1. Introduction

The existence of an interface between two fluid molecules or a fluid element and a solid substrate generates interfacial tension: a state function that depends on the temperature, fluid electric charge density and fluid composition, for example (Scriven Reference Scriven1960). Therefore, a variation of temperature, concentration, electric charge density, and so on, along an interface creates an interfacial tension gradient, which leads to Marangoni flow. If temperature fluctuations create a gradient in the interfacial tension, the phenomenon is called the thermocapillary effect or thermal Marangoni effect. Likewise, electro-capillarity, the solutal Marangoni effect, and so on, also exist depending on the genesis of the flow. Thermocapillary (TC) flow is noted to influence several practically relevant processes, such as in weld pools (Ramanan & Korpela Reference Ramanan and Korpela1990), in liquid combustion processes (Prokofiev & Smolyakov Reference Prokofiev and Smolyakov2019), during crystal growth (Cuvelier & Driessen Reference Cuvelier and Driessen1986), in droplet coalescence (Rother & Davis Reference Rother and Davis1999) and during bubble migration (Chen & Lee Reference Chen and Lee1992).

The thermal Marangoni effect is important for understanding and manipulating liquid–liquid systems. The constant formation of dimples on unevenly heated silicone-oil films (mean thickness varying from 0.125 to 1.684 mm) was experimentally studied and was reported to be due to the TC effect (Burelbach, Bankoff & Davis Reference Burelbach, Bankoff and Davis1990). Liu and Roux (Reference Liu and Roux1998) explored the TC flow in a molten B2O3-GaAs binary system, and Binghong et al. (Reference Binghong, Qiushen, Liang, Yonglong and Wenrui2002) studied TC flows in a two-layer binary system of paraffin and 2 FC-70 inclusive of air entrainment. During the IML2 mission of Spacelab aboard the US Space Shuttle, Georis et al. (Reference Georis, Hennenberg, Lebon and Legros1999) conducted microgravity experiments to examine the TC effect in a sandwiched liquid film (ternary-liquid) system. Alexeev, Roisman & Stephan (Reference Alexeev, Roisman and Stephan2005) and Fath et al. (Reference Fath, Horn, Roisman, Stephan and Bothe2015) explored the TC effect in a microchannel due to wall topology, both experimentally and numerically. Microscale particle image velocimetry is generally used to visualize the flow pattern within such systems (Amador et al. Reference Amador, Ren, Tabak, Alapan, Yasa and Sitti2019). These microfluidic devices exploiting the TC effect can be used for precision clinical assays at the point of care.

The Marangoni effect has also been studied mathematically owing to the rich physics it offers. Birikh (Reference Birikh1966) reported an exact solution for the TC convection of a planar horizontal liquid layer, for a constant temperature gradient at the boundaries. Sen and Davis (Reference Sen and Davis1982) theoretically explored the steady TC flow of liquid in a two-dimensional rectangular slot with a free top surface using the asymptotic approach. Tan, Bankoff & Davis (Reference Tan, Bankoff and Davis1990) employed the long-wave theory to study a thin liquid film's TC flow over a flat surface, subjected to the two-dimensional periodic (spatially varying) temperature distribution. Pendse & Esmaeeli (Reference Pendse and Esmaeeli2010) semi-analytically solved the Navier–Stokes and energy equations to explain the thermal Marangoni flow in a binary-liquid system. They considered a periodic thermal stimulus at the lower surface, while the upper surface was maintained at a uniform temperature.

The standard methodologies employed to obtain a theoretical solution for the flow dynamics at small scales are lubrication-theory-based models (Saprykin, Trevelyan, Koopmans, & Kalliadasis Reference Saprykin, Trevelyan, Koopmans and Kalliadasis2007; Frumkin & Oron Reference Frumkin and Oron2016; Pham, Cheng, & Kumar Reference Pham, Cheng and Kumar2017) and the asymptotic approach (Strani, Piva, & Graziani Reference Strani, Piva and Graziani1983; Chan, Chen & Mazumder Reference Chan, Chen and Mazumder1988). Numerous types of convections caused by buoyancy or the TC force have been effectively studied using asymptotic theory. Poulikakos & Bejan (Reference Poulikakos and Bejan1983) studied flows in an attic heated from below, while Cormack, Leal & Imberger (Reference Cormack, Leal and Imberger1974) considered buoyancy-driven flows in a rectangular container delimited by differently heated lateral walls.

Several past TC studies are mainly focused on instability analysis (Smith & Davis Reference Smith and Davis1983; Goussis & Kelly Reference Goussis and Kelly1990; Mercier & Normand Reference Mercier and Normand1996; Burguete Reference Burguete2001). Oron and Nepomnyashchy (Reference Oron and Nepomnyashchy2004) investigated the beginning of Marangoni instability in a binary-liquid system with a non-deformable interface under the influence of the Soret effect. Patne, Agnon & Oron (Reference Patne, Agnon and Oron2021) performed a stability analysis in a liquid layer with an imposed oblique temperature gradient. Thermal instability due to Bénard convection is also explored (Eckert, Bestehorn, & Thess Reference Eckert, Bestehorn and Thess1998; Tomita & Abe Reference Tomita and Abe2000; Schatz & Neitzel Reference Schatz and Neitzel2001). However, we assume low capillary number flow in the current study, which leads to a stable TC flow in the liquid layers with nearly flat interfaces.

Most of the theoretical analysis performed on TC assumes no-slip conditions at the walls (Pimputkar & Ostrach Reference Pimputkar and Ostrach1980; Liu & Roux Reference Liu and Roux1998; Pendse & Esmaeeli Reference Pendse and Esmaeeli2010; Agrawal, Das & Dhar Reference Agrawal, Das and Dhar2022). Although a few works are reported on the TC flow in microchannels with wall slip boundary conditions, they are primarily focused on the stability analysis of the system (Tiwari & Davis Reference Tiwari and Davis2014; Kowal, Davis, & Voorhees Reference Kowal, Davis and Voorhees2018; Chattopadhyay, Mukhopadhyay, Barua, & Gaonkar Reference Chattopadhyay, Mukhopadhyay, Barua and Gaonkar2021). Ghosh and Chakraborty (Reference Ghosh and Chakraborty2012) observed that the introduction of patterned wettability at the microchannel walls prompts mixing in an electroosmotic flow. Here, we explore the role of the interplay of the patterned wall wettability and the TC effect by the periodic wall thermal stimuli on the mixing dynamics.

Owing to the importance and controllability of the TC effect, we aim to harness its capabilities for fluidic actuation and solute transport in microscale fluid handling systems. This study theoretically explores the TC effect in a ternary-liquid system due to periodic wall thermal stimuli within a microchannel with patterned wall wettability. Such a system appears in certain modern technologies working with intricate multilayer systems. One such example is a crystal formation technique used in space laboratory missions called the liquid encapsulation crystal growth technique (Ratke, Walter & Feuerbacher Reference Ratke, Walter and Feuerbacher1996). This technique produces high quality crystals by sandwiching the melt between fluid layers. The present work aims to understand the interplay of the periodic thermal stimuli, wall wettability patterns and the fluids’ thermophysical properties in the system's mixing phenomenon. Given the importance of the mixing process and to obtain quick sample processing at small scales, numerous experimental, numerical and theoretical analyses have been performed to understand the TC-driven flow in multilayer systems (Nepomnyashchy & Simanovskii Reference Nepomnyashchy and Simanovskii1999; Shevtsova et al. Reference Shevtsova, Simanovskii, Nepomnyashchy and Legros2005; Simanovskii Reference Simanovskii2007). However, none of the earlier works address the role of surface wettability of the microchannel walls. Also, the past works on the TC effect in multilayer systems are restricted to directional temperature gradients, and do not consider periodic thermal boundary conditions on the confining walls, which justifies the novelty of the present work.

We solve the decoupled energy and Navier–Stokes equation for a ternary-liquid system by employing the perturbation method to obtain the temperature and the streamfunction distribution within the microchannel. The mathematical analyses are performed under the assumption of negligible Marangoni number and flat interfaces. Our study also confirms the credibility of the above assumptions by evaluating the Marangoni and the capillary numbers for the problem using the characteristic parameters. Further, we also obtain an estimated profile of the interfaces, which reveals that the interfacial deformation is negligible relative to the system length scales. Lastly, the transport of solute in the system is numerically explored.

2. Description of the physical system

Our study considers a ternary-liquid system which is sandwiched between the two parallel plates of a microchannel in microgravity conditions. The participating fluids are assumed to be immiscible with each other. A typical example of such a combination of fluids is mentioned in table 1. The bottom and the top walls are exposed to periodic thermal stimuli: ![]() $\overline {{T_l}} (1 + {\delta _l}\cos (\alpha (\bar{x}/\overline {{l_c}} )) + \delta _l^2\cos (2\alpha (\bar{x}/\overline {{l_c}} )))$ and

$\overline {{T_l}} (1 + {\delta _l}\cos (\alpha (\bar{x}/\overline {{l_c}} )) + \delta _l^2\cos (2\alpha (\bar{x}/\overline {{l_c}} )))$ and ![]() $ \overline {{T_u}} (1 + {\delta _u}\cos (\alpha (\bar{x}/\overline {{l_c}} ) + \theta ) + \delta _u^2\cos (2\alpha (\bar{x}/\overline {{l_c}} ) + 2\theta ))$, where

$ \overline {{T_u}} (1 + {\delta _u}\cos (\alpha (\bar{x}/\overline {{l_c}} ) + \theta ) + \delta _u^2\cos (2\alpha (\bar{x}/\overline {{l_c}} ) + 2\theta ))$, where ![]() $\overline {{T_l}} /\overline {{T_u}} $,

$\overline {{T_l}} /\overline {{T_u}} $, ![]() $\overline {{l_c}} $,

$\overline {{l_c}} $, ![]() $\alpha $ and

$\alpha $ and ![]() $\theta $ are the mean temperature, characteristic length scale and oscillation constants, and

$\theta $ are the mean temperature, characteristic length scale and oscillation constants, and ![]() ${\delta _i}({\sim} O(0.1))$ is the perturbation parameter (here,

${\delta _i}({\sim} O(0.1))$ is the perturbation parameter (here, ![]() $i = l\ \textrm{and}\ u$ represent the bottom and the top walls, respectively) (figure 1). Usually, any periodic function can be written as the summation of n harmonic terms using Fourier series, where n is an integer whose value tends to infinity. Inspired by the Fourier expansion, we have considered a temperature function up to the second harmonics. Although a few past works are reported to consider periodic wall temperature up to the first harmonic (Pendse & Esmaeeli Reference Pendse and Esmaeeli2010; Agrawal et al. Reference Agrawal, Das and Dhar2022), in this study we have deemed the second-harmonic function to illustrate how to accommodate for the higher-order terms. Further, the inclusion of the second harmonic in the thermal boundary condition is a mathematical requirement of the problem to incorporate the periodic behaviour of wall slip in the subsequent analysis. The symbols with an overhead bar represent the dimensional quantities and those without a bar are dimensionless quantities (normalized by their corresponding reference values) in the subsequent analysis.

