INTRODUCTION

The study of the end of the second millennium bc has long been focused upon events connected to the demise of the palatial Late Bronze Age (LBA: 1700–1050 bc) centres in the eastern Mediterranean, which either collapsed or experienced periods of upheaval (Middleton Reference Middleton2010; Jung Reference Jung and Cline2012; Knapp and Manning Reference Knapp and Manning2016). The weakened palace-based economies were replaced by modified systems of exchange. Concomitant readjustment of trade routes and emergent sociopolitical dynamics have been associated with transformations in metal consumption (Knapp Reference Knapp2000; Sherratt Reference Sherratt and Pare2000; Reference Sherratt and Moreno Garcia2016; Snodgrass Reference Snodgrass2000; Kassianidou and Knapp Reference Kassianidou, Knapp, Blake and Knapp2005; Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012; Molloy Reference Molloy and Molloy2016; Murray Reference Murray2017, 160–209), including the rise of iron metallurgy just before the turn of the first millennium bc. While iron had first been used as early as the late Early Bronze Age (EBA: 3000–2100 bc) in eastern Anatolia and the Near East (Erb-Satullo Reference Erb-Satullo2019, 562–3), it was used sparingly in the LBA, and the ‘iron revolution’ took place only in the Early Iron Age (EIA: 1050–700 bc).

Formative studies addressing the advance of iron in the Aegean have identified major centres in the Levant and Cyprus as the early adopters and distributors of this technology, which was then rapidly introduced into Crete and Euboea as well as the Greek mainland, at the beginning of the Protogeometric (PG) period (1050–900 bc) (Pleiner Reference Pleiner1969; Snodgrass Reference Snodgrass1980; Reference Snodgrass1982; Reference Snodgrass2000; Waldbaum Reference Waldbaum1980; Reference Waldbaum and Pigott1999; Wertime and Muhly Reference Wertime and Muhly1980; Maddin Reference Maddin1982; Wertime Reference Wertime1982; Muhly, Maddin and Karageorghis Reference Muhly, Maddin and Karageorghis1982; Muhly et al. Reference Muhly, Maddin, Stech and Özgen1985). Yet while metal resources and technologies have been increasingly studied, there has been much less effort to compare data between regions, with the notable exception of the Cypriot material due to its central role in transmitting and developing eastern Mediterranean metalworking technologies in the Bronze Age (BA). Moreover, many reconstructions have focused on the spatial distribution of iron artefacts and their co-occurrence with the PG pottery styles during the early stages of the EIA. In Anatolia, much attention has been directed at the central and eastern regions with their large BA administrative centres and the way in which palatial nodes controlled and integrated production at the end of the second millennium bc.Footnote 1

The focus on the role of Cyprus, the Levant and eastern Anatolia as metallurgical innovators resulted in a relative lack of interest in this question in the Aegean. While a very few recent synthetic studies applying cutting edge analytical methods in the Aegean have been published so far, new multipronged investigations in the eastern Mediterranean have incorporated theoretically driven approaches to ancient technology earlier on, including an emphasis on how technological innovation occurred and on investigating the impact of social context on technology (Yahalom-Mack and Eliyahu-Behar Reference Yahalom-Mack and Eliyahu-Behar2015; Lehner Reference Lehner and Schachner2017; Erb-Satullo Reference Erb-Satullo2019). In this respect, future studies in the Aegean have the potential to yield equally important observations, as new discoveries related to both production debris and objects of daily use have partially begun to overcome some of these challenges (in the Aegean: Yalçın Reference Yalçın1999; Verčík Reference Verčík2017a; Vetta Reference Vetta2020; in Anatolia and the Levant: McConchie Reference McConchie2004; Bunimovitz and Lederman Reference Bunimovitz, Lederman, Webb and Frankel2012; Veldhuijzen Reference Veldhuijzen, Kassianidou and Papasavvas2012; Yahalom-Mack and Eliyahu-Behar Reference Yahalom-Mack and Eliyahu-Behar2015; Erb-Satullo Reference Erb-Satullo2019).

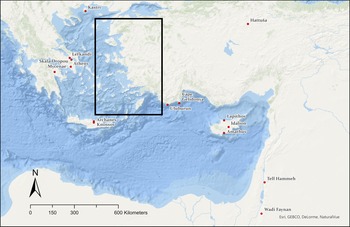

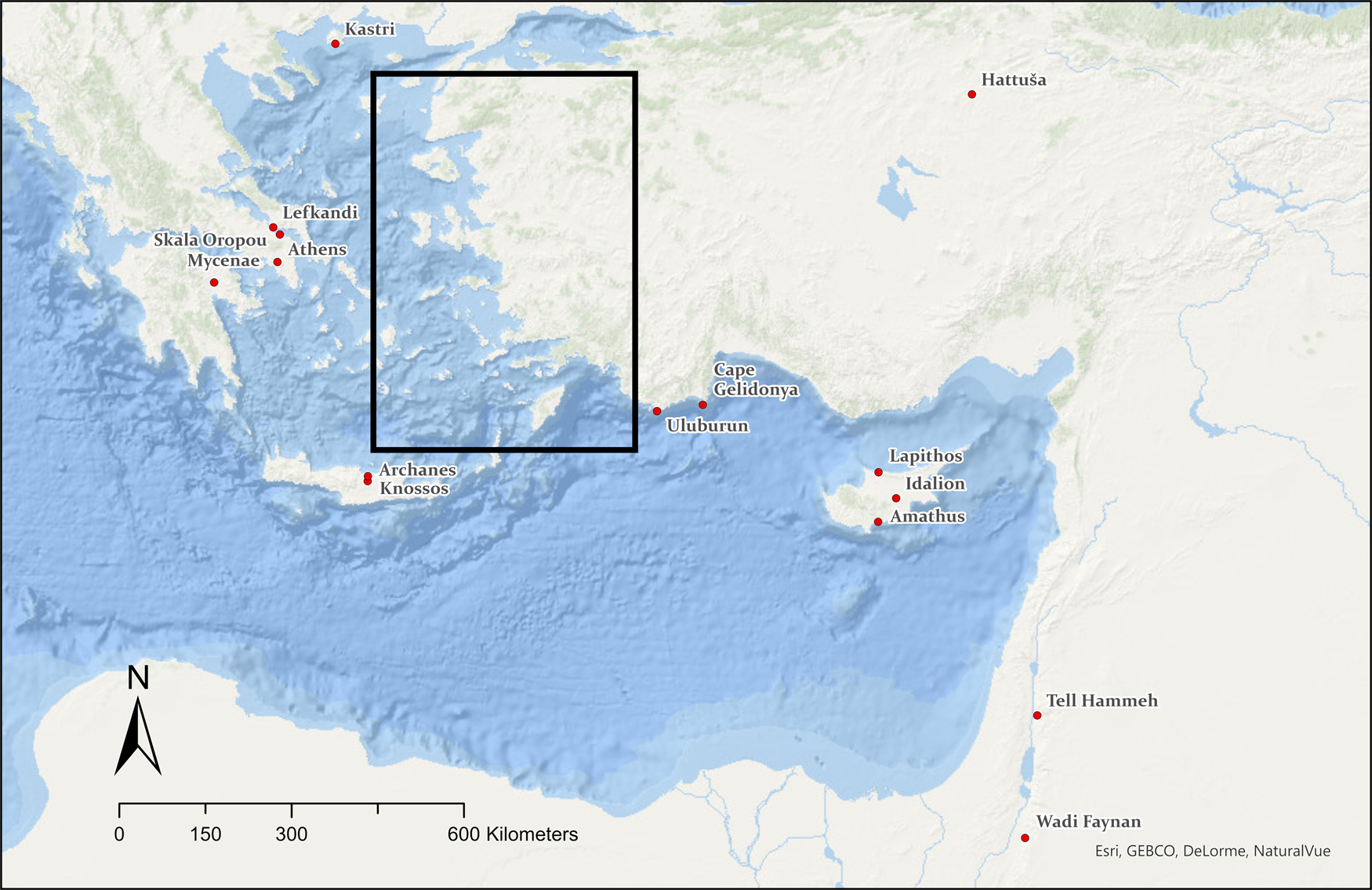

In this contribution, we shed light on the rise of iron in the Aegean by examining the latest evidence from archaeological and archaeometallurgical research in western Anatolia, which was one of the key areas for EIA socioeconomic developments (Figs 1 and 2). Namely, we will demonstrate that the recent finds from the EIA settlement strata in the Gulf of Izmir complement the metallographically analysed finds from Lydian Sardis and strengthen the proposition that iron circulated in local settlements – rather than being limited to the funerary milieu (in contrast to the published evidence from the western part of the Aegean) – already in the tenth century bc, if not earlier. Moreover, the blacksmith's workshop excavated in Phokaia might represent the only known production context dated to the eleventh century bc (in addition to the remains of a workshop discovered at Kastri on Thasos; Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016), even if uncertainties in terms of stratigraphy and chronology persist (Yalçın and Özyiğit Reference Yalçın, Özyiğit and Yalçın2013). Yet discussions rarely engage with the Ionian evidence and emphasise developments in mainland Greece and other Aegean regions instead (but see Yalçın Reference Yalçın1999; Cevizoğlu Reference Cevizoğlu, Gönül Yalçın and Stegemeier2020). These regions, however, have been considered as throughways of technological transfer ex silencio (Snodgrass Reference Snodgrass1971; Morris Reference Morris1989; Dickinson Reference Dickinson2006, 145–8), and a holistic and integrative treatment of the evidence is still missing. It is thus our aim to contribute to the fledgling scholarship on early iron technologies by presenting a regional synthesis and revising the established debate on the character of the adoption of iron in the Aegean.

Fig. 1. Map of the eastern Mediterranean showing sites mentioned in the text. For the area inside the black box, see Fig. 2.

Fig. 2. Map of western Anatolia and the eastern Aegean showing sites mentioned in the text.

