1. Introduction

The aerodynamics of flapping wings inspired by insects and birds has been studied extensively due to its importance in unsteady aerodynamic fundamental and micro-aerial vehicle (MAV) designs (Wang Reference Wang2005; Shyy et al. Reference Shyy, Aono, Chimakurthi, Trizila, Kang, Cesnik and Liu2010; Deng et al. Reference Deng, Xu, Chen, Dai, Wu and Tian2013; Shyy et al. Reference Shyy, Kang, Chirarattananon, Ravi and Liu2016; Eldredge & Jones Reference Eldredge and Jones2019). One of the typical features of insect wings is flapping forward and backward, implementing pitch reversal to maintain a positive angle of attack throughout both half-strokes to maximise the lift production (Dickinson, Lehmann & Sane Reference Dickinson, Lehmann and Sane1999). The lift production can be enhanced by employing a variety of mechanisms, as can be found in Shyy et al. (Reference Shyy, Lian, Tang, Viieru and Liu2008, Reference Shyy, Aono, Chimakurthi, Trizila, Kang, Cesnik and Liu2010).

A few mechanisms of force production for biolocomotion work through a variety of synchronisations (see e.g. Somps & Luttges Reference Somps and Luttges1985; Kang & Shyy Reference Kang and Shyy2013; Van Buren, Floryan & Smits Reference Van Buren, Floryan and Smits2019; Wang et al. Reference Wang, Du, Zhao, Thompson and Sun2020; De & Sarkar Reference De and Sarkar2021; Cai et al. Reference Cai, Xue, Kolomenskiy, Xu and Liu2022; Liu et al. Reference Liu, Hefler, Shyy and Qiu2022a). For example, the wake capture mechanism works by synchronising the translational reversal of the wing and the vortex wake created during the previous stroke, so that the effective flow velocity increases, resulting in an additional aerodynamic force peak (Dickinson et al. Reference Dickinson, Lehmann and Sane1999; Birch & Dickinson Reference Birch and Dickinson2003; Shyy et al. Reference Shyy, Aono, Chimakurthi, Trizila, Kang, Cesnik and Liu2010; Bomphrey et al. Reference Bomphrey, Nakata, Phillips and Walker2017). Rapid pitching rotation mechanism synchronises the pitch and flapping stroke (translational) motions to form an advanced rotation, gaining additional lift in a way similar to the Magnus effect (Dickinson et al. Reference Dickinson, Lehmann and Sane1999; Sun & Tang Reference Sun and Tang2002; Shyy et al. Reference Shyy, Aono, Chimakurthi, Trizila, Kang, Cesnik and Liu2010). For propulsive-type flapping foils, the motion is well synchronised to avoid uncontrolled flow separation and vortex shedding, and thus, to save the energy expended (Triantafyllou et al. Reference Triantafyllou, Techet, Zhu, Beal, Hover and Yue2002). Dragonflies often synchronise their forewings and hindwings, maintaining a specific phase relationship between the wings to enhance the lift generation (Somps & Luttges Reference Somps and Luttges1985). Detailed studies show that the anti-phase wing motion generates uniform forces with nearly minimal power, which is commonly observed in steady hovering. On the other hand, the in-phase motion generates higher lift, providing an additional force to accelerate, which is normally observed during takeoffs (Wang & Russell Reference Wang and Russell2007; Hu & Deng Reference Hu and Deng2014). In addition, the lift enhancement is obtained via the downwash and the leading-edge–vortex interactions (Hu & Deng Reference Hu and Deng2014). The synchronisation between the foil motion and the vortex wake generated by a leading body can enhance the thrust of the foil to save energy, and to provide sufficient lift for the foil to maintain its location in the wake (see e.g. Beal Reference Beal2003; Taguchi & Liao Reference Taguchi and Liao2011; Tian et al. Reference Tian, Luo, Zhu, Liao and Lu2011; Stewart et al. Reference Stewart, Tian, Akanyeti, Walker and Liao2016).

As discussed above, the synchronisations between motions (pitching and heaving), multiple wings (fore and hind wings), motion–self-generated vortex and motion–leading-body-generated vortex have been extensively studied. However, the synchronisation due to the elasticity of wing material has not been well explored. Actually, wing flexibility has a significant influence on force production and flight efficiency (see e.g. Shyy et al. Reference Shyy, Aono, Chimakurthi, Trizila, Kang, Cesnik and Liu2010; Dai, Luo & Doyle Reference Dai, Luo and Doyle2012; Tian et al. Reference Tian, Luo, Song and Lu2013). Increasing evidence gained through direct kinematics measurements (Bergou, Xu & Wang Reference Bergou, Xu and Wang2007; Gehrke et al. Reference Gehrke, Richeux, Uksul and Mulleners2022; Mathai et al. Reference Mathai, Tzezana, Das and Breuer2022), numerical (Bergou et al. Reference Bergou, Xu and Wang2007; Dai et al. Reference Dai, Luo and Doyle2012; Tian et al. Reference Tian, Luo, Song and Lu2013; Chen et al. Reference Chen, Gravish, Desbiens, Malka and Wood2016; Kolomenskiy et al. Reference Kolomenskiy2019; Cai et al. Reference Cai, Xue, Kolomenskiy, Xu and Liu2022) and analytical modelling (Ennos Reference Ennos1988; Whitney & Wood Reference Whitney and Wood2010) have shown that the wing flexibility and passive deformation could significantly enhance the force production and flight performance of flapping wings. Specifically, the flexible wing with medium flexibility enjoys a higher lift force (see e.g. Tian et al. Reference Tian, Luo, Song and Lu2013; Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a,Reference Shahzad, Tian, Young and Laib; Gehrke et al. Reference Gehrke, Richeux, Uksul and Mulleners2022; Mathai et al. Reference Mathai, Tzezana, Das and Breuer2022). Mathai et al. (Reference Mathai, Tzezana, Das and Breuer2022) and Gehrke et al. (Reference Gehrke, Richeux, Uksul and Mulleners2022) particularly reported that camber is enhanced by the hydrodynamic forces during the flapping motion. Kang & Shyy (Reference Kang and Shyy2013) found that the optimal lift is obtained when the wing deformation synchronises with the prescribed translational motion.

One of the important consequences of wing flexibility is passive pitching, which has received significant interest over the last decade (Bergou et al. Reference Bergou, Xu and Wang2007; Tian et al. Reference Tian, Luo, Song and Lu2013; Liu et al. Reference Liu, Hefler, Shyy and Qiu2022a). In MAV designs, purely passive pitching could reduce mechanical complexity and the system mass required in miniature robotic systems as it removes the need to actuate the wing in the pitching direction (Whitney & Wood Reference Whitney and Wood2010). To facilitate this application, passively pitching flapping wings have been implemented in several experimental models and MAV designs (Lentink, Jongerius & Bradshaw Reference Lentink, Jongerius and Bradshaw2009; Keennon, Klingebiel & Won Reference Keennon, Klingebiel and Won2012; Ma et al. Reference Ma, Chirarattananon, Fuller and Wood2013; Farrell Helbling & Wood Reference Farrell Helbling and Wood2018). Passive pitching during a flapping stroke is a consequence of flexibility and mediated by the interplay of elastic restoring, wing inertial and aerodynamic forces, associated with energy transfer between the fluid and structural kinetic and elastic energies (Peng & Milano Reference Peng and Milano2013; Tian et al. Reference Tian, Luo, Song and Lu2013; Ishihara & Horie Reference Ishihara and Horie2016; Kolomenskiy et al. Reference Kolomenskiy2019; Cai et al. Reference Cai, Xue, Kolomenskiy, Xu and Liu2022), and thus, it is governed by many factors, including the architectural and material properties of the wings. The surface density, flexural stiffness as well as the vein distribution of real insect wings vary in the chordwise and spanwise directions (Combes & Daniel Reference Combes and Daniel2001; Shahzad et al. Reference Shahzad, Tian, Young and Lai2018b).

To simplify the complicated variation, the torsional flexibility can be lumped together and be modelled by an elastic spring (see e.g. Bergou et al. Reference Bergou, Xu and Wang2007; Ishihara et al. Reference Ishihara, Yamashita, Horie, Yoshida and Niho2009; Zhang, Liu & Lu Reference Zhang, Liu and Lu2010; Lei & Li Reference Lei and Li2020). To understand the passive pitching mechanism of flapping wings, various experimental and numerical studies have been conducted (see e.g. Ennos Reference Ennos1988; Bergou et al. Reference Bergou, Xu and Wang2007; Ishihara et al. Reference Ishihara, Yamashita, Horie, Yoshida and Niho2009; Eldredge, Toomey & Medina Reference Eldredge, Toomey and Medina2010; Spagnolie et al. Reference Spagnolie, Moret, Shelley and Zhang2010; Whitney & Wood Reference Whitney and Wood2010; Zhang et al. Reference Zhang, Liu and Lu2010; Ishihara, Horie & Niho Reference Ishihara, Horie and Niho2014; Beatus & Cohen Reference Beatus and Cohen2015; Chen et al. Reference Chen, Gravish, Desbiens, Malka and Wood2016; Wang, Goosen & van Keulen Reference Wang, Goosen and van Keulen2017; Bluman, Sridhar & Kang Reference Bluman, Sridhar and Kang2018; Kolomenskiy et al. Reference Kolomenskiy2019; Wu, Nowak & Breuer Reference Wu, Nowak and Breuer2019; Lei & Li Reference Lei and Li2020; Mazharmanesh et al. Reference Mazharmanesh, Stallard, Medina, Fisher, Ando, Tian, Young and Ravi2021. Specifically, Chen et al. (Reference Chen, Gravish, Desbiens, Malka and Wood2016) performed experiments on an insect-scale passively pitching robotic flapper and compared the results with a quasi-steady dynamic model and a computational fluid dynamic solver incorporating fluid–structure interaction (FSI). They showed that the wing kinematics and flapping efficiency depend on the hinge stiffness and found that stiffer wing hinges achieve favourable pitching kinematics leading to larger mean lift forces. Lei & Li (Reference Lei and Li2020) numerically investigated the effects of different flapping trajectories on the wing's passive pitching dynamics for a fruit fly wing, finding that the optimal lift and lift-to-power ratio are achieved with medium flexural stiffness (i.e. with Cauchy number of approximately 0.3). A special note is given to Bergou et al. (Reference Bergou, Xu and Wang2007), who numerically analysed the aerodynamic pitching power expenditures in four different insect species with passive pitching kinematics. They calculated the pitching power about the torsion axis due to aerodynamic and wing inertial forces and found that the net pitching rotational power is negative, suggesting the feasibility of passive wing pitching without the additional rotational power input from the muscles. The time and rate of the elastic energy released during the supination of a flexible wing can significantly affect its performance. For example, there is a delayed effective pitching motion (related to the active pitching component) for a lower-mass-ratio wing compared with a higher-mass-ratio one, resulting in a higher power economy (Tian et al. Reference Tian, Luo, Song and Lu2013). Therefore, the synchronisation between fluid-mechanic, structural kinetic and elastic energies is very important in determining the aerodynamics and efficiency of flexible flapping wings and needs to be carefully studied.