$i = l\ \textrm{and}\ u$ represent the bottom and the top walls, respectively) (figure 1). Usually, any periodic function can be written as the summation of n harmonic terms using Fourier series, where n is an integer whose value tends to infinity. Inspired by the Fourier expansion, we have considered a temperature function up to the second harmonics. Although a few past works are reported to consider periodic wall temperature up to the first harmonic (Pendse & Esmaeeli Reference Pendse and Esmaeeli2010; Agrawal et al. Reference Agrawal, Das and Dhar2022), in this study we have deemed the second-harmonic function to illustrate how to accommodate for the higher-order terms. Further, the inclusion of the second harmonic in the thermal boundary condition is a mathematical requirement of the problem to incorporate the periodic behaviour of wall slip in the subsequent analysis. The symbols with an overhead bar represent the dimensional quantities and those without a bar are dimensionless quantities (normalized by their corresponding reference values) in the subsequent analysis.

Table 1. Details of immiscible ternary-liquid system.

Figure 1. The ternary-liquid layers in a micro-conduit with periodic thermal stimuli applied at the channel walls. Here, coordinate axes ![]() $\bar{x}$ and

$\bar{x}$ and ![]() $\bar{y}$ represent the axial and the lateral directions of the microchannel, respectively, and

$\bar{y}$ represent the axial and the lateral directions of the microchannel, respectively, and ![]() $\bar{a},\bar{b},\bar{c}$ denote the thicknesses of the fluid layers. The expressions for wall temperature and slip velocities are shown in the figure.

$\bar{a},\bar{b},\bar{c}$ denote the thicknesses of the fluid layers. The expressions for wall temperature and slip velocities are shown in the figure.

We consider patterned wettability at the walls, which creates slip boundary conditions as

\begin{equation}{\bar{u}^a}{|_{\bar{y} ={-} (\bar{b}/2 + \bar{a})}} = \bar{\gamma }(\epsilon + {\delta _l}\cos (\alpha x)){\left. {\frac{{\partial {\bar{u}^a}}}{{\partial \bar{y}}}} \right|_{\bar{y} ={-} (\bar{b}/2 + \bar{a})}},\end{equation}

\begin{equation}{\bar{u}^a}{|_{\bar{y} ={-} (\bar{b}/2 + \bar{a})}} = \bar{\gamma }(\epsilon + {\delta _l}\cos (\alpha x)){\left. {\frac{{\partial {\bar{u}^a}}}{{\partial \bar{y}}}} \right|_{\bar{y} ={-} (\bar{b}/2 + \bar{a})}},\end{equation}and

\begin{equation}{\bar{u}^c}{|_{\bar{y} = (\bar{b}/2 + \bar{c})}} ={-} \bar{\gamma }(\epsilon + {\delta _u}\cos (\alpha x + \theta )){\left. {\frac{{\partial {\bar{u}^c}}}{{\partial \bar{y}}}} \right|_{\bar{y} = (\bar{b}/2 + \bar{c})}},\end{equation}

\begin{equation}{\bar{u}^c}{|_{\bar{y} = (\bar{b}/2 + \bar{c})}} ={-} \bar{\gamma }(\epsilon + {\delta _u}\cos (\alpha x + \theta )){\left. {\frac{{\partial {\bar{u}^c}}}{{\partial \bar{y}}}} \right|_{\bar{y} = (\bar{b}/2 + \bar{c})}},\end{equation}

where ![]() ${\bar{u}^a}$ and

${\bar{u}^a}$ and ![]() ${\bar{u}^c}$ are the velocity of the bottom and the top layers, respectively.

${\bar{u}^c}$ are the velocity of the bottom and the top layers, respectively. ![]() $\bar{\gamma }$ and

$\bar{\gamma }$ and ![]() $\epsilon $ are slip parameters such that

$\epsilon $ are slip parameters such that ![]() $\epsilon \ll {\delta _l}\ (\textrm{or}\ {\delta _u})$. Hence,

$\epsilon \ll {\delta _l}\ (\textrm{or}\ {\delta _u})$. Hence, ![]() $\bar{\gamma }{\delta _l}/\overline {{l_c}} $ and

$\bar{\gamma }{\delta _l}/\overline {{l_c}} $ and ![]() $\bar{\gamma }{\delta _u}/\overline {{l_c}} $ represent the normalized slip length

$\bar{\gamma }{\delta _u}/\overline {{l_c}} $ represent the normalized slip length ![]() $({l_s})$ at the bottom and the top walls, respectively. It is to be noted that the wall wettability patterns can be created independently of the wall temperature via chemical etching in practice. In the present analysis, we choose the wall slip to be in phase with the corresponding wall temperature for mathematical ease. Further, we have observed in our earlier work (Agrawal, Das & Dhar Reference Agrawal, Das and Dhar2023) that the influence of a periodic wavenumber and the phase of the wall slip is minimal compared with the slip length, the effect of which is discussed in detail in this paper (see § 4.3).

$({l_s})$ at the bottom and the top walls, respectively. It is to be noted that the wall wettability patterns can be created independently of the wall temperature via chemical etching in practice. In the present analysis, we choose the wall slip to be in phase with the corresponding wall temperature for mathematical ease. Further, we have observed in our earlier work (Agrawal, Das & Dhar Reference Agrawal, Das and Dhar2023) that the influence of a periodic wavenumber and the phase of the wall slip is minimal compared with the slip length, the effect of which is discussed in detail in this paper (see § 4.3).

The mathematical analysis performed in the present work is based on two critical assumptions: (a) the governing non-dimensional numbers i.e. Reynolds number ![]() $(Re = \overline {\rho V{l_c}} /\bar{\mu })$, capillary number

$(Re = \overline {\rho V{l_c}} /\bar{\mu })$, capillary number ![]() $(Ca = \overline {\mu V} /\bar{\sigma })$ and Marangoni number

$(Ca = \overline {\mu V} /\bar{\sigma })$ and Marangoni number ![]() $(Ma ={-} \overline {{\sigma _T}{l_c}\Delta T} /\overline {\mu {D_t}} \sim \overline {V{l_c}} /\overline {{D_t}} )$, as

$(Ma ={-} \overline {{\sigma _T}{l_c}\Delta T} /\overline {\mu {D_t}} \sim \overline {V{l_c}} /\overline {{D_t}} )$, as ![]() $\bar{V}\sim{-} \overline {{\sigma _T}\Delta T} /\bar{\mu }$ for TC flow (Pendse & Esmaeeli Reference Pendse and Esmaeeli2010), are much smaller than 1. Here,

$\bar{V}\sim{-} \overline {{\sigma _T}\Delta T} /\bar{\mu }$ for TC flow (Pendse & Esmaeeli Reference Pendse and Esmaeeli2010), are much smaller than 1. Here, ![]() $\bar{\rho }$,

$\bar{\rho }$, ![]() $\bar{\mu }$,

$\bar{\mu }$, ![]() $\bar{\sigma }$,

$\bar{\sigma }$, ![]() $\overline {{\sigma _T}} $ and

$\overline {{\sigma _T}} $ and ![]() $\overline {{D_t}} $ represent the fluid density, viscosity, surface tension coefficient, temperature coefficient of the surface tension and thermal diffusivity and

$\overline {{D_t}} $ represent the fluid density, viscosity, surface tension coefficient, temperature coefficient of the surface tension and thermal diffusivity and ![]() $\bar{V}$,

$\bar{V}$, ![]() $\overline {{l_c}} $ and

$\overline {{l_c}} $ and ![]() $\overline {\Delta T} $ are the characteristic velocity, length and temperature difference of the system. (b) The fluid–fluid interfaces remain undeformed and flat during the dynamics. The characteristic values of the problem's governing non-dimensional numbers can be determined using the typical values of the parameters. The usual orders of the length scale and the velocity in a microchannel are

$\overline {\Delta T} $ are the characteristic velocity, length and temperature difference of the system. (b) The fluid–fluid interfaces remain undeformed and flat during the dynamics. The characteristic values of the problem's governing non-dimensional numbers can be determined using the typical values of the parameters. The usual orders of the length scale and the velocity in a microchannel are ![]() $10\ \mathrm{\mu }\textrm{m}$ and

$10\ \mathrm{\mu }\textrm{m}$ and ![]() ${10^{ - 4}}\ \textrm{m}\ {\textrm{s}^{ - 1}}$, respectively (Das & Chakraborty Reference Das and Chakraborty2018). Taking the thermophysical properties of water at

${10^{ - 4}}\ \textrm{m}\ {\textrm{s}^{ - 1}}$, respectively (Das & Chakraborty Reference Das and Chakraborty2018). Taking the thermophysical properties of water at ![]() $300\ \textrm{K}$ (

$300\ \textrm{K}$ (![]() $\bar{\rho } = 997\ \textrm{kg}\ {\textrm{m}^{ - 3}}$,

$\bar{\rho } = 997\ \textrm{kg}\ {\textrm{m}^{ - 3}}$, ![]() $\bar{\mu } = 0.00086\ \textrm{Ns}\ {\textrm{m}^{ - 2}}$,

$\bar{\mu } = 0.00086\ \textrm{Ns}\ {\textrm{m}^{ - 2}}$, ![]() $\bar{\sigma } = 0.072\ \textrm{N}\ {\textrm{m}^{ - 1}}$,

$\bar{\sigma } = 0.072\ \textrm{N}\ {\textrm{m}^{ - 1}}$, ![]() $\overline {{D_t}} = 1.5 \times {10^{ - 7}}\ {\textrm{m}^2}\ {\textrm{s}^{ - 1}}$) (Bergman et al. Reference Bergman, Lavine, Incropera and Dewitt2011), the non-dimensional numbers can be evaluated as:

$\overline {{D_t}} = 1.5 \times {10^{ - 7}}\ {\textrm{m}^2}\ {\textrm{s}^{ - 1}}$) (Bergman et al. Reference Bergman, Lavine, Incropera and Dewitt2011), the non-dimensional numbers can be evaluated as: ![]() $Re\sim {10^{ - 3}}$,

$Re\sim {10^{ - 3}}$, ![]() $Ca\sim {10^{ - 6}}$ and

$Ca\sim {10^{ - 6}}$ and ![]() $Ma\sim {10^{ - 3}}$. The credibility of the second assumption (flat and undeformed interfaces) is demonstrated by obtaining the estimated profiles of the deformed interfaces in a later part of the paper.

