Introduction

Welfare is a multidimensional concept: it embraces the absence of suffering, high levels of biological functioning, absence of disease and potential for animals to have positive experiences (Fraser, Reference Fraser1993). Animal wellbeing has become a top priority for citizens in wealth countries, leading the development of assessment methods and the subsequent certification schemes.

Animal welfare assessment methods have evolved over the last decades. At the beginning, single measures were proposed to provide a broad assessment of animal welfare, such as corticosteroids (Barnett and Hemsworth, Reference Barnett and Hemsworth1990) or longevity (Geers et al., Reference Geers, Petersen, Huysmans, Knura-Deszczka, De Becker, Gymnich, Henot, Hiss and Sauerwein2003). However, none of these single measures attempts to cover all the dimensions of welfare. Consequently, several methods were proposed to make an overall assessment combining the results obtained from individual welfare measures. They ranged from informal aggregation by experts to the use of weighted sums of scores obtained for each measure. Botreau et al. (Reference Botreau, Bonde, Butterworth, Perny, Bracke, Capdeville and Veissier2007a) published a review of nine of these overall assessment methods, highlighting their strengths and weaknesses.

Welfare Quality® was an EU FP6 project that proposed a sequential aggregation of welfare measures, first from measures to welfare criteria (corresponding to dimensions with pre-set objectives) and then to an overall welfare assessment, using rules determined at each level depending on the nature and number of variables to be considered and the level of compensation to be permitted (Botreau et al., Reference Botreau, Bracke, Perny, Butterworth, Capdeville, Van Reenen and Veissier2007b). The Welfare Quality® protocol has been adopted as a standard and is being used both in commercial farms and with research purposes (Franchi et al., Reference Franchi, Garcia and da Silva2014; Molina et al., Reference Molina, Agüera, Maroto-Molina and Pérez-Marín2019). However, the protocol has also been criticised, since it is time consuming and costly. Even those researchers involved in the development of Welfare Quality® protocols have recommended the development of automatic measures of welfare to reduce the duration of the assessment while still retaining its holistic nature (Blokhuis et al., Reference Blokhuis, Veissier, Miele and Jones2010). De Vries et al. (Reference de Vries, Engel, den Uijl, van Schaik, Dijkstra, de Boer and Bokkers2013) also criticised that a small number of individual measures have a major impact on the classification and may thus lead efforts to improve classification rather than actual animal wellbeing. Furthermore, the approach does not provide the farmer with a toolbox for the ongoing assessment of cow wellbeing (Caja et al., Reference Caja, Castro-Costa and Knight2016) and punctual evaluations may not be representative of welfare status: those measures related to cow dirtiness can be strongly influenced by weather conditions, for instance.

Several papers on animal welfare and PLF technologies have been published in the last years. For example, based upon DairyCare (COST Action FA1308) results, Caja et al. (Reference Caja, Castro-Costa and Knight2016) published an extensive review about existing PLF solutions to support wellbeing of dairy animals. That review and this paper start from a similar premise, but we specifically address Welfare Quality® measures, as this protocol is currently being used by commercial farms to be certified as welfare friendly. On the other hand, we did not limit our considerations to available PLF solutions, considering some technologies under development and to be developed.

Therefore, the main objective of this paper is to discuss the potential use of precision livestock farming (PLF) technologies to assess the measures included in Welfare Quality® protocol for dairy cattle, providing objective and continuous data about animal welfare.

To what extent would a sensor-based Welfare Quality® assessment be possible?

