1. Introduction

Liquid drop impact on solids and liquids abound in nature (Yarin, Roisman & Tropea Reference Yarin, Roisman and Tropea2017) and are essential for several industrial applications, such as inkjet printing (Lohse Reference Lohse2022) and criminal forensics (Smith, Nicloux & Brutin Reference Smith, Nicloux and Brutin2018). Consequently, drop impact has garnered extensive attention (Rein Reference Rein1993; Weiss & Yarin Reference Weiss and Yarin1999; Yarin Reference Yarin2006; Thoroddsen, Etoh & Takehara Reference Thoroddsen, Etoh and Takehara2008; Josserand & Thoroddsen Reference Josserand and Thoroddsen2016) ever since the seminal work of Worthington (Reference Worthington1877, Reference Worthington1908). Impacts can result in either contact or levitation outcomes, depending on whether the air layer trapped between the drop and the substrate drains completely during impact.

For low-impact velocities, the buildup of the lubrication pressure in the draining air layer prevents the drop from contacting the underlying surface, leading to drop bouncing/floating on this layer (Reynolds Reference Reynolds1881; Davis, Schonberg & Rallison Reference Davis, Schonberg and Rallison1989; Yiantsios & Davis Reference Yiantsios and Davis1990, Reference Yiantsios and Davis1991; Smith, Li & Wu Reference Smith, Li and Wu2003; van der Veen et al. Reference van der Veen, Tran, Lohse and Sun2012). Drops that bounce/float in such a scenario are realized in several configurations, for example on solid surfaces (Kolinski, Mahadevan & Rubinstein Reference Kolinski, Mahadevan and Rubinstein2014; de Ruiter et al. Reference de Ruiter, Lagraauw, van den Ende and Mugele2015), liquid films (Pan & Law Reference Pan and Law2007; Hao et al. Reference Hao, Li, Liu, Zhou, Liu, Liu, Che, Zhou, Sun and Li2015; Tang et al. Reference Tang, Saha, Law and Sun2018, Reference Tang, Saha, Law and Sun2019), stationary liquid pools (Rodriguez & Mesler Reference Rodriguez and Mesler1985; Klyuzhin et al. Reference Klyuzhin, Ienna, Roeder, Wexler and Pollack2010; Wu et al. Reference Wu, Hao, Lu, Xu, Hu and Floryan2020) or vibrating liquid pools (Couder et al. Reference Couder, Fort, Gautier and Boudaoud2005a,Reference Couder, Protiere, Fort and Boudaoudb), or even soap films (Gilet & Bush Reference Gilet and Bush2009). Interfacial processes such as Marangoni flow (Geri et al. Reference Geri, Keshavarz, McKinley and Bush2017) or the generation of vapour below a drop deposited on a superheated substrate (the Leidenfrost effect, where the liquid levitates on a cushion of its own vapour; Leidenfrost Reference Leidenfrost1756; Quéré Reference Quéré2013; Chantelot & Lohse Reference Chantelot and Lohse2021) can further stabilize the sandwiched air/vapour layer to facilitate levitation, even for the dynamic case of drop impact (Chandra & Avedisian Reference Chandra and Avedisian1991; Tran et al. Reference Tran, Staat, Prosperetti, Sun and Lohse2012; Shirota et al. Reference Shirota, van Limbeek, Sun, Prosperetti and Lohse2016). Drops can also defy gravity and levitate thanks to the so-called inverse Leidenfrost effect (Adda-Bedia et al. Reference Adda-Bedia, Kumar, Lechenault, Moulinet, Schillaci and Vella2016; Gauthier et al. Reference Gauthier, Diddens, Proville, Lohse and van der Meer2019) or electromagnetic forces (Pal et al. Reference Pal, Miqdad, Datta, Das and Das2017; Singh, Das & Das Reference Singh, Das and Das2018).

At higher impact velocities, the air layer ruptures, leading to contact. The rupture occurs due to a strong attractive van der Waals force between the droplet and the solid or liquid substrate, which comes into play as the thickness of the air layer reduces to the order of ![]() $10 \unicode{x2013} 100\ {\rm nm}$ (see Appendix A, and Charles & Mason Reference Charles and Mason1960; Chubynsky et al. Reference Chubynsky, Belousov, Lockerby and Sprittles2020; Zhang et al. Reference Zhang, Soori, Rokoni, Kaminski and Sun2021b). Additionally, surface asperities that are of the order of the minimum gas layer thickness can also cause rupture, binding the drop to the surface (Thoroddsen, Etoh & Takehara Reference Thoroddsen, Etoh and Takehara2003; Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014; Li, Vakarelski & Thoroddsen Reference Li, Vakarelski and Thoroddsen2015).

$10 \unicode{x2013} 100\ {\rm nm}$ (see Appendix A, and Charles & Mason Reference Charles and Mason1960; Chubynsky et al. Reference Chubynsky, Belousov, Lockerby and Sprittles2020; Zhang et al. Reference Zhang, Soori, Rokoni, Kaminski and Sun2021b). Additionally, surface asperities that are of the order of the minimum gas layer thickness can also cause rupture, binding the drop to the surface (Thoroddsen, Etoh & Takehara Reference Thoroddsen, Etoh and Takehara2003; Kolinski et al. Reference Kolinski, Mahadevan and Rubinstein2014; Li, Vakarelski & Thoroddsen Reference Li, Vakarelski and Thoroddsen2015).

In this work, we focus on levitation outcomes that can be classified as either repellent (bouncing drops) or non-repellent (non-bouncing/floating) behaviours. We note that non-repellent scenarios lead ultimately to coalescence, a phenomenon that we do not investigate here and that occurs on a time scale much larger than that of impact (Lo, Liu & Xu Reference Lo, Liu and Xu2017; Duchemin & Josserand Reference Duchemin and Josserand2020). We perform experiments and direct numerical simulations (DNS) to investigate drop rebound on viscous liquid films. In the limit of thin-enough viscous coatings, the substrate mimics an atomically smooth solid and displays a superamphiphobic-like repellent behaviour (Hao et al. Reference Hao, Li, Liu, Zhou, Liu, Liu, Che, Zhou, Sun and Li2015; Lo et al. Reference Lo, Liu and Xu2017). This substrate-independent bouncing (Gilet & Bush Reference Gilet and Bush2012; Pack et al. Reference Pack, Hu, Kim, Zheng, Stone and Sun2017; Lakshman et al. Reference Lakshman, Tewes, Harth, Snoeijer and Lohse2021) can be compared with that observed on superhydrophobic substrates, where the apparent contact time is given by the oscillation time of a drop (Rayleigh Reference Rayleigh1879), owing to the drop impact–oscillation analogy (Richard, Clanet & Quéré Reference Richard, Clanet and Quéré2002). As a result, such an impacting drop can be modelled using a quasi-ideal spring, whose stiffness is given by the surface tension coefficient (Okumura et al. Reference Okumura, Chevy, Richard, Quéré and Clanet2003). Unlike ideal Rayleigh oscillations, the collisions are partially inelastic due to viscous dissipation (Prosperetti Reference Prosperetti1977). When the drop viscosity increases and viscous dissipation becomes significant, this spring couples with a linear damper whose strength is proportional to the drop's viscosity (see Appendix B, and Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020). The adoption of such a spring–mass–damper system has led to several successful predictions of the drop impact dynamics in a variety of configurations such as viscous bouncing (Moláček & Bush Reference Moláček and Bush2012; Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020), spontaneous levitation (Schutzius et al. Reference Schutzius, Jung, Maitra, Graeber, Köhme and Poulikakos2015), fast bouncing (Chantelot et al. Reference Chantelot, Coux, Clanet and Quéré2018) and walking drops (Terwagne et al. Reference Terwagne, Ludewig, Vandewalle and Dorbolo2013).

In the opposing limit of thick liquid films (pools), drops can also bounce/float (Reynolds Reference Reynolds1881; Jayaratne & Mason Reference Jayaratne and Mason1964). However, unlike solids and very thin films, these pools deform on impact and can absorb a part of the impact kinetic energy in the form of (i) surface energy owing to interfacial deformation, (ii) internal kinetic energy, and (iii) viscous dissipation (Galeano-Rios et al. Reference Galeano-Rios, Cimpeanu, Bauman, MacEwen, Milewski and Harris2021). Consequently, the impact outcomes also include a substrate-dependent regime that culminates in the transition from bouncing to non-bouncing (floating). In the latter case, the drop cannot take off, resulting in the liquid surface losing its repellent property. Hao et al. (Reference Hao, Li, Liu, Zhou, Liu, Liu, Che, Zhou, Sun and Li2015) studied this transition from the substrate-independent to substrate-dependent bouncing for water drops, and reported that the critical film thickness marking this transition depends on the film viscosity and the impact velocity of the drops.

In the present work, we elucidate how the thickness and viscosity of liquid coatings influence the rebound characteristics of an impacting drop, culminating in the loss of repellency: the transition from bouncing to non-bouncing (floating). We disentangle how the initial kinetic energy of an impacting drop can be absorbed through dissipation and energy transfers in the drop and the liquid film.

The paper is organized as follows. Section 2 describes the experimental and numerical methods. In § 3, we discuss the phenomenology of the drop impact dynamics on viscous liquid films. Guided by our experimental and numerical observations, we develop a phenomenological model in § 4, extending the spring–mass–damper analogy by considering the liquid coating as an additional source of dissipation. In § 5, we test the validity and applicability of this model by comparing the predicted values of the coefficient of restitution with our observations when both the drop and film properties are varied. We also delineate the various regimes observed in this work by measuring the critical film thicknesses at which the substrate-independent to substrate-dependent and bouncing to non-bouncing (floating) transitions occur, and compare their observed values with the model predictions. Further, § 6 investigates the cases where our phenomenological model fails to predict the observed dynamics, and gives alternate explanations. The paper ends with a conclusion and an outlook in § 7.

2. Methods

2.1. Experimental details

Our experiments, whose set-up is sketched in figure 1, consist of silicone oil droplets with radius ![]() $R$, density

$R$, density ![]() $\rho _d$ and viscosity

$\rho _d$ and viscosity ![]() $\eta _d$, impacting on silicone oil films with thickness

$\eta _d$, impacting on silicone oil films with thickness ![]() $h_f$, density

$h_f$, density ![]() $\rho _f$ and viscosity

$\rho _f$ and viscosity ![]() $\eta _f$. We choose silicone oil as a working fluid as its viscosity can be varied over a wide range, here from

$\eta _f$. We choose silicone oil as a working fluid as its viscosity can be varied over a wide range, here from ![]() $0.8\ {\rm mPa}\ {\rm s}$ to

$0.8\ {\rm mPa}\ {\rm s}$ to ![]() $96\ {\rm mPa}\ {\rm s}$, while keeping its density and surface tension coefficient

$96\ {\rm mPa}\ {\rm s}$, while keeping its density and surface tension coefficient ![]() $\gamma$ nearly constant, as evidenced in table 1. Droplets with radius

$\gamma$ nearly constant, as evidenced in table 1. Droplets with radius ![]() $R = 1.0 \pm 0.1\ {\rm mm}$ are released from a calibrated needle whose height can be varied to adjust the impact velocity

$R = 1.0 \pm 0.1\ {\rm mm}$ are released from a calibrated needle whose height can be varied to adjust the impact velocity ![]() $V$ from

$V$ from ![]() $0.1\ {\rm m}\ {\rm s}^{-1}$ to

$0.1\ {\rm m}\ {\rm s}^{-1}$ to ![]() $0.5\ {\rm m}\ {\rm s}^{-1}$. The rupture of the air layer, that mediates the interaction between the drop and the film, determines the upper bound of the bouncing regime. This rupture sets the critical impact velocity, expressed as the Weber number (i.e. the ratio of inertial to capillary stresses)

$0.5\ {\rm m}\ {\rm s}^{-1}$. The rupture of the air layer, that mediates the interaction between the drop and the film, determines the upper bound of the bouncing regime. This rupture sets the critical impact velocity, expressed as the Weber number (i.e. the ratio of inertial to capillary stresses) ![]() $\mathit {We}_{d} \equiv \rho _d R V^{2} /\gamma \lesssim {O}(10)$, above which coalescence between the miscible drop and film occurs (see Appendix A and Chubynsky et al. Reference Chubynsky, Belousov, Lockerby and Sprittles2020; Sharma & Dixit Reference Sharma and Dixit2021). We further fix the impact velocity at

$\mathit {We}_{d} \equiv \rho _d R V^{2} /\gamma \lesssim {O}(10)$, above which coalescence between the miscible drop and film occurs (see Appendix A and Chubynsky et al. Reference Chubynsky, Belousov, Lockerby and Sprittles2020; Sharma & Dixit Reference Sharma and Dixit2021). We further fix the impact velocity at ![]() $V = 0.3 \pm 0.03\ {\rm m}\ {\rm s}^{-1}$, corresponding to

$V = 0.3 \pm 0.03\ {\rm m}\ {\rm s}^{-1}$, corresponding to ![]() $\mathit {We}_{d} = 4\pm 1$, and focus on the influence of the material properties of the drop and the film on the impact process (see § 2.2). Indeed, this process is fairly independent of

$\mathit {We}_{d} = 4\pm 1$, and focus on the influence of the material properties of the drop and the film on the impact process (see § 2.2). Indeed, this process is fairly independent of ![]() $\mathit {We}_{d}$ in the narrow range of

$\mathit {We}_{d}$ in the narrow range of ![]() $\mathit {We}_{d}$ in which bouncing occurs without air layer rupture (see Appendices A and C).

$\mathit {We}_{d}$ in which bouncing occurs without air layer rupture (see Appendices A and C).