$Ma\sim {10^{ - 3}}$. The credibility of the second assumption (flat and undeformed interfaces) is demonstrated by obtaining the estimated profiles of the deformed interfaces in a later part of the paper.

Further, we have assumed stable parallel flows in the three liquid layers as it is well established in the literature that an instability arises in a multilayer system only above a critical value of the Marangoni number ![]() $(Ma)$, which is usually of the order of

$(Ma)$, which is usually of the order of ![]() ${\sim} O({10^3})$. For instance, the stability analysis performed by Simanovskii (Reference Simanovskii2007) demonstrates that the critical value of the Marangoni number

${\sim} O({10^3})$. For instance, the stability analysis performed by Simanovskii (Reference Simanovskii2007) demonstrates that the critical value of the Marangoni number ![]() $(Ma)$ to incite instability is

$(Ma)$ to incite instability is ![]() $Ma = 1250$ for a 47v2 silicone-oil–water–7v2 silicone-oil system, and

$Ma = 1250$ for a 47v2 silicone-oil–water–7v2 silicone-oil system, and ![]() $Ma = 450$ for an air–ethylene glycol–fluorinert FC75 system. Since the order of the Marangoni number in the present analysis is

$Ma = 450$ for an air–ethylene glycol–fluorinert FC75 system. Since the order of the Marangoni number in the present analysis is ![]() ${\sim} O({10^3})$, stable parallel flows can be comfortably considered.

${\sim} O({10^3})$, stable parallel flows can be comfortably considered.

3. Mathematical description of the system

3.1. Thermal transport analysis

We obtain the approximate analytical solution for the system by appealing to the asymptotic perturbation approach. We solve the energy equation in the limiting case of small Marangoni number (or Péclet number), which reduces the governing differential equation to the Laplacian of the temperature field, as

Here,

\begin{align}

{\bar{T}^i}(x,y) = \left\{{\begin{array}{@{}ll@{}} {{\bar{T}^a}(x,y); }&{ - a - \dfrac{b}{2} < y < - \dfrac{b}{2}}\\

{{\bar{T}^b}(x,y);}&{ - \dfrac{b}{2} < y < \dfrac{b}{2}}\\ {{\bar{T}^c}(x,y); }&{\dfrac{b}{2} <

y < \dfrac{b}{2} + c} \end{array}}\right.,\end{align}

\begin{align}

{\bar{T}^i}(x,y) = \left\{{\begin{array}{@{}ll@{}} {{\bar{T}^a}(x,y); }&{ - a - \dfrac{b}{2} < y < - \dfrac{b}{2}}\\

{{\bar{T}^b}(x,y);}&{ - \dfrac{b}{2} < y < \dfrac{b}{2}}\\ {{\bar{T}^c}(x,y); }&{\dfrac{b}{2} <

y < \dfrac{b}{2} + c} \end{array}}\right.,\end{align}

where a, b and c represent the properties of the lower, the middle and the upper liquid layers, respectively. Boundary conditions available to solve the above partial differential equation (3.1) are:

(a) Bottom wall surface temperature

(3.3) \begin{equation}{\bar{T}^a}{|_{y ={-} (b/2 + a)}} = \overline {{T_l}} (1 + {\delta _l}\cos (\alpha x) + \delta _l^2\cos (2\alpha x)).\end{equation}

\begin{equation}{\bar{T}^a}{|_{y ={-} (b/2 + a)}} = \overline {{T_l}} (1 + {\delta _l}\cos (\alpha x) + \delta _l^2\cos (2\alpha x)).\end{equation}(b) Top wall surface temperature

(3.4) \begin{equation}{\bar{T}^c}{|_{y = (b/2 + c)}} = \overline {{T_u}} (1 + {\delta _u}\cos (\alpha x + \theta ) + \delta _u^2\cos (2\alpha x + 2\theta )).\end{equation}

\begin{equation}{\bar{T}^c}{|_{y = (b/2 + c)}} = \overline {{T_u}} (1 + {\delta _u}\cos (\alpha x + \theta ) + \delta _u^2\cos (2\alpha x + 2\theta )).\end{equation}(c) Temperature at the separating interface between fluid ‘

$a$’ and fluid ‘

$a$’ and fluid ‘ $b$’

(3.5)

$b$’

(3.5) \begin{equation}{\bar{T}^a}{|_{y ={-} b/2}} = {\bar{T}^b}{|_{y ={-} b/2}}.\end{equation}

\begin{equation}{\bar{T}^a}{|_{y ={-} b/2}} = {\bar{T}^b}{|_{y ={-} b/2}}.\end{equation}(d) Temperature at the separating interface between fluid ‘

$b$’ and fluid ‘

$b$’ and fluid ‘ $c$’

(3.6)

$c$’

(3.6) \begin{equation}{ {{\bar{T}^b}} |_{y = b/2}} = { {{\bar{T}^c}} |_{y = b/2}}.\end{equation}

\begin{equation}{ {{\bar{T}^b}} |_{y = b/2}} = { {{\bar{T}^c}} |_{y = b/2}}.\end{equation}(e) Heat flux across the separating interface between fluid ‘

$a$’ and fluid ‘

$a$’ and fluid ‘ $b$’

(3.7)

$b$’

(3.7) \begin{equation}{\bar{\lambda }^a}{\left. {\frac{{\partial {\bar{T}^a}}}{{\partial y}}} \right|_{y ={-} b/2}} = {\bar{\lambda }^b}{\left. {\frac{{\partial {\bar{T}^b}}}{{\partial y}}} \right|_{y ={-} b/2}}.\end{equation}

\begin{equation}{\bar{\lambda }^a}{\left. {\frac{{\partial {\bar{T}^a}}}{{\partial y}}} \right|_{y ={-} b/2}} = {\bar{\lambda }^b}{\left. {\frac{{\partial {\bar{T}^b}}}{{\partial y}}} \right|_{y ={-} b/2}}.\end{equation}(f ) Heat flux across the separating interface between fluid ‘

$b$’ and fluid ‘

$b$’ and fluid ‘ $c$’

(3.8)

$c$’

(3.8) \begin{equation}{\bar{\lambda }^b}{\left. {\frac{{\partial {\bar{T}^b}}}{{\partial y}}} \right|_{y = b/2}} = {\bar{\lambda }^c}{\left. {\frac{{\partial {\bar{T}^c}}}{{\partial y}}} \right|_{y = b/2}}.\end{equation}

\begin{equation}{\bar{\lambda }^b}{\left. {\frac{{\partial {\bar{T}^b}}}{{\partial y}}} \right|_{y = b/2}} = {\bar{\lambda }^c}{\left. {\frac{{\partial {\bar{T}^c}}}{{\partial y}}} \right|_{y = b/2}}.\end{equation}

Here, ![]() ${\bar{\lambda }^i}$ represents the thermal conductivity of fluid ‘

${\bar{\lambda }^i}$ represents the thermal conductivity of fluid ‘![]() $i$’. We solve the required partial differential equation (2.1) to obtain the temperature distribution within the microchannel by an asymptotic approach using the perturbation method, as

$i$’. We solve the required partial differential equation (2.1) to obtain the temperature distribution within the microchannel by an asymptotic approach using the perturbation method, as

Now, the governing equation for each term can be written as

The modified boundary conditions are summarized in table 2.

Table 2. Modified boundary conditions for the temperature field.

A close observation of the boundary conditions mentioned in table 2 reveals that the zeroth-order term of the temperature field is a function of ‘y’ ![]() $(\bar{T}_0^i(\kern0.7pt y))$ and is obtained by solving the second-order ordinary differential equation

$(\bar{T}_0^i(\kern0.7pt y))$ and is obtained by solving the second-order ordinary differential equation ![]() $({\textrm{d}^2}\bar{T}_0^i(\kern0.7pt y)/\textrm{d}{y^2} = 0)$, which gives

$({\textrm{d}^2}\bar{T}_0^i(\kern0.7pt y)/\textrm{d}{y^2} = 0)$, which gives

\begin{align}

\bar{T}_0^i(\kern0.7pt y) = \left\{

\begin{aligned}

\bar{T}_0^a(\kern0.7pt y) &= \dfrac{{({{\bar{T}}_u} - {{\bar{T}}_l})y}}{{c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a}}\notag\\

&\quad + \dfrac{{2{{\bar{T}}_l}c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) +

2{{\bar{T}}_l}b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) - {{\bar{T}}_l}b + 2{{\bar{T}}_u}a + {{\bar{T}}_u}b}}{{2\left( {c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a} \right)}},\quad

- a - \dfrac{b}{2} < y < - \dfrac{b}{2}\notag\\

\bar{T}_0^b(\kern0.7pt y) &= \dfrac{{({{\bar{T}}_u} -

{{\bar{T}}_l})\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right)y}}{{c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right) + a}}\notag\\ &\quad + \dfrac{{2{{\bar{T}}_l}c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) +

{{\bar{T}}_l}b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right) + {{\bar{T}}_u}b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) +

2{{\bar{T}}_u}a}}{{2\left( {c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a}

\right)}},\quad - \dfrac{b}{2} < y < \dfrac{b}{2}\notag\\

\bar{T}_0^c(\kern0.7pt y) &= \dfrac{{({{\bar{T}}_u} -

{{\bar{T}}_l})\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right)y}}{{c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right) + a}}\notag\\ &\quad + \dfrac{{{{\bar{T}}_l}b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) +

2{{\bar{T}}_l}c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) -

{{\bar{T}}_u}b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right) + 2{{\bar{T}}_u}b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) +

2{{\bar{T}}_u}a}}{{2\left( {c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a}

\right)}},\quad\dfrac{b}{2} < y < \dfrac{b}{2} + c.

