1 Introduction

The start of the laser story goes back over a hundred years when in 1917 Albert Einstein suggested the concept of stimulated emission. Prior to optical lasers there were operational masers, the equivalent to lasers working in the microwave region of the spectrum, for which Charles Townes, Aleksandr Prokhorov, and Nikolay Basov were awarded the 1964 Nobel Prize in Physics[1]. Arthur Schawlow and Charles Townes, Bell Labs/Columbia University, are generally credited with ‘inventing’ the laser[Reference Schawlow and Townes2], although Gordon Gould is considered by many to be its inventor as he coined the term LASER (‘Light Amplification by Stimulated Emission of Radiation’[Reference Gould3]) and eventually was awarded patents on many types of lasers. In 1960 Theodore Maiman at Hughes Research Laboratories, USA, demonstrated the first optical laser[Reference Maiman4]. This was a pivotal moment globally and groups from around the world took up the challenge to develop laser systems leading to them being used in a broad range of applications.

This review covers the history of the UK contribution to the development of high-power lasers and is presented in five sections. In the four following sections we present the work in the UK academic community; the role of the national laboratories (Central Laser Facility at Rutherford Appleton Laboratory; AWE, Aldermaston, and UKAEA Culham); UK industry; and the defence sector. What is not covered are applications associated with industrial material processing, welding and cutting for instance, and the vast field of medical applications, although reference is made to these sectors where appropriate developments were achieved.

Academia are driven by research interest and from the earliest days the UK community realized the potential of lasers. Several key individuals have established world leading reputations in laser development and their applications. Contributions are detailed from the leading university groups across the UK including those at Oxford, Imperial College London, Queen’s University Belfast (QUB), Southampton and Hull. It is also of note that the academic community have also exploited their successful research activities through spin-out companies from groups in many of the universities discussed.

The Central Laser Facility (CLF) was established at the Rutherford Laboratory (later to be renamed Rutherford Appleton Laboratory (RAL)) in 1976 to provide a national facility for conducting research by the UK academic community. Its first user facility, later to be called VULCAN, became operational in the following year. VULCAN is a multi-beam high-power Nd:glass laser and is still operational today although upgraded extensively such that it is unrecognizable from its original form. Over the years the CLF has developed and operated a range of lasers to cover, not only the high-energy density physics (HEDP) community, but photochemistry, photobiology, materials studies and micromachining. It provides its facilities for both the national and international communities and has established itself as a world leader in many aspects of its development and operations.

At AWE (formally AWRE, the Atomic Weapons Research Establishment) the potential of lasers was seen at a very early stage with a High Power Laser Group set up in 1962. The use of lasers for stockpile stewardship was realized in the early 1970s and construction began on the first large-scale laser facility at AWE, HELEN (High Energy Laser Embodying Neodymium), in 1976. After nearly 30 years of successful operations HELEN was replaced by the much larger facility, Orion, which became fully operational in 2013.

