1. Introduction

The possibility of improving wind farm efficiency without physical changes to the turbines has driven the interest in wind farm control strategies. The goal is to find a control strategy for the turbines that maximises the total power production, minimises the loads on the turbine, or both. The approaches can be cast into two categories: wake steering and axial induction control.

Wake-steering approaches seek to redirect the wake of upstream turbines such that they do not overlap with the downstream rotors. This is often achieved through yaw misalignment, that is, turning the turbine in such a way that the normal of the rotor plane is at an angle relative to the mean inflow direction. Many studies have shown the potential of this method to increase total power production, for example Adaramola & Krogstad (Reference Adaramola and Krogstad2011) or Gebraad et al. (Reference Gebraad, Teeuwisse, van Wingerden, Fleming, Ruben, Marden and Pao2016). Yaw misalignment not only increases power production but also leads to a distinctive kidney-shaped wake velocity deficit, which is often referred to as a curled wake and not captured by regular wake models. The counter-rotating vortex pair responsible for the curled wake was first observed in Howland et al. (Reference Howland, Bossuyt, Martínez-Tossas, Meyers and Meneveau2016) and the mechanism for its formation was explained in Bastankhah & Porté-Agel (Reference Bastankhah and Porté-Agel2016). An aerodynamic model based on modelling the turbine as a lifting surface is developed in Shapiro, Gayme & Meneveau (Reference Shapiro, Gayme and Meneveau2018), while Martínez-Tossas et al. (Reference Martínez-Tossas, Annoni, Fleming and Churchfield2019) presented a simplified wake model that incorporates the curled wake.

Axial induction control reduces the induction of upstream turbines, such that downstream turbines can produce more power; see, for example, Nilsson et al. (Reference Nilsson, Ivanell, Hansen, Mikkelsen, Sørensen, Breton and Henningson2015). Some studies also combine these two strategies (Bossanyi Reference Bossanyi2018). A large number of studies, both experimental and numerical, has been conducted testing different optimisation strategies for both axial induction control and yaw misalignment. A recent review of methodologies for control optimisation can be found in Andersson et al. (Reference Andersson, Anaya-Lara, Tande, Merz and Imsland2021). Kheirabadi & Nagamune (Reference Kheirabadi and Nagamune2019) provided an overview of gains through power-maximising control strategies. The authors concluded that wake steering yields more consistent efficiency gains, while axial induction control has a higher potential for reducing loads. Furthermore, the authors stress that the fidelity used to determine wind farm efficiency is of particular importance, especially in studies concerning axial induction control. They found that gains seen with low- to medium-fidelity models can often not be reproduced in experiments or high-fidelity simulations. While most investigations focus on the search for optimal set-points in steady-state conditions for individual turbine controllers, an increasing number of studies consider dynamic inflow conditions, such as Hulsman, Andersen & Göçmen (Reference Hulsman, Andersen and Göçmen2020) and Doekemeijer, van der Hoek & van Wingerden (Reference Doekemeijer, van der Hoek and van Wingerden2020). However, these studies still consider optimal set-points given a steady state. Another recent development is the search for control strategies based on a dynamic variation of set-points, such as Howland et al. (Reference Howland, Ghate, Lele and Dabiri2020) or Ciri et al. (Reference Ciri, Rotea, Santoni and Leonardi2017).

Goit & Meyers (Reference Goit and Meyers2015) introduced a framework to find optimal dynamic control through a receding-horizon adjoint gradient optimisation based on large-eddy simulations (LES). The approach was first applied to axial induction control which was expanded upon by Munters & Meyers (Reference Munters and Meyers2017) and later extended to yaw control in Munters & Meyers (Reference Munters and Meyers2018a). However, despite notable performance gains, the approach is not feasible for real-world applications due to the very high computational cost. Instead, the results of the study were used by Munters & Meyers (Reference Munters and Meyers2018b) to identify explicit control strategies. The authors identified the shedding of vortex rings by the turbines as a crucial feature of the optimised flow. A sinusoidal variation of the thrust of upstream turbines was then applied to replicate this effect with an explicit control strategy. A further development of this approach was presented by Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020), introducing the helix approach. The helix approach exerts a rotating radial moment and force onto the wake, deflecting the wake in the shape of a helix, hence its name. This deflection is achieved by a sinusoidal pitching of the individual blades. The pitching frequency is governed by the rotational speed of the turbine and an arbitrarily chosen frequency of rotation of the helix, typically parameterised by a Strouhal number based on inflow velocity and turbine diameter. In their paper, Frederik et al. found an increase in the power produced by a downstream turbine of almost 40 % at an optimal Strouhal number of ![]() $0.25$. In this case, the second turbine operated at its static optimum. The effect of the helix approach when applied to a floating wind turbine was investigated by van den Berg, de Tavernier & van Wingerden (Reference van den Berg, de Tavernier and van Wingerden2022). They observed that the helix incites significant yawing of the turbine, further aiding the wake recovery process. Muscari et al. (Reference Muscari, Schito, Viré, Zasso, van der Hoek and van Wingerden2022) conducted a dynamic mode decomposition of a wake of a turbine with the helix approach and find that helicoidal shapes at the frequency of the excitation and its harmonics are the dominant modes of the wake. Furthermore, the authors report, in contrast to Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020), an optimal Strouhal number for the helix approach is

$0.25$. In this case, the second turbine operated at its static optimum. The effect of the helix approach when applied to a floating wind turbine was investigated by van den Berg, de Tavernier & van Wingerden (Reference van den Berg, de Tavernier and van Wingerden2022). They observed that the helix incites significant yawing of the turbine, further aiding the wake recovery process. Muscari et al. (Reference Muscari, Schito, Viré, Zasso, van der Hoek and van Wingerden2022) conducted a dynamic mode decomposition of a wake of a turbine with the helix approach and find that helicoidal shapes at the frequency of the excitation and its harmonics are the dominant modes of the wake. Furthermore, the authors report, in contrast to Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020), an optimal Strouhal number for the helix approach is ![]() $0.4$. In Korb et al. (Reference Korb, Asmuth, Stender and Ivanell2021), we applied reinforcement learning to optimise this control strategy for a row of three turbines. Although not the main focus of the study, it was found that the application of the helix approach to multiple turbines requires a closer understanding of the processes within the helical wake. Namely, it is not yet understood what influence the helix has on the transition from near to far wake, how it affects the wake recovery, to what extent the wake is deflected and whether the deflection plays a noticeable role in the improved efficiency. Here, we distinguish between meandering, deflection and deformation of the wake: we understand meandering as the fluctuation of the wake centre around a mean position, whereas deflection is a translation of the mean wake centre position due to forces exerted by the turbine. A deformation of the wake is a change of the wake shape without a change of the wake centre position. To facilitate the analysis of the helix, we extend the definition of a deflection from a static frame of reference to a frame of reference that rotates with the angular speed of the helix. Furthermore, the interaction of multiple turbines, each operating in helix mode, has not been investigated. However, our earlier research indicates that this is an important aspect for the extension of the helix approach to a wind farm.

$0.4$. In Korb et al. (Reference Korb, Asmuth, Stender and Ivanell2021), we applied reinforcement learning to optimise this control strategy for a row of three turbines. Although not the main focus of the study, it was found that the application of the helix approach to multiple turbines requires a closer understanding of the processes within the helical wake. Namely, it is not yet understood what influence the helix has on the transition from near to far wake, how it affects the wake recovery, to what extent the wake is deflected and whether the deflection plays a noticeable role in the improved efficiency. Here, we distinguish between meandering, deflection and deformation of the wake: we understand meandering as the fluctuation of the wake centre around a mean position, whereas deflection is a translation of the mean wake centre position due to forces exerted by the turbine. A deformation of the wake is a change of the wake shape without a change of the wake centre position. To facilitate the analysis of the helix, we extend the definition of a deflection from a static frame of reference to a frame of reference that rotates with the angular speed of the helix. Furthermore, the interaction of multiple turbines, each operating in helix mode, has not been investigated. However, our earlier research indicates that this is an important aspect for the extension of the helix approach to a wind farm.

In this paper, we seek to address the aforementioned questions. To this end, we discuss several theoretical aspects of the characteristics of helically deflected wind turbine wakes. Furthermore, a suite of LES is conducted to confirm the analytical deductions. First, a description of the conducted simulations is given, followed by a theoretical and numerical analysis of the helical wake of a single turbine with a focus on the effects of the rotating force. Thereafter, the interaction of multiple helical wakes is first described analytically and finally analysed using the results of simulations with multiple turbines. We conclude with a recapitulation of the findings and an outlook into possible future works.