\end{aligned} \right.\end{align}

\begin{align}

\bar{T}_0^i(\kern0.7pt y) = \left\{

\begin{aligned}

\bar{T}_0^a(\kern0.7pt y) &= \dfrac{{({{\bar{T}}_u} - {{\bar{T}}_l})y}}{{c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a}}\notag\\

&\quad + \dfrac{{2{{\bar{T}}_l}c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) +

2{{\bar{T}}_l}b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) - {{\bar{T}}_l}b + 2{{\bar{T}}_u}a + {{\bar{T}}_u}b}}{{2\left( {c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a} \right)}},\quad

- a - \dfrac{b}{2} < y < - \dfrac{b}{2}\notag\\

\bar{T}_0^b(\kern0.7pt y) &= \dfrac{{({{\bar{T}}_u} -

{{\bar{T}}_l})\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right)y}}{{c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right) + a}}\notag\\ &\quad + \dfrac{{2{{\bar{T}}_l}c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) +

{{\bar{T}}_l}b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right) + {{\bar{T}}_u}b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) +

2{{\bar{T}}_u}a}}{{2\left( {c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a}

\right)}},\quad - \dfrac{b}{2} < y < \dfrac{b}{2}\notag\\

\bar{T}_0^c(\kern0.7pt y) &= \dfrac{{({{\bar{T}}_u} -

{{\bar{T}}_l})\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right)y}}{{c\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right) + b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_b}}}}

\right) + a}}\notag\\ &\quad + \dfrac{{{{\bar{T}}_l}b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) +

2{{\bar{T}}_l}c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) -

{{\bar{T}}_u}b\!\left( {\dfrac{{{\lambda_a}}}{{{\lambda_c}}}}

\right) + 2{{\bar{T}}_u}b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) +

2{{\bar{T}}_u}a}}{{2\left( {c\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_c}}}} \right) + b\!\left(

{\dfrac{{{\lambda_a}}}{{{\lambda_b}}}} \right) + a}

\right)}},\quad\dfrac{b}{2} < y < \dfrac{b}{2} + c.

\end{aligned} \right.\end{align}

Using the variable separation approach to replace ![]() $\bar{T}_j^i(x,y) = X_j^i(x)Y_j^i(\kern0.7pt y)$ in (3.10) for the higher-order terms of the temperature field and noticing the periodicity of the temperature boundary conditions along the axial direction, we obtain

$\bar{T}_j^i(x,y) = X_j^i(x)Y_j^i(\kern0.7pt y)$ in (3.10) for the higher-order terms of the temperature field and noticing the periodicity of the temperature boundary conditions along the axial direction, we obtain

Here, ![]() $\bar{A}_j^i,B_j^i,C_j^i,\bar{D}_j^i\ \textrm{and}\ n_j^i$ are arbitrary constants. By comparing the wall temperatures, evaluated by the general formula derived above (3.14) with the applied thermal stimuli, the general expressions for the temperature terms can be simplified, as mentioned in table 3.

$\bar{A}_j^i,B_j^i,C_j^i,\bar{D}_j^i\ \textrm{and}\ n_j^i$ are arbitrary constants. By comparing the wall temperatures, evaluated by the general formula derived above (3.14) with the applied thermal stimuli, the general expressions for the temperature terms can be simplified, as mentioned in table 3.

Table 3. Expressions for different terms of the temperature field.

The values of the constants ![]() $A_j^i$ and

$A_j^i$ and ![]() $B_j^i$, where

$B_j^i$, where ![]() $i = a,b,c\ \textrm{and}\ j = 1\unicode{x2013} 5$, are determined by applying the boundary conditions mentioned in table 2. The expressions of the constants obtained are intricated functions of the characteristic parameters and, hence, are not provided here to maintain the brevity of the paper. However, the behaviour of the temperature field and its dependence on different parameters are presented in § 4.1.

$i = a,b,c\ \textrm{and}\ j = 1\unicode{x2013} 5$, are determined by applying the boundary conditions mentioned in table 2. The expressions of the constants obtained are intricated functions of the characteristic parameters and, hence, are not provided here to maintain the brevity of the paper. However, the behaviour of the temperature field and its dependence on different parameters are presented in § 4.1.

3.2. Hydrodynamic analysis

The temperature field obtained in the previous section clearly indicates the existence of interfacial temperature gradients along both the separating interfaces. We also know that the interfacial surface tensions are strong and inverse functions of the temperature (Kou et al. Reference Kou, Li, Zhang, Xu, Zhang, Shao, Ma, Deng and Li2019). The variation in the surface tension thus produced acts as a driving force to create periodic circulations (TC flow) of the participating fluids in the microchannel. We solve the continuity and the Navier–Stokes equations under the creeping flow assumption to obtain the flow characteristics of the TC flow, which are given as

Here, ![]() ${\bar{\boldsymbol{u}}^i},{\bar{p}^i}\ \textrm{and}\ {\bar{\mu }^i}$ represent the velocity field, the pressure distribution and the fluid's dynamic viscosity. The above two equations (3.15) can be merged into a single governing equation by introducing the streamfunction

${\bar{\boldsymbol{u}}^i},{\bar{p}^i}\ \textrm{and}\ {\bar{\mu }^i}$ represent the velocity field, the pressure distribution and the fluid's dynamic viscosity. The above two equations (3.15) can be merged into a single governing equation by introducing the streamfunction ![]() $({\bar{\psi }^i}(x,y))$, which is defined as

$({\bar{\psi }^i}(x,y))$, which is defined as

Here, ![]() ${\bar{u}^i}$ and

${\bar{u}^i}$ and ![]() ${\bar{v}^i}$ are the horizontal and the vertical component of the velocity of the fluid ‘

${\bar{v}^i}$ are the horizontal and the vertical component of the velocity of the fluid ‘![]() $i$’. The existence of the streamfunction identically satisfies the continuity equation. Now, by substituting the velocities as a function of the streamfunction in the Navier–Stokes equation and taking the curl of the whole equation, we obtain

$i$’. The existence of the streamfunction identically satisfies the continuity equation. Now, by substituting the velocities as a function of the streamfunction in the Navier–Stokes equation and taking the curl of the whole equation, we obtain

Here,

\begin{equation}

{\bar{\psi }^i}(x,y) = \left\{{\begin{array}{@{}ll@{}}

{{\bar{\psi }^a}(x,y),}&{- a - \dfrac{b}{2} < y < - \dfrac{b}{2}}\\

{{\bar{\psi }^b}(x,y), }&{ - \dfrac{b}{2} < y < \dfrac{b}{2}}\\

{{\bar{\psi }^c}(x,y),}&{\dfrac{b}{2} < y <

\dfrac{b}{2} + c} \end{array}}

\right..\end{equation}

\begin{equation}

{\bar{\psi }^i}(x,y) = \left\{{\begin{array}{@{}ll@{}}

{{\bar{\psi }^a}(x,y),}&{- a - \dfrac{b}{2} < y < - \dfrac{b}{2}}\\

{{\bar{\psi }^b}(x,y), }&{ - \dfrac{b}{2} < y < \dfrac{b}{2}}\\

{{\bar{\psi }^c}(x,y),}&{\dfrac{b}{2} < y <

\dfrac{b}{2} + c} \end{array}}

\right..\end{equation}

The governing equation for the streamfunction (3.17) is constrained to the boundary conditions mentioned below:

(a) Wall slip velocities

(3.19a) \begin{gather}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial y}}} \right|_{y ={-} (b/2 + a)}} = \gamma (\epsilon + {\delta _l}\cos (\alpha x)){\left. {\frac{{{\partial^2}{\bar{\psi }^a}(x,y)}}{{\partial {y^2}}}} \right|_{y ={-} (b/2 + a)}},\end{gather}(3.19b)

\begin{gather}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial y}}} \right|_{y ={-} (b/2 + a)}} = \gamma (\epsilon + {\delta _l}\cos (\alpha x)){\left. {\frac{{{\partial^2}{\bar{\psi }^a}(x,y)}}{{\partial {y^2}}}} \right|_{y ={-} (b/2 + a)}},\end{gather}(3.19b) \begin{gather}{\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial y}}} \right|_{y = (b/2 + c)}} ={-} \gamma (\epsilon + {\delta _u}\cos (\alpha x + \theta )){\left. {\frac{{{\partial^2}{\bar{\psi }^c}(x,y)}}{{\partial {y^2}}}} \right|_{y = (b/2 + c)}}.\end{gather}

\begin{gather}{\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial y}}} \right|_{y = (b/2 + c)}} ={-} \gamma (\epsilon + {\delta _u}\cos (\alpha x + \theta )){\left. {\frac{{{\partial^2}{\bar{\psi }^c}(x,y)}}{{\partial {y^2}}}} \right|_{y = (b/2 + c)}}.\end{gather}(b) No-penetration boundary condition across the walls

(3.20) \begin{equation}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial x}}} \right|_{y ={-} (b/2 + a)}} = {\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial x}}} \right|_{y = (b/2 + a)}} = 0.\end{equation}

\begin{equation}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial x}}} \right|_{y ={-} (b/2 + a)}} = {\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial x}}} \right|_{y = (b/2 + a)}} = 0.\end{equation}(c) No-slip boundary condition at the fluid-fluid interfaces