In the following pages, we present the argument that Ionia was one of the key loci of metallurgical innovation during the transitional period from the late second to the early first millennium bc. We propose that the long-established tradition in the working of copper alloys in Ionia offered the best circumstances for a successful adoption of iron technologies – refining and (secondary) smithing in particular – coming from Cyprus, the Levant and eastern Anatolia relatively early at the dawn of the EIA. This is in part connected to an unusual feature of the region, which suffered a less pronounced impact of the LBA collapse than many other areas. Many Ionian BA settlements, such as Liman Tepe/Klazomenai and Ephesos, continued to be occupied, while some might have had short breaks in occupation, even coupled with a period of changing political allegiances, such as Miletos (Kerschner Reference Kerschner, Olshausen and Sonnabend2006; Lemos Reference Lemos, Cobet, Von Graeve, Niemeier and Zimmermann2007; Ersoy Reference Ersoy, Cobet, von Graeve, Niemeier and Zimmermann2007; Niemeier Reference Niemeier, Cobet, Von Graeve, Zimmermann and Niemeier2007; Mac Sweeney Reference Mac Sweeney2017; Kotsonas and Mokrišová Reference Kotsonas, Mokrišová, Lemos and Kotsonas2020). While the material evidence that can shed light on the transitional LBA to EIA period is increasing, much of the archaeological material remains obscured by taphonomic processes and environmental and landscape changes (e.g., Brückner et al. Reference Brückner, Herda, Kerschner, Müllenhoff and Stock2017). New evidence from Ionia – but also the south-western Anatolian region of Caria, which yielded evidence for the Early to Middle Protogeometric (EPG–MPG) period (1050–950 bc) as well as the transitional LBA to EIA pottery (Carstens Reference Carstens and Pedersen2008; various contributions in Rumscheid Reference Rumscheid2009) – suggests that the transition from the LBA to EIA was less disruptive than once thought (Koparal and Vaessen Reference Koparal and Vaessen2020; Kotsonas and Mokrišová Reference Kotsonas, Mokrišová, Lemos and Kotsonas2020). A second reason is the character of the production; in both LBA and EIA Ionia, production was organised on a small scale and was locally focused, which enabled flexibility. While production of sophisticated metal objects is well documented in the LBA (Avila Reference Avila1983; Roháček Reference Roháček2019) and the Archaic period (700–480 bc) (Klebinder-Gauss Reference Klebinder-Gauss2007; Pülz Reference Pülz2009; Baykan Reference Baykan, Laflı and Patacı2015; Cevizoğlu Reference Cevizoğlu, Gönül Yalçın and Stegemeier2020), it should not automatically be taken as suggestive of long-term continuity. However, new archaeological discoveries from recent fieldwork on the western Anatolian littoral suggest that we can productively fill the chronological gap, as they provide an indication that the better-documented Archaic metalworking was deeply rooted in the long-term local processes that were in place at the end of the second millennium bc (Verčík Reference Verčík2017a; Verčík and Güder Reference Verčík and Güderin preparation). In short, based on the evidence currently available, we argue that the Ionians built on the knowledge and experience gained already in the LBA and that this technological aptitude continued in the EIA.

We support this hypothesis by focusing on four key areas. First, we review explanations that have been proposed for the adoption and increasing use of iron in the Aegean in the late second and the early first millennium bc. Second, we reflect on innovations in ironworking within the context of cross-craft interaction, in particular the production and consumption of bronze as both metals continued to be used side by side (Kostoglou Reference Kostoglou, Humphris and Rehren2013, 313–14; Yahalom-Mack and Eliyahu-Behar Reference Yahalom-Mack and Eliyahu-Behar2015; Erb-Satullo Reference Erb-Satullo2019, 576–7). We thus evaluate arguments related to technological traditions and the spread of iron from a long-term regional perspective. Third, we engage with recent scholarship on the social and cultural context of metal technologies, which productively reorients the discussion from looking at the social impact of the spread of iron in favour of examining the locally driven social motivations behind the spread of iron technologies (cf. Erb-Satullo Reference Erb-Satullo2019). Fourth, we present the most recent evidence of iron working in Ionia dating to the first stages of the EIA. We contextualise these new datasets within the long-term developments in local technological traditions and exemplify how the Ionian metalworkers applied techniques similar to those used in the LBA. Overall, we demonstrate that the spread of this innovation did not come to Ionia via the Greek mainland (carried by various Greek migrants), as previously envisioned, but rather relied on a complex interplay of local and longstanding social and economic conditions as well as regional connectivity.

EARLY IRON TECHNOLOGY IN THE AEGEAN – ESTABLISHED PARADIGMS AND NEW DIRECTIONS

Metals – namely copper, gold, iron, and silver – are one of the most significant resources, and their utilisation has had a decisive impact on the development of human history. The exploitation of native metals permeated all spheres of ancient life as early as the Chalcolithic. In the BA, materials reduced from metal minerals constituted a major part of the local, regional and cross-regional economies and sociocultural interactions. Of all of them, iron is particularly intriguing. The craftspeople in Anatolia, Egypt and the Levant had made a prolonged use of meteoritic and terrestrial iron before it became utilised more widely at the end of the second millennium bc (Pare Reference Pare, Miroššayová, Pare and Stegmann-Rajtár2017; Erb-Satullo Reference Erb-Satullo2019; possible use of telluric iron: Pickles Reference Pickles1988, 4–5; Yalçın Reference Yalçın2000, 308–9).

In the Aegean, the earliest known objects made of iron or containing iron parts came from Archanes on Crete, dating to the Middle Minoan (MM) II (1900–1750 bc) period (Poursat and Loubet Reference Poursat, Loubet, Laffineur and Greco2005). The Middle Bronze Age (MBA; 2100–1700 bc) to LBA iron finds comprise rings, tools and knives with decorative, ceremonial and prestigious functions. Prestigious objects increased in number during the Late Helladic (LH) IIIC (1200–1050 bc) period (databases of iron objects: Waldbaum Reference Waldbaum1978; Reference Waldbaum and Pigott1999, 46, Appendix A; Sherratt Reference Sherratt and Karageorghis1994, Appendix I; Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016, 282–3; Pare Reference Pare, Miroššayová, Pare and Stegmann-Rajtár2017, 22–3; see also Maran Reference Maran, Deger-Jalkotzy and Lemos2006). During the EIA, iron became the preferred material in the eastern Mediterranean, as can be observed from the emergence of fully fledged iron production. However, the full potential of iron was only gradually recognised, and the experimental period extended well into the first millennium bc.Footnote 2 A changing attitude to iron in the form of an intensive spread of both objects and technology is thought to have correlated with the sociocultural changes after c. 1200 bc (Waldbaum Reference Waldbaum and Pigott1999, 27–8; Pare Reference Pare, Miroššayová, Pare and Stegmann-Rajtár2017).

In the last decade there has been a significant intensification of investigations in light of new field projects and expanding metallographic datasets. This trend has propelled a reassessment of previous models explaining the iron innovation at the turn of the first millennium bc. The re-evaluation has also led to a crucial conceptual shift of emphasis from investigating the impact of the spread of iron on Mediterranean societies to trying to understand how this spread was affected by the differing social, cultural and economic conditions of the various societies (Veldhuijzen Reference Veldhuijzen, Kassianidou and Papasavvas2012; Bunimovitz and Lederman Reference Bunimovitz, Lederman, Webb and Frankel2012; Yahalom-Mack and Eliyahu-Behar Reference Yahalom-Mack and Eliyahu-Behar2015; Erb-Satullo and Walton Reference Erb-Satullo and Walton2017; Lehner and Schachner Reference Lehner, Schachner, Maner, Gilbert and Horowitz2017; Erb-Satullo Reference Erb-Satullo2019). Recent studies now enable investigations of iron technologies during this pivotal period by addressing the organisation of production, the patterns of consumption and the relationship between craftspeople and political authorities (e.g., Lehner Reference Lehner and Schachner2017). Ultimately, they underscore the significance of long-established technological traditions with respect to metallurgy, metalworking and pyrotechnology, and point to a link between bronze and iron metallurgy (Pare Reference Pare, Miroššayová, Pare and Stegmann-Rajtár2017, 11–13; Erb-Satullo Reference Erb-Satullo2019, 557–8; see also Sherratt Reference Sherratt and Karageorghis1994, esp. 66; McConchie Reference McConchie2004, 39–51; cf. Erb-Satullo et al. Reference Erb-Satullo, Jachvliani, Kakhiani and Newman2020).

In the Aegean, however, research on the processes underlying the adoption of iron has been affected by a lack of archaeological evidence and scientific datasets, as Waldbaum (Reference Waldbaum and Pigott1999, 43) observed over 20 years ago (but see Popham, Sackett and Themelis Reference Popham, Sackett and Themelis1980; Popham et al. Reference Popham, Calligas, Sackett, Coulton and Catling1993; Papadopoulos and Smithson Reference Papadopoulos and Smithson2017). Consequently, the existing explanations rely on formative models proposed decades earlier characterised by a focus on the appearance of iron objects rather than an engagement with more recent methodologies and analyses. This section, therefore, examines formative paradigms as well as the emerging trends related to the adoption of iron in the Aegean, contending that regionally specific studies that treat technology as a social category within specific resource- and knowledge-scapes are the most promising area for future research.

Established paradigms and formative models

The main paradigm exploring the technological transition in the Aegean during the LBA and the EIA was established by Snodgrass (Reference Snodgrass1971; Reference Snodgrass1980; Reference Snodgrass2000). In The Dark Age of Greece (Reference Snodgrass1971), a ground-breaking contribution to the studies of the Greek EIA, Snodgrass highlighted that the beginning of the period (eleventh century bc) corresponded with a relatively abrupt replacement of bronze working with an economy based on iron.Footnote 3 According to his model, the change in the use of iron in the Mediterranean took place across three distinct phases with a significant shift corresponding to Phase 2, equivalent to the Late Cypriot (LC) IIIA to early IIIB (1150–1075/1050 bc; Snodgrass Reference Snodgrass1980, 335–7). In Phase 1, corresponding to the MBA and LBA, iron was not employed as a true utilitarian metal, and prestige iron objects had to be imported into the Aegean. The subsequent Phase 2, however, was marked by a start of the local production of utilitarian iron implements and weapons (Snodgrass Reference Snodgrass1980, 346–50; Blackwell Reference Blackwell, Lemos and Kotsonas2020 for a recent overview). In Phase 3, dated to the end of LC IIIB or the beginning of the Cypro-Geometric (CG) period (c. 1075/1050 bc), iron became more abundant than bronze as a functional metal in the eastern Mediterranean (Snodgrass Reference Snodgrass1980, 341; Pare Reference Pare, Miroššayová, Pare and Stegmann-Rajtár2017, 12–15 for a recent overview). However, the development in Greece was not of a brief duration but extended over almost 200 years. The Aegean did not pass into the full ‘age of iron’ until the ninth century bc (Snodgrass Reference Snodgrass1980, 354–5; Dickinson Reference Dickinson2006, 149).

