1. Introduction

Describing coating flow over a solid is a theoretical challenge, yet endlessly appealing because of the many simple phenomena that involve these kinds of flows: we withdraw spoons covered in honey from a jar, coat strawberries in chocolate, dip and remove a paintbrush from a bucket, lift ourselves out of the water at the swimming pool, and take pictures with film made of a light-sensitive chemical coated over a transparent strip. In general, in dip coating processes, the film thickness ![]() $h_0$ coated on objects pulled from a bath of viscous liquid depends on the capillary number

$h_0$ coated on objects pulled from a bath of viscous liquid depends on the capillary number ![]() $Ca = {\eta v_0}/{\gamma }$, which describes the balance between viscous and capillary forces, where

$Ca = {\eta v_0}/{\gamma }$, which describes the balance between viscous and capillary forces, where ![]() $v_0$ is the pulling velocity,

$v_0$ is the pulling velocity, ![]() $\eta$ is the liquid's dynamic viscosity, and

$\eta$ is the liquid's dynamic viscosity, and ![]() $\gamma$ is the liquid's surface tension. The initial model for dip coating a Newtonian liquid over a smooth, flat plate at small

$\gamma$ is the liquid's surface tension. The initial model for dip coating a Newtonian liquid over a smooth, flat plate at small ![]() $Ca$ gives the relation (Landau & Levich Reference Landau and Levich1942; Derjaguin Reference Derjaguin1943; Wilson Reference Wilson1982)

$Ca$ gives the relation (Landau & Levich Reference Landau and Levich1942; Derjaguin Reference Derjaguin1943; Wilson Reference Wilson1982)

where ![]() $a = \sqrt {\gamma /(\rho g)}$ is the capillary length,

$a = \sqrt {\gamma /(\rho g)}$ is the capillary length, ![]() $\rho$ is the liquid's density, and

$\rho$ is the liquid's density, and ![]() $g$ is the magnitude of gravitational acceleration. The model matched earlier experiments of Morey (Reference Morey1940), who found

$g$ is the magnitude of gravitational acceleration. The model matched earlier experiments of Morey (Reference Morey1940), who found ![]() $h_0 \sim Ca^{{2}/{3}}$.

$h_0 \sim Ca^{{2}/{3}}$.

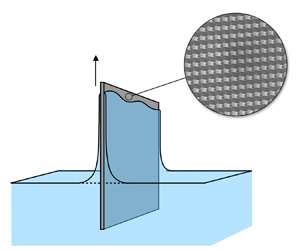

The model (1.1) has been extended to include corrections accounting for gravity and inertia at larger ![]() $Ca$ (Spiers, Subbaraman & Wilkinson Reference Spiers, Subbaraman and Wilkinson1974; de Ryck & Quéré Reference de Ryck and Quéré1998). Theoretical and experimental extensions have also been made with regard to the object coated – including tilted plates (Wilson Reference Wilson1982; Benilov & Zubkov Reference Benilov and Zubkov2008), horizontal and vertical cylinders (White & Tallmadge Reference White and Tallmadge1966; Spiers et al. Reference Spiers, Subbaraman and Wilkinson1974; Wilson Reference Wilson1982; Quéré Reference Quéré1999), compliant surfaces (Kajiya et al. Reference Kajiya, Brunet, Royon, Daerr, Receveur and Limat2014; Bertin et al. Reference Bertin, Snoeijer, Raphaël and Salez2022), and rough surfaces (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Seiwert, Clanet & Quéré Reference Seiwert, Clanet and Quéré2011; Sathyanath, Aarthi & Kalpathy Reference Sathyanath, Aarthi and Kalpathy2020) – as well as the liquid properties, as reviewed in Rio & Boulogne (Reference Rio and Boulogne2017). Given the multitude of realistic situations in which a surface to be coated is rough or porous, rather than smooth (Stauffer, Hajnal & Gendzwill Reference Stauffer, Hajnal and Gendzwill1976; Barthlott & Neinhuis Reference Barthlott and Neinhuis1997; Neinhuis & Barthlott Reference Neinhuis and Barthlott1997; Devauchelle, Josserand & Zaleski Reference Devauchelle, Josserand and Zaleski2007; Nong & Anderson Reference Nong and Anderson2010), we focus our attention on thin film flow over a rough surface pulled from a liquid bath (figure 1). The film profile is

$Ca$ (Spiers, Subbaraman & Wilkinson Reference Spiers, Subbaraman and Wilkinson1974; de Ryck & Quéré Reference de Ryck and Quéré1998). Theoretical and experimental extensions have also been made with regard to the object coated – including tilted plates (Wilson Reference Wilson1982; Benilov & Zubkov Reference Benilov and Zubkov2008), horizontal and vertical cylinders (White & Tallmadge Reference White and Tallmadge1966; Spiers et al. Reference Spiers, Subbaraman and Wilkinson1974; Wilson Reference Wilson1982; Quéré Reference Quéré1999), compliant surfaces (Kajiya et al. Reference Kajiya, Brunet, Royon, Daerr, Receveur and Limat2014; Bertin et al. Reference Bertin, Snoeijer, Raphaël and Salez2022), and rough surfaces (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Seiwert, Clanet & Quéré Reference Seiwert, Clanet and Quéré2011; Sathyanath, Aarthi & Kalpathy Reference Sathyanath, Aarthi and Kalpathy2020) – as well as the liquid properties, as reviewed in Rio & Boulogne (Reference Rio and Boulogne2017). Given the multitude of realistic situations in which a surface to be coated is rough or porous, rather than smooth (Stauffer, Hajnal & Gendzwill Reference Stauffer, Hajnal and Gendzwill1976; Barthlott & Neinhuis Reference Barthlott and Neinhuis1997; Neinhuis & Barthlott Reference Neinhuis and Barthlott1997; Devauchelle, Josserand & Zaleski Reference Devauchelle, Josserand and Zaleski2007; Nong & Anderson Reference Nong and Anderson2010), we focus our attention on thin film flow over a rough surface pulled from a liquid bath (figure 1). The film profile is ![]() $h = h(z)$, and in the dynamic meniscus region (region II), the profile tends towards a flat film of constant thickness

$h = h(z)$, and in the dynamic meniscus region (region II), the profile tends towards a flat film of constant thickness ![]() $h \to h_0$ as

$h \to h_0$ as ![]() $z \to \infty$. Although initial progress has been made to characterize the effect of roughness on the film thickness (Aradian, Raphaël & de Gennes Reference Aradian, Raphaël and de Gennes2000; Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Seiwert Reference Seiwert2010; Seiwert et al. Reference Seiwert, Clanet and Quéré2011; Sathyanath et al. Reference Sathyanath, Aarthi and Kalpathy2020), at present we lack a general model capable of predicting film thickness coated on an arbitrary periodic roughness pattern.

$z \to \infty$. Although initial progress has been made to characterize the effect of roughness on the film thickness (Aradian, Raphaël & de Gennes Reference Aradian, Raphaël and de Gennes2000; Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Seiwert Reference Seiwert2010; Seiwert et al. Reference Seiwert, Clanet and Quéré2011; Sathyanath et al. Reference Sathyanath, Aarthi and Kalpathy2020), at present we lack a general model capable of predicting film thickness coated on an arbitrary periodic roughness pattern.

Figure 1. Dip coating system. (a) A solid plate is pulled at constant velocity ![]() $\boldsymbol {v} = v_0 \hat {\boldsymbol {z}}$ from a liquid bath having density

$\boldsymbol {v} = v_0 \hat {\boldsymbol {z}}$ from a liquid bath having density ![]() $\rho$, surface tension

$\rho$, surface tension ![]() $\gamma$, and dynamic viscosity

$\gamma$, and dynamic viscosity ![]() $\eta$, where

$\eta$, where ![]() $\boldsymbol {v}$ is directed opposite to the direction of gravitational acceleration

$\boldsymbol {v}$ is directed opposite to the direction of gravitational acceleration ![]() $\boldsymbol {g}$. The plate is rough, with a periodic texture pattern. To model the rough surface, we apply an equivalent boundary condition to a flat equivalent surface

$\boldsymbol {g}$. The plate is rough, with a periodic texture pattern. To model the rough surface, we apply an equivalent boundary condition to a flat equivalent surface ![]() $\mathbb {ES}$ that is placed a distance

$\mathbb {ES}$ that is placed a distance ![]() $d_{\mathbb {ES}}$ from the bottom of the roughness. The thin film on the plate forms three regions: a flat film (region I) is connected to a static meniscus (region III) by a dynamic meniscus (region II). We wish to know the limiting film thickness

$d_{\mathbb {ES}}$ from the bottom of the roughness. The thin film on the plate forms three regions: a flat film (region I) is connected to a static meniscus (region III) by a dynamic meniscus (region II). We wish to know the limiting film thickness ![]() $h(z) = h_0$ in the flat film region. (b) The film thickness

$h(z) = h_0$ in the flat film region. (b) The film thickness ![]() $h(z)$ as a function of the coordinate

$h(z)$ as a function of the coordinate ![]() $z$ along the plate.

$z$ along the plate.

