Introduction

Over the last few decades, an increasing number of prehistoric copper mines have been discovered around the world (O'Brien Reference O'Brien2015; Ben-Yosef Reference Ben-Yosef2018). Archaeologists studying these complex and difficult-to-excavate sites face major challenges, especially when seeking to link mine ores to metalwork, establishing the scale of production and tracing associated trade/exchange networks. To achieve these aims requires the development of a methodology that combines the latest interdisciplinary expertise in ore geology, mineralogy, archaeometallurgy and analytical geochemistry. Such integrated approaches promise a firm foundation on which to discuss the social organisation of prehistoric mining and trade/exchange networks. Just such a methodology has now been developed to re-evaluate the Great Orme Bronze Age copper mine in north Wales, one of the largest in Europe (Figure 1). Based on claims that the mine produced only an insignificant, low-impurity type of copper, the mine's great size has been attributed to small-scale, seasonal working over nearly a millennium, rather than a more concentrated phase of large-scale exploitation.

Figure 1. Aerial view of the Great Orme mine site looking south-east towards Llandudno (© Great Orme Mines Ltd).

Bronze Age copper mining in Britain

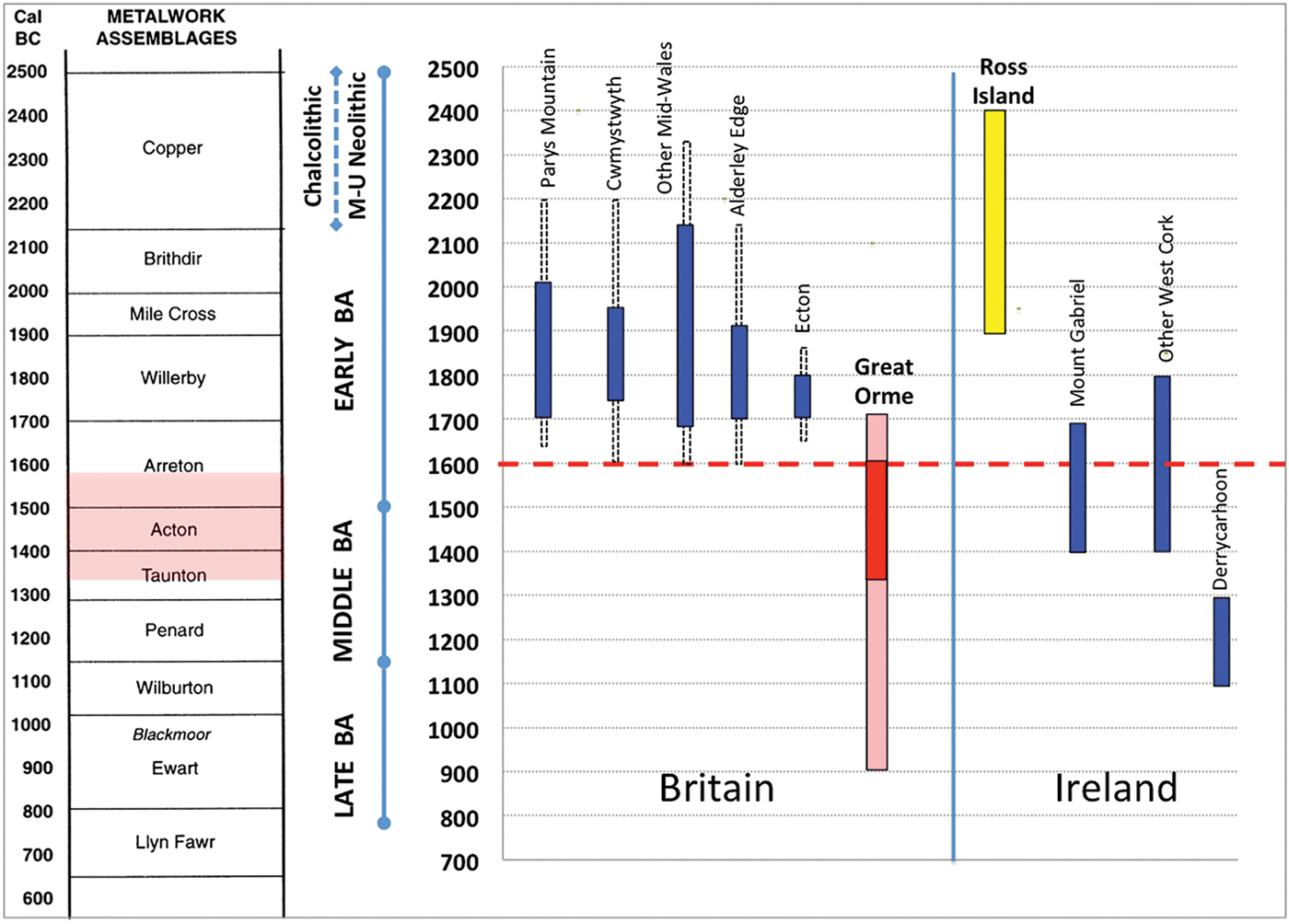

The Ross Island mine in south-west Ireland provided Britain with most of its earliest copper supply. Opening c. 2400 BC, the mine is associated with Beaker pottery, which suggests a link with the migration from continental Europe of people who spread the Beaker culture and introduced metallurgical knowledge (O'Brien Reference O'Brien2004). From around 2200 BC onwards, there was an apparent wave of exploration, possibly originating from Ireland, which gave rise to copper mining in north Wales at Parys Mountain, in mid Wales