The Lingnan area is a border region in southern China and includes Guangxi, Guangdong, Hong Kong and Macau. It is separated from the north by the Nanling Mountains and drained by the Pearl River system (Figure 1). Lingnan was the home of the Bai Yue 百越 (hundred Yue) tribes and, before Qin's conquest of Bai Yue in 214 BC, the region was relatively isolated from the Central Plains. Following the unification of China under Qin Shi Huang, society and culture in the Lingnan area developed rapidly and were influenced largely by the Qin and Han Dynasties. Qin's conquest brought new migration and economic policies, and advanced technologies, to Lingnan. The use of iron, and iron-production technologies, played an important role during this developing period (221 BC–AD 220).

Figure 1. Location of the sites in the Lingnan region, China (base map: National Platform for Common Geospatial Information Services).

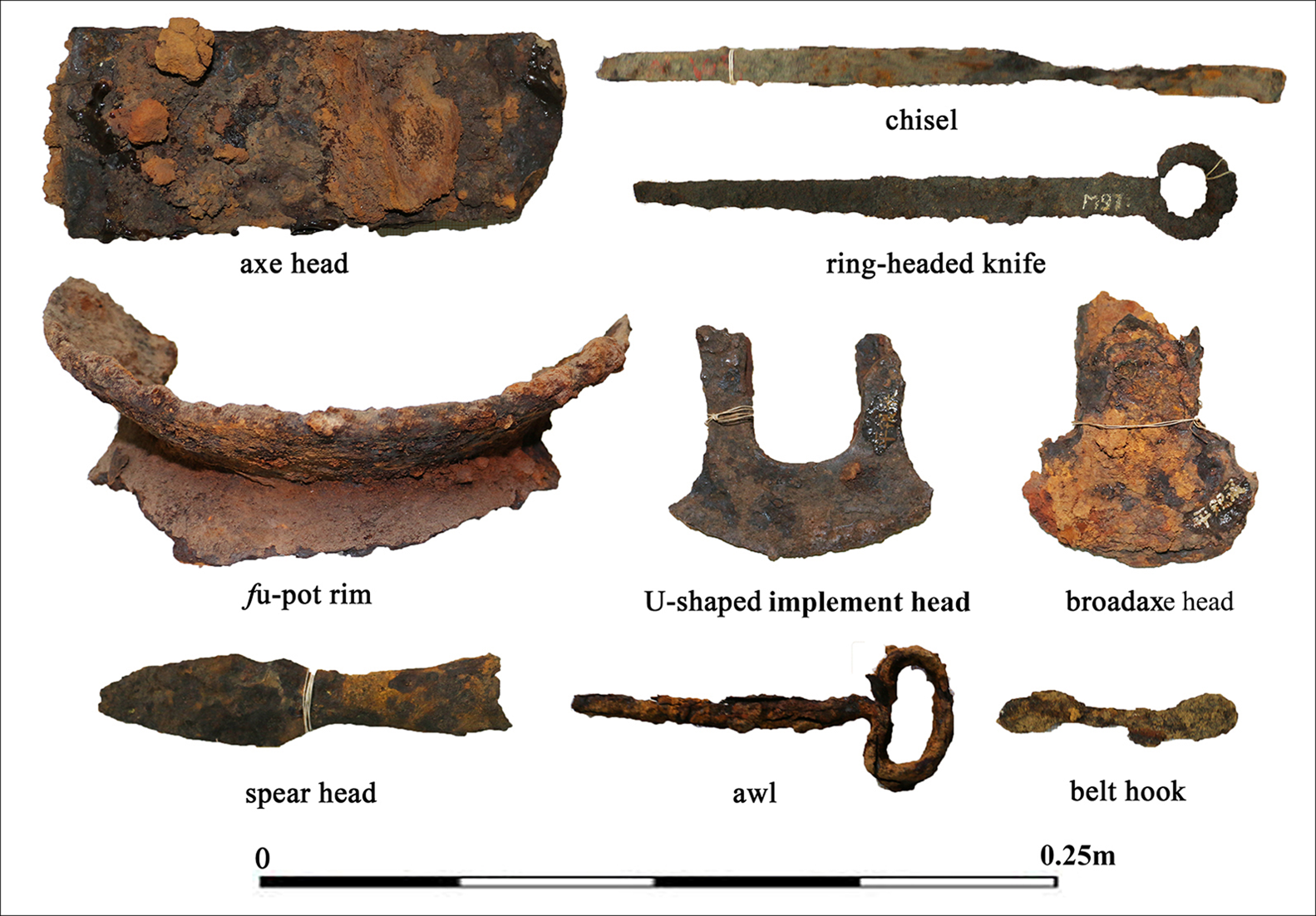

According to historical records, iron smelting in Lingnan appeared in the third century AD (Yang Reference Yang1977; Huang Reference Huang1996; Bai Reference Bai2005). More than 2700 iron objects, however, were recovered from excavations in the Lingnan region, all dating to earlier than AD 220. These include iron tools, weapons, domestic objects, personal accessories, and horse and chariot accessories (Figure 2). Most of these objects were excavated from cemetery sites close to ancient cities and roads; for example, in some of the regional commanderies (administrative regions), such as the Yulin commandery (modern Guigang), Hepu commandery (modern Hepu) and Nanhai commandery (modern Guangzhou). The metallurgical study of ancient iron objects in Lingnan is very limited, with only 14 iron objects so far analysed (Anonymous 1991; Huang et al. Reference Huang, Li, Zheng, Chen and Feng2016). The ‘Qin & Han Iron Smelting Site Investigation Project’ is a collaboration between Sichuan University and the Museum of Guangxi Zhuang Autonomous Region. In order to study the early use of iron, including the raw materials, production technologies and uses of iron objects in Lingnan, we carried out a systematic survey of the excavated iron objects, and selected 110 examples for scientific analyses. Samples were collected from a diverse range of iron objects with very different uses, including tools, weapons, domestic objects and accessories. These were excavated from sites at Yinshanling, Guigang, Hepu, Fenghuangling, Datangcheng, Liugaoshan and Putuocun. Most of these are cemetery sites; the iron objects were dated to the Qin and Han Dynasties based on the typology of grave goods found associated with the burials. This project addresses a lacuna in metallurgical studies in China, and provides valuable data that can further our understanding of the early production and use of iron objects in Lingnan.

Figure 2. Examples of iron objects excavated from sites in Lingnan (source: authors).

