1. Introduction

Viscoplasticity refers to the nonlinear behaviour of materials with a yield stress, above which these materials typically exhibit viscous deformation, whereas below which they usually behave as rigid solids (Bonn et al. Reference Bonn, Denn, Berthier, Divoux and Manneville2017; Thompson, Sica & de Souza Mendes Reference Thompson, Sica and de Souza Mendes2018). Examples of such materials are frequent in our daily life (e.g. butter, jam and toothpaste), various industries (e.g. waxy crude oils, cement slurries, cosmetics and food products) and even many biological systems (e.g. human blood and mucus) (Balmforth, Frigaard & Ovarlez Reference Balmforth, Frigaard and Ovarlez2014; Horner, Wagner & Beris Reference Horner, Wagner and Beris2021). The flow dynamics of viscoplastic fluids are influenced by the wall characteristics of their conduit, such as waviness (Putz, Frigaard & Martinez Reference Putz, Frigaard and Martinez2009), slipperiness (Panaseti & Georgiou Reference Panaseti and Georgiou2017) and superhydrophobicity (Rahmani & Taghavi Reference Rahmani and Taghavi2022); the latter is commonly enabled by micro-scale protrusions that trap air within surface cavities, inducing liquid slippage on the entrapped air layer (Lee, Choi & Kim Reference Lee, Choi and Kim2016). Thanks to advancements in micro- and nanotechnology (Lee, Charrault & Neto Reference Lee, Charrault and Neto2014; Lee et al. Reference Lee, Choi and Kim2016), groovy protrusions represent a prevalent superhydrophobic (SH) surface configuration. In addition, concerning a chemically patterned (CP) surface, arrays of hydrophobic (slippery) and hydrophilic (non-slippery) stripes can be periodically positioned on solid walls, leading to the heterogeneity of wall boundary conditions (Qian, Wang & Sheng Reference Qian, Wang and Sheng2005; Wang, Qian & Sheng Reference Wang, Qian and Sheng2008; Lee et al. Reference Lee, Charrault and Neto2014). In this context, the current article aims to analyse viscoplastic flows in SH and CP channels whose lower wall is patterned by arrays of slip and no-slip condition, while possessing longitudinal, transverse and oblique groove (stripe) orientations.

SH and CP surfaces have a variety of macro- and micro-scale applications, with examples such as drag reduction and flow manipulation (Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Lee et al. Reference Lee, Charrault and Neto2014, Reference Lee, Choi and Kim2016; Qi et al. Reference Qi, Niu, Ruck and Zhao2019). At the micro-scale, Newtonian and non-Newtonian fluids (e.g. viscoplastic materials) may flow through a microfluidic system, for which a considerable drag reduction can be achieved via SH coating of the walls (Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Asmolov & Vinogradova Reference Asmolov and Vinogradova2012). Considering the flow/drop handling and particle fractionation and focusing applications, SH and CP surfaces may be also used to manipulate the flow dynamics (Lee et al. Reference Lee, Charrault and Neto2014; Asmolov et al. Reference Asmolov, Dubov, Nizkaya, Kuehne and Vinogradova2015; Qi et al. Reference Qi, Niu, Ruck and Zhao2019; Nizkaya et al. Reference Nizkaya, Asmolov, Harting and Vinogradova2020). As an example, these surfaces can be designed and used in microfluidic systems to optimise synthesis of human blood (which exhibits a yield stress) for disease diagnosis and prognosis, e.g. separating circulating tumour cells from cancer patients’ blood (Burinaru et al. Reference Burinaru, Avram, Avram, Marculescu, Tincu, Tucureanu, Matei and Militaru2018). At the macro-scale, on the other hand, industries often transport viscoplastic materials through pipelines, e.g. in underwater transportation of waxy crude oil, with patterned wall coatings offering potential drag reduction solutions (Ijaola, Farayibi & Asmatulu Reference Ijaola, Farayibi and Asmatulu2020). In addition, such coatings can protect the pipeline system against corrosion, icing and bio-fouling (Ijaola et al. Reference Ijaola, Farayibi and Asmatulu2020).

Although the problem of Newtonian flows in contact with SH and CP wall surfaces has been studied extensively over the last two decades (Lauga & Stone Reference Lauga and Stone2003; Qian et al. Reference Qian, Wang and Sheng2005; Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Wang et al. Reference Wang, Qian and Sheng2008; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011; Lee et al. Reference Lee, Charrault and Neto2014; Asmolov, Nizkaya & Vinogradova Reference Asmolov, Nizkaya and Vinogradova2020), their non-Newtonian counterparts have received less attention; however, there have been a few studies limited to shear-thinning fluids over SH surfaces (Crowdy Reference Crowdy2017a; Haase et al. Reference Haase, Wood, Sprakel and Lammertink2017; Patlazhan & Vagner Reference Patlazhan and Vagner2017; Gaddam et al. Reference Gaddam, Sharma, Ahuja, Dimov, Joshi and Agrawal2021). Previous studies have mainly considered, analytically, numerically and experimentally, Newtonian flows with SH groovy and CP wall surfaces, for both thick and thin channels (Ou & Rothstein Reference Ou and Rothstein2005; Qian et al. Reference Qian, Wang and Sheng2005; Davies et al. Reference Davies, Maynes, Webb and Woolford2006; Wang et al. Reference Wang, Qian and Sheng2008; Teo & Khoo Reference Teo and Khoo2009; Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Feuillebois, Bazant & Vinogradova Reference Feuillebois, Bazant and Vinogradova2010; Schmieschek et al. Reference Schmieschek, Belyaev, Harting and Vinogradova2012; Lee et al. Reference Lee, Charrault and Neto2014; Kirk, Hodes & Papageorgiou Reference Kirk, Hodes and Papageorgiou2017). These studies have typically taken into account longitudinal and transverse groove (stripe) configurations, while assuming an ideal Cassie state, with a flat liquid/air interface for the SH surfaces. On the other hand, non-Newtonian flows with SH wall surfaces have been considered through perturbative corrections, e.g. for Carreau–Yasuda fluids (Crowdy Reference Crowdy2017a), and numerically for transverse and longitudinal grooves (Haase et al. Reference Haase, Wood, Sprakel and Lammertink2017; Patlazhan & Vagner Reference Patlazhan and Vagner2017; Gaddam et al. Reference Gaddam, Sharma, Ahuja, Dimov, Joshi and Agrawal2021). Very recently, some studies have begun to model viscoplastic material flows with SH wall surfaces, for both thick and thin channel limits, as well as creeping and inertial flows, albeit limited only to transverse groove orientations (Rahmani & Taghavi Reference Rahmani and Taghavi2022, Reference Rahmani and Taghavi2023; Rahmani et al. Reference Rahmani, Kumar, Greener and Taghavi2023; Rahmani, Larachi & Taghavi Reference Rahmani, Larachi and Taghavi2024). Regarding the flow stability picture, stability analyses have been conducted for Newtonian flows on SH surfaces, with a focus on the longitudinal groove orientation (Yu, Teo & Khoo Reference Yu, Teo and Khoo2016; Tomlinson & Papageorgiou Reference Tomlinson and Papageorgiou2022), leading to finding new modes of instabilities. On the other hand, relevant stability analyses for viscoplastic flows have been limited only to those in contact with hydrophobic walls (Rahmani & Taghavi Reference Rahmani and Taghavi2020), i.e. with homogeneous wall slip conditions, revealing stabilising/destabilising effects of streamwise/spanwise slip conditions.

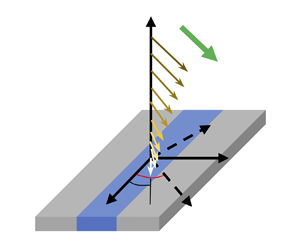

For fluid flows in contact with SH and CP surfaces having longitudinal or transverse groove (stripe) orientations (i.e. with respect to the flow direction), the pressure gradient and the slip velocity vectors are unidirectional (Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011). However, a secondary flow stream is generated normal to the pressure gradient direction in an oblique groove configuration, in which the direction of the grooves makes an angle ![]() $0< \theta < 90^\circ$ with respect to the direction of the applied pressure gradient (see figure 1); this is due to the directional anisotropic slip properties of the surface (Stone, Stroock & Ajdari Reference Stone, Stroock and Ajdari2004; Bazant & Vinogradova Reference Bazant and Vinogradova2008; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011). Therefore, such an oblique configuration leads to unique flow features that can be exploited for many applications, e.g. passive mixing and flow/particle manipulation (Stroock et al. Reference Stroock, Dertinger, Whitesides and Ajdari2002a,Reference Stroock, Dertinger, Ajdari, Mezic, Stone and Whitesidesb; Asmolov et al. Reference Asmolov, Dubov, Nizkaya, Harting and Vinogradova2018; Vagner & Patlazhan Reference Vagner and Patlazhan2019; Nizkaya et al. Reference Nizkaya, Asmolov, Harting and Vinogradova2020).

$0< \theta < 90^\circ$ with respect to the direction of the applied pressure gradient (see figure 1); this is due to the directional anisotropic slip properties of the surface (Stone, Stroock & Ajdari Reference Stone, Stroock and Ajdari2004; Bazant & Vinogradova Reference Bazant and Vinogradova2008; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011). Therefore, such an oblique configuration leads to unique flow features that can be exploited for many applications, e.g. passive mixing and flow/particle manipulation (Stroock et al. Reference Stroock, Dertinger, Whitesides and Ajdari2002a,Reference Stroock, Dertinger, Ajdari, Mezic, Stone and Whitesidesb; Asmolov et al. Reference Asmolov, Dubov, Nizkaya, Harting and Vinogradova2018; Vagner & Patlazhan Reference Vagner and Patlazhan2019; Nizkaya et al. Reference Nizkaya, Asmolov, Harting and Vinogradova2020).

Figure 1. Schematic of oblique Poiseuille flow of a Bingham fluid in an SH channel (for the CP channel the groove would be replaced by a flat slippery stripe). Pressure gradient is in ![]() $\hat z'$ direction at an angle

$\hat z'$ direction at an angle ![]() $\theta$ with

$\theta$ with ![]() $\hat z$ axis. Right panel shows

$\hat z$ axis. Right panel shows ![]() $s$ as the a priori unknown angle between slip velocity vector and groove direction. Here and throughout the text, the dimensional parameters and variables are shown with the hat sign

$s$ as the a priori unknown angle between slip velocity vector and groove direction. Here and throughout the text, the dimensional parameters and variables are shown with the hat sign ![]() $\widehat {(\cdot)}$ whereas for the dimensionless parameters and variables the hat sign is dropped (unless otherwise stated).

$\widehat {(\cdot)}$ whereas for the dimensionless parameters and variables the hat sign is dropped (unless otherwise stated).