at Cwmystwyth and in central north-west England at Alderley Edge (Timberlake Reference Timberlake and Clark2009). In addition, Cornish/Devonian tin in south-west England was probably also discovered around this time, as Britain rapidly switched from copper to full tin-bronze (around 10 per cent tin) c. 2150 BC—much earlier than most of the rest of Europe (Pare Reference Pare2000). All the known British Bronze Age copper mines appear to have been relatively small and had closed by c. 1600 BC (Timberlake & Marshall Reference Timberlake and Marshall2014); Great Orme, however, continued in use for another seven centuries (Figure 2).

Figure 2. Chronology of British and Irish Bronze Age mine sites (M-U = metal-using) (data from Rohl & Needham Reference Rohl and Needham1998; Timberlake & Marshall Reference Timberlake and Marshall2014; O'Brien Reference O'Brien2015) (figure by R.A. Williams).

The Great Orme copper mine

The extraordinary complex of surface and underground workings of the Great Orme Bronze Age mine was discovered in 1987 (Dutton & Fasham Reference Dutton and Fasham1994; O'Brien Reference O'Brien2015). Nineteen radiocarbon dates suggest that the mine was probably worked for approximately eight centuries (c. 1700–900 BC), from the late Early Bronze Age to the Late Bronze Age (Williams Reference Williams2018). The Great Orme is a prominent Carboniferous limestone headland on the north Wales coast above Llandudno. A series of mainly north–south-trending veins in dolomite contained primary chalcopyrite (copper iron sulphide) that had mostly been converted by supergene weathering into secondary green malachite (copper carbonate hydroxide) and brown goethite (iron oxide hydroxide). Archaeological evidence indicates that Bronze Age miners worked these secondary ores, which are much easier to smelt than the primary iron-rich sulphide ores (Williams Reference Williams2014).