At large ![]() $Ca$, the film thickness coated on a rough plate is found to be modelled well by (1.1), while experiments demonstrate that at small

$Ca$, the film thickness coated on a rough plate is found to be modelled well by (1.1), while experiments demonstrate that at small ![]() $Ca$, surface roughness significantly increases film thickness compared to the case of a smooth plate (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Seiwert et al. Reference Seiwert, Clanet and Quéré2011). The physical reason for this increase is that the roughness introduces a minimum film thickness due to viscous resistance to liquid flow against the additional solid walls or pore-like features, which have a greater area compared to the flat case (Seiwert et al. Reference Seiwert, Clanet and Quéré2011). For a rough plate, the film thickness no longer goes to zero as

$Ca$, surface roughness significantly increases film thickness compared to the case of a smooth plate (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Seiwert et al. Reference Seiwert, Clanet and Quéré2011). The physical reason for this increase is that the roughness introduces a minimum film thickness due to viscous resistance to liquid flow against the additional solid walls or pore-like features, which have a greater area compared to the flat case (Seiwert et al. Reference Seiwert, Clanet and Quéré2011). For a rough plate, the film thickness no longer goes to zero as ![]() $Ca \to 0$ as predicted by (1.1); instead, experiments demonstrate that a small film remains trapped within the rough features due to viscous resistance, such that

$Ca \to 0$ as predicted by (1.1); instead, experiments demonstrate that a small film remains trapped within the rough features due to viscous resistance, such that ![]() $h_0 \to h_{min}$ as

$h_0 \to h_{min}$ as ![]() $Ca \to 0$. The scale of this minimum thickness is

$Ca \to 0$. The scale of this minimum thickness is ![]() $h_{min} \sim r$, with

$h_{min} \sim r$, with ![]() $r$ being the typical peak-to-valley scale of the roughness. Seiwert et al. (Reference Seiwert, Clanet and Quéré2011) thus divide the film into two regions: a trapped fluid region located within the roughness features, and a free film region outside, separated by a flat plane located at the peak of the roughness features.

$r$ being the typical peak-to-valley scale of the roughness. Seiwert et al. (Reference Seiwert, Clanet and Quéré2011) thus divide the film into two regions: a trapped fluid region located within the roughness features, and a free film region outside, separated by a flat plane located at the peak of the roughness features.

Motivated by such physical reasoning, Krechetnikov & Homsy (Reference Krechetnikov and Homsy2005), Liao, Li & Wei (Reference Liao, Li and Wei2013) and Sathyanath et al. (Reference Sathyanath, Aarthi and Kalpathy2020) proposed a model for rough dip coating that would replace the no-slip boundary condition at the rough wall by a slip boundary condition at a fictitious flat boundary plane at the peak of the roughness features. Such a model is sensible if we consider that at the boundary plane, we find a mix of solid and fluid patches, meaning that at the boundary there is a non-zero slip velocity (Beavers & Joseph Reference Beavers and Joseph1967). Introducing slip has been used successfully to model experimentally observed velocity profiles in channels with rough walls (Lauga & Stone Reference Lauga and Stone2003; Maali & Bhushan Reference Maali and Bhushan2012), where flow velocities are similar to those in small-![]() $Ca$ dip coating experiments. However, Seiwert et al. (Reference Seiwert, Clanet and Quéré2011) found that a slip model was insufficient to explain their observation of a constant minimum film thickness (

$Ca$ dip coating experiments. However, Seiwert et al. (Reference Seiwert, Clanet and Quéré2011) found that a slip model was insufficient to explain their observation of a constant minimum film thickness (![]() $h_0 = h_{min}$) with no free film coated below a critical capillary number

$h_0 = h_{min}$) with no free film coated below a critical capillary number ![]() $Ca < Ca_c$; the slip model overestimated the experimentally observed free film thickness. A modified model was developed that proposed to augment the slip velocity by considering porous flow through the rough layer, but it lacked experimental comparison (Devauchelle et al. Reference Devauchelle, Josserand and Zaleski2007). Instead of using a slip model, Seiwert et al. (Reference Seiwert, Clanet and Quéré2011) proposed to model the system as two layers of liquid, where the trapped-fluid region is replaced by a liquid of higher viscosity

$Ca < Ca_c$; the slip model overestimated the experimentally observed free film thickness. A modified model was developed that proposed to augment the slip velocity by considering porous flow through the rough layer, but it lacked experimental comparison (Devauchelle et al. Reference Devauchelle, Josserand and Zaleski2007). Instead of using a slip model, Seiwert et al. (Reference Seiwert, Clanet and Quéré2011) proposed to model the system as two layers of liquid, where the trapped-fluid region is replaced by a liquid of higher viscosity ![]() $\eta ^* > \eta$, and subsequently solve for

$\eta ^* > \eta$, and subsequently solve for ![]() $h_0$. When

$h_0$. When ![]() $\eta ^*$ was used as a fitting parameter to the experimental data, this ‘two-layer model’ predicted the formation of a trapped film and the total depletion of the free film for

$\eta ^*$ was used as a fitting parameter to the experimental data, this ‘two-layer model’ predicted the formation of a trapped film and the total depletion of the free film for ![]() $Ca < Ca_c$.

$Ca < Ca_c$.

Despite the successes of prior modelling efforts (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Seiwert et al. Reference Seiwert, Clanet and Quéré2011; Liao et al. Reference Liao, Li and Wei2013; Sathyanath et al. Reference Sathyanath, Aarthi and Kalpathy2020), these models are not fully predictive since closure of the problem requires experimental data to fit either the slip length ![]() $\mathcal {L}$ or the viscosity increase parameter

$\mathcal {L}$ or the viscosity increase parameter ![]() $\eta ^*$. Here, we develop a model that provides further insight into the physical mechanism by which the microstructure affects the macroscopic flow, and in doing so, present a predictive model for the film thickness coated on rough surfaces by a viscous liquid. The key factor enabling the predictability of the model employed in the present work stems from the use of a homogenization technique (Hornung Reference Hornung1997; Espedal, Fasano & Mikelić Reference Espedal, Fasano and Mikelić2000; Mei & Vernescu Reference Mei and Vernescu2010), which allows us to derive effective macroscopic properties of a surface from its microscopic structure. The upscaling procedure involves taking a spatial average of microscopic flow quantities describing the flow around a single microscopic roughness feature to compute effective macroscopic properties. Properties upscaled from the microstructure can then be applied to the macroscopic problem via an interface condition imposed over a fictitious flat surface called the ‘equivalent surface’ (

$\eta ^*$. Here, we develop a model that provides further insight into the physical mechanism by which the microstructure affects the macroscopic flow, and in doing so, present a predictive model for the film thickness coated on rough surfaces by a viscous liquid. The key factor enabling the predictability of the model employed in the present work stems from the use of a homogenization technique (Hornung Reference Hornung1997; Espedal, Fasano & Mikelić Reference Espedal, Fasano and Mikelić2000; Mei & Vernescu Reference Mei and Vernescu2010), which allows us to derive effective macroscopic properties of a surface from its microscopic structure. The upscaling procedure involves taking a spatial average of microscopic flow quantities describing the flow around a single microscopic roughness feature to compute effective macroscopic properties. Properties upscaled from the microstructure can then be applied to the macroscopic problem via an interface condition imposed over a fictitious flat surface called the ‘equivalent surface’ (![]() $\mathbb {ES}$ in figure 1) placed between the trapped liquid layer and the free film.

$\mathbb {ES}$ in figure 1) placed between the trapped liquid layer and the free film.

Homogenization can be used to analyse fluid–solid interaction phenomena where there is a separation of scales between the typical microscopic roughness size and the whole macroscopic system size (Mei & Vernescu Reference Mei and Vernescu2010). The large scale may be given by the size of a macroscopic object (such as the radius of a sphere with a rough surface) or by the scale of the flow domain (such as the height of a channel) (Zampogna & Bottaro Reference Zampogna and Bottaro2016; Zampogna, Magnaudet & Bottaro Reference Zampogna, Magnaudet and Bottaro2019; Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2021). Thus homogenization has been employed extensively to calculate the effective flow of an incompressible fluid in domains with no free interface, such as through porous and poroelastic media (Levy & Sanchez-Palencia Reference Levy and Sanchez-Palencia1975; Carraro et al. Reference Carraro, Goll, Marciniak-Czochra and Mikelić2015; Zampogna & Bottaro Reference Zampogna and Bottaro2016; Lācis & Bagheri Reference Lācis and Bagheri2017; Lācis, Zampogna & Bagheri Reference Lācis, Zampogna and Bagheri2017; Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2021; Strohbeck, Eggenweiler & Rybak Reference Strohbeck, Eggenweiler and Rybak2023), over rough surfaces (Jiménez Bolaños & Vernescu Reference Jiménez Bolaños and Vernescu2017; Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019; Lācis et al. Reference Lācis, Sudhakar, Pasche and Bagheri2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021), and across periodic and weakly periodic microstructured permeable surfaces (Zampogna & Gallaire Reference Zampogna and Gallaire2020; Ledda et al. Reference Ledda, Boujo, Camarri, Gallaire and Zampogna2021; Zampogna, Ledda & Gallaire Reference Zampogna, Ledda and Gallaire2022). Bottaro & Naqvi (Reference Bottaro and Naqvi2020) have shown that the flow at an interface between a free-fluid region and a rough surface is described by the slip tensor ![]() $\boldsymbol {\mathcal {L}}$ and interface permeability tensor

$\boldsymbol {\mathcal {L}}$ and interface permeability tensor ![]() $\boldsymbol {\mathcal {K}}^{itf}$ (see also Naqvi & Bottaro Reference Naqvi and Bottaro2021). Following their work, in contrast to the slip models (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Sathyanath et al. Reference Sathyanath, Aarthi and Kalpathy2020), the boundary condition that we use considers both slip due to fluid patches at the equivalent surface (through

$\boldsymbol {\mathcal {K}}^{itf}$ (see also Naqvi & Bottaro Reference Naqvi and Bottaro2021). Following their work, in contrast to the slip models (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Sathyanath et al. Reference Sathyanath, Aarthi and Kalpathy2020), the boundary condition that we use considers both slip due to fluid patches at the equivalent surface (through ![]() $\boldsymbol {\mathcal {L}}$) and an excess tangential velocity driven by a pressure gradient over the rough layer (through

$\boldsymbol {\mathcal {L}}$) and an excess tangential velocity driven by a pressure gradient over the rough layer (through ![]() $\boldsymbol {\mathcal {K}}^{itf}$). We employ a boundary condition of this form to model the thin film flow. Using the homogenization framework to compute

$\boldsymbol {\mathcal {K}}^{itf}$). We employ a boundary condition of this form to model the thin film flow. Using the homogenization framework to compute ![]() $\boldsymbol {\mathcal {L}}$ and

$\boldsymbol {\mathcal {L}}$ and ![]() $\boldsymbol {\mathcal {K}}^{itf}$ for any surface with a periodic roughness pattern (Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019; Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021), we can predict the coated film thickness without any fitting parameter.

