1. Introduction

Turbulent flows over rough walls occur in many engineering applications and natural phenomena. The engineering challenge is to predict the increased drag due to the roughness for a given surface under operational conditions (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). In turbulence physics, extensive work has been conducted to elucidate the different phenomena and mechanisms between rough-wall turbulence and the traditional smooth-wall turbulent boundary layer (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991; Krogstad, Antonia & Browne Reference Krogstad, Antonia and Browne1992; Jiménez Reference Jiménez2004; Volino, Schultz & Flack Reference Volino, Schultz and Flack2009; Hong, Katz & Schultz Reference Hong, Katz and Schultz2011; Mejia-Alvarez & Christensen Reference Mejia-Alvarez and Christensen2013; Squire et al. Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016). For instance, the existence of roughness can obviously modify the well-known near-wall dynamics of smooth-wall flow because of the effects of local surface conditions. Qualitatively, such effects generally include substantial modifications of the wall drag (viscous and pressure drag components) and the intensity of the turbulent velocity fluctuations and other physical quantities compared with the flow over a smooth wall. Nevertheless, the effect of roughness upon a turbulence structure is not well understood, particularly in the near-wall flows and outer-layer flows.

1.1. Outer-layer similarity

In studies of rough-wall turbulence, the existence of outer-layer similarity is a pivotal condition because the downward shift of the mean velocity profile is often associated with an increase in drag. Townsend (Reference Townsend1976) proposed a similarity hypothesis that the turbulent flow in the outer region is independent of the wall roughness and viscosity. Raupach et al. (Reference Raupach, Antonia and Rajagopalan1991) further extended this hypothesis – specifically, that the influence of roughness is mainly limited to the roughness sublayer, which only determines the wall friction velocity, the virtual origin offset, the flow within the roughness sublayer and the boundary layer thickness. The statistical characteristics of turbulence and flow structures in the outer region are not affected by wall roughness. Here, the roughness sublayer is defined as the region above the roughness, where turbulent motions are directly influenced by the roughness length scales and are generally considered to be within the wall-normal position approximately two to five times the roughness height from the surface. The definitions of different roughness forms differ somewhat (Busse, Thakkar & Sandham Reference Busse, Thakkar and Sandham2017; Forooghi et al. Reference Forooghi, Stroh, Schlatter and Frohnapfel2018; Yuan & Jouybari Reference Yuan and Jouybari2018).

Throughout the years, verification of the outer-layer similarity hypothesis has been controversial. For example, the results of experimental studies of rough-wall boundary layers (Krogstad et al. Reference Krogstad, Antonia and Browne1992; Tachie, Bergstrom & Balachandar Reference Tachie, Bergstrom and Balachandar2000; Volino et al. Reference Volino, Schultz and Flack2009) and the results of numerical simulations of turbulent channel flow (Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003; Bhaganagar, Kim & Coleman Reference Bhaganagar, Kim and Coleman2004) and a turbulent boundary layer (Lee & Sung Reference Lee and Sung2007; Lee, Sung & Krogstad Reference Lee, Sung and Krogstad2011) all indicated substantial roughness effects in the outer region. On the contrary, various reports support the outer-layer similarity (Raupach & Shaw Reference Raupach and Shaw1982; Schultz & Flack Reference Schultz and Flack2007; Hong et al. Reference Hong, Katz and Schultz2011; Yuan & Piomelli Reference Yuan and Piomelli2014a; Squire et al. Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018). Jiménez (Reference Jiménez2004) stated that the conflicting views regarding the similarity hypothesis might be caused by the effect of the relative roughness on the flow and suggested that the ratio of the boundary layer thickness to the roughness height ![]() $\delta /k$ should be greater than 40 for the outer-layer similarity to be observed. Lee et al. (Reference Lee, Sung and Krogstad2011) summarized that the wall similarity and its necessary conditions might not be universal for the given flow types (Bakken et al. Reference Bakken, Krogstad, Ashrafian and Andersson2005; Flack, Schultz & Shapiro Reference Flack, Schultz and Shapiro2005) and that the wall similarity appears to be related to other factors (e.g. dimensions of roughness and geometric shape). Recently, Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2018) noted that the ratio between roughness streamwise and spanwise spacings and the boundary layer thickness are also important factors that can affect the outer-layer similarity.

$\delta /k$ should be greater than 40 for the outer-layer similarity to be observed. Lee et al. (Reference Lee, Sung and Krogstad2011) summarized that the wall similarity and its necessary conditions might not be universal for the given flow types (Bakken et al. Reference Bakken, Krogstad, Ashrafian and Andersson2005; Flack, Schultz & Shapiro Reference Flack, Schultz and Shapiro2005) and that the wall similarity appears to be related to other factors (e.g. dimensions of roughness and geometric shape). Recently, Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2018) noted that the ratio between roughness streamwise and spanwise spacings and the boundary layer thickness are also important factors that can affect the outer-layer similarity.

Overall, the conditions under which the outer-layer similarity is applicable in rough-wall turbulence remain unclear. In addition, roughness effects on coherent structures of different flow layers are poorly understood. In the actual turbulent flow fields, strong nonlinear interscale interactions occur and become stronger with increasing Reynolds number. In particular, the discovery of the inner–outer-layer interactions between different scale motions (Mathis, Hutchins & Marusic Reference Mathis, Hutchins and Marusic2009; Marusic, Mathis & Hutchins Reference Marusic, Mathis and Hutchins2010; Talluru et al. Reference Talluru, Baidya, Hutchins and Marusic2014; Hwang et al. Reference Hwang, Lee, Sung and Zaki2016; Squire et al. Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016) further confirms that the large-scale and very-large-scale structures of an outer region can affect the near-wall turbulence. All of these findings challenge the outer-layer similarity theory of rough-wall turbulence. Whether and how the roughness changes the interactions between coherent structures with different scales are the starting points of the present paper.

1.2. Energy transfer

Many physical processes in wall turbulence are accompanied by energy transfer, and the wall roughness can affect the coherent structures and momentum transfer. The scale and spatial characteristics of the energy transfer process can differ appreciably from those in canonical wall-bounded turbulent flows. Therefore, the influence of roughness on outer-region flow can be explained by the energy transfer mechanism between the inner and outer regions.

Spectral analysis based on the two-point correlation function (Lumley Reference Lumley1964; Lee & Moser Reference Lee and Moser2015, Reference Lee and Moser2019; Mizuno Reference Mizuno2016; Cho, Hwang & Choi Reference Cho, Hwang and Choi2018) and the analysis of the structure function in physical space (Hill Reference Hill2002; Marati, Casciola & Piva Reference Marati, Casciola and Piva2004; Cimarelli, De Angelis & Casciola Reference Cimarelli, De Angelis and Casciola2013; Cimarelli et al. Reference Cimarelli, De Angelis, Jimenez and Casciola2016; Gatti et al. Reference Gatti, Chiarini, Cimarelli and Quadrio2020) are both effective tools to study the energy transfer in wall-bounded turbulent flows. The main idea in the former case is to investigate the production, diffusion and dissipation of turbulent kinetic energy and energy redistribution among the velocity components via the transport equation of the two-point velocity correlation (Lee & Moser Reference Lee and Moser2015; Mizuno Reference Mizuno2016). The description in the spectral space can provide the characteristics of energy transfer among different length scales in the streamwise and spanwise directions and among different flow regions in the wall-normal direction. Some important multiscale behaviours of turbulent flows can then be observed, such as the classical energy cascade from large to small scales and the inverse energy cascade from small to large scales. In the latter case, the second-order structure function of velocity fluctuations is equivalent to the kinetic energy of eddies with length scale ![]() $r$ in physical space; in addition, the transfer path of the scale energy, i.e. the amount of energy contained at certain scales as dictated by the second-order structure function, or scale-energy flux in the space composed of wall-parallel scales and wall-normal distance can be investigated by the generalized Kolmogorov equation (Marati et al. Reference Marati, Casciola and Piva2004; Cimarelli et al. Reference Cimarelli, De Angelis and Casciola2013, Reference Cimarelli, De Angelis, Jimenez and Casciola2016). The scale-energy path can supply the interscale energy transfer involving the wall-normal scale information, which cannot be realized in the spectral analysis because of wall-normal inhomogeneity.

$r$ in physical space; in addition, the transfer path of the scale energy, i.e. the amount of energy contained at certain scales as dictated by the second-order structure function, or scale-energy flux in the space composed of wall-parallel scales and wall-normal distance can be investigated by the generalized Kolmogorov equation (Marati et al. Reference Marati, Casciola and Piva2004; Cimarelli et al. Reference Cimarelli, De Angelis and Casciola2013, Reference Cimarelli, De Angelis, Jimenez and Casciola2016). The scale-energy path can supply the interscale energy transfer involving the wall-normal scale information, which cannot be realized in the spectral analysis because of wall-normal inhomogeneity.