Excavations have revealed extensive surface ‘opencast’ workings (probably a collapsed chamber), beneath which is a large underground chamber (10 × 15m and 8m high), surrounded by several kilometres of mostly small, irregularly shaped underground workings on narrow veins (Dutton & Fasham Reference Dutton and Fasham1994; Lewis Reference Lewis1996). Artefacts recovered include over 2400 hammerstones, over 30 000 pieces of bone—many used as tools—and also abundant bronze fragments from tools (James Reference James2011; Jowett Reference Jowett2017). Fragmentary remains of a small smelting site at Pentrwyn, 1.2km from the Great Orme mine, are consistent with simple ‘hole-in-the ground’ smelting of secondary ores, and date to c. 900 BC—very late in the mine's life. Larger earlier smelting sites are yet to be discovered either on the Great Orme or in the vicinity (e.g. associated with settlements or areas with more fuel).

Metalwork from the predominant period of mine workings (the Middle Bronze Age) typically contains arsenic and nickel impurities, whose importance lies in providing a chemical ‘fingerprint’ for identifying potential mine ore sources. Influential articles, however, have claimed that the Great Orme ores produced only uncommon, low-impurity metal, and so could not be the main source of metal from the Middle Bronze Age (Craddock Reference Craddock1994; Ixer & Davies Reference Ixer and Davies1996; Ixer & Budd Reference Ixer and Budd1998; Northover Reference Northover, Hauptmann and Pernicka1999; O'Brien Reference O'Brien2015). This claim of only low-impurity ores was based on the absence of nickel and arsenic minerals, although the levels of these elements were not checked using chemical analyses. The extensive size of the mine has been explained as the result of small-scale, seasonal production spanning nearly a millennium (Budd & Taylor Reference Budd and Taylor1995; O'Brien Reference O'Brien2015). While some scholars believe that the Great Orme mine was an important source of metal, they have been unable to explain the conflicting chemical, isotopic and archaeological evidence (Rohl & Needham Reference Rohl and Needham1998; Lynch et al. Reference Lynch, Davies and Aldhouse-Green2000; Timberlake Reference Timberlake and Clark2009; Bray & Pollard Reference Bray and Pollard2012).

Samples and analyses

Drawing on interdisciplinary expertise, a robust, specific, mine-based metal group methodology was developed to characterise the chemical and isotopic ranges of the metal that could be produced from the ore variations established from extensive sampling at the Great Orme mine. The ranges established could then be checked for consistency with metals found in or close to the mine, followed by a comparison with metal artefacts from across Britain in existing databases. This procedure would establish artefacts consistent with Great Orme metal, while indicating the mine's importance over time and its geographic reach. The isotopic ‘fingerprint’—independent of the chemical ‘fingerprint’—is based on the ratios of the various isotopes of lead present as an impurity in copper ores (Rohl & Needham Reference Rohl and Needham1998). The materials analysed chemically and for lead isotopes were:

• Copper ore samples from throughout the Bronze Age workings.

• Bronze fragments recovered from the mine that originated from metal tools.

• Copper metal fragments (prills) from the Pentrwyn smelting site and also copper produced from smelting experiments undertaken for this study.

Chemical analyses were carried out using microwave plasma atomic emission spectroscopy (MP-AES), wavelength-dispersive X-ray fluorescence (WD-XRF), inductively coupled plasma atomic emission spectroscopy (ICP-AES) and laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS). Lead isotope measurements were taken using multicollector inductively coupled plasma mass spectrometry (MC-ICP-MS). The key data produced by this study are provided in Tables S1 and S2 in the online supplementary material (OSM).

Results

The ore results have been used to define both chemical impurity fields and lead isotope fields for Great Orme copper. In contrast to previous subjective, artefact-based metal reference groups, these fields form a specific, mine-based metal reference group. The chemical element fields are defined using four of the most common elemental impurities in Bronze Age metalwork: arsenic, nickel, antimony and silver. As the copper level in all the ores is very variable, the data were initially normalised to 100 per cent copper metal to allow for comparison and to represent the metal produced by smelting using the procedure adopted by Pernicka (Reference Pernicka, Roberts and Thornton2014) for mine ores elsewhere in Europe. This assumes that the key elemental impurities in copper ores can partition up to 100 per cent into the metal, rather than into the slag, as suggested by Tylecote et al. (Reference Tylecote, Ghaznavi and Boydell1977). Rather than accept these maximum partition figures based on ores and smelting techniques from very different sites in Europe, smelting experiments on pre-analysed Great Orme ore were undertaken to establish partition figures to use in this study. The results suggested a partition of 70 per cent was more realistic for arsenic and nickel, but that 100 per cent was reasonable for the low levels of silver and antimony present in the ores.