Our article presents a novel contribution to the analysis of viscoplastic flows in channels with longitudinal, transverse and most importantly oblique groove (stripe) orientations. Unlike the oblique flow of a Newtonian fluid, whose model equations can be solved via a linear vector transformation of known longitudinal and transverse flow variables (Bazant & Vinogradova Reference Bazant and Vinogradova2008; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011), the oblique flow of a viscoplastic fluid requires a distinct solution due to its nonlinear viscosity, implying that the transform matrix is unknown a priori. To address this challenge, here we consider the creeping Poiseuille flow of a Bingham fluid in thick patterned channels (where the half-channel height ![]() $\hat H$ is much larger than the pattern (i.e. groove or stripe) period

$\hat H$ is much larger than the pattern (i.e. groove or stripe) period ![]() $\hat L$, as illustrated in figure 1). In addition, we consider flow slippage on the patterned wall, assuming a flat liquid/air interface pinned at the groove edges for the SH wall and a flat slippery stripe for the CP wall, while employing the Navier slip law and the no-slip condition to account for the patterned wall condition. Using perturbation analysis, Fourier expansion method and dual trigonometric series solution (Sneddon Reference Sneddon1966), we develop a comprehensive model for viscoplastic flows in SH and CP channels; this includes semi-analytical, explicit-form and computational fluid dynamics (CFD) models, which allow us to systematically analyse the flow parameters effects on the key characteristics of our complex flow dynamics.

$\hat L$, as illustrated in figure 1). In addition, we consider flow slippage on the patterned wall, assuming a flat liquid/air interface pinned at the groove edges for the SH wall and a flat slippery stripe for the CP wall, while employing the Navier slip law and the no-slip condition to account for the patterned wall condition. Using perturbation analysis, Fourier expansion method and dual trigonometric series solution (Sneddon Reference Sneddon1966), we develop a comprehensive model for viscoplastic flows in SH and CP channels; this includes semi-analytical, explicit-form and computational fluid dynamics (CFD) models, which allow us to systematically analyse the flow parameters effects on the key characteristics of our complex flow dynamics.

The present article is structured as follows. In § 2, we introduce the flow governing equations, followed by § 3 where we develop our mathematical models for calculating the perturbation and slip velocities. In § 4, we discuss additional flow features, such as the total velocity profile, effective slip length tensor, slip angle and flow mixing index. The numerical simulation setup is described in § 5. In § 6, we present the results and, in § 7, we provide a summary of the main findings of our work.

2. Governing equations

2.1. Equations of motion

This section presents our plane Poiseuille flow of a Bingham fluid with an SH (or CP) lower wall, including the governing continuity and momentum balance equations, in a Cartesian coordinate system ![]() $(x,y,z)$ (see figure 1). Motivated by practical considerations, we consider a channel where the lower boundary is a groovy wall and the upper boundary has a no-slip condition; this is because, in practice, the construction of a channel with two symmetrically aligned patterned walls, typically on the micro- or nano-scale, is challenging (Schmieschek et al. Reference Schmieschek, Belyaev, Harting and Vinogradova2012) (we later discuss the extension of our models for the channels with two patterned walls in Appendix F). Considering a creeping flow motion, the dimensionless forms of the continuity and momentum balance equations are

$(x,y,z)$ (see figure 1). Motivated by practical considerations, we consider a channel where the lower boundary is a groovy wall and the upper boundary has a no-slip condition; this is because, in practice, the construction of a channel with two symmetrically aligned patterned walls, typically on the micro- or nano-scale, is challenging (Schmieschek et al. Reference Schmieschek, Belyaev, Harting and Vinogradova2012) (we later discuss the extension of our models for the channels with two patterned walls in Appendix F). Considering a creeping flow motion, the dimensionless forms of the continuity and momentum balance equations are

where ![]() $t$ is the time,

$t$ is the time, ![]() ${\boldsymbol {U} = U{\boldsymbol {e}_x} + V{\boldsymbol {e}_y} + W{\boldsymbol {e}_z}}$ is the dimensionless velocity vector,

${\boldsymbol {U} = U{\boldsymbol {e}_x} + V{\boldsymbol {e}_y} + W{\boldsymbol {e}_z}}$ is the dimensionless velocity vector, ![]() $P$ is the pressure and the deviatoric stress tensor is denoted by

$P$ is the pressure and the deviatoric stress tensor is denoted by ![]() ${\boldsymbol {\tau }}$. The pressure gradient is in the

${\boldsymbol {\tau }}$. The pressure gradient is in the ![]() $z'$ direction, which is at an angle

$z'$ direction, which is at an angle ![]() $\theta$ with the

$\theta$ with the ![]() $z$ axis (see figure 1). The dimensionless form of the equations of motion is obtained by considering the half-channel height (

$z$ axis (see figure 1). The dimensionless form of the equations of motion is obtained by considering the half-channel height (![]() $\hat H$) as the characteristic length and the average velocity (

$\hat H$) as the characteristic length and the average velocity (![]() $\hat U_{ave}$) as the velocity scale. In addition, the characteristic viscous stress, i.e.

$\hat U_{ave}$) as the velocity scale. In addition, the characteristic viscous stress, i.e. ![]() $\hat \mu _p ({\hat U_{ave}}/{\hat H})$ where

$\hat \mu _p ({\hat U_{ave}}/{\hat H})$ where ![]() $\hat \mu _p$ is the plastic viscosity, is used to obtain the dimensionless form of the pressure and stress terms.

$\hat \mu _p$ is the plastic viscosity, is used to obtain the dimensionless form of the pressure and stress terms.

The Bingham constitutive equation is considered to model the viscoplastic rheology, which in dimensionless form is presented as

\begin{equation} \left\{\begin{array}{@{}ll} {\boldsymbol {\tau }} = \left( {1 + \dfrac{B}{{\dot \gamma }}} \right) {\boldsymbol {\dot \gamma }}, & \tau > B,\\ \boldsymbol{\dot \gamma} = 0, & \tau \le B, \end{array}\right. \end{equation}

\begin{equation} \left\{\begin{array}{@{}ll} {\boldsymbol {\tau }} = \left( {1 + \dfrac{B}{{\dot \gamma }}} \right) {\boldsymbol {\dot \gamma }}, & \tau > B,\\ \boldsymbol{\dot \gamma} = 0, & \tau \le B, \end{array}\right. \end{equation}

where the strain rate tensor is shown by ![]() ${\boldsymbol {\dot \gamma } = \boldsymbol {\nabla } \boldsymbol {u} + {( {\boldsymbol {\nabla } \boldsymbol {u}} )^{\rm T}}}$, and the norms (magnitudes) of the stress and strain rate tensors are

${\boldsymbol {\dot \gamma } = \boldsymbol {\nabla } \boldsymbol {u} + {( {\boldsymbol {\nabla } \boldsymbol {u}} )^{\rm T}}}$, and the norms (magnitudes) of the stress and strain rate tensors are ![]() ${\tau = \sqrt {{{{\tau _{ij}}{\tau _{ij}}}/2}}}$ and

${\tau = \sqrt {{{{\tau _{ij}}{\tau _{ij}}}/2}}}$ and ![]() ${\dot \gamma = \sqrt {{{{{\dot \gamma }_{ij}}{{\dot \gamma }_{ij}}}/2}}}$, respectively (here,

${\dot \gamma = \sqrt {{{{{\dot \gamma }_{ij}}{{\dot \gamma }_{ij}}}/2}}}$, respectively (here, ![]() $i$ and

$i$ and ![]() $j$ refer to the coordinate axes, i.e.

$j$ refer to the coordinate axes, i.e. ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$). The ratio of the yield stress (

$z$). The ratio of the yield stress (![]() ${{{\hat \tau _0}}}$) to the characteristic viscous stress is represented by the Bingham number and defined as

${{{\hat \tau _0}}}$) to the characteristic viscous stress is represented by the Bingham number and defined as

\begin{equation} B = \frac{{{\hat \tau _0}\hat H}}{{{{\hat \mu }_p}{{\hat U}_{ave}}}}. \end{equation}

\begin{equation} B = \frac{{{\hat \tau _0}\hat H}}{{{{\hat \mu }_p}{{\hat U}_{ave}}}}. \end{equation}Based on (2.3), formation of plug zones are expected for a viscoplastic flow when the applied stress is smaller than the yield stress. For example, formation of an unyielded plug zone in the channel centre is a characteristic of the creeping Poiseuille flow of viscoplastic materials. Based on (2.3), at the yield surfaces and inside the plug, the strain-rate tensor and its norm vanish.

2.2. No-slip base flow

Given the symmetry condition for the no-slip base flow, i.e. with the no-slip condition at both walls, the base flow pressure (![]() $P_0^b$) and velocity (

$P_0^b$) and velocity (![]() $U^b_0$) for the lower half of the channel can be easily derived as

$U^b_0$) for the lower half of the channel can be easily derived as

$$\begin{gather}{U^b_0}(\kern0.7pt y) = \left\{\begin{array}{@{}ll} {C_1}y + {C_2}{y^2}, & 0 \le y \le {h_0}, \\ {C_3}, & {h_0} \le y \le 1, \end{array}\right. \end{gather}$$

$$\begin{gather}{U^b_0}(\kern0.7pt y) = \left\{\begin{array}{@{}ll} {C_1}y + {C_2}{y^2}, & 0 \le y \le {h_0}, \\ {C_3}, & {h_0} \le y \le 1, \end{array}\right. \end{gather}$$

where ![]() $C_1=\tau _w - B$,

$C_1=\tau _w - B$, ![]() $C_2=-({\tau _w}/{2})$,

$C_2=-({\tau _w}/{2})$, ![]() $C_3={(\tau _w - B)^2}/{2\tau _w}$ and

$C_3={(\tau _w - B)^2}/{2\tau _w}$ and ![]() $h_0$ denotes the location of the lower yield surface. The wall shear stress,

$h_0$ denotes the location of the lower yield surface. The wall shear stress, ![]() $\tau _w$, at

$\tau _w$, at ![]() $y=0$ corresponds to the largest positive root of the following equation:

$y=0$ corresponds to the largest positive root of the following equation:

Subsequently, one can find the location of lower yield surface as

Since the ![]() $U^b_0$ vector is in the

$U^b_0$ vector is in the ![]() $z'$ direction, the base no-slip velocity has two components in the

$z'$ direction, the base no-slip velocity has two components in the ![]() $x$ and

$x$ and ![]() $z$ directions, i.e.

$z$ directions, i.e. ![]() $U_0=U^b_0 \sin \theta$ and

$U_0=U^b_0 \sin \theta$ and ![]() $W_0=U^b_0 \cos \theta$, respectively.

$W_0=U^b_0 \cos \theta$, respectively.

2.3. Slip model

The linear Navier slip law is considered to account for the Bingham fluid slippage on the interface. Therefore, the following relation for the slip velocities in the ![]() $z$ (

$z$ (![]() $w_s$) and

$w_s$) and ![]() $x$ (

$x$ (![]() $u_s$) directions is derived for the Bingham fluid:

$u_s$) directions is derived for the Bingham fluid:

where ![]() $b$ represents the dimensionless slip number, defined as

$b$ represents the dimensionless slip number, defined as ![]() $b = {{\hat b {\hat \mu }_p}/{\hat H}}$. Here,

$b = {{\hat b {\hat \mu }_p}/{\hat H}}$. Here, ![]() $\hat b$ is the dimensional slip number, correlating the dimensional values of the slip velocity and shear stress.