As previously reviewed, considerable efforts have been devoted to understanding the energy transfer in classical smooth-wall turbulence, whereas few studies on the energy transfer process in the framework of rough-wall turbulence have been reported. For instance, Yuan & Piomelli (Reference Yuan and Piomelli2014b) investigated the energy transfer process between turbulent kinetic energy and roughness-induced wake kinetic energy within the roughness sublayer using the single-point Reynolds stress transport equation. However, their study lacked an analysis of the interscale energy transfer along different directions. More recently, the energy transfer of turbulent motions in the presence of surface waves was investigated through spectral analysis using the two-point correlation transport equation. Zhang, Huang & Xu (Reference Zhang, Huang and Xu2019) concluded that the wave-induced production provides additional input for the large-scale energy at low wave ages but plays the opposite role at high wave ages. Wang et al. (Reference Wang, Zhang, Hao, Huang, Shen, Xu and Zhang2020) found that surface waves carry a new energy source at the dominant wavelength scale in the near-surface region, which is mainly due to the contribution of the neighbouring streamwise turbulent motions, and those at the harmonic wavelength scales contribute the most. This paper enriches this research in rough-wall turbulence, providing a new perspective for gaining further insight into the outer-layer similarity failure.

The aim of the present work is to explore the effects of roughness on the outer-layer similarity of turbulence statistics and large-scale structures, and to investigate the turbulent energy transfer process. The roughness Reynolds number ![]() $k^{+}$ and the ratio of the roughness height to the half-channel height

$k^{+}$ and the ratio of the roughness height to the half-channel height ![]() $k / \delta$ are systematically varied. Direct numerical simulations (DNSs) were performed for a fully developed turbulent channel flow with three-dimensional sinusoidal roughness. A triple decomposition was adopted to extract the mean, wave-induced and turbulent components of the flow field. The turbulent statistics for rough-wall cases, including the mean velocity profiles and velocity defects, stress profiles, energy spectra and instantaneous flow fields, were then examined and the results were compared with those for the smooth-wall cases. In addition, spectral analysis of the two-point correlation transport equation and the scale-energy path display of the generalized Kolmogorov equation were performed to reveal the underlying mechanism by which roughness affects the overlying turbulent flow at different length scales and vertical positions. The paper is organized as follows: the problem formulation and numerical method are briefly introduced in § 2. Roughness effects on turbulence statistics and large-scale structures, along with detailed analyses of the turbulent energy transfer process, are discussed in § 3. Finally, conclusions are drawn in § 4.

$k / \delta$ are systematically varied. Direct numerical simulations (DNSs) were performed for a fully developed turbulent channel flow with three-dimensional sinusoidal roughness. A triple decomposition was adopted to extract the mean, wave-induced and turbulent components of the flow field. The turbulent statistics for rough-wall cases, including the mean velocity profiles and velocity defects, stress profiles, energy spectra and instantaneous flow fields, were then examined and the results were compared with those for the smooth-wall cases. In addition, spectral analysis of the two-point correlation transport equation and the scale-energy path display of the generalized Kolmogorov equation were performed to reveal the underlying mechanism by which roughness affects the overlying turbulent flow at different length scales and vertical positions. The paper is organized as follows: the problem formulation and numerical method are briefly introduced in § 2. Roughness effects on turbulence statistics and large-scale structures, along with detailed analyses of the turbulent energy transfer process, are discussed in § 3. Finally, conclusions are drawn in § 4.

2. Problem formulation

The problem considered here is a fully developed turbulent channel flow over rough walls. The rough surface consists of three-dimensional sinusoidal roughness elements according to

where ![]() $\eta _{d}$ is the rough surface elevation,

$\eta _{d}$ is the rough surface elevation, ![]() $k$ is the semi-amplitude and

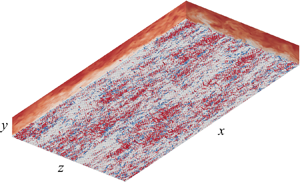

$k$ is the semi-amplitude and ![]() $\lambda$ is the wavelength of the roughness elements. A schematic of the computational domain and coordinate system is shown in figure 1. We adopt a Cartesian frame fixed in the physical space, with

$\lambda$ is the wavelength of the roughness elements. A schematic of the computational domain and coordinate system is shown in figure 1. We adopt a Cartesian frame fixed in the physical space, with ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ denoting the streamwise, vertical and spanwise coordinates, respectively. The corresponding velocity components in the three directions are

$z$ denoting the streamwise, vertical and spanwise coordinates, respectively. The corresponding velocity components in the three directions are ![]() $u$,

$u$, ![]() $v$ and

$v$ and ![]() $w$, respectively. The flow is driven by a mean pressure gradient that is dynamically adjusted to maintain a strictly constant flow rate over time. The governing equations for the turbulent flow are the dimensionless incompressible Navier–Stokes equations and the continuity equation

$w$, respectively. The flow is driven by a mean pressure gradient that is dynamically adjusted to maintain a strictly constant flow rate over time. The governing equations for the turbulent flow are the dimensionless incompressible Navier–Stokes equations and the continuity equation

where ![]() ${{u}_{i}}( i=1,2,3 )=( u,v,w )$ are the velocity components in the three directions

${{u}_{i}}( i=1,2,3 )=( u,v,w )$ are the velocity components in the three directions ![]() ${x_{i}}( i=1,2,3 )=( x,y,z )$,

${x_{i}}( i=1,2,3 )=( x,y,z )$, ![]() $p$ is the pressure and

$p$ is the pressure and ![]() $Re_b$ is the bulk Reynolds number. The governing equations are non-dimensionalized using the bulk velocity

$Re_b$ is the bulk Reynolds number. The governing equations are non-dimensionalized using the bulk velocity ![]() $U_b$, fluid density

$U_b$, fluid density ![]() $\rho$, half-channel height

$\rho$, half-channel height ![]() $\delta$ and the kinematic viscosity

$\delta$ and the kinematic viscosity ![]() $\nu$ as the characteristic quantities. The governing equations (2.2) and (2.3) are transformed into the computational domain by introducing an algebraic mapping

$\nu$ as the characteristic quantities. The governing equations (2.2) and (2.3) are transformed into the computational domain by introducing an algebraic mapping

where ![]() $\xi _{1}$,

$\xi _{1}$, ![]() $\xi _{2}$,

$\xi _{2}$, ![]() $\xi _{3}$ and

$\xi _{3}$ and ![]() $\tau$ are the space and time coordinates in the computational domain. Periodic boundary conditions are imposed on the streamwise and spanwise directions, and the walls of the channel are no slip. For spatial discretization, we use a pseudo-spectral method along the transformed horizontal coordinates. In the transformed vertical direction, a second-order finite difference method is used on a staggered grid. The third-order time-splitting method is adopted for time advancement. Further details of the numerical method can be found in Ge, Xu & Cui (Reference Ge, Xu and Cui2010).

$\tau$ are the space and time coordinates in the computational domain. Periodic boundary conditions are imposed on the streamwise and spanwise directions, and the walls of the channel are no slip. For spatial discretization, we use a pseudo-spectral method along the transformed horizontal coordinates. In the transformed vertical direction, a second-order finite difference method is used on a staggered grid. The third-order time-splitting method is adopted for time advancement. Further details of the numerical method can be found in Ge, Xu & Cui (Reference Ge, Xu and Cui2010).

Figure 1. Schematic of the turbulent channel flow over three-dimensional sinusoidal rough walls.

The flow and roughness parameters for all of the rough cases simulated are summarized in Table 1. The superscript ‘![]() $+$’ denotes physical quantities normalized by the friction velocity

$+$’ denotes physical quantities normalized by the friction velocity ![]() $u_\tau$ and the wall viscous length scale

$u_\tau$ and the wall viscous length scale ![]() $\delta _\nu$ (

$\delta _\nu$ (![]() $\delta _\nu =\nu / u_\tau$). In the present study, two groups of numerical cases were simulated: (i) group A, in which the friction Reynolds number

$\delta _\nu =\nu / u_\tau$). In the present study, two groups of numerical cases were simulated: (i) group A, in which the friction Reynolds number ![]() $Re_\tau$ is varied while

$Re_\tau$ is varied while ![]() $k^+$ is kept constant; (ii) group B, in which

$k^+$ is kept constant; (ii) group B, in which ![]() $Re_\tau$ is varied while

$Re_\tau$ is varied while ![]() $k/ \delta$ is kept constant. For group A, as the roughness elements have the same viscous scale, the physical geometrical size of the roughness element relative to the half-channel height reduces with increasing Reynolds number. For group B, all cases have the same physical geometrical size, and the viscous scale increases proportionally with the friction Reynolds number. For comparison, the simulation of full-channel flow over a smooth wall at the corresponding Reynolds numbers were also carried out. The dimensions of the computational domain are

$k/ \delta$ is kept constant. For group A, as the roughness elements have the same viscous scale, the physical geometrical size of the roughness element relative to the half-channel height reduces with increasing Reynolds number. For group B, all cases have the same physical geometrical size, and the viscous scale increases proportionally with the friction Reynolds number. For comparison, the simulation of full-channel flow over a smooth wall at the corresponding Reynolds numbers were also carried out. The dimensions of the computational domain are ![]() ${{L}_{x}}\times {{L}_{y}}\times {{L}_{z}}=2{\rm \pi} \delta \times 2\delta \times {\rm \pi}\delta$, and the corresponding grid number increases with the Reynolds number. The grid points in the streamwise and spanwise directions are uniform, and follow a cosine distribution in the vertical direction. Note that the grid resolution needs to meet the DNS requirements and ensure the smooth recognition of the roughness elements.