2. Simulation set-up

A total of 16 LES cases are investigated in order to confirm the analytical derivations in §§ 3 and 5 and examine the influence of turbulence intensity, turbulence length scale and tip-speed ratio. We conduct two highly resolved simulations of the wake of a single turbine to analyse the deformation of the tip vortices in § 3.2 and eight medium-resolution simulations of single wakes to study further characteristics such as deflection, entrainment and wake shape, and recovery with different inflow conditions. Furthermore, we examine the interaction of multiple helical wakes and their relative phase difference. Therefore, another set of five simulations with three turbines at medium resolution is performed. Finally, we conducted one simulation of an empty domain to generate reference spectra for § 3.4.

All LES are conducted with the lattice Boltzmann method (LBM) framework elbe. For a detailed description of the solver, see Janßen et al. (Reference Janßen, Mierke, Überrück, Gralher and Rung2015). The wind turbines are modelled using the actuator line method (ALM), closely resembling the original formulation by Sørensen & Shen (Reference Sørensen and Shen2002). The overall set-up is similar to previous studies and has been validated extensively in Asmuth, Olivares-Espinosa & Ivanell (Reference Asmuth, Olivares-Espinosa and Ivanell2020b); Asmuth et al. (Reference Asmuth, Navarro Diaz, Madsen, Branlard, Meyer Forsting, Nilsson, Jonkman and Ivanell2021). It uses the parameterised cumulant LBM as described in Geier, Pasquali & Schönherr (Reference Geier, Pasquali and Schönherr2017a) and Geier, Pasquali & Schönherr (Reference Geier, Pasquali and Schönherr2017b). The cumulant LBM recovers the weakly compressible Navier–Stokes equations with second-order accuracy in time and advection and fourth-order accuracy in diffusion (Geier et al. Reference Geier, Schönherr, Pasquali and Krafczyk2015, Reference Geier, Pasquali and Schönherr2017a). The subgrid-scale stresses are modelled explicitly via the anisotropic minimum dissipation subgrid-scale model with the model constant set to ![]() $1/12$ (Rozema et al. Reference Rozema, Bae, Moin and Verstappen2015). Due to the use of the subgrid-scale model, the stabilising limiter of the parameterised cumulant LBM is unnecessary and effectively turned off. The Mach number is set to

$1/12$ (Rozema et al. Reference Rozema, Bae, Moin and Verstappen2015). Due to the use of the subgrid-scale model, the stabilising limiter of the parameterised cumulant LBM is unnecessary and effectively turned off. The Mach number is set to ![]() $0.1$ (see Asmuth et al. (Reference Asmuth, Janßen, Olivares-Espinosa, Nilsson and Ivanell2020a) for a discussion of associated compressibility effects). The mean density and dynamic viscosity are set to

$0.1$ (see Asmuth et al. (Reference Asmuth, Janßen, Olivares-Espinosa, Nilsson and Ivanell2020a) for a discussion of associated compressibility effects). The mean density and dynamic viscosity are set to ![]() $1.225\,{\rm kg}\,{\rm m}^{-3}$ and

$1.225\,{\rm kg}\,{\rm m}^{-3}$ and ![]() $1.7841 \times 10^{-4}\,{\rm m}^2\,{\rm s}^{-1}$, respectively.

$1.7841 \times 10^{-4}\,{\rm m}^2\,{\rm s}^{-1}$, respectively.

In all cases, we simulate the NREL 5MW reference turbine as defined in Jonkman et al. (Reference Jonkman, Butterfield, Musial and Scott2009), with a rotor diameter of ![]() $D=126\,{\rm m}$. The first turbine is placed

$D=126\,{\rm m}$. The first turbine is placed ![]() $3D$ downstream of the inlet and all turbines are placed in the centre of the cross-stream plane to minimise the effects of the boundaries. In the three-turbine cases, the turbine spacing in the streamwise direction is

$3D$ downstream of the inlet and all turbines are placed in the centre of the cross-stream plane to minimise the effects of the boundaries. In the three-turbine cases, the turbine spacing in the streamwise direction is ![]() $S_{x} = 5D$. In the ALM the blades are discretised by 32 blade nodes. The smearing width is set to approximately one cell width of the highest resolution,

$S_{x} = 5D$. In the ALM the blades are discretised by 32 blade nodes. The smearing width is set to approximately one cell width of the highest resolution, ![]() $\Delta x$, except for the cases with a high resolution, where the smearing width is set to approximately

$\Delta x$, except for the cases with a high resolution, where the smearing width is set to approximately ![]() $1.5 \Delta x$ of the highest resolution. The global reference frame

$1.5 \Delta x$ of the highest resolution. The global reference frame ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ is defined along the streamwise, spanwise and vertical direction, respectively. The velocity vector is

$z$ is defined along the streamwise, spanwise and vertical direction, respectively. The velocity vector is ![]() $\boldsymbol {u}=\{u,v,w\}$. Mean and fluctuations of any quantity

$\boldsymbol {u}=\{u,v,w\}$. Mean and fluctuations of any quantity ![]() $a$ are denoted by

$a$ are denoted by ![]() $\bar {a}$ and

$\bar {a}$ and ![]() $a'$, respectively.

$a'$, respectively.

The key parameters of the simulations, such as the mean inflow velocity ![]() $V_{0}$, the inflow turbulence intensity

$V_{0}$, the inflow turbulence intensity ![]() $Ti = \sqrt {(u'^2+v'^2+w'^2)/3}/V_{0}$, the integral length scale of the turbulence

$Ti = \sqrt {(u'^2+v'^2+w'^2)/3}/V_{0}$, the integral length scale of the turbulence ![]() $L$ and the tip-speed ratio

$L$ and the tip-speed ratio ![]() $\lambda = \omega R / V_{0}$ can be found in table 1 for the simulations of a single turbine and in table 2 for the simulations of three turbines. The tables also include the names by which the simulations will be referred to later on. The name consists of a letter signifying the applied control strategy, the number of turbines, a letter indicating which quantity deviates from the base scenario and the value of that quantity. Thus, a case with greedy control (G), one turbine (1) and a turbulence length of 120 m will have the name G1L120.

$\lambda = \omega R / V_{0}$ can be found in table 1 for the simulations of a single turbine and in table 2 for the simulations of three turbines. The tables also include the names by which the simulations will be referred to later on. The name consists of a letter signifying the applied control strategy, the number of turbines, a letter indicating which quantity deviates from the base scenario and the value of that quantity. Thus, a case with greedy control (G), one turbine (1) and a turbulence length of 120 m will have the name G1L120.

Table 1. Simulation parameters of the single turbine cases.

Table 2. Simulation parameters of the three turbine cases.

The high-resolution cases are equal to G1V![]() $9$ and H1V

$9$ and H1V![]() $9$ of the single-turbine cases, but with a reduced turbulence intensity of 2.5 %. Simulations with a single turbine vary in mean inflow velocity

$9$ of the single-turbine cases, but with a reduced turbulence intensity of 2.5 %. Simulations with a single turbine vary in mean inflow velocity ![]() $V_0$, turbulence intensity

$V_0$, turbulence intensity ![]() $Ti$ and the integral length scale of the synthetic turbulence. Each simulation is conducted with and without the helix approach. The simulations are conducted in a domain of size

$Ti$ and the integral length scale of the synthetic turbulence. Each simulation is conducted with and without the helix approach. The simulations are conducted in a domain of size ![]() $L_x \times L_y \times L_z = 15D \times 8D \times 8D$, with a refined zone around the turbine and the wake of

$L_x \times L_y \times L_z = 15D \times 8D \times 8D$, with a refined zone around the turbine and the wake of ![]() $13D \times 6D \times 6D$. The LBM is limited to cubic cells and the grid refinement approach is based on Geier, Greiner & Korvink (Reference Geier, Greiner and Korvink2009). The outer domain has a grid spacing of

$13D \times 6D \times 6D$. The LBM is limited to cubic cells and the grid refinement approach is based on Geier, Greiner & Korvink (Reference Geier, Greiner and Korvink2009). The outer domain has a grid spacing of ![]() $\Delta x = D/16$, while the refined zone has a grid spacing of

$\Delta x = D/16$, while the refined zone has a grid spacing of ![]() $\Delta x = D/32$. The resulting blockage ratio is 1.2 %, which is well below the 5 % found by Sarlak et al. (Reference Sarlak, Nishino, Martínez-Tossas, Meneveau and Sørensen2016) to be the threshold for the onset of blockage effects.

$\Delta x = D/32$. The resulting blockage ratio is 1.2 %, which is well below the 5 % found by Sarlak et al. (Reference Sarlak, Nishino, Martínez-Tossas, Meneveau and Sørensen2016) to be the threshold for the onset of blockage effects.