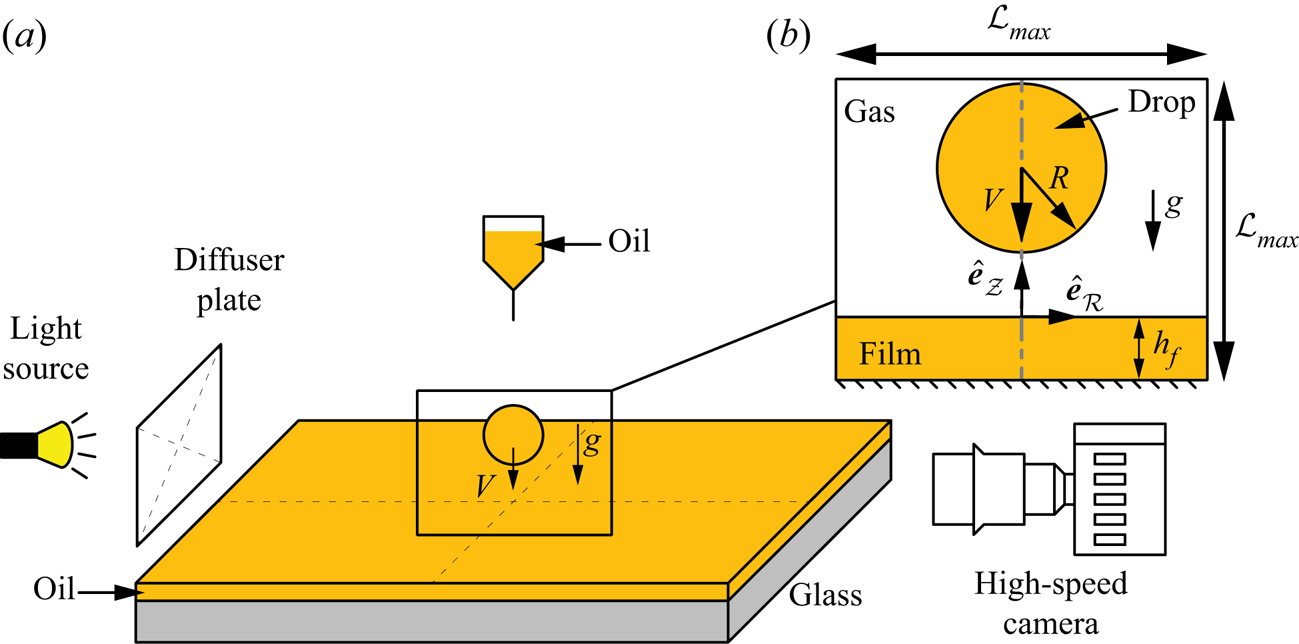

Figure 1. (a) Schematic (not to scale) of the experimental set-up. (b) Side-view visualization of the drop impact process as viewed using the high-speed camera. The inset also shows the axisymmetric domain used in the DNS, and defines the symbols used. The domain boundaries are chosen to be far enough not to influence the drop impact process. Furthermore, we ensure that the waves formed on the film are not reflected back from these boundaries. Consequently, for ![]() $\mathit {Oh}_{f} < 0.1$,

$\mathit {Oh}_{f} < 0.1$, ![]() $\mathcal {L}_{{max}} \gg 8R$. On the other hand, if

$\mathcal {L}_{{max}} \gg 8R$. On the other hand, if ![]() $\mathit {Oh}_{f} > 0.1$ and waves on the film are damped, then we choose

$\mathit {Oh}_{f} > 0.1$ and waves on the film are damped, then we choose ![]() $\mathcal {L}_{{max}} = 8R$.

$\mathcal {L}_{{max}} = 8R$.

Table 1. Properties of the liquids used in the experiments, where ![]() $\rho$ and

$\rho$ and ![]() $\eta$ are the density and viscosity of the liquid, and

$\eta$ are the density and viscosity of the liquid, and ![]() $\gamma$ denotes the liquid–air surface tension coefficient. Throughout the paper, the subscripts

$\gamma$ denotes the liquid–air surface tension coefficient. Throughout the paper, the subscripts ![]() $d$,

$d$, ![]() $f$ and

$f$ and ![]() $s$ represent drop, film and surrounding, respectively. The silicone oil manufacturers are Shin Etsu (SE) and Wacker Chemie AG (AK).

$s$ represent drop, film and surrounding, respectively. The silicone oil manufacturers are Shin Etsu (SE) and Wacker Chemie AG (AK).

Films of controlled thickness, varying from ![]() $0.01\ {\rm mm}$ to

$0.01\ {\rm mm}$ to ![]() $1\ {\rm mm}$, are prepared by spincoating the liquid for

$1\ {\rm mm}$, are prepared by spincoating the liquid for ![]() $h_f < 0.03\ {\rm mm}$, or by depositing a known volume of silicone oil on a glass slide and allowing it to spread when

$h_f < 0.03\ {\rm mm}$, or by depositing a known volume of silicone oil on a glass slide and allowing it to spread when ![]() $h_f > 0.03\ {\rm mm}$. We measure the thickness of spincoated films using reflectometry (Reizman Reference Reizman1965), with uncertainty

$h_f > 0.03\ {\rm mm}$. We measure the thickness of spincoated films using reflectometry (Reizman Reference Reizman1965), with uncertainty ![]() $\pm 0.1\ {\mathrm {\mu }}{\rm m}$, while the thicker films obtained from the deposition method are characterized from side-view imaging, using a procedure detailed in Appendix D, with uncertainty

$\pm 0.1\ {\mathrm {\mu }}{\rm m}$, while the thicker films obtained from the deposition method are characterized from side-view imaging, using a procedure detailed in Appendix D, with uncertainty ![]() $\pm 30\ {\mathrm {\mu }}{\rm m}$. We record the impact dynamics using high-speed side-view imaging at 10 000 frames per second (Photron UX100).

$\pm 30\ {\mathrm {\mu }}{\rm m}$. We record the impact dynamics using high-speed side-view imaging at 10 000 frames per second (Photron UX100).

2.2. Governing equations and numerical framework

This subsection describes the DNS framework used to study the drop impact process with the free software program Basilisk C (Popinet & Collaborators Reference Popinet2013–2022a), using the volume of fluid (VoF) method (see (2.1)) for tracking the interface (Tryggvason, Scardovelli & Zaleski Reference Tryggvason, Scardovelli and Zaleski2011). In this work, we have three fluids, namely, the drop, the film and air, denoted by ![]() $d$,

$d$, ![]() $f$ and

$f$ and ![]() $a$ subscripts, respectively (figure 1). In order to track the three fluids and enforce non-coalescence between the drop and the film, we use two VoF tracer fields,

$a$ subscripts, respectively (figure 1). In order to track the three fluids and enforce non-coalescence between the drop and the film, we use two VoF tracer fields, ![]() $\varPsi _1, \varPsi _2$ (Ramírez-Soto et al. Reference Ramírez-Soto, Sanjay, Lohse, Pham and Vollmer2020):

$\varPsi _1, \varPsi _2$ (Ramírez-Soto et al. Reference Ramírez-Soto, Sanjay, Lohse, Pham and Vollmer2020):

where ![]() $\boldsymbol {v}$ is the velocity field. The use of two VoF fields, followed by interface reconstruction and implicit tagging of the ambient medium (air tracer,

$\boldsymbol {v}$ is the velocity field. The use of two VoF fields, followed by interface reconstruction and implicit tagging of the ambient medium (air tracer, ![]() $\varPsi _a = 1 - \varPsi _1 - \varPsi _2$), ensures that the two tracers never overlap (Ramírez-Soto et al. Reference Ramírez-Soto, Sanjay, Lohse, Pham and Vollmer2020; Naru Reference Naru2021). As a result, there is always a thin air layer between the drop and the film. Our continuum-based simulations are thus not sufficient to predict the coalescence of interfaces (Chubynsky et al. Reference Chubynsky, Belousov, Lockerby and Sprittles2020), and we obtain the bounds of the non-coalescence regime, which sets the maximal Weber number probed in our simulations, from experiments (see Appendix A for details).

$\varPsi _a = 1 - \varPsi _1 - \varPsi _2$), ensures that the two tracers never overlap (Ramírez-Soto et al. Reference Ramírez-Soto, Sanjay, Lohse, Pham and Vollmer2020; Naru Reference Naru2021). As a result, there is always a thin air layer between the drop and the film. Our continuum-based simulations are thus not sufficient to predict the coalescence of interfaces (Chubynsky et al. Reference Chubynsky, Belousov, Lockerby and Sprittles2020), and we obtain the bounds of the non-coalescence regime, which sets the maximal Weber number probed in our simulations, from experiments (see Appendix A for details).

We use adaptive mesh refinement to resolve the length scales pertinent to capture the bouncing process, i.e. the flow inside the drop and the liquid coating. The adaption is based on minimizing the error estimated using the wavelet algorithm (Popinet Reference Popinet2015) in the VoF tracers, interfacial curvatures, velocity field, vorticity field and rate of viscous dissipation with tolerances ![]() $10^{-3}$,

$10^{-3}$, ![]() $10^{-4}$,

$10^{-4}$, ![]() $10^{-2}$,

$10^{-2}$, ![]() $10^{-2}$ and

$10^{-2}$ and ![]() $10^{-3}$, respectively (Sanjay Reference Sanjay2022). We ensure that at least

$10^{-3}$, respectively (Sanjay Reference Sanjay2022). We ensure that at least ![]() $15$–

$15$–![]() $20$ grid cells are present across the minimum liquid film thickness (

$20$ grid cells are present across the minimum liquid film thickness (![]() $\varGamma = h_f/R = 0.01$) studied in this work to resolve the velocity gradients in the film (Josserand, Ray & Zaleski Reference Josserand, Ray and Zaleski2016; Ling et al. Reference Ling, Fuster, Zaleski and Tryggvason2017). The minimum thickness of the air layer is of the order of the minimum grid size

$\varGamma = h_f/R = 0.01$) studied in this work to resolve the velocity gradients in the film (Josserand, Ray & Zaleski Reference Josserand, Ray and Zaleski2016; Ling et al. Reference Ling, Fuster, Zaleski and Tryggvason2017). The minimum thickness of the air layer is of the order of the minimum grid size ![]() $\varDelta = R/2048$. We further note that the thickness can be larger than this minimum owing to flow characteristics. For example, the shear stress balance across an interface with a high viscosity ratio delays the drainage of the air layer (Zhang, Ni & Magnaudet Reference Zhang, Ni and Magnaudet2021a).

$\varDelta = R/2048$. We further note that the thickness can be larger than this minimum owing to flow characteristics. For example, the shear stress balance across an interface with a high viscosity ratio delays the drainage of the air layer (Zhang, Ni & Magnaudet Reference Zhang, Ni and Magnaudet2021a).

For an incompressible flow, the mass conservation requires the velocity field to be divergence-free:

Furthermore, the momentum conservation reads (where tildes denote dimensionless quantities)

where the coordinate dimensions, velocity field ![]() $\boldsymbol {v}$ and pressure

$\boldsymbol {v}$ and pressure ![]() $p$ are normalized using the drop radius

$p$ are normalized using the drop radius ![]() $R$, inertio-capillary velocity scale

$R$, inertio-capillary velocity scale ![]() $v_\gamma = \sqrt {\gamma /\rho _d R}$, and capillary pressure

$v_\gamma = \sqrt {\gamma /\rho _d R}$, and capillary pressure ![]() $p_\gamma = \gamma /R$, respectively. The bracketed term on the left-hand side of (2.3) is the material derivative. On the right-hand side,

$p_\gamma = \gamma /R$, respectively. The bracketed term on the left-hand side of (2.3) is the material derivative. On the right-hand side, ![]() $\hat {\boldsymbol {e}}_{\boldsymbol {\mathcal {Z}}}$ is a unit vector in the vertically upward direction (see figure 1b), and the deformation tensor

$\hat {\boldsymbol {e}}_{\boldsymbol {\mathcal {Z}}}$ is a unit vector in the vertically upward direction (see figure 1b), and the deformation tensor ![]() $\tilde {\boldsymbol {\mathcal {D}}}$ is the symmetric part of the velocity gradient tensor (

$\tilde {\boldsymbol {\mathcal {D}}}$ is the symmetric part of the velocity gradient tensor (![]() $\tilde {\boldsymbol {\mathcal {D}}} = (\tilde {\boldsymbol {\nabla }}\tilde {\boldsymbol {v}} + (\tilde {\boldsymbol {\nabla }}\tilde {\boldsymbol {v}})^{\text {T}})/2$). Further, we employ the one-fluid approximation (Tryggvason et al. Reference Tryggvason, Scardovelli and Zaleski2011) to solve these equations, whereby the material properties (such as dimensionless density

$\tilde {\boldsymbol {\mathcal {D}}} = (\tilde {\boldsymbol {\nabla }}\tilde {\boldsymbol {v}} + (\tilde {\boldsymbol {\nabla }}\tilde {\boldsymbol {v}})^{\text {T}})/2$). Further, we employ the one-fluid approximation (Tryggvason et al. Reference Tryggvason, Scardovelli and Zaleski2011) to solve these equations, whereby the material properties (such as dimensionless density ![]() $\tilde {\rho } = \rho /\rho _d$ and dimensionless viscosity

$\tilde {\rho } = \rho /\rho _d$ and dimensionless viscosity ![]() $\mathit {Oh}$) change depending on which fluid is present at a given spatial location:

$\mathit {Oh}$) change depending on which fluid is present at a given spatial location:

where the Ohnesorge number ![]() $\mathit {Oh}$ is the ratio between the inertio-capillary and visco-capillary time scales. It is defined for all three phases, namely, the drop, the film and the air (ambient):

$\mathit {Oh}$ is the ratio between the inertio-capillary and visco-capillary time scales. It is defined for all three phases, namely, the drop, the film and the air (ambient):

and

respectively. Here, ![]() $\eta _d$,

$\eta _d$, ![]() $\eta _f$ and

$\eta _f$ and ![]() $\eta _a$ are the viscosity of the drop, film and air (ambient), respectively. Furthermore,

$\eta _a$ are the viscosity of the drop, film and air (ambient), respectively. Furthermore, ![]() $\rho _f/\rho _d$ and

$\rho _f/\rho _d$ and ![]() $\rho _a/\rho _d$ are the film–drop and air–drop density ratios. For simplification, we use

$\rho _a/\rho _d$ are the film–drop and air–drop density ratios. For simplification, we use ![]() $\rho _f/\rho _d = 1$ (see also table 1). In order to keep the surrounding medium as air,

$\rho _f/\rho _d = 1$ (see also table 1). In order to keep the surrounding medium as air, ![]() $\rho _a/\rho _d$ and

$\rho _a/\rho _d$ and ![]() $\mathit {Oh}_a$ are fixed at

$\mathit {Oh}_a$ are fixed at ![]() $10^{-3}$ and

$10^{-3}$ and ![]() $10^{-5}$, respectively. We also fix the Bond number (ratio of the gravitational to the capillary pressure), given by

$10^{-5}$, respectively. We also fix the Bond number (ratio of the gravitational to the capillary pressure), given by

at ![]() $0.5$ during this study. The initial condition (figure 1b) is given by the normalized impact velocity

$0.5$ during this study. The initial condition (figure 1b) is given by the normalized impact velocity ![]() $\tilde {V} = \sqrt {\mathit {We}_{d}}$.

$\tilde {V} = \sqrt {\mathit {We}_{d}}$.