While we do not wish to dwell on this three-stage model in detail, we wish to consider the broader explanations for the key transformation that occurred during Phases 2 and 3. Snodgrass assumed that there were two interlinked issues regarding the early spread of ‘working iron’ and the associated technologies: that of the material properties and that of the economy. He posited that while the former likely stimulated the change from bronze – which was predominantly used at the time as a material particularly suitable for manufacturing cutting and piercing implements – to iron, the rapid increase in the use of iron was linked to economic factors (Snodgrass Reference Snodgrass1971, 228–31). First, he proposed that a break in the supply of bronze following the collapse of a significant part of LBA long-distance trade networks drove the rise of iron. Second, he suggested that this trend was reinforced by the wider availability of usable iron ore deposits (without naming their specific locations) as opposed to copper and tin deposits, on the one hand, and by the existing links to Cyprus as a major metallurgical centre of this period, on the other hand (absolute chronology: Snodgrass Reference Snodgrass1982, 286–7, fig. 2).

Snodgrass’ reconstruction was primarily based on the quantitative analysis of iron objects (knives and daggers in particular) rather than a concomitant study of technology, although he was, of course, well aware of the methodological concerns (Snodgrass Reference Snodgrass1982, 285; see also Waldbaum Reference Waldbaum1978; Pare Reference Pare, Miroššayová, Pare and Stegmann-Rajtár2017, 19). In terms of the distribution of objects, therefore, he envisioned the transformation as a two-step process. The first step involved a spread of objects from Cyprus to Crete and the regions along the eastern coast of mainland Greece during the eleventh century bc, as iron and bimetallic knives and daggers occurred earlier in Cyprus than in the Argolid, Attica and Knossos (at the very end of LH IIIC, corresponding to the first half of the eleventh century bc: Snodgrass Reference Snodgrass1980, 341–55; 2000, 219–20; or already in the late twelfth century bc: Dickinson Reference Dickinson2006, 146–7).Footnote 4 The deposition of these objects was shortly followed by that of knives with bronze handles, iron blades and iron pins. Two observations related to these early items are necessary. First, these objects might not have functioned as strictly utilitarian tools, meaning that the function we can ascertain based on their findspot is that related to prestige as they were deposited in rich graves. Second, at least some of them might have been ready-made imports, and this might have been the case of some of their EIA counterparts. Yet distinguishing locally made and imported artefacts based on stylistic observation can be problematic.

Furthermore, in the second step, iron slowly ‘advanced’ in other regions within the Aegean, such as central and northern Greece (Thessaly and Macedonia respectively) and the western Anatolian littoral and co-occurred with the PG pottery. Snodgrass (Reference Snodgrass1971, 246–9; 1980, 354–5; Reference Snodgrass2000, 246–9), therefore, concluded that iron items became a commonplace phenomenon in the western part of the Aegean during the late phase of the PG period (c. 900 bc), as the spread of metallurgy and metalworking was a lengthy process linked to the movement of experts (Morris Reference Morris1989, 506; Sherratt Reference Sherratt and Pare2000, 82; 2003, 39; Dickinson Reference Dickinson2006, 149, 252; Murray Reference Murray, Pavúk, Klonzta-Jaklová and Harding2019, 82–3; Molloy and Mödlinger Reference Molloy and Mödlinger2020).

The set of explanations related to the question of origins and ‘destinations’ – when, where, and how iron emerged as a utilitarian metal in the Aegean – has been widely embraced and expanded upon in the subsequent archaeological literature. The following concepts shared either one or both characteristics previously elaborated by Snodgrass. In terms of the functional merit of iron over bronze, Muhly argued most prominently that technical factors ascertained the pioneering role of Cyprus in the transition to its utilitarian use. Relying on the metallurgical studies of a few exceptionally well-preserved artefacts from Amathus, Idalion and Lapithos, he emphasised the process of hardening as the key factor behind the success of Cypriot iron smithing as early as the beginning of the twelfth century bc (Muhly et al. Reference Muhly, Maddin, Stech and Özgen1985, 68; Muhly Reference Muhly, Tassios and Palyvou2006, 21–3; Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012, 134; see also Maddin Reference Maddin1982, 303; Reference Maddin, Betancourt and Ferrence2011, 204–7; Pickles and Peltenburg Reference Pickles and Peltenburg1998, 84; Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016, 281). Based on an assumption of a clear association between Cyprus and the early iron objects (iron knives with bronze rivets, knives fully made of iron, and slightly later also iron swords) found in Euboea and Crete dating to the eleventh and tenth centuries bc, Muhly (Reference Muhly, Tassios and Palyvou2006, 28–31) argued that it was not just these novel and also highly demanded products that were traded, but also the corresponding technologies (Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012, 125; cf. Desborough Reference Desborough1972, 113; Coldstream Reference Coldstream1975, 85; Dickinson Reference Dickinson2006, 147). Although this observation was directly tied to the previously assumed inherent superior quality of iron objects when compared to bronze (at least in terms of hardness), he substantiated and differentiated his view by analytical data (Waldbaum Reference Waldbaum and Pigott1999, 27 on previous research).

In comparison to cold-hammered and annealed bronze, however, the superior mechanical properties of iron – its hardness and tensile strength in particular – are not inherent characteristics of the material condition of the metal.Footnote 5 They are provided solely by the mastery of specific production steps that significantly enhance iron's properties either through smithing techniques involving carburisation, quenching and tempering of the finished items or an (un)controlled smelting operation that creates a mixed iron/steel semi-product, the bloom (EIA: Snodgrass Reference Snodgrass2000, 215; Pleiner Reference Pleiner2006, 18–22; Güder, Gates and Yalçın Reference Güder, Gates and Yalçın2017, 51; critical re-examination: Eliyahu-Behar and Yahalom-Mack Reference Eliyahu-Behar and Yahalom-Mack2018, 447–8). Muhly thus embraced the widely accepted assumption that Cyprus had been at the forefront of the development of iron technologies because of the long-established expertise of local craftspeople in copper smelting and alloying (Sherratt Reference Sherratt and Karageorghis1994, 44; Pickles and Peltenburg Reference Pickles and Peltenburg1998, 86–91; Muhly Reference Muhly, Tassios and Palyvou2006, 28–31; Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012, 134–5). The interplay between bronze and iron technologies might have indeed been essential to the invention of iron smelting beyond Cyprus as well, as research on the beginnings of iron metallurgy in the EIA Levant at Tell Hammeh and very recently also in Kastri on Thasos in the northern Aegean has shown, very likely stimulating the concurrent experimentation in the treatment and application of iron (Levant and Near East: Veldhuijzen Reference Veldhuijzen, Kassianidou and Papasavvas2012; Yahalom-Mack and Eliyahu-Behar Reference Yahalom-Mack and Eliyahu-Behar2015; Erb-Satullo and Walton Reference Erb-Satullo and Walton2017; cf. Liss, Levy and Day Reference Liss, Levy and Day2020; northern Aegean: Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016, 284–91).

With the increasing knowledge of ancient iron working, however, several methodological shortcomings emerge that problematise the arguments favouring technical factors as the main motivators for the spread of iron in the Aegean. First and foremost, we cannot fully understand the transfer of technological knowledge and objects in the current climate of an almost complete absence of analytical datasets from the Aegean. This situation does not allow a productive comparison with the much more detailed investigations of the Cypriot and Levantine material. While there is an increasing number of analytical studies conducted on iron objects from Archaic and Classical Greece, only two metallographic investigations of a small number of EIA objects from the Aegean have been published so far (Varoufakis Reference Varoufakis1979; Photos Reference Photos1989). This uneven state of research has prompted Snodgrass (Reference Snodgrass1971, 216–17; Reference Snodgrass2000, 287) to treat the evidence for the role of technical factors in the emergence of utilitarian iron with caution.

Furthermore, the results of archaeometallurgical analyses conducted during the 1970s by Tholander (Reference Tholander1971) and later by Maddin (Reference Maddin1982; Reference Maddin, Betancourt and Ferrence2011), which stressed the technical improvement in terms of hardness of iron objects belonging to the early stages of EIA Cypriot production, have been challenged as well. Both authors presented evidence for a regular use of carburisation – a process involving application of heat in a carbon-rich environment – and to a certain degree also quenching of Cypriot iron artefacts. Based on a metallographic re-examination, however, McConchie (Reference McConchie2004, 33) argued that while there is some evidence for a selective use of iron/steel blooms, there is very little evidence to suggest that increased hardness was achieved by intentional hardening techniques.Footnote 6 This observation corresponds with the current evidence from Anatolia, Assyria, Iran and the Levant, where the results of systematic analyses of iron objects dating to the first half of the first millennium bc have shown that the EIA blacksmiths did not yet have a consistent control of the quality of their steel (Güder, Gates and Yalçın Reference Güder, Gates and Yalçın2017, 52–3; Eliyahu-Behar and Yahalom-Mack Reference Eliyahu-Behar and Yahalom-Mack2018, 454–5). Consequently, it has been argued that mechanical properties of iron cannot be used as a key factor because they provide only a partial explanation for the significant increase in the production of iron during the EIA, at least in the eastern Mediterranean.Footnote 7

Only further analytical studies of larger datasets from the Aegean can determine the possibility of a deliberate pursuit of hardening of the metal in the region. The already mentioned lack of qualitatively and quantitatively comparable datasets from the Aegean precludes us from forming any decisive conclusions on the character of early iron working.Footnote 8 Fortunately, the results of recent metallographic analyses, especially of those from western Anatolia and the Levant, give hope for effective investigations in the future, as severely corroded iron objects, which are present but usually disregarded during the excavation, can now be included in the evaluation.Footnote 9

Circulation, deposition and fragmentary datasets

Let us now turn to the economic explanation for the spread of iron technologies in the Aegean. The quantitative analysis of available evidence led Snodgrass (Reference Snodgrass2000, xxvii) to argue that the shortage of bronze as a result of upheavals in the existing trade networks, which according to him formed a part of a broader background of isolation in the EIA, was the main impetus for the exploitation and use of local iron ores. This particular reconstruction has since come under scrutiny all over the eastern Mediterranean – starting with Cyprus, continuing with the Levant and very recently also central Anatolia – in light of increased datasets and better analytical techniques that highlight factors such as social choices underlying production and consumption and continued access to tin and copper.Footnote 10 While there are critics of the ‘shortage’ model for Cyprus as well as the Aegean, some scholars have maintained that it can be generally applied to at least certain Aegean regions, as metals were not always available in a sufficient amount.Footnote 11 Furthermore, one has to ponder whether the new patterns were a reflection of changing socioeconomic conditions and preferences rather than shifts in the supply–demand chains alone (Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012, 134–5; Lehner Reference Lehner and Schachner2017, 154–5; Erb-Satullo Reference Erb-Satullo2019, 580–3).