$\boldsymbol {\mathcal {K}}^{itf}$ for any surface with a periodic roughness pattern (Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019; Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021), we can predict the coated film thickness without any fitting parameter.

We first present the solution for the coated film thickness using a homogenized boundary condition to model the rough surface (§ 2). Using the effective macroscopic properties of each surface derived from its microstructure, we solve the macroscopic lubrication equations and predict the coated film thickness. We present the experimental methods in § 3, where we describe the fabrication of micropillar arrays, as well as the interferometry technique used to measure ![]() $h_0$. The model is compared to experimental data (§ 4), and finally we discuss our results and their implications for further study of thin film flow over rough surfaces (§ 5).

$h_0$. The model is compared to experimental data (§ 4), and finally we discuss our results and their implications for further study of thin film flow over rough surfaces (§ 5).

2. Model of thin film flow over a porous bed

The dip coating system is illustrated in figure 1, where a rough plate is pulled continuously from a liquid with density ![]() $\rho$, surface tension

$\rho$, surface tension ![]() $\gamma$, and dynamic viscosity

$\gamma$, and dynamic viscosity ![]() $\eta$. Three regions are observed: a flat film (region I) is connected by a dynamic meniscus (region II) to a static meniscus where the film meets the bath (region III). We consider the film profile

$\eta$. Three regions are observed: a flat film (region I) is connected by a dynamic meniscus (region II) to a static meniscus where the film meets the bath (region III). We consider the film profile ![]() $h(z)$ indicated in figure 1(b), and in particular aim to find its limiting value

$h(z)$ indicated in figure 1(b), and in particular aim to find its limiting value ![]() $h \to h_0$ as

$h \to h_0$ as ![]() $z \to \infty$.

$z \to \infty$.

We model the system by considering the flow of a thin liquid film over a rough or porous plate. The challenge in modelling such a system arises, first, because of the complex shape of the rough or porous surface, which is difficult to address by an analytical solution. The second challenge is the multiscale nature of the problem: the roughness amplitude ![]() $h_p$ may be much smaller than the film thickness

$h_p$ may be much smaller than the film thickness ![]() $h_0$, which makes a direct numerical simulation computationally expensive. In addition, we desire to develop a general model for thin film flow over surfaces with arbitrary roughness topography, and we cannot arrive at such insight from seeking a separate numerical solution for each surface texture that we wish to model. The homogenization method is an attractive choice for addressing these problems, because it can address arbitrarily complex periodic roughness patterns, yet requires a full numerical solution only within a periodic cell containing a single roughness feature to produce effective parameters for a simplified equivalent boundary condition (Mei & Vernescu Reference Mei and Vernescu2010; Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019; Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021). These constant parameters are found by averaging the solution of associated Stokes problems in the microscopic domain (Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019; Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021). The resulting boundary condition can be applied in an analytical approach to the full-scale problem, which is treated in a manner similar to the classic analysis for a smooth plate (Landau & Levich Reference Landau and Levich1942).

$h_0$, which makes a direct numerical simulation computationally expensive. In addition, we desire to develop a general model for thin film flow over surfaces with arbitrary roughness topography, and we cannot arrive at such insight from seeking a separate numerical solution for each surface texture that we wish to model. The homogenization method is an attractive choice for addressing these problems, because it can address arbitrarily complex periodic roughness patterns, yet requires a full numerical solution only within a periodic cell containing a single roughness feature to produce effective parameters for a simplified equivalent boundary condition (Mei & Vernescu Reference Mei and Vernescu2010; Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019; Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021). These constant parameters are found by averaging the solution of associated Stokes problems in the microscopic domain (Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019; Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021). The resulting boundary condition can be applied in an analytical approach to the full-scale problem, which is treated in a manner similar to the classic analysis for a smooth plate (Landau & Levich Reference Landau and Levich1942).

Before any simplification, our system consists of a Newtonian liquid flowing over a solid surface with arbitrary periodic roughness, which is governed by the Navier–Stokes equations (2.1)–(2.2) subject to the boundary condition that fluid cannot flow through the solid and that fluid velocity tangential to the solid is zero (no-slip). At the liquid–air interface, we apply the no-shear boundary condition and a capillary stress. The model proceeds in three steps. First, we present the governing equations in § 2.1, and after assuming a separation of scales between the texture's periodicity and the film thickness, in § 2.2 we identify a homogenized boundary condition that represents the roughness of the plate yet can be applied at an equivalent flat surface ![]() $\mathbb {ES}$ (see figures 2b,c) instead of the original complex roughness shape. Second, by assuming that the film is thin, we perform a lubrication expansion on the governing equations and boundary conditions: the resulting simplified equations are presented in each respective subsection. Finally, in § 2.3, we solve the resulting equations for the film thickness

$\mathbb {ES}$ (see figures 2b,c) instead of the original complex roughness shape. Second, by assuming that the film is thin, we perform a lubrication expansion on the governing equations and boundary conditions: the resulting simplified equations are presented in each respective subsection. Finally, in § 2.3, we solve the resulting equations for the film thickness ![]() $h_0$ coated on the plate as a function of velocity

$h_0$ coated on the plate as a function of velocity ![]() $v_0$ and the liquid properties (

$v_0$ and the liquid properties (![]() $\rho,\gamma,\eta$).

$\rho,\gamma,\eta$).

Figure 2. Boundary conditions for (a) smooth and (b,c) rough plates. Velocity profiles are sketched in a reference frame moving with the plate for three conditions: (a) no slip, (b) slip, (c) slip and porous flow. The yellow arrow represents the slip contribution, and the pink arrow represents the contribution from porous flow, driven by a pressure gradient through the rough layer. For a rough surface, the slip contribution is ![]() $O(\epsilon ^0)$ and the porous flow contribution is

$O(\epsilon ^0)$ and the porous flow contribution is ![]() $O(\epsilon ^1)$ (Naqvi & Bottaro Reference Naqvi and Bottaro2021).

$O(\epsilon ^1)$ (Naqvi & Bottaro Reference Naqvi and Bottaro2021).

2.1. Governing equations

The rough surfaces are pulled from a Newtonian liquid of density ![]() $\rho$ and dynamic viscosity

$\rho$ and dynamic viscosity ![]() $\eta$, such that the flow satisfies the three-dimensional incompressible Navier–Stokes equations,

$\eta$, such that the flow satisfies the three-dimensional incompressible Navier–Stokes equations,

where ![]() $\boldsymbol {u} = u_x \hat {\boldsymbol {x}} + u_y \hat {\boldsymbol {y}} + u_z \hat {\boldsymbol {z}}$ is the liquid velocity,

$\boldsymbol {u} = u_x \hat {\boldsymbol {x}} + u_y \hat {\boldsymbol {y}} + u_z \hat {\boldsymbol {z}}$ is the liquid velocity, ![]() $p$ is the pressure, and

$p$ is the pressure, and ![]() $\boldsymbol {g} = -g \hat {\boldsymbol {z}}$ (

$\boldsymbol {g} = -g \hat {\boldsymbol {z}}$ (![]() $g > 0$) is the gravitational acceleration. The operator

$g > 0$) is the gravitational acceleration. The operator ![]() $\boldsymbol {\nabla }$ is defined as

$\boldsymbol {\nabla }$ is defined as ![]() $\boldsymbol {\nabla } = \hat {\boldsymbol {x}} ({\partial }/{\partial x}) + \hat {\boldsymbol {y}} ({\partial }/{\partial y}) + \hat {\boldsymbol {z}} ({\partial }/{\partial z})$. In (2.1), assuming that the system is in steady state, we drop the unsteady term

$\boldsymbol {\nabla } = \hat {\boldsymbol {x}} ({\partial }/{\partial x}) + \hat {\boldsymbol {y}} ({\partial }/{\partial y}) + \hat {\boldsymbol {z}} ({\partial }/{\partial z})$. In (2.1), assuming that the system is in steady state, we drop the unsteady term ![]() $\partial \boldsymbol {u}/\partial t = 0$. Assuming that velocities are zero in the

$\partial \boldsymbol {u}/\partial t = 0$. Assuming that velocities are zero in the ![]() $y$-direction, we simplify the problem to two dimensions,

$y$-direction, we simplify the problem to two dimensions, ![]() $x$ and

$x$ and ![]() $z$ (see figure 1). We remark that while the assumption

$z$ (see figure 1). We remark that while the assumption ![]() $u_y = 0$ is clearly sensible for a case of two-dimensional periodic structures that are invariant in the

$u_y = 0$ is clearly sensible for a case of two-dimensional periodic structures that are invariant in the ![]() $y$-direction, such as ridges, it is not obvious that velocities should be zero along

$y$-direction, such as ridges, it is not obvious that velocities should be zero along ![]() $y$ for generic roughness patterns, such as a bed of pillars. Yet as long as the roughness pattern is periodic and isotropic in the

$y$ for generic roughness patterns, such as a bed of pillars. Yet as long as the roughness pattern is periodic and isotropic in the ![]() $(y,z)$-plane, there is no reason for any symmetry breaking flow along

$(y,z)$-plane, there is no reason for any symmetry breaking flow along ![]() $y$, and we may expect on average that that velocity is zero along

$y$, and we may expect on average that that velocity is zero along ![]() $y$. Thus for patterns that satisfy the condition of isotropy in the plane of the plate, this assumption is sensible.

