rho$ is the mixture density, given by

In the single-fluid approximation, ![]() $\boldsymbol {u}$ is taken to be continuous across the interface and the stress balance at the interface is not represented exactly. Instead, a heuristic harmonic mixing law is applied for the computation of mixture dynamic viscosity

$\boldsymbol {u}$ is taken to be continuous across the interface and the stress balance at the interface is not represented exactly. Instead, a heuristic harmonic mixing law is applied for the computation of mixture dynamic viscosity ![]() $\mu$

$\mu$ ![]() $({\rm Pa}~{\rm s})$ in the vicinity of the interface. In the simulations shown below, we use the harmonic mixing law (Prosperetti Reference Prosperetti2002):

$({\rm Pa}~{\rm s})$ in the vicinity of the interface. In the simulations shown below, we use the harmonic mixing law (Prosperetti Reference Prosperetti2002):

We have also conducted simulations of the validation problem presented in § 4 using other heuristic viscosity averaging schemes; no discernible differences in the overall dynamics have been observed. Note that, since the near-interface stress balance is anyway treated only approximately, we neglect the ![]() $(\boldsymbol {\nabla }\boldsymbol {u})^{\rm T}$ term in (2.6) for reasons of simplicity and robustness of the numerical implementation.

$(\boldsymbol {\nabla }\boldsymbol {u})^{\rm T}$ term in (2.6) for reasons of simplicity and robustness of the numerical implementation.

In PSI-BOIL, (2.6) is solved in the finite-volume formulation:

\begin{align} &\rho\left(\frac{\partial\boldsymbol{u}}{\partial t}\,\Delta V + \sum_i (\boldsymbol{u}\otimes\boldsymbol{u}) \boldsymbol{\cdot}\Delta\boldsymbol{S}_i - (\boldsymbol{\nabla}\boldsymbol{\cdot} \boldsymbol{u})\boldsymbol{u}\,\Delta V \right) \nonumber\\ & \quad ={-} \boldsymbol{\nabla} p\, \Delta V + \sum_i \mu\boldsymbol{\nabla}\boldsymbol{u}\boldsymbol{\cdot} \Delta\boldsymbol{S}_i + \rho\boldsymbol{g}\,\Delta V + \,\boldsymbol{f}_\sigma \,\Delta V. \end{align}

\begin{align} &\rho\left(\frac{\partial\boldsymbol{u}}{\partial t}\,\Delta V + \sum_i (\boldsymbol{u}\otimes\boldsymbol{u}) \boldsymbol{\cdot}\Delta\boldsymbol{S}_i - (\boldsymbol{\nabla}\boldsymbol{\cdot} \boldsymbol{u})\boldsymbol{u}\,\Delta V \right) \nonumber\\ & \quad ={-} \boldsymbol{\nabla} p\, \Delta V + \sum_i \mu\boldsymbol{\nabla}\boldsymbol{u}\boldsymbol{\cdot} \Delta\boldsymbol{S}_i + \rho\boldsymbol{g}\,\Delta V + \,\boldsymbol{f}_\sigma \,\Delta V. \end{align}The discretised variables are arranged using the staggered-grid approach of Harlow & Welch (Reference Harlow and Welch1965). For the spatial discretisation, a second-order-accurate, central-difference scheme and a second-order flux-limiting, total-variation-diminishing (TVD) scheme (Roe Reference Roe1986) are used for the diffusion and advection terms, respectively. For the time discretisation, backward and forward Euler methods are used to treat the diffusion and advection terms, respectively. The Boussinesq approximation (Gray & Giorgini Reference Gray and Giorgini1976) for density is adopted: i.e. the variability of densities with temperature is only taken into account in the calculation of the buoyancy force. The surface-tension force density is given by

with ![]() $\sigma$

$\sigma$ ![]() $({\rm N}~{\rm m}^{-1})$ being the surface tension (assumed constant), and

$({\rm N}~{\rm m}^{-1})$ being the surface tension (assumed constant), and ![]() $\kappa$

$\kappa$ ![]() $({\rm m}^{-1})$ the interfacial curvature, which is taken to be positive if the centre of curvature is in the liquid phase and negative otherwise. Note that Marangoni stresses (Faghri & Zhang Reference Faghri and Zhang2006) have been neglected based on our analysis of the heat-flux conditions within the microlayer for the experiment discussed in § 4 (see § 3 for the description of the relation between heat flux and interfacial temperature). Additionally, disjoining pressure (Faghri & Zhang Reference Faghri and Zhang2006; Janeček & Nikolayev Reference Janeček and Nikolayev2013) has not been considered, since this phenomenon becomes relevant at length scales well below the grid resolution employed in the simulations described in this paper.

$({\rm m}^{-1})$ the interfacial curvature, which is taken to be positive if the centre of curvature is in the liquid phase and negative otherwise. Note that Marangoni stresses (Faghri & Zhang Reference Faghri and Zhang2006) have been neglected based on our analysis of the heat-flux conditions within the microlayer for the experiment discussed in § 4 (see § 3 for the description of the relation between heat flux and interfacial temperature). Additionally, disjoining pressure (Faghri & Zhang Reference Faghri and Zhang2006; Janeček & Nikolayev Reference Janeček and Nikolayev2013) has not been considered, since this phenomenon becomes relevant at length scales well below the grid resolution employed in the simulations described in this paper.

As is common practice, (2.10) is discretised using the continuum surface force approach of Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992):

In our approach, the curvature ![]() $\kappa$ is calculated by means of the height function method (Popinet Reference Popinet2018), with a

$\kappa$ is calculated by means of the height function method (Popinet Reference Popinet2018), with a ![]() $3 \times 7$ stencil utilising the local-topology adaptation approach of López et al. (Reference López, Zanzi, Gómez, Zamora, Faura and Hernández2009), again modified for use in axisymmetric geometry.

$3 \times 7$ stencil utilising the local-topology adaptation approach of López et al. (Reference López, Zanzi, Gómez, Zamora, Faura and Hernández2009), again modified for use in axisymmetric geometry.