Finally, a singular body force ![]() $\tilde {\boldsymbol {f}}_\gamma$ is applied at the interfaces to respect the dynamic boundary condition across them. The approximate forms of these forces follow from Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992), Prosperetti & Tryggvason (Reference Prosperetti and Tryggvason2009) and Tryggvason et al. (Reference Tryggvason, Scardovelli and Zaleski2011) as

$\tilde {\boldsymbol {f}}_\gamma$ is applied at the interfaces to respect the dynamic boundary condition across them. The approximate forms of these forces follow from Brackbill, Kothe & Zemach (Reference Brackbill, Kothe and Zemach1992), Prosperetti & Tryggvason (Reference Prosperetti and Tryggvason2009) and Tryggvason et al. (Reference Tryggvason, Scardovelli and Zaleski2011) as

Here, ![]() $\kappa _1$ and

$\kappa _1$ and ![]() $\kappa _2$ are the curvatures associated with

$\kappa _2$ are the curvatures associated with ![]() $\varPsi _1$ and

$\varPsi _1$ and ![]() $\varPsi _2$, respectively, calculated using the height function method. During the simulations, the maximum time step needs to be set less than the oscillation period of the smallest wavelength capillary wave as the surface tension scheme is explicit in time (Popinet Reference Popinet2009; Popinet & Collaborators Reference Popinet2013–2022b).

$\varPsi _2$, respectively, calculated using the height function method. During the simulations, the maximum time step needs to be set less than the oscillation period of the smallest wavelength capillary wave as the surface tension scheme is explicit in time (Popinet Reference Popinet2009; Popinet & Collaborators Reference Popinet2013–2022b).

Figure 1(b) represents the axisymmetric computational domain. A tangential stress-free and non-penetrable boundary condition is applied on each of the domain boundaries. The pressure gradient is also set to zero at these boundaries. Furthermore, the domain boundaries are chosen to be far enough not to influence the drop impact process. When ![]() $\mathit {Oh}_{f} > 0.1$ and waves on the film are damped, we choose

$\mathit {Oh}_{f} > 0.1$ and waves on the film are damped, we choose ![]() $\mathcal {L}_{{max}} = 8R$. The cases with low

$\mathcal {L}_{{max}} = 8R$. The cases with low ![]() $\mathit {Oh}_{f}$ require extra attention due to the train of surface waves formed post-impact, as these waves can reflect back from the side-walls (here, we choose

$\mathit {Oh}_{f}$ require extra attention due to the train of surface waves formed post-impact, as these waves can reflect back from the side-walls (here, we choose ![]() $\mathcal {L}_{{max}} \gg 8R$).

$\mathcal {L}_{{max}} \gg 8R$).

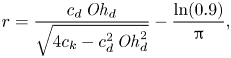

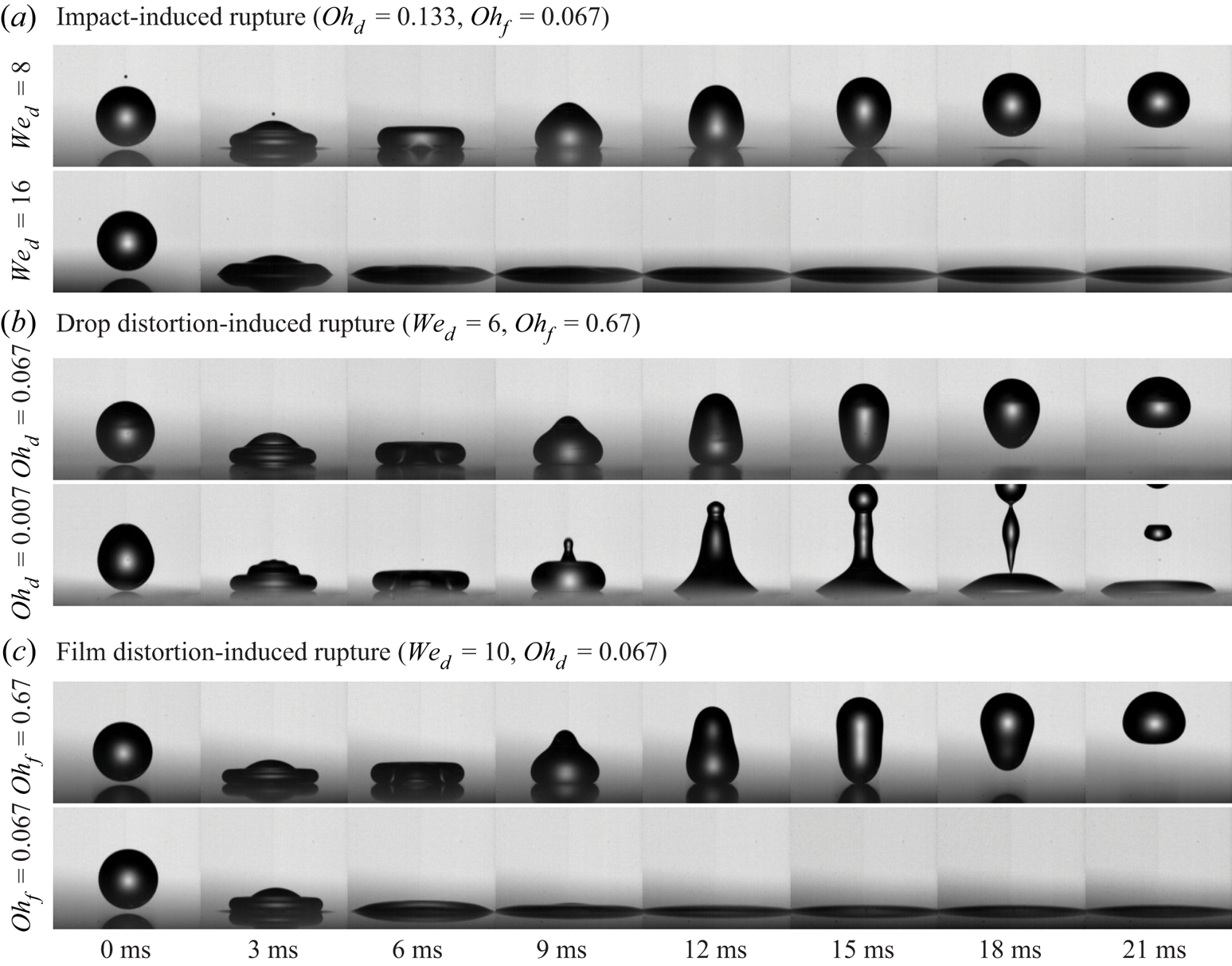

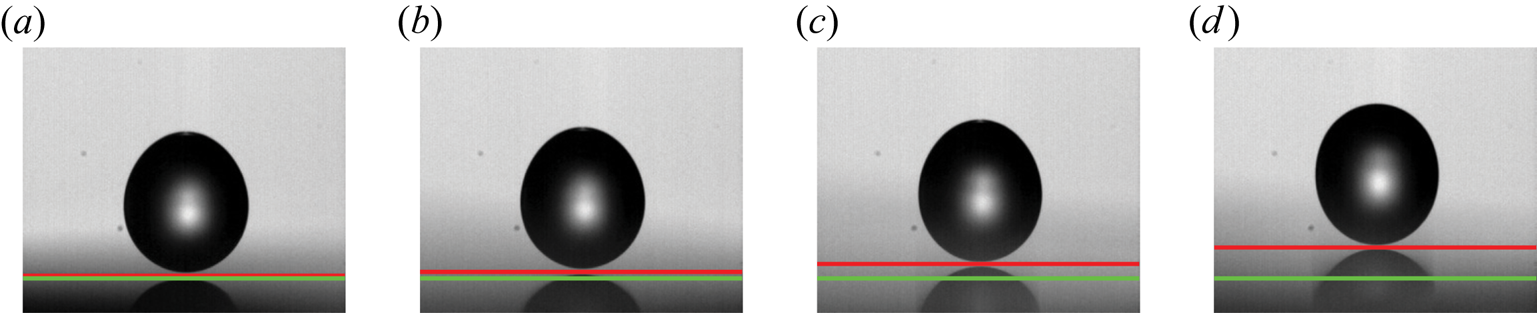

3. Phenomenology of the impact events

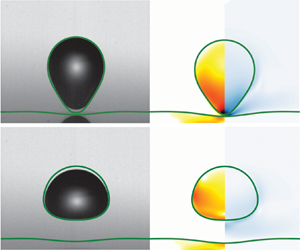

In figure 2, we compare the behaviour of a typical silicone oil drop (![]() $R = 1.0\ {\rm mm}$,

$R = 1.0\ {\rm mm}$, ![]() $V = 0.35\ {\rm m}\ {\rm s}^{-1}$ and

$V = 0.35\ {\rm m}\ {\rm s}^{-1}$ and ![]() $\eta _d = 4.6\ {\rm mPa}\ {\rm s}$, i.e.

$\eta _d = 4.6\ {\rm mPa}\ {\rm s}$, i.e. ![]() $(\mathit {We}_{d}, \mathit {Oh}_{d}, \mathit {Bo}_{d}) = (4, 0.034, 0.5)$) impacting on films with fixed viscosity

$(\mathit {We}_{d}, \mathit {Oh}_{d}, \mathit {Bo}_{d}) = (4, 0.034, 0.5)$) impacting on films with fixed viscosity ![]() $\eta _f = 96\ {\rm mPa}\ {\rm s}$ (

$\eta _f = 96\ {\rm mPa}\ {\rm s}$ (![]() $\mathit {Oh}_{f} = 0.67$) but contrasting thicknesses:

$\mathit {Oh}_{f} = 0.67$) but contrasting thicknesses: ![]() $h_{f} = 0.01$,

$h_{f} = 0.01$, ![]() $0.35$ and

$0.35$ and ![]() $0.85\ {\rm mm}$ (i.e.

$0.85\ {\rm mm}$ (i.e. ![]() $\varGamma = 0.01$,

$\varGamma = 0.01$, ![]() $0.35$ and

$0.35$ and ![]() $0.85$, respectively). We show a one-to-one comparison between experimental and DNS snapshots, and display three key pieces of information: the position of the liquid–air interfaces (green lines) that can be compared directly with experiments, the rate of viscous dissipation per unit volume (left-hand part of each numerical snapshot), and the magnitude of the velocity field (right-hand part of each numerical snapshot).

$0.85$, respectively). We show a one-to-one comparison between experimental and DNS snapshots, and display three key pieces of information: the position of the liquid–air interfaces (green lines) that can be compared directly with experiments, the rate of viscous dissipation per unit volume (left-hand part of each numerical snapshot), and the magnitude of the velocity field (right-hand part of each numerical snapshot).

Figure 2. Effect of the film thickness on the drop impact process: comparison of the experimental and DNS snapshots of the impact process on films with differing ![]() $h_f$ values (a)

$h_f$ values (a) ![]() $0.01\ {\rm mm}$, (b)

$0.01\ {\rm mm}$, (b) ![]() $0.35\ {\rm mm}$, and (c)

$0.35\ {\rm mm}$, and (c) ![]() $0.85\ {\rm mm}$. In each panel, the top row contains the experimental images with (green) interface outline from DNS, and the bottom row contains numerical snapshots showing the dimensionless rate of viscous dissipation per unit volume (

$0.85\ {\rm mm}$. In each panel, the top row contains the experimental images with (green) interface outline from DNS, and the bottom row contains numerical snapshots showing the dimensionless rate of viscous dissipation per unit volume (![]() $\tilde {\xi }_\eta = 2\,\mathit {Oh}\,(\tilde {\boldsymbol {\mathcal {D}}}:\tilde {\boldsymbol {\mathcal {D}}})$) on the left and the magnitude of the dimensionless velocity field (

$\tilde {\xi }_\eta = 2\,\mathit {Oh}\,(\tilde {\boldsymbol {\mathcal {D}}}:\tilde {\boldsymbol {\mathcal {D}}})$) on the left and the magnitude of the dimensionless velocity field (![]() $\tilde {\boldsymbol {v}}$) on the right. We show

$\tilde {\boldsymbol {v}}$) on the right. We show ![]() $\tilde {\xi }_\eta$ on a

$\tilde {\xi }_\eta$ on a ![]() $\log _{{10}}$ scale to identify regions of maximum dissipation (marked with black for

$\log _{{10}}$ scale to identify regions of maximum dissipation (marked with black for ![]() $\tilde {\xi }_\eta \geqslant 10$). For all cases in this figure,

$\tilde {\xi }_\eta \geqslant 10$). For all cases in this figure, ![]() $R = 1\ {\rm mm}$,

$R = 1\ {\rm mm}$, ![]() $V = 0.3\ {\rm m}\ {\rm s}^{-1}$,

$V = 0.3\ {\rm m}\ {\rm s}^{-1}$, ![]() $\eta _{d} = 4.6\ {\rm mPa}\ {\rm s}$ and

$\eta _{d} = 4.6\ {\rm mPa}\ {\rm s}$ and ![]() $\eta _{f} = 96\ {\rm mPa}\ {\rm s}$, corresponding to

$\eta _{f} = 96\ {\rm mPa}\ {\rm s}$, corresponding to ![]() $(\mathit {We}_{d}, \mathit {Oh}_{d}, \mathit {Oh}_{f}) = (4, 0.034, 0.67)$. Supplementary movies 1–3 are available at https://doi.org/10.1017/jfm.2023.13.

$(\mathit {We}_{d}, \mathit {Oh}_{d}, \mathit {Oh}_{f}) = (4, 0.034, 0.67)$. Supplementary movies 1–3 are available at https://doi.org/10.1017/jfm.2023.13.

For the thinnest film (![]() $h_f = 0.01\ {\rm mm}$, figure 2(a) and supplementary movie 1), the drop deforms as it comes into apparent contact with the film mediated by the air layer, an instant that we choose as the origin of time

$h_f = 0.01\ {\rm mm}$, figure 2(a) and supplementary movie 1), the drop deforms as it comes into apparent contact with the film mediated by the air layer, an instant that we choose as the origin of time ![]() $t = 0$. The drop spreads until it reaches its maximal lateral extent, recoils, and rebounds in an elongated shape after a time

$t = 0$. The drop spreads until it reaches its maximal lateral extent, recoils, and rebounds in an elongated shape after a time ![]() $t_c = 15.6 \pm 0.1\ {\rm ms}$, called the contact time. Throughout the impact process, viscous stresses inside the drop dissipate energy (see times

$t_c = 15.6 \pm 0.1\ {\rm ms}$, called the contact time. Throughout the impact process, viscous stresses inside the drop dissipate energy (see times ![]() $t = 1.5$ and 7.5 ms). Consequently, after take-off, the drop reaches a maximal centre of mass height

$t = 1.5$ and 7.5 ms). Consequently, after take-off, the drop reaches a maximal centre of mass height ![]() $H = 2.0 \pm 0.1\ {\rm mm}$ relative to the undisturbed film surface, from which we deduce the restitution coefficient defined as

$H = 2.0 \pm 0.1\ {\rm mm}$ relative to the undisturbed film surface, from which we deduce the restitution coefficient defined as ![]() $\varepsilon = \sqrt {2g(H-R)}/V$; here,

$\varepsilon = \sqrt {2g(H-R)}/V$; here, ![]() $\varepsilon = 0.48\pm 0.05$. The liquid–air interface profiles obtained from experiments and numerics are in excellent agreement, and we measure the same values of the contact time and restitution coefficient in simulations, using the method described in Appendix E. This behaviour is in quantitative agreement with that reported for the impact of a viscous drop on a superhydrophobic surface by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020), suggesting that the presence of both the air and liquid film has a negligible influence on the macroscopic dynamics of the rebound, and that viscous dissipation in the drop determines the rebound height.