${{L}_{x}}\times {{L}_{y}}\times {{L}_{z}}=2{\rm \pi} \delta \times 2\delta \times {\rm \pi}\delta$, and the corresponding grid number increases with the Reynolds number. The grid points in the streamwise and spanwise directions are uniform, and follow a cosine distribution in the vertical direction. Note that the grid resolution needs to meet the DNS requirements and ensure the smooth recognition of the roughness elements.

Table 1. Flow and roughness parameters. Here, ![]() ${{N}_{wx}}$ and

${{N}_{wx}}$ and ![]() ${{N}_{wz}}$ denote the numbers of roughness elements in the streamwise and spanwise directions, respectively;

${{N}_{wz}}$ denote the numbers of roughness elements in the streamwise and spanwise directions, respectively; ![]() $\Delta \xi _{1}^{+}$ and

$\Delta \xi _{1}^{+}$ and ![]() $\Delta \xi _{3}^{+}$ are the grid resolutions in the streamwise and spanwise directions; and

$\Delta \xi _{3}^{+}$ are the grid resolutions in the streamwise and spanwise directions; and ![]() $\Delta \xi _{2,b}^{+}$ and

$\Delta \xi _{2,b}^{+}$ and ![]() $\Delta \xi _{2,c}^{+}$ are the minimum grid resolution near the bottom boundary and the maximum grid resolution near the channel centreline in the vertical direction, respectively.

$\Delta \xi _{2,c}^{+}$ are the minimum grid resolution near the bottom boundary and the maximum grid resolution near the channel centreline in the vertical direction, respectively.

3. Results and discussion

3.1. Mean velocity profiles

In §§ 3.1 and 3.2, we mainly investigate the roughness effects on turbulence statistics. The effect of roughness elements on wall resistance is directly reflected in the variation of the mean velocity profile. Figure 2 shows the mean streamwise velocity profiles and velocity defects in semi-logarithmic coordinates. The mean velocity profiles are computed by ensemble average, including temporal and spatial averages. Different from the intrinsic and superficial averages on the Cartesian grid (Nikora et al. Reference Nikora, McEwan, McLean, Coleman, Pokrajac and Walters2007), the spatial average here is performed along the ![]() $\xi _{1}$ and

$\xi _{1}$ and ![]() $\xi _{3}$ directions in the curvilinear coordinate system, at each layer of grid corresponding to the mean vertical distance from the rough surface (

$\xi _{3}$ directions in the curvilinear coordinate system, at each layer of grid corresponding to the mean vertical distance from the rough surface (![]() $\bar {y}$). Regarding the selection of the virtual origin, Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2015) tested various methods and obtained the most consistently reliable estimation of the virtual origin by collapsing the total stress profile outside the roughness layer. According to their results, the zero-plane displacement is approximately equal to the mean height of rough surface. Therefore,

$\bar {y}$). Regarding the selection of the virtual origin, Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2015) tested various methods and obtained the most consistently reliable estimation of the virtual origin by collapsing the total stress profile outside the roughness layer. According to their results, the zero-plane displacement is approximately equal to the mean height of rough surface. Therefore, ![]() $y=0$ is employed as the virtual origin of the bottom wall for the present rough-wall cases. The velocity profiles still satisfy the logarithmic law in the presence of the roughness elements; however, a downward shift arises with respect to the results for the smooth wall, which is known as the Hama roughness function (Hama Reference Hama1954) and is represented by

$y=0$ is employed as the virtual origin of the bottom wall for the present rough-wall cases. The velocity profiles still satisfy the logarithmic law in the presence of the roughness elements; however, a downward shift arises with respect to the results for the smooth wall, which is known as the Hama roughness function (Hama Reference Hama1954) and is represented by ![]() $\Delta U^{+}$. The logarithmic law for the rough wall can be expressed as

$\Delta U^{+}$. The logarithmic law for the rough wall can be expressed as

where the subscript ![]() $r$ indicates the rough-wall case,

$r$ indicates the rough-wall case, ![]() $\kappa \approx 0.40$ is the von Kármán constant,

$\kappa \approx 0.40$ is the von Kármán constant, ![]() $C \approx 5.3$ is the offset constant and

$C \approx 5.3$ is the offset constant and ![]() $\Delta U^{+}$ reflects the increase in wall friction drag, which is closely related to practical applications. All the mean velocity profiles with different rough conditions follow a logarithmic variation beyond a certain normal position. Therefore, from the perspective of first-order statistics, the hypothesis of outer-layer similarity (Townsend Reference Townsend1976) is still retained for rough-wall flows. For group A, the mean velocity profiles basically coincide, appearing to be independent of the Reynolds number. However, for group B, the mean velocity profiles are shifted downward with increasing the Reynolds number; that is,

$\Delta U^{+}$ reflects the increase in wall friction drag, which is closely related to practical applications. All the mean velocity profiles with different rough conditions follow a logarithmic variation beyond a certain normal position. Therefore, from the perspective of first-order statistics, the hypothesis of outer-layer similarity (Townsend Reference Townsend1976) is still retained for rough-wall flows. For group A, the mean velocity profiles basically coincide, appearing to be independent of the Reynolds number. However, for group B, the mean velocity profiles are shifted downward with increasing the Reynolds number; that is, ![]() $\Delta U^{+}$ is a function of the viscous-scaled roughness height

$\Delta U^{+}$ is a function of the viscous-scaled roughness height ![]() $k^+$ and is independent of the friction Reynolds number, consistent with the conclusion of Zhang, Huang & Xu (Reference Zhang, Huang and Xu2020). Note that the current rough-wall cases keep the other roughness parameters unchanged, except

$k^+$ and is independent of the friction Reynolds number, consistent with the conclusion of Zhang, Huang & Xu (Reference Zhang, Huang and Xu2020). Note that the current rough-wall cases keep the other roughness parameters unchanged, except ![]() $k^+$. In fact, the previous studies have reported that the roughness function is also closely related to different roughness parameters, e.g. the roughness steepness (Napoli, Armenio & De Marchis Reference Napoli, Armenio and De Marchis2008; Ma et al. Reference Ma, Xu, Sung and Huang2020), anisotropy (Busse & Jelly Reference Busse and Jelly2020) and skewness (Flack, Schultz & Barros Reference Flack, Schultz and Barros2020). By plotting the velocity defect in figure 2(c,d), we observe that the profiles for groups A and B are self-similar in the outer layer. In addition, a good collapse is also observed in the inner layer for group B except at

$k^+$. In fact, the previous studies have reported that the roughness function is also closely related to different roughness parameters, e.g. the roughness steepness (Napoli, Armenio & De Marchis Reference Napoli, Armenio and De Marchis2008; Ma et al. Reference Ma, Xu, Sung and Huang2020), anisotropy (Busse & Jelly Reference Busse and Jelly2020) and skewness (Flack, Schultz & Barros Reference Flack, Schultz and Barros2020). By plotting the velocity defect in figure 2(c,d), we observe that the profiles for groups A and B are self-similar in the outer layer. In addition, a good collapse is also observed in the inner layer for group B except at ![]() $Re_\tau =180$, which differs from the results for group A. This phenomenon indicates that

$Re_\tau =180$, which differs from the results for group A. This phenomenon indicates that ![]() $k/\delta$ plays a more important role in determining the velocity defect; that is, the same physical model of roughness elements will show the velocity defect profile collapse as the Reynolds number increases.

$k/\delta$ plays a more important role in determining the velocity defect; that is, the same physical model of roughness elements will show the velocity defect profile collapse as the Reynolds number increases.

Figure 2. Profiles of (a,b) the mean streamwise velocity plotted against the viscous wall-normal height ![]() $\bar {y}^+$ and (c,d) the velocity defects plotted against the wall-normal height normalized by the half-channel height

$\bar {y}^+$ and (c,d) the velocity defects plotted against the wall-normal height normalized by the half-channel height ![]() $\bar {y}/ \delta$ for groups A and B, respectively. In the abscissa axis,

$\bar {y}/ \delta$ for groups A and B, respectively. In the abscissa axis, ![]() $\bar {y}$ represents the mean vertical distance from the wall in the boundary-fitted curvilinear coordinate system. Dash-dotted lines show

$\bar {y}$ represents the mean vertical distance from the wall in the boundary-fitted curvilinear coordinate system. Dash-dotted lines show ![]() $U^+=y^+$ and

$U^+=y^+$ and ![]() $U^+=1/\kappa \ln (y^+)+C$,

$U^+=1/\kappa \ln (y^+)+C$, ![]() $\kappa =0.40$ and

$\kappa =0.40$ and ![]() $C=5.3$. Green and red solid lines represent the smooth- and rough-wall results, respectively. Line colours gradually change with the Reynolds number. The vertical solid black lines show the maximum roughness height for each group of cases.