2.3. Mass conservation

As the densities of the phases are here considered constant, the mass continuity equation may be conveniently replaced by the equivalent volume-conservation condition, resulting from the application of the two-phase divergence theorem, as

\begin{equation} \sum_i \boldsymbol{u}\boldsymbol{\cdot}\Delta \boldsymbol{S}_i = \dot{m}'''\left(\frac{1}{\rho_v}-\frac{1}{\rho_l}\right)\Delta V. \end{equation}

\begin{equation} \sum_i \boldsymbol{u}\boldsymbol{\cdot}\Delta \boldsymbol{S}_i = \dot{m}'''\left(\frac{1}{\rho_v}-\frac{1}{\rho_l}\right)\Delta V. \end{equation}

Here, ![]() $\Delta \boldsymbol {S}_i$ is the (outward-oriented) area of the bounding surface

$\Delta \boldsymbol {S}_i$ is the (outward-oriented) area of the bounding surface ![]() $i$ within the given computational cell. This condition is enforced at each time step by the projection algorithm of Chorin (Reference Chorin1968), which consists of solving the discrete Poisson equation for the pressure

$i$ within the given computational cell. This condition is enforced at each time step by the projection algorithm of Chorin (Reference Chorin1968), which consists of solving the discrete Poisson equation for the pressure ![]() $p$ at the advanced time step

$p$ at the advanced time step ![]() $n+1$,

$n+1$,

\begin{equation} \sum_i \frac{\Delta t}{\rho}\,\boldsymbol{\nabla} p^{n+1} \boldsymbol{\cdot} \Delta\boldsymbol{S}_i = \sum_i \boldsymbol{u}^\star \boldsymbol{\cdot} \Delta\boldsymbol{S}_i - \dot{m}^{\prime\prime\prime,n}\left(\frac{1}{\rho_v}-\frac{1}{\rho_l}\right) \Delta V, \end{equation}

\begin{equation} \sum_i \frac{\Delta t}{\rho}\,\boldsymbol{\nabla} p^{n+1} \boldsymbol{\cdot} \Delta\boldsymbol{S}_i = \sum_i \boldsymbol{u}^\star \boldsymbol{\cdot} \Delta\boldsymbol{S}_i - \dot{m}^{\prime\prime\prime,n}\left(\frac{1}{\rho_v}-\frac{1}{\rho_l}\right) \Delta V, \end{equation}followed by the projection step,

In these equations, ![]() $\boldsymbol {u}^\star$ is a tentative estimate of the velocity field, obtained from the numerical solution of the following equation:

$\boldsymbol {u}^\star$ is a tentative estimate of the velocity field, obtained from the numerical solution of the following equation:

\begin{align} &\frac{\rho^n\boldsymbol{u}^\star}{\Delta t}\,\Delta V - \sum_i \mu\boldsymbol{\nabla}\boldsymbol{u}^{{\star}}\boldsymbol{\cdot} \Delta\boldsymbol{S}_i \nonumber\\ & \quad = \rho^n\left(\frac{\boldsymbol{u}^n}{\Delta t}\,\Delta V -\sum_i (\boldsymbol{u}^n\otimes\boldsymbol{u}^n) \boldsymbol{\cdot} \Delta\boldsymbol{S}_i + (\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{u}^n) \boldsymbol{u}^n\, \Delta V \right) + \rho^n\boldsymbol{g}\,\Delta V + \,\boldsymbol{f}^n_\sigma\,\Delta V. \end{align}

\begin{align} &\frac{\rho^n\boldsymbol{u}^\star}{\Delta t}\,\Delta V - \sum_i \mu\boldsymbol{\nabla}\boldsymbol{u}^{{\star}}\boldsymbol{\cdot} \Delta\boldsymbol{S}_i \nonumber\\ & \quad = \rho^n\left(\frac{\boldsymbol{u}^n}{\Delta t}\,\Delta V -\sum_i (\boldsymbol{u}^n\otimes\boldsymbol{u}^n) \boldsymbol{\cdot} \Delta\boldsymbol{S}_i + (\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{u}^n) \boldsymbol{u}^n\, \Delta V \right) + \rho^n\boldsymbol{g}\,\Delta V + \,\boldsymbol{f}^n_\sigma\,\Delta V. \end{align}

Note that, by assuming the validity of (2.12), we are effectively identifying the single-fluid velocity ![]() $\boldsymbol {u}$ with the volume-averaged velocity.

$\boldsymbol {u}$ with the volume-averaged velocity.

2.4. Energy conservation

The energy conservation equation is the only balance equation in PSI-BOIL not recast in integral form, but rather solved in a finite-difference approximation to its differential form:

The equation is discretised separately in the liquid and vapour regions of the domain, with the phasic interface being treated as an internal boundary, unlike for the momentum equations. Since the finite-volume scheme cannot be easily employed in the vicinity of the phasic interface, where the computational cells are cut, the finite-difference approach is employed here. In the above equations, ![]() $C_{p,l}=\rho _l c_{p,l}$ and

$C_{p,l}=\rho _l c_{p,l}$ and ![]() $C_{p,v}=\rho _v c_{p,v}$ are the volumetric heat capacities

$C_{p,v}=\rho _v c_{p,v}$ are the volumetric heat capacities ![]() $({\rm J}~({\rm m}^3~{\rm K})^{-1})$ for the liquid and vapour, respectively; and

$({\rm J}~({\rm m}^3~{\rm K})^{-1})$ for the liquid and vapour, respectively; and ![]() $c_{p,l}$ and

$c_{p,l}$ and ![]() $c_{p,v}$ are the respective specific heat capacities

$c_{p,v}$ are the respective specific heat capacities ![]() $({\rm J}~({\rm kg}~{\rm K})^{-1})$.

$({\rm J}~({\rm kg}~{\rm K})^{-1})$.

Note that the form of the energy conservation equation presented here could be derived from the internal energy balance equation, assuming zero internal heating and neglecting heat generation due to viscous stress work and compressibility effects, all justified within the context of the present application. A sharp-interface, finite-difference algorithm is employed for its spatial discretisation: the diffusion term is treated implicitly, with the interfacial position resolved with subgrid accuracy, utilising the information provided by the GVOF interface-tracking method referred to earlier. A three-point, central-difference scheme is employed, of second-order accuracy for steady-state conditions. For problems depending on the gradients of the solution, such as the bubble-growth problem of Scriven (Reference Scriven1959), first-order accuracy is retrieved (Gibou et al. Reference Gibou, Fedkiw, Cheng and Kang2002). (We thank one of the referees for clarifying this point during the review process.) The advection terms are treated explicitly, employing a second-order TVD scheme. The phasic velocities, ![]() $\boldsymbol {u}_l$ and

$\boldsymbol {u}_l$ and ![]() $\boldsymbol {u}_v$, are obtained from a variation of the extrapolation algorithm of Malan et al. (Reference Malan, Malan, Zaleski and Rousseau2021) and ‘ghost’ values of temperature are calculated by means of linear extrapolation across the interface, assuming continuity of temperature at the interface itself, calculated at the appropriate interface position. Note that the temperature gradient is not continuous at the interface, due to the step change in the thermal conductivities occurring there, and the presence of a non-zero phase-change rate (2.5).