$y$. Thus for patterns that satisfy the condition of isotropy in the plane of the plate, this assumption is sensible.

Supposing that a characteristic film thickness scale ![]() $\ell '$ is much smaller than a characteristic scale

$\ell '$ is much smaller than a characteristic scale ![]() $\ell ''$ of the interface profile variation along the film surface, we perform a lubrication expansion in the small parameter

$\ell ''$ of the interface profile variation along the film surface, we perform a lubrication expansion in the small parameter ![]() $\delta = \ell '/\ell ''$, arriving at the leading-order equations (Reynolds Reference Reynolds1886; Oron, Davis & Bankhoff Reference Oron, Davis and Bankhoff1997; Balestra Reference Balestra2018)

$\delta = \ell '/\ell ''$, arriving at the leading-order equations (Reynolds Reference Reynolds1886; Oron, Davis & Bankhoff Reference Oron, Davis and Bankhoff1997; Balestra Reference Balestra2018)

where ![]() $\tilde {\cdot }$ denotes dimensionless variables, and lengths and velocities have been normalized by characteristic scales

$\tilde {\cdot }$ denotes dimensionless variables, and lengths and velocities have been normalized by characteristic scales

The pressure is normalized as

In addition, the liquid velocity normal to the plate is much smaller than its velocity parallel to the plate, so ![]() $U_x \sim \delta U_z$. This relation is required for mass conservation to hold at each order (Oron et al. Reference Oron, Davis and Bankhoff1997). Later, we will require the dimensional forms of (2.3)–(2.4), which are given as

$U_x \sim \delta U_z$. This relation is required for mass conservation to hold at each order (Oron et al. Reference Oron, Davis and Bankhoff1997). Later, we will require the dimensional forms of (2.3)–(2.4), which are given as

Note that the characteristic scale ![]() $\ell ''$ in our case is of the order of the capillary length

$\ell ''$ in our case is of the order of the capillary length ![]() $a$, which sets the meniscus scale in region III (figure 1).

$a$, which sets the meniscus scale in region III (figure 1).

2.2. Boundary conditions

2.2.1. Interface condition at the plate

Supposing that the characteristic spacing ![]() $\ell$ between two periodic roughness elements is much smaller than the size of the liquid domain

$\ell$ between two periodic roughness elements is much smaller than the size of the liquid domain ![]() $\ell '$ (

$\ell '$ (![]() $\epsilon = \ell /\ell ' \ll 1$), we use the homogenized boundary condition described in Bottaro & Naqvi (Reference Bottaro and Naqvi2020), keeping terms up to

$\epsilon = \ell /\ell ' \ll 1$), we use the homogenized boundary condition described in Bottaro & Naqvi (Reference Bottaro and Naqvi2020), keeping terms up to ![]() $O(\epsilon ^2)$. The parameter

$O(\epsilon ^2)$. The parameter ![]() $\epsilon$ is a separation of scales parameter that is assumed to be small in the homogenization procedure. Before specifying the boundary condition, we must first define a fictitious equivalent surface, denoted

$\epsilon$ is a separation of scales parameter that is assumed to be small in the homogenization procedure. Before specifying the boundary condition, we must first define a fictitious equivalent surface, denoted ![]() $\mathbb {ES}$, where the macroscopic effective condition applies. Similar to Bottaro & Naqvi (Reference Bottaro and Naqvi2020), we define

$\mathbb {ES}$, where the macroscopic effective condition applies. Similar to Bottaro & Naqvi (Reference Bottaro and Naqvi2020), we define ![]() $\mathbb {ES}$ to be a flat plane located at a distance

$\mathbb {ES}$ to be a flat plane located at a distance ![]() $d_{\mathbb {ES}}$ from the bottom of the roughness features (figure 1a), and select the location

$d_{\mathbb {ES}}$ from the bottom of the roughness features (figure 1a), and select the location ![]() $d_{\mathbb {ES}} = h_p$, which means that

$d_{\mathbb {ES}} = h_p$, which means that ![]() $\mathbb {ES}$ is located at the interface between the rough layer and the free-fluid region (figures 2b,c). As has been discussed previously (Espedal et al. Reference Espedal, Fasano and Mikelić2000; Marciniak-Czochra & Mikelić Reference Marciniak-Czochra and Mikelić2012), there is some freedom in the choice of the distance

$\mathbb {ES}$ is located at the interface between the rough layer and the free-fluid region (figures 2b,c). As has been discussed previously (Espedal et al. Reference Espedal, Fasano and Mikelić2000; Marciniak-Czochra & Mikelić Reference Marciniak-Czochra and Mikelić2012), there is some freedom in the choice of the distance ![]() $d_{\mathbb {ES}}$: numerical results demonstrate empirically that shifting the equivalent surface position by

$d_{\mathbb {ES}}$: numerical results demonstrate empirically that shifting the equivalent surface position by ![]() $O(\epsilon )$ does not significantly change the macroscopic results predicted by a homogenized theory, as the variation of macroscopic results is within

$O(\epsilon )$ does not significantly change the macroscopic results predicted by a homogenized theory, as the variation of macroscopic results is within ![]() $O(\epsilon )$ (Lācis & Bagheri Reference Lācis and Bagheri2017; Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019). Our choice of

$O(\epsilon )$ (Lācis & Bagheri Reference Lācis and Bagheri2017; Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019). Our choice of ![]() $d_\mathbb {ES}$ is based on the assumption that liquid is always trapped within the rough layer, as has been observed in prior experiments (Seiwert et al. Reference Seiwert, Clanet and Quéré2011). In our case,

$d_\mathbb {ES}$ is based on the assumption that liquid is always trapped within the rough layer, as has been observed in prior experiments (Seiwert et al. Reference Seiwert, Clanet and Quéré2011). In our case, ![]() $h_p$ represents a pillar height, but in general,

$h_p$ represents a pillar height, but in general, ![]() $h_p$ represents the characteristic peak-to-valley scale of the rough layer.

$h_p$ represents the characteristic peak-to-valley scale of the rough layer.

Note that due to the position of ![]() $\mathbb {ES}$, we will later decompose the total film profile

$\mathbb {ES}$, we will later decompose the total film profile ![]() $h(z)$ into two parts,

$h(z)$ into two parts, ![]() $h(z) = h_p + \bar {h}(z)$, where

$h(z) = h_p + \bar {h}(z)$, where ![]() $h_p$ is the known height of the trapped layer, and

$h_p$ is the known height of the trapped layer, and ![]() $\bar {h}(z)$ is the unknown thickness of the free film above

$\bar {h}(z)$ is the unknown thickness of the free film above ![]() $\mathbb {ES}$: solving the macroscopic model will give the asymptotic free film thickness

$\mathbb {ES}$: solving the macroscopic model will give the asymptotic free film thickness ![]() $\bar {h}_0 \equiv \bar {h}(z \to \infty )$ measured with respect to

$\bar {h}_0 \equiv \bar {h}(z \to \infty )$ measured with respect to ![]() $\mathbb {ES}$. The total film thickness will then be

$\mathbb {ES}$. The total film thickness will then be ![]() $h_0 = h_p + \bar {h}_0$. Having selected the equivalent surface's position, the boundary condition at

$h_0 = h_p + \bar {h}_0$. Having selected the equivalent surface's position, the boundary condition at ![]() $\mathbb {ES}$ is

$\mathbb {ES}$ is

where ![]() $\mathcal {L}$ is the slip length, and

$\mathcal {L}$ is the slip length, and ![]() $\mathcal {K}^{itf}$ is the interface permeability (Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021). The conditions (2.9)–(2.10) on velocity

$\mathcal {K}^{itf}$ is the interface permeability (Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021). The conditions (2.9)–(2.10) on velocity ![]() $\boldsymbol {u}$ at the plate include the speed

$\boldsymbol {u}$ at the plate include the speed ![]() $v_0$ at which the plate is pulled in (2.10), which by itself represents a typical no-slip condition, as well as the effect of the roughness pattern on the liquid velocity at the plate, represented by the

$v_0$ at which the plate is pulled in (2.10), which by itself represents a typical no-slip condition, as well as the effect of the roughness pattern on the liquid velocity at the plate, represented by the ![]() $\mathcal {L}$ and

$\mathcal {L}$ and ![]() $\mathcal {K}^{itf}$ terms. The form of the boundary conditions (2.9)–(2.10) indicates how roughness changes the boundary condition at

$\mathcal {K}^{itf}$ terms. The form of the boundary conditions (2.9)–(2.10) indicates how roughness changes the boundary condition at ![]() $\mathbb {ES}$ as compared to the case of a smooth plate: the tangential velocity

$\mathbb {ES}$ as compared to the case of a smooth plate: the tangential velocity ![]() $u_z$ parallel to

$u_z$ parallel to ![]() $\mathbb {ES}$ is augmented by a contribution of slip

$\mathbb {ES}$ is augmented by a contribution of slip ![]() $\mathcal {L}$ and interface permeability

$\mathcal {L}$ and interface permeability ![]() $\mathcal {K}^{itf}$, and the velocity

$\mathcal {K}^{itf}$, and the velocity ![]() $u_x$ of liquid penetrating through

$u_x$ of liquid penetrating through ![]() $\mathbb {ES}$ can be non-zero, its value determined by

$\mathbb {ES}$ can be non-zero, its value determined by ![]() $\mathcal {K}^{itf}$ (Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021).

$\mathcal {K}^{itf}$ (Bottaro & Naqvi Reference Bottaro and Naqvi2020; Naqvi & Bottaro Reference Naqvi and Bottaro2021).

