Article contents

Bridging-droplet transfer from solid to porous surfaces

Published online by Cambridge University Press: 29 September 2022

Abstract

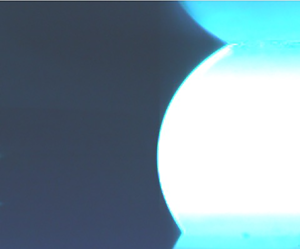

When the top of a sessile droplet is contacted by an opposing solid surface, the droplet can transfer depending on the wettabilities and relative velocity of the surfaces. What if the surface receiving the liquid was porous? High-speed imaging was used to capture the transfer of a droplet from a solid substrate to an opposing porous surface. The parameters that were varied include the wettability of the donor substrate, the pore size of the receiving surface and the droplet's volume and working fluid. Generally, the transfer process is split into two sequential regimes, wetting and wicking, with wicking being three orders of magnitude longer than wetting on average. The wetting regime is split into two sub-regimes, the donor-independent and donor-dependent regimes. The donor-independent regime follows the dynamics of droplet coalescence, starting in a mass-limited viscous regime followed by a capillary–inertial regime. The donor-dependent regime is driven by a global change in Laplace pressure across the liquid bridge, with the viscous wedge of the receding contact line being the rate-limiting factor. The wicking regime is governed by Darcy's law, completing the transfer process of the droplet.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press

References

Murphy and Boreyko Supplementary Movie 1

Bridging-droplet transfer corresponding to Fig. 2. The videos capture both the wetting and wicking regimes. Donor wettability is varied. Small flakes can be seen falling from the porous surface which we suspect to be microscopic pieces of the ceramic dislodged by the wetting process.

Murphy and Boreyko Supplementary Movie 2

Bridging-droplet transfer corresponding to Fig. 2. These videos focus on the wetting regime, using a higher frame rate which necessitates a lower exposure and therefore darker videos.

Murphy and Boreyko Supplementary Movie 3

Bridging-droplet transfer corresponding to Fig. 3, for varying working fluid, volume, and pore radius. The videos capture both the wetting and wicking regimes.

Murphy and Boreyko Supplementary Movie 4

Bridging-droplet transfer corresponding to Fig. 3. These videos focus on the wetting regime, using a higher frame rate which necessitates a lower exposure and therefore darker videos. We do not show the video corresponding to Fig. 3d, as varying the pore radius does not appreciably affect the wetting regime by itself.

- 5

- Cited by