$\boldsymbol {u}_v$, are obtained from a variation of the extrapolation algorithm of Malan et al. (Reference Malan, Malan, Zaleski and Rousseau2021) and ‘ghost’ values of temperature are calculated by means of linear extrapolation across the interface, assuming continuity of temperature at the interface itself, calculated at the appropriate interface position. Note that the temperature gradient is not continuous at the interface, due to the step change in the thermal conductivities occurring there, and the presence of a non-zero phase-change rate (2.5).

The interfacial temperature ![]() $T_\gamma$ is assumed to be constant and equal to the saturation temperature at the prevailing system pressure: see § 3 for a discussion of the role and implementation of the IHTR.

$T_\gamma$ is assumed to be constant and equal to the saturation temperature at the prevailing system pressure: see § 3 for a discussion of the role and implementation of the IHTR.

2.5. Treatment of the solid

In the solid part of the domain, only heat conduction needs to be considered:

where ![]() $q$

$q$ ![]() $({\rm W}~{\rm m}^{-3}$) is the volumetric heat source, e.g. due to electrical resistance heating. Note that a finite-volume formulation, rather than a finite-difference one, is employed, since it was found to have better convergence characteristics in the presence of a heat source in preliminary 1-D test studies. With the solid assumed to be a single phase, the finite-volume formulation can be employed without issues. If it is composed of several layered materials, simple averaging based on volume fractions is used to obtain the cell-specific values of

$({\rm W}~{\rm m}^{-3}$) is the volumetric heat source, e.g. due to electrical resistance heating. Note that a finite-volume formulation, rather than a finite-difference one, is employed, since it was found to have better convergence characteristics in the presence of a heat source in preliminary 1-D test studies. With the solid assumed to be a single phase, the finite-volume formulation can be employed without issues. If it is composed of several layered materials, simple averaging based on volume fractions is used to obtain the cell-specific values of ![]() $C_{p,s}$ and

$C_{p,s}$ and ![]() $\lambda _s$. This treatment is exact for

$\lambda _s$. This treatment is exact for ![]() $C_{p,s}$ but only approximate for

$C_{p,s}$ but only approximate for ![]() $\lambda _s$, the degree of approximation depending on the grid resolution.

$\lambda _s$, the degree of approximation depending on the grid resolution.

2.5.1. Wall boundary conditions for heat transfer

At the solid–fluid boundary, continuity of heat flux is assumed. The existence of a temperature contact discontinuity is permitted, and modelled in terms of a contact heat-transfer resistance ![]() $\mathcal {R}_c$

$\mathcal {R}_c$ ![]() $({\rm K~m}^2~{\rm W}^{-1})$. As a result, the solid-side and fluid-side boundary temperatures can be derived from

$({\rm K~m}^2~{\rm W}^{-1})$. As a result, the solid-side and fluid-side boundary temperatures can be derived from

where ![]() $T_s$ is the temperature in the solid at distance

$T_s$ is the temperature in the solid at distance ![]() $\Delta z_s$ from the boundary, and

$\Delta z_s$ from the boundary, and ![]() $T_f$ is the temperature in the fluid at distance

$T_f$ is the temperature in the fluid at distance ![]() $\Delta z_f$ from the boundary; this could be either the distance to the nearest mesh point or that to the phasic interface.

$\Delta z_f$ from the boundary; this could be either the distance to the nearest mesh point or that to the phasic interface.

For the purpose of implicit discretisation of the Laplacian operator in (2.16) and (2.17), we start with a generic, three-point central-difference formula:

Here, ![]() $T_C$ is the temperature at the point where the difference is calculated; for illustration, we choose the solid-adjacent fluid cell, shown as the central cell in figure 2. The coefficients

$T_C$ is the temperature at the point where the difference is calculated; for illustration, we choose the solid-adjacent fluid cell, shown as the central cell in figure 2. The coefficients ![]() $K_P$ and

$K_P$ and ![]() $K_B$ are functions of the distances to the solid–fluid boundary

$K_B$ are functions of the distances to the solid–fluid boundary ![]() $\Delta z_p$ and

$\Delta z_p$ and ![]() $\Delta z_b$, also illustrated in figure 2. Assuming that

$\Delta z_b$, also illustrated in figure 2. Assuming that ![]() $T_b$ has been computed from

$T_b$ has been computed from ![]() $T_M$ and

$T_M$ and ![]() $T_C$ using (2.21), we can then develop the second term on the right-hand side of (2.22) as follows:

$T_C$ using (2.21), we can then develop the second term on the right-hand side of (2.22) as follows:

\begin{align} K_B (T_b - T_C) &= K_B\left(\frac{\mathcal{R}_M T_C + \mathcal{R}_C T_M}{\mathcal{R}_M+\mathcal{R}_C}-T_C\right) = K_B\left(\frac{\mathcal{R}_C T_M-\mathcal{R}_C T_C}{\mathcal{R}_B+\mathcal{R}_C}\right)\nonumber\\ &= K_B\frac{\mathcal{R}_C}{\mathcal{R}_M+\mathcal{R}_C} (T_M - T_C)\equiv K_M (T_M - T_C). \end{align}

\begin{align} K_B (T_b - T_C) &= K_B\left(\frac{\mathcal{R}_M T_C + \mathcal{R}_C T_M}{\mathcal{R}_M+\mathcal{R}_C}-T_C\right) = K_B\left(\frac{\mathcal{R}_C T_M-\mathcal{R}_C T_C}{\mathcal{R}_B+\mathcal{R}_C}\right)\nonumber\\ &= K_B\frac{\mathcal{R}_C}{\mathcal{R}_M+\mathcal{R}_C} (T_M - T_C)\equiv K_M (T_M - T_C). \end{align}

Figure 2. Schematic representation of the stencil used for the implicit discretisation of the heat diffusion term of the energy transport equation in the vicinity of a solid–fluid boundary, indicated here by the thick vertical line: ![]() $T_{b,s}$ and

$T_{b,s}$ and ![]() $T_{b,f}$ are the solid-side and liquid-side boundary temperatures, respectively.

$T_{b,f}$ are the solid-side and liquid-side boundary temperatures, respectively.

Similar estimations are used within the solid finite-volume formulation on the solid side of the boundary. Thus, the conjugate heat-transfer problem between the solid and the fluid can be solved by means of a fully coupled algorithm, with heat conduction treated implicitly on both the fluid and solid sides of the boundary. Note that, in our application domain, the physical solid–liquid contact resistance is assumed to be zero; we use ![]() $\mathcal {R}_c$, however, for reduced-order modelling of IHTR. This is discussed further in § 3.5.

$\mathcal {R}_c$, however, for reduced-order modelling of IHTR. This is discussed further in § 3.5.