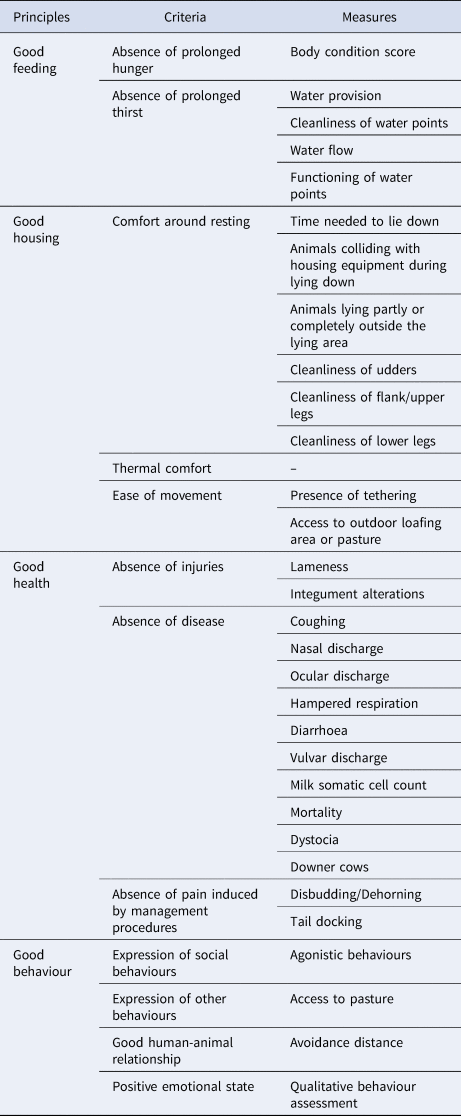

As shown in Table 1, the Welfare Quality® protocol for dairy cattle established four principles, 12 criteria and 31 measures (Welfare Quality®, 2009). The main technologies able, currently or potentially, to assess each of those measures are identified and discussed now.

Table 1. Principles, criteria and measures of Welfare Quality® protocol for dairy cows

Good feeding

This principle includes two criteria: absence of prolonged hunger and absence of prolonged thirst. The first one is measured as body condition score (BCS). According to Welfare Quality®, cows are scored 0, if they have a regular BCS, 1 if they are very lean and 2 if they are very fat (the last two mean that the cows obtained such score in at least three different body regions). This is less precise that what commercially available technologies can provide. DeLaval BCS camera (Krukowski, Reference Krukowski2009), based on 3D imaging, includes proprietary algorithms to assign a 5-point scale score in increments of 0.1 points. Rachah et al. (Reference Rachah, Reksen, Jansen and Lovendahl2018) presented an evaluation of this camera, which showed some errors, but of minor importance for the precision needed for Welfare Quality® assessment. Weighing scales, both walkover systems (Dickinson et al., Reference Dickinson, Morton, Beggs, Anderson, Pyman, Mansell and Blackwood2013) and those incorporated in milking robots would be another option to evaluate the absence of prolonged hunger.

The absence of prolonged hunger could also be evaluated through the monitoring of feed intake and feeding behaviour. However, these indicators are not easy to measure for individual cows, especially in grazing systems. Some technologies based on trough scales (Halachmi et al., Reference Halachmi, Edan, Maltz, Peiper, Moallem and Brukental1998), pressure sensors (Leiber et al., Reference Leiber, Holinger, Zehner, Dorn, Probst and Neff2016) or accelerometers (Oudshoorn et al., Reference Oudshoorn, Cornou, Hellwing, Hansen, Munksgaard, Lund and Kristensen2013) exist, but they are still mostly used at research level.

The absence of prolonged thirst is assessed through four indicators: number (or length) of water points, cleanliness of water points, water flow and functioning of water points. All these measures aim to assure a sufficient and accessible water supply to animals. From a PLF perspective, monitoring the number and status of water points has no relevance, as it is possible to actually measure water consumption of every cow. A combination of Radio Frequency Identification (RFID) and flowmeters could provide these data (Cardot et al., Reference Cardot, Le Roux and Jurjanz2008). Reticular boluses equipped with temperature-measuring electronics could also be used to monitor water intake, as rumen temperature decreases after every drinking bout. However, the magnitude of rumen temperature drop is correlated to water temperature (Bewley et al., Reference Bewley, Grott, Einstein and Schutz2008), so this type of monitoring system would require the integration of data from weather stations or thermometers in water troughs. As regards water quality, there are turbidity sensors able to measure water cleanliness, but it could be assumed to be adequate if water intake is normal.

Both feed and water intake could also be estimated from the position of the cow inside the barn: when the cow was located at the feeding line, eating behaviour would be assumed. These data could be gathered by radio-based location solutions, such as CowView, commercialised by GEA (Germany).