$\varepsilon = 0.48\pm 0.05$. The liquid–air interface profiles obtained from experiments and numerics are in excellent agreement, and we measure the same values of the contact time and restitution coefficient in simulations, using the method described in Appendix E. This behaviour is in quantitative agreement with that reported for the impact of a viscous drop on a superhydrophobic surface by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020), suggesting that the presence of both the air and liquid film has a negligible influence on the macroscopic dynamics of the rebound, and that viscous dissipation in the drop determines the rebound height.

For ![]() $h_f = 0.35\ {\rm mm}$ (figure 2(b) and supplementary movie 2), despite the noticeable deformation of the liquid film, the qualitative features of the bounce are similar. We further observe that as the drop takes off, the film free surface has not yet recovered its undisturbed position. We measure an increase of the contact time to

$h_f = 0.35\ {\rm mm}$ (figure 2(b) and supplementary movie 2), despite the noticeable deformation of the liquid film, the qualitative features of the bounce are similar. We further observe that as the drop takes off, the film free surface has not yet recovered its undisturbed position. We measure an increase of the contact time to ![]() $t_c = 17 \pm 0.1\ {\rm ms}$, and a decrease in the rebound elasticity, with

$t_c = 17 \pm 0.1\ {\rm ms}$, and a decrease in the rebound elasticity, with ![]() $H = 1.6 \pm 0.1\ {\rm mm}$ implying

$H = 1.6 \pm 0.1\ {\rm mm}$ implying ![]() $\varepsilon = 0.37 \pm 0.04$. The DNS snapshots show that in this case, viscous dissipation occurs in both the drop and the underlying liquid. Qualitatively, the instantaneous rate of viscous dissipation in the drop is similar for

$\varepsilon = 0.37 \pm 0.04$. The DNS snapshots show that in this case, viscous dissipation occurs in both the drop and the underlying liquid. Qualitatively, the instantaneous rate of viscous dissipation in the drop is similar for ![]() $h_f = 0.01\ {\rm mm}$ and

$h_f = 0.01\ {\rm mm}$ and ![]() $h_f = 0.35\ {\rm mm}$, suggesting that the decrease in rebound elasticity is linked primarily to the increased film dissipation.

$h_f = 0.35\ {\rm mm}$, suggesting that the decrease in rebound elasticity is linked primarily to the increased film dissipation.

Finally, for ![]() $h_f = 0.85\ {\rm mm}$ (figure 2(c) and supplementary movie 3), the film deformation increases and the substrate loses its repellent ability. The drop centre of mass does not take off above

$h_f = 0.85\ {\rm mm}$ (figure 2(c) and supplementary movie 3), the film deformation increases and the substrate loses its repellent ability. The drop centre of mass does not take off above ![]() $H=R$; the drop floats on top of the liquid film, a situation that corresponds to the inhibition of bouncing for which

$H=R$; the drop floats on top of the liquid film, a situation that corresponds to the inhibition of bouncing for which ![]() $\varepsilon \approx 0$, and the contact time diverges. In this case, we notice that the experimental and numerical interface profiles differ at

$\varepsilon \approx 0$, and the contact time diverges. In this case, we notice that the experimental and numerical interface profiles differ at ![]() $t= 0\ {\rm ms}$. This initial discrepancy, caused by drop oscillations upon detachment from the needle, does not affect the subsequent impact dynamics and the impact outcome, as evidenced by the good agreement of the interface profiles at later instants.

$t= 0\ {\rm ms}$. This initial discrepancy, caused by drop oscillations upon detachment from the needle, does not affect the subsequent impact dynamics and the impact outcome, as evidenced by the good agreement of the interface profiles at later instants.

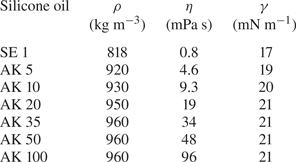

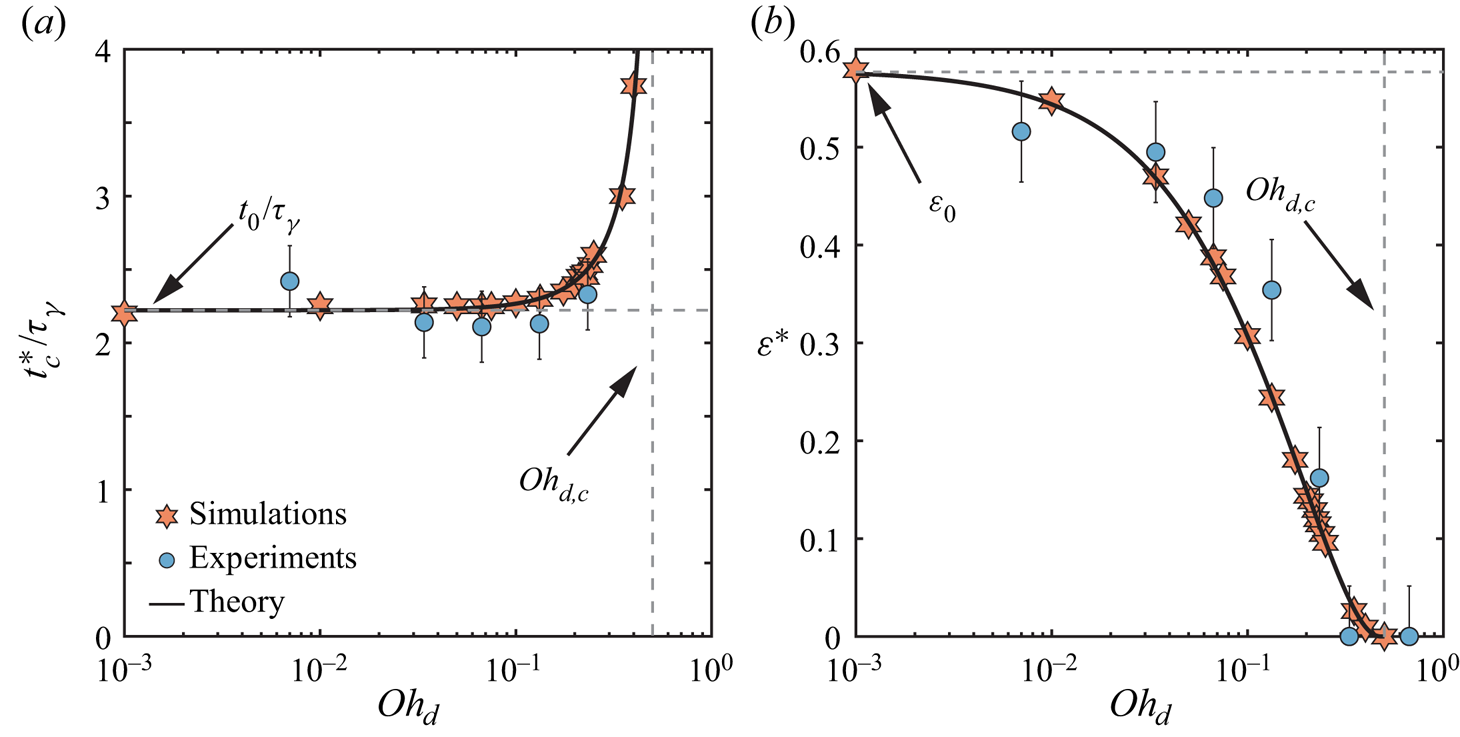

We now vary systematically the film thickness ![]() $h_{f}$ while keeping the drop and film viscosities constant (

$h_{f}$ while keeping the drop and film viscosities constant (![]() $\eta _d = 4.6\ {\rm mPa}\ {\rm s}$ and

$\eta _d = 4.6\ {\rm mPa}\ {\rm s}$ and ![]() $\eta _f = 96\ {\rm mPa} {\rm s}$), and plot in figures 3(a) and 3(b) the contact time

$\eta _f = 96\ {\rm mPa} {\rm s}$), and plot in figures 3(a) and 3(b) the contact time ![]() $t_c$ and the coefficient of restitution

$t_c$ and the coefficient of restitution ![]() $\varepsilon$ extracted from experiments (circles) and DNS (hexagrams). Experiments and simulations are in excellent agreement when varying the film thickness by two orders of magnitude,

$\varepsilon$ extracted from experiments (circles) and DNS (hexagrams). Experiments and simulations are in excellent agreement when varying the film thickness by two orders of magnitude, ![]() $h_{f} = 0.01\unicode{x2013}1\ {\rm mm}$. The existence of two regimes is readily apparent.

$h_{f} = 0.01\unicode{x2013}1\ {\rm mm}$. The existence of two regimes is readily apparent.

Figure 3. Effect of the film thickness on the rebound characteristics for ![]() $R = 1\ {\rm mm}$,

$R = 1\ {\rm mm}$, ![]() $V = 0.3\ {\rm m}\ {\rm s}^{-1}$,

$V = 0.3\ {\rm m}\ {\rm s}^{-1}$, ![]() $\eta _{d} = 4.6\ {\rm mPa}\ {\rm s}$ and

$\eta _{d} = 4.6\ {\rm mPa}\ {\rm s}$ and ![]() $\eta _{f} = 96\ {\rm mPa}\ {\rm s}$, i.e.

$\eta _{f} = 96\ {\rm mPa}\ {\rm s}$, i.e. ![]() $(\mathit {We}_{d}, \mathit {Oh}_{d}, \mathit {Oh}_{f}) = (4, 0.034, 0.67)$: (a) contact time

$(\mathit {We}_{d}, \mathit {Oh}_{d}, \mathit {Oh}_{f}) = (4, 0.034, 0.67)$: (a) contact time ![]() $t_{c}$, and (b) restitution coefficient

$t_{c}$, and (b) restitution coefficient ![]() $\varepsilon$, as a function of film thickness

$\varepsilon$, as a function of film thickness ![]() $h_{f}$. Circles and hexagrams represent experiments and DNS, respectively. In (a,b), the horizontal black dashed lines represent the substrate-independent limits of contact time and restitution coefficient, respectively, while the solid black lines show the results from the phenomenological model (see § 4) with parameters

$h_{f}$. Circles and hexagrams represent experiments and DNS, respectively. In (a,b), the horizontal black dashed lines represent the substrate-independent limits of contact time and restitution coefficient, respectively, while the solid black lines show the results from the phenomenological model (see § 4) with parameters ![]() $c_{k} = 2$,

$c_{k} = 2$, ![]() $c_{d} = 5.6$ and

$c_{d} = 5.6$ and ![]() $c_{f} = 0.46$. The vertical grey dashed line marks the transition from the bouncing to the non-bouncing (floating) regime. The inset of (b) illustrates the variation of the restitution coefficient normalized by its substrate-independent value

$c_{f} = 0.46$. The vertical grey dashed line marks the transition from the bouncing to the non-bouncing (floating) regime. The inset of (b) illustrates the variation of the restitution coefficient normalized by its substrate-independent value ![]() $\varepsilon ^*$ as a function of the film thickness. Here, the horizontal grey line represents

$\varepsilon ^*$ as a function of the film thickness. Here, the horizontal grey line represents ![]() $\varepsilon = 0.9\varepsilon ^*$, marking the transition from substrate-independent to substrate-dependent bouncing at

$\varepsilon = 0.9\varepsilon ^*$, marking the transition from substrate-independent to substrate-dependent bouncing at ![]() $h_f = h_{f, 1}$. (c) Schematic diagram of the phenomenological model that describes the drop impact process on a liquid film. The parameters

$h_f = h_{f, 1}$. (c) Schematic diagram of the phenomenological model that describes the drop impact process on a liquid film. The parameters ![]() $\rho _d R^{3}$,

$\rho _d R^{3}$, ![]() $\eta _{d}R$ and

$\eta _{d}R$ and ![]() $\gamma$ are associated with the drop properties, and

$\gamma$ are associated with the drop properties, and ![]() $\eta _{f} \varGamma ^{-3} R$ is associated with the film properties.

$\eta _{f} \varGamma ^{-3} R$ is associated with the film properties.

First, for ![]() $h_{f} \lesssim 0.1\ {\rm mm}$, both

$h_{f} \lesssim 0.1\ {\rm mm}$, both ![]() $t_{c}$ and

$t_{c}$ and ![]() $\varepsilon$ are independent of

$\varepsilon$ are independent of ![]() $h_f$. The value of the contact time in this regime,

$h_f$. The value of the contact time in this regime, ![]() $t_c = 15.6 \pm 0.5\ {\rm ms}$, corresponds to that expected from the inertio-capillary scaling (Wachters & Westerling Reference Wachters and Westerling1966; Richard et al. Reference Richard, Clanet and Quéré2002). The contact time is proportional to

$t_c = 15.6 \pm 0.5\ {\rm ms}$, corresponds to that expected from the inertio-capillary scaling (Wachters & Westerling Reference Wachters and Westerling1966; Richard et al. Reference Richard, Clanet and Quéré2002). The contact time is proportional to ![]() $\tau _\gamma = \sqrt {\rho _d R^3/ \gamma }$, with a prefactor

$\tau _\gamma = \sqrt {\rho _d R^3/ \gamma }$, with a prefactor ![]() $2.2 \pm 0.1$, in good agreement with that calculated by Rayleigh (Reference Rayleigh1879) for the fundamental mode of drop oscillation

$2.2 \pm 0.1$, in good agreement with that calculated by Rayleigh (Reference Rayleigh1879) for the fundamental mode of drop oscillation ![]() ${\rm \pi} /\sqrt 2$. Similarly, the plateau value of the coefficient of restitution

${\rm \pi} /\sqrt 2$. Similarly, the plateau value of the coefficient of restitution ![]() $\varepsilon = 0.47 \pm 0.04$ is in reasonable agreement with that reported for the impact of water drops on superhydrophobic substrates for a similar drop Ohnesorge number

$\varepsilon = 0.47 \pm 0.04$ is in reasonable agreement with that reported for the impact of water drops on superhydrophobic substrates for a similar drop Ohnesorge number ![]() $\mathit {Oh}_{d}$ and impact Weber number

$\mathit {Oh}_{d}$ and impact Weber number ![]() $\mathit {We}_{d}$ (Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020). We therefore refer to this regime as substrate-independent rebound (see also Appendix B).