2.5.2. Wall boundary conditions for interface reconstruction

Our subgrid-accurate implementation of phase change using (2.5) necessitates the calculation of the interfacial area density ![]() $a_\gamma$ in all wall-adjacent cells. The nodal values of

$a_\gamma$ in all wall-adjacent cells. The nodal values of ![]() $\phi$ required by the marching cubes algorithm (Lorensen & Cline Reference Lorensen and Cline1987) necessitate the use of ghost values in the wall cells. These are obtained using the following iterative extrapolation procedure:

$\phi$ required by the marching cubes algorithm (Lorensen & Cline Reference Lorensen and Cline1987) necessitate the use of ghost values in the wall cells. These are obtained using the following iterative extrapolation procedure:

(i) Perform the GVOF reconstruction of the interfacial geometry in wall-adjacent cells, utilising only information in the fluid cells themselves. Here, GVOF reconstruction means computing normal vectors and line constants defining the GVOF interfacial orientation based on the

$\phi$ stencil described in Bureš et al. (Reference Bureš, Sato and Pautz2021).

$\phi$ stencil described in Bureš et al. (Reference Bureš, Sato and Pautz2021).(ii) Extend the linear interface from wall-adjacent cells to the ghost cells to obtain

$\phi ^{{ghost}}$.

$\phi ^{{ghost}}$.(iii) Perform the GVOF reconstruction of the interfacial geometry in wall-adjacent cells again, utilising the full stencil this time, and including the ghost-cell estimates. Note that the normal vector calculated at this step could be different from the one obtained in step (i).

(iv) Compare the new normal vector field with the previous estimate. If the change is outside the specified tolerance, go back to step (ii) and repeat.

In practical terms, the method converges very rapidly, requiring only one or two iterations to reach negligible variation of the normal vector field, as stipulated in the predefined tolerances. A schematic representation of the result of the wall iterative extrapolation procedure is presented in figure 3.

Figure 3. Schematic representation of the wall iterative extrapolation procedure. Note that the shape of the interface in the fluid domain is slightly perturbed in the process due to realignment of the normal vector. Note also that the linear extension of the interface is limited only to the adjacent ‘ghost’ cell.

2.5.3. Wall boundary conditions for curvature

Multiphase DNS requires the implementation of hydrodynamic BCs at the solid wall; in this work, we assume the natural no-slip/no-penetration BC for velocity. Consequently, the hydrodynamic BC reduces to a contact-angle condition (i.e. a Dirichlet BC for the interfacial slope at the wall), which augments the computation of the surface tension force (2.11) in the near-wall cells. In this work, we explicitly impose the contact angle using the height-function approach of Afkhami & Bussmann (Reference Afkhami and Bussmann2008), again adapted for axisymmetric geometry. The contact angle model employed in our simulations is explained fully in § 3.6.

2.6. Overall solution algorithm

In summary, the following algorithm is employed to solve the governing equations in PSI-BOIL:

(i) Calculate the interfacial area density

$a_\gamma$ using the marching cubes algorithm needed for (2.5).

$a_\gamma$ using the marching cubes algorithm needed for (2.5).(ii) Calculate the mass transfer

$\dot {m}'''$ between the phases directly using (2.5).

$\dot {m}'''$ between the phases directly using (2.5).(iii) Calculate the curvature

$\kappa$ using the height-function method, and use it to estimate the surface tension force

$\kappa$ using the height-function method, and use it to estimate the surface tension force  $\,\boldsymbol {f}_\sigma$ via (2.11).

$\,\boldsymbol {f}_\sigma$ via (2.11).(iv) Solve the momentum conservation equations (2.9) to obtain a tentative estimate of the velocity field

$\boldsymbol {u}^\star$.

$\boldsymbol {u}^\star$.(v) Solve the Poisson equation for pressure, (2.13), and project the tentative velocity field

$\boldsymbol {u}^\star$ to ensure volume conservation using (2.14), obtaining a new estimate of the velocity field

$\boldsymbol {u}^\star$ to ensure volume conservation using (2.14), obtaining a new estimate of the velocity field  $\boldsymbol {u}$.

$\boldsymbol {u}$.(vi) Calculate the intermediate volume fraction field using (2.3).

(vii) Calculate the liquid and vapour velocity fields

$\boldsymbol {u}_l$ and

$\boldsymbol {u}_l$ and  $\boldsymbol {u}_v$ (individual phasic velocities) using our version of the extrapolation algorithm of Malan et al. (Reference Malan, Malan, Zaleski and Rousseau2021), as detailed in Bureš & Sato (Reference Bureš and Sato2021b).

$\boldsymbol {u}_v$ (individual phasic velocities) using our version of the extrapolation algorithm of Malan et al. (Reference Malan, Malan, Zaleski and Rousseau2021), as detailed in Bureš & Sato (Reference Bureš and Sato2021b).(viii) Advect the intermediate volume fraction field using directional splitting, (2.4).

(ix) Ensure energy conservation by the simultaneous solution of (2.16), (2.17) and (2.19).

(x) Advance the time step.

(xi) Go back to step (i).

3. Interfacial heat-transfer resistance

In § 2.4, we indicated that the liquid and vapour phases are constrained during the solution of the energy conservation equation by a Dirichlet BC for temperature at the phasic interfaces. An estimate of the interfacial temperature ![]() $T_\gamma$ can then be derived from the assumption of thermostatic equilibrium: i.e. that the temperature is continuous across the interface, with

$T_\gamma$ can then be derived from the assumption of thermostatic equilibrium: i.e. that the temperature is continuous across the interface, with ![]() $T_\gamma$ equal to the saturation temperature at the ambient system pressure

$T_\gamma$ equal to the saturation temperature at the ambient system pressure ![]() $T_{{sat}}$, with local pressure variations and the Kelvin effect (Thomson Reference Thomson1872) being neglected.

$T_{{sat}}$, with local pressure variations and the Kelvin effect (Thomson Reference Thomson1872) being neglected.