Good housing

This principle includes three criteria: comfort around resting, thermal comfort and ease of movement. The first criterion is measured as time needed to lie down, animals colliding with housing equipment during lying down, number of animals lying partly or completely outside the lying area, and cleanliness of different body parts (udders, flank/upper legs and lower legs). Several sensors have been used for monitoring lying behaviour, such as pedometers (Mattachini et al., Reference Mattachini, Antler, Riva, Arbel and Provolo2013) or accelerometers (Darr and Epperson, Reference Darr and Epperson2009). These solutions can provide data on lying time and lying bouts, but Welfare Quality® protocol requires a more detailed information. No references to sensor systems enabling the measurement of time needed to lie down, collisions with equipment or cow positioning in the resting area were found. However, there are some computer vision-based systems aimed at detecting cows at cubicles (Porto et al., Reference Porto, Arcidiacono, Anguzza and Cascone2013) or monitoring cow posture (Cangar et al., Reference Cangar, Leroy, Guarino, Vranken, Fallon, Lenehan, Mee and Berckmans2008), which could be used for these purposes. Regarding cow dirtiness, no automatic monitoring systems were found in the literature, but image analysis systems could be used for that. For example, there are some technologies developed to monitor faeces in carcasses (Windham et al., Reference Windham, Lawrence, Park and Buhr2003; Seo et al., Reference Seo, Lee, Mo, Kim, Baek, Lee and Cho2019), which could be adapted to evaluate cow dirtiness.

No measures have been defined for the second Welfare Quality® criterion, thermal comfort. However, this measure can be easily automatised. The use of weather stations to calculate temperature humidity index (THI) has been available for a long time; they are used by commercial farms. Furthermore, heat stress can be indirectly detected through cow activity monitoring systems (Abeni and Galli, Reference Abeni and Galli2017) or reticular boluses (Bewley and Schutz, Reference Bewley and Schutz2010). Ji et al. (Reference Ji, Banhazi, Wang and Li2017) analysed the possibilities of PLF technologies for heat stress management.

Ease of movement is measured as presence of tethering and access to an outdoor loafing area or pasture. These measures could be substituted by, respectively, indoor and outdoor location monitoring systems. Indoor location systems are generally based on RFID (CowView), Bluetooth (Tøgersen et al., Reference Tøgersen, Skjøth, Munksgaard and Højsgaard2010) or Ultrawideband (Pastell et al., Reference Pastell, Frondelius, Jarvinen and Backman2018), although image processing can be used for this purpose too (Dao et al., Reference Dao, Le, Harle, Murray, Tachtatzis, Marshall, Michie and Andonovic2015). For outdoor tracking, GPS would be the preferred option (Turner et al., Reference Turner, Udal, Larson and Shearer2000). It could even be possible to distinguish between outdoor loafing areas and pasture by using satellite imagery (Viña et al., Reference Viña, Henebry and Gitelson2004).

Good health

There are three criteria for good health principle: absence of injuries, absence of disease and absence of pain induced by management procedures. Absence of injuries is measured through lameness and integument alterations. Lameness is one of the topics most extensively addressed by PLF developers, as it is among the top three most expensive health disorders in dairy cows (Thorup, Reference Thorup2015). Accelerometers (Thorup et al., Reference Thorup, Munksgaard, Robert, Erhard, Thomsen and Friggens2015), pressure mats (Van De Gucht et al., Reference Van De Gucht, Saeys, Van Weyenberg, Lauwers, Mertens, Vandaele, Vangeyte and Van Nuffel2017) or image analysis (Poursaberi et al., Reference Poursaberi, Bahr, Pluk, Van Nuffel and Berckmans2010) have been used to detect lame cows. Multi-sensor systems, based on milk, activity and posture monitoring, have also been tested, showing good precision (Van Hertem, Reference Van Hertem2015). Welfare Quality® only requires discriminating among not lame, lame and severely lame cows. Sensor systems have a higher resolution, as they normally use a 5-point scale. Sensor systems for detecting integument alterations have not been found in literature. Nevertheless, there are some computer-vision systems able to detect skin problems in humans (Wei et al., Reference Wei, Gan and Ji2018), which could be adapted to animals.

Disease detection has been a major target of PLF systems. Welfare Quality® measures for the absence of disease are numerous: coughing, nasal discharge, ocular discharge, hampered respiration, diarrhoea, vulvar discharge, milk somatic cell count, mortality, dystocia and downer cows. Coughing, nasal discharge, ocular discharge and hampered respiration can be indicators of respiratory disease. Sound analysis has been used to monitor coughs associated to bovine respiratory disease (Vandermeulen et al., Reference Vandermeulen, Bahr, Johnston, Earley, Tullo, Fontana, Guarino, Exadaktylos and Berckmans2016). Image analysis techniques have also been tested in pigs with respiratory problems (Chen et al., Reference Chen, Huang, Hou, Huo and Jin2013). Nevertheless, these alterations could also be detected without specific sensor systems, for instance by integrating body temperature sensors to feed and water intake monitoring systems.