Apart from the flexibility, the wing planform (i.e. shape and aspect ratio) can also significantly affect the passive pitching and thus energy/power synchronisation and flight efficiency (Stanford et al. Reference Stanford, Kurdi, Beran and McClung2012). In the MAV designs, it is technically easier to change the wing planform compared with implementing changes in the wing kinematics (Ansari, Knowles & Zbikowski Reference Ansari, Knowles and Zbikowski2008a,Reference Ansari, Knowles and Zbikowskib). Therefore, several studies have been conducted to seek the optimal wing shape for various sizes and Reynolds number scales (Luo & Sun Reference Luo and Sun2005; Ansari et al. Reference Ansari, Knowles and Zbikowski2008b; Young et al. Reference Young, Walker, Bomphrey, Taylor and Thomas2009; Stanford et al. Reference Stanford, Kurdi, Beran and McClung2012; Li & Dong Reference Li and Dong2016; Shahzad et al. Reference Shahzad, Tian, Young and Lai2016, Reference Shahzad, Tian, Young and Lai2018a; Bhat et al. Reference Bhat, Zhao, Sheridan, Hourigan and Thompson2019b; Wang & Tian Reference Wang and Tian2020; Ji et al. Reference Ji, Wang, Ravi, Tian, Young and Lai2022; Wang, Tian & Liu Reference Wang, Tian and Liu2022). Specifically, Ansari et al. (Reference Ansari, Knowles and Zbikowski2008b) numerically studied the effects of various synthetic wing planforms with fully prescribed kinematics on the aerodynamic performance. They found that wing planforms having larger area outboard produce the highest lift. The recent work of Bhat & Thompson (Reference Bhat and Thompson2022) showed that increasing the leading-edge curvature can further enhance the lift. Shahzad et al. (Reference Shahzad, Tian, Young and Lai2016) numerically investigated the effects of wing shape on the aerodynamic performance in hover. The wing shapes were defined by the radius of the first moment of the wing area ![]() $\bar {r}_{1}$ and aspect ratio (

$\bar {r}_{1}$ and aspect ratio (![]() $AR$) while the power economy

$AR$) while the power economy ![]() $PE$ was defined as the ratio of the mean lift coefficient to the mean aerodynamic power coefficient. They found that maximum

$PE$ was defined as the ratio of the mean lift coefficient to the mean aerodynamic power coefficient. They found that maximum ![]() $PE$ was achieved at

$PE$ was achieved at ![]() $AR=2.96$. Although the maximum lift was observed at high

$AR=2.96$. Although the maximum lift was observed at high ![]() $\bar {r}_{1}$ (i.e. large area outboard of the wing) and high-

$\bar {r}_{1}$ (i.e. large area outboard of the wing) and high-![]() $AR$ wings, they recommended low

$AR$ wings, they recommended low ![]() $\bar {r}_{1}$ (i.e. large area inboard of the wing) and high

$\bar {r}_{1}$ (i.e. large area inboard of the wing) and high ![]() $AR$ to maximise

$AR$ to maximise ![]() $PE$ for a given lift at the Reynolds numbers of insects. Similar conclusions were obtained for flexible flapping wings (Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a,Reference Shahzad, Tian, Young and Laib). Despite the above studies, it is unclear how the planform would affect power synchronisation.

$PE$ for a given lift at the Reynolds numbers of insects. Similar conclusions were obtained for flexible flapping wings (Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a,Reference Shahzad, Tian, Young and Laib). Despite the above studies, it is unclear how the planform would affect power synchronisation.

This work numerically investigates the performance of flexible flapping wings, with a focus on power synchronisation. The wings undergo prescribed flapping (stroke) motion and passive pitching motion, of which the latter is determined by the torsional flexibility. Following previous studies (Spagnolie et al. Reference Spagnolie, Moret, Shelley and Zhang2010; Zhang et al. Reference Zhang, Liu and Lu2010; Lei & Li Reference Lei and Li2020), the torsional flexibility is lumped together and modelled by an elastic torsional spring at the wing root, with the wing itself being modelled as a rigid plate. The FSI system is solved by an in-house FSI solver based on an immersed-boundary–lattice Boltzmann method. Two parameters are particularly considered. The first parameter is the Cauchy number (![]() $Ch$), which is defined by the ratio of aerodynamic forces acting on the wing and the elastic torsional spring force, and is varied from

$Ch$), which is defined by the ratio of aerodynamic forces acting on the wing and the elastic torsional spring force, and is varied from ![]() $0.05$ to

$0.05$ to ![]() $0.6$ covering low-, medium- and high-flexible cases. The other parameter is the radius of the first moment of the wing area normalised with the wingspan (

$0.6$ covering low-, medium- and high-flexible cases. The other parameter is the radius of the first moment of the wing area normalised with the wingspan (![]() $\bar {r}_1$), which is used to describe the wing shape and is varied from 0.39 to 0.63. The forces and the power economy are studied, and power synchronisation is discussed. Compared with our previous work on flexible flapping wings (see e.g. Tian et al. Reference Tian, Luo, Song and Lu2013; Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a,Reference Shahzad, Tian, Young and Laib), this work particularly focuses on how power synchronisations determine the hovering flight efficiency of passively pitching flapping wings. Here, hovering flight is selected as it is considered a vital flight profile in artificial and natural flyers alike.

$\bar {r}_1$), which is used to describe the wing shape and is varied from 0.39 to 0.63. The forces and the power economy are studied, and power synchronisation is discussed. Compared with our previous work on flexible flapping wings (see e.g. Tian et al. Reference Tian, Luo, Song and Lu2013; Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a,Reference Shahzad, Tian, Young and Laib), this work particularly focuses on how power synchronisations determine the hovering flight efficiency of passively pitching flapping wings. Here, hovering flight is selected as it is considered a vital flight profile in artificial and natural flyers alike.

This paper is organised as follows. The physical and mathematical models are described in § 2 with more details of the derivation provided in Appendix A. The numerical method is given in § 3 with validation presented in Appendix B. The numerical results are presented and discussed in § 4, and concluding remarks are provided in § 5.

2. Model description

As the flight speed of insects is low (generally less than 20 m s![]() $^{-1}$) and the flapping frequency ranges from

$^{-1}$) and the flapping frequency ranges from ![]() $10$ to 1000 Hz, the Mach number is much lower than

$10$ to 1000 Hz, the Mach number is much lower than ![]() $0.3$ and the flapping period is much larger than the time of sound propagation over the characteristic length (Taylor, Nudds & Thomas Reference Taylor, Nudds and Thomas2003; Wang Reference Wang2005; Landau & Lifshitz Reference Landau and Lifshitz2013). Therefore, the flow around the flapping wing is considered incompressible and is governed by

$0.3$ and the flapping period is much larger than the time of sound propagation over the characteristic length (Taylor, Nudds & Thomas Reference Taylor, Nudds and Thomas2003; Wang Reference Wang2005; Landau & Lifshitz Reference Landau and Lifshitz2013). Therefore, the flow around the flapping wing is considered incompressible and is governed by

where ![]() $\boldsymbol {u}$ is the fluid velocity,

$\boldsymbol {u}$ is the fluid velocity, ![]() $\rho$ is the fluid density,

$\rho$ is the fluid density, ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\mu$ is the dynamic viscosity and

$\mu$ is the dynamic viscosity and ![]() $\boldsymbol {f}$ is the body force density. A wing of mean chord

$\boldsymbol {f}$ is the body force density. A wing of mean chord ![]() $c$ and span

$c$ and span ![]() $L$ is modelled to undergo two-angle flapping kinematics, where the two angles of concern are the flapping (stroke) position angle

$L$ is modelled to undergo two-angle flapping kinematics, where the two angles of concern are the flapping (stroke) position angle ![]() $\phi$ and the pitching angle

$\phi$ and the pitching angle ![]() $\theta$, as shown in figure 1. The deviation angle outside the stroke plane is taken as zero as a simplified case of normal hovering (Ellington & Lighthill Reference Ellington and Lighthill1984). In such a case, the straight leading edge of the wing remains parallel to the horizontal plane throughout the flapping motion. The flapping axis is situated along the

$\theta$, as shown in figure 1. The deviation angle outside the stroke plane is taken as zero as a simplified case of normal hovering (Ellington & Lighthill Reference Ellington and Lighthill1984). In such a case, the straight leading edge of the wing remains parallel to the horizontal plane throughout the flapping motion. The flapping axis is situated along the ![]() $z$-axis, passing through the wing root, and the pitching axis is aligned with the leading edge of the wing. Such a wing model is used because Ansari et al. (Reference Ansari, Knowles and Zbikowski2008b) showed that wings with straight leading edges produce higher lift and that the pitching axis located within 0–0.25

$z$-axis, passing through the wing root, and the pitching axis is aligned with the leading edge of the wing. Such a wing model is used because Ansari et al. (Reference Ansari, Knowles and Zbikowski2008b) showed that wings with straight leading edges produce higher lift and that the pitching axis located within 0–0.25![]() $c$ from the leading edge provides an optimised compound performance for the wings similar to those in the current study. Thus, the leading edge is used as the pitching axis for simplicity.

$c$ from the leading edge provides an optimised compound performance for the wings similar to those in the current study. Thus, the leading edge is used as the pitching axis for simplicity.