The high-resolution cases only differ in that the streamwise length of the first refinement layer is shortened to ![]() $8D$ and an additional refinement layer of dimensions

$8D$ and an additional refinement layer of dimensions ![]() $5D \times 3D \times 3D$ is added with a resolution of

$5D \times 3D \times 3D$ is added with a resolution of ![]() $\Delta x = D/64$. The simulations with three turbines have a domain of size

$\Delta x = D/64$. The simulations with three turbines have a domain of size ![]() $18D \times 8D \times 8D$ and a refined zone of size

$18D \times 8D \times 8D$ and a refined zone of size ![]() $16D \times 6D \times 6D$, the cell sizes are the same as for the single-turbine cases. The layout of the three-turbine cases is schematically shown in figure 1. To isolate the effects of the helix from interactions with boundary layer effects, all simulations are run without shear. At the sides, a slip boundary condition is implemented via a bounce-forward method (Krüger et al. Reference Krüger, Kusumaatmaja, Kuzmin, Shardt, Silva and Viggen2017). At the inlet, a constant velocity is superimposed with fluctuations from a precomputed synthetic turbulence field based on the method by Mann (Reference Mann1998). Previous studies using the same set-up showed very little degradation in turbulence intensity throughout the domain (see Asmuth et al. Reference Asmuth, Olivares-Espinosa and Ivanell2020b). The inflow velocity is either

$16D \times 6D \times 6D$, the cell sizes are the same as for the single-turbine cases. The layout of the three-turbine cases is schematically shown in figure 1. To isolate the effects of the helix from interactions with boundary layer effects, all simulations are run without shear. At the sides, a slip boundary condition is implemented via a bounce-forward method (Krüger et al. Reference Krüger, Kusumaatmaja, Kuzmin, Shardt, Silva and Viggen2017). At the inlet, a constant velocity is superimposed with fluctuations from a precomputed synthetic turbulence field based on the method by Mann (Reference Mann1998). Previous studies using the same set-up showed very little degradation in turbulence intensity throughout the domain (see Asmuth et al. Reference Asmuth, Olivares-Espinosa and Ivanell2020b). The inflow velocity is either ![]() $V_0=9\,{\rm m}\,{\rm s}^{-1}$ or

$V_0=9\,{\rm m}\,{\rm s}^{-1}$ or ![]() $V_0=13\,{\rm m}\,{\rm s}^{-1}$. The first velocity is chosen to be in Region 2 of the controller where the turbine operates at an optimal tip-speed ratio. The second inflow velocity is within Region 3, where the controller reduces the tip-speed ratio. The turbulence intensity of the inflow is either

$V_0=13\,{\rm m}\,{\rm s}^{-1}$. The first velocity is chosen to be in Region 2 of the controller where the turbine operates at an optimal tip-speed ratio. The second inflow velocity is within Region 3, where the controller reduces the tip-speed ratio. The turbulence intensity of the inflow is either ![]() $Ti = 5\,\%$ or

$Ti = 5\,\%$ or ![]() $Ti = 10\,\%$ and a characteristic length-scale is either 40 m or 120 m. Higher levels of turbulence intensity are known to increase turbulent mixing whereas larger turbulent length scales amplify the meandering of the wake (Porté-Agel, Bastankhah & Shamsoddin Reference Porté-Agel, Bastankhah and Shamsoddin2020). The velocity is imposed by injection of momentum in a simple bounce-back boundary condition (Bouzidi, Firdaouss & Lallemand Reference Bouzidi, Firdaouss and Lallemand2001).

$Ti = 10\,\%$ and a characteristic length-scale is either 40 m or 120 m. Higher levels of turbulence intensity are known to increase turbulent mixing whereas larger turbulent length scales amplify the meandering of the wake (Porté-Agel, Bastankhah & Shamsoddin Reference Porté-Agel, Bastankhah and Shamsoddin2020). The velocity is imposed by injection of momentum in a simple bounce-back boundary condition (Bouzidi, Firdaouss & Lallemand Reference Bouzidi, Firdaouss and Lallemand2001).

Figure 1. Schematic of the domain of the three turbine cases. Grey discs represent the rotor-swept area.

The simulations serving as baseline cases are conducted without the helix approach. The turbines have a constant rotor speed, which was determined in a cascading manner: Initially, the first turbine is operated with a standard greedy controller, i.e. the turbine extracts as much power as possible, for one flow-through time ![]() $T_{ft} = L_{x}/V_{0}$. To this end, we implemented the reference controller given in the definition of the NREL 5MW turbine by Jonkman et al. (Reference Jonkman, Butterfield, Musial and Scott2009). The average rotor speed of that period is then set as the constant rotor speed. After one flow-through time, this procedure is repeated with the second turbine downstream and so on. In the cases with the helix approach, the constant rotor speeds are determined in a similar manner. After the first turbine's rotor speed has been determined, we begin to apply the helix approach on that turbine, while the others still operate in greedy mode. After one flow-through time, we average the rotor speed of the second turbine. The same procedure is repeated with the third turbine. A schematic of the optimisation routine is provided in figure 2. This methodology ensures that the turbines operate close to their optimal tip-speed ratio while avoiding interactions of the helix approach with a varying rotor speed due to the greedy controller.

$T_{ft} = L_{x}/V_{0}$. To this end, we implemented the reference controller given in the definition of the NREL 5MW turbine by Jonkman et al. (Reference Jonkman, Butterfield, Musial and Scott2009). The average rotor speed of that period is then set as the constant rotor speed. After one flow-through time, this procedure is repeated with the second turbine downstream and so on. In the cases with the helix approach, the constant rotor speeds are determined in a similar manner. After the first turbine's rotor speed has been determined, we begin to apply the helix approach on that turbine, while the others still operate in greedy mode. After one flow-through time, we average the rotor speed of the second turbine. The same procedure is repeated with the third turbine. A schematic of the optimisation routine is provided in figure 2. This methodology ensures that the turbines operate close to their optimal tip-speed ratio while avoiding interactions of the helix approach with a varying rotor speed due to the greedy controller.

Figure 2. Timeline of the routine to determine the angular velocity and pitch. Solid line marks operation according to greedy control, whereas a dashed line signifies the turbine operating with constant angular velocity but with application of the helix approach. Averaging is done for one flow-through time under greedy operation.

The simulations are run for ![]() $65T_{ft}$ after the startup time. The Strouhal number of the pitch variations, see (3.3), is set to 0.25 in all cases, based on the recommendation by Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020). In § 4 we examine multiple turbines operating in helix mode. We study the influence of the phase difference of the individual helices. To that end, we apply a phase shift

$65T_{ft}$ after the startup time. The Strouhal number of the pitch variations, see (3.3), is set to 0.25 in all cases, based on the recommendation by Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020). In § 4 we examine multiple turbines operating in helix mode. We study the influence of the phase difference of the individual helices. To that end, we apply a phase shift ![]() $\varPhi$ to the helices, which is determined a priori based on the results of the single turbine cases, see § 3.7 for the details on determining the phase shift. The desired phase shift is then applied by setting the angle of the helix at the turbine to

$\varPhi$ to the helices, which is determined a priori based on the results of the single turbine cases, see § 3.7 for the details on determining the phase shift. The desired phase shift is then applied by setting the angle of the helix at the turbine to

where ![]() $\bar {u}_{helix}$ is an average transport velocity of the helix. We use

$\bar {u}_{helix}$ is an average transport velocity of the helix. We use ![]() $\bar {u}_{helix}/V_0=0.7$ based on the results in § 3.7. The same procedure is used for the third turbine, i.e.

$\bar {u}_{helix}/V_0=0.7$ based on the results in § 3.7. The same procedure is used for the third turbine, i.e.

3. The helical wake of a single turbine

Applying the helix approach to a turbine improves the wake recovery, as shown by Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020). Yet, it is not clear what causes this improved recovery. Frederik et al. argue that this is due to an increased mixing, but do not discuss any effects of a deflection of the wake or further details of the flow in general. Furthermore, how exactly the helical wake comes to be is also not very clear.