Figure 3 shows the arsenic-nickel plot of the Great Orme ores. Natural ores often show a wide range of compositions—especially on the micro scale—but they are greatly reduced by mixing during mining and ore-processing. Hence, in this study, a composite ore sample was taken at each sample location, and the sample was crushed and mixed to maximise homogenisation before an aliquot was taken for analysis. To identify which Bronze Age artefacts are consistent with Great Orme metal, the limits of the chemical field need to be defined, and while no method is perfect statistically, the most pragmatic method identified was to use confidence ellipses.

Figure 3. Great Orme ores: nickel-arsenic and antimony-silver data are used to define composition fields (ellipses). Also shown are the bronze fragments (yellow circles) from the mine and copper prills (blue rhombuses) from the Pentrwyn smelting site (figure by R.A. Williams).

The most notable result from the arsenic-nickel plot (Figure 3) is the relatively high levels of both arsenic and nickel, contrary to the longstanding claims in the literature of low impurity levels. Micro-analyses (LA-ICP-MS) showed that the main source of the high level of impurities is in the goethite, due to its exceptionally accommodating crystal structure that allows isomorphous substitution of iron 3+ ions by other metal ions, such as nickel, and can reach significant percentages by weight (Bowles et al. Reference Bowles, Howie, Vaughan and Zussman2011). The consistency of the newly defined chemical composition field was tested against metals associated with the mine. Firstly, the bronze fragments recovered from the mine (Figure 3) plot close to the mean composition of the ores. Secondly, the copper prills from the Pentrwyn smelting site also fall within the field defined, mainly towards the lower end. The same consistency was seen in the antimony-silver plot (Figure 3), in which antimony levels are characteristically very low and silver levels are moderately low.

Having gained confidence in the defined chemical fields, artefacts consistent with Great Orme metal can now be identified in existing Bronze Age metalwork databases. Data were plotted for each of the 10 metalwork assemblages or phases from across Britain that correspond broadly with time periods covering the Bronze Age in Britain (Figure 2). As with all past studies, it was assumed that impurities originate predominantly from the copper in the bronze, rather than the usually low-impurity tin (Pernicka Reference Pernicka, Roberts and Thornton2014), and that recycling does not significantly obscure changes in the dominant copper source. The two-stage procedure employed to identify metalwork chemically consistent with Great Orme metal used the antimony-silver plot as an initial filter, before progressing to the arsenic-nickel plot for assessment. This was carried out for all metalwork phases using data from Rohl and Needham (Reference Rohl and Needham1998). Figure 4, for example, presents data from the Late Bronze Age Wilburton phase (c. 1140–1020 BC), showing high levels of antimony and silver, with only a few plotting in the Great Orme field. Those within the ellipse field were then plotted on the nickel-arsenic plot. As all of them, however, have virtually no nickel, they are probably not made from Great Orme metal. Plots for the other metalwork phases show little or no metal consistent with the central core of the Great Orme field, with the clear exceptions of the Acton Park phase and part of the subsequent Taunton phase.

Figure 4. Metalwork artefacts. Top) Wilburton phase: antimony-silver plot filter followed by nickel-arsenic plots; bottom) Acton Park phase, showing mainly Group I palstaves (left: British finds; right: European hoards) (data from: this study; Rohl & Needham Reference Rohl and Needham1998; OXSAM database; Tréboul data (various artefact types) from Le Carlier de Veslud) (figure by R.A. Williams).

