No CrossRef data available.

Published online by Cambridge University Press: 29 July 2024

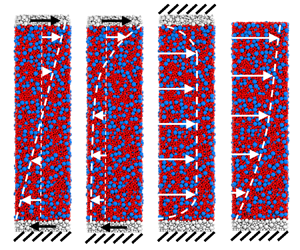

Particle segregation in dense flowing size-disperse granular mixtures is driven by gravity and shear, but predicting the associated segregation force due to both effects has remained an unresolved challenge. Here, a model of the combined gravity- and kinematics-induced segregation force on a single intruder particle is integrated with a model of the concentration dependence of the gravity-induced segregation force. The result is a general model of the net particle segregation force in flowing size-bidisperse granular mixtures. Using discrete element method simulations for comparison, the model correctly predicts the segregation force for a variety of mixture concentrations and flow conditions in both idealized and natural shear flows.