(3.21a,b) \begin{align}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial y}}} \right|_{y ={-} b/2}} = {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial y}}} \right|_{y ={-} b/2}}\quad \textrm{and}\quad {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial y}}} \right|_{y = b/2}} = {\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial y}}} \right|_{y = b/2}}.\end{align}

\begin{align}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial y}}} \right|_{y ={-} b/2}} = {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial y}}} \right|_{y ={-} b/2}}\quad \textrm{and}\quad {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial y}}} \right|_{y = b/2}} = {\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial y}}} \right|_{y = b/2}}.\end{align}(d) No-penetration boundary condition at the fluid-fluid interfaces

(3.22a,b) \begin{align}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial x}}} \right|_{y ={-} b/2}} = {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial x}}} \right|_{y ={-} b/2}} = 0\quad \textrm{and}\quad {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial x}}} \right|_{y = b/2}} = {\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial x}}} \right|_{y = b/2}} = 0.\end{align}

\begin{align}{\left. {\frac{{\partial {\bar{\psi }^a}(x,y)}}{{\partial x}}} \right|_{y ={-} b/2}} = {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial x}}} \right|_{y ={-} b/2}} = 0\quad \textrm{and}\quad {\left. {\frac{{\partial {\bar{\psi }^b}(x,y)}}{{\partial x}}} \right|_{y = b/2}} = {\left. {\frac{{\partial {\bar{\psi }^c}(x,y)}}{{\partial x}}} \right|_{y = b/2}} = 0.\end{align}(e) Shear stress balance at the interfaces

(3.23a) \begin{gather}{\left. {{\bar{\mu }^a}\left( {\frac{{{\partial^2}{\bar{\psi }^a}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^a}}}{{\partial {x^2}}}} \right)} \right|_{y ={-} b/2}} - {\left. {{\bar{\mu }^b}\left( {\frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {x^2}}}} \right)} \right|_{y ={-} b/2}} = \overline {{\sigma _T}{l_c}} {\left. {\frac{{\partial \bar{T}}}{{\partial x}}} \right|_{y ={-} b/2}},\end{gather}(3.23b)We obtain the solution for the streamfunction by the perturbation method, assuming

\begin{gather}{\left. {{\bar{\mu }^a}\left( {\frac{{{\partial^2}{\bar{\psi }^a}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^a}}}{{\partial {x^2}}}} \right)} \right|_{y ={-} b/2}} - {\left. {{\bar{\mu }^b}\left( {\frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {x^2}}}} \right)} \right|_{y ={-} b/2}} = \overline {{\sigma _T}{l_c}} {\left. {\frac{{\partial \bar{T}}}{{\partial x}}} \right|_{y ={-} b/2}},\end{gather}(3.23b)We obtain the solution for the streamfunction by the perturbation method, assuming \begin{gather}{\left. {{\bar{\mu }^b}\left( {\frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {x^2}}}} \right)} \right|_{y = b/2}} - {\left. {{\bar{\mu }^c}\left( {\frac{{{\partial^2}{\bar{\psi }^c}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^c}}}{{\partial {x^2}}}} \right)} \right|_{y = b/2}} = \overline {{\sigma _T}{l_c}} {\left. {\frac{{\partial \bar{T}}}{{\partial x}}} \right|_{y = b/2}}.\end{gather}(3.24)

\begin{gather}{\left. {{\bar{\mu }^b}\left( {\frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^b}}}{{\partial {x^2}}}} \right)} \right|_{y = b/2}} - {\left. {{\bar{\mu }^c}\left( {\frac{{{\partial^2}{\bar{\psi }^c}}}{{\partial {y^2}}} - \frac{{{\partial^2}{\bar{\psi }^c}}}{{\partial {x^2}}}} \right)} \right|_{y = b/2}} = \overline {{\sigma _T}{l_c}} {\left. {\frac{{\partial \bar{T}}}{{\partial x}}} \right|_{y = b/2}}.\end{gather}(3.24) \begin{equation}{\bar{\psi }^i} = {\delta _l}\bar{\psi }_1^i + {\delta _u}\bar{\psi }_2^i + {\delta _l}{\delta _u}\bar{\psi }_3^i + {\delta _l}^2\bar{\psi }_4^i + {\delta _u^2}\bar{\psi }_5^i,\quad \textrm{where}\ i = a,b,c.\end{equation}

\begin{equation}{\bar{\psi }^i} = {\delta _l}\bar{\psi }_1^i + {\delta _u}\bar{\psi }_2^i + {\delta _l}{\delta _u}\bar{\psi }_3^i + {\delta _l}^2\bar{\psi }_4^i + {\delta _u^2}\bar{\psi }_5^i,\quad \textrm{where}\ i = a,b,c.\end{equation}

By observing the boundary conditions, we choose approximate forms for the different terms of the streamfunction, as mentioned in table 4. The governing differential equations for each term of the series expansion of the streamfunction (3.24) are mentioned in table 5 and the corresponding boundary conditions are provided in the Appendix (see tables 7 and 8). The term-wise boundary conditions are obtained by substituting the general form of each term in ((3.19)–(3.23)) and then comparing the coefficients of the perturbation parameters.

Table 4. General forms for the different terms of the streamfunction.

Table 5. The term-wise governing differential equations of the streamfunction.

The general solution for ![]() $g_j^i(\kern0.7pt y),\ \textrm{where}\ i = a,b,c\ \textrm{and}\ j = 1\unicode{x2013} 5$, is obtained by choosing

$g_j^i(\kern0.7pt y),\ \textrm{where}\ i = a,b,c\ \textrm{and}\ j = 1\unicode{x2013} 5$, is obtained by choosing ![]() $g_j^i(\kern0.7pt y) = {e^{q_j^iy}}$ to convert the governing differential equation into its characteristic form, as

$g_j^i(\kern0.7pt y) = {e^{q_j^iy}}$ to convert the governing differential equation into its characteristic form, as

which gives ![]() ${(q_j^{{i^2}} - {\alpha ^2})^2} = 0$ or

${(q_j^{{i^2}} - {\alpha ^2})^2} = 0$ or ![]() $q_j^i ={\pm} \alpha $ for

$q_j^i ={\pm} \alpha $ for ![]() $j = 1, 2$ and

$j = 1, 2$ and ![]() ${(q_j^{{i^2}} - 4{\alpha ^2})^2} = 0$ or

${(q_j^{{i^2}} - 4{\alpha ^2})^2} = 0$ or ![]() $q_j^i ={\pm} 2\alpha \ \textrm{for}\ j = 3\unicode{x2013} 5$. Therefore, the general solution of the above biharmonic equation (3.24) is given by

$q_j^i ={\pm} 2\alpha \ \textrm{for}\ j = 3\unicode{x2013} 5$. Therefore, the general solution of the above biharmonic equation (3.24) is given by

Here, ![]() $m = 1$ for

$m = 1$ for ![]() $j = 1, 2$ and

$j = 1, 2$ and ![]() $m = 2$ for

$m = 2$ for ![]() $j = 3\unicode{x2013} 5$. We assume the general form of

$j = 3\unicode{x2013} 5$. We assume the general form of ![]() $h_j^i(\kern0.7pt y)$ to be

$h_j^i(\kern0.7pt y)$ to be ![]() $E_j^iy + F_j^i{y^2}$, as adopted by Ghosh and Chakraborty (Reference Ghosh and Chakraborty2012) in an allied problem. The constants

$E_j^iy + F_j^i{y^2}$, as adopted by Ghosh and Chakraborty (Reference Ghosh and Chakraborty2012) in an allied problem. The constants ![]() $P_j^i,Q_j^i,R_j^i,S_j^i,E_j^i\ \textrm{and}\ F_j^i$ are determined by appealing to the boundary conditions mentioned in the Appendix (tables 7 and 8). The expressions of the constants are involved functions of the parameters and, hence, are not provided in the manuscript to maintain its brevity. However, the dependences of the streamfunction (or the flow velocity) on different parameters are discussed in detail in § 4.2.

$P_j^i,Q_j^i,R_j^i,S_j^i,E_j^i\ \textrm{and}\ F_j^i$ are determined by appealing to the boundary conditions mentioned in the Appendix (tables 7 and 8). The expressions of the constants are involved functions of the parameters and, hence, are not provided in the manuscript to maintain its brevity. However, the dependences of the streamfunction (or the flow velocity) on different parameters are discussed in detail in § 4.2.

3.3. Interface deformation dynamics

The asymptotic solutions obtained in the previous sections are valid for small governing non-dimensional numbers ![]() $(Ma,Re\ \textrm{and}\ Ca)$ and flat (or undeformed) fluid–fluid interfaces. The credibility of the first assumption

$(Ma,Re\ \textrm{and}\ Ca)$ and flat (or undeformed) fluid–fluid interfaces. The credibility of the first assumption ![]() $(\textrm{i}\textrm{.e}\textrm{.}\ \textrm{negligible}\ Ma,Re\ \textrm{and}\ Ca)$ is discussed in § 2. Even though the small magnitude of Ca guarantees that the extent of deformations occurring in the interfaces is negligible, we obtain the deformed profiles of the two fluid–fluid interfaces using the results for the hydrodynamic characteristics to support the assumption of flat and undeformed interfaces. Knowing the velocity field in the microchannel, the deformation of the interfaces can be estimated by using the normal stress balance across the interfaces, as

$(\textrm{i}\textrm{.e}\textrm{.}\ \textrm{negligible}\ Ma,Re\ \textrm{and}\ Ca)$ is discussed in § 2. Even though the small magnitude of Ca guarantees that the extent of deformations occurring in the interfaces is negligible, we obtain the deformed profiles of the two fluid–fluid interfaces using the results for the hydrodynamic characteristics to support the assumption of flat and undeformed interfaces. Knowing the velocity field in the microchannel, the deformation of the interfaces can be estimated by using the normal stress balance across the interfaces, as

and

where ![]() $\overline {{\tau _{yy}}} ={-} 2\bar{\mu }({\partial ^2}\bar{\psi }(x,y)/\partial \bar{x}\partial \bar{y})$ is the normal stress,

$\overline {{\tau _{yy}}} ={-} 2\bar{\mu }({\partial ^2}\bar{\psi }(x,y)/\partial \bar{x}\partial \bar{y})$ is the normal stress, ![]() $\bar{p}$ the pressure distribution,