$\mathit {We}_{d}$ (Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020). We therefore refer to this regime as substrate-independent rebound (see also Appendix B).

Second, for ![]() $h_{f} \gtrsim 0.1\ {\rm mm}$, the contact time and coefficient of restitution are influenced by the film thickness. We observe that

$h_{f} \gtrsim 0.1\ {\rm mm}$, the contact time and coefficient of restitution are influenced by the film thickness. We observe that ![]() $t_c$ increases (figure 3a) and

$t_c$ increases (figure 3a) and ![]() $\varepsilon$ decreases (figure 3b) with increasing

$\varepsilon$ decreases (figure 3b) with increasing ![]() $h_f$ until

$h_f$ until ![]() $t_c$ diverges and bouncing ceases (

$t_c$ diverges and bouncing ceases (![]() $\varepsilon = 0$) for

$\varepsilon = 0$) for ![]() $h_f \approx 0.75$ mm. This critical thickness marks the threshold of the rebound behaviour and the transition to the non-bouncing (floating) regime. Here, the rebound characteristics vary significantly with

$h_f \approx 0.75$ mm. This critical thickness marks the threshold of the rebound behaviour and the transition to the non-bouncing (floating) regime. Here, the rebound characteristics vary significantly with ![]() $h_f$ and we therefore refer to this regime as substrate-dependent.

$h_f$ and we therefore refer to this regime as substrate-dependent.

Finally, we characterize the transition from the substrate-independent to the substrate-dependent regime by introducing the thickness ![]() $h_{f,1}$ (in dimensionless form

$h_{f,1}$ (in dimensionless form ![]() $\varGamma _1 = h_{f,1}/R$) that marks the decrease of

$\varGamma _1 = h_{f,1}/R$) that marks the decrease of ![]() $\varepsilon$ to

$\varepsilon$ to ![]() $0.9$ times its plateau value

$0.9$ times its plateau value ![]() $\varepsilon ^*$. Similarly, we define the critical thickness

$\varepsilon ^*$. Similarly, we define the critical thickness ![]() $h_{f,2}$ (respectively,

$h_{f,2}$ (respectively, ![]() $\varGamma _2 = h_{f,2}/R$) associated with the transition from the substrate-dependent to the non-bouncing (floating) regime as the smallest film thickness that results in

$\varGamma _2 = h_{f,2}/R$) associated with the transition from the substrate-dependent to the non-bouncing (floating) regime as the smallest film thickness that results in ![]() $\varepsilon = 0$. The impact dynamics can be categorized into three distinct regimes: a substrate-independent regime for

$\varepsilon = 0$. The impact dynamics can be categorized into three distinct regimes: a substrate-independent regime for ![]() $\varGamma = h_{f}/R \leqslant \varGamma _1$, a substrate-dependent regime for

$\varGamma = h_{f}/R \leqslant \varGamma _1$, a substrate-dependent regime for ![]() $\varGamma _1 < \varGamma < \varGamma _2$, and a non-bouncing (floating) regime for

$\varGamma _1 < \varGamma < \varGamma _2$, and a non-bouncing (floating) regime for ![]() $\varGamma \geqslant \varGamma _2$.

$\varGamma \geqslant \varGamma _2$.

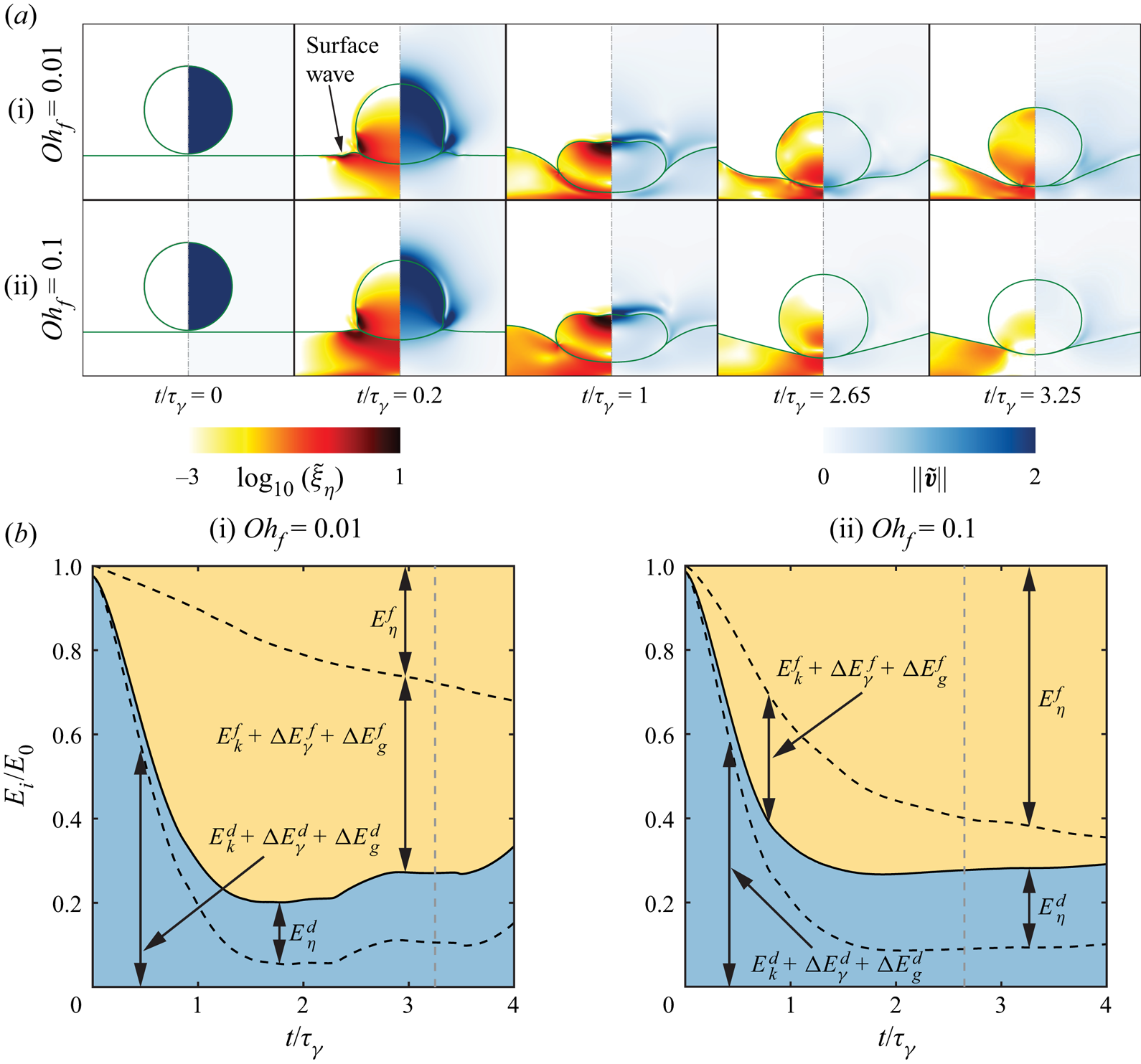

4. Phenomenological model

We now seek to rationalize the dependence of the rebound time and elasticity with the substrate and drop properties by constructing a minimal model, guided by our experimental and numerical observations. We build on the classical description of a drop as a liquid spring that reflects the balance of inertia and capillarity during a rebound (Richard et al. Reference Richard, Clanet and Quéré2002; Okumura et al. Reference Okumura, Chevy, Richard, Quéré and Clanet2003). Here, we consider viscous drops and further add a damping term to the liquid spring, an approach that has been shown to capture successfully the variation of contact time and coefficient of restitution across over two orders of magnitude variation in liquid viscosities (Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020). Similarly, we interpret the film behaviour through the liquid spring analogy. The film motion contrasts with that of the drop: while the latter displays a full cycle of oscillation during a rebound, the former never returns to its undisturbed position (see figure 2 and supplementary movies 1–3). This observation leads us to consider that the damping component dominates the behaviour of the liquid film, and to neglect the contributions of inertia and surface tension. We further discuss this assumption and its validity in § 6.

In figure 3(c), we present a sketch of the model, where we assume that the droplet and the film are connected in series during apparent contact, and show the scaling forms of the drop and film components. The scaling relations for the drop mass, stiffness and damping are taken from the work of Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020) as proportional to ![]() $\rho _d R^3$,

$\rho _d R^3$, ![]() $\gamma$ and

$\gamma$ and ![]() $\eta _d R$, respectively, with corresponding prefactors

$\eta _d R$, respectively, with corresponding prefactors ![]() $1$,

$1$, ![]() $c_k$ and

$c_k$ and ![]() $c_d$. We determine the values of

$c_d$. We determine the values of ![]() $c_k$ and

$c_k$ and ![]() $c_d$ from results in the substrate-independent bouncing regime (see Appendix B). The scaling form of the film damping term is chosen as proportional to

$c_d$ from results in the substrate-independent bouncing regime (see Appendix B). The scaling form of the film damping term is chosen as proportional to ![]() $\eta _{f} \varGamma ^{-3} R$, where

$\eta _{f} \varGamma ^{-3} R$, where ![]() $\varGamma = h_f/R$, with corresponding prefactor of

$\varGamma = h_f/R$, with corresponding prefactor of ![]() $c_{f}$ (figure 3c). This is built on two key assumptions. First, we assume that the viscous lubrication approximation holds in the film as, for sufficiently high film Ohnesorge numbers (

$c_{f}$ (figure 3c). This is built on two key assumptions. First, we assume that the viscous lubrication approximation holds in the film as, for sufficiently high film Ohnesorge numbers (![]() $\mathit {Oh}_{f} \gtrsim 0.1$), the slopes associated with the film deformations are small (

$\mathit {Oh}_{f} \gtrsim 0.1$), the slopes associated with the film deformations are small (![]() $\varGamma \ll 1$,

$\varGamma \ll 1$, ![]() $\mathit {Oh}_{f} \sim {O}(1)$; see § 6 for limitations). And second, we choose to consider the drop as an impacting disk rather than a sphere, owing to the rapid drop spreading upon impact (Eggers et al. Reference Eggers, Fontelos, Josserand and Zaleski2010; Wildeman et al. Reference Wildeman, Visser, Sun and Lohse2016), which results in a damping term proportional to

$\mathit {Oh}_{f} \sim {O}(1)$; see § 6 for limitations). And second, we choose to consider the drop as an impacting disk rather than a sphere, owing to the rapid drop spreading upon impact (Eggers et al. Reference Eggers, Fontelos, Josserand and Zaleski2010; Wildeman et al. Reference Wildeman, Visser, Sun and Lohse2016), which results in a damping term proportional to ![]() $\varGamma ^{-3}$ instead of

$\varGamma ^{-3}$ instead of ![]() $\varGamma ^{-1}$ (Leal Reference Leal2007). Finally, we fit the prefactor

$\varGamma ^{-1}$ (Leal Reference Leal2007). Finally, we fit the prefactor ![]() $c_f$ to our experiments and simulations.

$c_f$ to our experiments and simulations.

With these assumptions, the equations of motion for the model system (figure 3c) read

where ![]() $y$ and

$y$ and ![]() $x$ are the displacements of the drop and the film relative to their initial positions in the reference frame of the laboratory, and the dots denote time derivatives. We point out that by setting

$x$ are the displacements of the drop and the film relative to their initial positions in the reference frame of the laboratory, and the dots denote time derivatives. We point out that by setting ![]() $\dot {x} = x = 0$, we recover the model proposed by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020), which extends the analogy between the drop impact process and a spring–mass system (Okumura et al. Reference Okumura, Chevy, Richard, Quéré and Clanet2003) by adding a damper to account for viscous dissipation in the drop. Here, additionally, we consider viscous dissipation in the liquid coating and model the film as a damper without inertia. We make this modelling assumption, guided by the overdamped dynamics of the film (figure 2), to keep the number of free parameters to as few as possible (namely

$\dot {x} = x = 0$, we recover the model proposed by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020), which extends the analogy between the drop impact process and a spring–mass system (Okumura et al. Reference Okumura, Chevy, Richard, Quéré and Clanet2003) by adding a damper to account for viscous dissipation in the drop. Here, additionally, we consider viscous dissipation in the liquid coating and model the film as a damper without inertia. We make this modelling assumption, guided by the overdamped dynamics of the film (figure 2), to keep the number of free parameters to as few as possible (namely ![]() $c_k$,

$c_k$, ![]() $c_d$ and

$c_d$ and ![]() $c_f$). We stress here that

$c_f$). We stress here that ![]() $c_k$ and

$c_k$ and ![]() $c_d$ are fixed in this study, and that their values are in quantitative agreement with the corresponding prefactors derived by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020).

$c_d$ are fixed in this study, and that their values are in quantitative agreement with the corresponding prefactors derived by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020).