3.1. Angles and forces

The idea of the helix approach is to define a pitch angle ![]() $\boldsymbol {\varTheta }$ in the global reference frame, also referred to as the global pitch, and letting the direction of that pitch rotate. We define the global pitch as

$\boldsymbol {\varTheta }$ in the global reference frame, also referred to as the global pitch, and letting the direction of that pitch rotate. We define the global pitch as

\begin{equation} \boldsymbol{\varTheta} = \begin{bmatrix} \varTheta_0 \\ \varTheta_{tilt} \\ \varTheta_{yaw} \end{bmatrix} = A \begin{bmatrix} 0 \\ \sin\left(\beta\right) \\ \cos\left(\beta\right) \end{bmatrix}, \end{equation}

\begin{equation} \boldsymbol{\varTheta} = \begin{bmatrix} \varTheta_0 \\ \varTheta_{tilt} \\ \varTheta_{yaw} \end{bmatrix} = A \begin{bmatrix} 0 \\ \sin\left(\beta\right) \\ \cos\left(\beta\right) \end{bmatrix}, \end{equation}

where ![]() $A$ is the magnitude of the pitch and

$A$ is the magnitude of the pitch and ![]() $\beta$ is the angle between the direction of the pitch and the

$\beta$ is the angle between the direction of the pitch and the ![]() $z$-axis. The multiblade coordinate transformation transforms coordinates from the rotating reference frame of the blade to the global reference frame (Bir Reference Bir2008). Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020) showed that applying the inverse transformation to (3.1), i.e. from the static global reference frame onto the rotating reference of each blade

$z$-axis. The multiblade coordinate transformation transforms coordinates from the rotating reference frame of the blade to the global reference frame (Bir Reference Bir2008). Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020) showed that applying the inverse transformation to (3.1), i.e. from the static global reference frame onto the rotating reference of each blade ![]() $b$ yields

$b$ yields

where ![]() $\varTheta _b$ and

$\varTheta _b$ and ![]() $\varPsi _b$ are the pitch and azimuth of blade

$\varPsi _b$ are the pitch and azimuth of blade ![]() $b$, respectively. Switching the sign of

$b$, respectively. Switching the sign of ![]() $\omega _{e}$ will lead to a clockwise rotation. However, note that this case will not be discussed any further in this paper, since Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020) found that a counter-clockwise rotation yields higher power gains. The change in pitch angle results in a varying angle of attack

$\omega _{e}$ will lead to a clockwise rotation. However, note that this case will not be discussed any further in this paper, since Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020) found that a counter-clockwise rotation yields higher power gains. The change in pitch angle results in a varying angle of attack ![]() $\alpha$ and therefore differences in lift within one rotation of the rotor. The differences in lift result in a radial force and moment.

$\alpha$ and therefore differences in lift within one rotation of the rotor. The differences in lift result in a radial force and moment.

There are two parameters that control the pitch angle: the amplitude ![]() $A$ and the excitation frequency

$A$ and the excitation frequency ![]() $\omega _{e}$. The relation of the excitation frequency to the velocity of the flow and the turbine length scale is expressed by the Strouhal number

$\omega _{e}$. The relation of the excitation frequency to the velocity of the flow and the turbine length scale is expressed by the Strouhal number

where by convention the frequency ![]() $f_{e}$ is used instead of the angular frequency

$f_{e}$ is used instead of the angular frequency ![]() $\omega _{e}$. Alternatively, the Strouhal number can be expressed by means of the rotor speed

$\omega _{e}$. Alternatively, the Strouhal number can be expressed by means of the rotor speed ![]() $\omega$ and the tip speed ratio as

$\omega$ and the tip speed ratio as

This relation makes it possible to define the excitation frequency based on the rotor speed if Strouhal number and tip-speed ratio are known. The optimal tip-speed ratio is usually dictated by the design of the turbine (see, for example, Jonkman et al. (Reference Jonkman, Butterfield, Musial and Scott2009)) and Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020) found a value of ![]() ${St} = 0.25$ to yield the highest power gains. Thus,

${St} = 0.25$ to yield the highest power gains. Thus, ![]() $f_{e}$ can be determined without any knowledge of the flow, as it only depends on the rotational speed of the turbine which is set by the controller. A further discussion of the Strouhal number in the case of multiple turbines can be found in § 4.

$f_{e}$ can be determined without any knowledge of the flow, as it only depends on the rotational speed of the turbine which is set by the controller. A further discussion of the Strouhal number in the case of multiple turbines can be found in § 4.

Later in this section, we examine the phase of the helix. To do so we must know in which direction the wake is deflected. We assume that the deflection is dominated by the radial force due to the helix approach. Thus, the direction of the deflection is the same as the direction of the force exerted onto the flow. We note that ![]() $\omega _e \ll \omega$ due to (3.4), hence the pitch angle varies much slower than the turbine rotates. Therefore, we assume that we can examine the blade forces in a quasi-steady state. Furthermore, we neglect any influence of the drag and only consider the lift of the airfoil, and assume that the angle of attack

$\omega _e \ll \omega$ due to (3.4), hence the pitch angle varies much slower than the turbine rotates. Therefore, we assume that we can examine the blade forces in a quasi-steady state. Furthermore, we neglect any influence of the drag and only consider the lift of the airfoil, and assume that the angle of attack ![]() $\alpha$ is below the onset of stall. Finally, we ignore any changes in induced velocities and only consider changes in forces.

$\alpha$ is below the onset of stall. Finally, we ignore any changes in induced velocities and only consider changes in forces.

The normal and tangential forces acting on the fluid are proportional to ![]() $F_n \propto -C_L(\alpha )\cos \left (\phi \right )$ and

$F_n \propto -C_L(\alpha )\cos \left (\phi \right )$ and ![]() $F_t \propto -C_L(\alpha )\sin \left (\phi \right )$, where

$F_t \propto -C_L(\alpha )\sin \left (\phi \right )$, where ![]() $\phi$ is the angle between the relative velocity

$\phi$ is the angle between the relative velocity ![]() $V_{rel}$ and the plane of rotation. A diagram of the angles and forces is shown in figure 3(a). A Taylor expansion of

$V_{rel}$ and the plane of rotation. A diagram of the angles and forces is shown in figure 3(a). A Taylor expansion of ![]() $C_L$ around

$C_L$ around ![]() $\alpha _0=\phi$ and the geometric relationship

$\alpha _0=\phi$ and the geometric relationship ![]() $\alpha =\phi -\varTheta _b$ yields

$\alpha =\phi -\varTheta _b$ yields

The forces ![]() $\boldsymbol {F}$ exerted on the flow by all blades in the global frame of reference are then proportional to

$\boldsymbol {F}$ exerted on the flow by all blades in the global frame of reference are then proportional to

\begin{equation} \boldsymbol{F} \propto \sum_{b=0}^{N_b-1}\begin{bmatrix} -C_L(\alpha) \cos\left(\phi\right) \\ C_L(\alpha) \sin\left(\phi\right)\cos\left(\varPsi_b\right) \\ C_L(\alpha) \sin\left(\phi\right)\sin\left(\varPsi_b\right) \end{bmatrix}.\end{equation}

\begin{equation} \boldsymbol{F} \propto \sum_{b=0}^{N_b-1}\begin{bmatrix} -C_L(\alpha) \cos\left(\phi\right) \\ C_L(\alpha) \sin\left(\phi\right)\cos\left(\varPsi_b\right) \\ C_L(\alpha) \sin\left(\phi\right)\sin\left(\varPsi_b\right) \end{bmatrix}.\end{equation}By inserting (3.2) and (3.5) and after some manipulation, the total force can be shown to be

\begin{equation} \boldsymbol{F} \propto{-}N_b\begin{bmatrix} \cos\left(\phi\right)C_L(\alpha_0) \\ C_1\sin\left(\omega_et\right)\\ C_1\cos\left(\omega_et\right) \end{bmatrix}, \end{equation}

\begin{equation} \boldsymbol{F} \propto{-}N_b\begin{bmatrix} \cos\left(\phi\right)C_L(\alpha_0) \\ C_1\sin\left(\omega_et\right)\\ C_1\cos\left(\omega_et\right) \end{bmatrix}, \end{equation}

where ![]() $C_1 = A({\partial C_L}/{\partial \alpha })({\sin \left (\phi \right )}/{2})$. Thus, the radial component, i.e. the force in the rotor plane, has a magnitude proportional to

$C_1 = A({\partial C_L}/{\partial \alpha })({\sin \left (\phi \right )}/{2})$. Thus, the radial component, i.e. the force in the rotor plane, has a magnitude proportional to ![]() $N_bC_1$ and points in the opposite direction of the global pitch

$N_bC_1$ and points in the opposite direction of the global pitch ![]() $\boldsymbol {\varTheta }$. The conservation of momentum dictates that the flow is accelerated in the direction of the force. We define the angle of the direction as

$\boldsymbol {\varTheta }$. The conservation of momentum dictates that the flow is accelerated in the direction of the force. We define the angle of the direction as ![]() $\varphi$. To keep the definition of

$\varphi$. To keep the definition of ![]() $\varphi$ in line with the definition of the azimuth angle

$\varphi$ in line with the definition of the azimuth angle ![]() $\varPsi$, we define

$\varPsi$, we define ![]() $\varphi$ to be zero when the wake is deflected in positive

$\varphi$ to be zero when the wake is deflected in positive ![]() $z$-direction, i.e. upwards and

$z$-direction, i.e. upwards and ![]() $\varphi$ to increase counterclockwise. Therefore,

$\varphi$ to increase counterclockwise. Therefore, ![]() $\beta$ and

$\beta$ and ![]() $\varphi$ are related as

$\varphi$ are related as

The relation of force, moment, global pitch and their respective angles are shown in figure 3(b,c). A more detailed derivation of the forces can be found in Appendix A. There, we also derive the radial component of the moment induced by the helix approach. As stated previously, we will not consider the effect of the moment in the remainder of this paper. We assume that the force causes the wake deflection and that the moment only affects the wake mixing.

