The main difficulty in zinc-metal production is that while zinc oxide is not reduced by carbon below 1000°C, zinc-metal boils at 907°C, becoming vapour that must be condensed to liquid metal before it comes into contact with enough air to oxidise it back to zinc oxide (Tylecote Reference Tylecote1988: 132).

A great deal of research has been done on zinc smelting in India (Craddock et al. Reference Craddock, Gurjar and Hegde1983; Hegde Reference Hegde1989; Biswas Reference Biswas2006; Craddock Reference Craddock2009, Reference Craddock2018; Gandhi Reference Gandhi2014). It is widely acknowledged that India was the first country in the world to smelt zinc; the earliest archaeological evidence comes from Zawar in Rajasthan and dates as early as AD 1025–1280 (Bunney Reference Bunney1983: 738). Ancient Chinese zinc production can be traced back to at least the early Ming Dynasty (early sixteenth century). Chinese and Indian zinc-smelting technologies are quite different in their condensing techniques, furnaces and retorts (the condensing pots). The discovery of zinc-smelting sites in the Upper and Middle Yangtze River region shows that Chinese zinc-smelting technology probably has an independent technical origin and tradition.

According to historical records, brass was used instead of bronze during the Jiajing period of the Ming Dynasty (AD 1522–1566) (Shen Reference Shen2002 [1586]: 336); this significantly reduced the cost of coin casting. The scale of zinc smelting, however, suggests that it was an important element of the economy during the Ming and Qing Dynasties. Interest in ancient Chinese zinc-smelting technology has increased in recent years (Huang et al. Reference Huang, Li, Liang and Tan2012; Zhou et al. Reference Zhou, Martinón-Torres and Chen2012, Reference Zhou, Martinón-Torres, Chen and Li2014, Reference Zhou, Luo, Mo and Chen2018; Fan et al. Reference Fan, Jin, Liu, Li, ZhangSun and Wu2015; Luo et al. Reference Luo, Li, Mu, Bai and Xiao2016, Reference Luo, Zhou and Mo2018; Chen & Souza Reference Chen and Souza2017).

During a project underway since 2004, the authors have conducted a series of archaeological surveys and excavations of zinc-smelting sites in the Upper and Middle Yangtze River region. Some 40 zinc-related sites have been discovered and recorded (Figure 1). The majority of the sites are located along the banks of the Yangtze River, probably for convenience of transportation. Our study suggests that people in this region mastered the retort method (reduction and condensation) of extracting zinc as early as the middle of the Ming Dynasty (AD 1435–1572).

Figure 1. Locations of the zinc-smelting sites in the Upper and Middle Yangtze River region (figure by the authors).

The smelting sites can be identified in three regions: on the banks of the Yangtze River; the Qiyao Mountain region; and the Wu River region in Youyang County. One of the best-preserved sites is Linjiangerdui in Zhong County. This site was excavated in 2013, 2017 and 2018. As the site lies within what is now a reservoir (as part of the Three Gorges scheme) it is partially submerged and excavation can only be carried out between May and September each year when water levels are low. The Linjiangerdui site lies to the south of the Yangtze River, west of the Shuiyang stream, and east of a Han Dynasty cemetery site (202 BC–AD 220). The site lies on a slope with the elevation varying between 155m on the north side and 170m on the south; it covers a total area of 15 000m2 (Figure 2). Over the three seasons, 22 zinc-smelting furnaces were excavated and recorded (Figure 3), together with a large number of pits and postholes representing places of preparation and storage for ore and coal, over 1000 retorts (both used and unused) and domestic pottery and porcelain (Figure 4).

Figure 2. Site view of Linjiangerdui (figure by the authors).

Figure 3. Example of zinc-smelting furnace at Linjiangerdui (figure by the authors).

Figure 4. a) Unused retorts; b) used retorts; c) retort pockets; d) porcelain of the Ming Dynasty (figure by the authors).

The ore recovered is lead-zinc ore, which possibly comes from the Qiyao Mountain region. A number of samples of unsmelted ore and slag were analysed (Luo et al. Reference Luo, Li, Mu, Bai and Xiao2016), and 14 radiocarbon assays were taken from charcoal samples. These produced dates between AD 1408 and 1650 (at 95.4% confidence).

