Impact statement

Society has benefited from plastic food packaging: many foodstuffs have become widely available to humanity throughout the year. However, a downside of plastic food packaging is its environmental persistence when local waste management fails or is not available at all. The increasing plastic pollution is being tackled by different means, one of them being a shift to using more recycled content in plastic articles. Another approach is to ramp up reusable packaging by introducing refillable containers. But both approaches – reusing and recycling plastic food packaging – must address the issue of chemicals that transfer from packaging into food and that may lead to food safety issues due to the presence of hazardous chemicals that accumulate in plastics throughout their life cycle. In this review article, we zoom in on this issue of chemicals in reusable and/or recyclable plastic food containers, such as packaging and other plastic items that come into contact with food, like kitchen utensils and tableware. We highlight the scientific evidence and key knowledge gaps on chemicals in plastics and how some chemicals of concern found in plastics affect human health.

Introduction

Plastic materials are highly functional and economically used in today’s globalised food systems (Millican and Agarwal, Reference Millican and Agarwal2021). Plastics make for lightweight food packaging, can be engineered to extend shelf-life significantly (De Hoe et al., Reference De Hoe, Şucu and Shaver2022) and at the same time, they enable profitable products by allowing for at-scale, high-throughput production and filling, globalised logistics and retail selling (Matthews et al., Reference Matthews, Moran and Jaiswal2021). Most food packaging is made of plastics (Poças et al., Reference Poças, Oliveira, Pinto, Zacarias and Hogg2009), and around 20% of global plastics production is used for this purpose (Plastics Europe, 2022). The extensive use of plastic packaging for foodstuffs is also often justified as a means for preventing food waste (Heller et al., Reference Heller, Selke and Keoleian2019). This makes single-use plastic food packaging an enabler of the current, globalised, processed foods system that provides convenience to consumers, making it very difficult to replace (Chakori et al., Reference Chakori, Aziz, Smith and Dargusch2021; Chakori et al., Reference Chakori, Richards, Smith, Hudson and Abdul Aziz2022).

But despite its many advantages, the intense and increasing use of plastic food packaging is associated with serious environmental damage (Jambeck et al., Reference Jambeck, Geyer, Wilcox, Siegler, Perryman, Andrady, Narayan and Law2015; Wilcox et al., Reference Wilcox, Van Sebille and Hardesty2015; Borrelle et al., Reference Borrelle, Ringma, Law, Monnahan, Lebreton, McGivern, Murphy, Jambeck, Leonard, Hilleary, Eriksen, Possingham, De Frond, Gerber, Polidoro, Tahir, Bernard, Mallos, Barnes and Rochman2020; MacLeod et al., Reference MacLeod, Arp, Tekman and Jahnke2021; Morales-Caselles et al., Reference Morales-Caselles, Viejo, Martí, González-Fernández, Pragnell-Raasch, González-Gordillo, Montero, Arroyo, Hanke, Salvo, Basurko, Mallos, Lebreton, Echevarría, van Emmerik, Duarte, Gálvez, van Sebille, Galgani, García, Ross, Bartual, Ioakeimidis, Markalain, Isobe and Cózar2021; Persson et al., Reference Persson, Carney Almroth, Collins, Cornell, de Wit, Diamond, Fantke, Hassellöv, MacLeod, Ryberg, Søgaard Jørgensen, Villarrubia-Gómez, Wang and Hauschild2022) and has led to increasing calls for amelioration (Geyer et al., Reference Geyer, Jambeck and Law2017; Borrelle et al., Reference Borrelle, Ringma, Law, Monnahan, Lebreton, McGivern, Murphy, Jambeck, Leonard, Hilleary, Eriksen, Possingham, De Frond, Gerber, Polidoro, Tahir, Bernard, Mallos, Barnes and Rochman2020; Lau et al., Reference Lau, Shiran, Bailey, Cook, Stuchtey, Koskella, Velis, Godfrey, Boucher, Murphy, Thompson, Jankowska, Castillo Castillo, Pilditch, Dixon, Koerselman, Kosior, Favoino, Gutberlet, Baulch, Atreya, Fischer, He, Petit, Sumaila, Neil, Bernhofen, Lawrence and Palardy2020). Therefore, the United Nations Environmental Programme has been tasked with preparing a Global Plastics Treaty to ‘end plastic pollution’ and develop ‘an international legally binding instrument’ (UNEP, 2022). The call for reducing plastic pollution from (food) packaging waste has also been heard in several countries across the globe, and novel approaches are being developed that would allow for the continued use of plastic materials in food packaging while addressing its end-of-life challenges (Prata et al., Reference Prata, Silva, da Costa, Mouneyrac, Walker, Duarte and Rocha-Santos2019; Matthews et al., Reference Matthews, Moran and Jaiswal2021). This includes designing packaging so that it allows for recycling (Eriksen et al., Reference Eriksen, Christiansen, Daugaard and Astrup2019; Schyns and Shaver, Reference Schyns and Shaver2021; De Hoe et al., Reference De Hoe, Şucu and Shaver2022), for example, by using only certain polymer types as mono-materials with additional, specific material properties such as transparency and colourlessness.

However, the focus on plastic packaging recycling is a less favourable option according to the European Union (EU)’s waste hierarchy, which sees reduction and reuse as preferable approaches (EEA, 2019). For this reason, there is an increasing push towards reducing overall plastics packaging waste, for example, by setting binding national reduction targets and promoting the reuse of food packaging (EU 2019/904, 2019; Klemeš et al., Reference Klemeš, Fan and Jiang2021; EC, 2022b), even though this requires far bigger changes to food production, logistics and retail, and is, therefore, more difficult to implement (Borrelle et al., Reference Borrelle, Ringma, Law, Monnahan, Lebreton, McGivern, Murphy, Jambeck, Leonard, Hilleary, Eriksen, Possingham, De Frond, Gerber, Polidoro, Tahir, Bernard, Mallos, Barnes and Rochman2020; Phelan et al., Reference Phelan, Meissner, Humphrey and Ross2022; Wagner, Reference Wagner and Bank2022).

In this review, we focus on the important issue of chemicals, as this is an aspect that is often overlooked when solutions to end plastic pollution from food packaging waste are discussed (Dey et al., Reference Dey, Trasande, Altman, Wang, Krieger, Bergmann, Allen, Allen, Walker, Wagner, Syberg, Brander and Almroth2022; Wang and Praetorius, Reference Wang and Praetorius2022). Indeed, plastics are chemically very complex materials, containing hundreds of different, synthetic compounds which are more often than not, poorly characterised for their hazard properties and which in many cases even remain unknown regarding their chemical identities (Crippa et al., Reference Crippa, De Wilde, Koopmans, Leyssens, Muncke, Ritschkoff, Van Doorsselaer, Velis and Wagner2019). Still, it is well established that chemicals transfer from plastic food packaging into foodstuffs, and this process of chemical migration has been the focus of over 800 scientific publications (Geueke et al., Reference Geueke, Groh, Maffini, Martin, Boucher, Chiang, Gwosdz, Jieh, Kassotis, Łańska, Myers, Odermatt, Parkinson, Schreier, Srebny, Zimmermann, Scheringer and Muncke2022). At the same time, there is concern about the adverse health impacts of chemical migration when almost the entire population is ingesting plastic-associated chemicals that are often not studied adequately for their health risks (Muncke et al., Reference Muncke, Andersson, Backhaus, Boucher, Carney Almroth, Castillo Castillo, Chevrier, Demeneix, Emmanuel, Fini, Gee, Geueke, Groh, Heindel, Houlihan, Kassotis, Kwiatkowski, Lefferts, Maffini, Martin, Myers, Nadal, Nerin, Pelch, Fernández, Sargis, Soto, Trasande, Vandenberg, Wagner, Wu, Zoeller and Scheringer2020; Groh et al., Reference Groh, Geueke, Martin, Maffini and Muncke2021; Symeonides et al., Reference Symeonides, Brunner, Mulders, Toshniwal, Cantrell, Mofflin and Dunlop2021; Landrigan et al., Reference Landrigan, Raps, Cropper, Bald, Brunner, Canonizado, Charles, Chiles, Donohue, Enck, Fenichel, Fleming, Ferrier-Pages, Fordham, Gozt, Griffin, Hahn, Haryanto, Hixson, Ianelli, James, Kumar, Laborde, Law, Martin, Mu, Mulders, Mustapha, Niu, Pahl, Park, Pedrotti, Pitt, Ruchirawat, Seewoo, Spring, Stegeman, Suk, Symeonides, Takada, Thompson, Vicini, Wang, Whitman, Wirth, Wolff, Yousuf and Dunlop2023).

These concerns about migration of hazardous chemicals and their impacts on human health are especially relevant for plastic food contact materials (FCMs) made from recycled plastics (Geueke et al., Reference Geueke, Groh and Muncke2018; Cook et al., Reference Cook, Derks and Velis2023) because unknown and/or hazardous chemicals can accumulate in recycled material and then migrate into foodstuffs, leading to chronic human exposure, as has been shown in the case of beverage bottles made from polyethylene terephthalate (PET) plastics (Gerassimidou et al., Reference Gerassimidou, Lanska, Hahladakis, Lovat, Vanzetto, Geueke, Groh, Muncke, Maffini, Martin and Iacovidou2022; Steimel et al., Reference Steimel, Hwang, Dinh, Donnell, More and Fung2022; Tsochatzis et al., Reference Tsochatzis, Lopes and Corredig2022). Illicit plastic recycling, where non-food grade plastics containing hazardous brominated flame retardants are used to make FCMs, is prevalent, as data from the European, U.S. and Korean markets reveal (Samsonek and Puype, Reference Samsonek and Puype2013; Rani et al., Reference Rani, Shim, Han, Jang, Song and Hong2014; Turner, Reference Turner2018; Paseiro-Cerrato et al., Reference Paseiro-Cerrato, Ackerman, de Jager and Begley2021). Additionally, technical limitations exist with respect to the recyclability of commonly used plastic food packaging into chemically safe recycled food packaging because of the inherent physico-chemical properties of the materials that hamper the efficient removal of chemical contaminants (Palkopoulou et al., Reference Palkopoulou, Joly, Feigenbaum, Papaspyrides and Dole2016). Especially concerning is the use of recovered plastic waste, for example, from ocean clean ups, for food contact applications, as persistent organic pollutants may be present (Gallo et al., Reference Gallo, Fossi, Weber, Santillo, Sousa, Ingram, Nadal and Romano2018).