Quite in contrast to Snodgrass, Sherratt (Reference Sherratt and Karageorghis1994; Reference Sherratt and Pare2000; Reference Sherratt and Moreno Garcia2016) argues for continuing commercial activity in a more decentralised form in the late thirteenth and throughout the twelfth centuries bc. She suggests that bronze remained in circulation even more widely throughout the eastern Mediterranean, reaching social groups previously without, or only with a restricted, access to metals. Against this devaluation of bronze, iron appeared as a relatively unrestricted material with a merit of ‘technologically determined rarity’ and a related ostentatious nature.Footnote 12 Iron thus posed an ideal product for the growing demand-led sub-elite market and a welcome addition to the expanding metal economy of the Cypriot traders already by the twelfth century bc.Footnote 13 In the Aegean, Sherratt (Reference Sherratt and Pare2000, 88) argues, iron knives and swords were injected into a system that still regarded iron objects as immensely precious. The decline of Greek–Cypriot contacts in the EPG, as postulated by Snodgrass, does not interfere with this model of exchange system.

Morris interprets the dominance of iron weapons and personal ornaments in graves after 1050 bc in a relatively analogous manner. In his deposition model, iron is both a symbol and a means to enforce the power of the elites, a monopoly-forming stratum of a new, more stable ideological system as part of the rise of small-scale hierarchical communities (Morris Reference Morris1989, 514). The main features of this model, however, are more fitting for later stages of the EIA and can be compared with the interpretation of the function of iron as associated with military status and prestige during the Neo-Assyrian period (Pleiner and Bjorkman Reference Pleiner and Bjorkman1974; Pigott Reference Pigott1989). There is no comparable firm archaeological dataset available to support such a function for the earlier stages of the EIA in the Aegean.

Sherratt's and Morris's models thus make a step away from direct cause-and-effect explanations for the advent of the iron economy in the Aegean. They should therefore be seen as part of broader research efforts that sought to re-evaluate the organisational aspects of iron production in the eastern Mediterranean. In effect, iron became more attractive than bronze because of the particular conditions of the associated social, political and cultural contexts (Bunimovitz and Lederman Reference Bunimovitz, Lederman, Webb and Frankel2012, 104–5; Erb-Satullo Reference Erb-Satullo2019, 582–3). Yet despite their sensitivity to these contexts, the models pertaining to the Aegean still rely on quantitative collation focused on general counts and types of iron artefacts at different sites as opposed to interdisciplinary studies. Beside the fact that the evidence for iron smelting and smithing from the Aegean is hardly attested before the Late Geometric (LG) period (750–700 bc), this trend imposes certain expectations and limits when exploring usage patterns.Footnote 14

The first challenge related to quantitative analyses is the limited representation of settlement assemblages. The disequilibrium in the archaeological evidence in favour of burial assemblages (such as at the Athenian Agora and Lefkandi) – with specifically selected types of objects – as opposed to settlement contexts – featuring a range of objects used in daily activities – influenced, explicitly or not, conclusions derived from the quantitative analyses. Although there is an increase in EIA settlement contexts studied today, the bulk of metals, and iron finds in particular, are still known from graves. The frequently cited exceptions represent the settlement finds from Nichoria, Malthi, Kastri and Tiryns (Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016, 282–3; Blackwell Reference Blackwell, Lemos and Kotsonas2020, 532). Yet in the wake of an increasing number of finds and better conservation as well as analytical techniques, Morris's (Reference Morris1989, 514) conclusions that Greece was almost free of metals until around 700 bc and that metal tools were much more common in Cyprus and the Levant no longer hold. Morris originally compared the EIA assemblages with Late Classical and Hellenistic sites, but the amount of excavated iron and bronze artefacts from the chronologically closer pre-Classical sites has become significantly higher only in recent years (even, for example, at Miletos and Selinus; Baitinger Reference Baitinger2016).

At a basic level, the archaeological record from settlement contexts is affected by preservation issues, and any quantitative analysis comparing burials and settlements needs to be regarded with caution.Footnote 15 In terms of material characteristics, the greatest concern related to the identification and classification of the finds is corrosion. Corrosion, induced by soil conditions and often also unsuitable storage conditions, causes extensive chemical and morphological alteration of metal objects and their components. Of all ancient metals, iron is one of the most reactive to oxidation, and therefore, one often encounters just rusty chunks instead of a complete iron object. Moreover, advanced corrosion can lead to varying degrees of fragmentation and even to disintegration of the physical structure. This process is often accelerated by taphonomic processes or past human actions before and after the deposition, especially in settlement contexts that were often intensively occupied for several centuries.Footnote 16 Iron objects in EIA settlement contexts are strikingly rare; objects were used here for longer periods of time in comparison to objects taken out of circulation when deposited in burials. Therefore, the absence of iron finds does not necessarily equate to the absence of the use of iron.

Even if exact quantity and quality of iron artefacts in Aegean settlements remains beyond our reach due to the limits of preservation, the enormous potential of this type of archaeological material can be reached through a better recognition of rusty bits during retrieval through more sensitive excavation techniques, detailed contextualisation of finds and new types of archaeometallurgical examinations. Such advances have already been applied in the Levant, resulting in a successful documentation of an increasing number of Iron Age (IA) iron finds and, more importantly, also iron production debris (Eliyahu-Behar and Yahalom-Mack Reference Eliyahu-Behar and Yahalom-Mack2018; Erb-Satullo Reference Erb-Satullo2019, 566–8). In the following section (‘Metallurgy in Western Anatolia during the Bronze and Early Iron Ages’), we will argue that new research in Ionia has a similar potential.

The second challenge related to quantitative approaches concerns the location of the first full deployment of iron in the Aegean. Both older and more recent models postulate that the technology came from Cyprus and followed the routes along which the first iron objects travelled. This reconstruction is based on the observation that finished artefacts of local Greek production were found in regions located on maritime routes frequented by the Cypriots in the thirteenth to the eleventh centuries bc and were of slightly later date than their counterparts from Cyprus.Footnote 17 Furthermore, it is assumed that these particularly ‘advanced’ regions were characterised by an ease of access to local bi-metallic or iron-enriched copper ores used to produce metallic iron or iron-rich copper (Kassianidou Reference Kassianidou1994; Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012; critical review: Liss, Levy and Day Reference Liss, Levy and Day2020). In other words, distribution maps based on quantitative collation of iron finds seem to reflect favourable conditions in Attica, the Argolid, Euboea and Crete at the time when iron technology was introduced. We suggest that the regions of the north-western Aegean (Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016) and Caria in south-western Anatolia might fit the bill as well, as will be discussed below. Datasets from these regions complement prima facie the picture of Cypriot, and later also Euboean and Phoenician, ventures and quests for resources relying on the pre-existing LBA networks and trajectories. However, such a reconstruction still links the uptake of iron in a cause-and-effect relationship, which is at the root of all economic or socioeconomic interpretations. Essentially, models that emphasise bronze shortage implicitly draw on the so-called ‘push’ factors, while models that stress the incentives provided by iron rely on the ‘pull’ factors (cf. Bunimovitz and Lederman Reference Bunimovitz, Lederman, Webb and Frankel2012, 104; Erb-Satullo Reference Erb-Satullo2019, 582).

Lastly, investigations often neglect to interrogate the complexity of the process of innovation, which begins with a discovery and ends with a final implementation or a rejection of technology or individual technological steps (Renfrew Reference Renfrew, Green, Haselgrove and Spriggs1978; Hjärthner-Holdar and Risberg Reference Hjärthner-Holdar and Risberg2009; Bunimovitz and Lederman Reference Bunimovitz, Lederman, Webb and Frankel2012). Of particular importance is the specific point that even if a certain innovation is accepted at approximately the same time in a number of regions, the technological change might have happened for different reasons in different places and, crucially, under varying local conditions. These considerations need to be taken into account with respect to the recent evidence of continuing supra-regional movement of raw material in the EIA Aegean (Kiderlen et al. Reference Kiderlen, Bode, Hauptmann and Bassiakos2016; Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016), on the one hand, and the possibility of an independent discovery of iron production in the Levant (at Faynan) that was not directly associated with copper smelting, on the other hand (Veldhuijzen and Rehren Reference Veldhuijzen, Rehren, La Niece, Hook and Craddock2007; Liss, Levy and Day Reference Liss, Levy and Day2020). In either case, it has increasingly become apparent that we cannot regard technological change as an economic and functional process only (Costin Reference Costin and Schiffer1991; McConchie Reference McConchie2004; Hjärthner-Holdar and Risberg Reference Hjärthner-Holdar and Risberg2009; Bunimovitz and Lederman Reference Bunimovitz, Lederman, Webb and Frankel2012; Eliyahu-Behar and Yahalom-Mack Reference Eliyahu-Behar and Yahalom-Mack2018; Martinón-Torres Reference Martinón-Torres, Armada, Murillo-Barroso and Charlton2018; Erb-Satullo Reference Erb-Satullo2019). In this contribution we thus wish to emphasise that while the socioeconomic structure of a society could govern the introduction of iron as a novel and prestige metal, the process of technological innovation involved a variety of additional aspects – environmental, ideological and cultural combined with the prerequisite knowledge of technology, resources and the socioeconomic milieu – situated within their respective local circumstances.