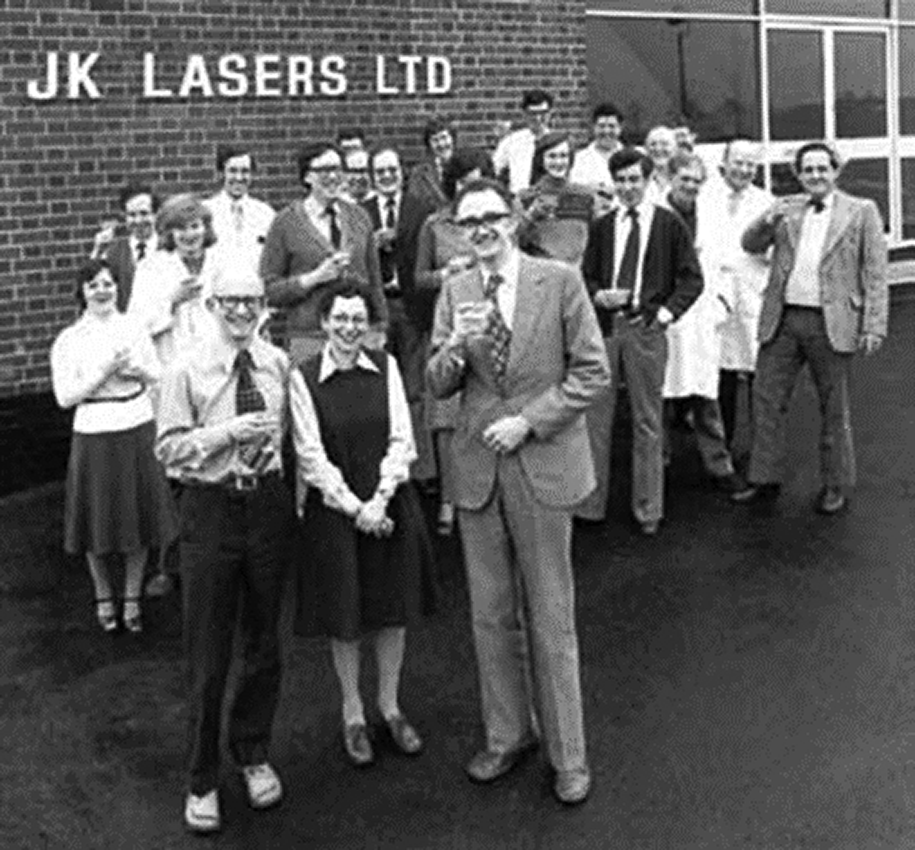

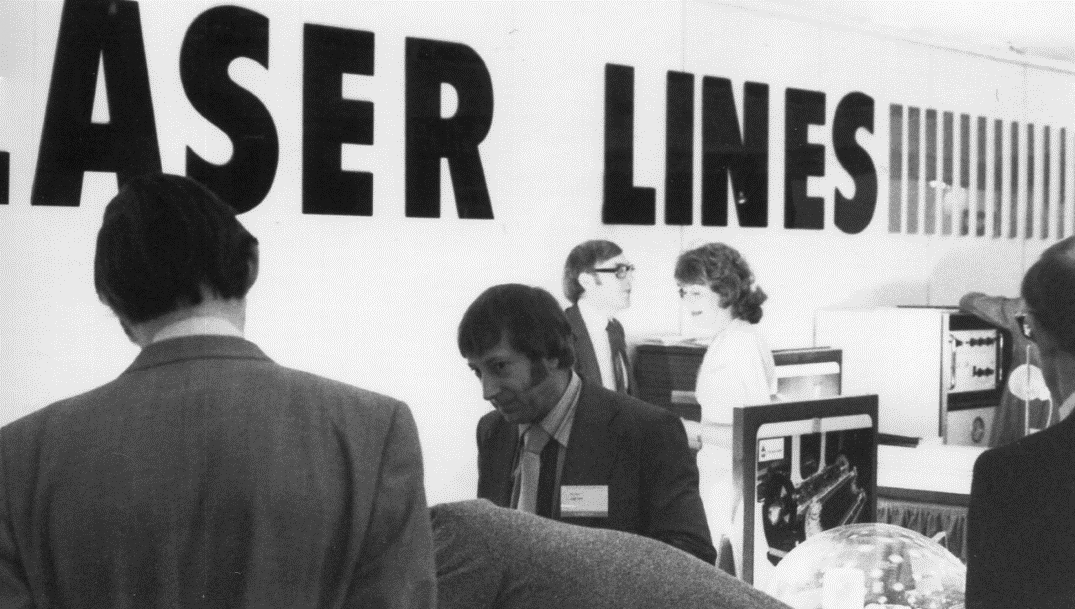

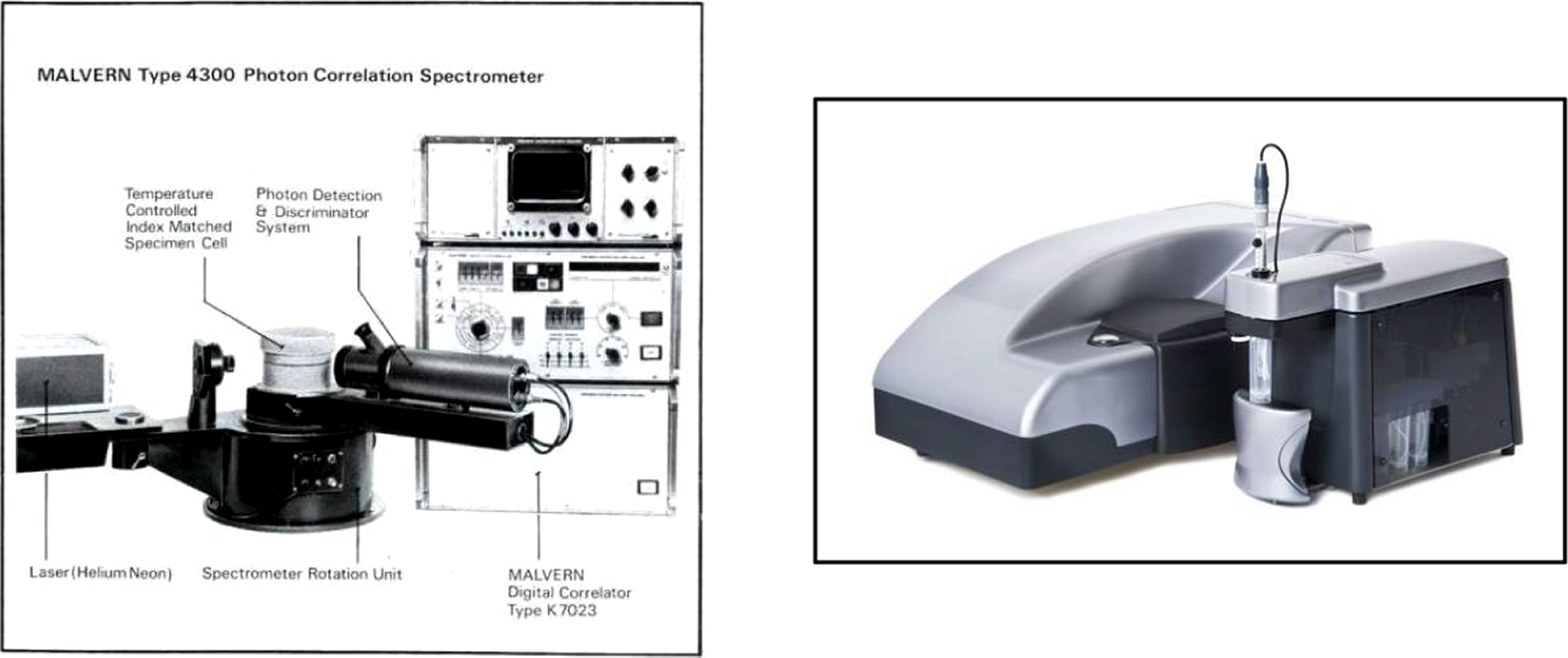

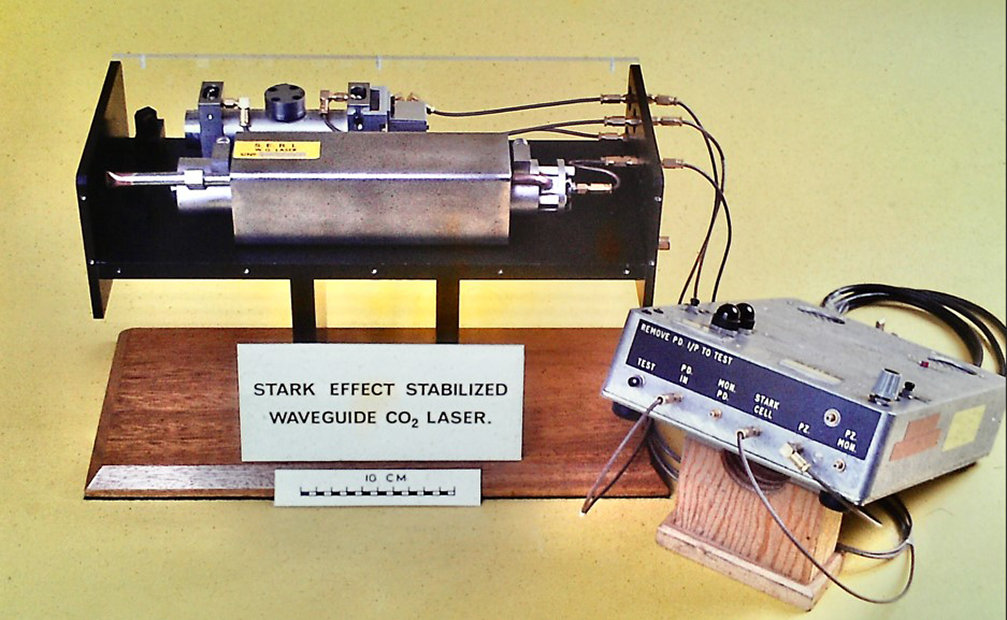

UK industry has played a key role in developing and exploiting lasers, systems and component technology since the 1960s. Several of these companies were spin-offs from universities, some spun out of other companies, with some starting life as cottage industries and going on to be world leaders in their field. There was a lot of collaboration between companies, universities and government laboratories with much cross-fertilization as people moved around.