Similarly as for the governing equations in DNS, we make (4.1) and (4.2) dimensionless using the length scale ![]() $R$ and the time scale

$R$ and the time scale ![]() $\tau _{\gamma }$, and use tildes to identify dimensionless variables. Next, we obtain an equation of motion for the drop deformation

$\tau _{\gamma }$, and use tildes to identify dimensionless variables. Next, we obtain an equation of motion for the drop deformation ![]() $\tilde {z} = \tilde {y} - \tilde {x}$, namely

$\tilde {z} = \tilde {y} - \tilde {x}$, namely

which admits oscillatory solutions (i.e. drop rebound) under the condition

We note that ![]() $\omega ^2$ decreases with increasing

$\omega ^2$ decreases with increasing ![]() $\varGamma$ for fixed

$\varGamma$ for fixed ![]() $\mathit {Oh}_{d}$ and

$\mathit {Oh}_{d}$ and ![]() $\mathit {Oh}_{f}$, in qualitative agreement with the existence of a critical film height above which bouncing stops (figure 3b). Equation (4.4) allows us to determine the bounds of the bouncing regime in terms of a critical drop Ohnesorge number

$\mathit {Oh}_{f}$, in qualitative agreement with the existence of a critical film height above which bouncing stops (figure 3b). Equation (4.4) allows us to determine the bounds of the bouncing regime in terms of a critical drop Ohnesorge number ![]() $\mathit {Oh}_{d,c}$ and film thickness

$\mathit {Oh}_{d,c}$ and film thickness ![]() $\varGamma _2$. Discarding the two roots of the equation

$\varGamma _2$. Discarding the two roots of the equation ![]() $\omega ^2 = 0$ that yield unphysical negative values of

$\omega ^2 = 0$ that yield unphysical negative values of ![]() $\mathit {Oh}_{d,c}$ and

$\mathit {Oh}_{d,c}$ and ![]() $\varGamma _2$, we obtain

$\varGamma _2$, we obtain

and

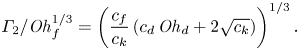

\begin{equation} \varGamma_2/\mathit{Oh}_{f}^{1/3} = \left(\frac{c_{f}}{c_{k}}\left( c_{d}\,\mathit{Oh}_{d} + 2 \sqrt{c_{k}} \right)\right)^{1/3}. \end{equation}

\begin{equation} \varGamma_2/\mathit{Oh}_{f}^{1/3} = \left(\frac{c_{f}}{c_{k}}\left( c_{d}\,\mathit{Oh}_{d} + 2 \sqrt{c_{k}} \right)\right)^{1/3}. \end{equation}

Equations (4.4)–(4.6) evidence that the role of the film viscosity and height are intertwined as we find the combination ![]() $\varGamma /\mathit {Oh}_{f}^{1/3}$ that can be inferred as the effective film thickness or mobility. Furthermore, the substrate-independent bouncing threshold is recovered when this film mobility,

$\varGamma /\mathit {Oh}_{f}^{1/3}$ that can be inferred as the effective film thickness or mobility. Furthermore, the substrate-independent bouncing threshold is recovered when this film mobility, ![]() $\varGamma /\mathit {Oh}_{f}^{1/3}$, tends to 0, that is, for very thin and/or very viscous films. Indeed, (4.5) and (4.6) become

$\varGamma /\mathit {Oh}_{f}^{1/3}$, tends to 0, that is, for very thin and/or very viscous films. Indeed, (4.5) and (4.6) become

and

\begin{equation} \varGamma_2/\mathit{Oh}_{f}^{1/3} = \left(2\,\frac{c_{f}}{\sqrt{c_{k}}}\right)^{1/3}, \end{equation}

\begin{equation} \varGamma_2/\mathit{Oh}_{f}^{1/3} = \left(2\,\frac{c_{f}}{\sqrt{c_{k}}}\right)^{1/3}, \end{equation}

for the limiting cases of substrate-independent (![]() $\varGamma /\mathit {Oh}_{f}^{1/3} \to 0$), and inviscid drop (

$\varGamma /\mathit {Oh}_{f}^{1/3} \to 0$), and inviscid drop (![]() $\mathit {Oh}_{d} \to 0$) asymptotes, respectively.

$\mathit {Oh}_{d} \to 0$) asymptotes, respectively.

To go further, we solve (4.3) with the initial conditions ![]() $\tilde {z} = 0$ and

$\tilde {z} = 0$ and ![]() $\dot {\tilde {z}} = \sqrt {\mathit {We}_{d}}$ at

$\dot {\tilde {z}} = \sqrt {\mathit {We}_{d}}$ at ![]() $\tilde {t} = 0$, yielding

$\tilde {t} = 0$, yielding

where

and

can be interpreted as an effective damper and angular frequency, respectively, by comparing the above expression (4.9) to the one obtained by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020) for ![]() $\varGamma /\mathit {Oh}_{f}^{1/3} \to 0$. We can deduce the expressions for both the contact time and the coefficient of restitution using these pieces of information. The contact time is taken as the instant at which the drop deformation

$\varGamma /\mathit {Oh}_{f}^{1/3} \to 0$. We can deduce the expressions for both the contact time and the coefficient of restitution using these pieces of information. The contact time is taken as the instant at which the drop deformation ![]() $\tilde {z}$ comes back to zero, which occurs at

$\tilde {z}$ comes back to zero, which occurs at ![]() $\varOmega \tilde {t} = 2{\rm \pi}$, giving

$\varOmega \tilde {t} = 2{\rm \pi}$, giving

Equation (4.12) is then used to compute the coefficient of restitution ![]() $\varepsilon$ as the ratio of the rebound velocity

$\varepsilon$ as the ratio of the rebound velocity ![]() $\dot {\tilde {z}}(\tilde {t}_c)$ to the impact velocity

$\dot {\tilde {z}}(\tilde {t}_c)$ to the impact velocity ![]() $\sqrt {\mathit {We}_{d}}$. We notice immediately that this definition yields an expression for

$\sqrt {\mathit {We}_{d}}$. We notice immediately that this definition yields an expression for ![]() $\varepsilon$ that does not depend on

$\varepsilon$ that does not depend on ![]() $\mathit {We}_{d}$, in contrast with the experimentally observed decrease of

$\mathit {We}_{d}$, in contrast with the experimentally observed decrease of ![]() $\varepsilon$ with

$\varepsilon$ with ![]() $\mathit {We}_{d}$. We account for the Weber number dependence of

$\mathit {We}_{d}$. We account for the Weber number dependence of ![]() $\varepsilon$, which is not captured by spring–mass models (Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020), by scaling the coefficient of restitution by

$\varepsilon$, which is not captured by spring–mass models (Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020), by scaling the coefficient of restitution by ![]() $\varepsilon _0(\mathit {We}_{d})$, its

$\varepsilon _0(\mathit {We}_{d})$, its ![]() $\mathit {We}_{d}$-dependent value in the substrate-independent limit for inviscid drops:

$\mathit {We}_{d}$-dependent value in the substrate-independent limit for inviscid drops:

where the prefactor ![]() $\varepsilon _0(\mathit {We}_{d})$ is not a model prediction. We obtain the other prefactors,

$\varepsilon _0(\mathit {We}_{d})$ is not a model prediction. We obtain the other prefactors, ![]() $c_k$ and

$c_k$ and ![]() $c_d$, by fitting the substrate-independent experiments following Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020). This simplification allows us to recover the expressions for

$c_d$, by fitting the substrate-independent experiments following Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020). This simplification allows us to recover the expressions for ![]() $t_c$ and

$t_c$ and ![]() $\varepsilon$ for viscous drop impact on non-wetting substrates (Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020), and thus to determine

$\varepsilon$ for viscous drop impact on non-wetting substrates (Jha et al. Reference Jha, Chantelot, Clanet and Quéré2020), and thus to determine ![]() $c_k = 2$ and

$c_k = 2$ and ![]() $c_d = 5.6$, which we keep fixed during this study. For details of this simplification and on the determination of the prefactors, see Appendix B.

$c_d = 5.6$, which we keep fixed during this study. For details of this simplification and on the determination of the prefactors, see Appendix B.

We test the model predictions for the contact time and rebound elasticity in the substrate-dependent regime by comparing the data (symbols) presented in figures 3(a) and 3(b) to least squares fits of (4.12) and (4.13), with ![]() $c_f$ as a free parameter (solid lines), and taking

$c_f$ as a free parameter (solid lines), and taking ![]() $\varepsilon _0 = 0.58$ (see Appendix B). We find that the model predicts accurately the variation of

$\varepsilon _0 = 0.58$ (see Appendix B). We find that the model predicts accurately the variation of ![]() $t_c$ and

$t_c$ and ![]() $\varepsilon$ with

$\varepsilon$ with ![]() $\varGamma$ for

$\varGamma$ for ![]() $c_f = 0.46 \pm 0.1$. For the rest of this work, we fix

$c_f = 0.46 \pm 0.1$. For the rest of this work, we fix ![]() $c_f = 0.46$ and assess the predictive ability of the simplified model.

$c_f = 0.46$ and assess the predictive ability of the simplified model.

5. Influence of drop and film parameters

We now test the model predictions and limits by varying experimentally and numerically the drop and film Ohnesorge numbers. We give particular attention to the value of the coefficient ![]() $c_f$ (fixed at

$c_f$ (fixed at ![]() $0.46$) necessary to fit the model to these data, and to the two asymptotes predicted by the model that bound the bouncing domain (4.7)–(4.8).

$0.46$) necessary to fit the model to these data, and to the two asymptotes predicted by the model that bound the bouncing domain (4.7)–(4.8).

5.1. Influence of the film Ohnesorge number  $\mathit {Oh}_{f}$

$\mathit {Oh}_{f}$

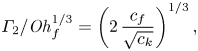

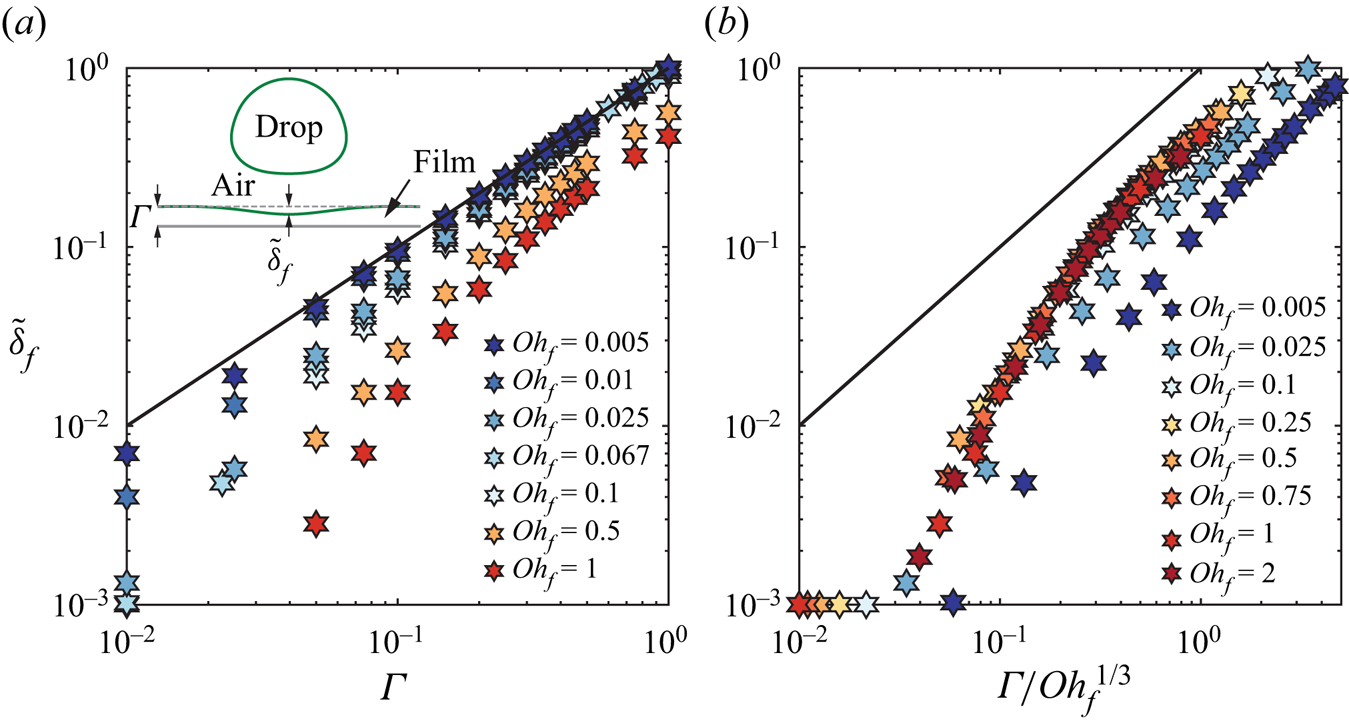

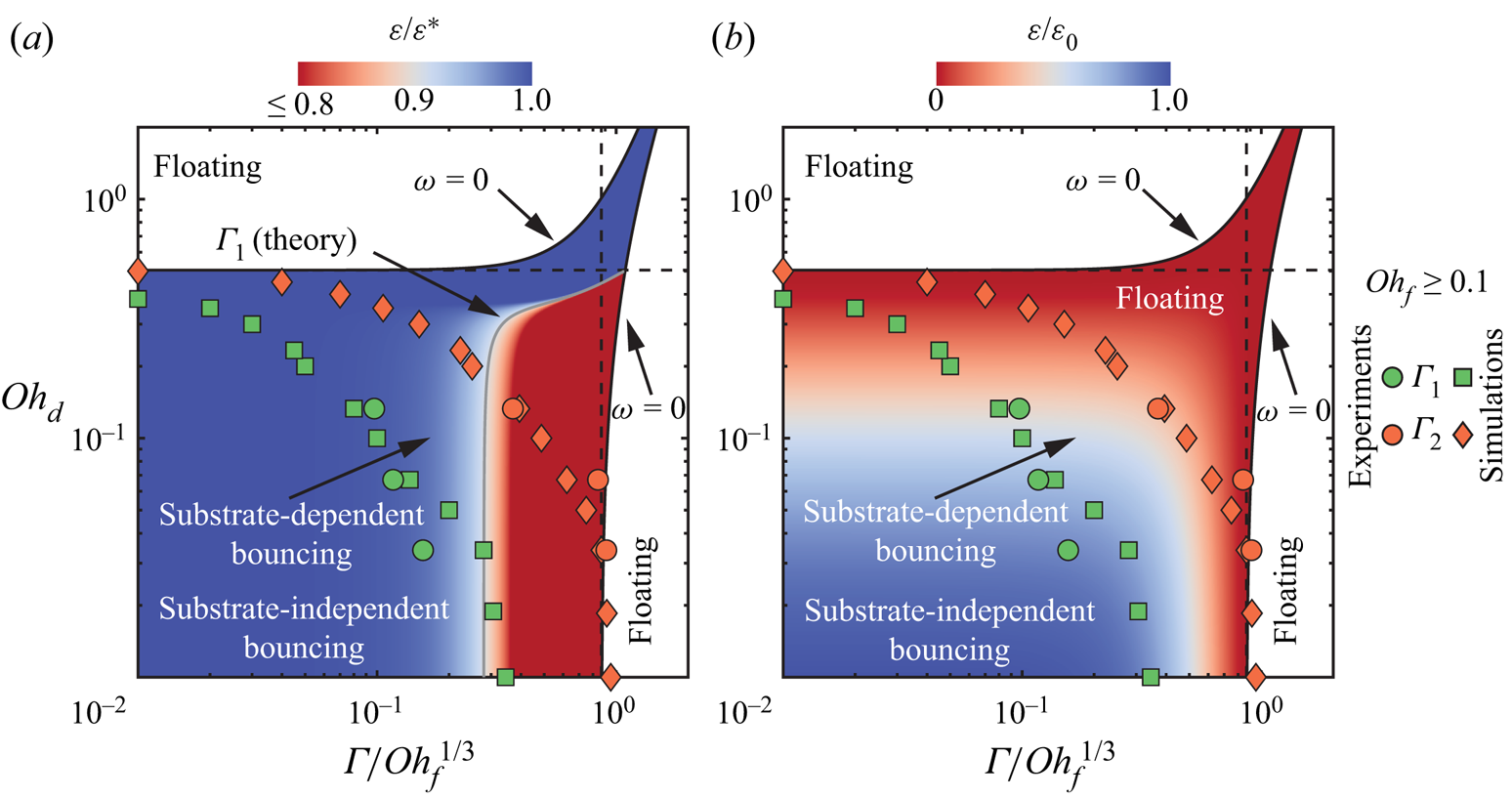

We first vary the film Ohnesorge number ![]() $\mathit {Oh}_{f}$ while keeping the drop and impact properties constant. In figure 4(a), we show the evolution of the coefficient of restitution