Figure 3. Schematics of angles, velocities, forces and moments acting on the flow. (a) Top view of a cross-section of a blade at azimuth ![]() $\varPsi =0$, showing the local angles and forces. (b) View of the rotor looking downstream, showing azimuth and global pitch as well as force and moment due to the helix approach. (c) Top view of the rotor showing the total moment and force on the flow. Gray shaded area illustrates the deformed wake.

$\varPsi =0$, showing the local angles and forces. (b) View of the rotor looking downstream, showing azimuth and global pitch as well as force and moment due to the helix approach. (c) Top view of the rotor showing the total moment and force on the flow. Gray shaded area illustrates the deformed wake.

3.2. Tip vortices

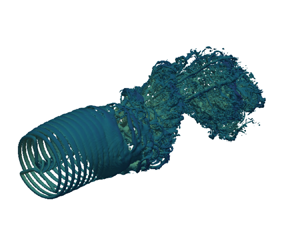

An important aspect of the wake recovery is the breakdown of the tip vortices. The tip vortices shield the wake from the ambient turbulence. Only after the breakdown of the tip vortices does the wake recovery begin, as discussed, for example, in Lignarolo et al. (Reference Lignarolo, Ragni, Scarano, Simão Ferreira and van Bussel2015). Therefore, it is of great importance to the process of wake recovery, when the breakdown occurs. The vorticity contours of a snapshot of the flow field of the high-resolution case with greedy and helix operation are shown in figure 4. Recall that the high-resolution case has a resolution of ![]() $\Delta x=D/64$, in order to resolve the tip vortices. The resolution corresponds, e.g. , to the coarse resolution used by Ivanell et al. (Reference Ivanell, Mikkelsen, Sørensen and Henningson2010), where tip vortex instabilities were studied. Compared with the tip vortices in greedy operation, the tip vortices of a turbine in helix operation exhibit some important differences. Due to the changing pitch of the blade, the vorticity generated by the blade changes with time. This is also visible in the tip vortices. Furthermore, the deformation of the wake stretches and squishes the vortices. This also changes the distance between the vortices and thus the strength of their interaction see, e.g. , Ivanell et al. (Reference Ivanell, Mikkelsen, Sørensen and Henningson2010). Both aspects lead to an earlier breakdown, as can be seen in figure 4. In the helix wake, the vortices are merged where the blades were pitched to stall and thinned where the blades were pitched to feather. Furthermore, the deformation of the wake is clearly visible. While the classical pairing and leapfrogging of vortices, as reported, for example, by Tophøj & Aref (Reference Tophøj and Aref2013) or Sarmast et al. (Reference Sarmast, Dadfar, Mikkelsen, Schlatter, Ivanell, Sørensen and Henningson2014), and the following breakdown is apparent in the greedy case, the breakdown of the helical wake is not as orderly. A pairing of vortices is barely visible since the vortices have already begun to merge. The deformation also leads to changing distances between the vortices. In summary, we found that the tip vortices of the helix approach vary in thickness due to the varying pitch angle, which, in turn, leads to the merging of vortices. Furthermore, the helix approach leads to a clear helical deformation of the wake. Finally, we could not observe the leap-frogging of vortex pairs, which is a typical feature of tip vortices in regular operation. A more thorough investigation of the interplay of deformation and vortices is omitted here for the sake of brevity.

$\Delta x=D/64$, in order to resolve the tip vortices. The resolution corresponds, e.g. , to the coarse resolution used by Ivanell et al. (Reference Ivanell, Mikkelsen, Sørensen and Henningson2010), where tip vortex instabilities were studied. Compared with the tip vortices in greedy operation, the tip vortices of a turbine in helix operation exhibit some important differences. Due to the changing pitch of the blade, the vorticity generated by the blade changes with time. This is also visible in the tip vortices. Furthermore, the deformation of the wake stretches and squishes the vortices. This also changes the distance between the vortices and thus the strength of their interaction see, e.g. , Ivanell et al. (Reference Ivanell, Mikkelsen, Sørensen and Henningson2010). Both aspects lead to an earlier breakdown, as can be seen in figure 4. In the helix wake, the vortices are merged where the blades were pitched to stall and thinned where the blades were pitched to feather. Furthermore, the deformation of the wake is clearly visible. While the classical pairing and leapfrogging of vortices, as reported, for example, by Tophøj & Aref (Reference Tophøj and Aref2013) or Sarmast et al. (Reference Sarmast, Dadfar, Mikkelsen, Schlatter, Ivanell, Sørensen and Henningson2014), and the following breakdown is apparent in the greedy case, the breakdown of the helical wake is not as orderly. A pairing of vortices is barely visible since the vortices have already begun to merge. The deformation also leads to changing distances between the vortices. In summary, we found that the tip vortices of the helix approach vary in thickness due to the varying pitch angle, which, in turn, leads to the merging of vortices. Furthermore, the helix approach leads to a clear helical deformation of the wake. Finally, we could not observe the leap-frogging of vortex pairs, which is a typical feature of tip vortices in regular operation. A more thorough investigation of the interplay of deformation and vortices is omitted here for the sake of brevity.

Figure 4. Vorticity contour of a single turbine in (a) greedy and (b) helix operation.

3.3. Wake deflection

The helix approach leads to a rotating radial force exerted onto the flow as shown in § 3.1. This force must also lead to an acceleration of the fluid in the radial direction, causing the helical shape of the wake illustrated in figure 4. However, we show that this radial force not only deforms but also deflects the wake. Recall, that we define deflection as an imposed translation of the mean wake centre due to the forces exerted by the turbine, whereas meandering is the stochastic fluctuation of the wake centre position due to the ambient turbulence, and deformation is a change in wake shape without translation of the mean wake centre position. The differentiation between deformation and deflection is of high relevance since deflection potentially reduces the overlap of the wake and the downstream turbine, while deformation may lead to increased wake mixing but does not necessarily reduce overlap. In established yaw-based wake-steering approaches, the force exerted onto the wake is stationary and so is the deflection of the wake. However, in the helix approach, the radial force rotates, thus the deflection also rotates. Therefore, we have to extend the concept of deflection to a rotating frame of reference, in order to analyse the rotating wake of the helix. Thus, we describe deflection as a mean translation of the wake centre in coordinates rotating with the frequency of rotation of the helix ![]() $f_e$. We want to point out that the distance between the wake centre and the cross-stream position of the turbine is the same in the static and rotating frames of reference and is therefore easily computed from the static frame of reference, which is why we will focus our analysis on this quantity. To quantify the deflection, we compute the wake centres from the instantaneous streamwise velocity in cross-stream planes downstream of the turbine, by fitting a two-dimensional Gaussian velocity deficit with the width of the rotor (Quon, Doubrawa & Debnath Reference Quon, Doubrawa and Debnath2020). For the latter, we employ the samwich toolbox (https://ewquon.github.io/waketracking). The wake centre distance

$f_e$. We want to point out that the distance between the wake centre and the cross-stream position of the turbine is the same in the static and rotating frames of reference and is therefore easily computed from the static frame of reference, which is why we will focus our analysis on this quantity. To quantify the deflection, we compute the wake centres from the instantaneous streamwise velocity in cross-stream planes downstream of the turbine, by fitting a two-dimensional Gaussian velocity deficit with the width of the rotor (Quon, Doubrawa & Debnath Reference Quon, Doubrawa and Debnath2020). For the latter, we employ the samwich toolbox (https://ewquon.github.io/waketracking). The wake centre distance ![]() $d$ is then defined as the distance of the wake centre to the centre of the rotor plane.

$d$ is then defined as the distance of the wake centre to the centre of the rotor plane.