New directions – regional approaches to knowledge-scapes and cross-craft interaction

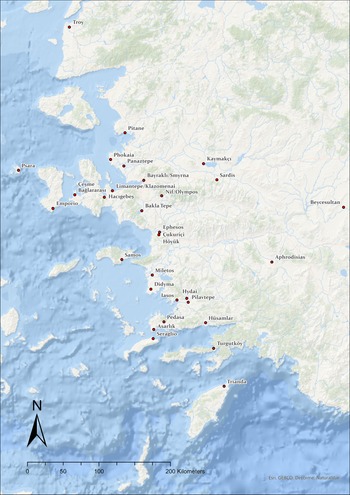

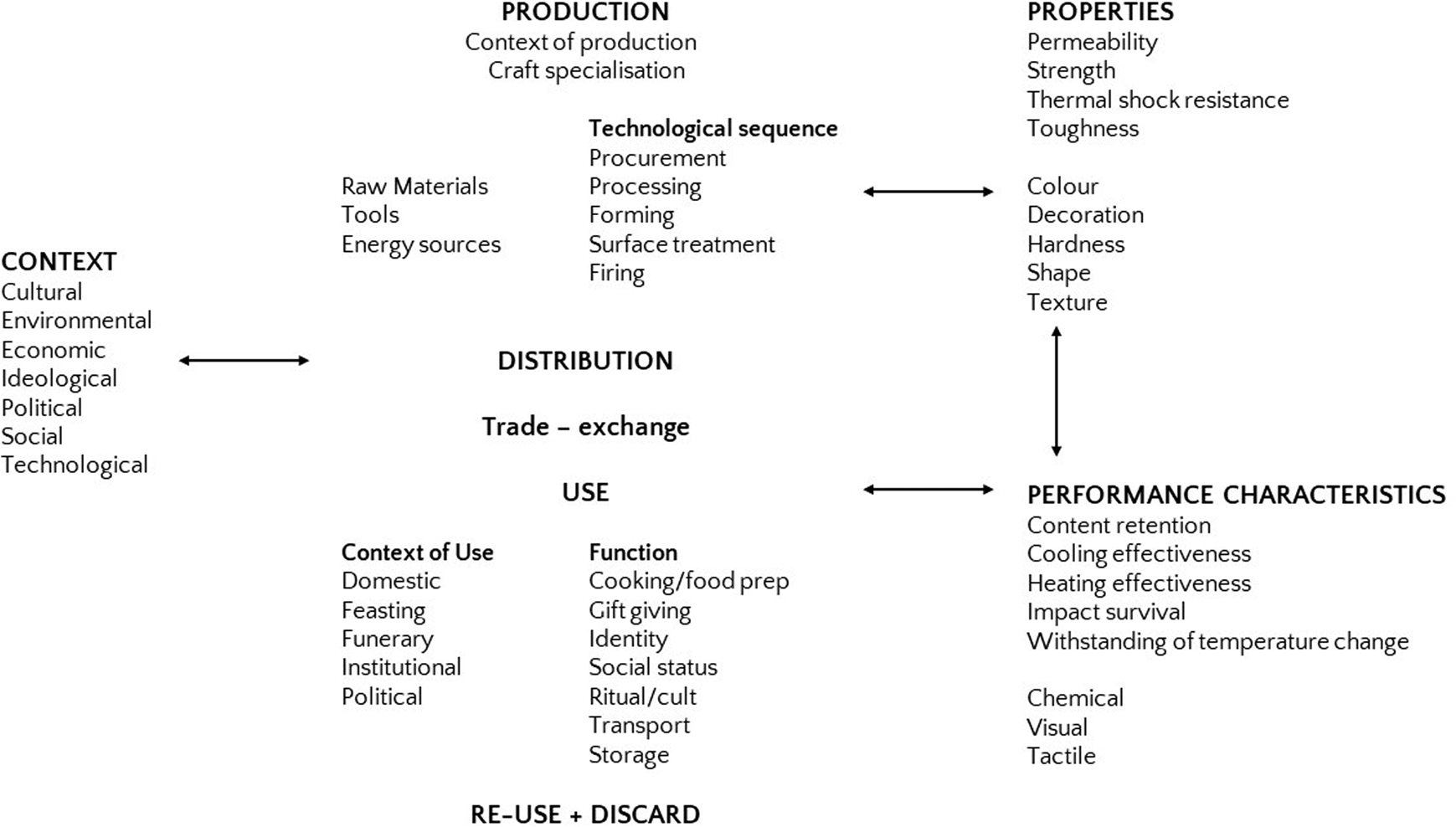

In a recent synthesis of Greek bronze casting Zimmer (Reference Zimmer1990; Reference Zimmer and Baas2019) addressed the questions of innovation and tradition in Aegean workshops active between the LG and Hellenistic periods. According to his observations, craftspeople in competitive settings tended to experiment despite the satisfactory or even high quality of the already existing products. Such a setting appeared to have spurred a search for new innovations with respect to techniques, tools and processes. Most significantly, as Zimmer (Reference Zimmer and Baas2019, 10) has argued, the technological development of bronze casting was only possible if bronze workers, casters, ironsmiths and potters worked together in one workshop or at least shared their knowledge on a regular basis (see also Molloy and Mödlinger Reference Molloy and Mödlinger2020). This brings us to the character of technological development, the study of which should be informed by a close analysis of choices and behaviour applied in the production process and its organisation, subsumed under the concept of the chaîne opératoire (Fig. 3).

Fig. 3. Schematic overview of the interplay between production and consumption of objects and the social context of technologies.

Contemplating cross-craft interaction can benefit the analysis as it investigates interplay between technologies.Footnote 18 Cross-craft interaction conveys a range of deeper knowledge of material properties and integration across materials, namely the transfer of skills and techniques in an unchanged or adapted form to fit a new medium (McGovern Reference McGovern, McGovern, Notis and Kingery1989; Brysbaert Reference Brysbaert, Antoniadou and Pace2007). The process requires spatial proximity and is deeply rooted within the respective economic (e.g., structure and scale of industry, mode of control of production and administrative oversight), social (e.g., social organisation, status of individuals and openness to non-members), cultural (e.g., perception and attitude to novelties) and technical (e.g., resources and construction capabilities) constraints (McGovern Reference McGovern, McGovern, Notis and Kingery1989, 2–4). Considering the possibility of cross-craft interaction enables us to hypothesise that some diachronic technological changes might have been local with respect to both the tradition and transfer of the necessary knowledge. Pyro-technologies, for example, are an ideal candidate for such a transfer (Amicone et al. Reference Amicone, Radivojević, Sean and Berthold2020).

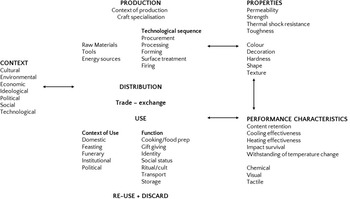

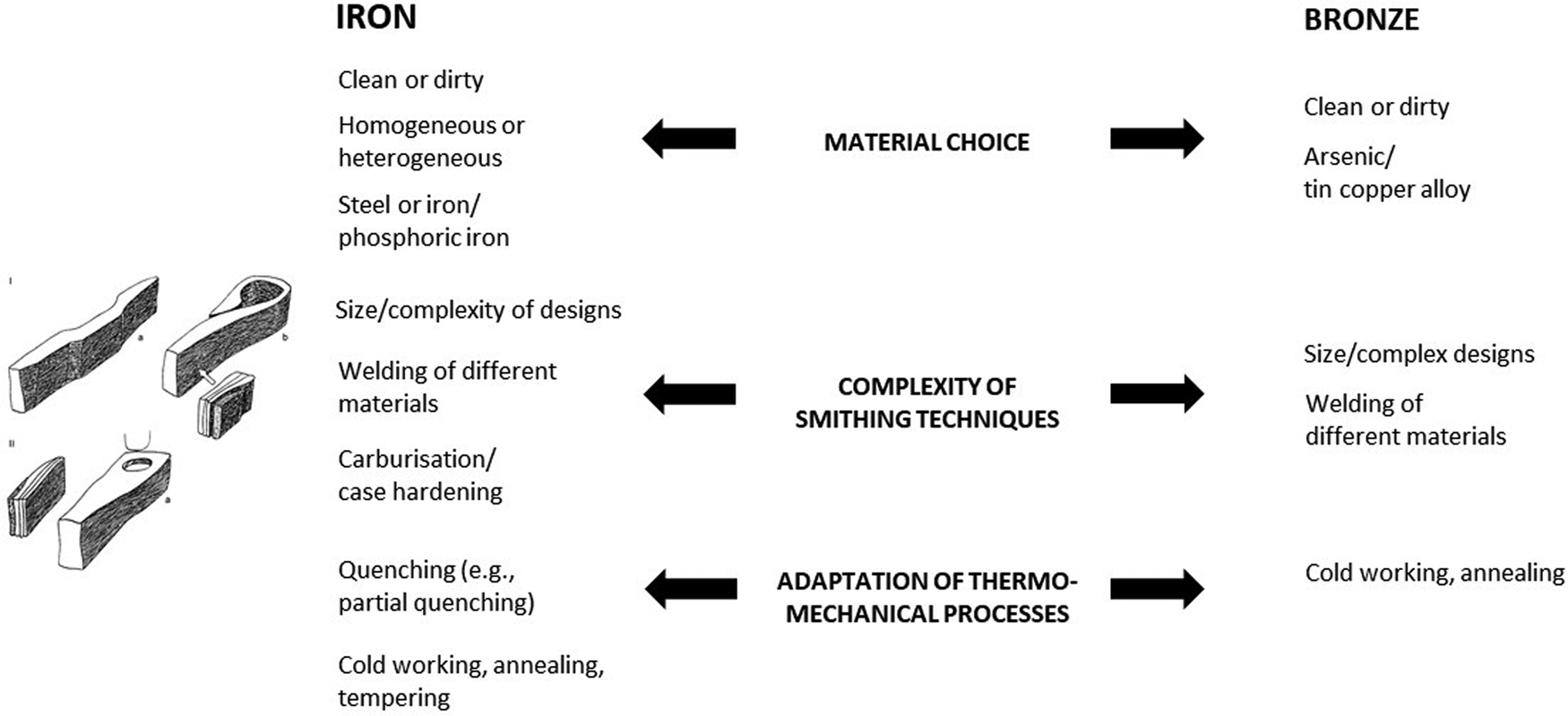

The observations on cross-craft interaction certainly apply in the EIA technological setting, as reflected by the lively debates on the link between bronze and early iron technology in the eastern Mediterranean (Fig. 4; Erb-Satullo et al. Reference Erb-Satullo, Jachvliani, Kakhiani and Newman2020; Liss, Levy and Day Reference Liss, Levy and Day2020). As for the Aegean, the rather deterministic idea that the knowledge gained from copper and tin bronze metallurgy was crucial for the mastering of iron – based on a linear understanding of technological development – has not yet been dismissed in favour of a more complex investigation of a set of practices and behaviours in production techniques (both smelting and melting). The recent studies on the longstanding metallurgical tradition on Thasos from as early as the EBA have demonstrated the utility of multipronged research to technological trajectories (Nerantzis, Bassiakos and Papadopoulos Reference Nerantzis, Bassiakos and Papadopoulos2016; Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016; Bassiakos, Nerantzis and Papadopoulos Reference Bassiakos, Nerantzis and Papadopoulos2019). A similar shift in the analytical scope can also benefit the examination of manufacturing techniques (alloying, casting, refining and smithing) within the chaîne opératoire, as the recent evidence from the Levant suggests a strong correlation between the bronze working and iron production at the beginning of the EIA (Yahalom-Mack and Eliyahu-Behar Reference Yahalom-Mack and Eliyahu-Behar2015; Erb-Satullo et al. Reference Erb-Satullo, Jachvliani, Kakhiani and Newman2020). Given the relative scarcity of easily available iron ore deposits of high or at least sufficient quality around the Aegean (Muhly Reference Muhly, Tassios and Palyvou2006) and the continuing supra-regional movement of raw or semi-finished material in the region (Kiderlen et al. Reference Kiderlen, Bode, Hauptmann and Bassiakos2016), the possibility of an early adoption of new iron technologies by Aegean bronzesmiths remains intriguing, namely in terms of locally specific modes of adoption.