Figure 1. The schematic shows the two-angle flapping kinematics of an insect wing, with the stroke angle (![]() $\phi$) and the pitching angle (

$\phi$) and the pitching angle (![]() $\theta$). Here,

$\theta$). Here, ![]() $\dot {\phi }$ and

$\dot {\phi }$ and ![]() $\dot {\theta }$ are the stroke and pitching angular velocities, respectively;

$\dot {\theta }$ are the stroke and pitching angular velocities, respectively; ![]() $c$ is the mean wing chord and

$c$ is the mean wing chord and ![]() $L$ is the wingspan;

$L$ is the wingspan; ![]() $x^{\prime }$,

$x^{\prime }$, ![]() $y^{\prime }$ and

$y^{\prime }$ and ![]() $z^{\prime }$ are the coordinate axes in the laboratory coordinate system, whereas

$z^{\prime }$ are the coordinate axes in the laboratory coordinate system, whereas ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ are the axes in the body-fixed coordinate system.

$z$ are the axes in the body-fixed coordinate system.

The wing flapping motion is prescribed by the stroke angle according to

where ![]() $\phi _{A}$ is the peak-to-peak flapping amplitude, and

$\phi _{A}$ is the peak-to-peak flapping amplitude, and ![]() $f$ is the flapping frequency. The stroke amplitude is maintained to be

$f$ is the flapping frequency. The stroke amplitude is maintained to be ![]() $\phi _A=140^{\circ }$, which corresponds to that of fruit flies (Altshuler et al. Reference Altshuler, Dickson, Vance, Roberts and Dickinson2005; Berman & Wang Reference Berman and Wang2007). The flapping motion profile used here is similar to that used in several previous studies (Li, Dong & Zhao Reference Li, Dong and Zhao2018; Lei & Li Reference Lei and Li2020) as it nominally matches the kinematics of real insects (Li et al. Reference Li, Dong and Zhao2018).

$\phi _A=140^{\circ }$, which corresponds to that of fruit flies (Altshuler et al. Reference Altshuler, Dickson, Vance, Roberts and Dickinson2005; Berman & Wang Reference Berman and Wang2007). The flapping motion profile used here is similar to that used in several previous studies (Li, Dong & Zhao Reference Li, Dong and Zhao2018; Lei & Li Reference Lei and Li2020) as it nominally matches the kinematics of real insects (Li et al. Reference Li, Dong and Zhao2018).

Initially, the wing surface is vertically oriented. The passive pitching dynamics is modelled using a torsional spring at the wing hinge, which provides the restoring torque to the wing and returns it to its neutral position (vertical orientation). The passive pitching angle ![]() $\theta$ is determined by solving the dynamical equation for the pitching motion of the wing, as described in Kolomenskiy et al. (Reference Kolomenskiy2019),

$\theta$ is determined by solving the dynamical equation for the pitching motion of the wing, as described in Kolomenskiy et al. (Reference Kolomenskiy2019),

\begin{equation} \underbrace{-J_{yy}\ddot{\theta}+J_{zy} \ddot{\phi} \cos \theta + \tfrac{1}{2} J_{yy} \dot{\phi}^2 \sin 2\theta}_{T_{iner}^{pitch}}+T_{aero}^{pitch} \underbrace{-K_{s}(\theta - \theta_0)}_{T_{spri}^{pitch}} -C\dot{\theta} =T_{input}^{pitch},\end{equation}

\begin{equation} \underbrace{-J_{yy}\ddot{\theta}+J_{zy} \ddot{\phi} \cos \theta + \tfrac{1}{2} J_{yy} \dot{\phi}^2 \sin 2\theta}_{T_{iner}^{pitch}}+T_{aero}^{pitch} \underbrace{-K_{s}(\theta - \theta_0)}_{T_{spri}^{pitch}} -C\dot{\theta} =T_{input}^{pitch},\end{equation}

where ![]() $J_{yy}$ is the moment of inertia around the pitching axis

$J_{yy}$ is the moment of inertia around the pitching axis ![]() $y$,

$y$, ![]() $J_{zy}$ is the moment of inertia around the pitching axis when the wing is rotated around the

$J_{zy}$ is the moment of inertia around the pitching axis when the wing is rotated around the ![]() $z$-axis (i.e. flapping axis),

$z$-axis (i.e. flapping axis), ![]() $\dot {\theta }$ and

$\dot {\theta }$ and ![]() $\ddot {\theta }$ are the pitching angular velocity and acceleration, respectively,

$\ddot {\theta }$ are the pitching angular velocity and acceleration, respectively, ![]() $\dot {\phi }$ and

$\dot {\phi }$ and ![]() $\ddot {\phi }$ are the flapping angular velocity and acceleration, respectively,

$\ddot {\phi }$ are the flapping angular velocity and acceleration, respectively, ![]() $C$ is the damping coefficient of the spring and set as zero here,

$C$ is the damping coefficient of the spring and set as zero here, ![]() $K_s$ is the torsional stiffness of the spring,

$K_s$ is the torsional stiffness of the spring, ![]() $\theta _0$ is the rest pitching angle,

$\theta _0$ is the rest pitching angle, ![]() $T_{iner}^{pitch}$ is the pitching inertial torque,

$T_{iner}^{pitch}$ is the pitching inertial torque, ![]() $T_{aero}^{pitch}$ is the aerodynamic pitching moment on the wing,

$T_{aero}^{pitch}$ is the aerodynamic pitching moment on the wing, ![]() $T_{spri}^{pitch}$ is the torque of the spring and

$T_{spri}^{pitch}$ is the torque of the spring and ![]() $T_{input}^{pitch}$ is the input torque to actuate the wing pitch (note,

$T_{input}^{pitch}$ is the input torque to actuate the wing pitch (note, ![]() $T_{input}^{pitch}=0$ for purely passive pitching). Please note that the angles are defined in the body-fixed coordinate system. Then, the pitching inertial power (

$T_{input}^{pitch}=0$ for purely passive pitching). Please note that the angles are defined in the body-fixed coordinate system. Then, the pitching inertial power (![]() $P_{iner}^{pitch}$), the pitching aerodynamic power (

$P_{iner}^{pitch}$), the pitching aerodynamic power (![]() $P_{aero}^{pitch}$), the pitching elastic power (

$P_{aero}^{pitch}$), the pitching elastic power (![]() $P_{spri}^{pitch}$) and the total input power for pitching (

$P_{spri}^{pitch}$) and the total input power for pitching (![]() $P_{input}^{pitch}$) can be calculated, respectively, as

$P_{input}^{pitch}$) can be calculated, respectively, as

The dimensional torsional spring stiffness is defined using a non-dimensional Cauchy number (![]() $Ch$)

$Ch$)

which provides a relative measure of the aerodynamic forces acting on the wing and the elastic torsional spring force at the wing hinge. Note that the mean wing chord ![]() $c$ and wing length

$c$ and wing length ![]() $L$ are maintained as constant across all wing planforms in this study. Thus, the parameters

$L$ are maintained as constant across all wing planforms in this study. Thus, the parameters ![]() $Ch$ and

$Ch$ and ![]() $\bar {r}_1$, by definition, are independent of each other in this study. For all wing planforms,

$\bar {r}_1$, by definition, are independent of each other in this study. For all wing planforms, ![]() $Ch$ is systematically varied from

$Ch$ is systematically varied from ![]() $0.05$ to

$0.05$ to ![]() $0.6$ by changing the stiffness

$0.6$ by changing the stiffness ![]() $K_s$ of the torsional spring. This range of

$K_s$ of the torsional spring. This range of ![]() $Ch$ includes values for realistic passive pitching flapping-wing kinematics (Ishihara et al. Reference Ishihara, Yamashita, Horie, Yoshida and Niho2009; Lei & Li Reference Lei and Li2020) to well beyond those tested in previous studies, covering low-, medium- and high-flexible cases. The other non-dimensional parameters include the Reynolds number

$Ch$ includes values for realistic passive pitching flapping-wing kinematics (Ishihara et al. Reference Ishihara, Yamashita, Horie, Yoshida and Niho2009; Lei & Li Reference Lei and Li2020) to well beyond those tested in previous studies, covering low-, medium- and high-flexible cases. The other non-dimensional parameters include the Reynolds number ![]() $Re$ and mass ratio

$Re$ and mass ratio ![]() $M$, which are respectively given by

$M$, which are respectively given by

where ![]() $U=2 f \phi _A L$ is the mean wingtip velocity,

$U=2 f \phi _A L$ is the mean wingtip velocity, ![]() $m_s$ is the surface density of the wing material,

$m_s$ is the surface density of the wing material, ![]() $M_c$ is the mass ratio based on the mean chord and

$M_c$ is the mass ratio based on the mean chord and ![]() $AR$ is the aspect ratio of the wing. The value of

$AR$ is the aspect ratio of the wing. The value of ![]() $M$ dictates the relative effects of the inertial force vs the aerodynamic force (Tian et al. Reference Tian, Luo, Song and Lu2013). Here,

$M$ dictates the relative effects of the inertial force vs the aerodynamic force (Tian et al. Reference Tian, Luo, Song and Lu2013). Here, ![]() $M_c$ is maintained to be

$M_c$ is maintained to be ![]() $1.0$ as this value is close to the mass ratios found in a variety of insect species, such as fruit flies and honeybees (Lei & Li Reference Lei and Li2020).

$1.0$ as this value is close to the mass ratios found in a variety of insect species, such as fruit flies and honeybees (Lei & Li Reference Lei and Li2020).