In addition, for reused plastic food packaging, there is concern about the migration of hazardous chemicals, for example, from consumer (mis-)use of the packaging, or from detergents that can accumulate in the packaging (Tisler and Christensen, Reference Tisler and Christensen2022). Indeed, food packaging is often soiled with food remains and needs thorough cleaning before reuse, but the plastic polymer may even absorb components of the food or cleaning agents, leading to discolouring and organoleptic changes, or even unwanted chemical contamination of the packaging that may migrate into the food during reuse. Also, non-packaging plastic items for food contact, such as kitchen utensils, tableware, baby bottles, water dispensers and tubing of milking machines, are often used in repeated contact with food and are a source of chemicals that migrate into foodstuffs. Common plastic polymers used to make these items are polyamide (PA), polypropylene (PP), polycarbonate (PC), melamine resin (MelRes) and polyvinylchloride (PVC). At present, little attention is paid to this source of chemical food contamination.

This review provides a systematic overview of food contact chemicals (FCCs) detected in migrates and extracts of recycled plastic FCMs, with a special focus on recycled PET that is typically used in single-use packaging. Additionally, we provide evidence for migrating and extractable FCCs from reusable food contact articles (FCAs) made of plastics, such as kitchen utensils, plates, cups and containers. The data are obtained from the Database on Migrating and Extractable Food Contact Chemicals (FCCmigex) (Geueke et al., Reference Geueke, Groh, Maffini, Martin, Boucher, Chiang, Gwosdz, Jieh, Kassotis, Łańska, Myers, Odermatt, Parkinson, Schreier, Srebny, Zimmermann, Scheringer and Muncke2022). Human health implications of exposure to frequently detected FCCs are discussed. This work enables evidence-based decision-making regarding the use of plastic food packaging in the circular economy.

Methods

Evidence for the presence of FCCs in migrates and extracts

This review is based on the data and references of a systematic evidence map on FCCs measured in migrates and extracts of FCMs (Geueke et al., Reference Geueke, Groh, Maffini, Martin, Boucher, Chiang, Gwosdz, Jieh, Kassotis, Łańska, Myers, Odermatt, Parkinson, Schreier, Srebny, Zimmermann, Scheringer and Muncke2022). The results are accessible via an interactive tool, the FCCmigex dashboard (Food Packaging Forum, 2023). The latest data update considered all relevant and publicly available studies and reports through October 2022. On 24 April 2023, the FCCmigex dashboard included 24,810 database entries and 4,266 FCCs. This information was retrieved from 1,311 references. The terms FCC, FCM and food contact article (FCA) were used according to the definitions in Muncke et al. (Reference Muncke, Backhaus, Geueke, Maffini Maricel, Martin, Myers, Soto Ana, Trasande, Trier and Scheringer2017).

To find information on FCCs that were detected in migrates and extracts of recycled plastics, we first filtered the FCCmigex database for data and references on PET and recycled PET, which are listed as distinct FCM types if the relevant references provide this information. We also filtered the full dataset for ‘food contact material: plastics’ and searched the term ‘recyc’ in the titles and abstracts of the resulting references, which were then screened with respect to the recycled content of the investigated plastic FCMs.

For data and references on reusable plastics, we applied the filters ‘food contact material: plastics’ and ‘food contact article: repeat-use’ in the FCCmigex database. Additionally, we filtered for ‘detection: yes’.

We also searched the FCCmigex database for specific chemicals by using their Chemical Abstracts Service Registry Numbers (CAS RN) and combined these searches with the FCM of interest. For example, to obtain information about bisphenol A (BPA, CAS RN 80-05-7) that was detected in migrates and extracts of reusable PC, we used the following search term and filters: CAS RN: 80-05-7, food contact material: plastic >polycarbonate, food contact article: repeat-use and detection: yes.

Hazards of FCCs

For FCCs that were frequently detected in migrates and extracts of recycled and reusable plastic FCMs, we compiled the hazard properties according to the criteria mentioned in the European Chemicals Strategy for Sustainability (CSS) (EC, 2020). The CSS aims at removing the most harmful chemicals from consumer products, including FCMs. Chemicals that are carcinogenic, mutagenic or toxic to reproduction (CMR), and have specific target organ toxicity (STOT) or endocrine disrupting properties, were defined as ‘most harmful’ by the CSS. Also, chemicals with persistence and bioaccumulation-related hazards (PBT and vPvB) and persistent and mobile chemicals (PMT/vPvT) were included as chemicals of concern in the CSS.

We applied the methodology as described by Zimmermann et al. (Reference Zimmermann, Scheringer, Geueke, Boucher, Parkinson, Groh and Muncke2022) and referred to the following hazard sources: European Chemical Agency’s (ECHA) Classification and Labelling Inventory that is aligned with the Globally Harmonized System (GHS) for classification and labelling of chemicals (ECHA, 2023f), GHS-aligned classification by the Japanese Government (NITE, 2023), EU Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) Substances of Very High Concern list (ECHA, 2023g), California’s Office of Environmental Health Hazard Assessment’s (OEHHA) Proposition 65 List (OEHHA, 2023), substances identified as endocrine disruptors at the EU level (Endocrine Disruptor List, 2022), PBT/vPvB assessments carried out under the previous EU chemicals legislation (ECHA, 2007), U.S. Environmental Protection Agency’s (EPA) list of PBT substances (U.S. EPA, 2023), U.S. EPA’s archived list of Priority Chemicals (U.S. EPA, 2016), ECHA’s PBT assessment list (ECHA, 2023a), Stockholm convention (POP) (Stockholm Convention, 2022), ECHA’s list for inclusion in POPs Regulation, ECHA’s list of substances subject to POPs Regulation (ECHA, 2023e) and German Environment Agency (UBA) report (Arp and Hale, Reference Hale2019). All hazard sources were accessed between 24 and 30 January 2023.

Based on the GHS for classification and labelling, we defined chemicals with CMR properties that were assigned to categories 1A and 1B (known and presumed CMR, respectively) and chemicals with STOT that were classified as category 1 after repeated exposure as having hazard properties of concern. Chemicals with respiratory system hazards leading to a classification as STOT RE 1 were not included as they were not considered relevant for FCMs, where chemical exposure is oral.

FCCs that were not listed in any of the 12 sources above were labelled as ‘no data available’. For FCCs that have data in any of these sources, but were not categorised as chemical of concern, we searched for ongoing assessments and notifications in the respective Substance Infocard published by ECHA (ECHA, 2023b). We also added references from the peer-reviewed literature regarding potential hazards of concern if no priority hazards were assigned to a chemical according to Zimmermann et al. (Reference Zimmermann, Scheringer, Geueke, Boucher, Parkinson, Groh and Muncke2022) or no ongoing regulatory assessments were reported by ECHA (2023b).

Results

Plastic data in the FCCmigex database

In the most recent version of the FCCmigex database, we included 824 scientific studies and reports on plastic FCMs. From these references, 13,958 database entries have been generated, where a database entry corresponds to one experimental finding (Geueke et al., Reference Geueke, Groh, Maffini, Martin, Boucher, Chiang, Gwosdz, Jieh, Kassotis, Łańska, Myers, Odermatt, Parkinson, Schreier, Srebny, Zimmermann, Scheringer and Muncke2022). More specifically, each database entry is linked to the reference from which it was generated and provides information about the FCC, what type of FCA (single or repeat-use) and which FCM(s) were investigated, whether the experimental set-up was a migration or extraction experiment and if the chemical was detected or not. Notably, a reference can contain multiple experimental findings and, therefore, result in several database entries. In total, 3,009 FCCs were detected in migrates and extracts of plastic FCMs. We integrated data from nine different types of plastic polymers (PA, PC, polyethylene (PE), PET, PP, PVC, MelRes, polyurethane (PU) and polystyrene [PS]). Additionally, plastic FCMs that consist of multilayers and those that were not further specified or made of another polymer, such as Tritan and polylactic acid, form two more categories of plastic FCMs in the database.

Recycled plastic FCMs

Recycled PET

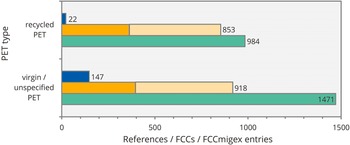

The FCCmigex database contains 1,436 FCCs detected in migrates and extracts of PET, represented by 2,455 database entries. Twenty-two of 156 references on PET specifically refer to the detection of FCCs in migrates and extracts of recycled PET (Figure 1). This percentage does not necessarily reflect the actual share of recycled content in the investigated samples as in many references no distinction was made between virgin and recycled PET.

Figure 1. Aggregated numbers from the FCCmigex database on FCMs made of recycled and virgin/unspecified PET. Numbers of references, FCCs and FCCmigex database entries are shown in blue, yellow and green, respectively. FCCs that were detected only once in any of the PET samples are shown in light yellow. Filter applied in the FCCmigex: Detection – yes.