Fig. 4. Schematic overview of the interplay between knowledge and skills needed in bronze and iron working (after Pleiner Reference Pleiner2006, 210, fig. 70; Verčík and Güder Reference Verčík and Güderin preparation).

In sum, the new evidence from the Aegean further questions the vision of a rather consistent and linear diffusion of iron innovation and, as a result, challenges the assumed diffusion of the technology predominantly via the western part of the region (Lemos Reference Lemos2002, 103; Dickinson Reference Dickinson2006, 117; Kostoglou Reference Kostoglou2008, 77–80; Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016, 283; Verčík Reference Verčík2017a). Examining the specific regional trajectories as well as socioeconomic or cultural developments is, therefore, crucial for a meaningful assessment on a supra-regional level (Hjärthner-Holdar and Risberg Reference Hjärthner-Holdar and Risberg2009). Regional studies inject the necessary detail into debates on invention, innovation and technological change, while at the same time they are receptive to varying local conditions. Such an approach allows us to test different models of technological change and the impact of varying sociocultural and environmental circumstances on the process of introduction, spread and adaptation of iron in adjacent and connected, yet distinct, regions in the Aegean during the EIA.

As a result, our contribution highlights sociocultural aspects of western Anatolian technological developments. Such an investigation is particularly timely as the persisting reconstructions related to the broader questions of sociocultural significance of the transition into the EIA continue to rely on the purported EIA migrations of the Greeks into Anatolia rather than on analyses contextualised within the long-term local developments. In order to do so, in what follows we provide a longue durée overview of regional technological knowledge-scapes in relation to the chaîne opératoire, as their understanding is a prerequisite for a successful contextualisation of technological adoption and adaptation at the beginning of the EIA.

METALLURGY IN WESTERN ANATOLIA DURING THE BRONZE AND EARLY IRON AGES

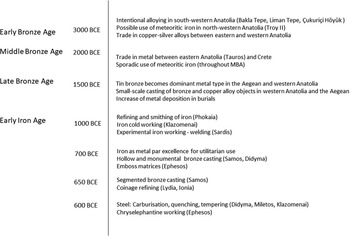

In this section we present the current state of knowledge of metalworking in central western Anatolia and the regions immediately to the east and west in order to highlight the importance of east–west connections across the Anatolian landmass rather than only those enabled by the sea. Our aim is to illustrate longstanding patterns of processes of innovation, including both adoption and adaptation, which in turn enable us to isolate locally specific characteristics of production and consumption at the beginning of the EIA (Fig. 5).

Fig. 5. Overview of the main Bronze and Iron Age developments related to metalworking in western Anatolia.

The Bronze Ages

Scholars have traced the beginnings of metal extraction and the constellation of technological knowledge in central Anatolia to the early fourth millennium bc, if not earlier, based on the evidence from Demircihüyük, Küllüoba and other sites in the region (Müller-Karpe Reference Müller-Karpe1994; Efe Reference Efe and Yalçın2002, 53–5; Massa Reference Massa2016, 169; comparison with eastern Anatolia: Lehner and Yener Reference Lehner, Yener, Roberts and Thornton2014; see also Yener Reference Yener2000). Traces of developed technology of metalworking in the form of intentional alloying and utilisation of copper-rich ores can be documented in central Anatolia from the mid-fourth millennium bc and in western Anatolia and the north-eastern Aegean from around 3300–3000 bc (Schoop Reference Schoop, Bilgen, von den Hoff, Sandalcı and Siler2011; Lehner and Yener Reference Lehner, Yener, Roberts and Thornton2014; Nerantzis, Bassiakos and Papadopoulos Reference Nerantzis, Bassiakos and Papadopoulos2016; Lehner Reference Lehner and Schachner2017, 148; Massa, McIlfatrick and Fidan Reference Massa, McIlfatrick and Fidan2017, 68). Troy II, moreover, yielded evidence for an early use of meteoritic iron.Footnote 19 On the western Anatolian littoral, multifaceted metallurgical production and metalworking were documented at settlements of Bakla Tepe, Çukuriçi Höyük and Liman Tepe during EB I, if not earlier, possibly as early as the Late Chalcolithic to EBA transition (Efe Reference Efe and Yalçın2002, 50–1; H. Erkanal Reference Erkanal, Erkanal, Hauptmann, Şahoğlu and Tuncel2008a, 168; Reference Erkanal, Erkanal, Hauptmann, Şahoğlu and Tuncel2008b, 180; Kaptan Reference Kaptan, Erkanal, Hauptmann, Şahoğlu and Tuncel2008, 245; Mehofer Reference Mehofer, Horejs and Mehofer2014; Horejs and Mehofer Reference Horejs, Mehofer, Hauptmann and Modarressi-Tehrani2015; Keskin Reference Keskin2009).

Broadly speaking, since EBA II–III (c. 2300–2200 bc) this region was part of supra-regional networks in terms of metal resources that stretched from eastern Anatolia to the northern and southern Aegean (Efe Reference Efe and Yalçın2002, 57; Şahoğlu Reference Şahoğlu2005; Horejs and Mehofer Reference Horejs, Mehofer, Hauptmann and Modarressi-Tehrani2015). Western Anatolia was incorporated into the edges of these long-distance connections. And while the presence of overlapping networks of distribution and production did not necessarily determine sophistication in terms of metallurgy, it must have created an environment especially receptive to effective technological development. Overall, however, our knowledge of western Anatolian local sources and their exploitation in prehistory is still rather fragmented (Massa Reference Massa2016, 169–96). While the presence of mineral deposits, such as copper, silver and gold, has been confirmed in western Anatolia, it is difficult to ascertain their exploitation in prehistory (Maden Tetkik Arama Genel Müdürlüğü 2017, 14–17, fig. 7; Massa Reference Massa2016, 175–9; Karatak, Akyol and Bingöl Reference Karatak, Akyol and Bingöl2019; Cevizoğlu Reference Cevizoğlu, Gönül Yalçın and Stegemeier2020, 245, fig. 1; Baykan Reference Baykan2021).

In comparison, evidence for the succeeding periods is more pronounced. While extractive iron technology might have been invented as early as the beginning of the second millennium bc in eastern Anatolia, the earliest sign of iron smelting in the form of slags can be attributed to Stratum IIIc at Kaman Kalehöyük (Akanuma Reference Akanuma2007, 125–7). The general pattern suggests a sporadic use of most probably meteoritic iron in the MBA, documented in Anatolia, Crete, Egypt, Mesopotamia and Cyprus (Erb-Satullo Reference Erb-Satullo2019, 562–6). There were certainly some links in place between Anatolia (more specifically, the sources in the Tauros mountains) and Crete (eighteenth century bc Malia: Poursat and Loubet Reference Poursat, Loubet, Laffineur and Greco2005, 120; Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012, 121). The circulation of meteoritic and increasingly also smelted iron in the LBA is attested by finds from Anatolia as well as the Levant and Greece (Waldbaum Reference Waldbaum and Pigott1999, 28). Copper alloys were used much more widely, of course. In the fifteenth century bc, tin bronze became the dominant metal type utilised in both the Aegean and mainland Greece, which indicates a reliable supply chain of tin at the beginning of LBA III (fourteenth century bc).Footnote 20 In Cyprus, this supply can be dated to slightly earlier than in the Aegean, to around the sixteenth century bc.

Textual and archaeological evidence from the Hittite empire suggests that the Hittites oversaw the production and distribution of tin bronze, arsenical copper, and even some iron, though in relatively smaller quantities than previously envisioned (Waldbaum Reference Waldbaum1980, 76–81; Müller-Karpe Reference Müller-Karpe1994, 81; Yalçın Reference Yalçın, Yalçın, Pulak and Slotta2005; Lehner Reference Lehner and Schachner2014; Reference Lehner and Schachner2017, 149–53). There is some textual evidence suggesting that iron, perhaps in its meteoritic form, was an item of high value at least in the Old Assyrian period, and that its presence increased in the course of the second millennium bc (Muhly et al. Reference Muhly, Maddin, Stech and Özgen1985, 73–6; Dercksen Reference Dercksen and Yalçın2005; Siegelová Reference Siegelová and Yalçın2005; Siegelová and Tsumoto Reference Siegelová, Tsumoto, Genz and Mielke2011). Its use rose during the Middle Hittite and the Empire periods (the fifteenth to thirteenth centuries bc), but iron continued to be relatively rare and restricted to high status knives, daggers, swords, spears and pins. There is only isolated evidence for smelting, so it is probable that meteoritic iron was more commonly in circulation.Footnote 21