Samples were taken by making two incisions to extract a thin section from the centre of the iron object. The sections were compression mounted, ground, polished and then examined using a Leica CM6000M optical microscope before and after etching with 2% nital (a solution of nitric acid and alcohol commonly used for etching metals). Scanning electron microscope energy dispersive spectroscopy analyses were carried out with an Oxford X-Max N 50mm2 EDS system at the Jinsha Museum in Chengdu, China. Most of the samples have now been analysed, and publication of the full results is forthcoming. Preliminary results of the study show that the iron objects were made by a process of forging or casting using raw materials that included wrought iron, steel, malleable cast iron, white cast iron and mottled cast iron. Iron tools and domestic objects were more likely to be cast, while weapons were forged. Decarburisation (the reduction of carbon in the metal, making it softer) and carburisation (the increased absorption of carbon to make the metal harder) were used on most of the implements and weapons (Figure 3). Decarburisation was generally used on tools, while carburisation was applied to weaponry. When compared with studies of the raw materials and production technologies of iron objects in other areas of ancient China, the processes in use at Lingnan are similar (Zhang Reference Zhangn.d.).

Figure 3. Microstructures of sampled iron objects: a) mottled cast iron; b) malleable cast iron; c) cast iron; d) steel (source: authors).

Figure 4. Top left) view of the Guigang smelting site; top right) furnace base; bottom left) slags; bottom right) tuyere (source: authors).

Slags collected during excavation of one of the early iron smelting sites in Guigang, in the Lingnan region, were subjected to both macro and micro studies in order to investigate the early use of iron smelting technology and perhaps identify the source of iron ores used in the smelting process. Preliminary data show that Guigang may have been a bloomery smelting site. Bloomery smelting uses a furnace to smelt iron from its oxides. Analysis of more data is necessary before the results from Guigang can be compared with those from other bloomery smelting sites. A future aim of the project is to collect more data in order to identify the source of the raw materials used to produce the iron objects found at Lingnan, and to discuss the application of bloomery technology in the region.

Under the control of the Qin and Han Dynasties (221 BC–AD 220), and especially after 119 BC when Han Wu Di established a state monopoly on iron and salt, the production and the trade of iron objects were strictly controlled by the central authority. According to the Han Shu—the history of the Former Han Dynasty (206 BC–23 AD)—compiled by Ban Gu in 80 AD (Ban Reference Ban1962: 1628), Lingnan did not have a tieguan (an official iron industry under state monopoly). This suggests that Lingnan had no officially managed, large-scale iron-smelting activities. The production technologies of the iron objects excavated in Lingnan are similar to those known to be in use in the Central Plains, south-west China and the middle and lower reaches of the Yangtze River at this time. Given that the majority of these excavated iron objects were not made in a bloomery smelting site, we believe that most of the iron artefacts discovered in Lingnan were imported from these areas. Future work will focus on how these iron objects may have been imported to Lingnan by considering the trading policies of this frontier area during the Qin and Han Dynasties, and the role of iron objects in the social life of Lingnan.

Acknowledgements

This research was funded by The National Social Science Fund of China (grant number 15ZDB056) and the China Postdoctoral Science Foundation (grant number 2019M653456).