No automatic systems for monitoring diarrhoea problems were identified but, once again, image-based solutions are proposed as an alternative to address this problem. Vulvar discharge is associated with reproductive pathologies or could be due to fever or irregular heat duration. Electronic noses have been used to analyse vaginal discharge in dairy cows (Burfeind et al., Reference Burfeind, Bruins, Bos, Sannmann, Voigtsberger and Heuwieser2014), but these devices cannot be considered as PLF solutions, as they do not allow the automatic monitoring of animals. For humans, wearable biosensors for monitoring pH and lactic acid of vaginal discharge able to detect reproductive problems are under development (Almeida and Tomasello, Reference Almeida and Tomasello2019). This type of solutions seems to be too sophisticated for dairy farms, where oestrus monitoring could be sufficient to detect reproductive problems. Mottram (Reference Mottram2016) reviewed the diverse technologies used for oestrus detection.

Milk somatic cell count can be monitored by near infrared spectroscopy (NIRS), even for the individual cow by incorporating this technology into milking robots (Kawasaki et al., Reference Kawasaki, Kawamura, Tsukahara, Morita, Komiya and Natsuga2008). Mortality, dystocia and downer cows are Welfare Quality® measures based on farmer records. From a PLF perspective, sensor systems should serve to prevent mortality, dystocia and downer cows. For example, regarding dystocia, there are several systems focused on calving prediction in order to assist cows when needed (Borchers et al., Reference Borchers, Chang, Proudfoot, Wadsworth, Stone and Bewley2017).

The third criteria of the good health principle, absence of pain, includes the assessment of disbudding/dehorning and tail docking procedures. Sensor systems cannot provide these specific measures, but they can be used for monitoring pain. Prunier et al. (Reference Prunier, Mounier, Le Neindre, Leterrier, Mormède, Paulmier, Prunet, Terlouw and Guatteo2013) reviewed pain indicators in farm animals, and some of them could be automatically monitored. In this regard, facial expression measurement is a promising research topic (Descovich et al., Reference Descovich, Wathan, Leach, Buchanan-Smith, Flecknell, Farningham and Vick2017).

Appropriate behaviour

This principle includes four criteria: expression of social behaviours, expression of other behaviours, good human-animal relationship and positive emotional state. Expression of social behaviour is assessed by observing agonistic behaviours, such as displacement, chasing or fighting. Although social behaviour has not been a priority topic for PLF researchers, some developments can be found in literature. Guzhva et al. (Reference Guzhva, Ardö, Herlin, Nilsson, Åström and Bergsten2016) used top-view cameras in the waiting area of automated milking systems, together with machine learning algorithms, to automatically detect social interactions (head pressing and body pushing). Moreover, proximity loggers and location solutions have been used to characterise social network structure of dairy herds, detecting positive social behaviours such as grooming (Boyland et al., Reference Boyland, Mlynski, James, Brent and Croft2016).

Welfare Quality® measure for a good human-animal relationship is avoidance distance, that is to say, the size of the animals' front flight zone. Johansson et al. (Reference Johansson, Blokhuis, Berckmans and Butterworth2015) used video imaging technology to assess this measure in bird flocks. They hypothesise that the time it takes for the animals to return to their normal activity and distribution levels after being disturbed by human presence, would reflect the fear of humans. To our knowledge, PLF solutions to assess avoidance distance at individual level are not available, but sensor networks based on Bluetooth or other radio-based technologies (Maroto-Molina et al., Reference Maroto-Molina, Navarro-García, Príncipe-Aguirre, Gómez Maqueda, Guerrero-Ginel, Garrido-Varo and Pérez-Marín2019) could be used for this purpose. Another approach is the fear-related response monitorisation. Stewart et al. (Reference Stewart, Schaefer, Haley, Colyn, Cook, Stafford and Webster2008) used infrared thermography to detect these responses during cattle handling.

The last criterion of Welfare Quality® protocol for dairy cows is the positive emotional state, which is characterised through a qualitative behaviour assessment. Facial expressions, especially ear posture and eye white, have been used to monitor cow emotional state (Battini et al., Reference Battini, Agostini and Mattiello2019). These indicators can be monitored through image and video analysis. Sound analysis can also be used to monitor animal emotional state (Manteuffel et al., Reference Manteuffel, Puppe and Schön2004).