$C=5.3$. Green and red solid lines represent the smooth- and rough-wall results, respectively. Line colours gradually change with the Reynolds number. The vertical solid black lines show the maximum roughness height for each group of cases.

3.2. Profiles of dispersive and Reynolds stresses

In a rough-wall turbulent flow, we must consider the effect of rough spatial geometry on turbulence statistics. To this end, a triple decomposition method can be applied to decompose the instantaneous velocity into three components (Reynolds & Hussain Reference Reynolds and Hussain1972)

where ![]() $\bar {u}_{i}$ denotes the time and

$\bar {u}_{i}$ denotes the time and ![]() $\xi _{2}$-plane average,

$\xi _{2}$-plane average, ![]() $\langle u_{i}\rangle$ denotes the phase-averaged component and

$\langle u_{i}\rangle$ denotes the phase-averaged component and ![]() $\tilde {u}_{i}$ and

$\tilde {u}_{i}$ and ![]() $u_{i}^{\prime }$ denote the wave-induced and turbulent fluctuations, respectively. Accordingly, the second-order velocity correlation can be decomposed into the mean, dispersive and Reynolds stresses as follows:

$u_{i}^{\prime }$ denote the wave-induced and turbulent fluctuations, respectively. Accordingly, the second-order velocity correlation can be decomposed into the mean, dispersive and Reynolds stresses as follows:

Figure 3 shows the profiles of the Reynolds stresses against the wall-normal height normalized by the half-channel height ![]() $\bar {y}/ \delta$ for group A. As shown in figure 3(a), the roughness elements elevate the inner peak location where the near-wall cycle occupies, compared with the smooth-wall results. The inner peak intensity of the streamwise Reynolds stress decreases, indicating that the typical coherent structures near the wall are disrupted by roughness and that the turbulent fluctuations are weakened. Even so, the Reynolds number effect still exists and the inner peak intensity increases with increasing Reynolds number. Different from the streamwise component, the spanwise Reynolds stress is larger than the smooth-wall results, especially in the near-wall region, whereas the vertical Reynolds stress and Reynolds shear stress are marginally affected by roughness. The peak locations of these three components are basically unchanged as compared with those of the smooth-wall case. A good collapse in the outer region of the flow is not obtained for the streamwise Reynolds stress profiles, especially for

$\bar {y}/ \delta$ for group A. As shown in figure 3(a), the roughness elements elevate the inner peak location where the near-wall cycle occupies, compared with the smooth-wall results. The inner peak intensity of the streamwise Reynolds stress decreases, indicating that the typical coherent structures near the wall are disrupted by roughness and that the turbulent fluctuations are weakened. Even so, the Reynolds number effect still exists and the inner peak intensity increases with increasing Reynolds number. Different from the streamwise component, the spanwise Reynolds stress is larger than the smooth-wall results, especially in the near-wall region, whereas the vertical Reynolds stress and Reynolds shear stress are marginally affected by roughness. The peak locations of these three components are basically unchanged as compared with those of the smooth-wall case. A good collapse in the outer region of the flow is not obtained for the streamwise Reynolds stress profiles, especially for ![]() $Re_\tau =1080$. In this region, the profiles demonstrate a shoulder lifting phenomenon. The streamwise Reynolds stress increases with the presence of roughness and the outer-layer similarity fails. In the current context, the term ‘outer region’ is used to denote where the rough-wall turbulence statistics collapse well to the smooth-wall cases, such as the Reynolds stresses and the energy spectra. However, for the vertical and spanwise Reynolds stresses and Reynolds shear stress, remarkable collapses are still observed in the outer region (

$Re_\tau =1080$. In this region, the profiles demonstrate a shoulder lifting phenomenon. The streamwise Reynolds stress increases with the presence of roughness and the outer-layer similarity fails. In the current context, the term ‘outer region’ is used to denote where the rough-wall turbulence statistics collapse well to the smooth-wall cases, such as the Reynolds stresses and the energy spectra. However, for the vertical and spanwise Reynolds stresses and Reynolds shear stress, remarkable collapses are still observed in the outer region (![]() $\bar {y}/ \delta >0.4$) at all the Reynolds numbers considered here.

$\bar {y}/ \delta >0.4$) at all the Reynolds numbers considered here.

Figure 3. Profiles of the Reynolds stresses: (a) streamwise component, (b) vertical component, (c) spanwise component and (d) shear stress plotted against the wall-normal height normalized by the half-channel height ![]() $\bar {y}/ \delta$ for group A. The definitions of the line colours and line types are the same as those in figure 2.

$\bar {y}/ \delta$ for group A. The definitions of the line colours and line types are the same as those in figure 2.

Similarly, figure 4 shows the profiles of the Reynolds stresses against ![]() $\bar {y}/ \delta$ for group B. As seen in figure 4(a), the inner peak intensity of the streamwise Reynolds stress decreases with increasing

$\bar {y}/ \delta$ for group B. As seen in figure 4(a), the inner peak intensity of the streamwise Reynolds stress decreases with increasing ![]() $k^+$, which indicates that a larger roughness viscous scale causes more significant suppression of the inner-layer turbulence and results in weakened turbulent fluctuations. The peak locations are invariant with the Reynolds number except at

$k^+$, which indicates that a larger roughness viscous scale causes more significant suppression of the inner-layer turbulence and results in weakened turbulent fluctuations. The peak locations are invariant with the Reynolds number except at ![]() $Re_\tau =180$, unlike those of group A. In the outer region, the profiles collapse with the smooth-wall case at higher vertical positions (

$Re_\tau =180$, unlike those of group A. In the outer region, the profiles collapse with the smooth-wall case at higher vertical positions (![]() $\bar {y}/ \delta >0.7$), supporting the Townsend's outer-layer similarity hypothesis. For the vertical and spanwise Reynolds stresses, the peaks exhibit an extrapolation tendency with increasing Reynolds numbers and an obvious bimodal phenomenon is observed at higher Reynolds numbers. The difference is that the first peak of spanwise Reynolds stress appears below the roughness height and the value tends to the second peak value; by contrast, the two peak locations of vertical Reynolds stress are above the roughness crest and the first peak value is obviously larger than the second one at

$\bar {y}/ \delta >0.7$), supporting the Townsend's outer-layer similarity hypothesis. For the vertical and spanwise Reynolds stresses, the peaks exhibit an extrapolation tendency with increasing Reynolds numbers and an obvious bimodal phenomenon is observed at higher Reynolds numbers. The difference is that the first peak of spanwise Reynolds stress appears below the roughness height and the value tends to the second peak value; by contrast, the two peak locations of vertical Reynolds stress are above the roughness crest and the first peak value is obviously larger than the second one at ![]() $Re_\tau =1080$. For the Reynolds shear stress, the peak location is pushed to higher vertical positions; however, the intensity increases slightly with increasing Reynolds number. Some negative regions occur at

$Re_\tau =1080$. For the Reynolds shear stress, the peak location is pushed to higher vertical positions; however, the intensity increases slightly with increasing Reynolds number. Some negative regions occur at ![]() $\bar {y}^{+}<10$, and this phenomenon becomes more obvious with increasing

$\bar {y}^{+}<10$, and this phenomenon becomes more obvious with increasing ![]() $k^+$. This result is mainly related to the backflow within the roughness elements. In the outer region, the vertical and spanwise Reynolds stresses and the Reynolds shear stress profiles of both the smooth-wall and rough-wall cases are self-similar. The initial locations for the profile collapse are slightly different.

$k^+$. This result is mainly related to the backflow within the roughness elements. In the outer region, the vertical and spanwise Reynolds stresses and the Reynolds shear stress profiles of both the smooth-wall and rough-wall cases are self-similar. The initial locations for the profile collapse are slightly different.

Figure 4. Profiles of the Reynolds stresses: (a) streamwise component, (b) vertical component, (c) spanwise component and (d) shear stress plotted against the wall-normal height normalized by the half-channel height ![]() $\bar {y}/ \delta$ for group B. The definitions of the line colours and line types are the same as those in figure 2.

$\bar {y}/ \delta$ for group B. The definitions of the line colours and line types are the same as those in figure 2.