The distribution of ![]() $d$ at

$d$ at ![]() $3D$,

$3D$, ![]() $5D$ and

$5D$ and ![]() $7D$ downstream of the turbine for all single-turbine cases is shown in figure 5. Without the helix, the median of the wake centre distance increases downstream due to the naturally occurring wake meandering, which is in line with other experimental and numerical studies (Kang, Yang & Sotiropoulos Reference Kang, Yang and Sotiropoulos2014; Howard et al. Reference Howard, Singh, Sotiropoulos and Guala2015; Bastankhah & Porté-Agel Reference Bastankhah and Porté-Agel2017). The distribution is heavily skewed to the right. We find a slight increase in spread with a higher inflow velocity (i.e. lower tip-speed ratio), in (a), but that finding does not persist further downstream. If the helix approach is applied, the mode of the distribution is shifted to the right and the distribution has a higher variance. In the case with a lower tip-speed ratio, the shift to the right is less pronounced, indicating that the helix approach does not deflect the wake as much as when the turbine is operated at the optimal tip-speed ratio. In figure 5(d–f) we can examine the influence of increased turbulence intensity on the wake centre distance. We see that mode of the distribution of G1I

$7D$ downstream of the turbine for all single-turbine cases is shown in figure 5. Without the helix, the median of the wake centre distance increases downstream due to the naturally occurring wake meandering, which is in line with other experimental and numerical studies (Kang, Yang & Sotiropoulos Reference Kang, Yang and Sotiropoulos2014; Howard et al. Reference Howard, Singh, Sotiropoulos and Guala2015; Bastankhah & Porté-Agel Reference Bastankhah and Porté-Agel2017). The distribution is heavily skewed to the right. We find a slight increase in spread with a higher inflow velocity (i.e. lower tip-speed ratio), in (a), but that finding does not persist further downstream. If the helix approach is applied, the mode of the distribution is shifted to the right and the distribution has a higher variance. In the case with a lower tip-speed ratio, the shift to the right is less pronounced, indicating that the helix approach does not deflect the wake as much as when the turbine is operated at the optimal tip-speed ratio. In figure 5(d–f) we can examine the influence of increased turbulence intensity on the wake centre distance. We see that mode of the distribution of G1I![]() $10$ is shifted to the right and that the distribution has a much longer tail compared with G1I

$10$ is shifted to the right and that the distribution has a much longer tail compared with G1I![]() $5$. For case H1I

$5$. For case H1I![]() $10$, the mode is similar to that of G1I

$10$, the mode is similar to that of G1I![]() $5$, yet the density of occurrences in the range of

$5$, yet the density of occurrences in the range of ![]() $0.2D$ to

$0.2D$ to ![]() $0.4D$ is larger in the first plane. However, in the planes further downstream the mode is increased if the helix is applied. Overall, we observe that the influence of the helix approach is stronger at lower turbulence intensities. This is in line with other studies, which have found a reduced effect of wake-steering approaches at high turbulence intensities (Kheirabadi & Nagamune Reference Kheirabadi and Nagamune2019). Wake meandering is dominated by ambient turbulent structures larger than the rotor diameter (Larsen et al. Reference Larsen, Madsen, Thomsen and Larsen2008; España et al. Reference España, Aubrun, Loyer and Devinant2011). Therefore, the wake meandering, that is, the spread of the distribution, should increase with an increase in turbulence length scale, shown in figure 5(g–i). Indeed we find that the distribution has a significantly higher spread in all three planes, with and without the helix approach. Nevertheless, the helix approach shifts the mode of the distribution to the right. Thus, the density of samples with a low wake centre distance is decreased. Therefore, we can deduce that the helix approach is still able to deflect the wake centre effectively. It should be noted that with stronger turbulence intensity, the identification of the wake centre tends to become more difficult (Doubrawa et al. Reference Doubrawa2020). Yet, since the results of the cases without the helix match the expectations, we take our findings to be of reasonable quality.

$0.4D$ is larger in the first plane. However, in the planes further downstream the mode is increased if the helix is applied. Overall, we observe that the influence of the helix approach is stronger at lower turbulence intensities. This is in line with other studies, which have found a reduced effect of wake-steering approaches at high turbulence intensities (Kheirabadi & Nagamune Reference Kheirabadi and Nagamune2019). Wake meandering is dominated by ambient turbulent structures larger than the rotor diameter (Larsen et al. Reference Larsen, Madsen, Thomsen and Larsen2008; España et al. Reference España, Aubrun, Loyer and Devinant2011). Therefore, the wake meandering, that is, the spread of the distribution, should increase with an increase in turbulence length scale, shown in figure 5(g–i). Indeed we find that the distribution has a significantly higher spread in all three planes, with and without the helix approach. Nevertheless, the helix approach shifts the mode of the distribution to the right. Thus, the density of samples with a low wake centre distance is decreased. Therefore, we can deduce that the helix approach is still able to deflect the wake centre effectively. It should be noted that with stronger turbulence intensity, the identification of the wake centre tends to become more difficult (Doubrawa et al. Reference Doubrawa2020). Yet, since the results of the cases without the helix match the expectations, we take our findings to be of reasonable quality.

Figure 5. Distributions of wake centre distance at cross-stream planes ![]() $3D$ (a,d,g),

$3D$ (a,d,g), ![]() $5D$ (b,e,h) and

$5D$ (b,e,h) and ![]() $7D$ (c,f,i) downstream of the turbine. Panels (a–c), (d–f) and (g–i) show different tips speed ratios, turbulence intensities and turbulent length scales, respectively.

$7D$ (c,f,i) downstream of the turbine. Panels (a–c), (d–f) and (g–i) show different tips speed ratios, turbulence intensities and turbulent length scales, respectively.

Due to meandering, the position of the wake centre is a symmetric bivariate normal random variable. If deflection is present, the wake centre will not be zero in the mean, if we take the mean in the rotating frame of reference. Therefore, the wake centre distance ![]() $d$ should be distributed according to a Rice distribution:

$d$ should be distributed according to a Rice distribution:

where ![]() $f$ is the probability density function with two parameters

$f$ is the probability density function with two parameters ![]() $\nu$ an

$\nu$ an ![]() $\sigma$ and

$\sigma$ and ![]() ${\rm I}_0$ denotes the modified Bessel function of the first kind of order zero (Rice Reference Rice1944, Reference Rice1945). The magnitude of the meandering is characterised by

${\rm I}_0$ denotes the modified Bessel function of the first kind of order zero (Rice Reference Rice1944, Reference Rice1945). The magnitude of the meandering is characterised by ![]() $\sigma$ whereas the deflection determines

$\sigma$ whereas the deflection determines ![]() $\nu$. In the case without the helix, there is no deflection, thus

$\nu$. In the case without the helix, there is no deflection, thus ![]() $\nu =0$, in which case the Rice distribution becomes a Rayleigh distribution. If the ratio of deflection to meandering is high, the Rice distribution approximates a normal distribution, which explains the results observed for the helix cases in figure 5.

$\nu =0$, in which case the Rice distribution becomes a Rayleigh distribution. If the ratio of deflection to meandering is high, the Rice distribution approximates a normal distribution, which explains the results observed for the helix cases in figure 5.

It is also possible to estimate the parameters ![]() $\sigma$ and

$\sigma$ and ![]() $\nu$ from the computed wake centre distances. The results of such an estimation, performed according to Koay & Basser (Reference Koay and Basser2006), are shown in figure 6. Note that this method for estimating parameters has much higher accuracy than general methods for estimating parameters of distributions, but does not always converge. The method is prone to failure for very small values of

$\nu$ from the computed wake centre distances. The results of such an estimation, performed according to Koay & Basser (Reference Koay and Basser2006), are shown in figure 6. Note that this method for estimating parameters has much higher accuracy than general methods for estimating parameters of distributions, but does not always converge. The method is prone to failure for very small values of ![]() $\nu$. First, we show the meandering parameter

$\nu$. First, we show the meandering parameter ![]() $\sigma$ in figure 6(a–c). In all these cases,

$\sigma$ in figure 6(a–c). In all these cases, ![]() $\sigma$ grows with downstream distance. Overall, the cases with and without helix behave somewhat similarly, while the meandering without helix is slightly lower. The comparison of the deflection parameter

$\sigma$ grows with downstream distance. Overall, the cases with and without helix behave somewhat similarly, while the meandering without helix is slightly lower. The comparison of the deflection parameter ![]() $\nu$, however, shows a clear distinction between the helix and non-helix cases. The non-helix cases have low values for

$\nu$, however, shows a clear distinction between the helix and non-helix cases. The non-helix cases have low values for ![]() $\nu$ throughout the wake whereas the deflection in the helix cases increases with downstream distance. Finally, figure 6(g–i) compares deflection with meandering. If the helix is applied, the ratio of

$\nu$ throughout the wake whereas the deflection in the helix cases increases with downstream distance. Finally, figure 6(g–i) compares deflection with meandering. If the helix is applied, the ratio of ![]() $\nu /\sigma$ is almost constant after

$\nu /\sigma$ is almost constant after ![]() $3D$ downstream at a value around 2. Without the helix, the ratio is significantly lower and a slight decrease with distance is observable. As pointed out before, in theory, without the helix

$3D$ downstream at a value around 2. Without the helix, the ratio is significantly lower and a slight decrease with distance is observable. As pointed out before, in theory, without the helix ![]() $\nu =0$, which is not the case in our results. We attribute this offset to the difficulty of determining the wake centre correctly and the low sensitivity of the Rice distribution to changes in

$\nu =0$, which is not the case in our results. We attribute this offset to the difficulty of determining the wake centre correctly and the low sensitivity of the Rice distribution to changes in ![]() $\nu$ if

$\nu$ if ![]() $\nu$ is close to zero. Therefore, we have included complementary computations of the meandering parameter based on a Rayleigh distribution, that is, assuming that

$\nu$ is close to zero. Therefore, we have included complementary computations of the meandering parameter based on a Rayleigh distribution, that is, assuming that ![]() $\nu =0$. It is shown in figure 6(a–c). If

$\nu =0$. It is shown in figure 6(a–c). If ![]() $\nu =0$ is enforced, the meandering parameter of the wake is estimated to be very similar between helix and non-helix cases and only slightly higher if the helix is applied.