Designing the future

As reviewed in this Research Reflection, existing precision livestock farming technologies could assess most of Welfare Quality® measures. Moreover, new technologies are expected to be available in upcoming years. However, some measures are inappropriate for sensing technologies and they could be substituted by other measures assessing the same welfare criteria.

A sensor-based assessment of dairy cow welfare could provide objective and continuous data, overcoming some of the drawbacks of current assessment methods. However, when designing these future assessment systems, it should be considered that one of the main drivers of welfare assessment is the increasing societal concern about the treatment of dairy cows in modern farms. It seems reasonable to assume that an excessive artificialisation of production systems, due to the use of many different sensors, will be perceived as negative for animal welfare (Veissier et al., Reference Veissier, Kling-Eveillard, Mialon, Silberberg, De Boyer, Terlouw, Ledoux, Meunier and Hostiou2019). This assumption could be especially true for animal-mounted sensors. Taking this into account, research efforts should concentrate on multi-purpose precision technologies, which could reduce the number of sensor systems needed for an overall assessment of animal welfare. Furthermore, sensors that are less invasive and disruptive for the animal should also be prioritised. Image and video processing technologies, including visible, infrared and thermal imaging, meet both requirements. Nevertheless, they have large computational requirements and they are often not as accurate and precise as alternative technologies at the level of individual animal monitoring.

The development of 5G networks and artificial intelligence in the next years will help to overcome these problems, boosting the possibilities of researchers and developers within this topic. Non-technological issues should also be considered while developing image based PLF solutions. Recording images of farm animals may involve registering images of farmers as well, which directly affects their privacy. In this sense, close-view solutions, such as cameras placed at feeding lines or water troughs, would be preferred to broad-view solutions recording images or videos of large areas.

Accelerometry is another research area that has been intensively addressed by PLF researchers. Accelerometers are multi-purpose sensors, as they can be used to assess several Welfare Quality® criteria. However, they must be attached to cows. The need for batteries ‘in direct contact’ with animals, could be one of the major concerns regarding animal welfare. Collar-mounted accelerometers could be perceived as less invasive for the animal than other attachment systems, such as leg bracelets, ear tags or boluses. Cow collars have been used for a long time now, and they could be conceived as sensor platforms integrating radio frequency identifiers, accelerometers and other small-sized sensors, together with visual identifiers. There are large opportunities associated to sensor integration, in terms of accuracy and precision of sensing solutions. An additional advantage of collar-mounted sensors is that they face an environment less challenging for electronics than, for example, leg-mounted sensors, as they are further away from wetness and dirt.

Societal challenges should also be kept in mind by PLF developers. Precision farming technologies can be conceived as data providers to support farmer management and decision-making or as a means for the automation of some tasks. The second one could have a major impact on the dairy farming job market, both positive and negative depending on the context. A broad review on this topic was published by Hostiou et al. (Reference Hostiou, Fagon, Chauvat, Turlot, Kling-Eveillard, Boivin and Allain2017). On the other hand, as previously described, automatisation could impact animal welfare, specifically in those criteria related to the human-animal bond. In this sense, those tasks requiring a close interaction between farmers and their animals, such as feeding or moving cows, would be less preferred for automatisation than those repetitive or dangerous tasks with no human-animal interaction. A different approach to that issue, is to assume that farmers would use their extra time due to automatisation in reinforcing the human-animal bond (Veissier et al., Reference Veissier, Kling-Eveillard, Mialon, Silberberg, De Boyer, Terlouw, Ledoux, Meunier and Hostiou2019).

In conclusion, a number of the criteria contained in the Welfare Quality® protocol can already be addressed by commercial PLF technologies, and it is to be anticipated that more will become available in the future. In all likelihood it will be necessary to modify some of the criteria if the advantages of continuous measurement and individual monitoring provided by technological approaches are to be fully exploited.

Acknowledgements

This article is based upon work from COST Action FA1308 DairyCare, supported by COST (European Cooperation in Science and Technology, www.cost.eu). COST is a funding agency for research and innovation networks. COST Actions help connect research initiatives across Europe and enable scientists to grow their ideas by sharing them with their peers. This boosts their research, career and innovation.