The dispersive stresses profiles for groups A and B are plotted in figure 5. For the smooth-wall cases, the dispersive stresses are zero. For the rough-wall cases, the intensity of the streamwise dispersive stress is clearly substantial, even greater than the intensity of its turbulent counterpart. By contrast, the intensities of the dispersive stresses of other components are obviously weaker than those of the corresponding Reynolds stresses. For group A, the profiles are independent of the Reynolds number, except the locations that are closely related to ![]() $k/\delta$. This indicates that the dispersive stresses are mainly affected by the roughness height

$k/\delta$. This indicates that the dispersive stresses are mainly affected by the roughness height ![]() $k^+$, similar to the mean velocity profiles. Coincidentally, Zhang et al. (Reference Zhang, Huang and Xu2020) found that the roughness-induced velocity fluctuations and pressure fluctuations both show Reynolds number independence if the roughness element has the same

$k^+$, similar to the mean velocity profiles. Coincidentally, Zhang et al. (Reference Zhang, Huang and Xu2020) found that the roughness-induced velocity fluctuations and pressure fluctuations both show Reynolds number independence if the roughness element has the same ![]() $k^+$. In addition, the dispersive stresses are dominant within the roughness sublayer but decrease rapidly to zero above the crest of roughness element. The vertical and spanwise dispersive stresses achieve their peak values below the roughness crest, and the peak location of streamwise stress is slightly higher (

$k^+$. In addition, the dispersive stresses are dominant within the roughness sublayer but decrease rapidly to zero above the crest of roughness element. The vertical and spanwise dispersive stresses achieve their peak values below the roughness crest, and the peak location of streamwise stress is slightly higher (![]() $\bar {y}/ \delta \approx k/\delta$). The dispersive shear stress is negative in the inner-layer region and exhibits two weak peaks. For group B, the dispersive stresses profiles show an inward shift as the Reynolds number increases, although

$\bar {y}/ \delta \approx k/\delta$). The dispersive shear stress is negative in the inner-layer region and exhibits two weak peaks. For group B, the dispersive stresses profiles show an inward shift as the Reynolds number increases, although ![]() $k/ \delta$ remains the same. Above the roughness crest, the profiles decrease drastically to zero. The maximum values of the streamwise dispersive stress and shear stress do not show a monotonic variation, whereas the maximum values of the vertical and spanwise components increase substantially with increasing

$k/ \delta$ remains the same. Above the roughness crest, the profiles decrease drastically to zero. The maximum values of the streamwise dispersive stress and shear stress do not show a monotonic variation, whereas the maximum values of the vertical and spanwise components increase substantially with increasing ![]() $k^+$.

$k^+$.

Figure 5. Profiles of the dispersive stresses: (a) streamwise component, (b) vertical component, (c) spanwise component and (d) shear stress plotted against the wall-normal height normalized by the half-channel height ![]() $\bar {y}/ \delta$ for group A (blue) and group B (red), respectively. Line colours gradually change with the Reynolds number.

$\bar {y}/ \delta$ for group A (blue) and group B (red), respectively. Line colours gradually change with the Reynolds number.

To further compare the effect of ![]() $k^+$ on the turbulence statistics in the inner and outer regions at the same Reynolds number, we added some rough cases in figure 6 with rearrangement. The variation of the streamwise Reynolds stress in the outer region by increasing

$k^+$ on the turbulence statistics in the inner and outer regions at the same Reynolds number, we added some rough cases in figure 6 with rearrangement. The variation of the streamwise Reynolds stress in the outer region by increasing ![]() $k^+$ is non-monotonic at

$k^+$ is non-monotonic at ![]() $Re_\tau =720$; first increasing and then decreasing. Turbulent fluctuations are enhanced in the outer region for the cases of

$Re_\tau =720$; first increasing and then decreasing. Turbulent fluctuations are enhanced in the outer region for the cases of ![]() $k^+= 10$ and 13.33, whereas a good collapse between the smooth- and rough-wall profiles is observed for the cases of

$k^+= 10$ and 13.33, whereas a good collapse between the smooth- and rough-wall profiles is observed for the cases of ![]() $k^+= 6.67$ and 40. Unlike

$k^+= 6.67$ and 40. Unlike ![]() $Re_\tau =720$, the streamwise Reynolds stress in the outer region monotonically decreases with increasing

$Re_\tau =720$, the streamwise Reynolds stress in the outer region monotonically decreases with increasing ![]() $k^+$ at

$k^+$ at ![]() $Re_\tau =1080$. The effect of roughness on the outer-layer similarity may be induced by different mechanisms for small and large

$Re_\tau =1080$. The effect of roughness on the outer-layer similarity may be induced by different mechanisms for small and large ![]() $k^+$, if

$k^+$, if ![]() $k/ \delta$ is small but

$k/ \delta$ is small but ![]() $Re_\tau$ is high.

$Re_\tau$ is high.

Figure 6. Profiles of the streamwise Reynolds stresses plotted against the wall-normal height normalized by the half-channel height ![]() $\bar {y}/ \delta$ at different Reynolds numbers: (a)

$\bar {y}/ \delta$ at different Reynolds numbers: (a) ![]() $Re_\tau =720$ and (b)

$Re_\tau =720$ and (b) ![]() $Re_\tau =1080$. Black solid line shows the smooth-wall results. Line colours gradually change with the roughness height.

$Re_\tau =1080$. Black solid line shows the smooth-wall results. Line colours gradually change with the roughness height.

In addition, a quantitative evaluation of the collapse degree of the velocity defect and streamwise Reynolds stress profiles can be made by introducing the deviation factor as in Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016). The deviation factor is obtained by calculating the maximum relative deviations in the height range ![]() $\bar {y}/\delta =0.5 \sim 1.0$. For the streamwise velocity defect profiles (figure 2c,d), the deviation factor is 0.11

$\bar {y}/\delta =0.5 \sim 1.0$. For the streamwise velocity defect profiles (figure 2c,d), the deviation factor is 0.11 ![]() $\%$ for

$\%$ for ![]() $k^+=10$ and 0.35

$k^+=10$ and 0.35 ![]() $\%$ for

$\%$ for ![]() $k^+=60$ at

$k^+=60$ at ![]() $Re_\tau =1080$, indicating that the hypothesis of outer-layer similarity holds for both the small- and large-scale roughness elements with respect to the first-order statistics. For the streamwise Reynolds stress profiles (figure 6), the deviation factor is 2.7

$Re_\tau =1080$, indicating that the hypothesis of outer-layer similarity holds for both the small- and large-scale roughness elements with respect to the first-order statistics. For the streamwise Reynolds stress profiles (figure 6), the deviation factor is 2.7 ![]() $\%$ for

$\%$ for ![]() $k^+=6.67$ and 3.2

$k^+=6.67$ and 3.2 ![]() $\%$ for

$\%$ for ![]() $k^+=40$ at

$k^+=40$ at ![]() $Re_\tau =720$, and 8.21

$Re_\tau =720$, and 8.21 ![]() $\%$ for

$\%$ for ![]() $k^+=10$ and 4.43

$k^+=10$ and 4.43 ![]() $\%$ for

$\%$ for ![]() $k^+=60$ at

$k^+=60$ at ![]() $Re_\tau =1080$. A value of 5

$Re_\tau =1080$. A value of 5 ![]() $\%$ as suggested by Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016) is a reasonable criterion, such that the outer-layer similarity is applied for both the small- and large-scale roughness elements at

$\%$ as suggested by Squire et al. (Reference Squire, Morrill-Winter, Hutchins, Schultz, Klewicki and Marusic2016) is a reasonable criterion, such that the outer-layer similarity is applied for both the small- and large-scale roughness elements at ![]() $Re_\tau =720$ and for

$Re_\tau =720$ and for ![]() $k^+=60$ at

$k^+=60$ at ![]() $Re_\tau =1080$, but not for

$Re_\tau =1080$, but not for ![]() $k^+=10$ at

$k^+=10$ at ![]() $Re_\tau =1080$.

$Re_\tau =1080$.

The previous analysis indicates that the outer-layer similarity is closely related to the roughness parameters, especially when obvious scale separation occurs at high Reynolds numbers. Although ![]() $k^+=10$ corresponds to a smaller

$k^+=10$ corresponds to a smaller ![]() $k/ \delta$, the outer-layer similarity of streamwise Reynolds stress is lost, which is inconsistent with the conclusion of Jiménez (Reference Jiménez2004). As reviewed by Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021), a single scale

$k/ \delta$, the outer-layer similarity of streamwise Reynolds stress is lost, which is inconsistent with the conclusion of Jiménez (Reference Jiménez2004). As reviewed by Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021), a single scale ![]() $k/ \delta$ is insufficient to fully describe the influence of roughness topography on turbulent flows. Several previous studies on rough-wall turbulence have shown that the outer-layer similarity failure might be caused by the enhancement of scale interaction between the inner and outer regions (Hong et al. Reference Hong, Katz and Schultz2011; Yuan & Piomelli Reference Yuan and Piomelli2014b). For instance, Hong et al. (Reference Hong, Katz and Schultz2011) observed that the roughness-scale eddies are generated near the surface and are then advected rapidly away from the wall by large-scale structures that populate the outer layer in the experiments involving rough boundary layers. Consequently, the outer-region turbulent motions are enhanced. However, this explanation is presently speculative; we will further analyse the specific reason by examining the energy transfer process between different spatial locations and different scales in the following sections.