$\nu =0$ is enforced, the meandering parameter of the wake is estimated to be very similar between helix and non-helix cases and only slightly higher if the helix is applied.

Figure 6. Estimated parameters of the Rice distribution of the wake centre distances. Missing data are due to the lack of convergence of the method to estimate the parameters, which is the case for low ratios of ![]() $\nu /\sigma$. Dotted lines represent estimations of

$\nu /\sigma$. Dotted lines represent estimations of ![]() $\sigma$ based on a Rayleigh distribution.

$\sigma$ based on a Rayleigh distribution.

In conclusion, we find that the helix approach induces a significant deflection of the wake centre, which reduces the overlap of the wake with potential downstream turbines and consequently increases the kinetic energy available to the downstream turbines. We also find that the helix increases meandering in the far wake, although this effect is not very pronounced.

3.4. Spectra

In figure 7 we show the premultiplied spectra in streamwise, azimuthal and radial direction at three locations in the wake for cases G1V9 and H1V9. For the other cases, the results yield no substantial differences. The spectra are obtained at four locations in each plane, half a rotor diameter away from the centre of the plane along the ![]() $y$- and

$y$- and ![]() $z$-axis in positive and negative direction. The signals are transformed using Welch's method, with 50 segments and an overlap ratio of 0.4 (Welch Reference Welch1967). All resulting spectra from a plane are then averaged. We find that the presence of the turbine increases energy in the fluctuations across the spectrum, especially in the streamwise direction. Furthermore, we observe that the presence of the turbine leads to higher energy contained in azimuthal fluctuations at frequencies at

$z$-axis in positive and negative direction. The signals are transformed using Welch's method, with 50 segments and an overlap ratio of 0.4 (Welch Reference Welch1967). All resulting spectra from a plane are then averaged. We find that the presence of the turbine increases energy in the fluctuations across the spectrum, especially in the streamwise direction. Furthermore, we observe that the presence of the turbine leads to higher energy contained in azimuthal fluctuations at frequencies at ![]() ${St}\approx 0.7$. Other studies, such as Howard et al. (Reference Howard, Singh, Sotiropoulos and Guala2015) and Heisel, Hong & Guala (Reference Heisel, Hong and Guala2018), have found the meandering of the root vortex to fall into this frequency range. The effect is strongest in the near wake and decays further downstream. Finally, if the helix approach is used, a notable peak can be found near the helix frequency of

${St}\approx 0.7$. Other studies, such as Howard et al. (Reference Howard, Singh, Sotiropoulos and Guala2015) and Heisel, Hong & Guala (Reference Heisel, Hong and Guala2018), have found the meandering of the root vortex to fall into this frequency range. The effect is strongest in the near wake and decays further downstream. Finally, if the helix approach is used, a notable peak can be found near the helix frequency of ![]() $St=0.25$. In almost all cases it contains the most energy of all frequencies. However, in case G1V9, we can also observe a maximum of energy at that frequency in the streamwise fluctuations at

$St=0.25$. In almost all cases it contains the most energy of all frequencies. However, in case G1V9, we can also observe a maximum of energy at that frequency in the streamwise fluctuations at ![]() $x=5D$, although not as distinct as that of case H1V9. A variety of studies such as Okulov et al. (Reference Okulov, Naumov, Mikkelsen, Kabardin and Sørensen2014) and Howard et al. (Reference Howard, Singh, Sotiropoulos and Guala2015) have found a frequency in that range to be the naturally occurring frequency of wake meandering. Thus, we conjecture that the helix approach is most efficient if applied with the same frequency since it amplifies the naturally occurring instability of the wake and thus leading to a more rapid breakdown. This agrees with the observation in figure 6, where we observed slightly higher meandering if the helix is applied. The other frequencies show a slight decrease in energy. This is due to the position of the probes used to measure the spectrum. Due to the deflection of the wake, the probes are outside of the wake, thus reducing the turbulence intensity and leading to a decrease in the energy contained in the fluctuations.

$x=5D$, although not as distinct as that of case H1V9. A variety of studies such as Okulov et al. (Reference Okulov, Naumov, Mikkelsen, Kabardin and Sørensen2014) and Howard et al. (Reference Howard, Singh, Sotiropoulos and Guala2015) have found a frequency in that range to be the naturally occurring frequency of wake meandering. Thus, we conjecture that the helix approach is most efficient if applied with the same frequency since it amplifies the naturally occurring instability of the wake and thus leading to a more rapid breakdown. This agrees with the observation in figure 6, where we observed slightly higher meandering if the helix is applied. The other frequencies show a slight decrease in energy. This is due to the position of the probes used to measure the spectrum. Due to the deflection of the wake, the probes are outside of the wake, thus reducing the turbulence intensity and leading to a decrease in the energy contained in the fluctuations.

Figure 7. Premultiplied spectra of velocity fluctuations in planes ![]() $1D$,

$1D$, ![]() $3D$ and

$3D$ and ![]() $5D$ downstream of the turbine. Spectra are measured at 4 points, 1 radius up, down, left and right from the centre in the plane, and then averaged. The grey dashed line marks the frequency of the helix.

$5D$ downstream of the turbine. Spectra are measured at 4 points, 1 radius up, down, left and right from the centre in the plane, and then averaged. The grey dashed line marks the frequency of the helix.

3.5. Wake mitigation

Although § 3.3 showed that the helix approach also leads to wake steering, Frederik et al. (Reference Frederik, Doekemeijer, Mulders and van Wingerden2020) stressed the improvement in wake mixing, which is also suggested by the earlier tip-vortex breakdown observed in § 3.2. In this section, we examine the effect of wake mixing and wake steering on the mitigation of wake effects. Wake effects include a reduction in kinetic energy in the flow and increased turbulence intensity. Wake mixing leads to entrainment of kinetic energy into the wake from the surrounding flow, while wake steering reduces the overlap of the wake with a potential downstream turbine. To distinguish the effect of reduced overlap and wake mixing, we utilise a meandering frame of reference. The meandering frame of reference follows the wake. The mean flow is obtained by translating the cross-stream planes so that the wake centre determined in § 3.3 is in the centre of the plane. The resulting flow field is then averaged. Since this frame of reference can only be established a posteriori, we are limited to first-order statistics, i.e. averages.

To distinguish between the energy available due to wake mixing and due to wake deflection and meandering, we show the kinetic energy in the rotor area, ![]() $\bar {E}_{K,R}$, both in the static frame of reference and the meandering frame of reference in figure 8. By comparing G1V

$\bar {E}_{K,R}$, both in the static frame of reference and the meandering frame of reference in figure 8. By comparing G1V![]() $9$ and H1V

$9$ and H1V![]() $9$, we find that the application of the helix leads to a faster increase in kinetic energy downstream of the turbine in both frames of reference. In the static frame of reference, the flow has regained approximately 60 % of the kinetic energy of the undisturbed flow at

$9$, we find that the application of the helix leads to a faster increase in kinetic energy downstream of the turbine in both frames of reference. In the static frame of reference, the flow has regained approximately 60 % of the kinetic energy of the undisturbed flow at ![]() $x=5D$ if the helix is applied, whereas we observe only little above

$x=5D$ if the helix is applied, whereas we observe only little above ![]() $40\,\%$ in case G1V

$40\,\%$ in case G1V![]() $9$. A comparison of the kinetic energy between the two reference frames shows that a large amount of the additional kinetic energy present in the static frame of reference in case H1V

$9$. A comparison of the kinetic energy between the two reference frames shows that a large amount of the additional kinetic energy present in the static frame of reference in case H1V![]() $9$ is due to the reduced overlap due to wake meandering and deflection. In contrast, the difference between the two frames of reference is much smaller in case G1V

$9$ is due to the reduced overlap due to wake meandering and deflection. In contrast, the difference between the two frames of reference is much smaller in case G1V![]() $9$. The comparison with the cases with lower tip-speed ratio shows that the turbines extract significantly less energy from the flow, as to be expected. Interestingly, the helix approach leads to a higher extraction of energy compared with G1V