$\bar{p}$ the pressure distribution, ![]() $\overline {{\sigma _l}} /\overline {{\sigma _u}} $ the surface tension coefficient at the lower/upper interfaces and

$\overline {{\sigma _l}} /\overline {{\sigma _u}} $ the surface tension coefficient at the lower/upper interfaces and ![]() $\overline {{\kappa _l}} /\overline {{\kappa _u}} $ the local curvature of the deformed interfaces;

$\overline {{\kappa _l}} /\overline {{\kappa _u}} $ the local curvature of the deformed interfaces; ![]() $\bar{\kappa }$ is defined such that it is positive for the case where the centre of curvatures of the interfaces falls below them and is given by

$\bar{\kappa }$ is defined such that it is positive for the case where the centre of curvatures of the interfaces falls below them and is given by

\begin{equation}{\bar{\kappa }_i} = \frac{{\dfrac{{{\textrm{d}^2}{{\bar{y}}_i}}}{{\textrm{d}{\bar{x}^2}}}}}{{{{\left( {1 + {{\left( {\dfrac{{\textrm{d}{{\bar{y}}_i}}}{{\textrm{d}\kern0.06em \bar{x}}}} \right)}^2}} \right)}^{3/2}}}}\sim \frac{{{\textrm{d}^2}{{\bar{y}}_i}}}{{\textrm{d}{\bar{x}^2}}}\sim \frac{1}{{{{\bar{l}}_c}}}\frac{{{\textrm{d}^2}{y_i}}}{{\textrm{d}\kern 0.06em {x^2}}},\quad \textrm{where}\ i = l,u.\end{equation}

\begin{equation}{\bar{\kappa }_i} = \frac{{\dfrac{{{\textrm{d}^2}{{\bar{y}}_i}}}{{\textrm{d}{\bar{x}^2}}}}}{{{{\left( {1 + {{\left( {\dfrac{{\textrm{d}{{\bar{y}}_i}}}{{\textrm{d}\kern0.06em \bar{x}}}} \right)}^2}} \right)}^{3/2}}}}\sim \frac{{{\textrm{d}^2}{{\bar{y}}_i}}}{{\textrm{d}{\bar{x}^2}}}\sim \frac{1}{{{{\bar{l}}_c}}}\frac{{{\textrm{d}^2}{y_i}}}{{\textrm{d}\kern 0.06em {x^2}}},\quad \textrm{where}\ i = l,u.\end{equation}

Here, ![]() ${\bar{y}_i}$ is the vertical displacement of the interfaces relative to their initial undeformed position, and

${\bar{y}_i}$ is the vertical displacement of the interfaces relative to their initial undeformed position, and ![]() $l/u$ denotes the lower/upper interface. It is also discussed in the literature (Pendse & Esmaeeli Reference Pendse and Esmaeeli2010) that, for

$l/u$ denotes the lower/upper interface. It is also discussed in the literature (Pendse & Esmaeeli Reference Pendse and Esmaeeli2010) that, for ![]() $Ca \ll 1$, the interfacial deformation is small enough to assume

$Ca \ll 1$, the interfacial deformation is small enough to assume ![]() $(1 + {(\textrm{d}{\bar{y}_i}/\textrm{d}\kern0.06em \bar{x})^2})\sim 1$.

$(1 + {(\textrm{d}{\bar{y}_i}/\textrm{d}\kern0.06em \bar{x})^2})\sim 1$.

The extended expression of the normal stress ![]() $(\overline {{\tau _{yy}}} )$ is given by

$(\overline {{\tau _{yy}}} )$ is given by

Here, the different terms of the asymptotic series of the normal stress can be represented as

\begin{align} & {\begin{bmatrix} {\dfrac{{\overline {{\tau_{yy}}}_1^i}}{{\cos (\alpha x)}}}\\

{\dfrac{{\overline {{\tau_{yy}}}_2^i}}{{\cos (\alpha x +

\theta )}}}\\ {\dfrac{{\overline {{\tau_{yy}}}_3^i}}{{4\cos

(2\alpha x + \theta )}}}\\ {\dfrac{{\overline

{{\tau_{yy}}}_4^i}}{{4\cos (2\alpha x)}}}\\

{\dfrac{{\overline {{\tau_{yy}}}_5^i}}{{4\cos (2\alpha x +

2\theta )}}} \end{bmatrix}} \nonumber\\ & \quad ={-}

\frac{{2{\bar{\mu}^i}\alpha }}{{{{\overline {{l_c}}

}^2}}}\begin{bmatrix} {(S_1^iy +

R_1^i)\alpha + Q_1^i} & {(Q_1^iy + P_1^i)\alpha +

S_1^i} & 0 & 0\\ {(S_2^iy + R_2^i)\alpha + Q_2^i} & {(Q_2^iy +

P_2^i)\alpha + S_2^i} & 0 & 0\\ 0 & 0 & {(S_3^iy + R_3^i)\alpha +

\dfrac{{Q_3^i}}{2}} & {(Q_3^iy + P_3^i)\alpha +

\dfrac{{S_3^i}}{2}}\\ 0 & 0 & {(S_4^iy + R_4^i)\alpha +

\dfrac{{Q_4^i}}{2}} & {(Q_4^iy + P_4^i)\alpha +

\dfrac{{S_4^i}}{2}}\\ 0 & 0 & {(S_5^iy + R_5^i)\alpha +

\dfrac{{Q_5^i}}{2}} & {(Q_5^iy + P_5^i)\alpha +

\dfrac{{S_5^i}}{2}} \end{bmatrix}\nonumber\\ & \qquad\times \begin{bmatrix}

{\cosh (\alpha y)}\\ {\sinh

(\alpha y)}\\ {\cosh (2\alpha y)}\\ {\sinh (2\alpha y)}

\end{bmatrix}.

\end{align}

\begin{align} & {\begin{bmatrix} {\dfrac{{\overline {{\tau_{yy}}}_1^i}}{{\cos (\alpha x)}}}\\

{\dfrac{{\overline {{\tau_{yy}}}_2^i}}{{\cos (\alpha x +

\theta )}}}\\ {\dfrac{{\overline {{\tau_{yy}}}_3^i}}{{4\cos

(2\alpha x + \theta )}}}\\ {\dfrac{{\overline

{{\tau_{yy}}}_4^i}}{{4\cos (2\alpha x)}}}\\

{\dfrac{{\overline {{\tau_{yy}}}_5^i}}{{4\cos (2\alpha x +

2\theta )}}} \end{bmatrix}} \nonumber\\ & \quad ={-}

\frac{{2{\bar{\mu}^i}\alpha }}{{{{\overline {{l_c}}

}^2}}}\begin{bmatrix} {(S_1^iy +

R_1^i)\alpha + Q_1^i} & {(Q_1^iy + P_1^i)\alpha +

S_1^i} & 0 & 0\\ {(S_2^iy + R_2^i)\alpha + Q_2^i} & {(Q_2^iy +

P_2^i)\alpha + S_2^i} & 0 & 0\\ 0 & 0 & {(S_3^iy + R_3^i)\alpha +

\dfrac{{Q_3^i}}{2}} & {(Q_3^iy + P_3^i)\alpha +

\dfrac{{S_3^i}}{2}}\\ 0 & 0 & {(S_4^iy + R_4^i)\alpha +

\dfrac{{Q_4^i}}{2}} & {(Q_4^iy + P_4^i)\alpha +

\dfrac{{S_4^i}}{2}}\\ 0 & 0 & {(S_5^iy + R_5^i)\alpha +

\dfrac{{Q_5^i}}{2}} & {(Q_5^iy + P_5^i)\alpha +

\dfrac{{S_5^i}}{2}} \end{bmatrix}\nonumber\\ & \qquad\times \begin{bmatrix}

{\cosh (\alpha y)}\\ {\sinh

(\alpha y)}\\ {\cosh (2\alpha y)}\\ {\sinh (2\alpha y)}

\end{bmatrix}.

\end{align}

The constants ![]() $P_j^i,Q_j^i,R_j^i\ \textrm{and}\ S_j^i$ are as defined for the streamfunction, where

$P_j^i,Q_j^i,R_j^i\ \textrm{and}\ S_j^i$ are as defined for the streamfunction, where ![]() $i = a,b,c$ and

$i = a,b,c$ and ![]() $j = 1\unicode{x2013} 5$. Further, the pressure distribution is obtained by partially integrating the

$j = 1\unicode{x2013} 5$. Further, the pressure distribution is obtained by partially integrating the ![]() $x\ \textrm{and}\ y$ momentum equations (3.15) and combining the results. The final expression of the pressure distribution in the microchannel is given by

$x\ \textrm{and}\ y$ momentum equations (3.15) and combining the results. The final expression of the pressure distribution in the microchannel is given by

Here, the different terms of the asymptotic series of the pressure distribution can be represented as

\begin{align} &\begin{bmatrix} {\dfrac{{\bar{p}_1^i}}{{\cos

(\alpha x)}}}\\ {\dfrac{{\bar{p}_2^i}}{{\cos (\alpha x +

\theta )}}}\\ {\dfrac{{\bar{p}_3^i}}{{2\cos (2\alpha x +

\theta )}}}\\ {\dfrac{{\bar{p}_4^i}}{{2\cos (2\alpha

x)}}}\\ {\dfrac{{\bar{p}_5^i}}{{2\cos (2\alpha x + 2\theta

)}}} \end{bmatrix} \nonumber\\ &\quad ={-} \frac{{2{\bar{\mu}^i}\alpha

}}{{{{\overline {{l_c}} }^2}}}\begin{bmatrix} {Q_1^i} & {S_1^i} & 0 & 0\\

{Q_2^i}&{S_2^i} & 0 & 0\\ 0 & 0 & {Q_3^i} & {S_3^i}\\

0 & 0 & {Q_4^i} & {S_4^i}\\ 0 & 0 & {Q_5^i} & {S_5^i} \end{bmatrix}\begin{bmatrix} {\cosh (\alpha y)}\\

{\sinh (\alpha y)}\\ {\cosh (2\alpha y)}\\ {\sinh (2\alpha

y)} \end{bmatrix},\quad \textrm{where}\ i = a,b,c\ \textrm{and}\ j = 1\unicode{x2013}