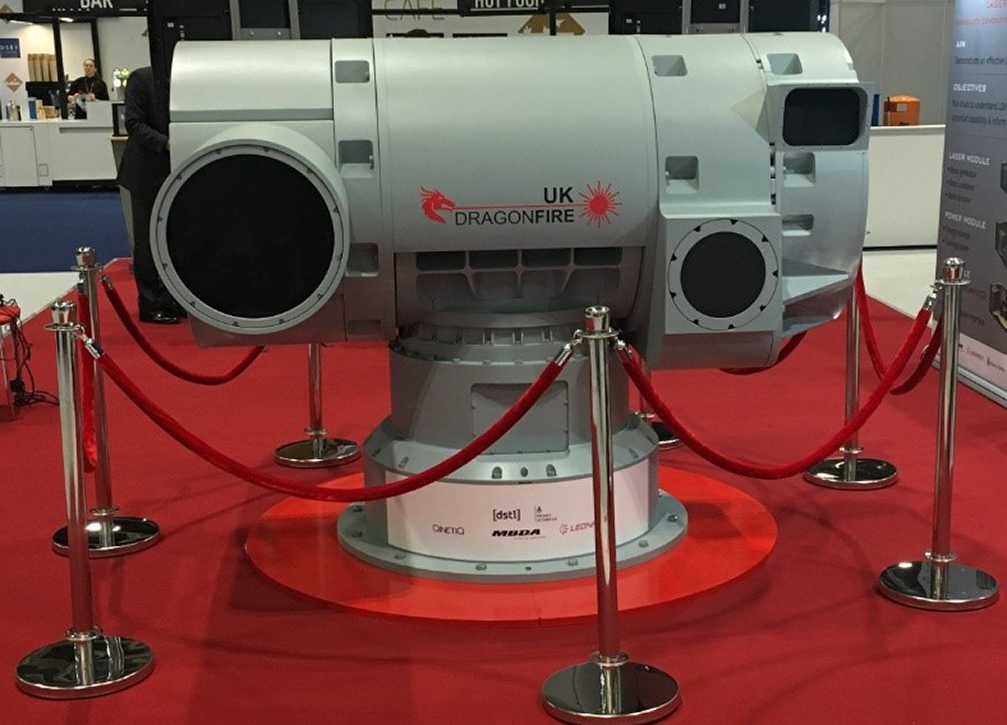

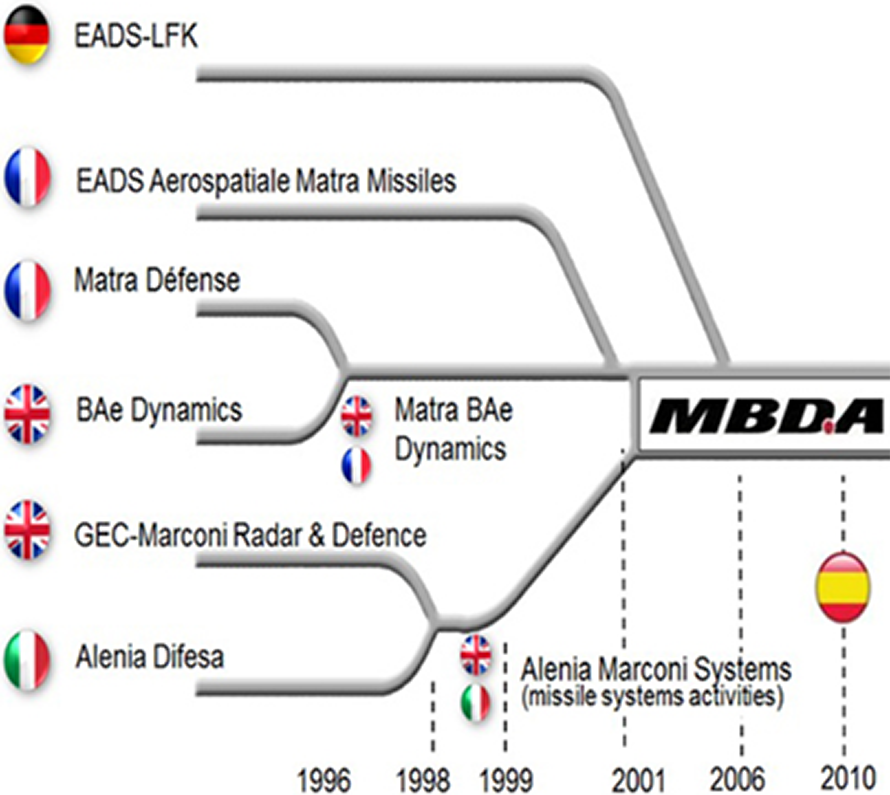

The UK defence sector has also played a key role in the story of high power lasers. Major engineering challenges have been overcome to make it possible for lasers to survive and to operate reliably, without any interventions, in the harsh military environment. Laser systems have made a significant contribution when the UK has gone to war, both in the Falklands and the Gulf War. UK products have successfully penetrated export markets and been selected for use in many high-profile contracts, for example the lasers for both the UK and US variants of the new F35 Lightning 2 aircraft.

2 Academia

Fundamental research into laser source generation together with strong interest in their applications associated with industry, medicine and enabling measurements and diagnostic techniques motivated academics in the furtherance of laser development. Later, in the 1970s the emerging concept of laser-driven fusion motivated strong interest among UK academics. This section details some of the research and development in high-power lasers at the leading universities in the UK. The universities covered are (in no particular order):

• University of Oxford;

• Imperial College London;

• QUB;

• University of Southampton;

• University of Hull;

• University of Manchester;

• University of St Andrews;

• Heriot-Watt University;

• University of Strathclyde;

• Swansea University;

• University of Essex;

• University of Reading;

• X-ray Laser Consortium.

2.1 University of Oxford

The story of laser research at Oxford goes back to 1959 when Dr. John Sanders, a Fellow of Oriel College, was on an eight-month sabbatical from Oxford to Bell Laboratories, Murray Hill, NJ, USA working in Jim Gordon’s group. He picked up ideas about inversions of population and got into this field as it looked like a good way of getting very reliable wavelength standards in the optical region. While still at the Bell Laboratories he published an early proposal for a laser in helium[Reference Sanders5], with the very next entry in the journal being the seminal paper by Ali Javan, also of the Bell Laboratories, in his proposal for the helium–neon laser[Reference Javan6].

Colin Webb joined the Oxford group in 1960 as a DPhil student after taking a physics degree at the University of Nottingham. He had carried out an undergraduate project at RRE Malvern using masers and his DPhil built on his interest generated in this working towards an optical maser. Following the work of the Russian authors, Butayeva and Fabrikant[Reference Butayeva and Fabrikant7], Colin built an apparatus which would look for gain using mercury and hydrogen in a discharge tube. Although the Russians claimed to have seen 10% gain down about a 50 cm path in a discharge mercury–hydrogen mixture, the Oxford research with Colin, Mike Taylor and John Sanders demonstrated that although there were many optical transitions there was no gain on any of them. Colin spent the next two years nailing down every parameter including measuring the populations in both the upper and lower levels[Reference Sanders, Taylor and Webb8]. On completion of his DPhil in 1964, Colin went to Bell Laboratories, for four years, to work with Gene Gordon’s group on the newly discovered argon ion laser.