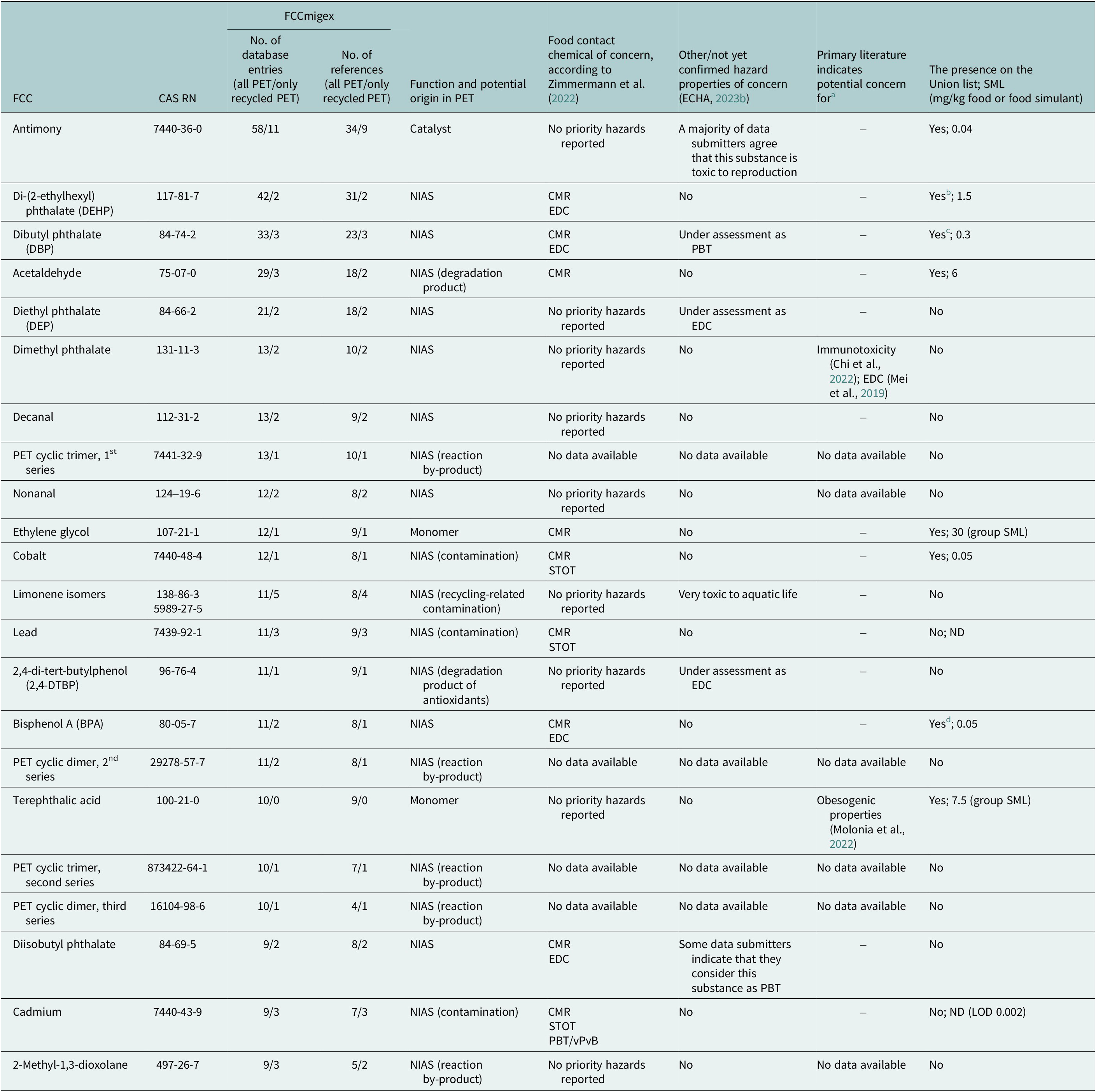

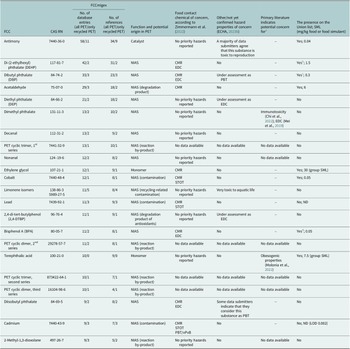

Antimony and acetaldehyde are very often detected FCCs in migrates and extracts of PET (Table 1). Ortho-phthalates, such as di-(2-ethylhexyl) phthalate (DEHP), dibutyl phthalate (DBP), diethyl phthalate, dimethyl phthalate and diisobutyl phthalate, heavy metals, the monomers ethylene glycol and terephthalic acid, more aldehydes, cyclic PET oligomers and 2,4-di-tert-butylphenol (2,4-DTBP) are also among the most frequently detected FCCs. On the contrary, 1,014 chemicals that have been detected in any PET sample were found only once (corresponding to one database entry). 523 and 491 of these FCCs are found in virgin/unspecified PET and recycled PET, respectively (Figure 1), which is mainly the result of untargeted analyses of migrates and extracts (Aznar et al., Reference Aznar, Domeño, Osorio and Nerin2020; Brenz et al., Reference Brenz, Linke and Simat2021; Jaén et al., Reference Jaén, Domeño, Alfaro and Nerín2021; Wu et al., Reference Wu, Wu, Li, Li, Zheng, Lin, Nerín, Zhong and Dong2022). Such untargeted screenings often lead to the detection of non-intentionally added substances (NIASs), including reaction by-products, contaminants and degradation products (Table 1).

Table 1. Overview of FCCs that were most frequently detected in migrates and/or extracts of FCMs made of PET (source: FCCmigex), their function and potential origin, hazard properties of concern and the presence on the Union list of authorised substances (EU 10/2011, 2011)

Note: CMR, carcinogenic, mutagenic or toxic to reproduction; EDC, endocrine disrupting chemical; LOD, level of detection; ND, the substance shall not migrate in detectable quantities; NIAS, non-intentionally added substance; PBT, persistent, bioaccumulative and toxic; SML, specific migration limit; STOT, specific target organ toxicity; vPvB, very persistent, very bioaccumulative; vPvM, very persistent, very mobile.

a Primary literature was only consulted when no priority hazards were assigned according to Zimmermann et al. (Reference Zimmermann, Scheringer, Geueke, Boucher, Parkinson, Groh and Muncke2022) or no ongoing assessments were reported by ECHA (2023b).

b Only to be used as (a) plasticiser in repeated use materials and articles contacting non-fatty foods and (b) technical support agent in polyolefins in concentrations up to 0,1% in the final product.

c Only to be used as (a) plasticiser in repeated use materials and articles contacting non-fatty foods and (b) technical support agent in polyolefins in concentrations up to 0,05% in the final product.

d Not to be used for the manufacture of PC infant feeding bottles and PC drinking cups or bottles which, due to their spill proof characteristics, are intended for infants and young children.

When focusing on the FCCs that have been detected in migrates and extracts of PET samples with confirmed recycled content, the data are sparse (Table 1). Antimony is most frequently detected, followed by limonene, a common aroma compound, that is considered a marker for recycled content (Fabris et al., Reference Fabris, Freire, Wagner and Reyes2010; Thoden van Velzen et al., Reference Thoden van Velzen, Brouwer, Stärker and Welle2020).

The FCCmigex contains data from a reference describing an untargeted analysis of volatile organic compounds (VOCs) where 1,247 chemicals have been detected and tentatively identified in 45 virgin and 82 recycled PET samples (Li et al., Reference Li, Wu, Wu, Chen, Kou, Zeng, Li, Lin, Zhong, Hao, Dong, Chen and Zheng2022). In this study, 524 VOCs have been detected only in PET samples with recycled content, versus 461 chemicals that are present only in virgin PET. 262 chemicals are detected in both types of PET. 1139 of these 1,247 chemicals reported by Li et al. have a CAS RN and are included in the FCCmigex interactive dashboard. 1017 of these 1,139 chemicals (or 90%) have not previously been detected in any PET migrate or extract, which illustrates the potential of untargeted studies and also shows the large individual variations of FCAs made of the same polymer. Hydrocarbons and benzenoids are predominant categories for virgin and recycled PET samples, respectively. Slip agents, which are commonly used to control friction during polymer production, have been proposed as possible sources of hydrocarbons in virgin PET, and some of the benzenoids that are highly prevalent in recycled PET could have originated from food additives and degradation products of surfactants. To the best of our knowledge, the results of this study form the most comprehensive, publicly available dataset systematically comparing chemicals in recycled and virgin PET samples.

Other recycled polymers

The FCCmigex contains only a few references on the chemical migration from specific recycled polymers other than PET, such as PS, PP, PE and Tritan. Typical FCCs reported in these references are VOCs, including styrene monomer and oligomers from recycled PS (Lin et al., Reference Lin, Song, Fang, Wu and Wang2017; Song et al., Reference Song, Wrona, Nerin, Q-B and Zhong2019), degradation products of antioxidants from recycled polyolefins (Coulier et al., Reference Coulier, Orbons and Rijk2007) and contaminations with bisphenols in recycled Tritan that may be explained by the ubiquitous presence of these substances (Banaderakhshan et al., Reference Banaderakhshan, Kemp, Breul, Steinbichl, Hartmann and Fürhacker2022).

In the decade after 2010, the detection of brominated flame retardants and heavy metals in black plastic FCAs was an unexpected finding and it indicated that plastic waste from electrical and electronic equipment is illegally recycled into FCAs (Samsonek and Puype, Reference Samsonek and Puype2013; Puype et al., Reference Puype, Samsonek, Knoop, Egelkraut-Holtus and Ortlieb2015; Guzzonato et al., Reference Guzzonato, Puype and Harrad2017; Turner, Reference Turner2018; Puype et al., Reference Puype, Ackerman and Samsonek2019).