Applying the same scaling (2.5a–d) as for the governing equations, we expand the boundary conditions (2.9)–(2.10) in ![]() $\delta$ and retrieve, at leading order in

$\delta$ and retrieve, at leading order in ![]() $\delta$,

$\delta$,

The result of the lubrication expansion for ![]() $u_x$ in (2.11) indicates that at leading order in

$u_x$ in (2.11) indicates that at leading order in ![]() $\delta$, velocities perpendicular to the equivalent surface are zero. Thus in the model, no fluid transfers from the free-fluid region to the rough layer. This result is sensible in light of findings that the wall-normal velocity

$\delta$, velocities perpendicular to the equivalent surface are zero. Thus in the model, no fluid transfers from the free-fluid region to the rough layer. This result is sensible in light of findings that the wall-normal velocity ![]() $u_x$ at

$u_x$ at ![]() $\mathbb {ES}$ is typically 1–2 orders of magnitude smaller than the tangential slip velocity (Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2021).

$\mathbb {ES}$ is typically 1–2 orders of magnitude smaller than the tangential slip velocity (Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2021).

The boundary condition (2.12) for flow tangential to ![]() $\mathbb {ES}$ is illustrated in figure 2(c), where it is compared to the typical no-slip condition (figure 2a) and Navier slip condition (figure 2b). Velocity profiles have been drawn in the reference frame of the moving plate. As illustrated in figure 2(b), the slip condition modifies the velocity profile by augmenting the velocity at

$\mathbb {ES}$ is illustrated in figure 2(c), where it is compared to the typical no-slip condition (figure 2a) and Navier slip condition (figure 2b). Velocity profiles have been drawn in the reference frame of the moving plate. As illustrated in figure 2(b), the slip condition modifies the velocity profile by augmenting the velocity at ![]() $\mathbb {ES}$ (the

$\mathbb {ES}$ (the ![]() $\mathcal {L} ({\partial u_z}/{\partial x})$ term). When we do not neglect the flow through the rough layer, the slip contribution is augmented further by a flow along the interface driven by the pressure gradient within and above the rough layer (the

$\mathcal {L} ({\partial u_z}/{\partial x})$ term). When we do not neglect the flow through the rough layer, the slip contribution is augmented further by a flow along the interface driven by the pressure gradient within and above the rough layer (the ![]() $({\mathcal {K}^{itf}}/{\eta }) ({\partial p}/{\partial z})$ term), illustrated as the pink arrow in figure 2(c). Even if the slip and permeability contributions in (2.12) are at the same order in terms of the lubrication parameter

$({\mathcal {K}^{itf}}/{\eta }) ({\partial p}/{\partial z})$ term), illustrated as the pink arrow in figure 2(c). Even if the slip and permeability contributions in (2.12) are at the same order in terms of the lubrication parameter ![]() $\delta$, one should note that these contributions are not equally important in terms of the homogenization parameter

$\delta$, one should note that these contributions are not equally important in terms of the homogenization parameter ![]() $\epsilon$ (Naqvi & Bottaro Reference Naqvi and Bottaro2021). The interface permeability term is usually found to be negligible (

$\epsilon$ (Naqvi & Bottaro Reference Naqvi and Bottaro2021). The interface permeability term is usually found to be negligible (![]() $O(\epsilon ^1)$) compared to the slip term (

$O(\epsilon ^1)$) compared to the slip term (![]() $O(\epsilon ^0)$) in the case of laminar flow over rough surfaces in an unbounded fluid domain (Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019), but, as we will see, this term cannot be neglected in the case of a thin film flow. Note that the interface permeability term is absent in previously proposed slip models (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Liao et al. Reference Liao, Li and Wei2013; Sathyanath et al. Reference Sathyanath, Aarthi and Kalpathy2020).

$O(\epsilon ^0)$) in the case of laminar flow over rough surfaces in an unbounded fluid domain (Zampogna et al. Reference Zampogna, Magnaudet and Bottaro2019), but, as we will see, this term cannot be neglected in the case of a thin film flow. Note that the interface permeability term is absent in previously proposed slip models (Krechetnikov & Homsy Reference Krechetnikov and Homsy2005; Liao et al. Reference Liao, Li and Wei2013; Sathyanath et al. Reference Sathyanath, Aarthi and Kalpathy2020).

2.2.2. Interface condition at the liquid–air interface

At leading order in ![]() $\delta$, we impose at the free surface a zero shear stress condition

$\delta$, we impose at the free surface a zero shear stress condition

as well as capillary pressure at the free interface, expressed as

\begin{equation} p(x = \bar{h}, z) ={-}\gamma\,\frac{\dfrac{\partial^2 \bar{h}}{\partial z^2}}{\left[1 + \left(\dfrac{\partial \bar{h}}{\partial z}\right)^2\right]^{3/2}} \approx{-}\gamma\, \frac{\partial^2 \bar{h}}{\partial z^2}, \end{equation}

\begin{equation} p(x = \bar{h}, z) ={-}\gamma\,\frac{\dfrac{\partial^2 \bar{h}}{\partial z^2}}{\left[1 + \left(\dfrac{\partial \bar{h}}{\partial z}\right)^2\right]^{3/2}} \approx{-}\gamma\, \frac{\partial^2 \bar{h}}{\partial z^2}, \end{equation}where the final expression for interface curvature assumes small slopes (Landau & Levich Reference Landau and Levich1942; Balestra Reference Balestra2018).

2.3. Solution

To find ![]() $h_0$ for a given surface, we solve the system of governing equations (2.7)–(2.8) combined with the boundary conditions (2.11)–(2.12). In the next section, we will compare the results from considering two cases for the boundary condition (2.12): a case where only the slip term is present, and a case where flow through the rough layer also contributes.

$h_0$ for a given surface, we solve the system of governing equations (2.7)–(2.8) combined with the boundary conditions (2.11)–(2.12). In the next section, we will compare the results from considering two cases for the boundary condition (2.12): a case where only the slip term is present, and a case where flow through the rough layer also contributes.

We begin by finding the velocity profile in the thin film. After integrating (2.8) once, we arrive at

and we integrate a second time to arrive at the velocity profile

where ![]() $F$ and

$F$ and ![]() $G$ are unknown functions of

$G$ are unknown functions of ![]() $z$. Applying the no-stress condition (2.13) at the liquid–air interface

$z$. Applying the no-stress condition (2.13) at the liquid–air interface ![]() $x = \bar {h}$, we solve for

$x = \bar {h}$, we solve for ![]() $F(z)$ using (2.15):

$F(z)$ using (2.15):

At the solid–liquid interface ![]() $x = 0$, substitute the boundary condition (2.12) into (2.16) to solve for

$x = 0$, substitute the boundary condition (2.12) into (2.16) to solve for ![]() $G(z)$:

$G(z)$:

\begin{align} u_z(x = 0, z) = G(z) &= v_0 + \mathcal{L}\,\frac{\partial u_z}{\partial x} - \frac{\mathcal{K}^{itf}}{\eta}\,\frac{\partial p}{\partial z} \nonumber\\ &= v_0 - \mathcal{L} \left(\frac{1}{\eta}\,\frac{\partial p}{\partial z} + \frac{\rho g}{\eta}\right) \bar{h} - \frac{\mathcal{K}^{itf}}{\eta}\,\frac{\partial p}{\partial z}, \end{align}

\begin{align} u_z(x = 0, z) = G(z) &= v_0 + \mathcal{L}\,\frac{\partial u_z}{\partial x} - \frac{\mathcal{K}^{itf}}{\eta}\,\frac{\partial p}{\partial z} \nonumber\\ &= v_0 - \mathcal{L} \left(\frac{1}{\eta}\,\frac{\partial p}{\partial z} + \frac{\rho g}{\eta}\right) \bar{h} - \frac{\mathcal{K}^{itf}}{\eta}\,\frac{\partial p}{\partial z}, \end{align}

where we know that ![]() ${\partial p}/{\partial z}$ depends only on z, because p does not depend on x by (2.7). From the form of

${\partial p}/{\partial z}$ depends only on z, because p does not depend on x by (2.7). From the form of ![]() $G(z)$ in (2.18), which gives the velocity profile (2.16) at

$G(z)$ in (2.18), which gives the velocity profile (2.16) at ![]() $x = 0$, it is apparent that the boundary condition at the rough interface acts as a correction to the no-slip boundary condition used in the dip coating problem for a smooth surface, in which

$x = 0$, it is apparent that the boundary condition at the rough interface acts as a correction to the no-slip boundary condition used in the dip coating problem for a smooth surface, in which ![]() $G(z) = v_0$ (Landau & Levich Reference Landau and Levich1942). The velocity profile in the thin film is thus

$G(z) = v_0$ (Landau & Levich Reference Landau and Levich1942). The velocity profile in the thin film is thus

and, substituting the pressure from (2.14), we have

For an incompressible fluid, the flux ![]() $j$ per unit plate width can be written

$j$ per unit plate width can be written

Integrating ![]() $u_z$ in (2.20) to compute

$u_z$ in (2.20) to compute ![]() $j$ via (2.21) produces

$j$ via (2.21) produces

Keeping in mind that ![]() $j$ is a constant, (2.22) defines the liquid layer thickness

$j$ is a constant, (2.22) defines the liquid layer thickness ![]() $\bar {h} = \bar {h}(z)$. We rewrite the ordinary differential equation (2.22) for

$\bar {h} = \bar {h}(z)$. We rewrite the ordinary differential equation (2.22) for ![]() $\bar {h}$ as

$\bar {h}$ as

To solve the third-order differential equation for ![]() $\bar {h}$, we require three boundary conditions, which will come from matching the dynamic meniscus profile

$\bar {h}$, we require three boundary conditions, which will come from matching the dynamic meniscus profile ![]() $\bar {h}(z)$ to the flat film (figure 1, region I). Prior to that, we non-dimensionalize (2.23) (Landau & Levich Reference Landau and Levich1942). Introducing a non-dimensional film thickness