To quantify the flapping inertial and aerodynamic power expenditures, the torque used to actuate the wing flapping motion in (2.3) is given (see the derivation in Appendix A) as

\begin{equation} \underbrace{(J_{z z}+J_{y y} \sin ^{2} \theta ) \ddot{\phi} + J_{y y} \sin (2 \theta) \dot{\theta} \dot{\phi} - J_{y z}(\ddot{\theta} \cos \theta-\dot{\theta}^{2} \sin \theta)}_{T_{iner}^{flap}} - T_{aero}^{flap} = T_{input}^{flap},\end{equation}

\begin{equation} \underbrace{(J_{z z}+J_{y y} \sin ^{2} \theta ) \ddot{\phi} + J_{y y} \sin (2 \theta) \dot{\theta} \dot{\phi} - J_{y z}(\ddot{\theta} \cos \theta-\dot{\theta}^{2} \sin \theta)}_{T_{iner}^{flap}} - T_{aero}^{flap} = T_{input}^{flap},\end{equation}

where ![]() $J_{zz}$ is the moment of inertia around the

$J_{zz}$ is the moment of inertia around the ![]() $z\hbox{-}$axis,

$z\hbox{-}$axis, ![]() $J_{yz}$ is the moment of inertia around the

$J_{yz}$ is the moment of inertia around the ![]() $z\hbox{-}$axis when the wing is rotated around the pitching axis

$z\hbox{-}$axis when the wing is rotated around the pitching axis ![]() $y$ (note,

$y$ (note, ![]() $J_{yz}=J_{zy}$),

$J_{yz}=J_{zy}$), ![]() $T_{iner}^{flap}$ is the flapping inertial torque,

$T_{iner}^{flap}$ is the flapping inertial torque, ![]() $T_{aero}^{flap}$ is the flapping aerodynamic torque and

$T_{aero}^{flap}$ is the flapping aerodynamic torque and ![]() $T_{input}^{flap}$ is the total input torque to actuate the wing flapping motion in (2.3). Then, the flapping inertial power (

$T_{input}^{flap}$ is the total input torque to actuate the wing flapping motion in (2.3). Then, the flapping inertial power (![]() $P_{iner}^{flap}$), the flapping aerodynamic power (

$P_{iner}^{flap}$), the flapping aerodynamic power (![]() $P_{aero}^{flap}$) and the total input power for flapping (

$P_{aero}^{flap}$) and the total input power for flapping (![]() $P_{input}^{flap}$) can be calculated, respectively, as

$P_{input}^{flap}$) can be calculated, respectively, as

The combination of (2.4), (2.5a–d), (2.8) and (2.9a–c) can provide a measure of the total power (![]() $=P_{input}^{flap} + P_{input}^{pitch}$) required for flapping (stroke) and pitching as well as the contributions of each parameter to the total power. Here, the total power consumption for the passively pitching wing is only the total input power for flapping

$=P_{input}^{flap} + P_{input}^{pitch}$) required for flapping (stroke) and pitching as well as the contributions of each parameter to the total power. Here, the total power consumption for the passively pitching wing is only the total input power for flapping ![]() $P_{input}^{flap}$, which has no net power consumption for pitching (

$P_{input}^{flap}$, which has no net power consumption for pitching (![]() $P_{input}^{pitch}=0$). The positive power indicates the work done by the wing on the fluid. For example, a positive flapping aerodynamic power means the work done by the wing on the fluid to overcome the drag.

$P_{input}^{pitch}=0$). The positive power indicates the work done by the wing on the fluid. For example, a positive flapping aerodynamic power means the work done by the wing on the fluid to overcome the drag.

The drag, lift and aerodynamic power coefficients are defined, respectively, as

\begin{equation} C_{D}=\frac{2 F_{x}}{\rho U^{2} A}\frac{\dot{\phi}}{|\dot{\phi|}},\quad C_{L}=\frac{2 F_{z}}{\rho U^{2} A},\quad \mathrm{and} \quad C_{P}=\frac{-2 P_{aero}}{\rho U^{3} A}, \end{equation}

\begin{equation} C_{D}=\frac{2 F_{x}}{\rho U^{2} A}\frac{\dot{\phi}}{|\dot{\phi|}},\quad C_{L}=\frac{2 F_{z}}{\rho U^{2} A},\quad \mathrm{and} \quad C_{P}=\frac{-2 P_{aero}}{\rho U^{3} A}, \end{equation}

where ![]() $F_x$ and

$F_x$ and ![]() $F_z$ are the forces acting on the wing by the ambient fluid in the

$F_z$ are the forces acting on the wing by the ambient fluid in the ![]() $x$ and

$x$ and ![]() $z$ directions, respectively,

$z$ directions, respectively, ![]() $P_{aero}$ is the aerodynamic power and

$P_{aero}$ is the aerodynamic power and ![]() $A$ is the surface area of the wing (

$A$ is the surface area of the wing (![]() $A=cL$ for a rectangular plate). Note that

$A=cL$ for a rectangular plate). Note that ![]() $C_D$ is defined in such a way as to measure the force coefficient along

$C_D$ is defined in such a way as to measure the force coefficient along ![]() $x$ in the opposite direction to the flapping motion. Here,

$x$ in the opposite direction to the flapping motion. Here, ![]() $P_{aero}$ consists of the flapping aerodynamic power and the pitching aerodynamic power (

$P_{aero}$ consists of the flapping aerodynamic power and the pitching aerodynamic power (![]() $P_{aero}= P_{aero}^{flap} + P_{aero}^{{pitch }}$). An example is provided in Appendix B.1 to demonstrate the calculation of the aerodynamic powers. The cycle-averaged lift, drag and power coefficients are respectively denoted as

$P_{aero}= P_{aero}^{flap} + P_{aero}^{{pitch }}$). An example is provided in Appendix B.1 to demonstrate the calculation of the aerodynamic powers. The cycle-averaged lift, drag and power coefficients are respectively denoted as ![]() $\bar {C}_L$,

$\bar {C}_L$, ![]() $\bar {C}_D$ and

$\bar {C}_D$ and ![]() $\bar {C}_P$. The power economy

$\bar {C}_P$. The power economy ![]() $PE = \bar {C}_L/\bar {C}_P$ is introduced to discuss the hovering efficacy, which measures the lift production per unit aerodynamic power.

$PE = \bar {C}_L/\bar {C}_P$ is introduced to discuss the hovering efficacy, which measures the lift production per unit aerodynamic power.

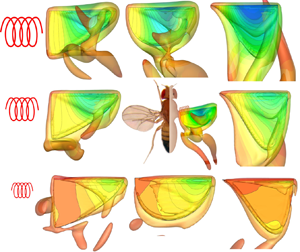

Eight different wing shapes are considered to systematically explore the interaction between wing-hinge properties and wing planform, as shown in figure 2. Each wing shape is generated using the beta function (![]() $\beta (p, q)$) by varying the radius of the first moment of area

$\beta (p, q)$) by varying the radius of the first moment of area ![]() $\bar {r}_{1}$. The equations for the wing-shape generation are adopted from Ellington (Reference Ellington1984a)

$\bar {r}_{1}$. The equations for the wing-shape generation are adopted from Ellington (Reference Ellington1984a)

where ![]() $\bar {c}$ is the wing chord normalised by

$\bar {c}$ is the wing chord normalised by ![]() $c$ and

$c$ and ![]() $\bar {r}$ is the spanwise distance from the wing root normalised by

$\bar {r}$ is the spanwise distance from the wing root normalised by ![]() $L$;

$L$; ![]() $\bar {r}_k$ is the non-dimensional radius of the

$\bar {r}_k$ is the non-dimensional radius of the ![]() $k$th moment of the wing area. The values of

$k$th moment of the wing area. The values of ![]() $\bar {r}_1$ chosen for wing-shape generation are varied between

$\bar {r}_1$ chosen for wing-shape generation are varied between ![]() $0.39$ and

$0.39$ and ![]() $0.63$, including the range of 0.43 and 0.6 for most insect wings (Ellington Reference Ellington1984a; Bhat et al. Reference Bhat, Zhao, Sheridan, Hourigan and Thompson2019a; Wang & Tian Reference Wang and Tian2020). The wing shapes are modelled with a constant planform area

$0.63$, including the range of 0.43 and 0.6 for most insect wings (Ellington Reference Ellington1984a; Bhat et al. Reference Bhat, Zhao, Sheridan, Hourigan and Thompson2019a; Wang & Tian Reference Wang and Tian2020). The wing shapes are modelled with a constant planform area ![]() $A$, aspect ratio

$A$, aspect ratio ![]() $AR$, wingspan

$AR$, wingspan ![]() $L$ and the mean chord length

$L$ and the mean chord length ![]() $c$ (

$c$ (![]() $c = L/AR$) for all cases to easily cross-compare performance metrics between them. As

$c = L/AR$) for all cases to easily cross-compare performance metrics between them. As ![]() $\bar {r}_1$ increases, the planform area of the wing shifts further outboard from the wing root. The value

$\bar {r}_1$ increases, the planform area of the wing shifts further outboard from the wing root. The value ![]() $AR=2.96$ is chosen because previous studies on rigid wing shapes with prescribed flapping kinematics (Shahzad et al. Reference Shahzad, Tian, Young and Lai2016) have shown that maximum power economy is achieved at this aspect ratio independent of

$AR=2.96$ is chosen because previous studies on rigid wing shapes with prescribed flapping kinematics (Shahzad et al. Reference Shahzad, Tian, Young and Lai2016) have shown that maximum power economy is achieved at this aspect ratio independent of ![]() $Re$ and

$Re$ and ![]() $\bar {r}_1$. The values of

$\bar {r}_1$. The values of ![]() $J_{yy}$,

$J_{yy}$, ![]() $J_{zz}$ and

$J_{zz}$ and ![]() $J_{yz}$ for different wings are provided in Appendix B.2.

$J_{yz}$ for different wings are provided in Appendix B.2.

Figure 2. Eight different wing planforms have been obtained by varying ![]() $\bar {r}_{1}$: (a)

$\bar {r}_{1}$: (a) ![]() $\bar {r}_1=0.39$; (b)

$\bar {r}_1=0.39$; (b) ![]() $\bar {r}_1=0.43$;(c)

$\bar {r}_1=0.43$;(c) ![]() $\bar {r}_1=0.48$; (d)

$\bar {r}_1=0.48$; (d) ![]() $\bar {r}_1=0.53$; (e)

$\bar {r}_1=0.53$; (e) ![]() $\bar {r}_1=0.565$; ( f)

$\bar {r}_1=0.565$; ( f) ![]() $\bar {r}_1=0.58$; (g)

$\bar {r}_1=0.58$; (g) ![]() $\bar {r}_1=0.605$; (h)

$\bar {r}_1=0.605$; (h) ![]() $\bar {r}_1=0.63$.