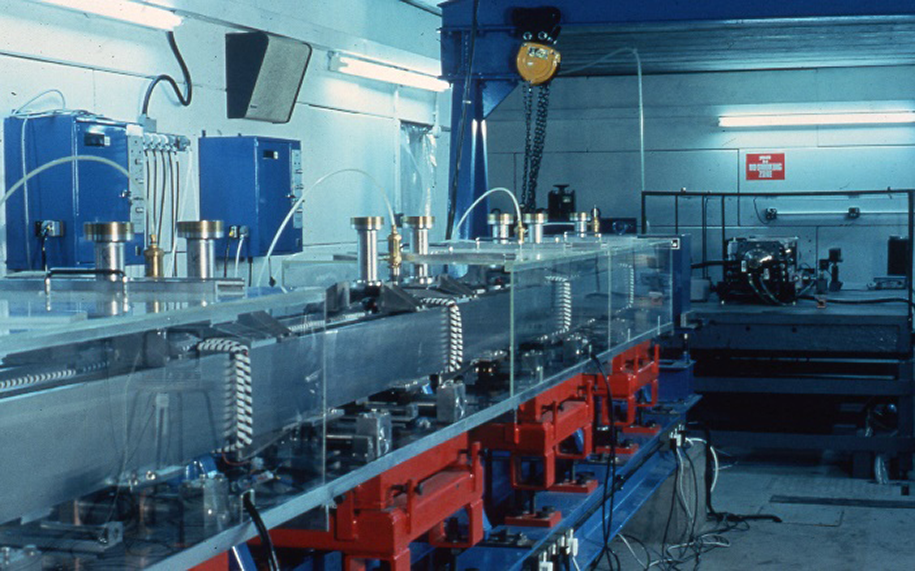

Another important contributor to the story at Oxford was Ed Ballik. Ed was the technician that put together the very first helium–neon laser in the Bell Laboratories and was enticed to do a DPhil at Oxford by John Sanders in 1962. He was an incredibly careful designer and engineer and made the most beautiful equipment. Ed put together a helium-neon laser operating at 1.15 μm, shown in Figure 1, with everything baked out in ultra-high vacuum at 400°C. The plane–plane mirrors were internal to the cavity and one meter apart, so they needed an auto-collimating telescope to get them near-parallel with final tweaking done using magnetic coils on the invar bars which contained nickel and were therefore magneto-strictive. Brian Garside took over from Ed and did some very elegant work on beating two different lasers together showing that you could, with two different sources, get beats stable enough to measure the audio frequency region of the spectrum under single-mode, two-mode and three-mode operation of these lasers.

Figure 1 Ed Ballik’s 1.15 μm HeNe laser at Oxford 1963–1964. (Picture courtesy of the University of Oxford.)

Bill Silfvast joined John Deech in John Sanders’ group to take up a PostDoc Fellowship at Oxford. They were able to measure huge gains in the super-radiant transition of lead vapour[Reference Silfvast and Deech9], something that Bill Silfvast had previously discovered as a graduate student in Utah, USA. Bill returned to the USA leaving just John Deech and John Sanders working in the Clarendon Laboratory. New laser transitions, self-terminating laser transitions in the ionized spectrum of calcium and strontium were discovered in those years.

Colin Webb returned to the Clarendon Laboratory in 1968 following his time at Bell Laboratories, having recently taken over from John Sanders as head of Oxford’s Gas Laser Research Group. With Jim Piper, a young New Zealand PostDoc who started in 1971, they built two nitrogen lasers; one for John Deech, who had moved to the University of Reading, and one for Oxford. At the time, this type of pulsed ultraviolet (UV) laser represented the cutting edge of technology for pumping the tuneable dye lasers used for atomic spectroscopy. Before Jim Piper left Oxford in 1975 to take up a position at Macquarie University, Sydney, Australia, he and Colin once again collaborated on building the world’s first transversely excited copper iodide laser, a development which drew heavily on experience with the nitrogen laser.

In 1975, Colin came across the idea of a potentially very powerful type of pulsed UV laser, the so-called excimer laser, at a summer school in Capri. One major problem with these early rare-gas halide excimer lasers was that in order to excite the high-pressure gas mixture forming the laser medium they required bulky and very expensive electron beam generators. However, to make them accessible to a large range of users, Colin realized they could be excited by a gas discharge rather than electron beams, analogous to the nitrogen and copper–iodide lasers of which the Oxford group, by then, had quite a lot of experience.

A new graduate student Andrew Kearsley was tasked with solving the problem of how to run stable and uniform gas discharges in the notoriously difficult combination of high-pressure rare gases and electro-negative components such as fluorine gas. Although the Naval Research Laboratory (NRL) in Washington, DC, USA, was the first to demonstrate laser action in a purely discharge-excited rare-gas halide excimer laser in November 1975, by April 1976 Andrew had succeeded in getting KrF to lase in a more powerful discharge device. Further, Andrew’s device was of a much more practical design and formed the basis for all subsequent development of this type of laser. A spin-out company Oxford Lasers was started to exploit the new excimer laser technology. Colin Webb, John Deech, Alan Corney and Andrew Kearsley built the first excimer laser in the garage of Alan Corney’s home in Victoria Road, Oxford.

Another important development in the group was in gas processors for excimer lasers under the terms of a Ministry of Defence (MoD) contract. The contract was set up to investigate the causes of fall off in performance of excimer laser output as the gas mixture aged in use. They discovered, while taking samples of the gas using a liquid nitrogen trap, that the gas lifetime improved considerably. The cold trap removed some polyatomic compounds harmful to laser performance. The idea of cryogenically purifying excimer laser gases was patented by the MoD and licensed to Oxford Lasers.