$k/ \delta$ is insufficient to fully describe the influence of roughness topography on turbulent flows. Several previous studies on rough-wall turbulence have shown that the outer-layer similarity failure might be caused by the enhancement of scale interaction between the inner and outer regions (Hong et al. Reference Hong, Katz and Schultz2011; Yuan & Piomelli Reference Yuan and Piomelli2014b). For instance, Hong et al. (Reference Hong, Katz and Schultz2011) observed that the roughness-scale eddies are generated near the surface and are then advected rapidly away from the wall by large-scale structures that populate the outer layer in the experiments involving rough boundary layers. Consequently, the outer-region turbulent motions are enhanced. However, this explanation is presently speculative; we will further analyse the specific reason by examining the energy transfer process between different spatial locations and different scales in the following sections.

3.3. Large-scale flow structures

This section mainly describes the effects of roughness on the large-scale structures of the outer region. We begin by examining the energy distribution at different length scales and vertical locations. One-dimensional pre-multiplied streamwise and spanwise energy spectra of streamwise velocity turbulent fluctuation are plotted in figure 7 for two rough-wall cases (![]() $k^+=10$ and 60), together with the smooth-wall case at

$k^+=10$ and 60), together with the smooth-wall case at ![]() $Re_\tau =1080$. For the smooth-wall case, two peaks are observed in the spanwise energy spectra of the streamwise velocity fluctuation that correspond to the inner/outer scale separation in high Reynolds number wall turbulence. The inner peak is located at the scale around

$Re_\tau =1080$. For the smooth-wall case, two peaks are observed in the spanwise energy spectra of the streamwise velocity fluctuation that correspond to the inner/outer scale separation in high Reynolds number wall turbulence. The inner peak is located at the scale around ![]() $\lambda _z^{+}\approx 130$, which corresponds to the spacing of near-wall low-speed streaks. The outer peak is located at the scale around

$\lambda _z^{+}\approx 130$, which corresponds to the spacing of near-wall low-speed streaks. The outer peak is located at the scale around ![]() $\lambda _z^{+}\approx 1120$, which represents the turbulent large-scale motions in the outer region. For the rough-wall results, the main wavenumber and its harmonics caused by roughness periodicity still exist in the streamwise energy spectra but obviously no longer exist in the spanwise energy spectra. The effect of roughness on the energy spectra is mainly concentrated below the height of the roughness elements as compared with the smooth-wall case, which becomes more obvious with increasing roughness height

$\lambda _z^{+}\approx 1120$, which represents the turbulent large-scale motions in the outer region. For the rough-wall results, the main wavenumber and its harmonics caused by roughness periodicity still exist in the streamwise energy spectra but obviously no longer exist in the spanwise energy spectra. The effect of roughness on the energy spectra is mainly concentrated below the height of the roughness elements as compared with the smooth-wall case, which becomes more obvious with increasing roughness height ![]() $k^+$. For the inner peak, the roughness elements elevate the peak locations of the streamwise and spanwise energy spectra, which approximately satisfy

$k^+$. For the inner peak, the roughness elements elevate the peak locations of the streamwise and spanwise energy spectra, which approximately satisfy ![]() $y_{p,r}^{+} \approx y_{p,s}^{+}+k^+$, where

$y_{p,r}^{+} \approx y_{p,s}^{+}+k^+$, where ![]() $y_{p,r}^{+}$ and

$y_{p,r}^{+}$ and ![]() $y_{p,s}^{+}$ represent the vertical heights of the inner peaks in the rough-wall and smooth-wall cases, respectively. As the roughness height

$y_{p,s}^{+}$ represent the vertical heights of the inner peaks in the rough-wall and smooth-wall cases, respectively. As the roughness height ![]() $k^+$ increases, the corresponding peak values are weakened more substantially, consistent with the changes shown in the stress profiles. For the outer peak, the roughness

$k^+$ increases, the corresponding peak values are weakened more substantially, consistent with the changes shown in the stress profiles. For the outer peak, the roughness ![]() $k^+=10$,

$k^+=10$, ![]() $\lambda ^+=71$ enhances the large-scale structures and the spanwise length scale of the peak increases (

$\lambda ^+=71$ enhances the large-scale structures and the spanwise length scale of the peak increases (![]() $\lambda _z^+ \approx 1695$); by contrast, the roughness

$\lambda _z^+ \approx 1695$); by contrast, the roughness ![]() $k^+=60$,

$k^+=60$, ![]() $\lambda ^+=424$ reduces the outer peak in energy and the length scale (

$\lambda ^+=424$ reduces the outer peak in energy and the length scale (![]() $\lambda _z^+ \approx 850$) is smaller than the smooth-wall result (

$\lambda _z^+ \approx 850$) is smaller than the smooth-wall result (![]() $\lambda _z^+ \approx 1120$). Roughness of different viscous scales might have different effects on the turbulent energy transport between the roughness sublayer and the outer layer. In the spanwise energy spectra, the contours of rough-wall cases become coincident with the smooth-wall result in the outer region. This observation indicates that a much higher vertical height is required for the energy spectra to satisfy the self-similarity in the outer region, as compared with the mean velocity and second-order statistics.

$\lambda _z^+ \approx 1120$). Roughness of different viscous scales might have different effects on the turbulent energy transport between the roughness sublayer and the outer layer. In the spanwise energy spectra, the contours of rough-wall cases become coincident with the smooth-wall result in the outer region. This observation indicates that a much higher vertical height is required for the energy spectra to satisfy the self-similarity in the outer region, as compared with the mean velocity and second-order statistics.

Figure 7. Contours of the one-dimensional pre-multiplied streamwise (left) and spanwise (right) energy spectra of streamwise velocity turbulent fluctuation: (a) ![]() $k^+=10$,

$k^+=10$, ![]() $\lambda ^+=71$; (b)

$\lambda ^+=71$; (b) ![]() $k^+=60$,

$k^+=60$, ![]() $\lambda ^+=424$ at

$\lambda ^+=424$ at ![]() $Re_\tau =1080$. Black solid lines represent the contours of smooth-wall energy spectra. Red solid lines correspond to the wavelength and height of the roughness elements, respectively.

$Re_\tau =1080$. Black solid lines represent the contours of smooth-wall energy spectra. Red solid lines correspond to the wavelength and height of the roughness elements, respectively.

Figure 8 displays the one-dimensional pre-multiplied spanwise energy spectra of vertical velocity and spanwise velocity turbulent fluctuations and shear stress. The selected cases are the same as those in figure 7. For the vertical component, little difference is observed between the rough-wall (![]() $k^+=10$) and smooth-wall cases. By contrast, the energy spectra vary greatly below the roughness height for the case of

$k^+=10$) and smooth-wall cases. By contrast, the energy spectra vary greatly below the roughness height for the case of ![]() $k^+=60$ and energy tends to be distributed at larger scales. For the spanwise component, when the roughness height is

$k^+=60$ and energy tends to be distributed at larger scales. For the spanwise component, when the roughness height is ![]() $k^+=10$, part of the extra energy region is observed in the energy spectra as compared with the smooth-wall results. When

$k^+=10$, part of the extra energy region is observed in the energy spectra as compared with the smooth-wall results. When ![]() $k^+$ increases to 60, two peaks are observed in the spanwise energy spectra; these peaks approximately correspond to the wall-normal heights of 10 and 100, respectively. The bimodal characteristics of the spanwise stress profile (figure 4c) are consistent with this phenomenon. However, for both roughness heights, the rough-wall contours of

$k^+$ increases to 60, two peaks are observed in the spanwise energy spectra; these peaks approximately correspond to the wall-normal heights of 10 and 100, respectively. The bimodal characteristics of the spanwise stress profile (figure 4c) are consistent with this phenomenon. However, for both roughness heights, the rough-wall contours of ![]() $k_z E_{v^{\prime }v^{\prime }}^{+}$ and

$k_z E_{v^{\prime }v^{\prime }}^{+}$ and ![]() $k_z E_{w^{\prime }w^{\prime }}^{+}$ both collapse to the smooth-wall cases in the outer region. Finally, in the spanwise energy spectra of shear stress, the overall variation trend is similar to the streamwise component. The peak energy in the outer region is increased, and the corresponding spanwise length scale is also increased for the small roughness height (

$k_z E_{w^{\prime }w^{\prime }}^{+}$ both collapse to the smooth-wall cases in the outer region. Finally, in the spanwise energy spectra of shear stress, the overall variation trend is similar to the streamwise component. The peak energy in the outer region is increased, and the corresponding spanwise length scale is also increased for the small roughness height (![]() $k^+=10$). On the contrary, the large-scale peak decreases when the roughness height increases.