$\bar {r}_1=0.63$.

The far-field boundary condition is applied at the external boundaries of the computational domain and the no-slip boundary condition is applied on the wing surface. Zero velocity and constant pressure are specified as the initial condition of the flow. The initial stroke position of the wing is at ![]() $-\phi _A/2$ with zero velocity, and the initial pitching angle is the rest pitching angle. Note that we have conducted simulations to verify that the results are independent of the initial condition of the wing (see Appendix B.3).

$-\phi _A/2$ with zero velocity, and the initial pitching angle is the rest pitching angle. Note that we have conducted simulations to verify that the results are independent of the initial condition of the wing (see Appendix B.3).

3. Numerical method

The flow over a flapping wing is solved by an immersed boundary-lattice Boltzmann method (IB–LBM) FSI solver based on the three-dimensional nineteen discrete velocity (D3Q19) lattice Boltzmann method (LBM) with a multi-relaxation-time (MRT) model for modelling the fluid dynamics and the feedback immersed-boundary method (IBM) for handling the boundary conditions at the fluid-solid interface. In the LBM, the macroscopic dynamics of the fluid is the result of the statistical behaviour of the fluid particles, which is described by the distribution function ![]() $g_i(\boldsymbol {x},t)$ according to (Lallemand & Luo Reference Lallemand and Luo2000; Luo et al. Reference Luo, Liao, Chen, Peng and Zhang2011)

$g_i(\boldsymbol {x},t)$ according to (Lallemand & Luo Reference Lallemand and Luo2000; Luo et al. Reference Luo, Liao, Chen, Peng and Zhang2011)

where ![]() $g_i(\boldsymbol {x},t)$ is the distribution function for particles with velocity

$g_i(\boldsymbol {x},t)$ is the distribution function for particles with velocity ![]() $\boldsymbol {e}_i$ at position

$\boldsymbol {e}_i$ at position ![]() $\boldsymbol {x}$ and time

$\boldsymbol {x}$ and time ![]() $t$,

$t$, ![]() ${\rm \Delta} t$ is the time increment,

${\rm \Delta} t$ is the time increment, ![]() $\varOmega _i(\boldsymbol {x},t)$ is the collision operator and

$\varOmega _i(\boldsymbol {x},t)$ is the collision operator and ![]() $G_i$ is the forcing term accounting for the body force

$G_i$ is the forcing term accounting for the body force ![]() $\boldsymbol {f}$. The D3Q19 model (D'Humieres et al. Reference D'Humieres, Ginzburg, Krafczyk, Lallemand and Luo2002) is used on a cube lattice. Compared with the single-relaxation-time collision model, the MRT model has been proven to be numerically more stable (Lallemand & Luo Reference Lallemand and Luo2000; Xu et al. Reference Xu, Tian, Young and Lai2018). Therefore, the MRT collision model is adopted here and is given by (Lallemand & Luo Reference Lallemand and Luo2000)

$\boldsymbol {f}$. The D3Q19 model (D'Humieres et al. Reference D'Humieres, Ginzburg, Krafczyk, Lallemand and Luo2002) is used on a cube lattice. Compared with the single-relaxation-time collision model, the MRT model has been proven to be numerically more stable (Lallemand & Luo Reference Lallemand and Luo2000; Xu et al. Reference Xu, Tian, Young and Lai2018). Therefore, the MRT collision model is adopted here and is given by (Lallemand & Luo Reference Lallemand and Luo2000)

where ![]() $\boldsymbol {M}$ is a

$\boldsymbol {M}$ is a ![]() $19\times 19$ transform matrix, and

$19\times 19$ transform matrix, and ![]() $\boldsymbol {S}=diag(\tau _0,\tau _1,\ldots,\tau _{18})^{-1}$ is a non-negative diagonal relaxation matrix. The determination of

$\boldsymbol {S}=diag(\tau _0,\tau _1,\ldots,\tau _{18})^{-1}$ is a non-negative diagonal relaxation matrix. The determination of ![]() $\boldsymbol {S}$ in a three-dimensional model can be found in D'Humieres et al. (Reference D'Humieres, Ginzburg, Krafczyk, Lallemand and Luo2002). The equilibrium distribution function

$\boldsymbol {S}$ in a three-dimensional model can be found in D'Humieres et al. (Reference D'Humieres, Ginzburg, Krafczyk, Lallemand and Luo2002). The equilibrium distribution function ![]() $g_i^{eq}$ is defined as

$g_i^{eq}$ is defined as

where ![]() $c_s={\rm \Delta} x/(\sqrt {3}{\rm \Delta} t)$ is the speed of sound,

$c_s={\rm \Delta} x/(\sqrt {3}{\rm \Delta} t)$ is the speed of sound, ![]() ${\rm \Delta} x$ is the lattice spacing,

${\rm \Delta} x$ is the lattice spacing, ![]() $\boldsymbol {I}$ is the unit tensor and the weighting factors

$\boldsymbol {I}$ is the unit tensor and the weighting factors ![]() $\omega _i$ are given by

$\omega _i$ are given by ![]() $\omega _0=1/3$,

$\omega _0=1/3$, ![]() $\omega _{1-6}=1/18$ and

$\omega _{1-6}=1/18$ and ![]() $\omega _{7-18}=1/36$. The velocity

$\omega _{7-18}=1/36$. The velocity ![]() $\boldsymbol {u}$, mass density

$\boldsymbol {u}$, mass density ![]() $\rho$ and pressure

$\rho$ and pressure ![]() $p$ can be obtained according to

$p$ can be obtained according to

\begin{equation} \rho=\sum_{i}g_i,\quad p=\rho c_s^2, \quad \mathrm{and} \quad \boldsymbol{u}=\left(\sum_{i}\textbf{e}_i g_i+\frac{1}{2}\, \boldsymbol{f}{\rm \Delta} t\right)\Bigg/\rho, \end{equation}

\begin{equation} \rho=\sum_{i}g_i,\quad p=\rho c_s^2, \quad \mathrm{and} \quad \boldsymbol{u}=\left(\sum_{i}\textbf{e}_i g_i+\frac{1}{2}\, \boldsymbol{f}{\rm \Delta} t\right)\Bigg/\rho, \end{equation}

respectively. The force scheme proposed in Guo, Zheng & Shi (Reference Guo, Zheng and Shi2002) is adopted to determine ![]() $G_i$

$G_i$

where ![]() $\tau$ is the non-dimensional relaxation time.

$\tau$ is the non-dimensional relaxation time.

The feedback IBM (e.g. Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1993; Huang & Tian Reference Huang and Tian2019; Huang et al. Reference Huang, Tian, Young and Lai2021b, Reference Huang, Liu, Wang, Ravi, Young, Lai and Tian2022) is adopted to handle the no-slip boundary conditions on the flapping wing. In this method, the body force ![]() $\boldsymbol {f}$ is added in the Navier–Stokes equations to mimic a boundary condition according to

$\boldsymbol {f}$ is added in the Navier–Stokes equations to mimic a boundary condition according to

where ![]() $\boldsymbol {F}_{ib}(s,t)$ is the Lagrangian force density,

$\boldsymbol {F}_{ib}(s,t)$ is the Lagrangian force density, ![]() $dA$ is the element surface area of the immersed boundary,

$dA$ is the element surface area of the immersed boundary, ![]() $\delta (\boldsymbol {x}-\boldsymbol {X}(s,t))$ is Dirac's delta function,

$\delta (\boldsymbol {x}-\boldsymbol {X}(s,t))$ is Dirac's delta function, ![]() $\boldsymbol {x}=(x^{\prime },y^{\prime },z^{\prime })$ is the coordinate of the fluid lattice nodes,

$\boldsymbol {x}=(x^{\prime },y^{\prime },z^{\prime })$ is the coordinate of the fluid lattice nodes, ![]() $\boldsymbol {X}$ is the coordinate of the structure (i.e. the flapping wing here),

$\boldsymbol {X}$ is the coordinate of the structure (i.e. the flapping wing here), ![]() $\kappa$ is the feedback coefficient and is set to

$\kappa$ is the feedback coefficient and is set to ![]() $\kappa =2$ m s

$\kappa =2$ m s![]() $^{-1}$ in the LBM simulations (Huang et al. Reference Huang, Tian, Young and Lai2021b, Reference Huang, Liu, Wang, Ravi, Young, Lai and Tian2022),

$^{-1}$ in the LBM simulations (Huang et al. Reference Huang, Tian, Young and Lai2021b, Reference Huang, Liu, Wang, Ravi, Young, Lai and Tian2022), ![]() $\boldsymbol {U}_{ib}(s,t)$ is the immersed-boundary velocity obtained by an interpolation at the immersed boundary and

$\boldsymbol {U}_{ib}(s,t)$ is the immersed-boundary velocity obtained by an interpolation at the immersed boundary and ![]() $\boldsymbol {U}(s,t)$ is the velocity of the wing. The 4-point discrete delta function

$\boldsymbol {U}(s,t)$ is the velocity of the wing. The 4-point discrete delta function ![]() $\delta _h(\boldsymbol {x}-\boldsymbol {X}(s,t))$ is used to approximate the Dirac delta function (Peskin Reference Peskin2002)

$\delta _h(\boldsymbol {x}-\boldsymbol {X}(s,t))$ is used to approximate the Dirac delta function (Peskin Reference Peskin2002)

$$\begin{gather}\zeta({r})=\left\{\begin{array}{ll} \dfrac{1}{8}\left(3-2|r|+\sqrt{1+4|r|-4r^2}\right), & 0\leq |r|\leq 1, \\ \dfrac{1}{8}\left(5-2|r|-\sqrt{-7+12|r|-4r^2}\right), & 1\leq |r|\leq 2, \\ 0, & |r|>2. \end{array}\right. \end{gather}$$

$$\begin{gather}\zeta({r})=\left\{\begin{array}{ll} \dfrac{1}{8}\left(3-2|r|+\sqrt{1+4|r|-4r^2}\right), & 0\leq |r|\leq 1, \\ \dfrac{1}{8}\left(5-2|r|-\sqrt{-7+12|r|-4r^2}\right), & 1\leq |r|\leq 2, \\ 0, & |r|>2. \end{array}\right. \end{gather}$$