3.1. Discrepancy

Although the above assumption is generally acceptable for single-component multiphase systems (Ishii & Hibiki Reference Ishii and Hibiki2011), it is known that it can induce non-negligible error in the calculation of heat flow through the microregion and microlayer of an expanding bubble from a heated surface (Giustini et al. Reference Giustini, Jung, Kim and Walker2016). For illustration, consider a typical data point from the experiment of Bucci (Reference Bucci2020), with a measured wall superheat ![]() $\Delta T_{{wall}} \!=\! T_{{wall}} - T_{{sat}}$ in the range of 5–10 K. Though the microlayer thickness

$\Delta T_{{wall}} \!=\! T_{{wall}} - T_{{sat}}$ in the range of 5–10 K. Though the microlayer thickness ![]() $d$ (m) was not explicitly measured in this experiment, during evaporation, values of

$d$ (m) was not explicitly measured in this experiment, during evaporation, values of ![]() $d = O(100~\text {nm})$ would be expected, as indicated by other recent experiments (e.g. Chen et al. Reference Chen, Hu, Hu, Utaka and Mori2020). Assuming steady-state 1-D conduction through the liquid microlayer beneath the expanding bubble (see § 4 for a discussion of the validity of this assumption), this gives for the heat flux

$d = O(100~\text {nm})$ would be expected, as indicated by other recent experiments (e.g. Chen et al. Reference Chen, Hu, Hu, Utaka and Mori2020). Assuming steady-state 1-D conduction through the liquid microlayer beneath the expanding bubble (see § 4 for a discussion of the validity of this assumption), this gives for the heat flux ![]() $j_q$ (W m

$j_q$ (W m![]() $^{-2}$):

$^{-2}$):

Such values should thus be routinely observed during an experiment of this type, but the maximal values reported by Bucci (Reference Bucci2020) are in the region of 2 MW m![]() $^{-2}$ in the 5–10 K superheat range. Such a discrepancy is not exceptional, and has often been reported in the literature (e.g. Giustini et al. Reference Giustini, Jung, Kim and Walker2016), and appears to indicate that the simple assumption of thermostatic equilibrium does not capture the actual heat-transfer situation occurring in the microlayer.

$^{-2}$ in the 5–10 K superheat range. Such a discrepancy is not exceptional, and has often been reported in the literature (e.g. Giustini et al. Reference Giustini, Jung, Kim and Walker2016), and appears to indicate that the simple assumption of thermostatic equilibrium does not capture the actual heat-transfer situation occurring in the microlayer.

3.2. Closure using statistical physics

An alternative closure model might be found in the framework of statistical physics. The Hertz–Knudsen relation expresses the interfacial heat flux in the following form (Knudsen Reference Knudsen1950):

\begin{equation} j_{q,\gamma} = L\sqrt{\frac{M_v}{2{\rm \pi} R_g}}\left(\omega_e\frac{p_s(T_{\gamma,l})}{\sqrt{T_{\gamma,l}}} -\omega_c\frac{p_v}{\sqrt{T_{\gamma,v}}}\right). \end{equation}

\begin{equation} j_{q,\gamma} = L\sqrt{\frac{M_v}{2{\rm \pi} R_g}}\left(\omega_e\frac{p_s(T_{\gamma,l})}{\sqrt{T_{\gamma,l}}} -\omega_c\frac{p_v}{\sqrt{T_{\gamma,v}}}\right). \end{equation}

Here, ![]() $M_v$ is the molar mass

$M_v$ is the molar mass ![]() $({\rm kg}~{\rm mol}^{-1})$ of vapour,

$({\rm kg}~{\rm mol}^{-1})$ of vapour, ![]() $R_g = 8.314~{\rm J}~({\rm mol}~{\rm K})^{-1}$ is the universal gas constant,

$R_g = 8.314~{\rm J}~({\rm mol}~{\rm K})^{-1}$ is the universal gas constant, ![]() $p_s(T_{\gamma,l})$ is the saturation pressure at the liquid interfacial temperature

$p_s(T_{\gamma,l})$ is the saturation pressure at the liquid interfacial temperature ![]() $T_{\gamma,l}$, while

$T_{\gamma,l}$, while ![]() $p_v$ is the vapour pressure and

$p_v$ is the vapour pressure and ![]() $T_{\gamma,v}$ is the vapour interfacial temperature. In addition,

$T_{\gamma,v}$ is the vapour interfacial temperature. In addition, ![]() $\omega _c$ and

$\omega _c$ and ![]() $\omega _e$ (–) represent the empirical accommodation coefficients for condensation and evaporation, introduced by Knudsen (Reference Knudsen1950) to account for the imperfect transport of molecules between the phases. Using statistical rate theory, Persad & Ward (Reference Persad and Ward2016) deduced closed-form expressions for

$\omega _e$ (–) represent the empirical accommodation coefficients for condensation and evaporation, introduced by Knudsen (Reference Knudsen1950) to account for the imperfect transport of molecules between the phases. Using statistical rate theory, Persad & Ward (Reference Persad and Ward2016) deduced closed-form expressions for ![]() $\omega _c$ and

$\omega _c$ and ![]() $\omega _e$ and demonstrated that

$\omega _e$ and demonstrated that

For small temperature variations in the domain, we can thus simplify the expression (3.2) accordingly:

\begin{equation} j_{q,\gamma} \approx L\sqrt{\frac{M_v}{2{\rm \pi} R_g T_{{ref}}}} (p_s(T_{\gamma,l})-p_v), \end{equation}

\begin{equation} j_{q,\gamma} \approx L\sqrt{\frac{M_v}{2{\rm \pi} R_g T_{{ref}}}} (p_s(T_{\gamma,l})-p_v), \end{equation}

with ![]() $T_{{ref}}$ being a representative temperature value, such as

$T_{{ref}}$ being a representative temperature value, such as ![]() $T_{{sat}}$. This equation includes two independent parameters: the liquid interfacial temperature

$T_{{sat}}$. This equation includes two independent parameters: the liquid interfacial temperature ![]() $T_{\gamma,l}$ and the vapour pressure

$T_{\gamma,l}$ and the vapour pressure ![]() $p_v$. Typically, it is assumed that the vapour is at saturation at the prevailing system pressure (Giustini et al. Reference Giustini, Jung, Kim and Walker2016), giving

$p_v$. Typically, it is assumed that the vapour is at saturation at the prevailing system pressure (Giustini et al. Reference Giustini, Jung, Kim and Walker2016), giving

\begin{equation} j_{q,\gamma} \approx L\sqrt{\frac{M_v}{2{\rm \pi} R_g T_{{ref}}}} (p_s(T_{\gamma,l})-p_s(T_{{sat}})). \end{equation}

\begin{equation} j_{q,\gamma} \approx L\sqrt{\frac{M_v}{2{\rm \pi} R_g T_{{ref}}}} (p_s(T_{\gamma,l})-p_s(T_{{sat}})). \end{equation}Using the linearised form of the Clausius–Clapeyron relation (Faghri & Zhang Reference Faghri and Zhang2006), we immediately deduce that

\begin{equation} j_{q,\gamma} \approx \rho_v L^2 \sqrt{\frac{M_v}{2{\rm \pi} R_g T^3_{{sat}} }} \,(T_{\gamma,l}-T_{{sat}}) =\frac{T_{\gamma,l}-T_{{sat}}}{\mathcal{R}_\gamma}. \end{equation}

\begin{equation} j_{q,\gamma} \approx \rho_v L^2 \sqrt{\frac{M_v}{2{\rm \pi} R_g T^3_{{sat}} }} \,(T_{\gamma,l}-T_{{sat}}) =\frac{T_{\gamma,l}-T_{{sat}}}{\mathcal{R}_\gamma}. \end{equation}