$9$. The comparison with the cases with lower tip-speed ratio shows that the turbines extract significantly less energy from the flow, as to be expected. Interestingly, the helix approach leads to a higher extraction of energy compared with G1V![]() $13$. Yet, due to increased entrainment of energy, the rotor disk contains more energy at

$13$. Yet, due to increased entrainment of energy, the rotor disk contains more energy at ![]() $x=3D$, if the helix is applied. We can also see that the increased mixing does not have so much of an effect in the region up to

$x=3D$, if the helix is applied. We can also see that the increased mixing does not have so much of an effect in the region up to ![]() $x=5D$. Since the difference between the two frames of reference is negligible in case G1V

$x=5D$. Since the difference between the two frames of reference is negligible in case G1V![]() $13$, we conclude that the reduced overlap has little to no effect in the case without the helix. However, in H1V

$13$, we conclude that the reduced overlap has little to no effect in the case without the helix. However, in H1V![]() $13$ we consistently find a difference between the two frames of reference. Since we know from figure 6, that the meandering is virtually the same in G1V

$13$ we consistently find a difference between the two frames of reference. Since we know from figure 6, that the meandering is virtually the same in G1V![]() $13$ and H1V

$13$ and H1V![]() $13$, this difference in the cases must stem from the deflection of the wake. In figure 8(b) we observe stronger increases in kinetic energy in the region

$13$, this difference in the cases must stem from the deflection of the wake. In figure 8(b) we observe stronger increases in kinetic energy in the region ![]() $2D$ to

$2D$ to ![]() $4D$ downstream of the turbine in cases G1I

$4D$ downstream of the turbine in cases G1I![]() $10$ and H1I

$10$ and H1I![]() $10$ compared with the respective baseline cases. In addition, the helix approach leads to more kinetic energy due to the reduced overlap in the static frame of reference. However, with higher ambient turbulence, the wake is not deflected as much. Therefore, the flow in case H1I

$10$ compared with the respective baseline cases. In addition, the helix approach leads to more kinetic energy due to the reduced overlap in the static frame of reference. However, with higher ambient turbulence, the wake is not deflected as much. Therefore, the flow in case H1I![]() $5$ contains more kinetic energy in the rotor area far downstream. The two effects balance each other at around

$5$ contains more kinetic energy in the rotor area far downstream. The two effects balance each other at around ![]() $x=6D$. Finally, we examine the influence of the length scale of turbulence in figure 8(c). We can also observe more available kinetic energy in the region between

$x=6D$. Finally, we examine the influence of the length scale of turbulence in figure 8(c). We can also observe more available kinetic energy in the region between ![]() $x=2D$ and

$x=2D$ and ![]() $x=5D$. However, in comparison with H1I

$x=5D$. However, in comparison with H1I![]() $10$, the helix approach is able to deflect the wake better, as was also shown in figure 6, and thus increases the amount of kinetic energy in the rotor area in the static frame of reference even more than in case H1L

$10$, the helix approach is able to deflect the wake better, as was also shown in figure 6, and thus increases the amount of kinetic energy in the rotor area in the static frame of reference even more than in case H1L![]() $40$.

$40$.

Figure 8. Kinetic energy of the mean flow in the rotor area at cross-stream planes with a distance of ![]() $1D$. Lines marked with crosses indicate averaging in the meandering frame of reference while the lines marked with a plus sign represent energy averaged in the static frame of reference.

$1D$. Lines marked with crosses indicate averaging in the meandering frame of reference while the lines marked with a plus sign represent energy averaged in the static frame of reference.

To gain a more thorough understanding of the wake recovery process the energy transport is analysed in the following. Based on the Reynolds-averaged momentum equation of an inviscid fluid (see, e.g., Stull Reference Stull1988, p. 90),

a transport equation for the kinetic energy of the mean flow, ![]() $\overline {E_K} = \tfrac {1}{2}\bar {u}_i^2$ can be derived by multiplying each component with the respective mean velocity and summing over all three equations, as used in Hamilton et al. (Reference Hamilton, Suk Kang, Meneveau and Bayoán Cal2012) and Lignarolo et al. (Reference Lignarolo, Ragni, Ferreira and van Bussel2014):

$\overline {E_K} = \tfrac {1}{2}\bar {u}_i^2$ can be derived by multiplying each component with the respective mean velocity and summing over all three equations, as used in Hamilton et al. (Reference Hamilton, Suk Kang, Meneveau and Bayoán Cal2012) and Lignarolo et al. (Reference Lignarolo, Ragni, Ferreira and van Bussel2014):

The first term of the right-hand side corresponds to a source or sink of ![]() $\overline {E_K}$ due to a pressure gradient, the second term corresponds to the conversion of kinetic energy to turbulent kinetic energy and the last term corresponds to the turbulent flux of kinetic energy. Since the problem is axisymmetric, a cylindrical coordinate system can offer some simplifications. In a cylindrical coordinate system, the kinetic energy is transported towards the wake centre by the term

$\overline {E_K}$ due to a pressure gradient, the second term corresponds to the conversion of kinetic energy to turbulent kinetic energy and the last term corresponds to the turbulent flux of kinetic energy. Since the problem is axisymmetric, a cylindrical coordinate system can offer some simplifications. In a cylindrical coordinate system, the kinetic energy is transported towards the wake centre by the term ![]() $-({\partial }/{\partial r})[\bar {u}_i\overline {u_i'u_r'}]$. Among others, Cal et al. (Reference Cal, Lebrón, Castillo, Kang and Meneveau2010) showed that this transport dominates the wake recovery, which was confirmed in preliminary examinations conducted for this study. The total transport of kinetic energy to the wake via radial turbulent transport,

$-({\partial }/{\partial r})[\bar {u}_i\overline {u_i'u_r'}]$. Among others, Cal et al. (Reference Cal, Lebrón, Castillo, Kang and Meneveau2010) showed that this transport dominates the wake recovery, which was confirmed in preliminary examinations conducted for this study. The total transport of kinetic energy to the wake via radial turbulent transport, ![]() $\varepsilon (x)$, is given by

$\varepsilon (x)$, is given by

where the rotor-swept area ![]() $A_{R}={\rm \pi} D^2/4$. The effect of the helix approach on

$A_{R}={\rm \pi} D^2/4$. The effect of the helix approach on ![]() $\varepsilon (x)$ is shown in figure 9. The entrainment is calculated in a vertical plane in the centre of the rotor plane. The results are normalised with the mean kinetic energy per rotor area of the undisturbed flow,

$\varepsilon (x)$ is shown in figure 9. The entrainment is calculated in a vertical plane in the centre of the rotor plane. The results are normalised with the mean kinetic energy per rotor area of the undisturbed flow, ![]() $E_{K,u}=1/2\,V_{0}^2 A_{R}$ multiplied with the inflow velocity. In the case G1V

$E_{K,u}=1/2\,V_{0}^2 A_{R}$ multiplied with the inflow velocity. In the case G1V![]() $9$ we find that little to no energy is entrained in the area of the near wake, as was to be expected due to the presence of the tip vortices. However, with the onset of the transition and more pronounced wake meandering more energy is entrained. The figure also shows clearly that the total transport increases earlier and faster if the helix approach is applied. The cases G1V13 and H1V13 show much lower entrainment compared with the baseline cases. However, as before, the application of the helix approach leads to an increase in

$9$ we find that little to no energy is entrained in the area of the near wake, as was to be expected due to the presence of the tip vortices. However, with the onset of the transition and more pronounced wake meandering more energy is entrained. The figure also shows clearly that the total transport increases earlier and faster if the helix approach is applied. The cases G1V13 and H1V13 show much lower entrainment compared with the baseline cases. However, as before, the application of the helix approach leads to an increase in ![]() $\varepsilon$. In figure 9(b) we can observe the influence of an increase in turbulence intensity. Generally, the entrainment is notably higher. Yet, the relative increase in entrainment due to the helix approach is smaller when compared with the lower ambient turbulence intensity. A similar observation can be made in figure 9(c), which shows the influence of the turbulence length scale. Entrainment increases even more compared with G1L

$\varepsilon$. In figure 9(b) we can observe the influence of an increase in turbulence intensity. Generally, the entrainment is notably higher. Yet, the relative increase in entrainment due to the helix approach is smaller when compared with the lower ambient turbulence intensity. A similar observation can be made in figure 9(c), which shows the influence of the turbulence length scale. Entrainment increases even more compared with G1L![]() $40$. However, the helix approach also improves entrainment more than in case H1I

$40$. However, the helix approach also improves entrainment more than in case H1I![]() $10$. Similarly to H1I

$10$. Similarly to H1I![]() $10$, the helix approach mostly improves entrainment in the region of

$10$, the helix approach mostly improves entrainment in the region of ![]() $1D$ to