$\bar {h}(z)$ to the flat film (figure 1, region I). Prior to that, we non-dimensionalize (2.23) (Landau & Levich Reference Landau and Levich1942). Introducing a non-dimensional film thickness ![]() $\mu$, defined as

$\mu$, defined as

we can rearrange (2.23) to arrive at

\begin{align} \frac{{\rm d}^3 \mu}{{\rm d} z^3} = \frac{3\eta}{\gamma}\,\frac{v_0^4}{j^3} \frac{1 - \mu}{\mu \left(\mu^2 + \dfrac{3v_0}{j}\,\mathcal{L} \mu + \dfrac{3 v_0^2}{j^2}\,\mathcal{K}^{itf}\right)} + \frac{v_0}{j}\,\frac{\rho g}{\gamma}\,\frac{\mu \left( \mu^2 + \dfrac{3v_0}{j}\, \mathcal{L} \mu \right)}{\mu \left(\mu^2 + \dfrac{3v_0}{j}\,\mathcal{L} \mu + \dfrac{3v_0^2}{j^2}\,\mathcal{K}^{itf} \right)}. \end{align}

\begin{align} \frac{{\rm d}^3 \mu}{{\rm d} z^3} = \frac{3\eta}{\gamma}\,\frac{v_0^4}{j^3} \frac{1 - \mu}{\mu \left(\mu^2 + \dfrac{3v_0}{j}\,\mathcal{L} \mu + \dfrac{3 v_0^2}{j^2}\,\mathcal{K}^{itf}\right)} + \frac{v_0}{j}\,\frac{\rho g}{\gamma}\,\frac{\mu \left( \mu^2 + \dfrac{3v_0}{j}\, \mathcal{L} \mu \right)}{\mu \left(\mu^2 + \dfrac{3v_0}{j}\,\mathcal{L} \mu + \dfrac{3v_0^2}{j^2}\,\mathcal{K}^{itf} \right)}. \end{align}

The scale ![]() $3\eta v_0^4 / (\gamma j^3)$ naturally provides a change of variables for the spatial coordinate

$3\eta v_0^4 / (\gamma j^3)$ naturally provides a change of variables for the spatial coordinate ![]() $z$, so along the plate we introduce the non-dimensional spatial coordinate

$z$, so along the plate we introduce the non-dimensional spatial coordinate ![]() $\lambda$, defined as

$\lambda$, defined as

\begin{equation} \lambda = \left(\frac{3\eta}{\gamma}\right)^{1/3} \frac{v_0^{4/3}}{j}\,z, \end{equation}

\begin{equation} \lambda = \left(\frac{3\eta}{\gamma}\right)^{1/3} \frac{v_0^{4/3}}{j}\,z, \end{equation}and arrive at a non-dimensional version of (2.23),

where we have defined a non-dimensional slip ![]() $\mathcal {L}^*$ and interface permeability

$\mathcal {L}^*$ and interface permeability ![]() $K^*$:

$K^*$:

Assuming that ![]() $\rho g j^2 / (3 \eta v_0^3) \ll 1$, which is valid for low pulling velocities

$\rho g j^2 / (3 \eta v_0^3) \ll 1$, which is valid for low pulling velocities ![]() $Ca \to 0$ (Landau & Levich Reference Landau and Levich1942; Wilson Reference Wilson1982), we neglect the final term of (2.27), giving the simplified equation

$Ca \to 0$ (Landau & Levich Reference Landau and Levich1942; Wilson Reference Wilson1982), we neglect the final term of (2.27), giving the simplified equation

relating film thickness ![]() $\mu$ to position

$\mu$ to position ![]() $\lambda$ along the plate. Following Landau & Levich (Reference Landau and Levich1942), we conclude that

$\lambda$ along the plate. Following Landau & Levich (Reference Landau and Levich1942), we conclude that ![]() $\mu \to 1$ in the flat film region, that is,

$\mu \to 1$ in the flat film region, that is,

since higher derivatives of ![]() $\mu$ must tend to zero if the film is flat. In other words, we have

$\mu$ must tend to zero if the film is flat. In other words, we have ![]() ${{\rm d}^3 \mu }/{{\rm d}\lambda ^3} \to 0$ in (2.29). At large values of

${{\rm d}^3 \mu }/{{\rm d}\lambda ^3} \to 0$ in (2.29). At large values of ![]() $\lambda$, we thus assume that

$\lambda$, we thus assume that ![]() $\mu$ has the form

$\mu$ has the form ![]() $\mu (\lambda ) = 1 + \mu _1(\lambda )$, where

$\mu (\lambda ) = 1 + \mu _1(\lambda )$, where ![]() $\mu _1 \ll 1$, and solving the resulting equations at the leading order produces the matching conditions in the dynamic meniscus region as

$\mu _1 \ll 1$, and solving the resulting equations at the leading order produces the matching conditions in the dynamic meniscus region as ![]() $\lambda \to \infty$:

$\lambda \to \infty$:

where ![]() $A$ is an unknown constant of integration (see Appendix A). The constant

$A$ is an unknown constant of integration (see Appendix A). The constant ![]() $A$ poses a problem, but this can be overcome by the variable transformation used in Landau & Levich (Reference Landau and Levich1942), one that is also favourable for numerical integration, because it transforms the boundary location to a finite value rather than

$A$ poses a problem, but this can be overcome by the variable transformation used in Landau & Levich (Reference Landau and Levich1942), one that is also favourable for numerical integration, because it transforms the boundary location to a finite value rather than ![]() $\lambda \to \infty$. To numerically solve the film thickness equation (2.29) together with boundary conditions (2.31)–(2.33), we define the transformation (see Appendix B)

$\lambda \to \infty$. To numerically solve the film thickness equation (2.29) together with boundary conditions (2.31)–(2.33), we define the transformation (see Appendix B)

and arrive at the differential equation

with boundary conditions

where we now apply the boundary condition at a finite value ![]() $\mu \to 1$, since we know

$\mu \to 1$, since we know ![]() $\mu \to 1$ as

$\mu \to 1$ as ![]() $\lambda \to \infty$. Note that (2.34) implies a transformation of the film curvature as

$\lambda \to \infty$. Note that (2.34) implies a transformation of the film curvature as

which will be important later. Reducing the order of the equations from third to second order has the consequence that we will not be able to solve exactly for the full film thickness profile ![]() $\mu (\lambda )$, since the unknown constant

$\mu (\lambda )$, since the unknown constant ![]() $A$ remains. However, as we will see, knowing that the film curvature

$A$ remains. However, as we will see, knowing that the film curvature ![]() ${{\rm d}^2\mu }/{{\rm d}\lambda ^2}$ is given by (2.38) will be sufficient to find the film thickness in the flat film region where

${{\rm d}^2\mu }/{{\rm d}\lambda ^2}$ is given by (2.38) will be sufficient to find the film thickness in the flat film region where ![]() $\mu (\lambda \to \infty ) = 1$, or equivalently, where

$\mu (\lambda \to \infty ) = 1$, or equivalently, where ![]() $\bar {h}_0 \equiv \bar {h}(z \to \infty ) = j / v_0$ (see (2.24)).

$\bar {h}_0 \equiv \bar {h}(z \to \infty ) = j / v_0$ (see (2.24)).

The system of equations (2.35) with (2.36)–(2.37) is not closed, because the unknown flux ![]() $j$ remains in the terms

$j$ remains in the terms ![]() $\mathcal {L}^* = \mathcal {L}^*(j)$ and

$\mathcal {L}^* = \mathcal {L}^*(j)$ and ![]() ${K}^* = K^*(j)$ (see (2.28a,b)). We know that the flux

${K}^* = K^*(j)$ (see (2.28a,b)). We know that the flux ![]() $j$ is governed by the flow of liquid through the meniscus region where the flat film meets the bath, because there the capillary suction competes with viscous stress to determine

$j$ is governed by the flow of liquid through the meniscus region where the flat film meets the bath, because there the capillary suction competes with viscous stress to determine ![]() $h_0$. Thus we can find

$h_0$. Thus we can find ![]() $j$ by considering the form of the static meniscus in region III (figure 1). Assuming that the meniscus is quasi-static, we solve equations balancing capillary and hydrostatic pressure to find the static meniscus shape, and arrive at a matching condition for the meniscus curvature at the bath (Landau & Levich Reference Landau and Levich1942):

$j$ by considering the form of the static meniscus in region III (figure 1). Assuming that the meniscus is quasi-static, we solve equations balancing capillary and hydrostatic pressure to find the static meniscus shape, and arrive at a matching condition for the meniscus curvature at the bath (Landau & Levich Reference Landau and Levich1942):

where we recall that ![]() $a = \sqrt {\gamma /(\rho g)}$ is the capillary length. Non-dimensionalizing from

$a = \sqrt {\gamma /(\rho g)}$ is the capillary length. Non-dimensionalizing from ![]() $(z, \bar {h})$ to

$(z, \bar {h})$ to ![]() $(\lambda, \mu )$ using (2.24) and (2.26), we have the curvature condition for the bottom of the dynamic meniscus,

$(\lambda, \mu )$ using (2.24) and (2.26), we have the curvature condition for the bottom of the dynamic meniscus,

\begin{equation} \frac{{\rm d}^2\mu}{{\rm d}\lambda^2}(\lambda \to 0) = \frac{\sqrt{2}\,\gamma^{2/3} j}{a v_0^{5/3} (3\eta)^{2/3}}, \end{equation}

\begin{equation} \frac{{\rm d}^2\mu}{{\rm d}\lambda^2}(\lambda \to 0) = \frac{\sqrt{2}\,\gamma^{2/3} j}{a v_0^{5/3} (3\eta)^{2/3}}, \end{equation}

now in terms of the unknown flux ![]() $j$ that we seek. Defining the meniscus curvature