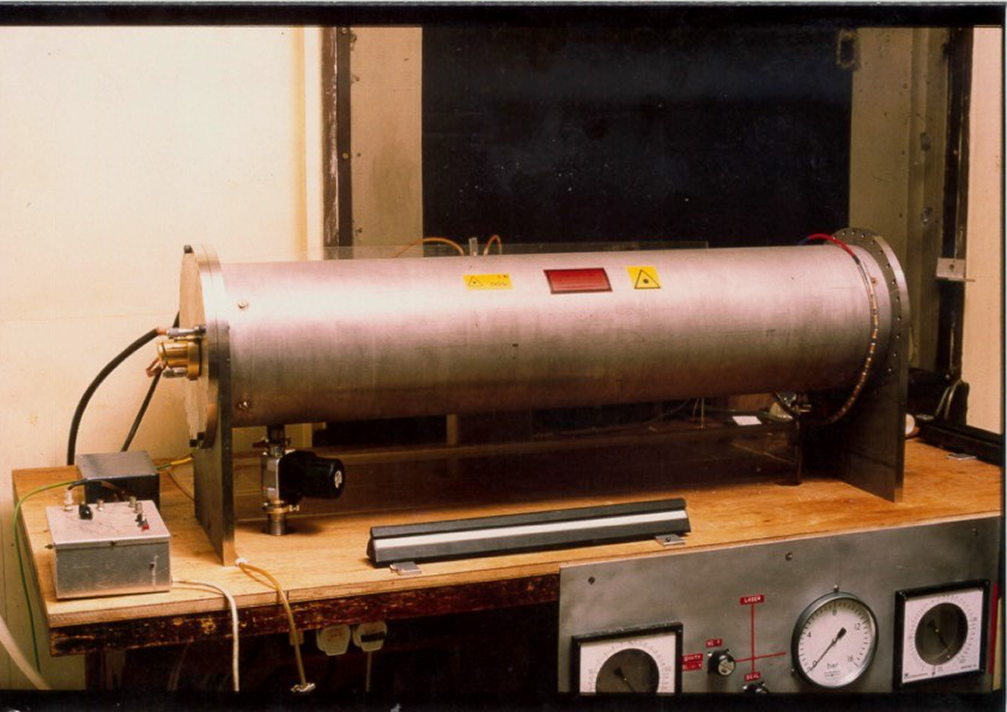

Colin’s group continued to work on discharge-pumped excimer lasers and their applications, as well as on related systems such as the vacuum ultraviolet (VUV) molecular fluorine (F2) laser. Simon Hooker joined the group as a graduate student in 1986 to work on line-tunable VUV lasers optically pumped by F2 lasers. He and Colin eventually devised a scheme based on a Franck–Condon loop in nitric oxide, which exploited the Zeeman effect to shift the pump transition into coincidence with the rather narrow emission from the F2 laser (believed to be the first time that Zeeman shifting had been used in this way). Line-tunable operation of the ‘NO laser’ was demonstrated on about half-a-dozen transitions in the UV and VUV[Reference Hooker and Webb10, Reference Haxell, Hooker and Webb11]. At the time, the F2 laser, shown in Figure 2, gave the highest pulse energy of any discharge-pumped F2 laser[Reference Hooker, Haxell and Webb12].

Figure 2 The F2 laser constructed in the Clarendon Laboratory in 1992. (Picture courtesy of the University of Oxford.)

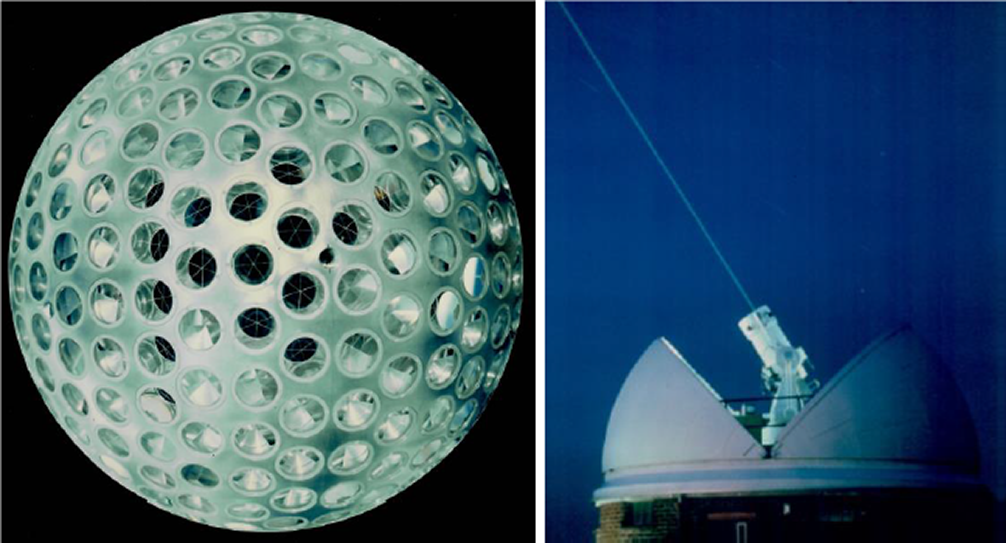

During the 1980s and 1990s Colin Webb and his group undertook leading research on metal-vapour lasers and their applications, such as isotope separation and laser guide stars, an artificial star image created for use in astronomical adaptive optics systems, which are employed in large telescopes to correct atmospheric distortion of light. A key member of the group in this period was Dr. Tony Andrews, who undertook work on metal-vapour lasers and who provided day-to-day supervision to all the graduate students in Colin’s group.