The Acton Park phase (c. 1600/1500–1400 BC) metalwork is virtually all consistent with Great Orme metal, when using the Rohl and Needham (Reference Rohl and Needham1998) data and the additional chemical-only data on shield-pattern palstaves from the OXSAM database (Figure 4). Instances of high lead levels can be explained by a lead vein that crosses the copper veins at Great Orme. As shield-pattern palstaves are also found in continental Europe, plotting existing chemical data from hoards in Brittany (Tréboul), South Holland in the Netherlands (Voorhout) and Sweden (Hönö, Boshuslän) shows that they all match closely with Great Orme metal (Figure 4). Similar results have also been obtained with dirks, rapiers (Group II) and spearheads (Group 6), all belonging to the Acton Park phase. The limited amount of Irish data from this period indicate significant amounts of Great Orme metal. British data from the Taunton phase, which follows the Acton Park phase, indicate a mixture of Great Orme metal and a new metal with higher nickel levels originating from the south, probably from a source in mainland Europe (e.g. the eastern Italian Alps; Melheim et al. Reference Melheim, Grandin, Persson, Billström, Stos-Gale, Ling, Williams, Angelini, Canovaro, Hjärthner-Holdar and Kristiansen2018).

The next stage is to define the lead isotope fields for Great Orme ores; these are completely independent from the chemical fields. The only partial overlap of the Great Orme field with another British Bronze Age mine is with the small Alderley Edge mine that was closed before the zenith of the Great Orme. Most of the Great Orme data (Figure 5) form clusters in one area, with a sharp cut off. A few data points form a long scattered irregular radiogenic tail. These are copper ores with low lead levels (away from the lead vein), combined with substantial amounts of uranium and/or thorium, whose radioactive decay produces lead that significantly alters the isotope ratios. Plotting the bronze fragments from the Great Orme mine shows an excellent correlation with the main ore cluster, while the correlation of Pentrwyn copper prills spans the whole radiogenic range of the ores.

Figure 5. Ores and metal artefacts: lead isotope plots for Great Orme ores, associated metals and Acton Park metalwork including continental hoards (data from: this study; Rohl & Needham Reference Rohl and Needham1998; OXALID database; Ling et al. Reference Ling, Stos-Gale, Grandin, Billström, Hjärthner-Holdar and Persson2014; Tréboul data from Le Carlier de Veslud).

Plotting the Acton Park metalwork assemblage data also shows that most of them have an excellent correlation with the main ore cluster area, while a few have a more variable correlation with the scatter of ores along the irregular radiogenic tail. In addition, the Acton Park shield-pattern palstaves from Brittany, South Holland and Sweden also lie within the Great Orme isotope range, independently confirming the chemical evidence. The isotope data for the subsequent Taunton phase suggest a mixture of Great Orme metal and a new source with very different lead isotope values; this also confirms the chemical analysis interpretation.

Combining the chemical and isotope evidence for all the metalwork assemblages produces Figure 6, which shows that the zenith of the Great Orme mine came in the Acton Park phase. Only compositional data were used for the Late Bronze Age metalwork, as the high levels of added lead produce isotope ratios that indicate the lead source, rather than the copper source.

Figure 6. Percentage of Great Orme metal consistent chemically and isotopically with each Bronze Age metalwork phase (figure by R.A. Williams using metalwork data from Rohl & Needham 1998).