Here, we have introduced the factor ![]() $\mathcal {R}_\gamma$

$\mathcal {R}_\gamma$ ![]() $({\rm K~m}^2~{\rm W}^{-1})$ as the IHTR:

$({\rm K~m}^2~{\rm W}^{-1})$ as the IHTR:

\begin{equation} \mathcal{R}_\gamma = \frac{1}{\rho_v L^2} \sqrt{\frac{2{\rm \pi} R_g T_{{sat}}^3}{M_v}}. \end{equation}

\begin{equation} \mathcal{R}_\gamma = \frac{1}{\rho_v L^2} \sqrt{\frac{2{\rm \pi} R_g T_{{sat}}^3}{M_v}}. \end{equation}

However, this expression, when applied to water under atmospheric conditions, gives ![]() $\mathcal {R}_\gamma \simeq 1.3 \times 10^{-7}~{\rm K~m}^2~{\rm W}^{-1}$. This value is too small to change the results of the calculations of heat flux in the microlayer, such as those represented in (3.1). As discussed by Persad & Ward (Reference Persad and Ward2016), assumptions on vapour conditions can significantly impact the accuracy of any expression deduced from the Hertz–Knudsen relation (3.2).

$\mathcal {R}_\gamma \simeq 1.3 \times 10^{-7}~{\rm K~m}^2~{\rm W}^{-1}$. This value is too small to change the results of the calculations of heat flux in the microlayer, such as those represented in (3.1). As discussed by Persad & Ward (Reference Persad and Ward2016), assumptions on vapour conditions can significantly impact the accuracy of any expression deduced from the Hertz–Knudsen relation (3.2).

To the best of our knowledge, a satisfactory closure model describing vapour conditions in the vicinity of the microlayer beneath a growing vapour bubble during boiling has not yet appeared in the literature, and thereby represents an unknown in the understanding of the physical processes taking place, which should be addressed in the future. For the present work, we are thus forced to resort to the classical approach, in which we assume that ![]() $p_v=p_s(T_{{sat}})$, and, although

$p_v=p_s(T_{{sat}})$, and, although ![]() $\omega _c\approx \omega _e\equiv \omega$, the accommodation coefficient is in fact not taken to be unity, and is a priori unknown. This gives, following the same steps as above,

$\omega _c\approx \omega _e\equiv \omega$, the accommodation coefficient is in fact not taken to be unity, and is a priori unknown. This gives, following the same steps as above,

\begin{equation} \mathcal{R}_\gamma = \frac{1}{\omega}\frac{1}{\rho_v L^2}\sqrt{\frac{2{\rm \pi} R_gT_{{sat}}^3}{M_v}}, \end{equation}

\begin{equation} \mathcal{R}_\gamma = \frac{1}{\omega}\frac{1}{\rho_v L^2}\sqrt{\frac{2{\rm \pi} R_gT_{{sat}}^3}{M_v}}, \end{equation}

leaving the unknown ![]() $\omega$ yet to be determined.

$\omega$ yet to be determined.

3.3. Value of the accommodation coefficient

To evaluate ![]() $\omega$, we appeal to the available experimental data. The dataset of Bucci (Reference Bucci2020) includes measurements of both wall superheat and heat flux, with a spatial resolution of 30

$\omega$, we appeal to the available experimental data. The dataset of Bucci (Reference Bucci2020) includes measurements of both wall superheat and heat flux, with a spatial resolution of 30 ![]() $\mathrm {\mu }$m, and a temporal resolution (i.e. exposure time of the camera) of 200

$\mathrm {\mu }$m, and a temporal resolution (i.e. exposure time of the camera) of 200 ![]() $\mathrm {\mu }$s. Employing the same 1-D steady-state conduction model as used before (see figure 23 in § 4 and the corresponding discussion for a justification of the use of this model), we can collate the given measurements according to the following formula:

$\mathrm {\mu }$s. Employing the same 1-D steady-state conduction model as used before (see figure 23 in § 4 and the corresponding discussion for a justification of the use of this model), we can collate the given measurements according to the following formula:

If we now assume that, for each temporal snapshot, the highest locally measured value of ![]() $j_q$ corresponds to the situation for which

$j_q$ corresponds to the situation for which ![]() $d\rightarrow 0$, we can deduce that, for each snapshot,

$d\rightarrow 0$, we can deduce that, for each snapshot,

where ![]() $\Delta T_{{wall,loc}}$ is the corresponding locally measured superheat value (see figure 4).

$\Delta T_{{wall,loc}}$ is the corresponding locally measured superheat value (see figure 4).

Figure 4. Schematic representation of the ![]() $\mathcal {R}_\gamma$ evaluation procedure. Here,

$\mathcal {R}_\gamma$ evaluation procedure. Here, ![]() $j_{q,{max}}$ is the maximal heat flux for the given snapshot, and

$j_{q,{max}}$ is the maximal heat flux for the given snapshot, and ![]() $T_{{wall,loc}}$ is the locally measured wall temperature.

$T_{{wall,loc}}$ is the locally measured wall temperature.

Figure 5 shows the result of this processing of the available data. It can be observed that, despite deviations from the norm, a justifiable prediction of ![]() $\mathcal {R}_\gamma$ can be estimated, with a mean value of

$\mathcal {R}_\gamma$ can be estimated, with a mean value of ![]() $\bar {\mathcal {R}}_\gamma \simeq 3.7 \times 10^{-6}~{\rm K~m}^2~{\rm W}^{-1}$. Note that this is at least one order of magnitude larger than the classical value (

$\bar {\mathcal {R}}_\gamma \simeq 3.7 \times 10^{-6}~{\rm K~m}^2~{\rm W}^{-1}$. Note that this is at least one order of magnitude larger than the classical value (![]() $\mathcal {R}_\gamma \simeq 1.3 \times 10^{-7}~{\rm K~m}^2~{\rm W}^{-1}$) based on the simplified Hertz–Knudsen relation (3.6). This new estimate corresponds to a value of the accommodation coefficient

$\mathcal {R}_\gamma \simeq 1.3 \times 10^{-7}~{\rm K~m}^2~{\rm W}^{-1}$) based on the simplified Hertz–Knudsen relation (3.6). This new estimate corresponds to a value of the accommodation coefficient ![]() $\omega _A$ in (3.8) of