Colin Webb was elected FRS in 1991 and was awarded an MBE in 2000. He finally gave up his tutorial duties at Jesus College in 1995 when he became Head of the sub-department of Atomic and Laser Physics. He held this post until 1999 when he handed over to Professor Keith Burnett. Upon Colin’s retirement, several members of his group including David Coutts, Graham Marshall, and David & Kristie Spence moved to join Jim Piper’s department at Macquarie University, Sydney, Australia.

After several years as a postdoc in Colin’s group, Simon Hooker went to work with Steve Harris in Stanford on optical-field ionized soft X-ray lasers. He returned to Oxford in 1996 to take up a Royal Society University Research Fellowship, and, later, a faculty position and fellowship at Merton College. He has recently followed in Colin’s footsteps to become Head of Atomic and Laser Physics. Simon’s group currently works on laser-driven plasma accelerators.

Paul Ewart came to Oxford in 1979 from Imperial College, London where he had been a member of Dan Bradley’s Laser Group having graduated from QUB and completed his PhD supervised by Bradley before moving with him to Imperial College London. The high power available from pulsed tuneable dye lasers was opening up a new type of spectroscopy and Paul and his colleagues had made the first recording of absorption spectra from short-lived excited singlet states in atoms[Reference Bradley, Ewart, Nicholas, Shaw and Thompson13].

Paul set up his own group in Atomic and Laser Spectroscopy at Oxford, specializing in non-linear laser spectroscopy where high power was essential, usually achieved by pumping the dye lasers with fixed-frequency Q-switched Nd:glass or Nd:YAG lasers. Narrow spectral widths were also important for such spectroscopy but the narrowest bandwidths achievable still contained several discrete longitudinal modes fixed by the laser cavity length. The intensity and frequency of the modes suffered random fluctuations from shot to shot leading to unacceptable noise on the signals obtained following atomic or molecular excitation.

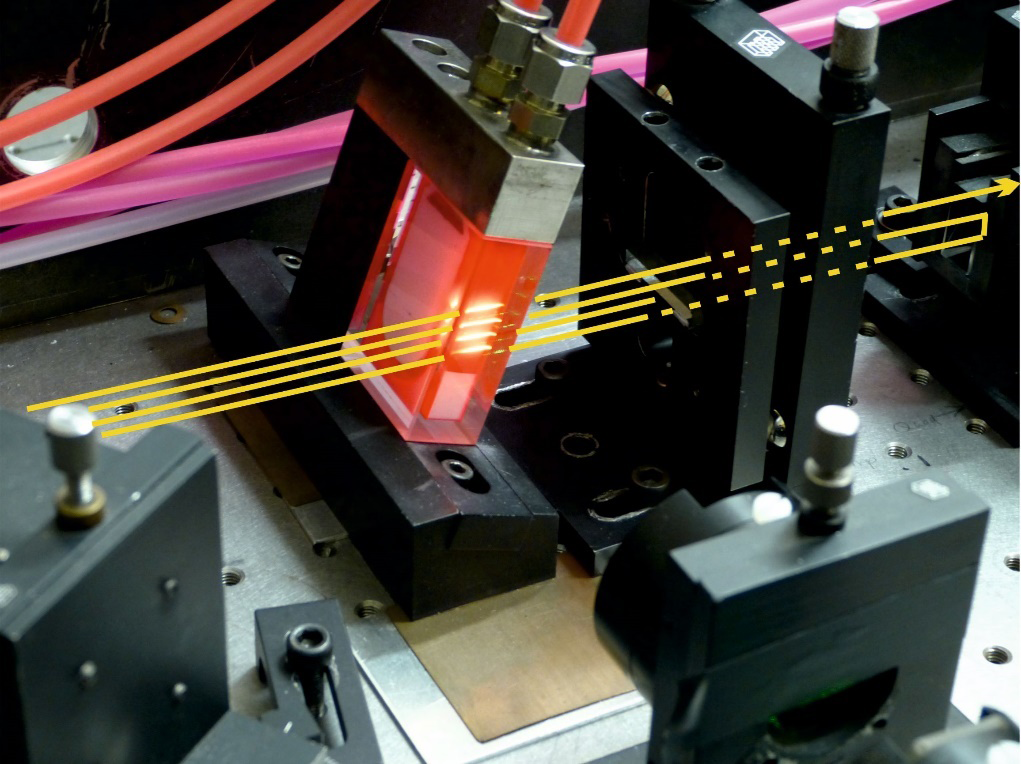

The pulse durations, of typically 10 ns, gave insufficient time for any feedback controls to stabilize the mode frequencies. With a bit of lateral thinking, Paul designed a laser with no resonant cavity and hence no longitudinal modes. By replacing the mirrors of a conventional standing-wave laser with two off-set right-angle prisms a travelling wave was established that passed in parallel lines through four separate gain regions in the dye-cell containing the laser medium, shown in Figure 3. Amplified spontaneous emission from one of the gain regions was retro-reflected, from a small mirror, to initiate the lasing process and define the axis of the propagating laser pulse. The resulting laser output had a continuous spectrum rather than a set of discrete randomly fluctuating longitudinal modes[Reference Ewart14].This device, the Modeless Laser, turned out to be the solution to another, but related, problem that was plaguing the emerging technique of broadband coherent anti-Stokes Raman spectroscopy (CARS) developed by Jean-Pierre Taran and others in the early 1980s[Reference Druet and Taran15].