Discussion

The results indicate that the peak of production at the Great Orme mine coincides with the Acton Park phase or metalwork assemblage (1600/1500–1400 BC), the starting date of which has been debated (Needham Reference Needham1983, Reference Needham1996). Indications that early forms of Acton Park palstaves overlapped with the Arreton metalwork phase (1700–1500 BC) suggest the most probable start date to be c. 1600 BC (Burgess Reference Burgess and Renfrew1974; Schmidt & Burgess Reference Schmidt and Burgess1981; Field & Needham Reference Field and Needham1985). After the apparent decline in Great Orme metal production in the Taunton phase (1400–1300 BC), the metal becomes virtually invisible within the databases of extant metalwork. How then do we explain the many later radiocarbon dates from the Great Orme mine, which extend through to c. 900 BC? In the centre of the mine, many of the parallel veins merge together to form two richly mineralised areas that have been completely mined out, forming the large underground chamber and the surface ‘opencast’ area. Once the rich supply of copper ore from these two areas had been exhausted—which may have taken up to two centuries—all that remained were the kilometres of narrow, low-grade veins. These would have required great effort underground to extract ore, while yielding only minimal quantities. This explanation is supported by the oldest radiocarbon dates being associated with the underground chamber and the opencast area (James Reference James2011). Overall, we propose a ‘golden age’ of ore production at Great Orme, c.1600–1400 BC, followed by a twilight period lasting many centuries, and during which only small amounts of ore were produced. The total amount of barren rock removed from the Bronze Age workings to obtain the ore was at least 16 000 tonnes and possibly as high as 40 000 tonnes (Lewis Reference Lewis1996).

How far did Great Orme metal spread across Britain? Having established a correlation between Great Orme metal and nearly all analysed Acton Park artefacts, the findspots of the characteristic artefact types from this phase indicate the probable distribution of Great Orme metal. Figure 7 shows the distribution of shield-pattern palstaves, which are widespread across Wales and lowland England. The relatively low density in northern Britain is explained by the regional preference for the rarely analysed flanged axes, which may reflect cultural boundaries. The density distribution highlights two high-density areas—namely the Fenlands, where modern agricultural activities favour the recovery of metalwork, and north-east Wales and the adjacent borderland. The latter is potentially the most significant, as it may indicate an area of metalwork production in the region immediately adjacent to the Great Orme mine. The density distribution plot for dirks and rapiers (Group II) also independently highlights the same area.

Figure 7. Distribution map of Acton Park phase Group I shield-pattern palstaves with density distribution (right) (data from OXSAM; Schmidt & Burgess Reference Schmidt and Burgess1981; PAS; figure by R.A. Williams).

Figure 8 highlights possible distribution routes for Great Orme metal based on the shield-pattern palstaves, suggesting that riverine routes, such as the Severn Valley corridor, and overland routes, such as the prehistoric Ridgeway, were used in addition to coastal routes.

Figure 8. Possible trade/exchange routes for Great Orme metal based on the distribution of Group I shield-pattern palstaves (figure by R.A. Williams).

The evidence for connections between Great Orme and continental Europe is also revealed from the distribution of shield-pattern palstaves (Figure 9). Three sites in Brittany, South Holland and Sweden show typological, chemical and isotopic data matches with Great Orme. These matches increase the probability that the shield-pattern palstaves at these continental locations originate from the Great Orme, rather than being local copies using metal from elsewhere. There is also chemical, isotopic and (after this study) chronological evidence (c. 1600–1500 BC) for some Great Orme metal in Denmark, although typological evidence is lacking (Melheim et al. Reference Melheim, Grandin, Persson, Billström, Stos-Gale, Ling, Williams, Angelini, Canovaro, Hjärthner-Holdar and Kristiansen2018).

Figure 9. Continental distribution map: Acton Park phase, Group I shield-pattern palstaves (base map by Esri, DeLorme, GEBCO, NOAA, NGDC and other contributors). Data from: Butler (Reference Butler1963); Rowlands (Reference Rowlands1976); O'Connor (Reference O'Connor1980); Cordier (Reference Cordier2009); Gabillot (Reference Gabillot2003) (figure by R.A. Williams).