$k^+=10$). On the contrary, the large-scale peak decreases when the roughness height increases.

Figure 8. Contours of the one-dimensional pre-multiplied spanwise energy spectra of vertical velocity fluctuation (left), spanwise velocity fluctuation (middle) and shear stress (right): (a) ![]() $k^+=10$,

$k^+=10$, ![]() $\lambda ^+=71$; (b)

$\lambda ^+=71$; (b) ![]() $k^+=60$,

$k^+=60$, ![]() $\lambda ^+=424$ at

$\lambda ^+=424$ at ![]() $Re_\tau =1080$. The definitions of the line colours and line types are the same as those in figure 7.

$Re_\tau =1080$. The definitions of the line colours and line types are the same as those in figure 7.

In addition, the instantaneous flow field in the ![]() $y$–

$y$–![]() $z$ plane at a certain streamwise location is shown in figure 9 to visually describe the large-scale structures. The two rough-wall cases of

$z$ plane at a certain streamwise location is shown in figure 9 to visually describe the large-scale structures. The two rough-wall cases of ![]() $k^+= 10$ and 60 at

$k^+= 10$ and 60 at ![]() $Re_\tau =1080$ are chosen. We intuitively observe that, as compared with the large roughness (

$Re_\tau =1080$ are chosen. We intuitively observe that, as compared with the large roughness (![]() $k^+=60$), the small roughness (

$k^+=60$), the small roughness (![]() $k^+=10$) affects the higher vertical position for both the streamwise turbulent velocity fluctuation and the pressure fluctuation. Although the large roughness induces large pressure drag, the pressure distribution is mainly concentrated near the roughness element and does not affect the outer region. Such difference is caused by the pressure-strain terms and the transport terms of the Reynolds stresses transport equations, which will be discussed in detail in the following section.

$k^+=10$) affects the higher vertical position for both the streamwise turbulent velocity fluctuation and the pressure fluctuation. Although the large roughness induces large pressure drag, the pressure distribution is mainly concentrated near the roughness element and does not affect the outer region. Such difference is caused by the pressure-strain terms and the transport terms of the Reynolds stresses transport equations, which will be discussed in detail in the following section.

Figure 9. Instantaneous streamwise turbulent (a,b) velocity fluctuation ![]() $u^{\prime }$ and (c,d) pressure fluctuation

$u^{\prime }$ and (c,d) pressure fluctuation ![]() $p^{\prime }$ in the

$p^{\prime }$ in the ![]() $y$–

$y$–![]() $z$ plane for (a,c)

$z$ plane for (a,c) ![]() $k^+=10$,

$k^+=10$, ![]() $\lambda ^+=71$ (left) and (b,d)

$\lambda ^+=71$ (left) and (b,d) ![]() $k^+=60$,

$k^+=60$, ![]() $\lambda ^+=424$ (right) at

$\lambda ^+=424$ (right) at ![]() $Re_\tau =1080$. The streamwise location is at

$Re_\tau =1080$. The streamwise location is at ![]() $x/ \delta ={\rm \pi}$.

$x/ \delta ={\rm \pi}$.

Figure 10 displays the instantaneous flow field in the ![]() $x$–

$x$–![]() $z$ plane. Corresponding to the analysis of energy spectra, two vertical locations

$z$ plane. Corresponding to the analysis of energy spectra, two vertical locations ![]() $\bar {y}/\delta =0.03$ in the inner region and

$\bar {y}/\delta =0.03$ in the inner region and ![]() $\bar {y}/\delta =0.3$ in the outer region are chosen. The streaky structures in the near-wall region are substantially disrupted because of the presence of roughness elements, especially for the large roughness height (figure 10b). The intensity of the velocity streaks is obviously diminished, consistent with the decrease of the inner peak of the energy spectra (figure 7). The modulation effects of roughness wavelengths can be discerned clearly for

$\bar {y}/\delta =0.3$ in the outer region are chosen. The streaky structures in the near-wall region are substantially disrupted because of the presence of roughness elements, especially for the large roughness height (figure 10b). The intensity of the velocity streaks is obviously diminished, consistent with the decrease of the inner peak of the energy spectra (figure 7). The modulation effects of roughness wavelengths can be discerned clearly for ![]() $k^+=10$, as also reflected in the roughness scale of the streamwise energy spectra. The large-scale streamwise elongated low- and high-speed streaks are observed in the outer region, and the large-scale structures at small roughness height are more coherent than the case of

$k^+=10$, as also reflected in the roughness scale of the streamwise energy spectra. The large-scale streamwise elongated low- and high-speed streaks are observed in the outer region, and the large-scale structures at small roughness height are more coherent than the case of ![]() $k^+=60$. Two pairs of low- and high-speed streaks are clearly identified for

$k^+=60$. Two pairs of low- and high-speed streaks are clearly identified for ![]() $k^+=10$, and the spanwise spacing is approximately

$k^+=10$, and the spanwise spacing is approximately ![]() $\lambda _z=L_z/2={\rm \pi} /2$, corresponding to the outer peak of the spanwise energy spectra locating at the scale of

$\lambda _z=L_z/2={\rm \pi} /2$, corresponding to the outer peak of the spanwise energy spectra locating at the scale of ![]() $\lambda _z^{+} \approx 1695$. The turbulent coherent structures of the instantaneous flow field are consistent with the spanwise energy spectra.

$\lambda _z^{+} \approx 1695$. The turbulent coherent structures of the instantaneous flow field are consistent with the spanwise energy spectra.

Figure 10. Instantaneous streamwise turbulent velocity fluctuation ![]() $u^{\prime }$ in the

$u^{\prime }$ in the ![]() $x$–

$x$–![]() $z$ plane for (a,c)

$z$ plane for (a,c) ![]() $k^+=10$,

$k^+=10$, ![]() $\lambda ^+=71$ (left) and (b,d)

$\lambda ^+=71$ (left) and (b,d) ![]() $k^+=60$,

$k^+=60$, ![]() $\lambda ^+=424$ (right) at

$\lambda ^+=424$ (right) at ![]() $Re_\tau =1080$. The vertical location is at (a,b)

$Re_\tau =1080$. The vertical location is at (a,b) ![]() $\bar {y}/ \delta =0.03$ and (c,d)

$\bar {y}/ \delta =0.03$ and (c,d) ![]() $\bar {y}/ \delta =0.3$.

$\bar {y}/ \delta =0.3$.

3.4. Spectral analysis on the transport equation of two-point velocity correlation

To reveal the mechanism by which the roughness affects the outer-layer similarity, we resort to the transport equation of two-point velocity correlation in the curvilinear coordinates and analyse the energy transfer process in the presence of roughness. Derivation of the transport equation and its spectral expression can be found in Wang et al. (Reference Wang, Zhang, Hao, Huang, Shen, Xu and Zhang2020). We here replace the classic Reynolds decomposition with the triple decomposition according to (3.2). The transport equation can be expressed as

where the subscript ![]() $r$ represents the quantity at the location with a certain distance in the spanwise direction from the reference point. The terms on the right-hand side correspond to the production, pressure-strain, turbulent transport, pressure transport, viscous transport, dissipation, wave-induced production terms and additional terms related to the effects of boundary deformation on the mean flow, sequentially. The specific expression for each term is provided in Appendix A.

$r$ represents the quantity at the location with a certain distance in the spanwise direction from the reference point. The terms on the right-hand side correspond to the production, pressure-strain, turbulent transport, pressure transport, viscous transport, dissipation, wave-induced production terms and additional terms related to the effects of boundary deformation on the mean flow, sequentially. The specific expression for each term is provided in Appendix A.