$\omega _A$ in (3.8) of ![]() $\sim$0.0345, a value consistent with the literature suggestions for water evaporation (Paul Reference Paul1962) and boiling (Giustini et al. Reference Giustini, Jung, Kim and Walker2016). Consequently, we have adopted this value for the remainder of the study presented here. Note that the equivalent liquid film thickness

$\sim$0.0345, a value consistent with the literature suggestions for water evaporation (Paul Reference Paul1962) and boiling (Giustini et al. Reference Giustini, Jung, Kim and Walker2016). Consequently, we have adopted this value for the remainder of the study presented here. Note that the equivalent liquid film thickness ![]() $d_{{eq}} = \lambda _l \bar {\mathcal {R}}_\gamma$ is approximately 2

$d_{{eq}} = \lambda _l \bar {\mathcal {R}}_\gamma$ is approximately 2 ![]() $\mathrm {\mu }$m; i.e. the resistance of the interface has essentially the same importance as the conductive resistance of the microlayer itself, this being equal to

$\mathrm {\mu }$m; i.e. the resistance of the interface has essentially the same importance as the conductive resistance of the microlayer itself, this being equal to ![]() $d/\lambda _l=O(1~\mathrm {\mu }\text {m})/\lambda _l = O(10^{-6}~\text {K~m}^2~\text {W}^{-1})$.

$d/\lambda _l=O(1~\mathrm {\mu }\text {m})/\lambda _l = O(10^{-6}~\text {K~m}^2~\text {W}^{-1})$.

Figure 5. The IHTR evaluated using (3.10), and based on the data of Bucci (Reference Bucci2020). The mean value has been obtained by an averaging procedure with respect to time, rather than one based on spatial position.

In the above analysis, it has been assumed that the experimental measurement technique can capture the location of the heat-flux extremum exactly. However, the IR camera used by Bucci (Reference Bucci2020) has finite spatial (![]() $\Delta x = 30~\mathrm {\mu }$m) and temporal (

$\Delta x = 30~\mathrm {\mu }$m) and temporal (![]() $\Delta t = 200~\mathrm {\mu }$s) resolutions. Thus,

$\Delta t = 200~\mathrm {\mu }$s) resolutions. Thus, ![]() $d$ in (3.9) should not be taken to be equal to zero, but rather has a value of

$d$ in (3.9) should not be taken to be equal to zero, but rather has a value of

the integrals representing averaging over a time step ![]() $\Delta t$ and a spatial segment with width

$\Delta t$ and a spatial segment with width ![]() $\Delta x$. Thus, we see that

$\Delta x$. Thus, we see that ![]() $\omega _A = 0.0345$ is a lower-bound estimate for the accommodation coefficient under the assumption

$\omega _A = 0.0345$ is a lower-bound estimate for the accommodation coefficient under the assumption ![]() $d\rightarrow 0$ in the above equation, and the actual value of

$d\rightarrow 0$ in the above equation, and the actual value of ![]() $\mathcal {R}_\gamma$ should be given as

$\mathcal {R}_\gamma$ should be given as

To account for the uncertainty in ![]() $\mathcal {R}_\gamma$ due to the unknown value of

$\mathcal {R}_\gamma$ due to the unknown value of ![]() $d$, we should also deduce an upper bound

$d$, we should also deduce an upper bound ![]() $\omega _B$. We have noted in our simulations in Bureš & Sato (Reference Bureš and Sato2021a,Reference Bureš and Satoc), as well as those presented in § 4, that the microlayer thickness does not gradually increase from zero near the contact line, but rather jumps abruptly to a non-zero value,

$\omega _B$. We have noted in our simulations in Bureš & Sato (Reference Bureš and Sato2021a,Reference Bureš and Satoc), as well as those presented in § 4, that the microlayer thickness does not gradually increase from zero near the contact line, but rather jumps abruptly to a non-zero value, ![]() $d_1$, as a result of the dynamics of dewetting. Thus, assuming the thickness of the microlayer to have a step-like profile in the vicinity of the contact line, the integral (3.11) reduces to

$d_1$, as a result of the dynamics of dewetting. Thus, assuming the thickness of the microlayer to have a step-like profile in the vicinity of the contact line, the integral (3.11) reduces to ![]() $d = d_1$. Based on our preliminary simulations, we have chosen this value as

$d = d_1$. Based on our preliminary simulations, we have chosen this value as ![]() $\sim$500 nm, a value we consider high enough to result in a reasonable upper-bound estimate

$\sim$500 nm, a value we consider high enough to result in a reasonable upper-bound estimate ![]() $\omega _B$. Indeed, setting

$\omega _B$. Indeed, setting ![]() $d$ in (3.12) as

$d$ in (3.12) as ![]() $d_1 \simeq 500$ nm and evaluating

$d_1 \simeq 500$ nm and evaluating ![]() $\mathcal {R}_\gamma$ corresponds to an increase of

$\mathcal {R}_\gamma$ corresponds to an increase of ![]() $\omega$ by approximately 33 %, giving

$\omega$ by approximately 33 %, giving ![]() $\omega _B \simeq 0.0460$. Although not derived in a fully rigorous manner, this upper bound should account for the uncertainty in the

$\omega _B \simeq 0.0460$. Although not derived in a fully rigorous manner, this upper bound should account for the uncertainty in the ![]() $\mathcal {R}_\gamma$ evaluation discussed here; results with both

$\mathcal {R}_\gamma$ evaluation discussed here; results with both ![]() $\omega _A = 0.0345$ and

$\omega _A = 0.0345$ and ![]() $\omega _B = 0.0460$ are presented in § 4.

$\omega _B = 0.0460$ are presented in § 4.

3.4. Full model implementation

To implement (liquid-side) IHTR into the PSI-BOIL code, the Dirichlet condition (2.18) must be replaced by a Robin-type (Papac, Gibou & Ratsch Reference Papac, Gibou and Ratsch2010) condition deduced from (3.6), with the interfacial heat flux evaluated using Fourier's law of heat conduction:

We further assume that the liquid-side heat flux in the direction tangential to the interface is negligible (which is typical both for boundary-layer situations at the interface within the bulk fluid and for 1-D conduction in the microlayer). Hence, ![]() $\,\boldsymbol {j}_{q}|_{\gamma,l} \approx j_{q}|_{\gamma,l}\,\boldsymbol {n}$, which is equivalent to the approximation introduced by Liu, Fedkiw & Kang (Reference Liu, Fedkiw and Kang2000) in the context of their solution approach for Poisson equations. This assumption immediately implies that

$\,\boldsymbol {j}_{q}|_{\gamma,l} \approx j_{q}|_{\gamma,l}\,\boldsymbol {n}$, which is equivalent to the approximation introduced by Liu, Fedkiw & Kang (Reference Liu, Fedkiw and Kang2000) in the context of their solution approach for Poisson equations. This assumption immediately implies that

and

Evidently, we can now decompose the Robin condition into two independent directional conditions as follows:

These conditions can be implemented into the implicit, sharp-interface discretisation scheme employed in PSI-BOIL to solve the energy conservation equation, by utilising conceptually similar methods to those described earlier in § 2.5.1, even though the resulting formulae are rather cumbersome.

