Article contents

Mechanisms of inkjet printing in a liquid environment

Published online by Cambridge University Press: 14 September 2022

Abstract

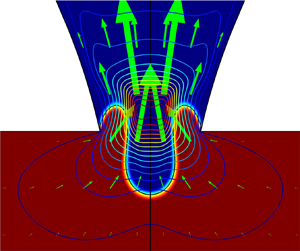

Inkjet printing, originally invented for text and pattern printing, is now central to many industrial applications, such as printed electronics, flexible electronics, 3-D printing of mechanical and even biological devices. However, constrained by the droplets’ ejection mechanism, the accuracy of traditional inkjet printing is limited by the size of its orifice, and it is difficult to achieve a volume of droplets at the femtolitre scale, which hinders its further application in the above fields. To this end, we propose the confined interface vibration inkjet printing (CIVIJP) technique, which is capable of printing patterns in a liquid environment with droplet size much smaller than the orifice from which they are dispensed. Here, further systematic study of the mechanism of printing in a liquid environment was carried out with the assistance of a high-speed imaging technique. It is found for the first time that a single pulse stimulation applied on the piezo-ceramic of the inkjet nozzle can trigger damping oscillations of the oil/water interface confined by the orifice, which can last more than 500  $\mathrm {\mu }$s. By adjusting the intensity of single pulse stimulation, the size and quantity of the dispensed droplets can be controlled in a wide range, which is obviously different from traditional droplet ejection in a gaseous environment. This work reveals the underlying physics between the pulse stimulation and the interface behaviours, as well as the physics between the interface behaviours and the size and number of dispensed droplets, enriching the fundamental theory of the inkjet printing in liquid phase.

$\mathrm {\mu }$s. By adjusting the intensity of single pulse stimulation, the size and quantity of the dispensed droplets can be controlled in a wide range, which is obviously different from traditional droplet ejection in a gaseous environment. This work reveals the underlying physics between the pulse stimulation and the interface behaviours, as well as the physics between the interface behaviours and the size and number of dispensed droplets, enriching the fundamental theory of the inkjet printing in liquid phase.

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2022. Published by Cambridge University Press

References

- 9

- Cited by