$\hat b$ is the dimensional slip number, correlating the dimensional values of the slip velocity and shear stress.

Based on the analyses developed for the Newtonian flows (Schönecker & Hardt Reference Schönecker and Hardt2013; Nizkaya, Asmolov & Vinogradova Reference Nizkaya, Asmolov and Vinogradova2014; Schönecker, Baier & Hardt Reference Schönecker, Baier and Hardt2014), in general, ![]() $\hat b$ can be related to the air viscosity (

$\hat b$ can be related to the air viscosity (![]() $\hat \mu _a$) and the groove aspect ratio (

$\hat \mu _a$) and the groove aspect ratio (![]() $A_r=\hat d/\hat \delta$). In addition,

$A_r=\hat d/\hat \delta$). In addition, ![]() $\hat b$ (and, hence,

$\hat b$ (and, hence, ![]() $b$) has been proven to show a tensorial form for SH surfaces, i.e. with different values of the local slip length (number) in the longitudinal and transverse directions. For large values of the local slip length, where the flow condition on the liquid/air interface approaches the no-shear condition, the tensorial form of

$b$) has been proven to show a tensorial form for SH surfaces, i.e. with different values of the local slip length (number) in the longitudinal and transverse directions. For large values of the local slip length, where the flow condition on the liquid/air interface approaches the no-shear condition, the tensorial form of ![]() $\hat b$ (and, hence,

$\hat b$ (and, hence, ![]() $b$) becomes less important and can be effectively replaced by a scalar form, i.e. an equal value can be considered for the slip number in both the longitudinal and transverse directions (Schönecker & Hardt Reference Schönecker and Hardt2013; Nizkaya et al. Reference Nizkaya, Asmolov and Vinogradova2014; Schönecker et al. Reference Schönecker, Baier and Hardt2014). On the other hand, for the CP surfaces, the local slip length can be identical in the longitudinal and transverse conditions, rendering a scalar form of the slip number (Qian et al. Reference Qian, Wang and Sheng2005; Wang et al. Reference Wang, Qian and Sheng2008; Lee et al. Reference Lee, Charrault and Neto2014). Since the tensorial form of the slip number has not yet been explored for the viscoplastic flows (refer to the discussion in § 7), here we assume a scalar form of the slip number, i.e. a similar value of

$b$) becomes less important and can be effectively replaced by a scalar form, i.e. an equal value can be considered for the slip number in both the longitudinal and transverse directions (Schönecker & Hardt Reference Schönecker and Hardt2013; Nizkaya et al. Reference Nizkaya, Asmolov and Vinogradova2014; Schönecker et al. Reference Schönecker, Baier and Hardt2014). On the other hand, for the CP surfaces, the local slip length can be identical in the longitudinal and transverse conditions, rendering a scalar form of the slip number (Qian et al. Reference Qian, Wang and Sheng2005; Wang et al. Reference Wang, Qian and Sheng2008; Lee et al. Reference Lee, Charrault and Neto2014). Since the tensorial form of the slip number has not yet been explored for the viscoplastic flows (refer to the discussion in § 7), here we assume a scalar form of the slip number, i.e. a similar value of ![]() $\hat b$ (and, hence,

$\hat b$ (and, hence, ![]() $b$) for longitudinal, transverse and oblique configurations. However, assuming a tensorial slip number, i.e. any functionality of

$b$) for longitudinal, transverse and oblique configurations. However, assuming a tensorial slip number, i.e. any functionality of ![]() $\hat b$ (and, hence,

$\hat b$ (and, hence, ![]() $b$) with respect to the angle

$b$) with respect to the angle ![]() $\theta$, the models developed in this study would remain valid (see preliminary tensorial form analysis of the local slip number in Appendix D). We may expect that the assumed scalar form for the slip number can provide us with reasonably accurate predictions of the flow dynamics over the CP surfaces, while capturing leading physical trends for the flow over SH surfaces at large values of the slip number. In addition, the upcoming solutions may provide some insight about the viscoplastic flow dynamics over the liquid-infused (LI) surfaces; however, to provide accurate results for this case, the exact tensorial form of the slip number must be employed and the corresponding scalar form is not valid (Schönecker et al. Reference Schönecker, Baier and Hardt2014).

$\theta$, the models developed in this study would remain valid (see preliminary tensorial form analysis of the local slip number in Appendix D). We may expect that the assumed scalar form for the slip number can provide us with reasonably accurate predictions of the flow dynamics over the CP surfaces, while capturing leading physical trends for the flow over SH surfaces at large values of the slip number. In addition, the upcoming solutions may provide some insight about the viscoplastic flow dynamics over the liquid-infused (LI) surfaces; however, to provide accurate results for this case, the exact tensorial form of the slip number must be employed and the corresponding scalar form is not valid (Schönecker et al. Reference Schönecker, Baier and Hardt2014).

Before proceeding, it is worth mentioning that both the groove (stripe) period (width) (Sbragaglia & Prosperetti Reference Sbragaglia and Prosperetti2007; Hodes et al. Reference Hodes, Kirk, Karamanis and MacLachlan2017; Game, Hodes & Papageorgiou Reference Game, Hodes and Papageorgiou2019) and channel height (or pipe diameter) (Lauga & Stone Reference Lauga and Stone2003; Schnitzer & Yariv Reference Schnitzer and Yariv2017, Reference Schnitzer and Yariv2019; Kirk et al. Reference Kirk, Karamanis, Crowdy and Hodes2020) have been used within the literature as the characteristic lengths to make the slip length dimensionless. In this work, for definition of the slip number, i.e. ![]() $b={\hat b \hat \mu _p}/{\hat H}$, the half-channel height (

$b={\hat b \hat \mu _p}/{\hat H}$, the half-channel height (![]() $\hat H$) is used as the characteristic length. Although employing the groove (stripe) period (

$\hat H$) is used as the characteristic length. Although employing the groove (stripe) period (![]() $\hat L$) as the characteristic length can be useful when interpreting the local slip dynamics on the patterned wall, our definition of the slip number is also physically relevant, as it provides an understanding regarding the overall patterned wall effects on the channel flow dynamics. In addition, the defined dimensionless slip number in our work can be simply converted to the slip number that is made dimensionless using the groove (stripe) period (

$\hat L$) as the characteristic length can be useful when interpreting the local slip dynamics on the patterned wall, our definition of the slip number is also physically relevant, as it provides an understanding regarding the overall patterned wall effects on the channel flow dynamics. In addition, the defined dimensionless slip number in our work can be simply converted to the slip number that is made dimensionless using the groove (stripe) period (![]() $b_L$) as

$b_L$) as ![]() $b_L=b/\ell$. Therefore, one can also use such a conversion to be able to interpret the results, if required. In addition, the usage of

$b_L=b/\ell$. Therefore, one can also use such a conversion to be able to interpret the results, if required. In addition, the usage of ![]() $\hat H$ as the characteristic length is prevalent and advantageous in defining the Bingham number (

$\hat H$ as the characteristic length is prevalent and advantageous in defining the Bingham number (![]() $B$), which is a key parameter of our viscoplastic flow.

$B$), which is a key parameter of our viscoplastic flow.

3. Mathematical modelling

3.1. Perturbation equations

In this work, semi-analytical and explicit-form solutions are developed for the Poiseuille flow of Bingham fluids in channels with a patterned wall, considering the limiting cases of longitudinal (![]() $\theta =0$) and transverse (

$\theta =0$) and transverse (![]() $\theta =90^\circ$) grooves (stripes), as well as the general case of the oblique (

$\theta =90^\circ$) grooves (stripes), as well as the general case of the oblique (![]() $0 < \theta < 90^\circ$) flow configuration. These solutions are developed for the thick channel limit (

$0 < \theta < 90^\circ$) flow configuration. These solutions are developed for the thick channel limit (![]() $\ell ={\hat {L}}/{\hat {H}} \ll 1$), where the lower yield surface (located at

$\ell ={\hat {L}}/{\hat {H}} \ll 1$), where the lower yield surface (located at ![]() $y=h$) remains flat (Rahmani & Taghavi Reference Rahmani and Taghavi2022). The solution can be derived by considering infinitesimal perturbations induced by the patterned wall (with respect to the no-slip flow) in the lower yielded zone (

$y=h$) remains flat (Rahmani & Taghavi Reference Rahmani and Taghavi2022). The solution can be derived by considering infinitesimal perturbations induced by the patterned wall (with respect to the no-slip flow) in the lower yielded zone (![]() $-\ell /2 \le x \le \ell /2$ and

$-\ell /2 \le x \le \ell /2$ and ![]() $0 \le y < h$) and solving for the leading-order terms. Therefore, the total velocity vector (

$0 \le y < h$) and solving for the leading-order terms. Therefore, the total velocity vector (![]() $\boldsymbol {U}$) is written as

$\boldsymbol {U}$) is written as

where ![]() $\boldsymbol {U}_0 = U_0{\boldsymbol {e}_x} + W_0{\boldsymbol {e}_z}$, i.e.

$\boldsymbol {U}_0 = U_0{\boldsymbol {e}_x} + W_0{\boldsymbol {e}_z}$, i.e. ![]() $(U_0,0,W_0)$, represents the no-slip velocity vector and

$(U_0,0,W_0)$, represents the no-slip velocity vector and

shows the perturbation velocity vector ![]() $(u,v,w)$. Here,

$(u,v,w)$. Here, ![]() $\epsilon =\kappa ^{-1}$ is the perturbation parameter where

$\epsilon =\kappa ^{-1}$ is the perturbation parameter where ![]() $\kappa =2{\rm \pi} /\ell$ is the patterned wall wavenumber. Based on this perturbation method, the effective viscosity of the Bingham fluid (

$\kappa =2{\rm \pi} /\ell$ is the patterned wall wavenumber. Based on this perturbation method, the effective viscosity of the Bingham fluid (![]() $\mu$) and the stress components are expanded as follows:

$\mu$) and the stress components are expanded as follows:

where ![]() $\dot \xi _{ij}$ and

$\dot \xi _{ij}$ and ![]() $\sigma _{ij}$ represent the component of the perturbation strain-rate and stress tensor, respectively. Henceforth, for presentation simplicity, we use

$\sigma _{ij}$ represent the component of the perturbation strain-rate and stress tensor, respectively. Henceforth, for presentation simplicity, we use ![]() $\mu _0=\mu (\boldsymbol {U_0})$.

$\mu _0=\mu (\boldsymbol {U_0})$.