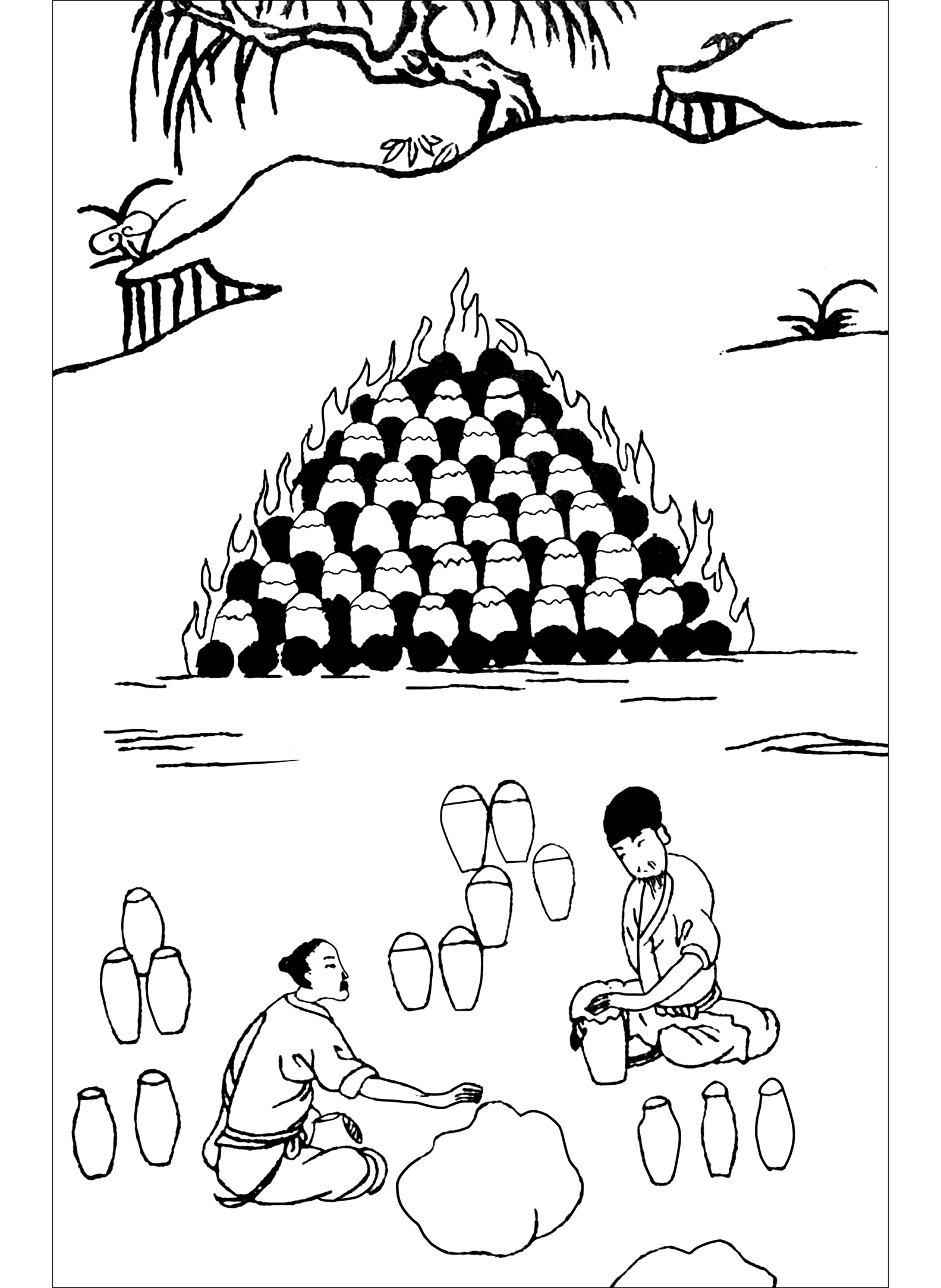

Historical documents provide some information on ancient zinc-smelting processes. The Tiangongkaiwu (The products of heaven and man by Song Yingxing, 1587–1666), records a zinc-smelting method of Luganshi (smithsonite) together with a drawing of the process (Figure 5) (Pan Reference Pan1993: 96). Many details of the process, including the precise dimensions of the retorts, the smelting process and the structure of the furnace are either inaccurate or missing from this text, however. Our fieldwork has revealed new archaeological evidence of the zinc-smelting process in this region. The excavated retorts were ceramic with a condensing zone at the top. The natural distillation effect is caused by the differential temperature gradient between the top and the bottom of the retorts, which causes zinc vapour to rise from the heated base and condense as metal in the upper condensing zone. Based on the historical texts and radiocarbon results, the zinc-smelting sites in the Upper and Middle Yangtze River region date to the middle of the Ming Dynasty (AD 1435–1572). Linjiangerdui is the earliest and largest ancient zinc-smelting site discovered in China to date and provides valuable data for understanding zinc-smelting technology as well as the social processes enmeshed in zinc smelting in ancient China.

Figure 5. Illustration of zinc smelting in Tiangongkaiwu (Pan Reference Pan1993: 96).

Conclusion and future work

The zinc-smelting sites in the Upper and Middle Yangtze River region vary in date, scale and technological complexity. While we have established the chronological sequence of these sites, further work is needed to understand the differences between sites and the reasons for variation. Comparison with other zinc-smelting sites known from the Hunan and Guangxi provinces will offer a macro-perspective on ancient Chinese zinc production, and illuminate the origin, development and spread of this technology.

Acknowledgements

This research was funded by the China Postdoctoral Science Foundation (grant number 2019M653456).