Estimating the amount of metal produced by any mine is always difficult as it relies on several assumptions, including the average ore grade and losses from ore-processing and smelting. Estimates for the copper metal produced from all the Bronze Age workings of the Great Orme mine, using interdisciplinary mining geology expertise combined with fieldwork observations, range from 232–830 tonnes, based on optimistic and pessimistic assumptions (Williams Reference Williams2018). Most of this production (202–756 tonnes) came from the two richest areas discussed earlier that probably provided around 200 years of high-output ore production (c. 1600–1400 BC). This equates to roughly one to four tonnes per year over two centuries, equivalent to about 2200–8900 palstave axes per year. The apparent widespread distribution of Great Orme metal across Britain and into continental Europe suggests major production levels, probably for commodity trade rather than simple gift exchange. Even higher total outputs have been estimated for the Mitterberg region in Austria, reaching up to 20 000 tonnes of copper between the sixteenth and thirteenth centuries BC (Pernicka et al. Reference Pernicka, Lutz and Stöllner2016).

A model of seasonal, part-time working by farmers is the generally accepted model for the organisation of British Bronze Age mines (Timberlake Reference Timberlake and Clark2009), and this seems reasonable for the earlier, smaller sites. The very high production levels suggested for the Great Orme mine, however, would require labour and material resources on an impressively large and organised scale, given the wide range of tasks involved (Figure S1). This suggests a predominantly full-time, locally based mining community that may have traded metal or ore for food and other resources in their agriculturally inhospitable area. Such a community could have been autonomous or possibly controlled or influenced by a regional elite based in the nearest fertile lowland area that could have produced surplus food for the miners. This could have been north-east Wales and the adjacent borderland that linked into the communication networks of lowland Britain. At the Mitterberg mines and elsewhere in the Eastern Alps, there are indications of autonomous mining communities prior to 1400 BC, and subsequently of centralised control (Shennan Reference Shennan, Knapp, Pigott and Herbert1998; Bartelheim Reference Bartelheim, Kienlin and Roberts2009). In north-east Wales, various indications of wealth, with implied social hierarchy, have been found (e.g. the Mold Cape with amber beads from Flintshire), and suggestions have been made of a direct link with the Great Orme mine (Lynch et al. Reference Lynch, Davies and Aldhouse-Green2000), or indirectly from the control of the metal distribution routes (Needham Reference Needham, Britnell and Silvester2012).

Estimating the numbers of potentially full-time miners required to achieve high-output production is very difficult without any evidence for associated settlement sites. Shennan (Reference Shennan, Knapp, Pigott and Herbert1998) used ethnographic and historical evidence to suggest that in the Mitterberg region, a population in the low hundreds could have easily produced at least several tonnes of copper per year. While family groups including children could have been involved in many low-skill tasks, certain activities would have required specialist and possibly ritual knowledge—particularly for the ‘magical’ art of smelting. Before the mine was rediscovered, Schmidt and Burgess (Reference Schmidt and Burgess1981) had suggested that the palstave—an icon of the Middle Bronze Age—could have been invented or developed in north Wales. The large quantities of copper being produced would have required many bronze smiths, potentially producing a favourable environment for innovation.

The start of major copper production at the Great Orme (c. 1600 BC) coincides with major changes in copper metal supply sources across Europe, and these were possibly linked to wider cultural changes involving long-distance trade/exchange networks (Roberts Reference Roberts, Fokkens and Harding2013; Radivojević et al. Reference Radivojević, Roberts, Pernicka, Stos-Gale, Martinón-Torres, Rehren, Bray, Brandherm, Ling, Mei and Vandkilde2018). The change in Europe to full tin-bronze—termed ‘bronzization’ by Vandkilde (Reference Vandkilde2016)—also gathered pace c. 1600 BC, spurring an increasing demand for copper and tin. Bronze Age Britain saw major changes around this time, evidenced by increasing numbers of settlements and associated field systems, at least in southern and eastern Britain, which may have boosted demand for bronze tools. Increasing bronze production c. 1600 BC would have required an expansion in tin production. This is consistent with the recent first ever Bronze Age radiocarbon date from a Cornish tin-working site (1620–1497 cal BC at 93.9 per cent confidence (3269±27)), obtained from a Carnon Valley antler tool (Timberlake pers. comm.).