The numerical method used here has been extensively validated (e.g. Xu et al. Reference Xu, Tian, Young and Lai2018; Ma et al. Reference Ma, Wang, Young, Lai, Sui and Tian2020; Huang Reference Huang2021; Huang et al. Reference Huang, Mazharmanesh, Tian, Young, Lai and Ravi2021a,Reference Huang, Tian, Young and Laib, Reference Huang, Liu, Wang, Ravi, Young, Lai and Tian2022; Liu, Tian & Feng Reference Liu, Tian and Feng2022b) for external and internal flows. The velocity error, the spurious flow penetration and their consequences in external and internal flows of the numerical method have been discussed in Huang et al. (Reference Huang, Liu, Wang, Ravi, Young, Lai and Tian2022). Here, the simulations of a rectangular flapping wing and a fruit fly flapping wing are used to further validate the computations for three-dimensional flapping-wing cases with grid and time-step-independence tests (see Appendix B). To reduce the computational effort, a multi-block LBM (Yu, Mei & Shyy Reference Yu, Mei and Shyy2002; Xu et al. Reference Xu, Tian, Young and Lai2018; Liu et al. Reference Liu, Tian and Feng2022b) has been implemented to provide a high-resolution Cartesian grid near the solid body, with relatively lower resolutions in the far field. The computational domain has a size of ![]() $30c \times 30c \times 30c$. Four blocks of grid are used, with a minimum grid size of

$30c \times 30c \times 30c$. Four blocks of grid are used, with a minimum grid size of ![]() $0.04c$ around the wing and the maximum grid size of

$0.04c$ around the wing and the maximum grid size of ![]() $0.32c$ in the far field, resulting in a total grid number of

$0.32c$ in the far field, resulting in a total grid number of ![]() $7.25\times 10^6$. The determination of the finest fluid grid size is based on the two validation cases shown in Appendix B. The grid size of the wing is half of the finest fluid grid size (i.e.

$7.25\times 10^6$. The determination of the finest fluid grid size is based on the two validation cases shown in Appendix B. The grid size of the wing is half of the finest fluid grid size (i.e. ![]() $0.02c$) which is required by the IBM employed here. The far-field boundary conditions along six sides of the computational domain are set to be the Dirichlet boundary conditions for the velocity and pressure, which produce almost identical results as the Neumann boundary conditions due to the large computational domain used. The in-house solver is parallelised by a hybrid open multi-processing (OpenMP) and open message-passing interface (OpenMPI). Six stroke cycles are simulated to ensure that all force histories (e.g.

$0.02c$) which is required by the IBM employed here. The far-field boundary conditions along six sides of the computational domain are set to be the Dirichlet boundary conditions for the velocity and pressure, which produce almost identical results as the Neumann boundary conditions due to the large computational domain used. The in-house solver is parallelised by a hybrid open multi-processing (OpenMP) and open message-passing interface (OpenMPI). Six stroke cycles are simulated to ensure that all force histories (e.g. ![]() $C_D$ and

$C_D$ and ![]() $C_L$) and kinematics are periodic, and the time-averaged values are calculated over the last cycle. Validation has been conducted to show that the cycle-to-cycle variations in

$C_L$) and kinematics are periodic, and the time-averaged values are calculated over the last cycle. Validation has been conducted to show that the cycle-to-cycle variations in ![]() $C_L$ and

$C_L$ and ![]() $C_D$ are negligible, as shown in Appendix B.4.

$C_D$ are negligible, as shown in Appendix B.4.

4. Results and discussion

4.1. Flight performance on the plane of  $\bar {r}_1$ and

$\bar {r}_1$ and  $Ch$

$Ch$

The flight performance of the wing measured by cycle-averaged lift coefficient ![]() $\bar {C}_L$ and power economy

$\bar {C}_L$ and power economy ![]() $PE$ on the plane of

$PE$ on the plane of ![]() $\bar {r}_1$ and

$\bar {r}_1$ and ![]() $Ch$ is shown in figure 3, where several interesting results are obtained. Firstly,

$Ch$ is shown in figure 3, where several interesting results are obtained. Firstly, ![]() $\bar {C}_L$ increases with

$\bar {C}_L$ increases with ![]() $\bar {r}_1$ when

$\bar {r}_1$ when ![]() $Ch<0.15$ where the passive pitching is small. This behaviour is similar to the discussion for rigid wings (Ellington Reference Ellington1984b; Shahzad et al. Reference Shahzad, Tian, Young and Lai2016; Bhat et al. Reference Bhat, Zhao, Sheridan, Hourigan and Thompson2019b), which is understandable as the area of the wing is shifted towards the wingtip when

$Ch<0.15$ where the passive pitching is small. This behaviour is similar to the discussion for rigid wings (Ellington Reference Ellington1984b; Shahzad et al. Reference Shahzad, Tian, Young and Lai2016; Bhat et al. Reference Bhat, Zhao, Sheridan, Hourigan and Thompson2019b), which is understandable as the area of the wing is shifted towards the wingtip when ![]() $\bar {r}_1$ increases (see also figure 2) generating increasing aerodynamic forces. Secondly, when

$\bar {r}_1$ increases (see also figure 2) generating increasing aerodynamic forces. Secondly, when ![]() $Ch$ is large (e.g.

$Ch$ is large (e.g. ![]() ${\ge }0.2$),

${\ge }0.2$), ![]() $\bar {C}_L$ first increases and then decreases with

$\bar {C}_L$ first increases and then decreases with ![]() $\bar {r}_1$. The decrease of

$\bar {r}_1$. The decrease of ![]() $\bar {C}_L$ is caused by the large passive pitching and the inertia force during stroke reversal, which have a significant negative effect on lift generation. This observation is consistent with the results obtained with wings modelled by flexible plates of low mass ratio (

$\bar {C}_L$ is caused by the large passive pitching and the inertia force during stroke reversal, which have a significant negative effect on lift generation. This observation is consistent with the results obtained with wings modelled by flexible plates of low mass ratio (![]() $M_c\le 1$) and aspect ratio (

$M_c\le 1$) and aspect ratio (![]() $AR<3.0$) (Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a,Reference Shahzad, Tian, Young and Laib), and the compliant membrane wings (Gehrke et al. Reference Gehrke, Richeux, Uksul and Mulleners2022; Mathai et al. Reference Mathai, Tzezana, Das and Breuer2022). Such complex behaviour is because flexibility becomes important at large

$AR<3.0$) (Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a,Reference Shahzad, Tian, Young and Laib), and the compliant membrane wings (Gehrke et al. Reference Gehrke, Richeux, Uksul and Mulleners2022; Mathai et al. Reference Mathai, Tzezana, Das and Breuer2022). Such complex behaviour is because flexibility becomes important at large ![]() $Ch$, and the FSI system undergoes complex power synchronisation, which will be further discussed in § 4.2. Thirdly, when

$Ch$, and the FSI system undergoes complex power synchronisation, which will be further discussed in § 4.2. Thirdly, when ![]() $Ch$ increases from

$Ch$ increases from ![]() $0.05$ to

$0.05$ to ![]() $0.6$,

$0.6$, ![]() $\bar {C}_L$ first increases and then decreases, with the peak located in the band of

$\bar {C}_L$ first increases and then decreases, with the peak located in the band of ![]() $0.05\le Ch \le 0.2$. This observation is consistent with the studies with wings modelled by flexible plates (see e.g. Dai et al. Reference Dai, Luo and Doyle2012; Tian et al. Reference Tian, Luo, Song and Lu2013; Shahzad et al. Reference Shahzad, Tian, Young and Lai2018b). Overall, a high

$0.05\le Ch \le 0.2$. This observation is consistent with the studies with wings modelled by flexible plates (see e.g. Dai et al. Reference Dai, Luo and Doyle2012; Tian et al. Reference Tian, Luo, Song and Lu2013; Shahzad et al. Reference Shahzad, Tian, Young and Lai2018b). Overall, a high ![]() $\bar {r}_1$ (

$\bar {r}_1$ (![]() ${\geq }0.565$) and a low

${\geq }0.565$) and a low ![]() $Ch$ (

$Ch$ (![]() ${\approx }0.1$) is useful in maximising

${\approx }0.1$) is useful in maximising ![]() $\bar {C}_L$ with an optimal value of

$\bar {C}_L$ with an optimal value of ![]() ${\approx }0.67$. Finally, the behaviours of

${\approx }0.67$. Finally, the behaviours of ![]() $PE$ in relation to

$PE$ in relation to ![]() $Ch$ are similar to

$Ch$ are similar to ![]() $\bar {C}_L$, but its maximum value (

$\bar {C}_L$, but its maximum value (![]() ${\approx }0.71$) is obtained with

${\approx }0.71$) is obtained with ![]() $\bar {r}_1\approx 0.45$ and

$\bar {r}_1\approx 0.45$ and ![]() $Ch\approx 0.2$. This

$Ch\approx 0.2$. This ![]() $\bar {r}_1$ value is very close to that of hawkmoth wings, which has been reported to be

$\bar {r}_1$ value is very close to that of hawkmoth wings, which has been reported to be ![]() $\bar {r}_1\approx 0.47$ (Willmott & Ellington Reference Willmott and Ellington1997). However, in relation to

$\bar {r}_1\approx 0.47$ (Willmott & Ellington Reference Willmott and Ellington1997). However, in relation to ![]() $\bar {r}_1$,

$\bar {r}_1$, ![]() $PE$ shows negligible changes for

$PE$ shows negligible changes for ![]() $Ch<0.15$. This will be further investigated in § 4.3.

$Ch<0.15$. This will be further investigated in § 4.3.

Figure 3. Flight performance on the plane of ![]() $\bar {r}_1$ and

$\bar {r}_1$ and ![]() $Ch$: (a) mean lift coefficient

$Ch$: (a) mean lift coefficient ![]() $\bar {C}_L$, and (b) power economy

$\bar {C}_L$, and (b) power economy ![]() $PE$.

$PE$.