$j$ that we seek. Defining the meniscus curvature

we see that the dynamic meniscus governed by (2.29), or equivalently, (2.35), must exhibit a profile ![]() $\mu (\lambda )$ whose curvature

$\mu (\lambda )$ whose curvature ![]() $\kappa = ({{\rm d}^2\mu }/{{\rm d}\lambda ^2})(\lambda \to 0)$ matches the value on the right-hand side of (2.40). The left-hand side of (2.40) can be solved for using (2.35)–(2.37) and the transformation (2.38), yet its solution still depends on the value of the unknown

$\kappa = ({{\rm d}^2\mu }/{{\rm d}\lambda ^2})(\lambda \to 0)$ matches the value on the right-hand side of (2.40). The left-hand side of (2.40) can be solved for using (2.35)–(2.37) and the transformation (2.38), yet its solution still depends on the value of the unknown ![]() $j$ because

$j$ because ![]() $\mathcal {L}^* = \mathcal {L}^*(j)$ and

$\mathcal {L}^* = \mathcal {L}^*(j)$ and ![]() $K^* = K^*(j)$. The right-hand side is also determined except for the unknown

$K^* = K^*(j)$. The right-hand side is also determined except for the unknown ![]() $j$. Putting aside for now that

$j$. Putting aside for now that ![]() $j$ is unknown, knowing that

$j$ is unknown, knowing that ![]() $\mu \to 1$ in the flat film region as

$\mu \to 1$ in the flat film region as ![]() $\lambda \to \infty$ (see (2.30)), from (2.40) we have an expression for the free film thickness

$\lambda \to \infty$ (see (2.30)), from (2.40) we have an expression for the free film thickness ![]() $\bar {h} \to \bar {h}_0$, where

$\bar {h} \to \bar {h}_0$, where

\begin{equation} \bar{h}_0 = \frac{j}{v_0} = \frac{\kappa}{\sqrt{2}}\, \frac{v_0^{2/3} (3\eta)^{2/3}}{\gamma^{1/6} (\rho g)^{1/2}}. \end{equation}

\begin{equation} \bar{h}_0 = \frac{j}{v_0} = \frac{\kappa}{\sqrt{2}}\, \frac{v_0^{2/3} (3\eta)^{2/3}}{\gamma^{1/6} (\rho g)^{1/2}}. \end{equation}

The last equality comes from using the expression for ![]() $j$ derived in (2.40), where it becomes clear how matching to the static meniscus curvature provides the information needed to determine

$j$ derived in (2.40), where it becomes clear how matching to the static meniscus curvature provides the information needed to determine ![]() $\bar {h}_0$. In terms of capillary length

$\bar {h}_0$. In terms of capillary length ![]() $a$ and capillary number

$a$ and capillary number ![]() $Ca$, (2.42) becomes

$Ca$, (2.42) becomes

which has the form of (1.1), except that the curvature ![]() $\kappa = \kappa (\mathcal {L}, \mathcal {K}^{itf})$ is no longer constant but is a function of the slip

$\kappa = \kappa (\mathcal {L}, \mathcal {K}^{itf})$ is no longer constant but is a function of the slip ![]() $\mathcal {L}$ and interface permeability

$\mathcal {L}$ and interface permeability ![]() $\mathcal {K}^{itf}$.

$\mathcal {K}^{itf}$.

To determine the value of the curvature and close the solution (2.43), we examine the equation for ![]() $\kappa$ given in (2.40): after rearranging the right-hand side and defining the non-dimensional parameter

$\kappa$ given in (2.40): after rearranging the right-hand side and defining the non-dimensional parameter ![]() $H = \bar {h}_0 / a = j/(v_0 a)$, we notice that (2.40) has the form

$H = \bar {h}_0 / a = j/(v_0 a)$, we notice that (2.40) has the form

For completeness, we provide the definition of ![]() $\kappa (H)$ (2.41) in terms of the transformation (2.38) as

$\kappa (H)$ (2.41) in terms of the transformation (2.38) as

where this last term can be obtained from the integration of differential equation (2.35) with boundary conditions (2.36)–(2.37). This makes clear the dependence of ![]() $\kappa$ on the unknown flux

$\kappa$ on the unknown flux ![]() $j$, or equivalently, the unknown parameter

$j$, or equivalently, the unknown parameter ![]() $H$. Note that

$H$. Note that

A nonlinear equation of the form (2.44)–(2.45) can be solved numerically by fixed-point iteration (Burden & Faires Reference Burden and Faires2011) with the following algorithm:

(i) We first provide an initial guess

$H_0$ to solve for

$H_0$ to solve for  $\kappa _0 = \kappa (H_0)$. The solution for

$\kappa _0 = \kappa (H_0)$. The solution for  $\kappa$ is retrieved by solving (2.35)–(2.37) and using the transformation (2.38) to compute

$\kappa$ is retrieved by solving (2.35)–(2.37) and using the transformation (2.38) to compute  $\kappa = ({{\rm d}^2\mu }/{{\rm d}\lambda ^2})(\lambda \to 0)$.

$\kappa = ({{\rm d}^2\mu }/{{\rm d}\lambda ^2})(\lambda \to 0)$.(ii) For

$i > 0$, compute

$i > 0$, compute  $H_i = ({3^{2/3}}/{\sqrt {2}})\,Ca^{2/3}\,\kappa _{i-1}$, and solve for

$H_i = ({3^{2/3}}/{\sqrt {2}})\,Ca^{2/3}\,\kappa _{i-1}$, and solve for  $\kappa _i = \kappa (H_i)$.

$\kappa _i = \kappa (H_i)$.(iii) If the difference

$\varDelta = (H_i - H_{i-1})/H_{i-1}$ is acceptably small, then stop the iteration. Otherwise, continue the iteration. Here, we stop the iteration using a relative tolerance value

$\varDelta = (H_i - H_{i-1})/H_{i-1}$ is acceptably small, then stop the iteration. Otherwise, continue the iteration. Here, we stop the iteration using a relative tolerance value  $\varDelta \leq 10^{-6}$.

$\varDelta \leq 10^{-6}$.

The iteration is implemented in Python, where we solve (2.35)–(2.37) for ![]() $\kappa$ using the SciPy package (Virtanen Reference Virtanen2020). Code is provided in the supplementary material at https://doi.org/10.1017/jfm.2024.1015. Knowing the non-dimensional free film thickness

$\kappa$ using the SciPy package (Virtanen Reference Virtanen2020). Code is provided in the supplementary material at https://doi.org/10.1017/jfm.2024.1015. Knowing the non-dimensional free film thickness ![]() $H$ from the fixed-point iteration, we immediately arrive at the dimensional free film thickness

$H$ from the fixed-point iteration, we immediately arrive at the dimensional free film thickness ![]() $\bar {h}_0 = Ha$, or equivalently, the fixed-point iteration provides the solution for

$\bar {h}_0 = Ha$, or equivalently, the fixed-point iteration provides the solution for ![]() $\kappa$, meaning that the expressions (2.42) and (2.43) are fully determined.

$\kappa$, meaning that the expressions (2.42) and (2.43) are fully determined.

3. Dip coating experiments

To probe how roughness modifies the coated film thickness for varied roughness parameters, we perform experiments in which a viscous silicone oil coats rough silicon wafers. Rough surfaces are etched from silicon using photolithography and dry etching to produce a square grid of micropillars (figure 3). Pillar height is ![]() $h_p = 7.2 \pm 0.2\,\mathrm {\mu }$m, and pillar diameter is

$h_p = 7.2 \pm 0.2\,\mathrm {\mu }$m, and pillar diameter is ![]() $d = 3.3 \pm 0.1\,\mathrm {\mu }$m. Spacing between the pillars varies in the range

$d = 3.3 \pm 0.1\,\mathrm {\mu }$m. Spacing between the pillars varies in the range ![]() $\ell = 5\unicode{x2013}72\,\mathrm {\mu }$m, so that the solid area fraction varies in the range

$\ell = 5\unicode{x2013}72\,\mathrm {\mu }$m, so that the solid area fraction varies in the range ![]() $\phi = 0.2\unicode{x2013}34\,\%$. Parameters for the surfaces tested are listed in table 1, where

$\phi = 0.2\unicode{x2013}34\,\%$. Parameters for the surfaces tested are listed in table 1, where

for cylindrical pillars.

Figure 3. Scanning electron microscopy images of rough surfaces etched into silicon wafers. In these three examples, pillars have height ![]() $h_p = 7.2 \pm 0.2\,\mathrm {\mu }$m, diameter

$h_p = 7.2 \pm 0.2\,\mathrm {\mu }$m, diameter ![]() $d = 3.3 \pm 0.1\,\mathrm {\mu }$m, and spacings (a)

$d = 3.3 \pm 0.1\,\mathrm {\mu }$m, and spacings (a) ![]() $\ell = 5\,\mathrm {\mu }$m, (b)

$\ell = 5\,\mathrm {\mu }$m, (b) ![]() $\ell = 12\,\mathrm {\mu }$m, and (c)

$\ell = 12\,\mathrm {\mu }$m, and (c) ![]() $\ell =36\,\mathrm {\mu }$m. Scale bars are

$\ell =36\,\mathrm {\mu }$m. Scale bars are ![]() $20\,\mathrm {\mu }$m.

$20\,\mathrm {\mu }$m.

