No CrossRef data available.

Published online by Cambridge University Press: 29 April 2024

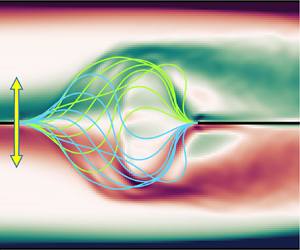

This study presents a dual-channel vortex generator (VG) that leverages the snap-through behaviour of flexible sheets. The VG outperforms a similar-sized rigid VG in generating vortices within dual-channel flows while minimizing pressure loss. Numerical simulations using the immersed boundary-lattice Boltzmann method analyse the dynamics and vortex generation performance of the sheet under various system parameters. Two distinct modes are identified for the elastic sheet: a sustained snap-through mode (SSTM) and a dormant mode (DM). The sheet's mode is predominantly influenced by its length ratio (L*), bending stiffness  $(K_b^\ast )$ and flow strength, with the mass ratio having a minimal impact. The sheet exhibiting regular SSTM can effectively generate vortices in both channels and the vortex generation performance can be conveniently tuned by altering the sheet's initial buckling (i.e. L*). An increase in

$(K_b^\ast )$ and flow strength, with the mass ratio having a minimal impact. The sheet exhibiting regular SSTM can effectively generate vortices in both channels and the vortex generation performance can be conveniently tuned by altering the sheet's initial buckling (i.e. L*). An increase in  $K_b^\ast $ results in a higher critical Reynolds number (Rec) required for mode transition. An increase in L*, however, initially raises Rec and then lowers it, suggesting an optimal length ratio (approximately 0.7 for our considered system) for minimizing the Rec necessary to trigger SSTM. Furthermore, a disparity in the flow strength between channels is found to suppress the snap-through of the sheet; a greater disparity, however, is permissible to induce the SSTM of more compliant sheets. These findings underscore the potential of snap-through behaviour for enhanced flow manipulation in dual-channel systems.

$K_b^\ast $ results in a higher critical Reynolds number (Rec) required for mode transition. An increase in L*, however, initially raises Rec and then lowers it, suggesting an optimal length ratio (approximately 0.7 for our considered system) for minimizing the Rec necessary to trigger SSTM. Furthermore, a disparity in the flow strength between channels is found to suppress the snap-through of the sheet; a greater disparity, however, is permissible to induce the SSTM of more compliant sheets. These findings underscore the potential of snap-through behaviour for enhanced flow manipulation in dual-channel systems.