We should point out that, even though the above observations are obtained at ![]() $Re=300$,

$Re=300$, ![]() $M_c=1.0$ and a specific wing shape, they can be generalised to other conditions (e.g. different

$M_c=1.0$ and a specific wing shape, they can be generalised to other conditions (e.g. different ![]() $Re$ and

$Re$ and ![]() $M_c$), with the optimal values and locations dependent on these conditions. This statement is made based on the results from previous studies. Specifically, the optimal

$M_c$), with the optimal values and locations dependent on these conditions. This statement is made based on the results from previous studies. Specifically, the optimal ![]() $\bar {C}_L$ is larger, but the optimal

$\bar {C}_L$ is larger, but the optimal ![]() $PE$ is smaller for higher

$PE$ is smaller for higher ![]() $AR$, as reported by Shahzad et al. (Reference Shahzad, Tian, Young and Lai2018a), who considered flexible wings at

$AR$, as reported by Shahzad et al. (Reference Shahzad, Tian, Young and Lai2018a), who considered flexible wings at ![]() $Re=400$. Moreover, the optimal locations of

$Re=400$. Moreover, the optimal locations of ![]() $\bar {C}_L$ and

$\bar {C}_L$ and ![]() $PE$ are shifted to larger

$PE$ are shifted to larger ![]() $\bar {r}_1$ for higher

$\bar {r}_1$ for higher ![]() $AR$ (Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a). In addition, insects may fly close to, but not exactly in, the optimal region. For example, the wings of fruit flies are found to be of

$AR$ (Shahzad et al. Reference Shahzad, Tian, Young and Lai2018a). In addition, insects may fly close to, but not exactly in, the optimal region. For example, the wings of fruit flies are found to be of ![]() $\bar {r}_1 \approx 0.53$ (Meng, Liu & Sun Reference Meng, Liu and Sun2017) and

$\bar {r}_1 \approx 0.53$ (Meng, Liu & Sun Reference Meng, Liu and Sun2017) and ![]() $Ch \approx 0.27$ (Lei & Li Reference Lei and Li2020). According to figure 3,

$Ch \approx 0.27$ (Lei & Li Reference Lei and Li2020). According to figure 3, ![]() $\bar {C}_L=0.43$ might be just sufficient to balance their weight and

$\bar {C}_L=0.43$ might be just sufficient to balance their weight and ![]() $PE \approx 0.58$ might be the near-optimal power economy. Overall, the current analysis highlights the strong influence of the coupled effects of wing shape and pitching spring stiffness on wing performance, which will be helpful for designing the flapping-wing flyers and further explain the mechanisms of insect flight.

$PE \approx 0.58$ might be the near-optimal power economy. Overall, the current analysis highlights the strong influence of the coupled effects of wing shape and pitching spring stiffness on wing performance, which will be helpful for designing the flapping-wing flyers and further explain the mechanisms of insect flight.

To summarise this section, two distinct regions of maximum lift production and efficiency are identified. It is found that a high ![]() $\bar {r}_1$ (

$\bar {r}_1$ (![]() ${\geq }0.565$) and a low

${\geq }0.565$) and a low ![]() $Ch$ (

$Ch$ (![]() ${\approx }0.1$) is useful in maximising

${\approx }0.1$) is useful in maximising ![]() $\bar {C}_L$, and the power economy is maximised for wings with lower

$\bar {C}_L$, and the power economy is maximised for wings with lower ![]() $\bar {r}_1$ (

$\bar {r}_1$ (![]() ${\approx }0.45$) near

${\approx }0.45$) near ![]() $Ch=0.2$.

$Ch=0.2$.

4.2. Effects of the torsional spring stiffness

To discuss the mechanisms of high lift generation and flight performance, we present the results obtained by varying ![]() $Ch$ for three values of

$Ch$ for three values of ![]() $\bar {r}_1$ (0.39, 0.48 and 0.58). The forces, power economy, passive pitching and power components are particularly analysed.

$\bar {r}_1$ (0.39, 0.48 and 0.58). The forces, power economy, passive pitching and power components are particularly analysed.

We first discuss ![]() $\bar {C}_L$,

$\bar {C}_L$, ![]() $\bar {C}_D$ and

$\bar {C}_D$ and ![]() $PE$, as shown in figure 4. The trends of

$PE$, as shown in figure 4. The trends of ![]() $\bar {C}_L$ and

$\bar {C}_L$ and ![]() $PE$ are similar when

$PE$ are similar when ![]() $Ch$ increases from 0.05 to 0.6, as introduced in § 4.1. The peak values of

$Ch$ increases from 0.05 to 0.6, as introduced in § 4.1. The peak values of ![]() $\bar {C}_L$ are approximately 0.36, 0.52 and 0.65 for

$\bar {C}_L$ are approximately 0.36, 0.52 and 0.65 for ![]() $\bar {r}_1=0.39$, 0.48 and 0.58, respectively (see figure 4a). For all three

$\bar {r}_1=0.39$, 0.48 and 0.58, respectively (see figure 4a). For all three ![]() $\bar {r}_1$ values, the highest value of

$\bar {r}_1$ values, the highest value of ![]() $\bar {C}_L$ is observed between

$\bar {C}_L$ is observed between ![]() $Ch=0.1$ and

$Ch=0.1$ and ![]() $0.15$, suggesting an optimum range of

$0.15$, suggesting an optimum range of ![]() $Ch$ to achieve the highest possible

$Ch$ to achieve the highest possible ![]() $\bar {C}_L$. The exact value of the optimum

$\bar {C}_L$. The exact value of the optimum ![]() $Ch$ is found to vary within this small range with a change in the wing shape. For all the wings,

$Ch$ is found to vary within this small range with a change in the wing shape. For all the wings, ![]() $\bar {C}_D$ is observed to decrease monotonically with

$\bar {C}_D$ is observed to decrease monotonically with ![]() $Ch$, see figure 4(b). This observation is consistent with that of the two-dimensional hovering wing studied, for example, by Yin & Luo (Reference Yin and Luo2010). The decrease in

$Ch$, see figure 4(b). This observation is consistent with that of the two-dimensional hovering wing studied, for example, by Yin & Luo (Reference Yin and Luo2010). The decrease in ![]() $\bar {C}_D$ for a higher

$\bar {C}_D$ for a higher ![]() $Ch$ is caused by the larger passive pitching motion resulting in a smaller angle of attack. On the other hand,

$Ch$ is caused by the larger passive pitching motion resulting in a smaller angle of attack. On the other hand, ![]() $PE$ increases with

$PE$ increases with ![]() $Ch$, reaching its maximum value at

$Ch$, reaching its maximum value at ![]() $Ch\approx 0.15$ before decreasing with

$Ch\approx 0.15$ before decreasing with ![]() $Ch$, similar to the trend observed in

$Ch$, similar to the trend observed in ![]() $\bar {C}_L$ (see figure 4c). From

$\bar {C}_L$ (see figure 4c). From ![]() $Ch=0.05$ to

$Ch=0.05$ to ![]() $0.15$,

$0.15$, ![]() $PE$ is increased due to the increase of lift and the decrease of aerodynamic power (

$PE$ is increased due to the increase of lift and the decrease of aerodynamic power (![]() $\bar {C}_P$) caused by the softening of the spring. For

$\bar {C}_P$) caused by the softening of the spring. For ![]() $Ch>0.15$,

$Ch>0.15$, ![]() $PE$ is found to decrease as the rate of the decrease in

$PE$ is found to decrease as the rate of the decrease in ![]() $\bar {C}_L$ is higher than that in

$\bar {C}_L$ is higher than that in ![]() $\bar {C}_P$. The significant and quick decrease of

$\bar {C}_P$. The significant and quick decrease of ![]() $\bar {C}_L$ is due to the negative lift caused by the delayed pitch for soft springs and the reduced size of the leading-edge vortex, which will be demonstrated in the analysis of wing kinematics and vortex structures.

$\bar {C}_L$ is due to the negative lift caused by the delayed pitch for soft springs and the reduced size of the leading-edge vortex, which will be demonstrated in the analysis of wing kinematics and vortex structures.

Figure 4. Variations in (a) ![]() $\bar {C}_L$, (b)

$\bar {C}_L$, (b) ![]() $\bar {C}_D$ and (c)

$\bar {C}_D$ and (c) ![]() $PE$ are shown as functions of

$PE$ are shown as functions of ![]() $Ch$ for three different wing shapes of

$Ch$ for three different wing shapes of ![]() $\bar {r}_1=0.39$, 0.48 and 0.58.

$\bar {r}_1=0.39$, 0.48 and 0.58.

We then present the flapping and pitching power expenditures from various sources, as shown in figure 5, from which several important observations are obtained. Firstly, the flapping aerodynamic power dominates power consumption with peak values roughly 3 times those of the flapping inertial power. This is consistent with the definition of the mass ratio, ![]() $M=M_c/AR\approx 1/3$, which indicates that the scale of the inertial forces is approximately 1/3rd of that of the aerodynamic forces. The exception is the case of

$M=M_c/AR\approx 1/3$, which indicates that the scale of the inertial forces is approximately 1/3rd of that of the aerodynamic forces. The exception is the case of ![]() $Ch=0.6$, where the spring is very soft, resulting in a much smaller aerodynamic force (thus much smaller aerodynamic power) and larger pitching inertial power compared with that of lower

$Ch=0.6$, where the spring is very soft, resulting in a much smaller aerodynamic force (thus much smaller aerodynamic power) and larger pitching inertial power compared with that of lower ![]() $Ch$ cases. Secondly, the flapping aerodynamic power almost always remains positive due to a low mass ratio considered and the continuous work required to overcome the drag. The exception is the case of a very stiff wing (i.e.

$Ch$ cases. Secondly, the flapping aerodynamic power almost always remains positive due to a low mass ratio considered and the continuous work required to overcome the drag. The exception is the case of a very stiff wing (i.e. ![]() $Ch=0.05$) with a negative aerodynamic power just before the end of each half-stroke, similar to that observed with a two-dimensional flapping wing in Tian et al. (Reference Tian, Luo, Song and Lu2013), and is caused by the deceleration of the stroke motion. According to two-dimensional simulations (Yin & Luo Reference Yin and Luo2010; Tian et al. Reference Tian, Luo, Song and Lu2013), the cases with high mass ratios could also generate negative aerodynamic power due to a delayed rotation. Normally, the flapping aerodynamic power reaches its maximum value at around midstroke (e.g.