Repeat-use plastic FCAs

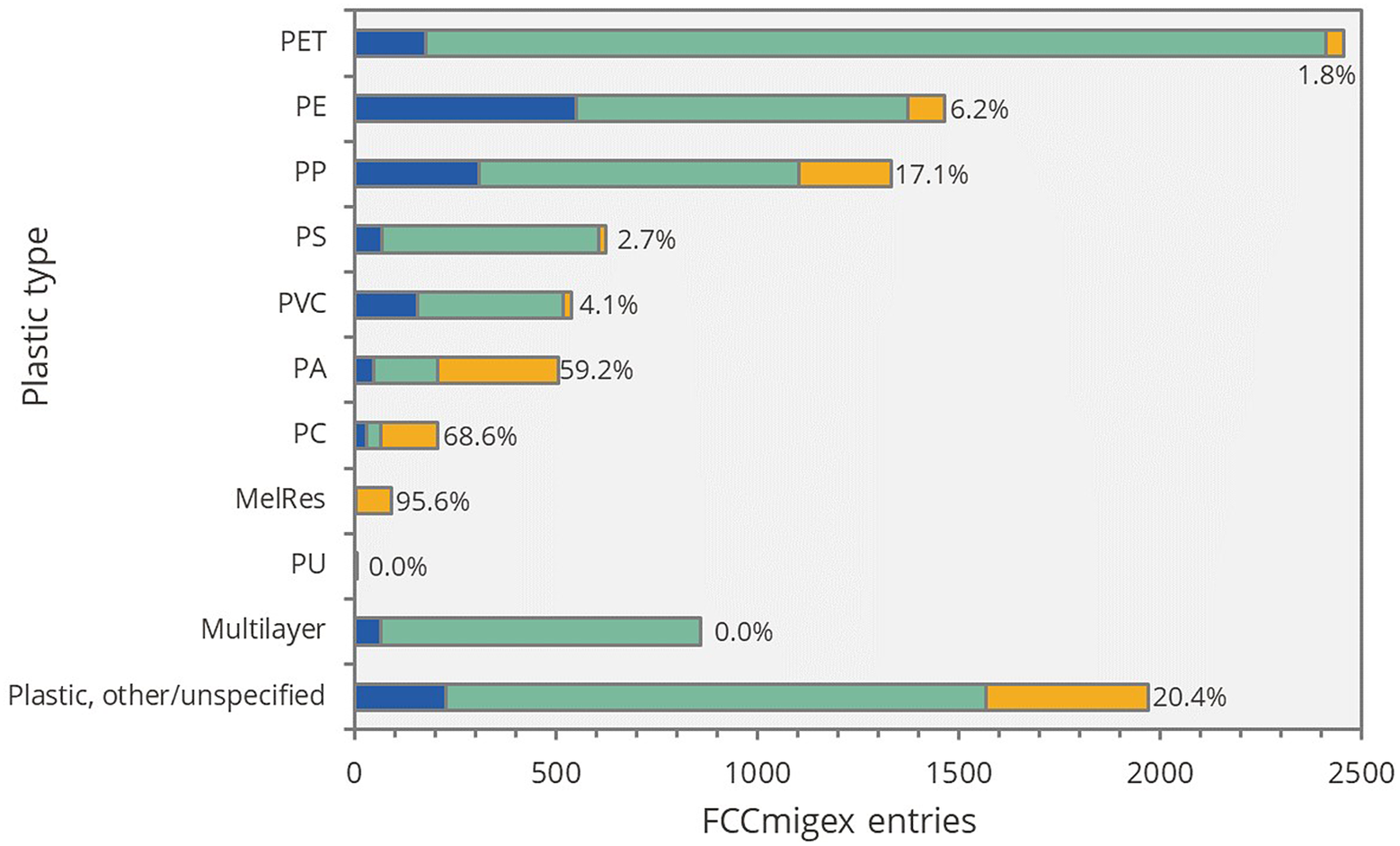

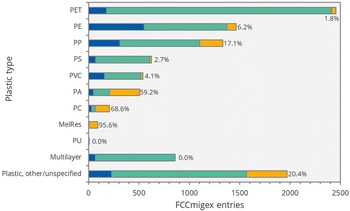

In the FCCmigex, 1,332 database entries from 177 references are related to the detection of 509 FCCs in repeat-use plastics. The polymer types for which the highest percentage of repeat-use articles has been studied are MelRes (95.6% repeat-use), PC (68.6%), PA (59.2%) and PP (17.1%) (Figure 2). Typical FCAs made of MelRes and studied for their chemical migration potential are reusable kitchen utensils and tableware, often especially designed for babies and children. Examples of repeat-use FCAs made of PP, PC and PA that are included in the FCCmigex database are food containers, baby bottles and kitchen utensils, respectively.

Figure 2. Number of FCCmigex database entries for 11 categories of plastic FCMs. The plastic FCMs are divided into nine different polymers (PE, PP, PET, PS, PVC, PA, PC, MelRes and PU) and two other categories (‘multilayer plastics’ and ‘plastics, non-specified and others’). Each bar displays the number of database entries for single-use FCAs (blue), repeat-use FCAs (yellow) and FCAs that were not specified (green). The data labels show the percentage of repeat-use FCAs for each category. Filter applied in the FCCmigex: Detection – yes.

The most commonly used type of PC contains BPA as monomer. In the last decade, BPA-containing baby bottles have been banned all over the world due to health and safety concerns, leading to the replacement of BPA-based PC by other plastic polymers. PA is widely used in kitchen utensils, such as cooking spoons and spatulas, and other repeat-use FCAs, such as coffee mugs and electric kitchen appliances. Besides, single-use plastic packaging is also commonly made of PA, such as tea bags and multilayer plastic films. Food containers are often made of PP, for both single-use and repeat-use. Further food-contact applications of PP are, for example, films, bags and bottle caps.

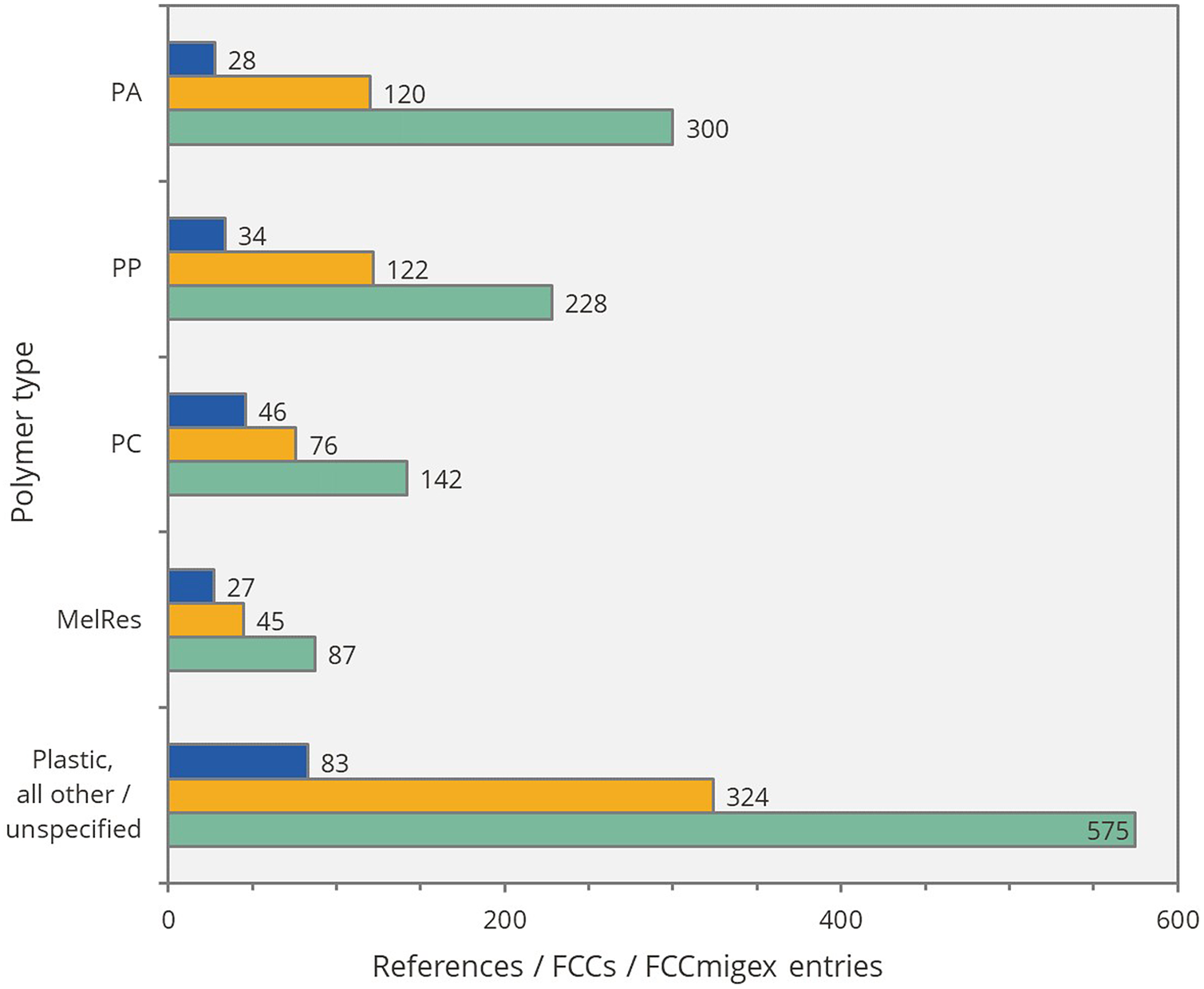

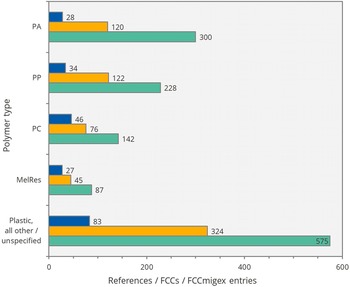

Across all polymers, PA, PP, PC and MelRes also have the highest total number of database entries for repeat-use FCAs (Figure 3). For four polymer types in the FCCmigex database (PE, PET, PS and PVC), between 1.8% and 6.2% of their respective database entries are on repeat use (Figure 2). The FCM categories ‘multilayer plastics’ and PU do not include any information on repeat-use FCAs, whereas 20.4% of the database entries refer to repeat-use in the category ‘plastics, non-specified or other’.

Figure 3. Aggregated numbers from the FCCmigex database on repeat-use plastic FCAs by polymer type (polyamide [PA]; polypropylene [PP]; polycarbonate [PC]; melamine resin [MelRes] and plastic, other/non-specified). Numbers of references, FCCs and FCCmigex database entries are shown in blue, yellow and green, respectively. Filters applied in the FCCmigex: Detection – yes, FCA – repeat-use. For example, for PA, the FCCmigex contains 27 references with 120 FCCs detected and results from 277 experimental findings.

In migrates and extracts of PA and PP, 120 and 122 different FCCs have been identified, respectively, while 76 different FCCs originate from PC and 45 FCCs from MelRes (Figure 3). On average, 4.4 and 3.6 FCCs per reference have been detected for PA and PP, respectively, which contrasts with only 1.7 FCCs per reference for PC and MelRes.

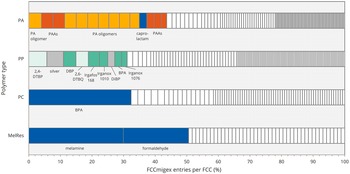

The frequencies of database entries for the most detected FCCs per polymer type are shown in Figure 4. For PC, 32.4% of the database entries are related to the detection of BPA, whereas the remaining 67.6% cover 75 other FCCs. Melamine and formaldehyde account for 50.6% of all database entries related to MelRes. In contrast, a much higher number of different FCCs has been detected in the migrates and extracts of PA and PP. Primary aromatic amines (PAAs), the monomer of PA6 (caprolactam) and cyclic PA oligomers are most frequently detected in PA. Plastic additives, for example, Irgafos 168, Irganox 1010 and Irganox 1070, ortho-phthalates, silver and degradation products of antioxidants (2,4-DTBP and 2,6-di-tert-butylbenzoquinone [2,6-DTBQ]) are found with the highest frequencies in migrates and extracts of PP.

Figure 4. Relative frequency of FCCmigex database entries per FCC for four repeat-use plastic FCAs by polymer type (polyamide [PA]; polypropylene [PP]; polycarbonate [PC] and melamine resin [MelRes]). Function and potential origin of the most frequently detected FCCs were coded by colours: red – restricted substances; yellow – reaction by-products; blue – monomers; green – authorised plastic additives; light green – degradation products of antioxidants (NIASs) and grey – not authorised for plastic FCMs in the EU. Filters applied in the FCCmigex database: Detection – yes; FCA – repeat-use.