$\mathit {Oh}_{f}$ while keeping the drop and impact properties constant. In figure 4(a), we show the evolution of the coefficient of restitution ![]() $\varepsilon$ for drops with

$\varepsilon$ for drops with ![]() $\mathit {Oh}_{d} = 0.034$ as a function of the dimensionless film thickness

$\mathit {Oh}_{d} = 0.034$ as a function of the dimensionless film thickness ![]() $\varGamma$, while exploring two decades in film viscosity,

$\varGamma$, while exploring two decades in film viscosity, ![]() $\mathit {Oh}_{f} = 0.01 \unicode{x2013} 2.0$. On the one hand, as expected, the values of the coefficient of restitution are not affected in the substrate-independent limit. On the other hand, the substrate-dependent behaviour shows the influence of

$\mathit {Oh}_{f} = 0.01 \unicode{x2013} 2.0$. On the one hand, as expected, the values of the coefficient of restitution are not affected in the substrate-independent limit. On the other hand, the substrate-dependent behaviour shows the influence of ![]() $\mathit {Oh}_{f}$, and we identify two regimes. For

$\mathit {Oh}_{f}$, and we identify two regimes. For ![]() $\mathit {Oh}_{f} < 0.1$, the evolution of

$\mathit {Oh}_{f} < 0.1$, the evolution of ![]() $\varepsilon$ with

$\varepsilon$ with ![]() $\varGamma$ does not depend on

$\varGamma$ does not depend on ![]() $\mathit {Oh}_{f}$, as illustrated by the data collapse in figure 4(a). However, for

$\mathit {Oh}_{f}$, as illustrated by the data collapse in figure 4(a). However, for ![]() $\mathit {Oh}_{f} > 0.1$, increasing the film viscosity leads to a larger extent of the substrate-independent plateau and to an increase of the critical film thickness at which bouncing stops. This change in the

$\mathit {Oh}_{f} > 0.1$, increasing the film viscosity leads to a larger extent of the substrate-independent plateau and to an increase of the critical film thickness at which bouncing stops. This change in the ![]() $\mathit {Oh}_{f}$ dependence can be characterized by the two dimensionless critical film thicknesses

$\mathit {Oh}_{f}$ dependence can be characterized by the two dimensionless critical film thicknesses ![]() $\varGamma _1 = h_{f,1}/R$ and

$\varGamma _1 = h_{f,1}/R$ and ![]() $\varGamma _2 = h_{f,2}/R$, which increase from

$\varGamma _2 = h_{f,2}/R$, which increase from ![]() $0.17$ to

$0.17$ to ![]() $0.33$, and from

$0.33$, and from ![]() $0.58$ to

$0.58$ to ![]() $1.1$, respectively, when

$1.1$, respectively, when ![]() $\mathit {Oh}_{f}$ is increased from

$\mathit {Oh}_{f}$ is increased from ![]() $0.1$ to

$0.1$ to ![]() $2.0$.

$2.0$.

Figure 4. Influence of the film parameters on the impact characteristics: variation of the coefficient of restitution ![]() $\varepsilon$ as a function of (a) the film thickness

$\varepsilon$ as a function of (a) the film thickness ![]() $\varGamma$, and (b) the film mobility

$\varGamma$, and (b) the film mobility ![]() $\varGamma / \mathit {Oh}_{f}^{1/3}$. In (a,b), the circles and hexagrams correspond to the results from experiments and simulations, respectively. The coloured dashed lines in (a) and the solid black line in (b) illustrate the results from the phenomenological model (4.13) with parameters

$\varGamma / \mathit {Oh}_{f}^{1/3}$. In (a,b), the circles and hexagrams correspond to the results from experiments and simulations, respectively. The coloured dashed lines in (a) and the solid black line in (b) illustrate the results from the phenomenological model (4.13) with parameters ![]() $c_{k} = 2$,

$c_{k} = 2$, ![]() $c_{d} = 5.6$ and

$c_{d} = 5.6$ and ![]() $c_{f} = 0.46$. Black dashed lines in (a,b) mark the substrate-independent limit of the restitution coefficient

$c_{f} = 0.46$. Black dashed lines in (a,b) mark the substrate-independent limit of the restitution coefficient ![]() $\varepsilon ^*$. For all cases in this figure,

$\varepsilon ^*$. For all cases in this figure, ![]() $\mathit {Oh}_{d} = 0.034$ and

$\mathit {Oh}_{d} = 0.034$ and ![]() $\mathit {We}_{d} = 4$.

$\mathit {We}_{d} = 4$.

We interpret the two types of behaviour in the substrate-dependent regime in the light of our minimal model, which predicts that the film mobility ![]() $\varGamma /\mathit {Oh}_{f}^{1/3}$ controls the dissipation in the substrate. In figure 4(b), we plot the coefficient of restitution data presented in figure 4(a) after rescaling the horizontal axis by

$\varGamma /\mathit {Oh}_{f}^{1/3}$ controls the dissipation in the substrate. In figure 4(b), we plot the coefficient of restitution data presented in figure 4(a) after rescaling the horizontal axis by ![]() $\mathit {Oh}_{f}^{-1/3}$. The data now collapse for

$\mathit {Oh}_{f}^{-1/3}$. The data now collapse for ![]() $\mathit {Oh}_{f} > 0.1$, indicating that the proposed approximations capture the large viscosity limit but break down for lower film Ohnesorge numbers. We further evidence the validity and failure of the minimal model by plotting the predictions of (4.13) with

$\mathit {Oh}_{f} > 0.1$, indicating that the proposed approximations capture the large viscosity limit but break down for lower film Ohnesorge numbers. We further evidence the validity and failure of the minimal model by plotting the predictions of (4.13) with ![]() $c_f = 0.46$ (dashed coloured lines in figure 4(a) and solid black line in figure 4(b)). The minimal model predicts the restitution coefficient accurately for

$c_f = 0.46$ (dashed coloured lines in figure 4(a) and solid black line in figure 4(b)). The minimal model predicts the restitution coefficient accurately for ![]() $\mathit {Oh}_{f} > 0.1$, suggesting that our modelling assumptions are valid in this regime: the liquid film dynamics is dominated by viscous dissipation, and the flow can be modelled successfully in the lubrication approximation by assimilating the impacting drop to a cylinder.

$\mathit {Oh}_{f} > 0.1$, suggesting that our modelling assumptions are valid in this regime: the liquid film dynamics is dominated by viscous dissipation, and the flow can be modelled successfully in the lubrication approximation by assimilating the impacting drop to a cylinder.

5.2. Influence of the drop Ohnesorge number  $\mathit {Oh}_{d}$

$\mathit {Oh}_{d}$

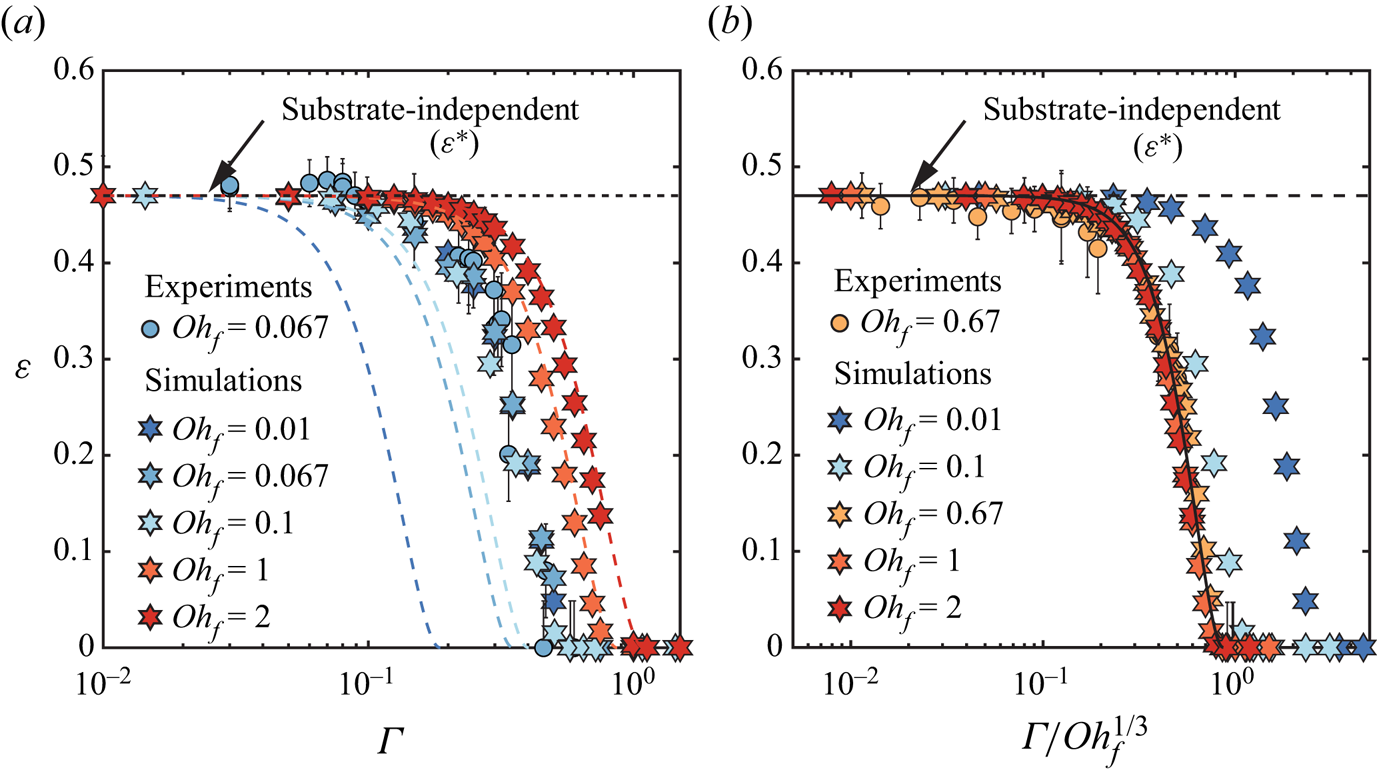

In this subsection, we focus on the influence of the drop Ohnesorge number on the rebound elasticity. In figure 5(a), we plot the coefficient of restitution as a function of the dimensionless film thickness for a fixed ![]() $\mathit {Oh}_{f} = 0.667$ and for varying

$\mathit {Oh}_{f} = 0.667$ and for varying ![]() $\mathit {Oh}_{d}$ spanning the range 0.01–0.133. Increasing

$\mathit {Oh}_{d}$ spanning the range 0.01–0.133. Increasing ![]() $\mathit {Oh}_{d}$ affects

$\mathit {Oh}_{d}$ affects ![]() $\varepsilon$ across all film thicknesses. In the substrate-independent region, the coefficient of restitution decreases with increasing drop Ohnesorge number. In Appendix B, we show that the plateau values reported in figure 5(a) decay exponentially with increasing

$\varepsilon$ across all film thicknesses. In the substrate-independent region, the coefficient of restitution decreases with increasing drop Ohnesorge number. In Appendix B, we show that the plateau values reported in figure 5(a) decay exponentially with increasing ![]() $\mathit {Oh}_{d}$ as predicted by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020). To better illustrate the influence of

$\mathit {Oh}_{d}$ as predicted by Jha et al. (Reference Jha, Chantelot, Clanet and Quéré2020). To better illustrate the influence of ![]() $\mathit {Oh}_{d}$ in the substrate-dependent regime, we normalize the coefficient of restitution

$\mathit {Oh}_{d}$ in the substrate-dependent regime, we normalize the coefficient of restitution ![]() $\varepsilon$ by its substrate-independent value

$\varepsilon$ by its substrate-independent value ![]() $\varepsilon ^*$ (figure 5b). With this normalization, we expect the data to follow the prediction of (4.13) (solid line). The data collapse only for small

$\varepsilon ^*$ (figure 5b). With this normalization, we expect the data to follow the prediction of (4.13) (solid line). The data collapse only for small ![]() $\varGamma$, indicating that the phenomenological model predicts the influence of

$\varGamma$, indicating that the phenomenological model predicts the influence of ![]() $\mathit {Oh}_{d}$ only in the substrate-independent limit. This suggests that the model fails to account for the interplay between the drop and the film properties that affects dissipation in both liquids, and ultimately the coefficient of restitution. Here as well, we monitor the

$\mathit {Oh}_{d}$ only in the substrate-independent limit. This suggests that the model fails to account for the interplay between the drop and the film properties that affects dissipation in both liquids, and ultimately the coefficient of restitution. Here as well, we monitor the ![]() $\mathit {Oh}_{d}$ dependence of the coefficient of restitution, and its deviation from the prediction of (4.13), through the evolution of

$\mathit {Oh}_{d}$ dependence of the coefficient of restitution, and its deviation from the prediction of (4.13), through the evolution of ![]() $\varGamma _1$ and

$\varGamma _1$ and ![]() $\varGamma _2$, that both decrease with increasing Ohnesorge number.

$\varGamma _2$, that both decrease with increasing Ohnesorge number.