$Ch=0.05$) with a negative aerodynamic power just before the end of each half-stroke, similar to that observed with a two-dimensional flapping wing in Tian et al. (Reference Tian, Luo, Song and Lu2013), and is caused by the deceleration of the stroke motion. According to two-dimensional simulations (Yin & Luo Reference Yin and Luo2010; Tian et al. Reference Tian, Luo, Song and Lu2013), the cases with high mass ratios could also generate negative aerodynamic power due to a delayed rotation. Normally, the flapping aerodynamic power reaches its maximum value at around midstroke (e.g. ![]() $tf=5.25$ and

$tf=5.25$ and ![]() $tf=5.75$), where the drag and the stroke velocity are maximal. Thirdly, for pitching motion, the elastic power of the spring balances the pitching–inertial and pitching–aerodynamic powers and, thus, no net power consumption is observed. Fourthly, the flapping aerodynamic power decreases monotonically with

$tf=5.75$), where the drag and the stroke velocity are maximal. Thirdly, for pitching motion, the elastic power of the spring balances the pitching–inertial and pitching–aerodynamic powers and, thus, no net power consumption is observed. Fourthly, the flapping aerodynamic power decreases monotonically with ![]() $Ch$ similar to the trend observed in

$Ch$ similar to the trend observed in ![]() $C_D$ (figure 4b), while the flapping and pitching inertial powers increase monotonically with

$C_D$ (figure 4b), while the flapping and pitching inertial powers increase monotonically with ![]() $Ch$ because the wing of higher

$Ch$ because the wing of higher ![]() $Ch$ travels over a larger

$Ch$ travels over a larger ![]() $\theta$ range, resulting in higher

$\theta$ range, resulting in higher ![]() $\dot \theta$ and

$\dot \theta$ and ![]() $\ddot \theta$. As a result, the pitching elastic power increases correspondingly to balance the increased pitching inertial and aerodynamic powers.

$\ddot \theta$. As a result, the pitching elastic power increases correspondingly to balance the increased pitching inertial and aerodynamic powers.

Figure 5. Time traces of power coefficients (![]() $CP$ values) at

$CP$ values) at ![]() $\bar {r}_1=0.48$ for six different spring stiffness values indicated by

$\bar {r}_1=0.48$ for six different spring stiffness values indicated by ![]() $Ch=0.05$,

$Ch=0.05$, ![]() $Ch=0.1$,

$Ch=0.1$, ![]() $Ch=0.15$,

$Ch=0.15$, ![]() $Ch=0.2$,

$Ch=0.2$, ![]() $Ch=0.3$ and

$Ch=0.3$ and ![]() $Ch=0.6$.

$Ch=0.6$. ![]() $CP_{iner}^{flap}$: flapping inertial power coefficient;

$CP_{iner}^{flap}$: flapping inertial power coefficient; ![]() $CP_{aero}^{flap}$: flapping aerodynamic power coefficient;

$CP_{aero}^{flap}$: flapping aerodynamic power coefficient; ![]() $CP_{iner}^{pitch}$: pitching inertial power coefficient;

$CP_{iner}^{pitch}$: pitching inertial power coefficient; ![]() $CP_{aero}^{pitch}$: pitching aerodynamic power coefficient;

$CP_{aero}^{pitch}$: pitching aerodynamic power coefficient; ![]() $CP_{spri}^{pitch}$: pitching elastic power coefficient;

$CP_{spri}^{pitch}$: pitching elastic power coefficient; ![]() $CP_{total}$: total power coefficient.

$CP_{total}$: total power coefficient. ![]() $CP=power/(0.5 \rho U^3 A)$, where

$CP=power/(0.5 \rho U^3 A)$, where ![]() $A$ is the surface area of the wing. Here,

$A$ is the surface area of the wing. Here, ![]() $tf$ is non-dimensional time, normalised by flapping frequency

$tf$ is non-dimensional time, normalised by flapping frequency ![]() $f$.

$f$.

Finally, for ![]() $Ch\in [0.1$,

$Ch\in [0.1$, ![]() $0.2]$, a nearly in-phase synchronisation (with a phase difference

$0.2]$, a nearly in-phase synchronisation (with a phase difference ![]() ${\rm \Delta} \phi _{flap} \in [18^\circ, 30^\circ ]$ as measured in figure 6a) is observed between the flapping aerodynamic power and the total system input power. Simultaneously, an anti-phase synchronisation (with a mean phase difference

${\rm \Delta} \phi _{flap} \in [18^\circ, 30^\circ ]$ as measured in figure 6a) is observed between the flapping aerodynamic power and the total system input power. Simultaneously, an anti-phase synchronisation (with a mean phase difference ![]() ${\rm \Delta} \phi _{pitch} \approx 180^\circ$ as measured in figure 6a) between the pitching elastic power and the pitching aerodynamic and inertial powers is observed. The nearly in-phase synchronisation between the flapping aerodynamic power and the total system input power ensures that the total system input power is mainly used to drive the flapping motion without being wasted in other power components, while the anti-phase synchronisation between the pitching powers ensures that the pitching aerodynamic and inertial powers are fully stored in the elastic pitching power and vice versa. The phase difference between flapping aerodynamic power and the total system input power shows an increasing trend as the increase of

${\rm \Delta} \phi _{pitch} \approx 180^\circ$ as measured in figure 6a) between the pitching elastic power and the pitching aerodynamic and inertial powers is observed. The nearly in-phase synchronisation between the flapping aerodynamic power and the total system input power ensures that the total system input power is mainly used to drive the flapping motion without being wasted in other power components, while the anti-phase synchronisation between the pitching powers ensures that the pitching aerodynamic and inertial powers are fully stored in the elastic pitching power and vice versa. The phase difference between flapping aerodynamic power and the total system input power shows an increasing trend as the increase of ![]() $Ch$. The nearly in-phase synchronisation between the flapping aerodynamic power and the total system input power is also reflected by the timing of pitch rotation, which will be further analysed below. As shown in figure 6(b), the maximal absolute value of the peak pitching elastic power occurs at

$Ch$. The nearly in-phase synchronisation between the flapping aerodynamic power and the total system input power is also reflected by the timing of pitch rotation, which will be further analysed below. As shown in figure 6(b), the maximal absolute value of the peak pitching elastic power occurs at ![]() $Ch\in [0.1$,

$Ch\in [0.1$, ![]() $0.2]$, indicating an efficient storage and release process of the elastic energy in this region. This is consistent with the work by Cai et al. (Reference Cai, Xue, Kolomenskiy, Xu and Liu2022) who reported that the elastic storage minimises the high energetic cost of flapping wings. For

$0.2]$, indicating an efficient storage and release process of the elastic energy in this region. This is consistent with the work by Cai et al. (Reference Cai, Xue, Kolomenskiy, Xu and Liu2022) who reported that the elastic storage minimises the high energetic cost of flapping wings. For ![]() $Ch=0.05$, the wing is stiff, and while the synchronisation between flapping and pitching is similar to that required for high lift, the wing's minimal angle of attack is much higher than

$Ch=0.05$, the wing is stiff, and while the synchronisation between flapping and pitching is similar to that required for high lift, the wing's minimal angle of attack is much higher than ![]() $45^{\circ }$ where the optimum lift is produced. In addition, the drag is high for

$45^{\circ }$ where the optimum lift is produced. In addition, the drag is high for ![]() $Ch=0.05$ resulting in a low power economy. Wings with

$Ch=0.05$ resulting in a low power economy. Wings with ![]() $Ch \in [0.1, 0.2]$ produce an optimal lift and a relatively small drag as the wing experiences the minimal angle of attack

$Ch \in [0.1, 0.2]$ produce an optimal lift and a relatively small drag as the wing experiences the minimal angle of attack ![]() ${\approx }45^{\circ }$, which will be analysed and discussed in the following parts of this section.

${\approx }45^{\circ }$, which will be analysed and discussed in the following parts of this section.

Figure 6. (a) Phase difference (![]() ${\rm \Delta} \phi$) of power coefficients, as a function of

${\rm \Delta} \phi$) of power coefficients, as a function of ![]() $Ch$. Here,

$Ch$. Here, ![]() ${\rm \Delta} \phi _{flap}$: phase difference between the flapping aerodynamic power and the total system input power;

${\rm \Delta} \phi _{flap}$: phase difference between the flapping aerodynamic power and the total system input power; ![]() ${\rm \Delta} \phi _{pitch}$: mean phase difference between the pitching elastic power and the pitching aerodynamic and inertial powers. (b) The absolute value of the peak pitching elastic power.

${\rm \Delta} \phi _{pitch}$: mean phase difference between the pitching elastic power and the pitching aerodynamic and inertial powers. (b) The absolute value of the peak pitching elastic power.

To further study the reasons for high ![]() $\bar {C}_L$ and

$\bar {C}_L$ and ![]() $PE$ with various

$PE$ with various ![]() $Ch$, the time histories of

$Ch$, the time histories of ![]() $C_L$,

$C_L$, ![]() $C_D$, the pitching angle

$C_D$, the pitching angle ![]() $\theta$ and the corresponding angle of attack

$\theta$ and the corresponding angle of attack ![]() $\alpha$ are shown in figure 7; the minimal angle of attack

$\alpha$ are shown in figure 7; the minimal angle of attack ![]() $\alpha _{min}$ and the pitch rotation delay

$\alpha _{min}$ and the pitch rotation delay ![]() $\delta _{\alpha }$ are shown in figure 8. It should be noted that the pitching angle

$\delta _{\alpha }$ are shown in figure 8. It should be noted that the pitching angle ![]() $\theta$ about the pitching axis is measured with reference to the

$\theta$ about the pitching axis is measured with reference to the ![]() $z$-axis. Hence, the angle of attack

$z$-axis. Hence, the angle of attack ![]() $\alpha$ is defined as

$\alpha$ is defined as

\begin{equation} \alpha=\begin{cases} 90^{{\circ}}-\theta, & \text{if $\dot{\phi}<0$},\\ 90^{{\circ}}+\theta, & \text{if $\dot{\phi}\geq 0$}. \end{cases} \end{equation}