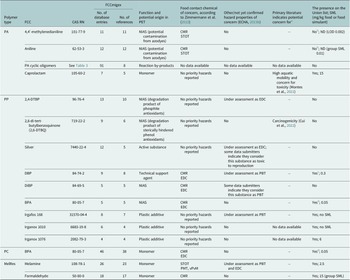

Case studies of chemicals of concern

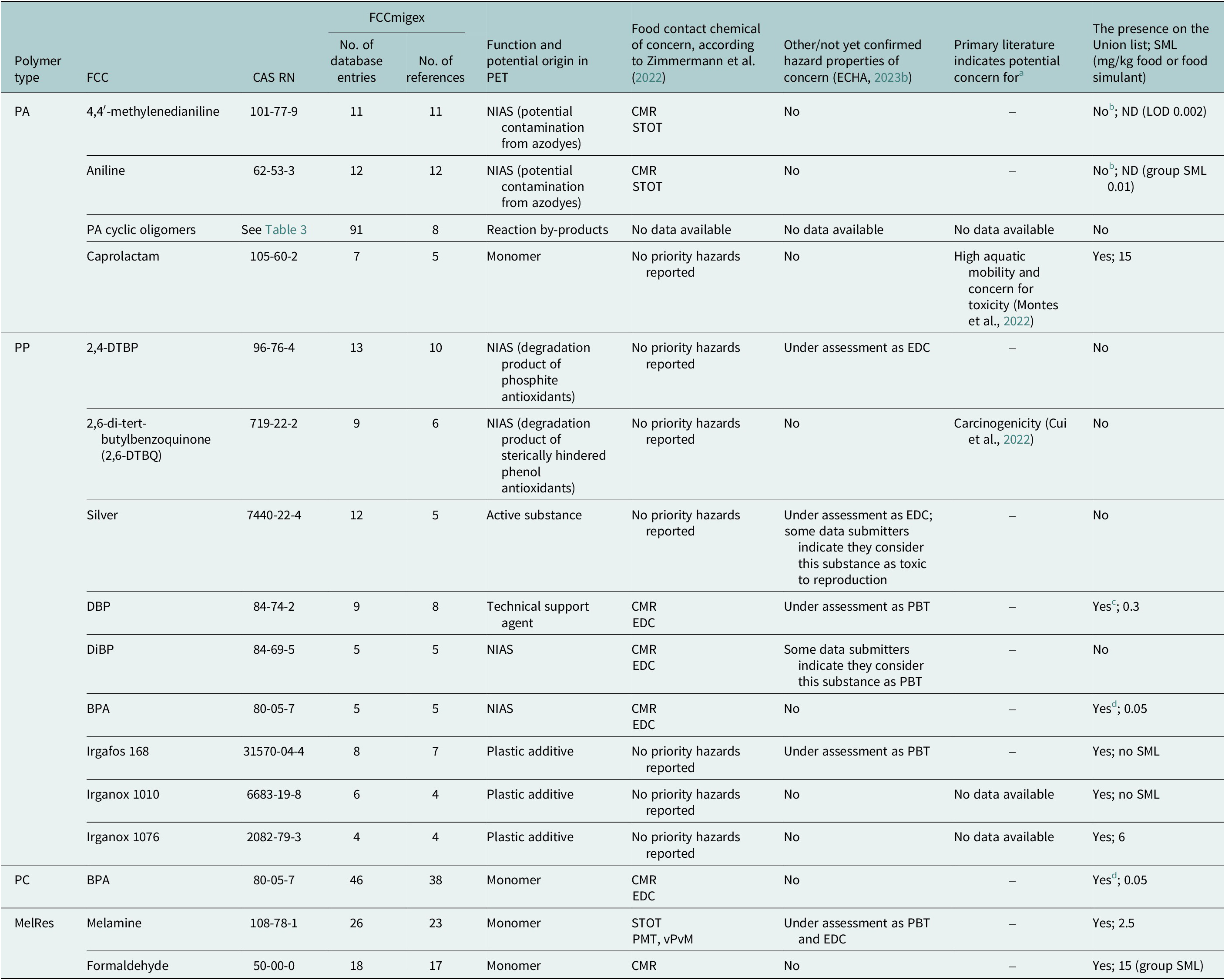

Table 2 summarises the highly prevalent FCCs and groups of FCCs that have been detected in migrates and extracts of repeat-use FCAs and informs about their function, potential origin, hazards and their presence on the Union list of authorised substances (EU 10/2011, 2011). Based on these data, we present three case studies to illustrate the implications of chemical migration from repeat-use plastic FCAs. In the following, we will focus in more detail on cyclic oligomers from PA, the degradation products of antioxidants commonly used in PP (2,4-DTBP and 2,6-DTBQ) and melamine from MelRes. All these FCCs are known to be present in plastics after manufacturing or formed during use, and they have the potential to migrate into foods. However, there is very limited information on the toxicity of the cyclic PA oligomers as well as 2,4-DTBP, and 2,6-DTBQ (Tables 2 and 3). The safety of melamine was assessed by the European Food Safety Authority (EFSA) in 2010 (EFSA, 2010), but further research on the human health and environmental hazards of melamine since then has led to its classification as a substance of very high concern and to its assessment as an endocrine disrupting chemical (EDC) and PBT (ECHA, 2023c).

Table 2. Overview of FCCs that were most frequently detected in migrates and/or extract of repeat-use plastic FCAs (source: FCCmigex), their function and potential origin, hazard properties of concern and the presence on the Union list of authorised substances (EU 10/2011, 2011)

Note: CMR, carcinogenic, mutagenic or toxic to reproduction; EDC, endocrine disrupting chemical; LOD, level of detection; ND, the substance shall not migrate in detectable quantities; NIAS, non-intentionally added substance; PA, polyamide; PAA, primary aromatic amine; PBT, persistent, bioaccumulative and toxic; PC, polycarbonate; PP, polypropylene; SML, specific migration limit; STOT, specific target organ toxicity; vPvM, very persistent, very mobile.

a Primary literature was only consulted when no priority hazards were assigned according to Zimmermann et al. (Reference Zimmermann, Scheringer, Geueke, Boucher, Parkinson, Groh and Muncke2022), or no ongoing assessments were reported by ECHA (2023b).

b ‘ND’ if PAA on REACH Annex XVII (detection limit 0.02 mg/kg); if not listed: 0.01 mg/kg (group SML).

c Only to be used as (a) plasticiser in repeated use materials and articles contacting non-fatty foods and (b) technical support agent in polyolefins in concentrations up to 0.05% in the final product.

d Not to be used for the manufacture of PC infant feeding bottles and PC drinking cups or bottles which, due to their spill proof characteristics, are intended for infants and young children.

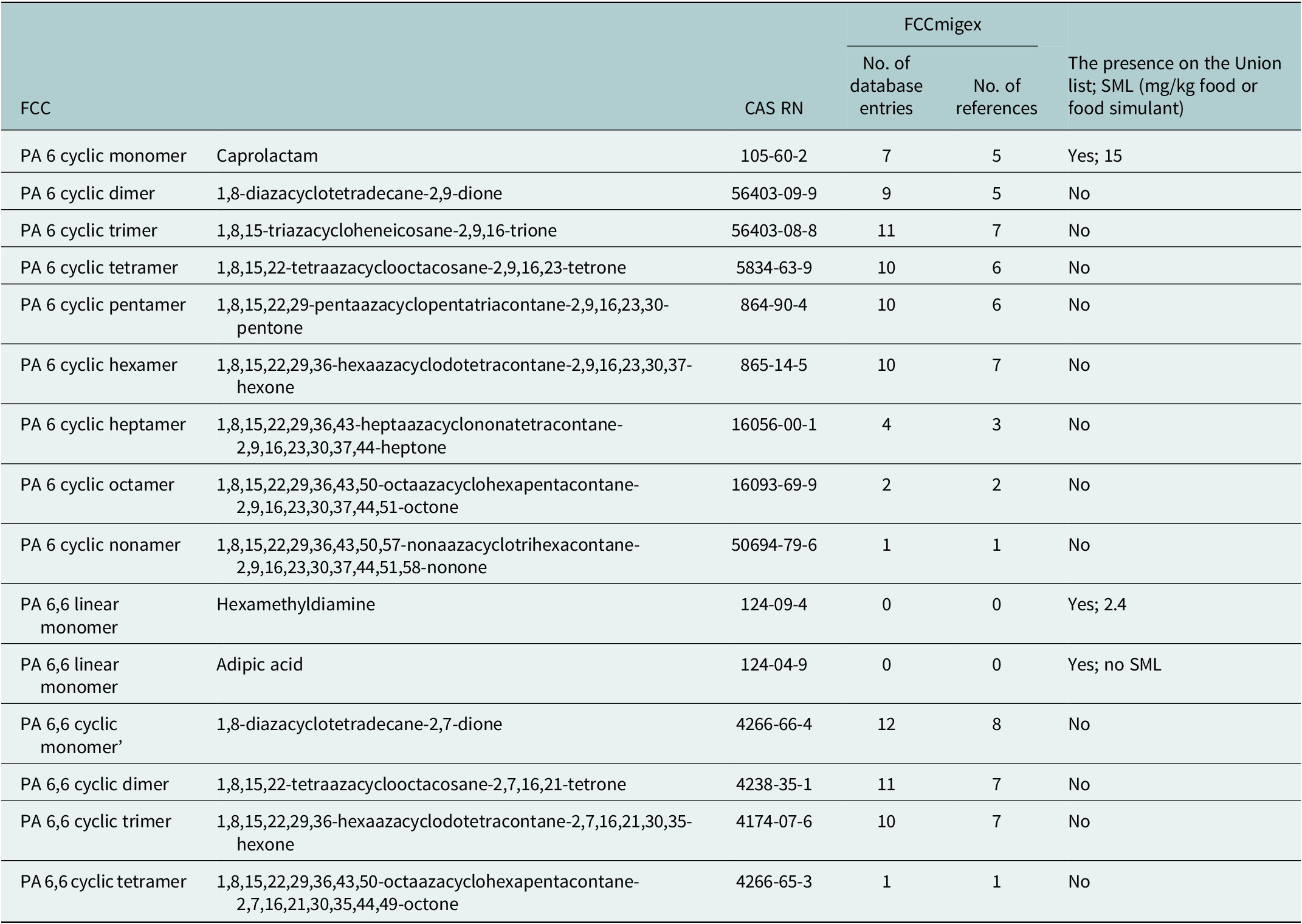

Table 3. Polyamide (PA) monomers and cyclic oligomers in extracts and migrates of repeat-use FCAs made of PA. Cyclic oligomers are reaction by-products formed during the manufacture of PA 6 and PA 6,6

Other FCCs that have been frequently detected in repeat-use plastic FCAs, such as ortho-phthalates, PAAs, silver and BPA (Figure 4 and Table 2), are not selected here as case studies. However, it is noteworthy that the EFSA recently established a tolerable daily intake (TDI) of 0.2 ng BPA per kg body weight per day, which is based on BPA’s immunotoxicity (EFSA, 2023). In comparison with dietary exposure estimates for BPA, this TDI is exceeded by two to three orders of magnitude in all age groups. The human health effects of exposure to ortho-phthalates have also been recently reassessed (EFSA, 2022), and for silver-containing active substances, human health risk assessment is under discussion (EFSA–ECHA, 2020; ECHA, 2021a,b,c). For PAAs, strict regulatory measures are already in place (EU 10/2011, 2011) (Table 2).