Shipwreck evidence from the second half of the LBA exemplifies the expansion of the eastern-Mediterranean-wide networks that led along the southern Anatolian coast. The Uluburun and Cape Gelidonya shipwrecks, sunk off the coast of south-western Anatolia, provide a snapshot of the movement of finished objects, and raw and scrap metals along the main long-distance routes, and perhaps even artisans and metalworkers (documented by the presence of chisels and punches as part of the cargo). While the ship that sank at Uluburun (just before 1300 bc) carried a large amount of Cypriot copper and tin ingots as well as weapons and tools (Pulak Reference Pulak1998; Reference Pulak, Aruz, Benzel and Evans2008), the Cape Gelidonya wreck (which sank around 1200 bc) carried mostly scrap bronze and broken agricultural tools (Muhly, Wheeler and Maddin Reference Muhly, Wheeler and Maddin1977; Hirschfeld and Bass Reference Hirschfeld and Bass2013; Blackwell and Hirschfeld Reference Blackwell and Hirschfeld2020; Lehner et al. Reference Lehner, Kuruçayırlı, Hirschfeld, Jansen, Langis-Barsetti and Martin2020). Most of the scrap metal came from Cyprus, but a small part of the material was traced to Laurion in Attica and the Tauros in southern Anatolia, and perhaps also Timna in the Levant and Sardinia (Stos Reference Stos, Shortland, Freestone and Rehren2009, 166–73). This dissimilarity can be attributed to not only the different purposes of ships’ voyages along the southern Anatolian coast, but also the changing character of the trade with metals. The state-level trade attested by the Uluburun is clearly documented through LBA written records, such as the Amarna tablets (Bass et al. Reference Bass, Throckmorton, Du Plat Taylor, Hennessy, Shulman and Buchholz1967; Sherratt Reference Sherratt and Pare2000; Hirschfeld and Bass Reference Hirschfeld and Bass2013; Pulak Reference Pulak, Aruz, Benzel and Evans2008), while the Cape Gelidonya shipwreck moved within entrepreneurial regional networks operated by private traders. The trade in scrap copper and bronze flourished especially during the thirteenth century bc and occurred alongside trade with bulk metal (Blackwell Reference Blackwell2018, 513–14). This phenomenon has traditionally been linked to the supposed decreased access to copper in the eastern Mediterranean as a result of ever-increasing consumption, but Sherratt's (Reference Sherratt and Pare2000, 87–8) arguments, outlined in the previous section, problematise such assumptions (see also Blackwell Reference Blackwell2018). The crucial implication is that Ionia enjoyed an indirect access to these routes via subsidiary and more localised branches along the western Anatolian coast, some of which might have reached all the way to the Balkans.Footnote 22 Thus, while Ionia tapped into long-distance networks, much of the access was indirect, because long-distance traffic turned west after passing Rhodes to reach the Greek mainland.

In western Anatolia and the adjacent Aegean islands, all major settlements yielded evidence for an extensive use of different metal types (Erdem Reference Erdem2015, 129–44; weapons: Roháček Reference Roháček, Franković, Popović, Files and Kramberger2018). Along the coast, important evidence for metalworking comes from Troy (Müller-Karpe Reference Müller-Karpe1994, 99; Begemann, Schmitt-Strecker and Pernicka Reference Begemann, Schmitt-Strecker, Pernicka, Wagner, Pernicka and Uerpmann2003) and the adjacent island of Lemnos (Pernicka et al. Reference Pernicka, Begemann, Schmitt-Strecker and Grimanis1990; Boulotis Reference Boulotis, Macdonald, Hallager and Niemeier2009, 202–3). It seems that small-scale casting of bronze or copper alloy objects took place in a number of settlements in the central part of western Anatolia and the adjacent islands of Chios and Psara (Hood Reference Hood1982, 653–4; Deligiorgi Reference Deligiorgi and Archontidou-Argiri2006). The large cemetery at Panaztepe is well known for its rich funerary assemblages, including copper alloy and precious metal objects from the Aegean and Anatolia (Erkanal-Öktü Reference Erkanal-Öktü2018). The excavators suggested that some of the bronze grave goods might have been produced locally, but so far no evidence of a workshop in the settlement has been found; only a mould and small tools have been documented (A. Erkanal Reference Erkanal1996, 333; Günel Reference Günel2018). The sites around the Gulf of Izmir, such as Smyrna, Baklatepe, Çeşme Bağlararası, and Liman Tepe utilised a range of copper alloy tools and weapons, and there is some evidence that a portion of these assemblages might have been produced locally (Sandars Reference Sandars1961; Cevizoğlu and Ersoy Reference Cevizoğlu, Ersoy and Piesker2016, 106). This suggestion also seems to apply to the recent discovery of an illicitly dug tomb at Hacıgebeş, roughly dated to the EIA by survey finds, in the vicinity of Klazomenai/Liman Tepe, which yielded a bronze dagger of an LBA type (Koparal and Vaessen Reference Koparal and Vaessen2020, 110–12, fig. 7). Archaeological work at the principal LBA mounds in west-central Anatolia, Aphrodisias, Beycesultan and Kaymakçı suggests that metal finds (tools such as knives and pins) were produced and used within settlement contexts (Erdem Reference Erdem2015, 148–53; Beycesultan: Mellaart and Murray Reference Mellaart and Murray1995, 114; Dedeoğlu and Abay Reference Dedeoğlu and Abay2014; Kaymakçı: Roosevelt et al. Reference Roosevelt, Luke, Ünlüsoy, Çakırlar, Marston, O'Grady, Pavúk, Pieniążek, Mokrišová, Scott, Shin and Slim2018, 661–73; Pieniążek et al. Reference Pieniążek, Roosevelt, Luke and Pavúk2019). A number of weapons from the area of ancient Pergamon, now in the collections of the Ashmolean Museum in Oxford and the Römisch-Germanisches Museum in Mainz, are currently being analysed to provide additional information on technology and material provenance of weapons from this region.Footnote 23

The south-western corner of Anatolia has produced evidence for the consumption of metal objects with stylistic origins in the Aegean and Anatolia. The items come primarily from tombs (Sandars Reference Sandars1963; Benzi Reference Benzi, Bruni, Massa and Caruso2004; Roháček Reference Roháček, Franković, Popović, Files and Kramberger2018; Reference Roháček2019) or were reported as isolated finds (Kilian-Dirlmeier Reference Kilian-Dirlmeier1993, pl. 58:445–6; Benzi Reference Benzi and Montanari2002). Miletos is the key site here in terms of maritime trade and connectivity to the major networks that relied on Rhodes as an access point into the Aegean. Even though the excavated LBA levels are relatively limited in Miletos, fragments of moulds were found in Level V (fifteenth century bc) which suggest copper and bronze casting (Niemeier Reference Niemeier and Yalçın2000). The rest of the area just south of Miletos, later known as Caria, yielded evidence for post-palatial and EIA metals, including bronze and iron objects found in the LBA chamber tomb at Pilavtepe (Benter Reference Benter2009; the evidence from this area will be further discussed in the following section). The geographically strategic Dodecanese produced rich tombs with metal finds, mostly jewellery and weaponry dating to the second half of the LBA, but so far there is only limited evidence for metalworking in the form of debris, moulds and equipment from LBA Trianda on Rhodes and the Serraglio on Kos (Morricone Reference Morricone1975, 275, fig. 228c; Waldbaum Reference Waldbaum1978, 19; Marketou Reference Marketou1998; Blackwell Reference Blackwell2011; Vitale et al. Reference Vitale, Ballan, Blackwell, Iliopoulos, Mantello, Marketou, McNamee, Morrison, Moulo, Moutafi, Passa and Vika2017, 269–77).

Early Iron Age

Iron artefacts became more numerous in the archaeological record of the eastern Mediterranean, especially in Cyprus and the Levant, in the course of the eleventh or even as early as the twelfth century bc. In general, there is a substantial uptake of iron smelting in the latter region from around 1000 bc (Veldhuijzen Reference Veldhuijzen, Kassianidou and Papasavvas2012; Yahalom-Mack and Eliyahu-Behar Reference Yahalom-Mack and Eliyahu-Behar2015; Erb-Satullo Reference Erb-Satullo2019, 564–7). In addition to iron, continuing production of tin bronzes has also been documented, albeit at a smaller scale than during the LBA.Footnote 24 Socioeconomic and technological factors, as previously discussed, including the expansion of maritime interaction and interregional trade, as well as a relative continuity at the LBA to EIA transition, figure as prominent factors in the explanation of the success of this region in increasing the consumption and export of iron (Snodgrass Reference Snodgrass1980, 359–60; 1982, 287–8; Sherratt Reference Sherratt and Pare2000; Muhly and Kassianidou Reference Muhly, Kassianidou, Cadogan, Iacovou, Kopaka and Whitley2012, 124–6). Additionally, as Erb-Satullo (Reference Erb-Satullo2019, 578–82, 587–90, 592) has stressed, innovation of iron smelting technologies, which resulted in a more consistent quality of the products, was the key enabler of, and the changing socioeconomic landscape at the onset of the EIA was the key drive for, an increased circulation and consumption of iron.

In Greece, Lefkandi on the island of Euboea emerged as a central Aegean participant in maritime commerce linked to the broader regional networks of the Near East, Cyprus, Egypt and Mesopotamia. The tombs contained a large number of metal objects, mostly bronze jewellery, but iron pins and a knife were also present in the eleventh-century bc assemblages.Footnote 25 The evidence from Lefkandi presented so far has illustrated that while using assemblages from cemeteries as a proxy for patterns of iron circulation is problematic, it nonetheless shows that the emerging EIA elite at well-connected centres desired ownership of iron objects. The same applies to the Sub-Mycenaean cemeteries in Attica, which yielded a small number of metal tools and weapons (Snodgrass Reference Snodgrass2000, 231–6; Papadopoulos and Smithson Reference Papadopoulos and Smithson2017). In the Aegean, an iron bracelet was found in the Marmaro cemetery at Ialysos in eleventh-century bc Tomb 17 and in a number of PG tombs by the Serraglio on Kos, which contained ten iron pins, two knives, and an iron ring (Waldbaum Reference Waldbaum1978, 34). Iron in settlement contexts, however, has been found in central western Anatolia, in contrast to the so far published evidence from Greece and the Aegean.

In Anatolia, new studies come from prominent centres such as the settlements of Gordion (Voigt and Henrickson Reference Voigt and Henrickson2000) and Sardis (Waldbaum Reference Waldbaum1983; Ramage, Ramage and Gürtekin-Demir Reference Ramage, Ramage and Gürtekin-Demir2021), which enjoyed contacts with Ionia (Kerschner Reference Kerschner, Schwertheim and Winter2005; Cevizoğlu Reference Cevizoğlu, Gönül Yalçın and Stegemeier2020). In these regions, which had been in the Hittite peripheries in the LBA, the use of iron can be dated to the eleventh (Sardis) and the ninth (Gordion) centuries bc. At Hattuša, production of copper alloys continued in a workshop located on the middle plateau of Büyükkaya, dated to the twelfth century bc as a recent analysis by Lehner (Reference Lehner and Schachner2017) suggests. Most items manufactured in this workshop consisted of tin bronzes, while a few objects of arsenical copper and arsenical copper alloyed with lead and tin were present, too.Footnote 26 Thus, the continuity of tin bronze production in the EIA attests to the persistence of certain technologies even when faced with changes in political and administrative structures.