Our preliminary results indicate that introducing the IHTR everywhere on the bubble surface results in an unrealistically small growth rate. This would indicate that IHTR only plays a significant role in the immediate vicinity of the heated surface. Although this might appear to be unphysical, i.e. we would expect that the interface has the same heat-transfer resistance everywhere, it is important to remember that the very concept of IHTR is speculative in itself. Indeed, referring back to (3.4), we should actually be concerned with the near-interface vapour conditions, which could vary around the bubble surface. Since we do not have any information on the vapour pressure distribution, we have decided to continue our numerical exercise using the approach we introduced in our conference paper (Bureš & Sato Reference Bureš and Sato2021a): i.e. we localise the effects of IHTR only in the microlayer, and then critically assess its success, or otherwise, against measured data. This approach is detailed below, while an example of results of a simulation with IHTR prescribed everywhere on the bubble surface is given in § 5, for comparison purposes, and where results of a simulation with ![]() $\omega =1$ are also given.

$\omega =1$ are also given.

3.5. Near-wall implementation

Since any significant effect of IHTR is now assumed to be localised in the microlayer, for which conduction in the wall-normal direction represents the dominant heat-transfer mechanism, a simplified implementation of IHTR can be introduced directly at the solid wall boundary by means of a numerically equivalent, contact heat-transfer resistance factor ![]() $\mathcal {R}_c$ (see § 2.5.1). This approach automatically preserves the overall conduction resistance, since

$\mathcal {R}_c$ (see § 2.5.1). This approach automatically preserves the overall conduction resistance, since

provided that ![]() $\mathcal {R}_c=\mathcal {R}_\gamma$. This simplification is illustrated schematically in figure 6. As can be seen, the temperature discontinuity due to heat-transfer resistance has been effectively moved from the liquid–vapour interface to the solid–liquid boundary; the overall temperature difference between the wall temperature

$\mathcal {R}_c=\mathcal {R}_\gamma$. This simplification is illustrated schematically in figure 6. As can be seen, the temperature discontinuity due to heat-transfer resistance has been effectively moved from the liquid–vapour interface to the solid–liquid boundary; the overall temperature difference between the wall temperature ![]() $T_{b,s}$ and the vapour temperature

$T_{b,s}$ and the vapour temperature ![]() $T_{{sat}}$ has been preserved in the process.

$T_{{sat}}$ has been preserved in the process.

Figure 6. Illustration of the concept of equivalent conductive resistance: (a) IHTR located at the liquid–vapour interface; and (b) IHTR located at the solid–liquid boundary. Note that ![]() $T_{\gamma,l}-T_{{sat}} = T_{b,s}-T_{b,l}$.

$T_{\gamma,l}-T_{{sat}} = T_{b,s}-T_{b,l}$.

3.6. Apparent contact angle in the high-IHTR limit

In spite of the reported importance of the wetting conditions for microlayer formation (Urbano et al. Reference Urbano, Tanguy, Huber and Colin2018; Bureš & Sato Reference Bureš and Sato2021c), relevant experimental data remain sparse. Although static wetting conditions are usually reported – e.g. perfect wetting in the case of Bucci (Reference Bucci2020) – it is generally accepted (Raj et al. Reference Raj, Kunkelmann, Stephan, Plawsky and Kim2012; Janeček & Nikolayev Reference Janeček and Nikolayev2013; Fourgeaud et al. Reference Fourgeaud, Ercolani, Duplat, Gully and Nikolayev2016; Schweikert et al. Reference Schweikert, Sielaff and Stephan2019) that the presence of phase change, together with the motion of the contact line (see figure 1), significantly affect the wetting phenomenon. Note that in the case of DNS-BRM, the effects of the numerical slip length, as described by Afkhami et al. (Reference Afkhami, Buongiorno, Guion, Popinet, Saade, Scardovelli and Zaleski2018) and Bureš & Sato (Reference Bureš and Sato2021c), should also be taken into account, further complicating the issue.

The traditional approach to the problem of dynamic wetting of volatile liquids is to appeal to the so-called microregion model: a set of equations derived from 2-D lubrication theory extended to include heat transfer by including 1-D steady-state conduction through the film thickness. The classical result of Voinov (Reference Voinov1976) and Cox (Reference Cox1986) describes dynamic wetting under adiabatic conditions in the form of the Cox–Voinov law thus:

Here ![]() $\theta (x)$ is the local interfacial slope, and

$\theta (x)$ is the local interfacial slope, and ![]() $\theta _0$ is the microscopic contact angle, conventionally assumed to be constant (i.e. any hysteresis effects are neglected), and derived from force balance arguments at the triple line (Snoeijer et al. Reference Snoeijer, Andreotti, Delon and Fermigier2007). In addition,

$\theta _0$ is the microscopic contact angle, conventionally assumed to be constant (i.e. any hysteresis effects are neglected), and derived from force balance arguments at the triple line (Snoeijer et al. Reference Snoeijer, Andreotti, Delon and Fermigier2007). In addition, ![]() $l_s$ (m) is the slip length,

$l_s$ (m) is the slip length, ![]() $\chi =x/l_s$ is a dimensionless distance and

$\chi =x/l_s$ is a dimensionless distance and ![]() $Ca_u$ is the standard capillary number,

$Ca_u$ is the standard capillary number,

with ![]() $U_{{CL}}$ being the contact-line velocity, taken positive for spreading of the liquid over the surface and negative for dewetting. In a like manner, Hocking (Reference Hocking1995) gives a closed-form solution for the apparent contact angle in the presence of phase change in the form

$U_{{CL}}$ being the contact-line velocity, taken positive for spreading of the liquid over the surface and negative for dewetting. In a like manner, Hocking (Reference Hocking1995) gives a closed-form solution for the apparent contact angle in the presence of phase change in the form

where ![]() $Ca_e$ is the evaporation capillary number of Morris (Reference Morris2001), namely,

$Ca_e$ is the evaporation capillary number of Morris (Reference Morris2001), namely,