Case Study 1: cyclic PA oligomers

Caprolactam is a cyclic starting substance used in the synthesis of PA 6, whereas PA 6,6 is made from two linear monomers hexamethyldiamine and adipic acid. Both types of PA have global production volumes >1 million metric tons per year, of which a small proportion is used in the manufacture of repeat-use FCAs, such as kitchen utensils and appliances. Caprolactam and cyclic PA oligomers were reported to be the most abundant group of FCCs in migrates and extracts of repeat-use FCAs made of PA in general (Song et al., Reference Song, Canellas, Dreolin, Goshawk and Nerin2022). In contrast, the linear starting substances of PA 6,6 were typically not detected (Table 3). Early studies on caprolactam and cyclic PA oligomer migration from repeat-use PA FCAs were published in the 2000s (Brede and Skjevrak, Reference Brede and Skjevrak2004; Skjevrak et al., Reference Skjevrak, Brede, Steffensen, Mikalsen, Alexander, Fjeldal and Herikstad2005; Bustos et al., Reference Bustos, Sendón, Sánchez, Paseiro and Cirugeda2009), but evidence for their migration has increased especially over the last decade (BfR, 2018, 2019b; Kappenstein et al., Reference Kappenstein, Ebner, Förster, Richter, Weyer, Pfaff and Luch2018; Hu et al., Reference Hu, Du, Sun, Ma, Song, Sui and Debrah2021) (Table 3). This development is reflected by improved analytical methods and identification approaches (Song et al., Reference Song, Canellas, Dreolin, Goshawk and Nerin2022), and the custom synthesis of reference standards for PA oligomers, which are not commercially available yet (Canellas et al., Reference Canellas, Vera, Song, Nerin, Goshawk and Dreolin2021).

None of the detected PA oligomers have been found in any of the sources which we consulted to identify hazard properties of concern. This absence of hazard data has already been discussed when PA oligomers were increasingly found in migrates and extracts of repeat-use FCAs, and a first safety assessment of PA oligomers in 2018 relied on the threshold of toxicological concern concept to set specific migration limits (SMLs) of 90 μg/kg food for individual PA oligomers (BfR, 2018; Kappenstein et al., Reference Kappenstein, Ebner, Förster, Richter, Weyer, Pfaff and Luch2018). A year later, a group SML of 5 mg/kg food was proposed for PA 6 and PA 6,6 oligomers based on toxicity studies for 1,8-diazacyclotetradecan-2,7-dione, which is the smallest cyclic product of the PA 6,6 monomers hexamethyldiamine and adipic acid (BfR, 2019b). Nevertheless, oligomer migration from PA has been found to exceed the set values (BfR, 2018, 2019b; Hu et al., Reference Hu, Du, Sun, Ma, Song, Sui and Debrah2021).

Case Study 2: degradation products of antioxidants

In PP, antioxidants are needed to prevent oxidation and degradation of the polymer backbone during processing and service life, which would lead to, for example, discoloration and reduced stability of the plastic product. Sterically hindered phenols (e.g., butylated hydroxytoluene, Irganox 1010 and Irganox 1076) and phosphite antioxidants (e.g., Irgafos 168) are commonly used for this purpose (Dopico-García et al., Reference Dopico-García, López-Vilariñó and González-Rodríguez2007; Dorey et al., Reference Dorey, Gaston, Girard-Perier, Dupuy, Marque, Barbaroux and Audran2020). By intention, antioxidants fulfil their purpose by reacting in the polymer and forming new substances, of which 2,4-DTBP and 2,6-DTBQ were most frequently detected in extracts and migrates of repeat-use FCAs made of PP. 2,4-DTBP is a break-down product of Irgafos 168, whereas 2,6-DTBQ is a derivative of sterically hindered phenol antioxidants. Therefore, 2,4-DTBP and 2,6-DTBQ belong to the group of known and predictable NIASs.

2,4-DTBP is regularly detected in the migrates and extracts of baby bottles made of PP that have been used as substitutes for PC (Simoneau et al., Reference Simoneau, Van den Eede and Valzacchi2012; Onghena et al., Reference Onghena, van Hoeck, Vervliet, Scippo, Simon, van Loco and Covaci2014; Onghena et al., Reference Onghena, Negreira, Van Hoeck, Quirynen, Van Loco and Covaci2016; Onghena et al., Reference Onghena, Van Hoeck, Negreira, Quirynen, Van Loco and Covaci2016; da Silva Oliveira et al., Reference da Silva Oliveira, de Souza, Padula and Godoy2017; Oliveira et al., Reference Oliveira, Monsalve, Nerin, Padula and Godoy2020). Most of the database entries related to 2,4-DTBP in the FCCmigex are derived from untargeted studies (Onghena et al., Reference Onghena, van Hoeck, Vervliet, Scippo, Simon, van Loco and Covaci2014; da Silva Oliveira et al., Reference da Silva Oliveira, de Souza, Padula and Godoy2017; Carrero-Carralero et al., Reference Carrero-Carralero, Escobar-Arnanz, Ros, Jiménez-Falcao, Sanz and Ramos2019). Depending on the sample, migration levels of 10–100 μg/kg food are reported (Onghena et al., Reference Onghena, van Hoeck, Vervliet, Scippo, Simon, van Loco and Covaci2014). Degradation of Irgafos antioxidants and the formation and migration of 2,4-DTBP increases when PP is used at elevated temperatures and in contact with hydrophobic food simulants (Barkby, Reference Barkby1995). In another study, microwave heating shows stronger effects on the migration of 2,4-DTBP than conventional heating (Alin and Hakkarainen, Reference Alin and Hakkarainen2011). 2,6-DTBQ is also frequently detected together with 2,4-DTBP, indicating the simultaneous use of sterically hindered phenols and phosphite antioxidants in the same FCAs (Onghena et al., Reference Onghena, van Hoeck, Vervliet, Scippo, Simon, van Loco and Covaci2014; Onghena et al., Reference Onghena, Van Hoeck, Negreira, Quirynen, Van Loco and Covaci2016; Carrero-Carralero et al., Reference Carrero-Carralero, Escobar-Arnanz, Ros, Jiménez-Falcao, Sanz and Ramos2019).

In 2019, 2,4-DTBP was measured at ‘unexpectedly high’ concentrations in human urine and a lack of hazard data has been stated (Liu and Mabury, Reference Liu and Mabury2019). In the EU, 2,4-DTBP is currently under assessment as EDC (ECHA, 2023d). In contrast, even less data are available for 2,6-DTBQ. For example, the EPA’s CompTox Chemicals Dashboard does not list any hazard data, and the GHS-aligned classification results by the Japanese government do not include 2,6-DTBQ at all. However, 2,6-DTBQ recently has been found to have mechanistic evidence that indicates carcinogenic risk (Cui et al., Reference Cui, Yu, Zhan, Gao, Zhang, Zhang, Ge, Liu, Zhang and Zhuang2022).

Case Study 3: melamine

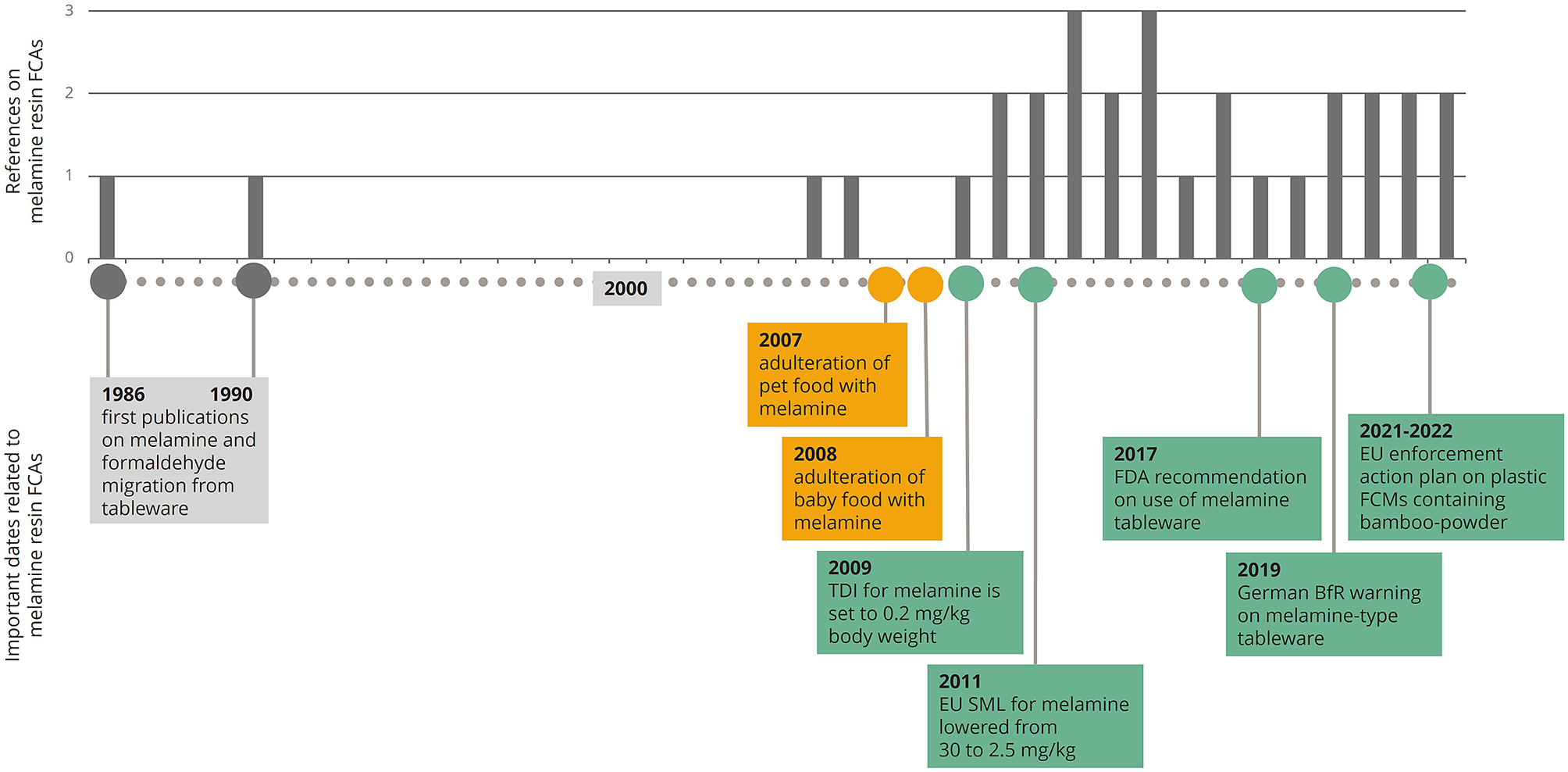

Melamine belongs to the high-production volume chemicals with an estimated yearly production of almost 2 million metric tons in 2021 (NexanTECA, 2021). Together with formaldehyde, melamine is mainly used in the manufacture of MelRes that is commonly used in reusable tableware and kitchen utensils, often marketed for children. In 2007 and 2008, melamine became a high-profile public issue after several food-related scandals in which baby milk powder (Chan et al., Reference Chan, Griffiths and Chan2008; Schoder, Reference Schoder2010) as well as pet food (Chen et al., Reference Chen, Liao, Cheng, Chou, Chang, Wu, Zen, Chen and Liao2009; Puschner and Reimschuessel, Reference Puschner and Reimschuessel2011) was adulterated using melamine. The high nitrogen content of the melamine molecule made it possible to use the industrial chemical as counterfeit for higher protein levels in feed and foods (Figure 5). In China, 50,000 infants were hospitalised because of these criminal food adulterations, and at least six died due to renal failure (Xiu and Klein, Reference Xiu and Klein2010).