5.\end{align}

\begin{align} &\begin{bmatrix} {\dfrac{{\bar{p}_1^i}}{{\cos

(\alpha x)}}}\\ {\dfrac{{\bar{p}_2^i}}{{\cos (\alpha x +

\theta )}}}\\ {\dfrac{{\bar{p}_3^i}}{{2\cos (2\alpha x +

\theta )}}}\\ {\dfrac{{\bar{p}_4^i}}{{2\cos (2\alpha

x)}}}\\ {\dfrac{{\bar{p}_5^i}}{{2\cos (2\alpha x + 2\theta

)}}} \end{bmatrix} \nonumber\\ &\quad ={-} \frac{{2{\bar{\mu}^i}\alpha

}}{{{{\overline {{l_c}} }^2}}}\begin{bmatrix} {Q_1^i} & {S_1^i} & 0 & 0\\

{Q_2^i}&{S_2^i} & 0 & 0\\ 0 & 0 & {Q_3^i} & {S_3^i}\\

0 & 0 & {Q_4^i} & {S_4^i}\\ 0 & 0 & {Q_5^i} & {S_5^i} \end{bmatrix}\begin{bmatrix} {\cosh (\alpha y)}\\

{\sinh (\alpha y)}\\ {\cosh (2\alpha y)}\\ {\sinh (2\alpha

y)} \end{bmatrix},\quad \textrm{where}\ i = a,b,c\ \textrm{and}\ j = 1\unicode{x2013}

5.\end{align}

By observing the form of the normal stress and the pressure distribution, we take approximate forms of the normalized interfacial profiles, as

Here, ![]() $l\ \textrm{and}\ u$ represent the lower and the upper interfaces, respectively. Now, by substituting the expressions of the normal stress, the pressure distribution and the approximate form of the interfacial profile in (3.27), we obtain the approximate profiles of the deformed interfaces

$l\ \textrm{and}\ u$ represent the lower and the upper interfaces, respectively. Now, by substituting the expressions of the normal stress, the pressure distribution and the approximate form of the interfacial profile in (3.27), we obtain the approximate profiles of the deformed interfaces ![]() $({y_i})$. The detailed expressions of the coefficients are intricate functions of the parameters involved and, hence, are not provided here to maintain the paper's conciseness. However, the influence of crucial parameters on the interfacial deformation is discussed in the results section (§ 4.3).

$({y_i})$. The detailed expressions of the coefficients are intricate functions of the parameters involved and, hence, are not provided here to maintain the paper's conciseness. However, the influence of crucial parameters on the interfacial deformation is discussed in the results section (§ 4.3).

3.4. Solute transport analysis

The periodic nature of the flow field within the microchannel leads to the circular (or vortical) motion of the fluid molecules in each liquid layer. These disturbances created within the fluid layers can be exploited to attain the efficient mixing of chemical reagents in the solvent fluid layer. In this section, we understand the solute transport and mixing mechanism in each fluid layer by solving the species transport equation, which is given in normalized form as

Here, ![]() ${C^i}(x,y)$ is the normalized solute concentration in fluid ‘

${C^i}(x,y)$ is the normalized solute concentration in fluid ‘![]() $i$’ and

$i$’ and ![]() $Pe = \overline {V{l_c}} /\overline {{D_c}} $ is the Péclet number, where

$Pe = \overline {V{l_c}} /\overline {{D_c}} $ is the Péclet number, where ![]() $\bar{V},\overline {{l_c}} \ \textrm{and}\ \overline {{D_c}} $ are the characteristic velocity, system length scale and species diffusion coefficient, respectively. The governing equation for the species transport is subjected to the following boundary conditions: we study the solute transport analysis by performing numerical simulation using the commercial solver COMSOL Multiphysics. The ‘transport of dilute species’ model under the ‘chemical species transport’ physics coupled with steady-state nonlinear solver (stationary solution) is used to solve the species transport equation in model wizard. Discretization of the geometry is done using extremely fine mesh grids by the physics-controlled mesh selection tool. The velocity distribution obtained in the previous analysis is used to define the flow pattern in the domain. The Dirichlet boundary condition at the inlet and the no-flux boundary conditions at the interfaces and the walls are applied to the flow domain (refer to table 6). The outlet condition for the species transport problem remains unknown as it depends on the flow pattern (Tang, Yang, Chai, & Gong Reference Tang, Yang, Chai and Gong2004). However, the convective flux boundary condition at the outlet is employed to perform the mixing simulation for liquid layers with large length to width ratio

$\bar{V},\overline {{l_c}} \ \textrm{and}\ \overline {{D_c}} $ are the characteristic velocity, system length scale and species diffusion coefficient, respectively. The governing equation for the species transport is subjected to the following boundary conditions: we study the solute transport analysis by performing numerical simulation using the commercial solver COMSOL Multiphysics. The ‘transport of dilute species’ model under the ‘chemical species transport’ physics coupled with steady-state nonlinear solver (stationary solution) is used to solve the species transport equation in model wizard. Discretization of the geometry is done using extremely fine mesh grids by the physics-controlled mesh selection tool. The velocity distribution obtained in the previous analysis is used to define the flow pattern in the domain. The Dirichlet boundary condition at the inlet and the no-flux boundary conditions at the interfaces and the walls are applied to the flow domain (refer to table 6). The outlet condition for the species transport problem remains unknown as it depends on the flow pattern (Tang, Yang, Chai, & Gong Reference Tang, Yang, Chai and Gong2004). However, the convective flux boundary condition at the outlet is employed to perform the mixing simulation for liquid layers with large length to width ratio ![]() $(L/i\sim 12.5)$, where

$(L/i\sim 12.5)$, where ![]() $i = a,b,c$ and L is the length of the channel (Das, Tilekar, Wangikar, & Patowari Reference Das, Tilekar, Wangikar and Patowari2017).

$i = a,b,c$ and L is the length of the channel (Das, Tilekar, Wangikar, & Patowari Reference Das, Tilekar, Wangikar and Patowari2017).

Table 6. Boundary conditions available to solve species transport equation.

4. Results and discussions

4.1. Validation of the approximate analytical solution with the literature

We validate the thermal and hydrodynamic part of the present study with the work of Pendse & Esmaeeli (Reference Pendse and Esmaeeli2010). The normalized temperature across the interface at ![]() $x = 0$ is plotted for the present study and is compared with the reference work (figure 2a). The temperature is normalized as

$x = 0$ is plotted for the present study and is compared with the reference work (figure 2a). The temperature is normalized as ![]() $T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} )$, where

$T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} )$, where ![]() $\bar{T}$,

$\bar{T}$, ![]() $\overline {{T_{min}}} $ and

$\overline {{T_{min}}} $ and ![]() $\overline {{T_{max}}} $ are the local, the minimum and the maximum temperature in the Kelvin scale at the

$\overline {{T_{max}}} $ are the local, the minimum and the maximum temperature in the Kelvin scale at the ![]() $x = 0$ location. A slight deviation in the two temperature profiles is observed as

$x = 0$ location. A slight deviation in the two temperature profiles is observed as ![]() $y \to 0$. This ambiguity is attributed to the fact that the reference work is performed on a binary-liquid system, while we worked on a ternary-liquid system, and the result is validated for a limiting case of a nearly zero but finite thickness of the middle layer. However, the axial velocity profile (normalized) for the reduced model of the present study at

$y \to 0$. This ambiguity is attributed to the fact that the reference work is performed on a binary-liquid system, while we worked on a ternary-liquid system, and the result is validated for a limiting case of a nearly zero but finite thickness of the middle layer. However, the axial velocity profile (normalized) for the reduced model of the present study at ![]() $x = 0.25$ coincides with the same of the reference work, which proves the credibility of the current model (refer to figure 2b). The normalized velocity is given by

$x = 0.25$ coincides with the same of the reference work, which proves the credibility of the current model (refer to figure 2b). The normalized velocity is given by ![]() $U = \bar{u}/\overline {{U_{max}}} $, where

$U = \bar{u}/\overline {{U_{max}}} $, where ![]() $\bar{u}$ and

$\bar{u}$ and ![]() $\overline {{U_{max}}} $ are the local and the maximum velocity at the

$\overline {{U_{max}}} $ are the local and the maximum velocity at the ![]() $x = 0.25$ line. The solute transport is validated by comparing the normalized concentration variation across the microchannel length at two axial locations

$x = 0.25$ line. The solute transport is validated by comparing the normalized concentration variation across the microchannel length at two axial locations ![]() $({x^\ast } = 2.2\ \textrm{and}\ {x^\ast } = 47.8,\ \textrm{where}\ {x^\ast } = \bar{x}/\bar{b})$ with that of Wu & Nguyen (Reference Wu and Nguyen2005). Here, the concentration is normalized with its maximum value at the corresponding axial location (see figure 2c). To perform the comparison, we adopted the same velocity profile of the base fluid in our model as taken in the reference work.

$({x^\ast } = 2.2\ \textrm{and}\ {x^\ast } = 47.8,\ \textrm{where}\ {x^\ast } = \bar{x}/\bar{b})$ with that of Wu & Nguyen (Reference Wu and Nguyen2005). Here, the concentration is normalized with its maximum value at the corresponding axial location (see figure 2c). To perform the comparison, we adopted the same velocity profile of the base fluid in our model as taken in the reference work.

Figure 2. Validation of the mathematical formulations made in the present study for (a) the thermal, (b) the hydrodynamic and (c) the species transport analysis.