Figure 11 shows the premultiplied one-dimensional spanwise spectra of the production and pressure-strain terms. For the smooth-wall case (figure 11a), the spectrum of the production term of ![]() $\overline {u^{\prime }u^{\prime }}$ has two peaks, with the inner peak located at the scale

$\overline {u^{\prime }u^{\prime }}$ has two peaks, with the inner peak located at the scale ![]() $\lambda _z^{+}\approx 100$ and the indistinct outer peak located at

$\lambda _z^{+}\approx 100$ and the indistinct outer peak located at ![]() $\lambda _z^{+}\approx 1000$. The intensity and scale of the outer peaks increase for the rough-wall case of

$\lambda _z^{+}\approx 1000$. The intensity and scale of the outer peaks increase for the rough-wall case of ![]() $k^+=10$ as compared with the intensity and scale of the outer peaks for smooth-wall turbulence. However, the outer peaks are weakened and their length scale is reduced for the rough-wall case of

$k^+=10$ as compared with the intensity and scale of the outer peaks for smooth-wall turbulence. However, the outer peaks are weakened and their length scale is reduced for the rough-wall case of ![]() $k^+=60$. In the spectra of the production term of

$k^+=60$. In the spectra of the production term of ![]() $\overline {u^{\prime }v^{\prime }}$ (figure 11d), the outer peak almost disappears for both the rough-wall and smooth-wall cases. The production term

$\overline {u^{\prime }v^{\prime }}$ (figure 11d), the outer peak almost disappears for both the rough-wall and smooth-wall cases. The production term ![]() $P_{11}$ provides the increased large-scale streamwise Reynolds stress (figure 3a) in the outer region, which is obtained from the mean shear flow. In addition, there is no production term in the transport equations of the vertical and spanwise components, which gain energy from the streamwise component via the pressure-strain term. For the smooth-wall case (figure 11b), the pressure-strain term

$P_{11}$ provides the increased large-scale streamwise Reynolds stress (figure 3a) in the outer region, which is obtained from the mean shear flow. In addition, there is no production term in the transport equations of the vertical and spanwise components, which gain energy from the streamwise component via the pressure-strain term. For the smooth-wall case (figure 11b), the pressure-strain term ![]() $\varPi _{s,22}$ transfers the energy from

$\varPi _{s,22}$ transfers the energy from ![]() $\overline {v^{\prime }v^{\prime }}$ to the other two components within the region

$\overline {v^{\prime }v^{\prime }}$ to the other two components within the region ![]() $\bar {y}^+<10$; in the region

$\bar {y}^+<10$; in the region ![]() $\bar {y}^+ \geq$10, the energy is reversely transferred to

$\bar {y}^+ \geq$10, the energy is reversely transferred to ![]() $\overline {v^{\prime }v^{\prime }}$. The large roughness of

$\overline {v^{\prime }v^{\prime }}$. The large roughness of ![]() $k^+=60$ enhances the energy transfer from

$k^+=60$ enhances the energy transfer from ![]() $\overline {v^{\prime }v^{\prime }}$ below the roughness height, leading to the increase of spanwise velocity fluctuations. This behaviour also explains the bimodal phenomenon of the spanwise energy spectra (figure 8b). In the spectra in figure 11(c), the pressure-strain term

$\overline {v^{\prime }v^{\prime }}$ below the roughness height, leading to the increase of spanwise velocity fluctuations. This behaviour also explains the bimodal phenomenon of the spanwise energy spectra (figure 8b). In the spectra in figure 11(c), the pressure-strain term ![]() $\varPi _{s,33}$ indicates that

$\varPi _{s,33}$ indicates that ![]() $\overline {w^{\prime }w^{\prime }}$ mainly gains energy from other components. An additional positive contribution can be observed below the roughness height for the case of

$\overline {w^{\prime }w^{\prime }}$ mainly gains energy from other components. An additional positive contribution can be observed below the roughness height for the case of ![]() $k^+=10$ as compared with the smooth-wall case. This corresponds to the variation of

$k^+=10$ as compared with the smooth-wall case. This corresponds to the variation of ![]() $\overline {w^{\prime }w^{\prime }}$ in the near-wall region in figure 3(c). In the case of

$\overline {w^{\prime }w^{\prime }}$ in the near-wall region in figure 3(c). In the case of ![]() $k^+=60$, an obvious difference lies in the increase of the negative contribution region in the vicinity of the roughness crest. At this location,

$k^+=60$, an obvious difference lies in the increase of the negative contribution region in the vicinity of the roughness crest. At this location, ![]() $\overline {w^{\prime }w^{\prime }}$ outputs energy to the other components, which corresponds to a weaker peak than that in the smooth-wall case (figure 4c). The results show that the roughness strengthens the energy transfer via the pressure-strain terms among the three velocity components.

$\overline {w^{\prime }w^{\prime }}$ outputs energy to the other components, which corresponds to a weaker peak than that in the smooth-wall case (figure 4c). The results show that the roughness strengthens the energy transfer via the pressure-strain terms among the three velocity components.

Figure 11. Contours of the one-dimensional pre-multiplied spanwise energy spectra of the production and pressure-strain terms: (top) ![]() $k^+=10$,

$k^+=10$, ![]() $\lambda ^+=71$; (middle)

$\lambda ^+=71$; (middle) ![]() $k^+=60$,

$k^+=60$, ![]() $\lambda ^+=424$ and (bottom) the smooth-wall case at

$\lambda ^+=424$ and (bottom) the smooth-wall case at ![]() $Re_\tau =1080$. Different terms, i.e. (a)

$Re_\tau =1080$. Different terms, i.e. (a) ![]() $P_{11}^{+}$, (b)

$P_{11}^{+}$, (b) ![]() $\varPi _{s,22}^{+}$, (c)

$\varPi _{s,22}^{+}$, (c) ![]() $\varPi _{s,33}^{+}$ and (d)

$\varPi _{s,33}^{+}$ and (d) ![]() $-P_{12}^{+}$ are presented. Red solid lines correspond to the wavelength and height of the roughness elements, respectively.

$-P_{12}^{+}$ are presented. Red solid lines correspond to the wavelength and height of the roughness elements, respectively.

In addition, figure 12 shows the pre-multiplied one-dimensional spanwise spectra of the dissipation terms, which make negative contributions to the Reynolds stresses. For the smooth-wall case, the dissipation terms are concentrated on small scales (![]() $\lambda _z^{+}<100$) in the inner region (

$\lambda _z^{+}<100$) in the inner region (![]() $y^{+}\approx 20$). With the increase of wall-normal distance, the dissipation terms decrease. For the case of

$y^{+}\approx 20$). With the increase of wall-normal distance, the dissipation terms decrease. For the case of ![]() $k^+=10$, the presence of roughness generates more small-scale eddies, which strengthens the dissipation. On the contrary, a large roughness

$k^+=10$, the presence of roughness generates more small-scale eddies, which strengthens the dissipation. On the contrary, a large roughness ![]() $k^+=60$ weakens the dissipation significantly. A possible reason for such a difference is that

$k^+=60$ weakens the dissipation significantly. A possible reason for such a difference is that ![]() $k^+=10$ corresponds to the transitionally rough regime and the near-wall self-sustaining cycle of turbulence is enhanced, whereas

$k^+=10$ corresponds to the transitionally rough regime and the near-wall self-sustaining cycle of turbulence is enhanced, whereas ![]() $k^+=60$ is close to the fully rough regime and the near-wall self-sustaining cycle is significantly disrupted (MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016). For the spanwise component (figure 12c), the dissipation is obviously increased both above and below the roughness crest, as compared with the smooth-wall case. On the other hand, for the vertical and shear stress component (figure 12b,d), the dissipation terms are marginally affected by the roughness. Moreover, the peak locations of the dissipation terms are elevated in the presence of large-scale roughness (

$k^+=60$ is close to the fully rough regime and the near-wall self-sustaining cycle is significantly disrupted (MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016). For the spanwise component (figure 12c), the dissipation is obviously increased both above and below the roughness crest, as compared with the smooth-wall case. On the other hand, for the vertical and shear stress component (figure 12b,d), the dissipation terms are marginally affected by the roughness. Moreover, the peak locations of the dissipation terms are elevated in the presence of large-scale roughness (![]() $k^+=60$).

$k^+=60$).

Figure 12. Contours of the one-dimensional pre-multiplied spanwise energy spectra of the dissipation terms: (top) ![]() $k^+=10$,

$k^+=10$, ![]() $\lambda ^+=71$; (middle)

$\lambda ^+=71$; (middle) ![]() $k^+=60$,

$k^+=60$, ![]() $\lambda ^+=424$ and (bottom) the smooth-wall case at

$\lambda ^+=424$ and (bottom) the smooth-wall case at ![]() $Re_\tau =1080$. Different terms, i.e. (a)

$Re_\tau =1080$. Different terms, i.e. (a) ![]() $\epsilon _{11}^{+}$, (b)

$\epsilon _{11}^{+}$, (b) ![]() $\epsilon _{22}^{+}$, (c)

$\epsilon _{22}^{+}$, (c) ![]() $\epsilon _{33}^{+}$ and (d)

$\epsilon _{33}^{+}$ and (d) ![]() $-\epsilon _{12}^{+}$ are presented. Red solid lines correspond to the wavelength and height of the roughness elements, respectively.

$-\epsilon _{12}^{+}$ are presented. Red solid lines correspond to the wavelength and height of the roughness elements, respectively.

Figure 13 shows the premultiplied one-dimensional spanwise spectra of the wave-induced production terms, which represent the energy exchange between the Reynolds stresses and the dispersive stresses. Thus, the variation trend of the spectra of the wave-induced production terms ![]() $WP_{ij}$ with respect to the vertical height is closely related to the profiles of the dispersive stresses in figure 5. For the smooth-wall case,

$WP_{ij}$ with respect to the vertical height is closely related to the profiles of the dispersive stresses in figure 5. For the smooth-wall case, ![]() $WP_{ij}$ values are zero. The results show that the contributions of the wave-induced production terms are mainly confined to within the roughness sublayer and are concentrated at roughness scales such as