Figure 5. Evidence for chemical migration from melamine resin FCAs into foods and food simulants represented by the number of publications by year and important dates related to melamine and food safety.

The migration of melamine and formaldehyde from MelRes tableware has been known since 1986 (Ishiwata et al., Reference Ishiwata, Inoue and Tanimura1986; Sugita et al., Reference Sugita, Ishiwata and Yoshihira1990). Since 2005, melamine has been regularly measured in migrates of tableware and kitchen utensils made of MelRes (Figure 5). Under typical migration conditions (70°C, 3% acetic acid, 2 hours and three repetitions), the SML is exceeded in several studies (Mannoni et al., Reference Mannoni, Padula, Panico, Maggio, Arena and Milana2017; BfR, 2019a; Osorio et al., Reference Osorio, Aznar, Nerín, Birse, Elliott and Chevallier2020). Conditions that increase melamine migration are high temperature, low pH of the food/food simulant and microwaving (Bradley et al., Reference Bradley, Castle, Day, Ebner, Ehlert, Helling, Koster, Leak and Pfaff2010; Ebner et al., Reference Ebner, Haberer, Sander, Kappenstein, Luch and Bruhn2020), as well as UV irradiation (Kim et al., Reference Kim, Lee, Koo, Pack, Lim and Choi2021).

To simulate repeat-use, three repetitions of the migration tests are recommended because it is generally expected that migration levels decrease during use (EC 10/2011, 2011). For three consecutive cycles, there is evidence that the migration of melamine from MelRes follows these expectations (García Ibarra et al., Reference García Ibarra, Rodríguez Bernaldo de Quirós and Sendón2016). However, other studies show a reversed trend when the actual use is simulated for more than three cycles, leading to MelRes degradation and increasing the release of its monomers over time (Mattarozzi et al., Reference Mattarozzi, Milioli, Cavalieri, Bianchi and Careri2012; Mannoni et al., Reference Mannoni, Padula, Panico, Maggio, Arena and Milana2017).

Significant differences in melamine migration have been observed between samples from different suppliers that were tested simultaneously (García Ibarra et al., Reference García Ibarra, Rodríguez Bernaldo de Quirós and Sendón2016). These results illustrate the heterogenous quality of MelRes FCAs, which may be caused by varying chemical compositions, impurities of the starting substances and diverse manufacturing processes.

Additionally, evidence exists that samples have been labelled as MelRes but instead were made of urea-formaldehyde resin, using only a melamine coating on the surface (Poovarodom et al., Reference Poovarodom, Tangmongkollert, Jinkarn and Chonhenchob2011). Such counterfeit samples show formaldehyde migration exceeding the SML of 15 mg/kg after successive washing cycles (Poovarodom and Tangmongkollert, Reference Poovarodom and Tangmongkollert2012).

In recent years, tableware made of MelRes and mixed with bio-based powders or fibres, such as bamboo, entered the market and was often labelled as ‘natural’, ‘compostable’ and ‘eco-friendly’. However, the materials of natural origin are generally only used as fillers for MelRes, which itself is fossil-carbon-based and not biodegradable. Therefore, such labelling is misleading and contains false claims. Even more, bio-based fillers decrease the materials’ stability, promote the migration of melamine and formaldehyde and lead to the exceedance of SMLs for these FCCs (BfR, 2019a; Osorio et al., Reference Osorio, Aznar, Nerín, Birse, Elliott and Chevallier2020). Consequently, the European Commission states that the use of bamboo and other plant-based fillers in plastic FCMs is not authorised according to Regulation (EU) 10/2011. Between May 2021 and April 2022, a European enforcement action plan on plastic FCMs resulted in 748 cases of plastic FCMs containing ground bamboo as filler that were destroyed, recalled or taken off the market (EC, 2022a).

In 2011, the European Commission (EC) lowered the SML of melamine by a factor of 12 to 2.5 mg/kg food (Commission Regulation [EU] No. 1282/2011), which is based on a TDI of 0.2 mg per kg body weight per day that was derived from the development of urinary bladder stones (WHO, 2009; EFSA, 2010). The EC also detailed the import conditions of kitchenware made of MelRes under Commission Regulation (EU) No. 284/2011. In 2017, the FDA issued a recommendation on the use of melamine tableware (U.S. FDA, 2017), and 2 years later, the German Federal Institute for Risk Assessment (BfR) published a warning on melamine-type tableware (BfR, 2019a).

Besides being a renal toxicant (WHO, 2009; NITE, 2023), melamine is recognised as vPvM/PMT chemical (Arp and Hale, Reference Hale2019; ChemSec, 2019; ECHA, 2023c). It is currently under assessment as an EDC and PBT chemical (ECHA, 2023c). Melamine is suspected of damaging the fertility of the unborn child (ECHA, 2023c) and is possibly carcinogenic to humans (IARC, 2019). It may be metabolised to cyanuric acid by the gut microbiome, which supports kidney stone formation (Zheng et al., Reference Zheng, Zhao, Xie, Chi, Zhao, Li, Wang, Bao, Jia, Luther, Su, Nicholson and Jia2013). In a scoping review, Bolden et al. (Reference Bolden, Rochester and Kwiatkowski2017) map evidence for neurotoxic properties of melamine and identify toxicological endpoints that are not well studied, including immune, mutagenic/DNA damage and haematological endpoints.

Discussion

Plastic is the most widely used packaging material for foods and beverages around the world. It generally turns into waste after being used a single time, leading to visible and invisible environmental problems, such as marine pollution by packaging items, microplastics and chemicals (Gallo et al., Reference Gallo, Fossi, Weber, Santillo, Sousa, Ingram, Nadal and Romano2018; Morales-Caselles et al., Reference Morales-Caselles, Viejo, Martí, González-Fernández, Pragnell-Raasch, González-Gordillo, Montero, Arroyo, Hanke, Salvo, Basurko, Mallos, Lebreton, Echevarría, van Emmerik, Duarte, Gálvez, van Sebille, Galgani, García, Ross, Bartual, Ioakeimidis, Markalain, Isobe and Cózar2021). Recycling and reuse of materials have been proposed as measures to reduce the impact of plastic packaging on the environment (Lau et al., Reference Lau, Shiran, Bailey, Cook, Stuchtey, Koskella, Velis, Godfrey, Boucher, Murphy, Thompson, Jankowska, Castillo Castillo, Pilditch, Dixon, Koerselman, Kosior, Favoino, Gutberlet, Baulch, Atreya, Fischer, He, Petit, Sumaila, Neil, Bernhofen, Lawrence and Palardy2020). The information on chemical migration that is available in the FCCmigex database and summarised in this review shows that recycling and reuse of plastic FCAs implies that human exposure to hazardous chemicals increases if this aspect is not carefully managed.

Recycled PET has been widely used in food contact applications for over 20 years. Especially the use of recycled beverage bottles has increased due to the establishment of bottle-to-bottle recycling processes, for which decontamination processes have been developed to reduce chemical contamination (Welle, Reference Welle2011). However, there is experimental evidence that recycled PET contains chemical contaminants that are introduced during use, waste handling and recycling and that can migrate into the packaged beverages. Associations have been found between the presence of recycled content and the migration of, for example, benzene and styrene (two carcinogenic chemicals) as well as the EDC BPA (Dreolin et al., Reference Dreolin, Aznar, Moret and Nerin2019; Thoden van Velzen et al., Reference Thoden van Velzen, Brouwer, Stärker and Welle2020). Based on a systematic evidence map on chemical migration from PET bottles into beverages, other authors conclude that research comparing the chemical migration from virgin and recycled PET bottles is relatively sparse (Gerassimidou et al., Reference Gerassimidou, Lanska, Hahladakis, Lovat, Vanzetto, Geueke, Groh, Muncke, Maffini, Martin and Iacovidou2022). This observation is based on the often-unknown level of recycled PET content in beverage bottles.

Recent research aims at developing methods using untargeted screening of PET samples and machine learning algorithms to effectively discriminate between virgin and recycled content. Chemometric methods have tentatively identified hundreds of VOCs that are associated with plastic, food and cosmetics and reveal significant differences among virgin and recycled PET as well as geographical regions where the recycled material was collected (Li et al., Reference Li, Wu, Wu, Chen, Kou, Zeng, Li, Lin, Zhong, Hao, Dong, Chen and Zheng2022; Peñalver et al., Reference Peñalver, Marín, Arroyo-Manzanares, Campillo and Viñas2022; Dong et al., Reference Dong, Wu, Wu, Li, Su, Li, Lin, Chen, Zheng, Zhu and Zhong2023). Such innovative studies provide highly valuable data on the chemicals that are present in recycled PET and other polymers (Su et al., Reference Su, Vera, Nerín, Lin and Zhong2021). However, whether this methodology can be used to reliably identify the recycled content in plastic food packaging on a routine basis remains to be seen. Even more, the question of how to assess the safety of the high number of chemicals found not only in recycled plastic polymers, but also in virgin plastics, needs to be urgently addressed.

