Article contents

Quantification of grain boundary connectivity for predicting intergranular corrosion resistance in BFe10-1-1 copper–nickel alloy

Published online by Cambridge University Press: 22 October 2018

Abstract

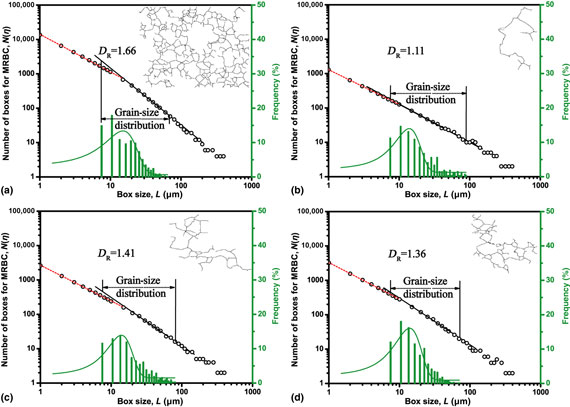

We investigated the connectivity of high-energy random grain boundaries through fractal analyses of specimens with different grain boundary (GB) microstructures in BFe10-1-1 copper–nickel alloy. It was found that the profile of maximum random boundary network possesses a fractal nature and more than one fractal dimension can exist. The fraction of special boundaries and grain size homogeneity can play an important role on GB character distribution. Here, GB microstructures are combined with quantitative materials structure–property relationship models to predict intergranular corrosion properties. The experimental results are accurately consistent with the theoretical predictions.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

- 4

- Cited by