Figure 5. Influence of the drop parameters on the rebound elasticity: variation of (a) the coefficient of restitution ![]() $\varepsilon$, and (b) the coefficient of restitution normalized with its substrate-independent value

$\varepsilon$, and (b) the coefficient of restitution normalized with its substrate-independent value ![]() $\varepsilon /\varepsilon ^*$, as a function of the normalized film thickness

$\varepsilon /\varepsilon ^*$, as a function of the normalized film thickness ![]() $\varGamma$. The circles and hexagrams correspond to the results from the experiments and simulations, respectively. In (a), the dashed lines denote the plateau values of the restitution coefficient

$\varGamma$. The circles and hexagrams correspond to the results from the experiments and simulations, respectively. In (a), the dashed lines denote the plateau values of the restitution coefficient ![]() $\varepsilon ^*(\mathit {Oh}_{d})$. In (a,b), the solid lines represent the results from the phenomenological model (4.13) with parameters

$\varepsilon ^*(\mathit {Oh}_{d})$. In (a,b), the solid lines represent the results from the phenomenological model (4.13) with parameters ![]() $c_{k} = 2$,

$c_{k} = 2$, ![]() $c_{d} = 5.6$ and

$c_{d} = 5.6$ and ![]() $c_{f} = 0.46$. For all cases in this figure,

$c_{f} = 0.46$. For all cases in this figure, ![]() $\mathit {Oh}_{f} = 0.667$ and

$\mathit {Oh}_{f} = 0.667$ and ![]() $\mathit {We}_{d} = 4$.

$\mathit {We}_{d} = 4$.

5.3. Influence of  $\mathit {Oh}_{f}$ and

$\mathit {Oh}_{f}$ and  $\mathit {Oh}_{d}$ on the critical film thicknesses

$\mathit {Oh}_{d}$ on the critical film thicknesses

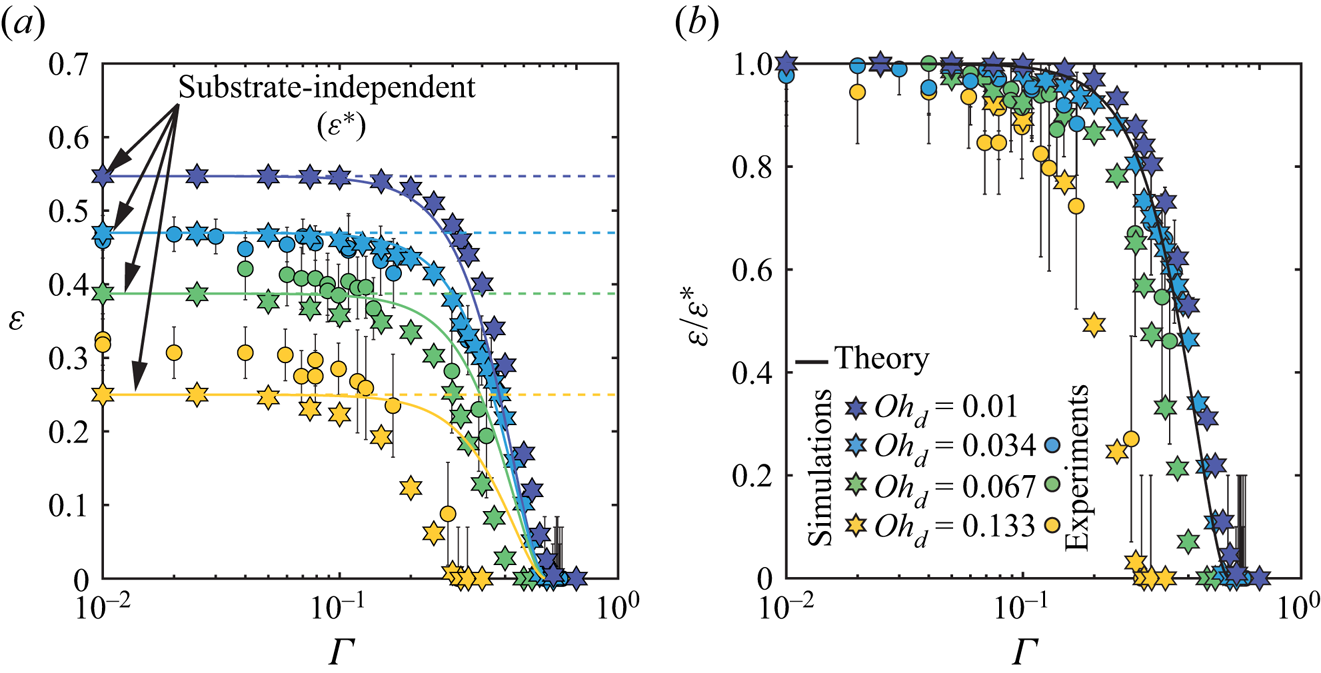

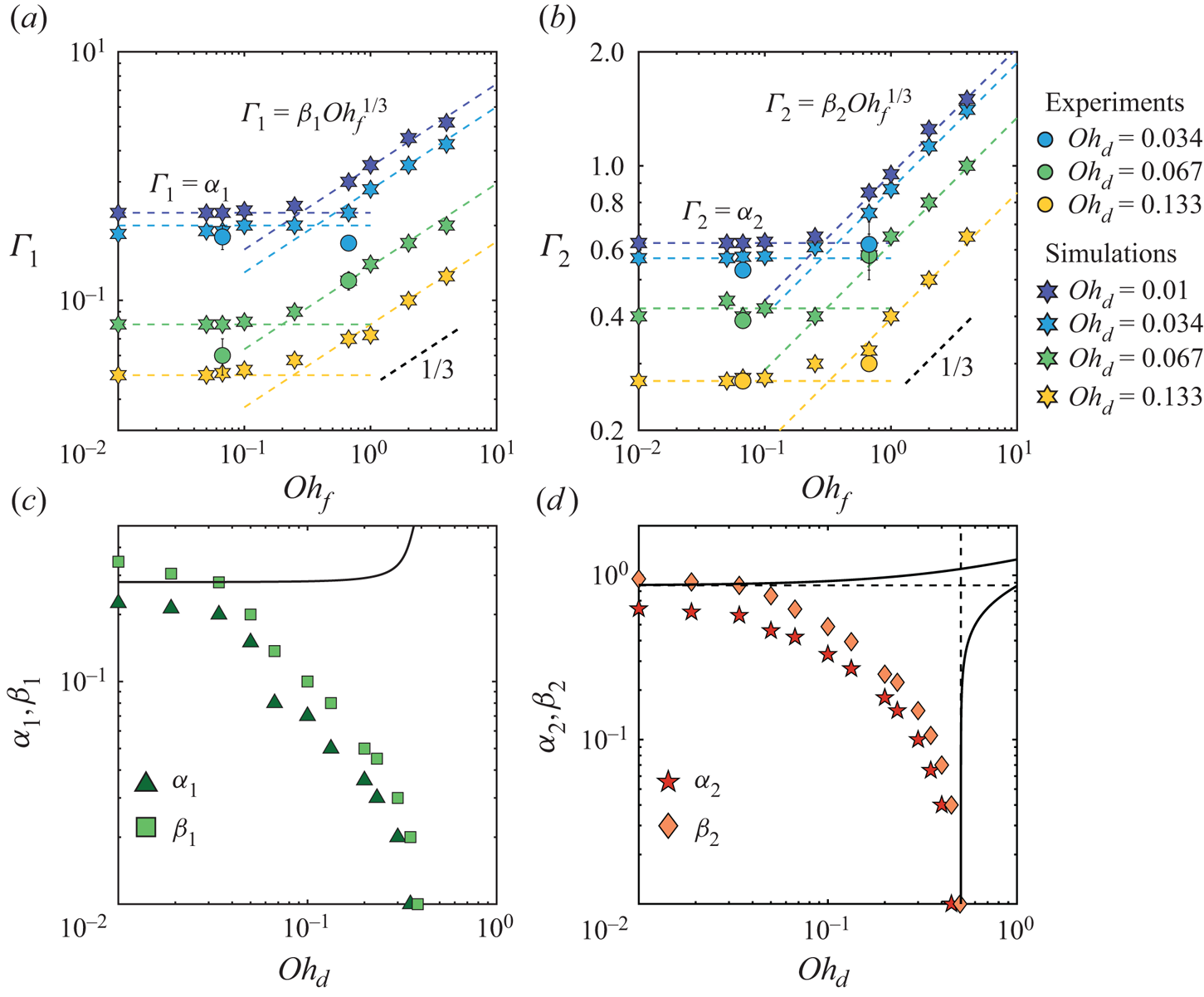

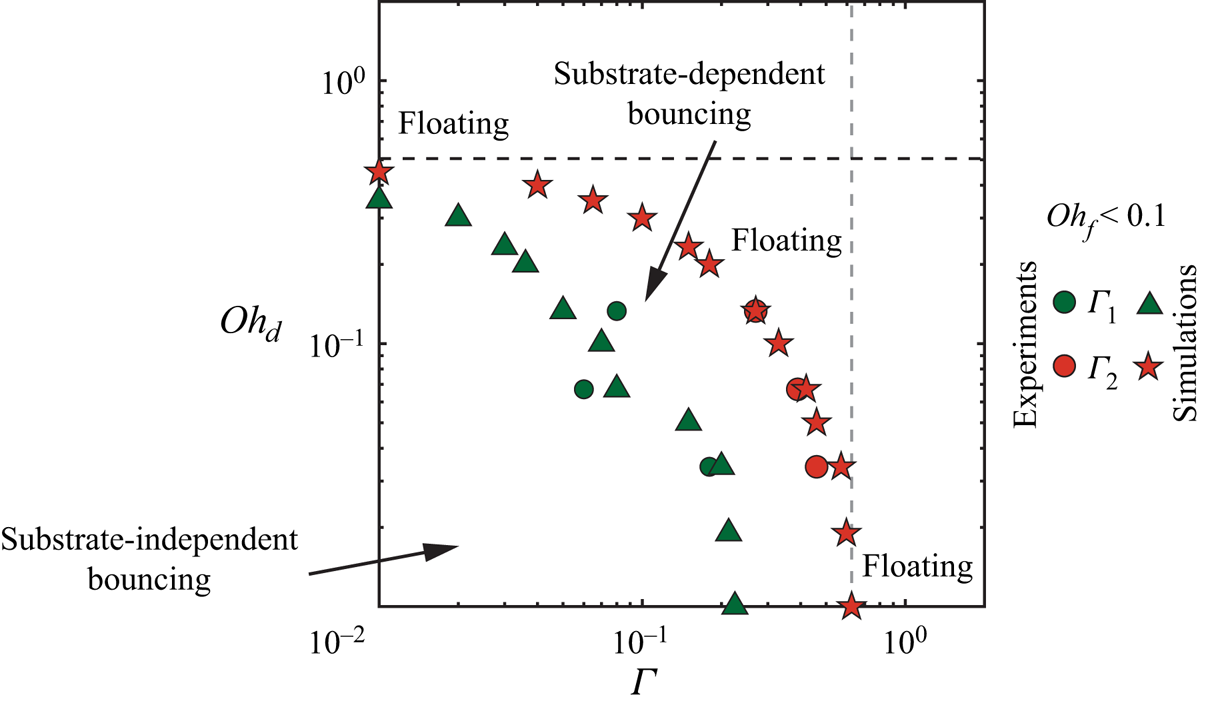

We now quantify the influence of the drop and film Ohnesorge numbers by reporting their effects on the critical thicknesses for substrate-independent to substrate-dependent (![]() $\varGamma _1$) and bouncing to non-bouncing (floating) (

$\varGamma _1$) and bouncing to non-bouncing (floating) (![]() $\varGamma _2$) transitions. Indeed, we have shown above that these two critical thicknesses are good proxies to characterize the continuous transition from substrate-independent bouncing to rebound inhibition. In figures 6(a,b), we show

$\varGamma _2$) transitions. Indeed, we have shown above that these two critical thicknesses are good proxies to characterize the continuous transition from substrate-independent bouncing to rebound inhibition. In figures 6(a,b), we show ![]() $\varGamma _1$ and

$\varGamma _1$ and ![]() $\varGamma _2$ as functions of the film Ohnesorge number for

$\varGamma _2$ as functions of the film Ohnesorge number for ![]() $\mathit {Oh}_{d}$ in the range 0.01–0.133. This representation reflects the existence of the two distinct regimes reported in figure 4.

$\mathit {Oh}_{d}$ in the range 0.01–0.133. This representation reflects the existence of the two distinct regimes reported in figure 4.

Figure 6. Critical film thickness marking the transition from (a) substrate-independent to substrate-dependent bouncing ![]() $\varGamma _1$, and (b) bouncing to non-bouncing (floating)

$\varGamma _1$, and (b) bouncing to non-bouncing (floating) ![]() $\varGamma _2$ as a function of

$\varGamma _2$ as a function of ![]() $\mathit {Oh}_{f}$ at different

$\mathit {Oh}_{f}$ at different ![]() $\mathit {Oh}_{d}$. Prefactors (c)

$\mathit {Oh}_{d}$. Prefactors (c) ![]() $\alpha _{1}$ and

$\alpha _{1}$ and ![]() $\beta _{1}$, and (d)

$\beta _{1}$, and (d) ![]() $\alpha _{2}$ and

$\alpha _{2}$ and ![]() $\beta _{2}$, as a function of

$\beta _{2}$, as a function of ![]() $\mathit {Oh}_{d}$. The solid black line in (c) represents the model prediction for

$\mathit {Oh}_{d}$. The solid black line in (c) represents the model prediction for ![]() $\beta _1$, (5.1). The solid black lines in (d) represent the model predictions for

$\beta _1$, (5.1). The solid black lines in (d) represent the model predictions for ![]() $\beta _2$ using (4.5) and (4.6), and the black dashed lines show the two asymptotes, (4.7) and (4.8).

$\beta _2$ using (4.5) and (4.6), and the black dashed lines show the two asymptotes, (4.7) and (4.8).

First, when ![]() $\mathit {Oh}_{f} < 0.1$,

$\mathit {Oh}_{f} < 0.1$, ![]() $\varGamma _1$ and

$\varGamma _1$ and ![]() $\varGamma _2$ are independent of

$\varGamma _2$ are independent of ![]() $\mathit {Oh}_{f}$. We write

$\mathit {Oh}_{f}$. We write ![]() $\varGamma _1 = \alpha _1(\mathit {Oh}_{d})$ and

$\varGamma _1 = \alpha _1(\mathit {Oh}_{d})$ and ![]() $\varGamma _2 = \alpha _2(\mathit {Oh}_{d})$, and report the values of

$\varGamma _2 = \alpha _2(\mathit {Oh}_{d})$, and report the values of ![]() $\alpha _1(\mathit {Oh}_{d})$ and

$\alpha _1(\mathit {Oh}_{d})$ and ![]() $\alpha _2(\mathit {Oh}_{d})$ in figures 6(c,d). This observation is in contradiction with the expectations from our minimal model, which predicts that

$\alpha _2(\mathit {Oh}_{d})$ in figures 6(c,d). This observation is in contradiction with the expectations from our minimal model, which predicts that ![]() $\mathit {Oh}_{f}$ influences the values of

$\mathit {Oh}_{f}$ influences the values of ![]() $\varGamma _1$ and