Compared with recycled PET, even less information is available on the chemical migration from other mechanically recycled polymers. However, within the last five years, the U.S. FDA issued an increasing number of favourable opinions on the suitability of recycling processes for producing FCAs made of polyolefins (U.S. FDA, 2023). These numbers may be a good indicator for the actual use of recycled polyolefins as FCMs. In the EU, it is expected that, besides PET, other types of recycled plastic polymers will be available on the market, as the new Commission Regulation EU 2022/2016 on recycled FCMs and FCAs provides the legal framework for such developments (EU 2022/1616, 2022; EC, 2022c). For example, in 2021, the first request for a safety evaluation of recycled PS was submitted to EFSA (OpenEFSA, 2021).

In addition to the evidence for chemical migration from FCMs with recycled content that is presented in this review, research exists on the chemical migration from recycled plastic polymers that are not used in direct contact with food yet but may be considered as FCMs in the future. However, these references were not included in the FCCmigex because we focused on FCAs that were already on the market (instead of experimental materials under development), and on polymer samples intended for the manufacture of FCMs. For example, research as well as official assessments investigating the chemical safety of recycled polyolefins, which are not broadly approved as FCMs yet, shows that chemical contamination and insufficient cleaning technologies limit the application in direct contact with food (EFSA, 2015, 2016; Palkopoulou et al., Reference Palkopoulou, Joly, Feigenbaum, Papaspyrides and Dole2016; Horodytska et al., Reference Horodytska, Cabanes and Fullana2020; Su et al., Reference Su, Vera, Nerín, Lin and Zhong2021; Zeng et al., Reference Zeng, Zeng, Guo, Hu and Wang2023). In this context, it is of concern that the new EU regulation on recycled plastic FCMs provides limited exemptions to allow FCMs produced with novel recycling technologies to be marketed until sufficient evidence has been gathered to decide on the suitability of the technology (EU 2022/1616, 2022).

FCCs that have been detected in migrates and extracts of PA, PP, PC and MelRes can be categorised into starting substances, that is, monomers and plastic additives, and NIASs, for example, reaction by-products, contaminants and degradation products (Table 2). Overall, these data indicate that especially some of the NIASs, such as the PA oligomers and degradation products of antioxidants, are still neglected by many regulators as they are only present in the final FCA or formed during use. Although there is evidence of the migration potential, toxicological data and risk assessment lag behind this knowledge. A solution could be to broaden the focus from testing the starting substances to also assessing the safety of the final FCA (after manufacture and over the life cycle of the FCA).

For PC and MelRes, most evidence is related to monomers that are detected in migrates and extracts. One reason for the frequent detection of BPA, melamine and formaldehyde may be the focus of researchers on these well-known and hazardous migrants for which analytical methods and standards are available, but this knowledge bias may result in other, equally relevant FCCs being overlooked. Alternatively, the abundance of these three FCCs may also be a strong indication for the instability of their respective polymer backbones, leading to migration of monomers that are released as a consequence of polymer degradation processes occurring during reuse and related cleaning. The literature is not clear on this, but there is evidence that PC and MelRes are degraded over repeated use cycles, and migration levels of these monomers increase when tested more than three times (Brede et al., Reference Brede, Fjeldal, Skjevrak and Herikstad2003; Nam et al., Reference Nam, Seo and Kim2010; Mattarozzi et al., Reference Mattarozzi, Milioli, Cavalieri, Bianchi and Careri2012; Mannoni et al., Reference Mannoni, Padula, Panico, Maggio, Arena and Milana2017). Similarly, oligomers are also formed during manufacture or released during the use of PC (Cavazza et al., Reference Cavazza, Bignardi, Grimaldi, Salvadeo and Corradini2021). Also, for PA, there is clear evidence that cyclic oligomers are common manufacturing by-products (Jenke et al., Reference Jenke, Poss, Sadain, Story, Smith and Reiber2005). Although decreasing concentrations of cyclic PA oligomers were reported after three subsequent migration tests (Kappenstein et al., Reference Kappenstein, Ebner, Förster, Richter, Weyer, Pfaff and Luch2018), it remains open whether degradation reactions will increase these levels over longer periods of use. Such cases are not reflected in the current regulation on plastic FCMs, where only three repetitions of the migration tests are required (EU 10/2011, 2011). Moreover, the recommended test conditions for repeat-use FCAs do not reflect realistic use conditions, such as dishwashing, that can, for example, lead to the adsorption of hundreds of dishwasher-related chemicals to the plastic material (Tisler and Christensen, Reference Tisler and Christensen2022). Therefore, it would be highly desirable to revise the recommendations and regulatory requirements for repeat-use plastic FCAs to be able to monitor the stability of the polymers over time as well as the uptake of chemicals under more realistic use conditions.

The degradation of antioxidants in PP and other polyolefins is an expected and well-studied process (Haider and Karlsson, Reference Haider and Karlsson2002; Dorey et al., Reference Dorey, Gaston, Girard-Perier, Dupuy, Marque, Barbaroux and Audran2020). However, typical degradation products, such as 2,4-DTBP and 2,6-DTBQ, have rarely been targeted in migration studies. Indeed, many of the results for these chemicals included in the FCCmigex are from untargeted screenings (Skjevrak et al., Reference Skjevrak, Brede, Steffensen, Mikalsen, Alexander, Fjeldal and Herikstad2005; Hu et al., Reference Hu, Du, Sun, Ma, Song, Sui and Debrah2021; Li et al., Reference Li, Wu, Wu, Chen, Kou, Zeng, Li, Lin, Zhong, Hao, Dong, Chen and Zheng2022). Already in 2014 it was stated that these anticipated degradation products were not addressed in the European FCM regulation (Onghena et al., Reference Onghena, van Hoeck, Vervliet, Scippo, Simon, van Loco and Covaci2014), and since then, the situation has not changed. This is especially concerning since 2,4-DTBP is under assessment as an EDC, and for 2,6-DTBQ limited hazard data indicate potential concern for carcinogenicity (Table 2). At the same time, these and structurally related NIASs can be assumed to be present ubiquitously in PP packaging, leading to significant human exposure (Liu and Mabury, Reference Liu and Mabury2019). Therefore, hazard data for these substances are urgently needed to fill data gaps.

In this review, we showed that chemical migration from recycled and repeat-use FCAs is of concern because FCCs with priority hazard properties are present in all investigated materials. What is more, for other frequently detected FCCs, no or only limited hazard data exist, like PA oligomers and 2,6-DTBQ. Plastic recycling can introduce unknown or known hazardous chemicals originating from all stages of the life cycle as well as from illicit sources into food packaging and other plastic FCAs. Further concern stems from the observation that it is very difficult to discriminate virgin and recycled materials. Additionally, there is evidence for a potential increase in migration rates after prolonged use of reusable plastic FCAs, which should be better tested in the future.

Many of the data presented here have been acquired in targeted analytical studies. However, there is currently a shift towards untargeted screening studies, which are more suited to represent the chemical complexity of a migrate or extract. While the growing body of evidence in this area is highly appreciated, the question arises how this information can be used to increase the safety of plastic FCMs, because many of the chemicals detected in such screenings do not have any hazard data and cannot be tested one by one. In the future, one solution could be the routine implementation of bioassays to test the safety of migrates and extracts (Groh and Muncke, Reference Groh and Muncke2017; Muncke et al., Reference Muncke, Andersson, Backhaus, Belcher, Boucher, Carney Almroth, Collins, Geueke, Groh, Heindel, von Hippel, Legler, Maffini, Martin, Myers, Nadal, Nerin, Soto, Trasande, Vandenberg, Wagner, Zimmermann, Zoeller and Scheringer2023). Alternatively, a shift towards materials that can be safely reused due to their favourable, inert material properties could be a promising option to reduce the impacts of single-use food packaging on the environment and of migrating chemicals on human health. There is an urgent need for establishing suitable analytical methods with low limits of detection to assess the inertness of FCMs, and for including such considerations in FCM and packaging regulations all over the world.

Based on these data, we know that many hazardous chemicals have been found in migrates and extracts of plastic FCMs, and we have evidence for a potential increase in migration rates after prolonged use of some repeat-use plastic FCAs. Importantly, the introduction of unknown and known hazardous chemicals during plastics recycling is of concern, and we caution stakeholders on this matter.

Open peer review

To view the open peer review materials for this article, please visit http://doi.org/10.1017/plc.2023.7.

Data availability statement

The most recent update of the FCCmigex database (version 2, release date: 11 April 2023) is publicly available as an interactive dashboard using Microsoft PowerBI under the following open access link: https://www.foodpackagingforum.org/fccmigex.

Author contribution

This overview review was conceptualised by B.G. and J.M. Literature screening and data extraction were performed by B.G. and D.W.P. Data were processed by L.V.P. The original draft of the manuscript was written by B.G. and J.M. All authors provided review and constructive feedback and approved the final version.

Financial support

This work was funded by the Food Packaging Forum Foundation (FPF), a charitable organisation financed by donations and project-related funding. All funding sources are listed on the FPF’s website (www.foodpackagingforum.org).

Competing interest

The authors have no competing interest to report. B.G., L.V.P. and J.M. are employees of the Food Packaging Forum Foundation (FPF), and D.W.P. was paid as a consultant by the FPF for this work. The authors were not restricted in any way to plan and execute this work.

Comments

Dear Prof. Farelly,

Thank you for the kind invitation to submit a review article to the launch issue of Cambridge Prisms:

Plastics. Our manuscript is entitled “Hazardous chemicals in recycled and reusable plastic food

packaging” by Birgit Geueke, Lindsey Parkinson, Drake Phelps, and Jane Muncke.

In our manuscript, we address the urgent and major societal challenge related to the current focus on

plastic food packaging waste management options, namely recycling and reusing packaging. This false

solution is of great concern because of known hazardous chemicals present in plastics throughout their

life cycle, leading to human exposure. Another related issue is the migration of many untested chemicals

from plastic packaging into foodstuffs. Both issues are enhanced by using recycled and reusable plastics

for food packaging.

As almost the entire human population is exposed chronically to food contact chemicals, and as the world

is negotiating a global plastics treaty where certain stakeholders are pushing for increased recycling of

plastic food packaging or its reuse, we think that this important aspect fits well into the scope of your

journal. We think that a broad discussion of this issue supported by the evidence base that we provide

here is urgently needed, and that Cambridge Prisms: Plastics is a highly suitable venue for this.

This manuscript is an original submission prepared by invitation for Cambridge Prisms: Plastics and is not

under consideration for any other journal. All authors have made substantial contributions to the

manuscript and have approved the submitted version, and all authors have provided a written statement

regarding conflict of interest. If you have any questions regarding our manuscript, please contact us.

Thank you for your consideration.

Sincerely,

Jane Muncke and Birgit Geueke