3.1.1. Longitudinal configuration

For the longitudinal groove (stripe) configuration, the no-slip and perturbation velocity vectors reduce to (![]() $0,0,W_0$) and (

$0,0,W_0$) and (![]() $0,0,w$), respectively. In addition, considering an infinitely long channel in both x and z directions, the velocity gradients in the

$0,0,w$), respectively. In addition, considering an infinitely long channel in both x and z directions, the velocity gradients in the ![]() $z$ direction are zero (

$z$ direction are zero (![]() $\partial \boldsymbol{U} /\partial z = 0$, a feature valid for any angle of

$\partial \boldsymbol{U} /\partial z = 0$, a feature valid for any angle of ![]() $\theta$), only two non-zero perturbation stress components remain for the Bingham fluid as

$\theta$), only two non-zero perturbation stress components remain for the Bingham fluid as

\begin{equation} \left.\begin{gathered} {\sigma _{yz}} = \frac{{\partial w}}{{\partial y}}, \\ {\sigma _{xz}} = \mu_0 \frac{{\partial w}}{{\partial x}}, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {\sigma _{yz}} = \frac{{\partial w}}{{\partial y}}, \\ {\sigma _{xz}} = \mu_0 \frac{{\partial w}}{{\partial x}}, \end{gathered}\right\} \end{equation}

where ![]() $\mu _0=1+{B}/{({\rm d} U^b_0/{{\rm d}y})}$. Therefore, the perturbed momentum balance equation shrinks to

$\mu _0=1+{B}/{({\rm d} U^b_0/{{\rm d}y})}$. Therefore, the perturbed momentum balance equation shrinks to

in which the perturbation parameter is dropped.

In the present study, to facilitate the identification of various orders of perturbed momentum balance equations for a given flow configuration, a rescaling is introduced as

where ![]() $\psi$ is the perturbation stream function such that

$\psi$ is the perturbation stream function such that ![]() $u = {{\partial \psi }}/{{\partial y}}$ and

$u = {{\partial \psi }}/{{\partial y}}$ and ![]() $v = -{{\partial \psi }}/{{\partial x}}$. The introduced rescaling is motivated by the decay of perturbations in the

$v = -{{\partial \psi }}/{{\partial x}}$. The introduced rescaling is motivated by the decay of perturbations in the ![]() $y$ direction, which renders the perturbation negligible beyond a distance comparable to the groove periodicity length. Consequently, the rescaled distance over which the perturbation field is considerable becomes of order

$y$ direction, which renders the perturbation negligible beyond a distance comparable to the groove periodicity length. Consequently, the rescaled distance over which the perturbation field is considerable becomes of order ![]() $\epsilon ^0$. Thus, we may expand the viscosity over

$\epsilon ^0$. Thus, we may expand the viscosity over ![]() $Y=0$ to reach

$Y=0$ to reach

in which coefficients ![]() $C_1$ and

$C_1$ and ![]() $C_2$ are given in § 2.2. Therefore, the rescaled form of (3.6) for the leading-order terms is obtained as

$C_2$ are given in § 2.2. Therefore, the rescaled form of (3.6) for the leading-order terms is obtained as

where ![]() $\epsilon$ drops from (3.9).

$\epsilon$ drops from (3.9).

Following the convention in the field (Lauga & Stone Reference Lauga and Stone2003; Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011), we consider our creeping flow to be periodic in the ![]() $x$ direction with a period of

$x$ direction with a period of ![]() $\ell$. Accordingly, in the rescaled system, the flow is periodic in the

$\ell$. Accordingly, in the rescaled system, the flow is periodic in the ![]() $X$ direction with a period of

$X$ direction with a period of ![]() $2{\rm \pi}$. Therefore, the solution for

$2{\rm \pi}$. Therefore, the solution for ![]() $w$ can be written in the Fourier series form as

$w$ can be written in the Fourier series form as

\begin{equation} w (X,Y) = \sum_{n = 0 }^\infty {B_n}{\hat w_n } (Y){\cos ({nX})}, \end{equation}

\begin{equation} w (X,Y) = \sum_{n = 0 }^\infty {B_n}{\hat w_n } (Y){\cos ({nX})}, \end{equation}

where ![]() $B_n$ are unknown coefficients that will be calculated later with the use of appropriate patterned wall conditions. Here, the hat sign is used to define the Fourier coefficient (i.e.

$B_n$ are unknown coefficients that will be calculated later with the use of appropriate patterned wall conditions. Here, the hat sign is used to define the Fourier coefficient (i.e. ![]() $\hat w_n$).

$\hat w_n$).

Substituting (3.10) into (3.9), one can find the following ordinary differential equation (ODE):

To close the boundary value problem, the following boundary conditions are considered (![]() $n \ne 0$):

$n \ne 0$):

where the first and second conditions from left to right ensure zero perturbation velocity and zero strain-rate magnitude at the lower yield surface (![]() $Y=\kappa h$), respectively. The zeroth term (

$Y=\kappa h$), respectively. The zeroth term (![]() $n=0$) has a linear distribution in

$n=0$) has a linear distribution in ![]() $Y$ and is discussed later in § 3.2.

$Y$ and is discussed later in § 3.2.

3.1.2. Transverse configuration

In the transverse configuration, the no-slip and perturbation velocity vectors reduce to ![]() $(U_0,0,0)$ and

$(U_0,0,0)$ and ![]() $(u,v,0)$, respectively. Perturbing the momentum balance equation, eliminating the pressure, using the definition of

$(u,v,0)$, respectively. Perturbing the momentum balance equation, eliminating the pressure, using the definition of ![]() $\varPsi$, considering the rescaling, and expanding

$\varPsi$, considering the rescaling, and expanding ![]() $\mu _0$, the following partial differential equation is eventually derived at the leading order:

$\mu _0$, the following partial differential equation is eventually derived at the leading order:

where ![]() $\epsilon$ drops from (3.13). Considering the flow periodicity in

$\epsilon$ drops from (3.13). Considering the flow periodicity in ![]() $X$, one can write

$X$, one can write

\begin{equation} \varPsi (X,Y) = \sum_{n = 0 }^\infty {A_n}{\hat \varPsi_n } (Y){\cos ({nX})}, \end{equation}

\begin{equation} \varPsi (X,Y) = \sum_{n = 0 }^\infty {A_n}{\hat \varPsi_n } (Y){\cos ({nX})}, \end{equation}

where ![]() $A_n$ are unknown coefficients and will be obtained later using the patterned wall condition. Here, the hat sign is used to define the Fourier coefficient (i.e.

$A_n$ are unknown coefficients and will be obtained later using the patterned wall condition. Here, the hat sign is used to define the Fourier coefficient (i.e. ![]() $\hat \varPsi _n$).

$\hat \varPsi _n$).

Substituting (3.14) into (3.13), we find the following ODE:

To close the boundary value problem, we consider the following conditions (![]() $n \ne 0$)

$n \ne 0$)

where the first condition from left to right ensures the no-penetration assumption at the patterned wall (i.e. ![]() $V=0$ at

$V=0$ at ![]() $Y=0$). The zero perturbation velocity field at the lower yield surface (

$Y=0$). The zero perturbation velocity field at the lower yield surface (![]() $Y=\kappa h$) is guaranteed using the second and third conditions (from left to right). Finally, the zero strain-rate magnitude at the lower yield surface is obtained using the fourth condition. Here, the zeroth term (

$Y=\kappa h$) is guaranteed using the second and third conditions (from left to right). Finally, the zero strain-rate magnitude at the lower yield surface is obtained using the fourth condition. Here, the zeroth term (![]() $n=0$) would show a quadratic functionality of

$n=0$) would show a quadratic functionality of ![]() $Y$, as discussed in § 3.2.

$Y$, as discussed in § 3.2.

3.1.3. Oblique configuration

In the oblique configuration, the no-slip and perturbation velocity vectors, i.e. ![]() $(U_0,0,W_0)$ and

$(U_0,0,W_0)$ and ![]() $(u,v,w)$, respectively, have their most general forms. Accordingly, the perturbation stress components can be obtained as given in Appendix A. Then, using the definition of

$(u,v,w)$, respectively, have their most general forms. Accordingly, the perturbation stress components can be obtained as given in Appendix A. Then, using the definition of ![]() $\varPsi$, adopting the rescaling introduced in (3.7a–c), expanding

$\varPsi$, adopting the rescaling introduced in (3.7a–c), expanding ![]() $\mu _0$ via (3.8) and performing considerable algebra, we derive a set of two coupled partial differential equations for

$\mu _0$ via (3.8) and performing considerable algebra, we derive a set of two coupled partial differential equations for ![]() $\varPsi$ and

$\varPsi$ and ![]() $w$ at the leading order:

$w$ at the leading order:

\begin{gather} {\left(1+\frac{B}{C_1}\right)}\left( {\frac{{{\partial

^4}\varPsi }}{{\partial {X^4}}} + \frac{{{\partial

^4}\varPsi }}{{\partial {Y^4}}} + 2\frac{{{\partial

^4}\varPsi }}{{\partial {X^2}\partial {Y^2}}}} \right) -

{\frac{B}{C_1}}\left( {\frac{{{\partial ^4}\varPsi

}}{{\partial {X^4}}} + \frac{{{\partial ^4}\varPsi

}}{{\partial {Y^4}}} - 2\frac{{{\partial ^4}\varPsi

}}{{\partial {X^2}\partial {Y^2}}}} \right){\sin ^2}\theta

\nonumber\\ -{\frac{B}{C_1}}\left( {\frac{{{\partial

^3}w}}{{\partial {Y^3}}} - \frac{{{\partial

^3}w}}{{\partial {X^2}\partial Y}}} \right) \sin \theta

\cos \theta = 0, \end{gather}

\begin{gather} {\left(1+\frac{B}{C_1}\right)}\left( {\frac{{{\partial

^4}\varPsi }}{{\partial {X^4}}} + \frac{{{\partial

^4}\varPsi }}{{\partial {Y^4}}} + 2\frac{{{\partial

^4}\varPsi }}{{\partial {X^2}\partial {Y^2}}}} \right) -

{\frac{B}{C_1}}\left( {\frac{{{\partial ^4}\varPsi

}}{{\partial {X^4}}} + \frac{{{\partial ^4}\varPsi

}}{{\partial {Y^4}}} - 2\frac{{{\partial ^4}\varPsi

}}{{\partial {X^2}\partial {Y^2}}}} \right){\sin ^2}\theta

\nonumber\\ -{\frac{B}{C_1}}\left( {\frac{{{\partial

^3}w}}{{\partial {Y^3}}} - \frac{{{\partial

^3}w}}{{\partial {X^2}\partial Y}}} \right) \sin \theta

\cos \theta = 0, \end{gather}

where ![]() $\epsilon$ is dropped from the above equations. Equations (3.17) and (3.18) are unique to viscoplastic Bingham materials, significantly differing from the corresponding equations for Newtonian fluids. In the case of Newtonian fluids, we have

$\epsilon$ is dropped from the above equations. Equations (3.17) and (3.18) are unique to viscoplastic Bingham materials, significantly differing from the corresponding equations for Newtonian fluids. In the case of Newtonian fluids, we have ![]() $B=0$ (i.e.

$B=0$ (i.e. ![]() $\mu _0=1$; see (3.8)); consequently, (3.17) and (3.18) decouple, and become independent of

$\mu _0=1$; see (3.8)); consequently, (3.17) and (3.18) decouple, and become independent of ![]() $\theta$, i.e. reducing to the corresponding equations for the transverse and longitudinal flows, respectively. Thus, for Newtonian fluids, it suffices to solve the perturbed equation only for the longitudinal and transverse configurations, and the solution for the oblique configuration can be simply obtained via a linear vector transformation through the transform (or rotation) matrix (Bazant & Vinogradova Reference Bazant and Vinogradova2008; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011). Therefore, it is clear that the nonlinear viscoplastic rheology sets our work apart from the Newtonian case, and it plays a crucial role in determining the slip dynamics on a patterned wall, i.e. a feature that we address in this study.

$\theta$, i.e. reducing to the corresponding equations for the transverse and longitudinal flows, respectively. Thus, for Newtonian fluids, it suffices to solve the perturbed equation only for the longitudinal and transverse configurations, and the solution for the oblique configuration can be simply obtained via a linear vector transformation through the transform (or rotation) matrix (Bazant & Vinogradova Reference Bazant and Vinogradova2008; Vinogradova & Belyaev Reference Vinogradova and Belyaev2011). Therefore, it is clear that the nonlinear viscoplastic rheology sets our work apart from the Newtonian case, and it plays a crucial role in determining the slip dynamics on a patterned wall, i.e. a feature that we address in this study.

Considering the flow periodicity in the ![]() $X$ direction, one can substitute (3.10) and (3.14) into (3.17) and (3.18) to arrive at the following coupled ODEs:

$X$ direction, one can substitute (3.10) and (3.14) into (3.17) and (3.18) to arrive at the following coupled ODEs:

\begin{align} & {A_n}\left[ {{\left(1+\frac{B}{C_1}\right)}\left({\frac{{{{\rm d}^4}\hat \varPsi_n }}{{{\rm d} {Y^4}}} - 2{n^2} \frac{{{{\rm d}^2}\hat \varPsi_n }}{{{\rm d} {Y^2}}} + {n^4}\hat \varPsi_n}\right) -{\frac{B}{C_1}}\left({\frac{{{{\rm d}^4}\hat \varPsi_n }}{{{\rm d} {Y^4}}} + 2{n^2} \frac{{{{\rm d}^2}\hat \varPsi_n }}{{{\rm d} {Y^2}}} + {n^4}\hat \varPsi_n } \right){{\sin }^2}\theta } \right] \nonumber\\ &\quad -{B_n}{\frac{B}{C_1}}\left( {\frac{{{{\rm d}^3}\hat w_n}}{{{\rm d} {Y^3}}} + {n^2}\frac{{{\rm d} \hat w_n}}{{{\rm d} Y}}} \right)\sin \theta \cos \theta = 0, \end{align}

\begin{align} & {A_n}\left[ {{\left(1+\frac{B}{C_1}\right)}\left({\frac{{{{\rm d}^4}\hat \varPsi_n }}{{{\rm d} {Y^4}}} - 2{n^2} \frac{{{{\rm d}^2}\hat \varPsi_n }}{{{\rm d} {Y^2}}} + {n^4}\hat \varPsi_n}\right) -{\frac{B}{C_1}}\left({\frac{{{{\rm d}^4}\hat \varPsi_n }}{{{\rm d} {Y^4}}} + 2{n^2} \frac{{{{\rm d}^2}\hat \varPsi_n }}{{{\rm d} {Y^2}}} + {n^4}\hat \varPsi_n } \right){{\sin }^2}\theta } \right] \nonumber\\ &\quad -{B_n}{\frac{B}{C_1}}\left( {\frac{{{{\rm d}^3}\hat w_n}}{{{\rm d} {Y^3}}} + {n^2}\frac{{{\rm d} \hat w_n}}{{{\rm d} Y}}} \right)\sin \theta \cos \theta = 0, \end{align} \begin{align} & -{A_n}{\frac{B}{C_1}}\left( {\frac{{{{\rm d}^3}\hat \varPsi_n }}{{{\rm d} {Y^3}}} + {n^2}\frac{{{\rm d} \hat \varPsi_n }}{{{\rm d} Y}}} \right)\sin \theta \cos \theta \nonumber\\ &\quad + {B_n}{\left[ {{\left(1+\frac{B}{C_1}\right)}\left( {\frac{{{{\rm d}^2}\hat w_n}}{{{\rm d} {Y^2}}} - {n^2}\hat w_n} \right) -{\frac{B}{C_1}}\frac{{{{\rm d}^2}\hat w_n}}{{{\rm d} {Y^2}}}{{\cos }^2}\theta } \right] = 0.} \end{align}

\begin{align} & -{A_n}{\frac{B}{C_1}}\left( {\frac{{{{\rm d}^3}\hat \varPsi_n }}{{{\rm d} {Y^3}}} + {n^2}\frac{{{\rm d} \hat \varPsi_n }}{{{\rm d} Y}}} \right)\sin \theta \cos \theta \nonumber\\ &\quad + {B_n}{\left[ {{\left(1+\frac{B}{C_1}\right)}\left( {\frac{{{{\rm d}^2}\hat w_n}}{{{\rm d} {Y^2}}} - {n^2}\hat w_n} \right) -{\frac{B}{C_1}}\frac{{{{\rm d}^2}\hat w_n}}{{{\rm d} {Y^2}}}{{\cos }^2}\theta } \right] = 0.} \end{align}

The boundary conditions for these equations are the combination of those for the longitudinal and transverse configurations, i.e. (3.12a,b) and (3.16a–d). In addition, the zeroth term solutions (![]() $n=0$) are treated similar to those of the longitudinal and transverse configurations and are discussed further in § 3.2.

$n=0$) are treated similar to those of the longitudinal and transverse configurations and are discussed further in § 3.2.

3.2. Semi-analytical solution

In this section, we attempt to solve the ODEs (3.11), (3.15), (3.19) and (3.20). These ODEs have constant coefficients; thus, the solutions for ![]() $\hat \varPsi _n$ and

$\hat \varPsi _n$ and ![]() $\hat w_n$ would be in the form

$\hat w_n$ would be in the form ![]() ${\rm e}^{\varLambda _n Y}$. In the thick channel limit, since the perturbation field quickly decays in the

${\rm e}^{\varLambda _n Y}$. In the thick channel limit, since the perturbation field quickly decays in the ![]() $Y$ direction, the contribution of the terms having positive

$Y$ direction, the contribution of the terms having positive ![]() ${\varLambda _n}$, i.e.

${\varLambda _n}$, i.e. ![]() $\varLambda _n>0$, becomes negligible. In other words, one can simply show that the terms with positive

$\varLambda _n>0$, becomes negligible. In other words, one can simply show that the terms with positive ![]() ${\varLambda _n}$ belong to the higher orders of perturbations. Therefore, in the following sections, the solutions for

${\varLambda _n}$ belong to the higher orders of perturbations. Therefore, in the following sections, the solutions for ![]() $\hat \varPsi _n$ and

$\hat \varPsi _n$ and ![]() $\hat w_n$ are obtained considering only the terms with negative

$\hat w_n$ are obtained considering only the terms with negative ![]() ${\varLambda _n}$.

${\varLambda _n}$.

Before proceeding, let us consider the perturbation velocity field as ![]() $\boldsymbol u$ instead of

$\boldsymbol u$ instead of ![]() $\epsilon \boldsymbol u$ in the following sections. This consideration leads to having simpler forms of equations, as the redundant

$\epsilon \boldsymbol u$ in the following sections. This consideration leads to having simpler forms of equations, as the redundant ![]() $\epsilon$ symbol disappears.

$\epsilon$ symbol disappears.

3.2.1. Longitudinal configuration

For the longitudinal configuration, (3.11) is solved analytically, keeping the term with the negative ![]() ${\varLambda _n}$, as

${\varLambda _n}$, as

where the symbol ![]() $\parallel$ represents the longitudinal flow, henceforth. The expression obtained for

$\parallel$ represents the longitudinal flow, henceforth. The expression obtained for ![]() $\hat w_n$ would satisfy the conditions of (3.12a,b), since at

$\hat w_n$ would satisfy the conditions of (3.12a,b), since at ![]() $Y=\kappa h$, i.e. the lower yield surface,

$Y=\kappa h$, i.e. the lower yield surface, ![]() $\hat w_n$ and

$\hat w_n$ and ![]() ${\rm d}\hat w_n/{\rm d} Y$ become negligible and belong to the higher orders of perturbation. After solving for

${\rm d}\hat w_n/{\rm d} Y$ become negligible and belong to the higher orders of perturbation. After solving for ![]() $\hat w_n$, the solution for

$\hat w_n$, the solution for ![]() $w$ can be written in the following form:

$w$ can be written in the following form:

\begin{equation} w(X,Y) = {B_0}\left( {1 - \frac{Y}{\kappa h}} \right) + \sum_{n = 1}^\infty {{B_n}} \hat w_n (Y)\cos (nX), \end{equation}

\begin{equation} w(X,Y) = {B_0}\left( {1 - \frac{Y}{\kappa h}} \right) + \sum_{n = 1}^\infty {{B_n}} \hat w_n (Y)\cos (nX), \end{equation}

where the zeroth term solution has a linear distribution in ![]() $Y$ and satisfies the zero perturbation velocity condition at the lower yield surface, i.e.

$Y$ and satisfies the zero perturbation velocity condition at the lower yield surface, i.e. ![]() $Y=\kappa h$. The remaining condition to be satisfied by the zeroth term solution is the zero strain-rate magnitude at the lower yield surface, which is satisfied through numerical iterations on

$Y=\kappa h$. The remaining condition to be satisfied by the zeroth term solution is the zero strain-rate magnitude at the lower yield surface, which is satisfied through numerical iterations on ![]() $h$, as explained in § 4.1.1.

$h$, as explained in § 4.1.1.

For the longitudinal configuration, the boundary conditions at the patterned wall is obtained as

where ![]() $\varphi ={\hat \delta }/{\hat L}$ is called the slip area fraction and represents the fraction of the patterned wall that undergoes the slip condition. Equations (3.23) and (3.24) together represent the patterned wall condition that has been already discussed.

$\varphi ={\hat \delta }/{\hat L}$ is called the slip area fraction and represents the fraction of the patterned wall that undergoes the slip condition. Equations (3.23) and (3.24) together represent the patterned wall condition that has been already discussed.

After substituting the solution for the perturbation velocity field, i.e. (3.22), into the patterned wall condition, i.e. (3.23) and (3.24), the following dual trigonometric series problem emerges:

$$\begin{gather} {B_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^\infty {{B_n}} \left[ {{{\hat w}_n}(0) - b\kappa{\frac{{\rm d}\hat w_n}{{\rm d} Y}(0)}} \right]\cos ({nX}) = b({B + {C_1}}),\quad 0 \leq X \leq {\rm \pi}\varphi, \end{gather}$$

$$\begin{gather} {B_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^\infty {{B_n}} \left[ {{{\hat w}_n}(0) - b\kappa{\frac{{\rm d}\hat w_n}{{\rm d} Y}(0)}} \right]\cos ({nX}) = b({B + {C_1}}),\quad 0 \leq X \leq {\rm \pi}\varphi, \end{gather}$$ $$\begin{gather}{B_0} + \sum_{n = 1}^\infty {{B_n}} {{\hat w}_n}(0)\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}. \end{gather}$$

$$\begin{gather}{B_0} + \sum_{n = 1}^\infty {{B_n}} {{\hat w}_n}(0)\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}. \end{gather}$$ To calculate the unknown coefficients ![]() $B_n$ (

$B_n$ (![]() $n=0,1,2,\ldots$), we first integrate (3.25) in

$n=0,1,2,\ldots$), we first integrate (3.25) in ![]() $[0\ X]$ and then multiply it by

$[0\ X]$ and then multiply it by ![]() ${\sin }(mX)$, where

${\sin }(mX)$, where ![]() $m$ is a positive integer. Afterwards, we integrate the resulting equation in

$m$ is a positive integer. Afterwards, we integrate the resulting equation in ![]() $[0\ {\rm \pi}\varphi ]$. Second, we multiply (3.26) by

$[0\ {\rm \pi}\varphi ]$. Second, we multiply (3.26) by ![]() ${\cos }(mX)$ and then integrate it in

${\cos }(mX)$ and then integrate it in ![]() $[{\rm \pi} \varphi \ {\rm \pi}]$. After the summation of the obtained terms, we establish a system of linear equations (truncated at the

$[{\rm \pi} \varphi \ {\rm \pi}]$. After the summation of the obtained terms, we establish a system of linear equations (truncated at the ![]() $N$th term):

$N$th term):

\begin{equation} \sum_{n = 0}^N {{P_{mn}^{{\parallel}}}{B_n}} = {M_m^{{\parallel}}}, \end{equation}

\begin{equation} \sum_{n = 0}^N {{P_{mn}^{{\parallel}}}{B_n}} = {M_m^{{\parallel}}}, \end{equation}where the above coefficient and constant matrices are obtained as

where ![]() $I_1$,

$I_1$, ![]() $I_2$,

$I_2$, ![]() $I_3$ and

$I_3$ and ![]() $I_4$ are the following integrals

$I_4$ are the following integrals

3.2.2. Transverse configuration

Solving the ODE (3.15) while keeping the terms with negative ![]() ${\varLambda _n}$, we find

${\varLambda _n}$, we find

\begin{align} {\hat \varPsi _n}\left( Y \right) = {{\exp({ - \lambda _1^ \bot nY})} - {\exp({ - \lambda _2^ \bot nY})}},\quad \left\{\begin{array}{@{}l} \lambda _1^ \bot = \dfrac{{\sqrt {{C_1}({2B + {C_1} + 2\sqrt {{B^2} + B{C_1}}})} }}{{{C_1}}},\\ \lambda _2^ \bot = \dfrac{{\sqrt {{C_1}({2B + {C_1} - 2\sqrt {{B^2} + B{C_1}}})} }}{{{C_1}}}, \end{array}\right. \end{align}

\begin{align} {\hat \varPsi _n}\left( Y \right) = {{\exp({ - \lambda _1^ \bot nY})} - {\exp({ - \lambda _2^ \bot nY})}},\quad \left\{\begin{array}{@{}l} \lambda _1^ \bot = \dfrac{{\sqrt {{C_1}({2B + {C_1} + 2\sqrt {{B^2} + B{C_1}}})} }}{{{C_1}}},\\ \lambda _2^ \bot = \dfrac{{\sqrt {{C_1}({2B + {C_1} - 2\sqrt {{B^2} + B{C_1}}})} }}{{{C_1}}}, \end{array}\right. \end{align}

where the symbol ![]() $\bot$ represents the transverse flow henceforth. The solution form developed previously for

$\bot$ represents the transverse flow henceforth. The solution form developed previously for ![]() $\hat \varPsi _n$ satisfies the no-penetration condition at the patterned wall, i.e.

$\hat \varPsi _n$ satisfies the no-penetration condition at the patterned wall, i.e. ![]() $\hat \varPsi _n(0)=0$, hence

$\hat \varPsi _n(0)=0$, hence ![]() $v(X,0)=0$ (see (3.38) further below). At

$v(X,0)=0$ (see (3.38) further below). At ![]() $Y=\kappa h$, the values of

$Y=\kappa h$, the values of ![]() $\hat \varPsi _n$,

$\hat \varPsi _n$, ![]() ${\rm d}\hat \varPsi _n/{\rm d} Y$ and

${\rm d}\hat \varPsi _n/{\rm d} Y$ and ![]() ${\rm d}^2\hat \varPsi _n/{\rm d} Y^2$ become negligible and they belong to higher orders of perturbations; thus, the conditions of zero perturbation velocity and zero strain-rate magnitude at the lower yield surface are satisfied (for

${\rm d}^2\hat \varPsi _n/{\rm d} Y^2$ become negligible and they belong to higher orders of perturbations; thus, the conditions of zero perturbation velocity and zero strain-rate magnitude at the lower yield surface are satisfied (for ![]() $n>0$ in the leading order). The zeroth term solution (i.e.

$n>0$ in the leading order). The zeroth term solution (i.e. ![]() $n=0$) would have a quadratic form for

$n=0$) would have a quadratic form for ![]() $\varPsi$, leading to a linear distribution for

$\varPsi$, leading to a linear distribution for ![]() $u$ (similar to

$u$ (similar to ![]() $w$). Again, the no-penetration condition at

$w$). Again, the no-penetration condition at ![]() $Y=0$ and the zero perturbation velocity at the lower yield surface (

$Y=0$ and the zero perturbation velocity at the lower yield surface (![]() $Y=\kappa h$) is satisfied by the zeroth term solution. However, the condition of zero strain rate magnitude at the yield surface should be satisfied through an iterative approach on

$Y=\kappa h$) is satisfied by the zeroth term solution. However, the condition of zero strain rate magnitude at the yield surface should be satisfied through an iterative approach on ![]() $h$, as described in § 4.1.1.

$h$, as described in § 4.1.1.

Having ![]() $\hat \varPsi _n$, one can now write the solution for

$\hat \varPsi _n$, one can now write the solution for ![]() $\varPsi$,

$\varPsi$, ![]() $u$ and

$u$ and ![]() $v$ as

$v$ as

$$\begin{gather} \varPsi (X,Y) = {A_0} \left( {Y - \frac{{{Y^2}}}{{2\kappa h}}} \right) + \sum_{n = 1}^\infty {{A_n}} \hat \varPsi_n (Y)\cos ({nX}), \end{gather}$$

$$\begin{gather} \varPsi (X,Y) = {A_0} \left( {Y - \frac{{{Y^2}}}{{2\kappa h}}} \right) + \sum_{n = 1}^\infty {{A_n}} \hat \varPsi_n (Y)\cos ({nX}), \end{gather}$$ $$\begin{gather}u(X,Y) = {A_0} \left({1 - \frac{Y}{\kappa h}} \right) + \sum_{n = 1}^\infty {{A_n}} {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(Y)} \cos ({nX}), \end{gather}$$

$$\begin{gather}u(X,Y) = {A_0} \left({1 - \frac{Y}{\kappa h}} \right) + \sum_{n = 1}^\infty {{A_n}} {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(Y)} \cos ({nX}), \end{gather}$$ $$\begin{gather}v(X,Y) = \sum_{n = 1}^\infty {{A_n}} \hat \varPsi_n (Y) n \sin ({nX}). \end{gather}$$

$$\begin{gather}v(X,Y) = \sum_{n = 1}^\infty {{A_n}} \hat \varPsi_n (Y) n \sin ({nX}). \end{gather}$$The patterned wall condition for the transverse configuration holds

Substituting (3.37) into (3.39) and (3.40) leads to a dual trigonometric series problem:

$$\begin{gather} {A_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^\infty {{A_n}} \left[ {{\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)} - b\kappa{\frac{{\rm d}^2\hat \varPsi_n}{{\rm d} Y^2}(0)}} \right]\cos ({nX}) = b({B + {C_1}}),\quad 0 \leq X \leq {\rm \pi}\varphi, \end{gather}$$

$$\begin{gather} {A_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^\infty {{A_n}} \left[ {{\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)} - b\kappa{\frac{{\rm d}^2\hat \varPsi_n}{{\rm d} Y^2}(0)}} \right]\cos ({nX}) = b({B + {C_1}}),\quad 0 \leq X \leq {\rm \pi}\varphi, \end{gather}$$ $$\begin{gather}{A_0} + \sum_{n = 1}^\infty {{A_n}} {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)}\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}, \end{gather}$$

$$\begin{gather}{A_0} + \sum_{n = 1}^\infty {{A_n}} {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)}\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}, \end{gather}$$

where (3.41) and (3.41) can be solved for ![]() $A_n$, using the same method described for the longitudinal flow configuration. Thus, the following system is obtained

$A_n$, using the same method described for the longitudinal flow configuration. Thus, the following system is obtained

\begin{equation} \sum_{n = 0}^N {{P_{mn}^{\bot}}{A_n}} = {M_m^{\bot}}, \end{equation}

\begin{equation} \sum_{n = 0}^N {{P_{mn}^{\bot}}{A_n}} = {M_m^{\bot}}, \end{equation}where the coefficient and constant matrices for (3.43) are calculated as

$$\begin{gather}{P_{mn}^{\bot}} = \frac{1}{{n}}\left[ {{\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)} - b\kappa{\frac{{\rm d}^2\hat \varPsi_n}{{\rm d} Y^2}(0)}} \right] I_1 + {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)} I_2,\quad n>0, \end{gather}$$

$$\begin{gather}{P_{mn}^{\bot}} = \frac{1}{{n}}\left[ {{\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)} - b\kappa{\frac{{\rm d}^2\hat \varPsi_n}{{\rm d} Y^2}(0)}} \right] I_1 + {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)} I_2,\quad n>0, \end{gather}$$3.2.3. Oblique configuration

Considering the solution for ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\hat \varPsi _n$ to be in the form of

$\hat \varPsi _n$ to be in the form of ![]() ${\rm e}^{\varLambda _nY}$, the ODEs (3.19) and (3.20) lead to the following relation:

${\rm e}^{\varLambda _nY}$, the ODEs (3.19) and (3.20) lead to the following relation:

where

In order to have non-zero solution for ![]() $A_n$ and

$A_n$ and ![]() $B_n$, the determinant of the coefficient matrix in (3.47) should be zero; thus,

$B_n$, the determinant of the coefficient matrix in (3.47) should be zero; thus, ![]() $\varOmega _{11}\varOmega _{22}-\varOmega _{12}\varOmega _{21}=0$. This condition leads to finding six solutions for

$\varOmega _{11}\varOmega _{22}-\varOmega _{12}\varOmega _{21}=0$. This condition leads to finding six solutions for ![]() ${\varLambda _n}$, with three being negative. Keeping the terms with negative

${\varLambda _n}$, with three being negative. Keeping the terms with negative ![]() ${\varLambda _n}$, the solution for

${\varLambda _n}$, the solution for ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\hat \varPsi _n$ can be written as (for

$\hat \varPsi _n$ can be written as (for ![]() $n>0$)

$n>0$)

where the symbol ![]() $\angle$ represents the oblique flow, henceforth, and

$\angle$ represents the oblique flow, henceforth, and

$$\begin{gather} {\lambda _1^\angle }{ =

\frac{{\sqrt {{C_1}\left( {2B \,{+}\, {C_1} \,{-}\,

\dfrac{3}{2}B{{\cos }^2}\theta + 2\sqrt {{B^2} + B{C_1} +

\dfrac{9}{{16}}{B^2}{{\cos }^4}\theta \,{-}\, B{{\cos

}^2}\theta \left( {\dfrac{3}{2}B \,{+}\, {C_1}} \right)} }

\,\right)} }}{{{C_1}}},}

\end{gather}$$

$$\begin{gather} {\lambda _1^\angle }{ =

\frac{{\sqrt {{C_1}\left( {2B \,{+}\, {C_1} \,{-}\,

\dfrac{3}{2}B{{\cos }^2}\theta + 2\sqrt {{B^2} + B{C_1} +

\dfrac{9}{{16}}{B^2}{{\cos }^4}\theta \,{-}\, B{{\cos

}^2}\theta \left( {\dfrac{3}{2}B \,{+}\, {C_1}} \right)} }

\,\right)} }}{{{C_1}}},}

\end{gather}$$ $$\begin{gather}{\lambda _2^\angle }{ =

\frac{{\sqrt {{C_1}\left( {2B \,{+}\, {C_1} \,{-}\,

\dfrac{3}{2}B{{\cos }^2}\theta - 2\sqrt {{B^2} + B{C_1} +

\dfrac{9}{{16}}{B^2}{{\cos }^4}\theta \,{-}\, B{{\cos

}^2}\theta \left({\dfrac{3}{2}B \,{+}\, {C_1}} \right)} }

\,\right)} }}{{{C_1}}}.}

\end{gather}$$

$$\begin{gather}{\lambda _2^\angle }{ =

\frac{{\sqrt {{C_1}\left( {2B \,{+}\, {C_1} \,{-}\,

\dfrac{3}{2}B{{\cos }^2}\theta - 2\sqrt {{B^2} + B{C_1} +

\dfrac{9}{{16}}{B^2}{{\cos }^4}\theta \,{-}\, B{{\cos

}^2}\theta \left({\dfrac{3}{2}B \,{+}\, {C_1}} \right)} }

\,\right)} }}{{{C_1}}}.}

\end{gather}$$ The solution for each ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\hat \varPsi _n$ contains three terms; thus, for each solution, two coefficients are required in order to determine the contribution of each term to that solution, i.e.

$\hat \varPsi _n$ contains three terms; thus, for each solution, two coefficients are required in order to determine the contribution of each term to that solution, i.e. ![]() $\varGamma _n^{(1)}$ and

$\varGamma _n^{(1)}$ and ![]() $\varGamma _n^{(2)}$ for

$\varGamma _n^{(2)}$ for ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\varDelta _n^{(1)}$ and

$\varDelta _n^{(1)}$ and ![]() $\varDelta _n^{(2)}$ for

$\varDelta _n^{(2)}$ for ![]() $\hat \varPsi _n$. Since the no-penetration condition should be satisfied at

$\hat \varPsi _n$. Since the no-penetration condition should be satisfied at ![]() $Y=0$, one finds

$Y=0$, one finds ![]() $\varDelta _n^{(2)}=1-\varDelta _n^{(1)}$. It is worth mentioning that the forms of solution written in (3.52) and (3.53) are comparable with those of the longitudinal and transverse configurations (3.21a,b) and (3.35a,b), as one might expect that when

$\varDelta _n^{(2)}=1-\varDelta _n^{(1)}$. It is worth mentioning that the forms of solution written in (3.52) and (3.53) are comparable with those of the longitudinal and transverse configurations (3.21a,b) and (3.35a,b), as one might expect that when ![]() $\theta \to 0$,

$\theta \to 0$, ![]() $\varGamma _n^{(1)} \to 0$ and

$\varGamma _n^{(1)} \to 0$ and ![]() $\varGamma _n^{(2)} \to 0$; however, when

$\varGamma _n^{(2)} \to 0$; however, when ![]() $\theta \to 90^\circ$,

$\theta \to 90^\circ$, ![]() $\varDelta _n^{(1)} \to 1$ and, hence,

$\varDelta _n^{(1)} \to 1$ and, hence, ![]() $\varDelta _n^{(2)} \to 0$. One should also note that when

$\varDelta _n^{(2)} \to 0$. One should also note that when ![]() $\theta \to 0$,

$\theta \to 0$, ![]() $\lambda _1^\angle \to \lambda ^\parallel$ and once

$\lambda _1^\angle \to \lambda ^\parallel$ and once ![]() $\theta \to 90^\circ$,

$\theta \to 90^\circ$, ![]() $\lambda _1^\angle \to \lambda _1^\bot$ and

$\lambda _1^\angle \to \lambda _1^\bot$ and ![]() $\lambda _2^\angle \to \lambda _2^\bot$.

$\lambda _2^\angle \to \lambda _2^\bot$.

Substituting the solution terms for ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\hat \varPsi _n$ with identical

$\hat \varPsi _n$ with identical ![]() ${\varLambda _n}$, e.g.

${\varLambda _n}$, e.g. ![]() ${\exp ({- {\lambda _1 ^\angle } nY})}$ and

${\exp ({- {\lambda _1 ^\angle } nY})}$ and ![]() $\varDelta ^{(1)}_n{\exp ({ - \lambda _1^ \angle nY})}$, into (3.20), one can obtain following relations:

$\varDelta ^{(1)}_n{\exp ({ - \lambda _1^ \angle nY})}$, into (3.20), one can obtain following relations:

$$\begin{gather} {\varDelta^{(1)} _n} ={-} \left( {\frac{{{B_n}}}{{{A_n}}}} \right){\left( {\frac{{{\varOmega _{22}}}}{{{\varOmega _{12}}}}} \right)_{\varLambda_n ={-}\lambda _1^\angle n }}, \end{gather}$$

$$\begin{gather} {\varDelta^{(1)} _n} ={-} \left( {\frac{{{B_n}}}{{{A_n}}}} \right){\left( {\frac{{{\varOmega _{22}}}}{{{\varOmega _{12}}}}} \right)_{\varLambda_n ={-}\lambda _1^\angle n }}, \end{gather}$$ $$\begin{gather}\varGamma _n^{(1)} = \left( {\frac{{{A_n}}}{{{B_n}}}} \right){\left( {\frac{{{\varOmega _{12}}}}{{{\varOmega _{22}}}}} \right)_{\varLambda_n ={-}\lambda _2^\angle n }}, \end{gather}$$

$$\begin{gather}\varGamma _n^{(1)} = \left( {\frac{{{A_n}}}{{{B_n}}}} \right){\left( {\frac{{{\varOmega _{12}}}}{{{\varOmega _{22}}}}} \right)_{\varLambda_n ={-}\lambda _2^\angle n }}, \end{gather}$$The numerical procedure for calculating the above-mentioned coefficients is discussed at the end of this section (i.e. § 3.2.3).

The solutions provided in (3.52) and (3.53) are for ![]() $n>0$. Indeed, the solution form for

$n>0$. Indeed, the solution form for ![]() $n=0$ of the oblique flow is identical to those of the longitudinal and transverse flow (i.e. the zero mode of the perturbation velocity is a linear function of

$n=0$ of the oblique flow is identical to those of the longitudinal and transverse flow (i.e. the zero mode of the perturbation velocity is a linear function of ![]() $Y$). In fact, when considering

$Y$). In fact, when considering ![]() $n=0$ in (3.52) and (3.53), the exponential forms vanish and the solutions for

$n=0$ in (3.52) and (3.53), the exponential forms vanish and the solutions for ![]() $n=0$ become similar to those obtained for the longitudinal and transverse flows (see (3.22) for

$n=0$ become similar to those obtained for the longitudinal and transverse flows (see (3.22) for ![]() $w_0$ and (3.36) for

$w_0$ and (3.36) for ![]() $\varPsi _0$).

$\varPsi _0$).

In the oblique configuration, the patterned wall conditions are as follows:

$$\begin{gather} w(X,0) - b{\left[

\begin{array}{@{}l@{}} ({B + C_1})\cos \theta \\ + \left( {1 +

\dfrac{B}{{{C_1}}}{{\sin}^2}\theta } \right){\kappa

}\dfrac{{\partial w}}{{\partial Y}}\\ - \dfrac{B}{C_1} \sin

\theta \cos \theta {\kappa }\dfrac{{\partial u}}{{\partial

Y}} \end{array}\right]_{Y = 0}} = 0,\quad 0 \le X \le {\rm \pi}

\varphi, \end{gather}$$

$$\begin{gather} w(X,0) - b{\left[

\begin{array}{@{}l@{}} ({B + C_1})\cos \theta \\ + \left( {1 +

\dfrac{B}{{{C_1}}}{{\sin}^2}\theta } \right){\kappa

}\dfrac{{\partial w}}{{\partial Y}}\\ - \dfrac{B}{C_1} \sin

\theta \cos \theta {\kappa }\dfrac{{\partial u}}{{\partial

Y}} \end{array}\right]_{Y = 0}} = 0,\quad 0 \le X \le {\rm \pi}

\varphi, \end{gather}$$

$$\begin{gather}u(X,0) - b{\left[

\begin{array}{@{}l@{}} ({B + C_1})\sin \theta \\ + \left( {1 +

\dfrac{B}{{{C_1}}}{{\cos}^2}\theta } \right){\kappa }

\dfrac{{\partial u}}{{\partial Y}}\\ - \dfrac{B}{C_1}\sin

\theta \cos \theta {\kappa } \dfrac{{\partial w}}{{\partial

Y}} \end{array}\right]_{Y = 0}} = 0,\quad 0 \le X \le {\rm \pi}

\varphi, \end{gather}$$

$$\begin{gather}u(X,0) - b{\left[

\begin{array}{@{}l@{}} ({B + C_1})\sin \theta \\ + \left( {1 +

\dfrac{B}{{{C_1}}}{{\cos}^2}\theta } \right){\kappa }

\dfrac{{\partial u}}{{\partial Y}}\\ - \dfrac{B}{C_1}\sin

\theta \cos \theta {\kappa } \dfrac{{\partial w}}{{\partial

Y}} \end{array}\right]_{Y = 0}} = 0,\quad 0 \le X \le {\rm \pi}

\varphi, \end{gather}$$

These coupled patterned wall conditions for the oblique configuration highlight the strong effects of the nonlinear viscoplastic rheology, since new terms emerge in the shear stress components originated from the nonlinear viscosity.

Substituting the solutions in the form of (3.22) and (3.37) into the patterned wall conditions, i.e. (3.59), (3.60), (3.61) and (3.62), the following dual trigonometric series problems emerge:

\begin{align} & {B_0}\left( {1 + \frac{{b( {{C_1} + B{{\sin }^2}\theta})}}{{{C_1}h}}} \right) - {A_0}\left( {\frac{{bB\sin \theta \cos \theta }}{{{C_1}h}}} \right) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{B_n}} \left[ {{{\hat w}_n}(0) - b\left( {1 + \frac{B}{{{C_1}}}{{\sin }^2}\theta } \right)\kappa \frac{{{\rm d}{{\hat w}_n}}}{{{\rm d} Y}}(0)} \right]\cos ({nX}) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{A_n}} b\frac{B}{{{C_1}}}\sin \theta \cos \theta \kappa \frac{{{{\rm d}^2}{{\hat \varPsi }_n}}}{{{\rm d}{Y^2}}}(0)\cos ({nX}) \nonumber\\ &\quad = b({B + {C_1}})\cos \theta,\quad 0 \leq X \leq {\rm \pi}\varphi, \end{align}

\begin{align} & {B_0}\left( {1 + \frac{{b( {{C_1} + B{{\sin }^2}\theta})}}{{{C_1}h}}} \right) - {A_0}\left( {\frac{{bB\sin \theta \cos \theta }}{{{C_1}h}}} \right) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{B_n}} \left[ {{{\hat w}_n}(0) - b\left( {1 + \frac{B}{{{C_1}}}{{\sin }^2}\theta } \right)\kappa \frac{{{\rm d}{{\hat w}_n}}}{{{\rm d} Y}}(0)} \right]\cos ({nX}) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{A_n}} b\frac{B}{{{C_1}}}\sin \theta \cos \theta \kappa \frac{{{{\rm d}^2}{{\hat \varPsi }_n}}}{{{\rm d}{Y^2}}}(0)\cos ({nX}) \nonumber\\ &\quad = b({B + {C_1}})\cos \theta,\quad 0 \leq X \leq {\rm \pi}\varphi, \end{align} \begin{equation} {B_0} + \sum_{n = 1}^\infty {{B_n}} {{\hat w}_n}(0)\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}, \end{equation}

\begin{equation} {B_0} + \sum_{n = 1}^\infty {{B_n}} {{\hat w}_n}(0)\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}, \end{equation} \begin{align} & {A_0}\left( {1 + \frac{{b( {{C_1} + B{{\cos }^2}\theta })}}{{{C_1}h}}} \right) - {B_0}\left( {\frac{{bB\sin \theta \cos \theta }}{{{C_1}h}}} \right) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{A_n}} \left[ {\frac{{{\rm d}{{\hat \varPsi }_n}}}{{{\rm d} Y}}(0) - b\left( {1 + \frac{B}{{{C_1}}}{{\cos }^2}\theta } \right)\kappa \frac{{{{\rm d}^2}{{\hat \varPsi }_n}}}{{{\rm d}{Y^2}}}(0)} \right]\cos ({nX}) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{B_n}} b\frac{B}{{{C_1}}}\sin \theta \cos \theta \kappa \frac{{{\rm d}{{\hat w}_n}}}{{{\rm d} Y}}(0)\cos \left( {nX} \right) \nonumber\\ &\quad = b({B + {C_1}})\sin \theta,\quad 0 \leq X \leq {\rm \pi}\varphi, \end{align}

\begin{align} & {A_0}\left( {1 + \frac{{b( {{C_1} + B{{\cos }^2}\theta })}}{{{C_1}h}}} \right) - {B_0}\left( {\frac{{bB\sin \theta \cos \theta }}{{{C_1}h}}} \right) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{A_n}} \left[ {\frac{{{\rm d}{{\hat \varPsi }_n}}}{{{\rm d} Y}}(0) - b\left( {1 + \frac{B}{{{C_1}}}{{\cos }^2}\theta } \right)\kappa \frac{{{{\rm d}^2}{{\hat \varPsi }_n}}}{{{\rm d}{Y^2}}}(0)} \right]\cos ({nX}) \nonumber\\ &\qquad + \sum_{n = 1}^\infty {{B_n}} b\frac{B}{{{C_1}}}\sin \theta \cos \theta \kappa \frac{{{\rm d}{{\hat w}_n}}}{{{\rm d} Y}}(0)\cos \left( {nX} \right) \nonumber\\ &\quad = b({B + {C_1}})\sin \theta,\quad 0 \leq X \leq {\rm \pi}\varphi, \end{align} \begin{equation} {A_0} + \sum_{n = 1}^\infty {{A_n}} {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)}\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}. \end{equation}

\begin{equation} {A_0} + \sum_{n = 1}^\infty {{A_n}} {\frac{{\rm d}\hat \varPsi_n}{{\rm d} Y}(0)}\cos ({nX}) = 0,\quad {\rm \pi}\varphi \leq X \leq {\rm \pi}. \end{equation} Note that for a Newtonian fluid, as ![]() $B=0$, the dual series problems given above become decoupled and, since the solutions for

$B=0$, the dual series problems given above become decoupled and, since the solutions for ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\hat \varPsi _n$ are identical to those of the longitudinal and transverse flow, respectively, we would simply have

$\hat \varPsi _n$ are identical to those of the longitudinal and transverse flow, respectively, we would simply have ![]() $B_n^\angle =B_n^\parallel \cos \theta$ and

$B_n^\angle =B_n^\parallel \cos \theta$ and ![]() $A_n^\angle =A_n^\bot \sin \theta$ for

$A_n^\angle =A_n^\bot \sin \theta$ for ![]() $n=0,1,2,\ldots$. However, in a viscoplastic material, the dependence of

$n=0,1,2,\ldots$. However, in a viscoplastic material, the dependence of ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\hat \varPsi _n$ solutions on

$\hat \varPsi _n$ solutions on ![]() $\theta$ and the coupling between the ODEs and the patterned wall conditions make the problem different and more challenging.

$\theta$ and the coupling between the ODEs and the patterned wall conditions make the problem different and more challenging.

Using the method developed for the longitudinal and transverse configurations, one can find the following coupled system of linear equations:

$$\begin{gather} \sum_{n = 0}^N {{P_{mn}^{w\angle}}{B_n}} = {M_m^{w\angle}}- \sum_{n = 0}^N{{E_{mn}^{w\angle}}{A_n}}, \end{gather}$$

$$\begin{gather} \sum_{n = 0}^N {{P_{mn}^{w\angle}}{B_n}} = {M_m^{w\angle}}- \sum_{n = 0}^N{{E_{mn}^{w\angle}}{A_n}}, \end{gather}$$ $$\begin{gather}\sum_{n = 0}^N {{P_{mn}^{u\angle}}{A_n}} = {M_m^{u\angle}}- \sum_{n = 0}^N{{E_{mn}^{u\angle}}{B_n}}, \end{gather}$$

$$\begin{gather}\sum_{n = 0}^N {{P_{mn}^{u\angle}}{A_n}} = {M_m^{u\angle}}- \sum_{n = 0}^N{{E_{mn}^{u\angle}}{B_n}}, \end{gather}$$where

and

$$\begin{gather}P_{mn}^{u\angle} = \frac{1}{n}\left[ {\frac{{{\rm d}{{\hat \varPsi }_n}}}{{{\rm d} Y}}(0) - b\left( {1 + \frac{B}{{{C_1}}}{{\cos }^2}\theta } \right)\kappa \frac{{{{\rm d}^2}{{\hat \varPsi }_n}}}{{{\rm d}{Y^2}}}(0)} \right]{I_1} + \frac{{{\rm d}{{\hat \varPsi }_n}}}{{{\rm d} Y}}(0){I_2},\quad n > 0, \end{gather}$$

$$\begin{gather}P_{mn}^{u\angle} = \frac{1}{n}\left[ {\frac{{{\rm d}{{\hat \varPsi }_n}}}{{{\rm d} Y}}(0) - b\left( {1 + \frac{B}{{{C_1}}}{{\cos }^2}\theta } \right)\kappa \frac{{{{\rm d}^2}{{\hat \varPsi }_n}}}{{{\rm d}{Y^2}}}(0)} \right]{I_1} + \frac{{{\rm d}{{\hat \varPsi }_n}}}{{{\rm d} Y}}(0){I_2},\quad n > 0, \end{gather}$$ Regarding the numerical procedure, in the first iteration, an initial guess for ![]() $\varDelta ^{(1)}_n$,

$\varDelta ^{(1)}_n$, ![]() $\varGamma ^{(1)}_n$ and

$\varGamma ^{(1)}_n$ and ![]() $\varGamma ^{(2)}_n$ is considered, e.g.

$\varGamma ^{(2)}_n$ is considered, e.g. ![]() $\varDelta ^{(1,0)}_n=1$,

$\varDelta ^{(1,0)}_n=1$, ![]() $\varGamma ^{(1,0)}_n=0$ and

$\varGamma ^{(1,0)}_n=0$ and ![]() $\varGamma ^{(2,0)}_n=0$. Then, one can find

$\varGamma ^{(2,0)}_n=0$. Then, one can find ![]() $\hat w_n$ and

$\hat w_n$ and ![]() $\hat \varPsi _n$ based on (3.52) and (3.53). Therefore, in the first iteration, one can form the system of linear equations (3.67) and (3.68), while ignoring the rightmost term on the right-hand side of these linear systems (i.e.

$\hat \varPsi _n$ based on (3.52) and (3.53). Therefore, in the first iteration, one can form the system of linear equations (3.67) and (3.68), while ignoring the rightmost term on the right-hand side of these linear systems (i.e. ![]() $E_{mn}^{w\angle } A_n$ and

$E_{mn}^{w\angle } A_n$ and ![]() $E_{mn}^{u\angle } B_n$), and solve for

$E_{mn}^{u\angle } B_n$), and solve for ![]() $A_n$ and

$A_n$ and ![]() $B_n$. In the next iteration, the new values of

$B_n$. In the next iteration, the new values of ![]() $A_n$ and

$A_n$ and ![]() $B_n$ should be used to update the coefficients

$B_n$ should be used to update the coefficients ![]() $\varDelta ^{(1)}_n$,

$\varDelta ^{(1)}_n$, ![]() $\varGamma ^{(1)}_n$ and

$\varGamma ^{(1)}_n$ and ![]() $\varGamma ^{(2)}_n$ based on (3.56), (3.57) and (3.58), and, hence, to update

$\varGamma ^{(2)}_n$ based on (3.56), (3.57) and (3.58), and, hence, to update ![]() $\hat w_n$ and