Conclusions

New evidence strongly suggests that the Great Orme Bronze Age copper mine had a ‘golden age’ of major production, c. 1600–1400 BC, constituting Britain's first mining boom. The mine probably dominated British copper supply, with some metal reaching continental Europe and Ireland. After 1400/1300 BC, the mine entered a twilight period of low production for many centuries, probably after the two richly mineralised areas were exhausted, leaving only narrow veins to work.

There must have been considerable organisation and coordination of resources in order to achieve the predicted high levels of production at the mine's zenith and to engage in long-distance trade/exchange networks. Mining on such a large scale (and smelting, if done locally) probably required a full-time mining community, whose food and other resources could have been provided by communities in the adjacent, agriculturally richer area of north-east Wales. These latter communities may have had some degree of involvement, or even full control, of one or more of the stages of the copper production and, in particular, the trade/exchange activities, as they would have controlled access to the Severn Valley networks.

Now that the temporal position and importance of the Great Orme mine has been established, it can be fitted into an emerging chronology of metal supply in Bronze Age Britain (Figure 10). After the initial centuries of Irish supply from Ross Island, supplemented by some continental sources, there was input from several small British mines. By c. 1600 BC, these had all probably given way to the rich and easily worked ores of the Great Orme mine. What followed was up to 200 years of the Great Orme copper ‘bonanza’, when Britain was probably self-sufficient in copper for the first and only time in the Bronze Age (Northover Reference Northover1982). This coincided with a time of major cultural changes in Britain. After the mine declined, there seems to have been a shift to reliance on copper coming from sources in mainland Europe, possibly the eastern Italian Alps (Melheim et al. Reference Melheim, Grandin, Persson, Billström, Stos-Gale, Ling, Williams, Angelini, Canovaro, Hjärthner-Holdar and Kristiansen2018).

Figure 10. Proposed emerging chronology of metal supply in Bronze Age Britain (lower scale: years BC; width of bars diagrammatic only) (figure by R.A. Williams).

The European distribution of Great Orme metal, from Brittany to the Baltic (the latter possibly linked to the amber trade), suggests that there were active, long-distance exchange networks in place. There is still much to be understood about how such networks were organised, who was doing the travelling and what else was being traded/exchanged (e.g. perishable goods). The later metalwork and tin/copper ingot cargoes from apparent shipwrecks at Salcombe and Landon Bay (Needham et al. Reference Needham, Parham and Frieman2013) also form part of the slowly emerging, complex picture of trade/exchange. Overall, the evidence from Great Orme metal suggests that Britain had a greater integration into European Bronze Age trade/exchange networks than had been previously suspected, particularly if Cornish/Devonian tin and possibly gold is also included. This also implies greater organisation and complexity of social interactions between the numerous small communities across Britain than previously thought. The interdisciplinary methodology developed here to analyse the output of the Great Orme mine provides a model that can be adapted for the investigation of other prehistoric mines across Europe and beyond, helping to deepen our understanding of the scale and complexity of early metal extraction and trade/exchange.

Acknowledgements

Analytical funding was received from Great Orme Mines, CADW/GAT, HMS and NERC. This study formed part of a PhD dissertation at the University of Liverpool. Thanks go to Matthew Ponting, Duncan Garrow, Rachel Pope, Ben Roberts, Jane Evans, Vanessa Pashley, Tony Hammond, Andy Lewis, Nick Jowett, Edric Roberts, David Wrenall, Peter Bray (OXSAM), Peter Northover, George Smith, Nick Marsh, Iain McDonald, Chris Somerfield, Dave Chapman, Simon Timberlake, Rob Ixer, Duncan Hook, Chris Green, Johan Ling, Gilberto Artioli, Stuart Needham, Helen Thomas and many others.

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.15184/aqy.2019.130