Article contents

Modelling silo clogging with non-local granular rheology

Published online by Cambridge University Press: 06 April 2022

Abstract

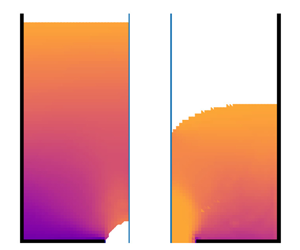

Granular flow in a silo demonstrates multiple non-local rheological phenomena due to the finite size of grains. We solve the non-local granular fluidity continuum model in quasi-two-dimensional silo geometries and evaluate its ability to predict these non-local effects, including flow spreading and, importantly, clogging (arrest) when the opening is small enough. The model is augmented to include a free-separation criterion and is implemented numerically with an extension of the trans-phase granular flow solver described in Dunatunga & Kamrin (J. Fluid Mech., vol. 779, 2015, pp. 483–513), to produce full-field solutions. The implementation is validated against analytical results of the model in the inclined chute geometry, such as the solution for the critical thickness for flow arrest, and the velocity profile as a function of layer height. We then implement the model in the silo geometry and vary the apparent grain size. The model predicts a clogging criterion when the opening competes with the scale of the mean grain size, which agrees with previous experimental studies. For larger openings, the flow within the silo obtains a diffusive characteristic whose spread depends on the model's non-local amplitude and the mean grain size. The numerical tests are controlled for grid effects and a comparison study of coarse vs refined numerical simulations shows agreement in the pressure field, the shape of the arch in a clogged silo configuration and the velocity field in a flowing configuration.

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press

References

REFERENCES

- 14

- Cited by