Table 1. Six rough surfaces are used for the experiments, having pillars with constant diameter ![]() $d = 3.3 \pm 0.1\,\mathrm {\mu }$m, constant height

$d = 3.3 \pm 0.1\,\mathrm {\mu }$m, constant height ![]() $h_p = 7.2 \pm 0.2\,\mathrm {\mu }$m, and varied spacing

$h_p = 7.2 \pm 0.2\,\mathrm {\mu }$m, and varied spacing ![]() $\ell$. The solid area fraction is

$\ell$. The solid area fraction is ![]() $\phi = {\rm \pi}d^2/(4\ell ^2)$. Computed slip and interface permeability values used in the model (see § 2 and Appendix C) are listed in dimensional (

$\phi = {\rm \pi}d^2/(4\ell ^2)$. Computed slip and interface permeability values used in the model (see § 2 and Appendix C) are listed in dimensional (![]() $\mathcal {L}$,

$\mathcal {L}$, ![]() $\mathcal {K}^{itf}$) and non-dimensional (

$\mathcal {K}^{itf}$) and non-dimensional (![]() $\mathcal {L}/\ell$,

$\mathcal {L}/\ell$, ![]() $\mathcal {K}^{itf}/\ell ^2$) forms.

$\mathcal {K}^{itf}/\ell ^2$) forms.

The dip coating experimental apparatus is illustrated in figure 4. A bath of dimensions ![]() $9.0\,{\rm cm} \times 9.0\,{\rm cm}\times 19.0$ cm (length

$9.0\,{\rm cm} \times 9.0\,{\rm cm}\times 19.0$ cm (length ![]() $\times$ width

$\times$ width ![]() $\times$ depth) is constructed from acrylic plates and filled with silicone oil (Silitech AG) of density

$\times$ depth) is constructed from acrylic plates and filled with silicone oil (Silitech AG) of density ![]() $\rho = 941 \pm 9$ kg m

$\rho = 941 \pm 9$ kg m![]() $^{-3}$, surface tension

$^{-3}$, surface tension ![]() $\gamma = 21.2 \pm 0.2$ mN m

$\gamma = 21.2 \pm 0.2$ mN m![]() $^{-1}$, and viscosity

$^{-1}$, and viscosity ![]() $\eta = 20.17 \pm 0.07$ mPa s, where the measured values are reported with 95 % confidence intervals. The bath's length/width (

$\eta = 20.17 \pm 0.07$ mPa s, where the measured values are reported with 95 % confidence intervals. The bath's length/width (![]() $9.0\,{\rm cm}\approx 60a$) and depth (

$9.0\,{\rm cm}\approx 60a$) and depth (![]() $19.0\,{\rm cm}\approx 125a$) are many times larger than the capillary length

$19.0\,{\rm cm}\approx 125a$) are many times larger than the capillary length ![]() $a \approx 1.5$ mm, such that the edges of the bath do not affect the flow (Mayer & Krechetnikov Reference Mayer and Krechetnikov2012; Kim & Nam Reference Kim and Nam2017). The solid plates are approximately

$a \approx 1.5$ mm, such that the edges of the bath do not affect the flow (Mayer & Krechetnikov Reference Mayer and Krechetnikov2012; Kim & Nam Reference Kim and Nam2017). The solid plates are approximately ![]() $5\,{\rm cm}\times 2\,{\rm cm}$ (length

$5\,{\rm cm}\times 2\,{\rm cm}$ (length ![]() $\times$ width), and 0.05 cm thick. The surfaces are wide enough (2 cm) that flow near the edges of the plate does not modify film thickness near the centre where the measurement is taken (Xue & Stone Reference Xue and Stone2020), which is verified visually and by confirming that measured film thicknesses match predicted values in the case of a smooth plate. The bath is placed on a stage that can be moved at speeds between

$\times$ width), and 0.05 cm thick. The surfaces are wide enough (2 cm) that flow near the edges of the plate does not modify film thickness near the centre where the measurement is taken (Xue & Stone Reference Xue and Stone2020), which is verified visually and by confirming that measured film thicknesses match predicted values in the case of a smooth plate. The bath is placed on a stage that can be moved at speeds between ![]() $v_0 = 1\ {\rm \mu}{\rm m}\ {\rm s}^{-1}$ and

$v_0 = 1\ {\rm \mu}{\rm m}\ {\rm s}^{-1}$ and ![]() $v_0 = 5\ {\rm mm}\ {\rm s}^{-1}$ by a linear motor (CONEX-LTA-HS, Newport).

$v_0 = 5\ {\rm mm}\ {\rm s}^{-1}$ by a linear motor (CONEX-LTA-HS, Newport).

Figure 4. Dip coating experimental apparatus. (a) Side view. A rough surface is held in place while a liquid bath of density ![]() $\rho$, surface tension

$\rho$, surface tension ![]() $\gamma$, and dynamic viscosity

$\gamma$, and dynamic viscosity ![]() $\eta$ moves downwards at speed

$\eta$ moves downwards at speed ![]() $v_0$. A camera records an interferometric image of the experiment. (b) Top view. A laser passes through a beam expander and into a beamsplitter, which directs it towards the thin film of liquid. The light interferes in the thin film, and an image of the interference pattern is recorded by the camera. (c) A typical interferometric image of a thin film of silicone oil on a rough silicon wafer (left-hand image) during the steady regime and (right-hand image) during the drainage regime after the bath has stopped moving. Scale bars are 0.5 mm.

$v_0$. A camera records an interferometric image of the experiment. (b) Top view. A laser passes through a beam expander and into a beamsplitter, which directs it towards the thin film of liquid. The light interferes in the thin film, and an image of the interference pattern is recorded by the camera. (c) A typical interferometric image of a thin film of silicone oil on a rough silicon wafer (left-hand image) during the steady regime and (right-hand image) during the drainage regime after the bath has stopped moving. Scale bars are 0.5 mm.

A rough surface is held stationary in the liquid, and the bath is moved downwards at a constant velocity ![]() $v_0$, while a camera (Nikon D850) records an interferometric image of the film (figure 4a). The optical path is illustrated in figure 4(b). A red laser (Arima ADL-63054TL) with wavelength

$v_0$, while a camera (Nikon D850) records an interferometric image of the film (figure 4a). The optical path is illustrated in figure 4(b). A red laser (Arima ADL-63054TL) with wavelength ![]() $\lambda _0 = 635$ nm is directed towards the thin liquid film and reflected back towards a camera (Nikon D850), where the measured intensity depends on the film thickness due to thin film interference (Schödel Reference Schödel2018). When the experiment is running, the bath has constant velocity

$\lambda _0 = 635$ nm is directed towards the thin liquid film and reflected back towards a camera (Nikon D850), where the measured intensity depends on the film thickness due to thin film interference (Schödel Reference Schödel2018). When the experiment is running, the bath has constant velocity ![]() $v_0$ relative to the plate, and the film thickness is approximately constant, so the intensity is fairly constant across the image (figure 4(c), left-hand image). After the bath stops moving downwards, we reach the drainage regime (Jeffreys Reference Jeffreys1930; Seiwert Reference Seiwert2010) and the film begins to thin, producing a stripe pattern (figure 4(c), right-hand image). We subsequently move the field of view until we locate the final fringe, which provides a reference height where the free film thickness is

$v_0$ relative to the plate, and the film thickness is approximately constant, so the intensity is fairly constant across the image (figure 4(c), left-hand image). After the bath stops moving downwards, we reach the drainage regime (Jeffreys Reference Jeffreys1930; Seiwert Reference Seiwert2010) and the film begins to thin, producing a stripe pattern (figure 4(c), right-hand image). We subsequently move the field of view until we locate the final fringe, which provides a reference height where the free film thickness is ![]() $\bar {h}(z) = 0$, thereby translating the number of fringes to an absolute film thickness. Material characterization and representative experimental videos may be found in the supplementary material.

$\bar {h}(z) = 0$, thereby translating the number of fringes to an absolute film thickness. Material characterization and representative experimental videos may be found in the supplementary material.

4. Results

Having solved for the free film thickness ![]() $\bar {h}_0$ (2.43) as a function of meniscus curvature

$\bar {h}_0$ (2.43) as a function of meniscus curvature ![]() $\kappa$, capillary length

$\kappa$, capillary length ![]() $a$, and capillary number

$a$, and capillary number ![]() $Ca$, we are able to compute

$Ca$, we are able to compute ![]() $h_0$ for varied surface roughness (given by particular

$h_0$ for varied surface roughness (given by particular ![]() $\mathcal {L}$ and

$\mathcal {L}$ and ![]() $\mathcal {K}^{itf}$ values), liquids (encoded within

$\mathcal {K}^{itf}$ values), liquids (encoded within ![]() $a$ and

$a$ and ![]() $Ca$), and dip coating velocities (given by

$Ca$), and dip coating velocities (given by ![]() $Ca$). In §§ 4.1 and 4.2, we solve the microscopic problem to compute effective parameters

$Ca$). In §§ 4.1 and 4.2, we solve the microscopic problem to compute effective parameters ![]() $\mathcal {L}$ and

$\mathcal {L}$ and ![]() $\mathcal {K}^{itf}$, and demonstrate how these parameters determine macroscopic model predictions. In § 4.3, we compare our model to experimental data.

$\mathcal {K}^{itf}$, and demonstrate how these parameters determine macroscopic model predictions. In § 4.3, we compare our model to experimental data.

4.1. Microtexture slip  $\mathcal {L}$ and interface permeability

$\mathcal {L}$ and interface permeability  $\mathcal {K}^{itf}$

$\mathcal {K}^{itf}$

To make a prediction for a given rough surface, we must compute the slip ![]() $\mathcal {L}$ and interface permeability

$\mathcal {L}$ and interface permeability ![]() $\mathcal {K}^{itf}$ associated with the structure of the rough features, for which we use the homogenization framework (Bottaro & Naqvi Reference Bottaro and Naqvi2020). Microscopic simulations are performed as described in Appendix C. In figure 5, we perform a parametric study of the normalized slip

$\mathcal {K}^{itf}$ associated with the structure of the rough features, for which we use the homogenization framework (Bottaro & Naqvi Reference Bottaro and Naqvi2020). Microscopic simulations are performed as described in Appendix C. In figure 5, we perform a parametric study of the normalized slip ![]() $\mathcal {L}/\ell$ (figure 5a) and interface permeability