Article contents

Granular internal dynamics in a silo discharged with a conveyor belt

Published online by Cambridge University Press: 26 August 2021

Abstract

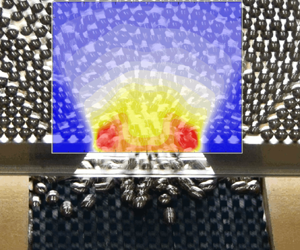

The dynamics of granular media within a silo in which the grain velocities are controlled by a conveyor belt has been experimentally investigated. To this end, the building of coarse-grained field maps of different magnitudes has allowed a deep analysis of the flow properties as a function of two parameters: the orifice size and the belt velocity. First, the internal dynamics of the particles within the silo has been fully characterized by the solid fraction, the velocity of the particles and the kinetic stress. Then, the analysis of the vertical profiles of the same magnitude (plus the acceleration) has allowed connection of the internal dynamics with the flow rate. In particular, we show that the gamma parameter – which accounts for the integration of the normalized acceleration along the vertical direction – can successfully discriminate the kind of flow established within the silo (from the quasistatic regime to the free discharge) depending on the outlet size and belt velocity.

JFM classification

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2021. Published by Cambridge University Press

References

REFERENCES

- 4

- Cited by