Figure 3. Thermal contours in the microchannel for different values of the phase difference between the wall thermal stimuli: (a) ![]() $\theta = 0$, (b)

$\theta = 0$, (b) ![]() $\theta = {\rm \pi}/2$ and (c)

$\theta = {\rm \pi}/2$ and (c) ![]() $\theta = {\rm \pi}$. Here,

$\theta = {\rm \pi}$. Here, ![]() $T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} )$. Parametric detail:

$T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} )$. Parametric detail: ![]() $\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$

$\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$ ![]() $a:b:c = 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

$a:b:c = 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

Figure 4. Interfacial temperatures for the ternary-liquid system for different values of the phase difference between the wall thermal stimuli at (a) the upper interface and (b) the lower interface. Here, ![]() $T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} )$. Parametric detail:

$T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} )$. Parametric detail: ![]() $\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$

$\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$ ![]() $a:b:c = 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

$a:b:c = 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

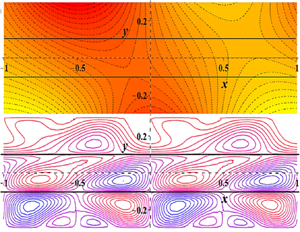

Figure 5. Streamfunction distribution in the microchannel, and its dependence on the phase difference and wall slip. Here, ![]() $\psi = (\bar{\psi } - \overline {{\psi _{min}}} )/(\overline {{\psi _{max}}} - \overline {{\psi _{min}}} )$. Parametric detail:

$\psi = (\bar{\psi } - \overline {{\psi _{min}}} )/(\overline {{\psi _{max}}} - \overline {{\psi _{min}}} )$. Parametric detail: ![]() $\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,a:b:c $

$\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,a:b:c $ ![]() $= 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1,{\sigma _T} ={-} {10^{ - 4}}\ \textrm{N}\ \textrm{m}{\textrm{K}^{ - 1}},$

$= 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1,{\sigma _T} ={-} {10^{ - 4}}\ \textrm{N}\ \textrm{m}{\textrm{K}^{ - 1}},$ ![]() ${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

Figure 6. Streamfunction distribution in the microchannel, and its dependence on the film thickness ratio of the three liquid layers and wall slip conditions. Here, ![]() $\psi = (\bar{\psi } - \overline {{\psi _{min}}} )/(\overline {{\psi _{max}}} - \overline {{\psi _{min}}} )$. Parametric detail:

$\psi = (\bar{\psi } - \overline {{\psi _{min}}} )/(\overline {{\psi _{max}}} - \overline {{\psi _{min}}} )$. Parametric detail: ![]() $\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$

$\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$ ![]() $\theta = {\rm \pi}/2,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1,{\sigma _T} ={-} {10^{ - 4}}\ \textrm{N}\ \textrm{m}{\textrm{K}^{ - 1}},$

$\theta = {\rm \pi}/2,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1,{\sigma _T} ={-} {10^{ - 4}}\ \textrm{N}\ \textrm{m}{\textrm{K}^{ - 1}},$ ![]() ${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

4.2. Thermal transport

To demonstrate the origin of the Marangoni convection, we first present the steady-state temperature distribution in the microchannel for the system configuration shown in figure 1. Figure 3 shows the distribution of the isotherms and its dependence on the phase difference between the two thermal stimuli applied at the top and the bottom wall ![]() $(\theta )$. The plot is prepared by keeping the other influencing parameters fixed as:

$(\theta )$. The plot is prepared by keeping the other influencing parameters fixed as: ![]() $\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$

$\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,$ ![]() $a:b:c = 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$. The local temperature is normalized using its extremums in the flow domain to make the charts more illuminating and understandable

$a:b:c = 1:1:1,{\lambda _a}:{\lambda _b}:{\lambda _c} = 1:1:1\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$. The local temperature is normalized using its extremums in the flow domain to make the charts more illuminating and understandable ![]() $(T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} ))$. Due to the equal thermal conductivity and film thickness of the three fluid layers, the oscillation behaviours of the top and the bottom wall temperatures are replicated in the adjacent fluid layers, whereas the middle layer exhibits an intermediate pattern. Since the cause of the Marangoni convection is the interfacial temperature gradient, it is more important to understand the thermal behaviour of the interfaces. Therefore, we plot the variation of the temperatures at the two interfaces and explore their dependence on the phase difference between the two wall temperatures

$(T = (\bar{T} - \overline {{T_{min}}} )/(\overline {{T_{max}}} - \overline {{T_{min}}} ))$. Due to the equal thermal conductivity and film thickness of the three fluid layers, the oscillation behaviours of the top and the bottom wall temperatures are replicated in the adjacent fluid layers, whereas the middle layer exhibits an intermediate pattern. Since the cause of the Marangoni convection is the interfacial temperature gradient, it is more important to understand the thermal behaviour of the interfaces. Therefore, we plot the variation of the temperatures at the two interfaces and explore their dependence on the phase difference between the two wall temperatures ![]() $(\theta )$ (refer to figure 4). The parametric combination chosen to prepare figure 4 is the same as that for figure 3. A lateral drift of the temperature profile is observed with changes in the thermal phase difference for the upper interface. However, the influence is marginal in the lower interface. The reason for this observation is the fact that the changes in the phase difference are incorporated by altering the top wall thermal stimulus, and due to equal thermal conductivity and film thickness of the fluid layers, the temperature of both the interfaces are decided by the walls closer to them.

$(\theta )$ (refer to figure 4). The parametric combination chosen to prepare figure 4 is the same as that for figure 3. A lateral drift of the temperature profile is observed with changes in the thermal phase difference for the upper interface. However, the influence is marginal in the lower interface. The reason for this observation is the fact that the changes in the phase difference are incorporated by altering the top wall thermal stimulus, and due to equal thermal conductivity and film thickness of the fluid layers, the temperature of both the interfaces are decided by the walls closer to them.

Figure 7. Interfacial velocity profiles and their dependence on the film thickness ratio of the three liquid layers and wall slip conditions: (a) upper interface and (b) lower interface. Here, ![]() $U = \bar{u}/\overline {{U_{max}}}$. Parametric detail:

$U = \bar{u}/\overline {{U_{max}}}$. Parametric detail: ![]() ${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$

${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$ ![]() ${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

Figure 8. Streamfunction distribution in the microchannel, and its dependence on the thermal conductivity ratio of the three liquid layers and wall slip conditions. Here, ![]() $\psi = (\bar{\psi } - \overline {{\psi _{min}}} )/(\overline {{\psi _{max}}} - \overline {{\psi _{min}}} )$. Parametric detail:

$\psi = (\bar{\psi } - \overline {{\psi _{min}}} )/(\overline {{\psi _{max}}} - \overline {{\psi _{min}}} )$. Parametric detail: ![]() $\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,\theta = {\rm \pi} /2,a:b:c$

$\overline {{T_l}} = 300\ \textrm{K},\overline {{T_u}} = 310\ \textrm{K},\alpha = 2{\rm \pi} ,\theta = {\rm \pi} /2,a:b:c$ ![]() $= 1:1:1,{\sigma _T} ={-} {10^{ - 4}}\ \textrm{N}\ \textrm{m}{\textrm{K}^{ - 1}},{\mu _a}:{\mu _b}:{\mu _c}$

$= 1:1:1,{\sigma _T} ={-} {10^{ - 4}}\ \textrm{N}\ \textrm{m}{\textrm{K}^{ - 1}},{\mu _a}:{\mu _b}:{\mu _c}$ ![]() $= 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

$= 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$.

4.3. Hydrodynamic transport

We observe in the previous section that the periodic thermal stimuli provided at the walls incite periodic interfacial temperature profiles, which create variations in the interfacial tensions leading to the Marangoni or the TC effect. Further, the oscillatory nature of the gradients in the interfacial temperature or the interfacial tension prompt the circular (or vortical) motion of the fluid molecules, stimulating better mixing within the system. It is also observed that the patterned wettability at the walls can augment the flow pattern in a microchannel to enhance the mixing performance (Ghosh & Chakraborty Reference Ghosh and Chakraborty2012).

In our study, we explore the interplay of the patterned wall slip and thermal stimuli to obtain enhanced mixing in a microchannel. Figure 5 presents the streamfunction distribution for different thermal (or slip) phase differences ![]() $(\theta )$ and compares the results for the no-slip and a finite slip

$(\theta )$ and compares the results for the no-slip and a finite slip ![]() $({l_s} = 0.1)$ condition at the microchannel walls (other parameters:

$({l_s} = 0.1)$ condition at the microchannel walls (other parameters: ![]() ${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$

${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$ ![]() ${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$). It is observed that, while churning of the fluid molecules is restricted to the middle layer for the no-slip condition, it occurs in all three fluid layers when a finite slip is present at the walls. While the cause of the churning effect in the middle layer is attributed to the phase difference between the two interfacial temperatures, it is due to the interaction of the patterned wall slip and the periodic TC in the top and the bottom fluid layers. Further, the distortion of the vortices in the top and the bottom fluid layers due to patterned slip facilitates the mixing occurrence at larger length scales, which otherwise is confined to the local vortices. It is also noted that, although the changes in the thermal (or slip) phase difference

${\mu _a}:{\mu _b}:{\mu _c} = 1:1:1,\mathrm{\epsilon } = {10^{ - 3}}\ \textrm{and}\ {\delta _l} = {\delta _u} = 0.1$). It is observed that, while churning of the fluid molecules is restricted to the middle layer for the no-slip condition, it occurs in all three fluid layers when a finite slip is present at the walls. While the cause of the churning effect in the middle layer is attributed to the phase difference between the two interfacial temperatures, it is due to the interaction of the patterned wall slip and the periodic TC in the top and the bottom fluid layers. Further, the distortion of the vortices in the top and the bottom fluid layers due to patterned slip facilitates the mixing occurrence at larger length scales, which otherwise is confined to the local vortices. It is also noted that, although the changes in the thermal (or slip) phase difference ![]() $(\theta )$ have no serious effect on the mixing dynamics of the top and the bottom layer, they significantly alter the same in the middle layer. For the non-zero

$(\theta )$ have no serious effect on the mixing dynamics of the top and the bottom layer, they significantly alter the same in the middle layer. For the non-zero ![]() $\theta $, the vortex enveloping phenomenon is observed in the middle layer, resulting in better mixing, which is missing for

$\theta $, the vortex enveloping phenomenon is observed in the middle layer, resulting in better mixing, which is missing for ![]() $\theta = 0$. However, the mixing performance in the middle layer does not seem to be affected much by the wall slip conditions.

$\theta = 0$. However, the mixing performance in the middle layer does not seem to be affected much by the wall slip conditions.

Figure 9. Interfacial velocity profiles and its dependence on the relative thermal conductivity of the three liquid layers and wall slip conditions: (a) upper interface and (b) lower interface. Here, ![]() $U = \bar{u}/\overline {{U_{max}}} $. Parametric detail: