Article contents

Colloidal exchange flow in ducts

Published online by Cambridge University Press: 16 May 2022

Abstract

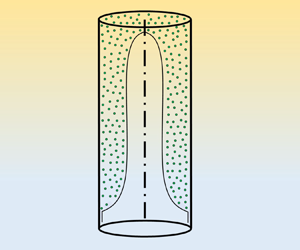

Buoyancy-driven exchange flow, i.e. drainage of a heavy colloidal suspension by an immiscible light pure fluid in a vertical duct, is studied analytically. A lubrication model is developed for two-dimensional channel and axisymmetric pipe geometries. The outcome transport equations are solved numerically to capture the effect of important governing dimensionless parameters: Péclet number, precursor film thickness, Reynolds number, mixtures’ viscosity ratio, initial volume fraction of hard-sphere particles, particles concentration within the precursor film, and capillary number. Recent study of colloidal film flow over a flat surface reveals interface thinning over time due to diffusion impact on suspension viscosity. However, the current model suggests that there is no such thinning phenomenon observed for colloidal flows within confined geometry unless in the absence of surface tension. The extent of the mixed particle zone along the duct grows as the Péclet number is decreased. Precursor film thickness is found to decrease the capillary ridge height forming at heavy suspension front. Either an increase in the Reynolds number or a decrease in light-to-heavy-fluid viscosity ratio extends the interpenetration rate of mixtures. As the bulk volume fraction of particles is increased close to 50 %, interesting secondary fronts emerge within the flow that coincide with the range where the diffusion coefficient is minimized. The heavy suspension layer drains slightly faster when the gradient in particle concentration between the bulk and precursor film regions is maximum. Finally, the non-monotonic impact of surface tension on the extent of mixtures’ exchange zone is uncovered via simulations conducted at various capillary numbers.

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press

References

REFERENCES

- 2

- Cited by