Evidence of EIA iron working comes from Sardis, the capital of the later Lydian kingdom, the only proto-state polity in western Anatolia. The EIA layers from the deep ‘Lydian trench’ in sector HoB by the Lydian fortification wall uncovered numerous iron finds (Ramage, Ramage and Gürtekin-Demir Reference Ramage, Ramage and Gürtekin-Demir2021, 271), of which three knives, a curved sickle blade, an adze blade, two double hooks and a nail date to the tenth century bc (Ramage, Ramage and Gürtekin-Demir Reference Ramage, Ramage and Gürtekin-Demir2021, 40–6, 137, 143, 156, pls 9 [cat. no. HoB 37: knife], 25 [cat. no. HoB 101; knife], 28 [cat. no. HoB 119: adze = Waldbaum Reference Waldbaum1983, cat. no. 127], 53 [cat. no. HoB 236: knife = Waldbaum Reference Waldbaum1983, 172; cat. no. HoB 237: sickle = Waldbaum Reference Waldbaum1983, 118], 53 [cat. no. HoB 238: hook], and 40 [n. 14: nail, uncatalogued and n. 16: double hook, uncatalogued]). Tools and metal fixtures deserve special attention (together with a clay rack for holding an iron spit; Ramage, Ramage and Gürtekin-Demir Reference Ramage, Ramage and Gürtekin-Demir2021, 39, cat. no. HoB 230, pl. 51), as these objects attest an early use of iron and its diversity within a household context throughout the tenth century bc. They can be compared to iron finds from the settlement at Nichoria (DA II; Dickinson Reference Dickinson2006, 147–50).Footnote 27 The sickle was made of pure unhardened iron with minimal cold working (Waldbaum Reference Waldbaum1983, 181; the metallographic analysis was conducted by R. Knox, Jr). The adze had a very heterogeneous microstructure with slag inclusions, which exhibits traces of layering sheets of carburised and uncarburised bloomery iron, which were heated and hammered a number of times (Waldbaum Reference Waldbaum1983, 178–9, pls 59–60; the emission spectrography and metallography were conducted by R. Maddin, J. Muhly and J.C. Waldbaum). Thus, the carburisation process employed here relied on welding of steel and iron to achieve a product of a higher quality rather than the conventional absorption in charcoal.Footnote 28 Waldbaum (Reference Waldbaum1983, 179–80), therefore, proposed that local experimentation with hardening took place at Sardis already in the early stages of the first millennium bc.

METALLURGY ON THE WESTERN ANATOLIAN COAST DURING THE EARLY IRON AGE: NEW DISCOVERIES

New research in Ionia complements the current knowledge from major Aegean and inland Anatolian centres. We suggest that this evidence challenges the way we understand the transfer of technologies at the dawn of the EIA in the broader eastern Mediterranean region and forces us to rethink the way we envision continuity and change at the transition into the EIA. Coastal Ionian cities tend to be investigated in light of their maritime activities and increased connectivity to the rest of the Aegean, but we wish to pay particular attention to regionally specific developments, as highlighted in our critical review of prior approaches to the spread of iron in the Aegean. Key evidence from Phokaia, the Gulf of Izmir and the region of Caria thus propels a revision of the status quaestionis of the exploitation of iron around the Aegean Sea.

Phokaia

Perhaps the most exciting evidence to date has come from Phokaia, a settlement well known for its participation in the Archaic maritime activity. The earliest architecture at the site of the later Temple of Athena consists of an oval house dated to the LBA, but EBA and MBA ceramics have been found in different areas of the Archaic city as well (Özyiğit Reference Özyiğit2017, 50–3). Crucially, there is evidence supporting continuity of habitation from at least the twelfth century bc and certainly throughout the EIA (Özyiğit Reference Özyiğit2003, 115; Reference Özyiğit2009–11). Namely, a well-preserved metal workshop in the southern PG settlement was identified in a layer cut by two apsidal houses dated to the PG period by the excavators. The stratigraphic sequence and the associated ceramic finds are important for the dating and consist of an amphora sunken into a floor dated to the LH IIIC (Late) or the transitional (‘Sub-Mycenaean’) phase (Yalçın and Özyiğit Reference Yalçın, Özyiğit and Yalçın2013, 240). The early date, as proposed by Özyiğit, has been contested by some as this type of amphora continued to be produced into the Early Archaic period (e.g., parallels from Klazomenai: Ersoy, Koparal and Vaessen forthcoming) and curvilinear houses were a staple of local architectural tradition as late as the sixth century bc (also based on parallels from Klazomenai: Ersoy Reference Ersoy, Cobet, von Graeve, Niemeier and Zimmermann2007, 165–9; see also Mazarakis-Ainian Reference Mazarakis-Ainian, Brandt and Karlsson2001). Moreover, ‘Sub-Mycenaean’ as a dating division is problematic in western Anatolia. Stylistic parallels for the amphora, however, do exist and can be dated to the LH IIIC (Late) (Mountjoy Reference Mountjoy1999, 1155 no. 16 [Chios]; Ramage, Ramage and Gürtekin-Demir Reference Ramage, Ramage and Gürtekin-Demir2021, pl. 38, cat. no. HoB 172 [P13.159; Sardis]), and therefore a late second-millennium bc date should not be dismissed based on the evidence published so far. The analysis of the metallurgical debris revealed refining and smithing, possibly making it the earliest evidence for iron working documented in the Aegean and western Anatolia. The carbon content in the slag varies between 0.1 and 0.8 per cent, suggesting carburisation, which most likely took place during the smelting process and corresponded with the general practices of EIA metallurgy in the eastern Mediterranean.Footnote 29 At the same time, it indicates a continuation of metalworking tradition during the transitional period of the first half to the second third of the eleventh century bc, if we accept the current dating.

Gulf of Izmir

The mound of Liman Tepe was an important regional centre in the Gulf of Izmir with a long settlement history that goes back to the Late Neolithic. After being a secondary centre in the shadow of the nearby Panaztepe during the LBA, the settlement rose to prominence as a flourishing community at the beginning of the EIA. The occupation gradually expanded beyond the limits of the LBA settlement, away from the summit of the mound to the lower parts of the mound in the south, and the settlement became known as the large Ionian polis of Klazomenai (Ersoy Reference Ersoy, Cobet, von Graeve, Niemeier and Zimmermann2007; Koparal and Vaessen Reference Koparal and Vaessen2020, 114–18). Recent excavations and analysis of local and wider Ionian communication networks have revealed that it was an important port within the existing trade system and communication routes, especially with the northern Aegean, that were sustained since the LBA without major disruption (Koparal and Vaessen Reference Koparal and Vaessen2020, 108, 114). This impression of continuity is further supported by the evidence of the pottery industry, which flourished in both periods (Cevizoğlu and Ersoy Reference Cevizoğlu, Ersoy and Piesker2016, 106–7). In particular, the apsidal PG kiln A1, dating to the first half of the tenth century bc, at the edge of what would become a craft district in the Archaic period, proves that the experience with pyro-technologies gained during the LBA were handed down to the EIA (Cevizoğlu and Ersoy Reference Cevizoğlu, Ersoy and Piesker2016, 112).

Even if a presence of metal production has not yet been documented for the habitation or craft area at Liman Tepe/Klazomenai during the EIA period (although it has been documented for the subsequent Archaic period), the ongoing excavations yielded evidence of early iron. A single edged iron knife with a straight back and a straight handle that is slightly offset from the blade was found in the settlement in a ritual context, dating to the second half of the tenth century bc, on the southern slope of the Liman Tepe mound in the sector KET, which was occupied in the PG period (Fig. 6).Footnote 30 Archaeometallurgical analyses of the knife took place in the Spring of 2020 with the aim of assessing the production techniques and chemical composition of slag inclusions (detailed analysis will be published in Verčík and Güder Reference Verčík and Güderin preparation). The results differ partly from similar analyses conducted on objects from Cyprus and Lydia (Waldbaum Reference Waldbaum1983, 178–9; McConchie Reference McConchie2004, 20, 31–3). The knife from Liman Tepe/Klazomenai was produced from wrought iron, and cold working was applied in order to harden the cutting edge. The micrographs indicate that the cold worked, and therefore deformed, grains added hardness (that is, unless they were annealed). This observation suggests that LBA smithing techniques were adapted to a new material, potentially supporting the impression of continuity of technological knowledge and preferences, or at least of the smithing techniques (Kleitsas, Mehofer and Jung Reference Kleitsas, Mehofer and Jung2018, 94–8; Molloy and Mödlinger Reference Molloy and Mödlinger2020, 209–18). Detailed evaluation of the archaeological context, currently in progress, will aid a better contextualisation of this find.

Fig. 6. Protogeometric knife from Klazomenai, excavated in sector KET (photo courtesy of Prof. Yaşar Ersoy, reproduced with permission).

Currently, it is reasonable to suggest that the knife represents a local product rather than a high-value import. As shown earlier, an increasing number of finds from settlements in the Gulf of Izmir and its surroundings have recently come to light, which indicates a more common utilisation of iron in the region rather than a solely high-value role within society. This pattern does not rule out the possibility that some iron was imported; after all, supra-regional movement of raw or semi-finished material in the eastern Aegean continued in the EIA. Yet a direct link to the northern Aegean and Thasos (Kastri) in particular, which is another important locus of EIA metallurgy, cannot be confirmed, even if Klazomenai had a close connection with the region during this period (Koparal and Vaessen Reference Koparal and Vaessen2020, 114–17). Iron ores from Thasos analysed so far show a characteristic combined barite and high manganese content (Sanidas et al. Reference Sanidas, Bassiakos, Georgakopoulou, Filippaki, Jagou and Nerantzis2016, 287–8), which is not present in the Klazomenaian knife (as indicated by the preliminary chemical analysis of the slag inclusions). Future isotopic characterisation of the iron ores in the Aegean and Anatolia are needed in order to shed new light on this matter.