Figure 3 Close-up of a modeless laser showing dye cell, small strip mirror and one 45° prism at one end with overlaid lines to show the four-pass path of the laser beam travelling wave. (Picture courtesy of the University of Oxford.)

Broadband or multiplex CARS used a high-power, fixed-frequency pump laser in combination with a broad bandwidth laser, the Stokes laser, to generate Raman signals simultaneously across a wide range of a molecular absorption spectrum. Experimental CARS profiles of molecular nitrogen then allowed the temperature to be derived when compared with a theoretically calculated spectrum. This technique was becoming a powerful tool in combustion diagnostics. Unfortunately, the random fluctuations of intensity and frequency in conventional broadband lasers produced spectral noise that severely limited the precision of temperature measurement to the order of 10%–20%. Paul had shown that the modeless laser was capable of producing multiplex spectra by using it to demonstrate the first broadband degenerate four-wave mixing spectroscopy of the two separate resonance lines in atomic sodium in a flame[Reference Ewart and Snowdon16].

Working with researchers at Shell Research at Thornton, Paul and his graduate student, Peter Snowdon, who later went to work with Shell, replaced the broadband dye laser, in the commercial CARS system being used, with a modeless laser and demonstrated improved precision in the CARS signals[Reference Snowdon, Skippon and Ewart17].

Paul set up a small spin-out company, Mode-x Laser Systems, to provide the modeless laser commercially. The CARS group at the National Research Council in Canada purchased two of the first commercial modeless lasers and, with their single-mode pump laser, achieved CARS temperature precisions of the order of 1%–2%: an order of magnitude improvement over the conventional systems[Reference Snelling, Sawchuk and Parameswaran18]. The modeless laser became the device of choice world-wide for CARS and systems were provided for many of the leading research labs in combustion science. Paul continued to push the precision of laser thermometry further by pioneering a related four-wave mixing technique of laser-induced grating spectroscopy (LIGS), which achieved temperature accuracy of around 0.4% and precision of order 0.1%: over two orders of magnitude better than the original CARS measurements[Reference Stevens and Ewart19].

Oxford’s involvement in extremely high-power lasers goes back to 1988 when Justin Wark joined the Department as a Royal Society University Research Fellow (although previously he went to Oxford in 1979 as an undergraduate with Paul Ewart as his tutor). He had recently returned from a postdoctoral position at the Laboratory for Laser Energetics at the University of Rochester (via a brief spell at Imperial College), where he had been developing the use of high-power nanosecond lasers to generate bursts of quasi-monochromatic X-rays that could in turn be used to scatter from other laser-irradiated targets, especially for ultra-fast X-ray diffraction[Reference Wark, Whitlock, Hauer, Swain and Solone20]. This concept is now widely used around the world to interrogate high-pressure solid-state matter (formed by laser ablation) at pressures comparable to those in planetary cores, and after the fusion shots, these sorts of experiments are now some of the most frequently deployed at the National Ignition Facility (NIF) laser at Lawrence Livermore National Laboratory (LLNL). Diffraction at terapascal pressures is a rapidly growing field both at high-power laser facilities and the new X-ray free-electron lasers (XFELs).

Not long after Justin joined Oxford, Mike Key the then Director of the CLF at RAL, joined Justin at Oxford as a Visiting Professor. Mike, along with Ciaran Lewis at QUB and Geoff Pert and Greg Tallents at York, was one of the prime movers in the development of novel extreme ultraviolet (XUV) lasers covered in the section on the work of the X-ray Laser Consortium.

Given the interest in developing ever shorter wavelength coherent light sources, Oxford was heavily involved in the generation of very high harmonics of intense laser beams. Much of the work was based on the adaptation of the VULCAN laser at RAL to employ chirped pulse amplification (CPA), so that it could produce high-energy picosecond pulses (interestingly CPA was invented at Rochester whilst Justin was there in 1985 and was the breakthrough in laser technology that led to Donna Strickland and Gerard Mourou winning the Nobel Prize in 2018[21]). Matt Zepf joined Justin’s group as a DPhil student in 1994 and worked with Peter Norreys at RAL to show how very high harmonics can be generated from solid targets at laser intensities of the order of 1019 W·cm–2[Reference Norreys, Zepf, Moustaizis, Fews, Zhang, Lee, Bakarezos, Danson, Dyson, Gibbon, Loukakos, Neely, Walsh, Wark and Dangor22]). This seminal result was one of many that spawned intense interest in laser–matter interactions at ultrahigh intensities and positioned the UK as a leader in this field. Matt went on to permanent positions at QUB and now Jena, Germany, whilst such were the strong links with the RAL program that Peter Norreys joined the Department in Oxford in 2012 for a joint RAL/Oxford position and continues to pioneer the Oxford research program on laser–matter interactions at the highest intensity, as well as leading efforts into inertial confinement fusion.

The work using high-power lasers for HEDP grew with the appointment of Steve Rose as a Visiting Professor in 2003, and then Oxford secured funding for a new faculty position that was filled by Gianluca Gregori in 2007. The theoretical side of the group was also strengthened considerably around the same time with the appointment of Tony Bell FRS in the same year. Tony’s complementary expertise in astrophysics has led to many interesting overlaps across the sub-departmental divides, and further expanded the applications of high-power lasers into areas such as pair production. Tony received his FRS in 2017 for this pioneering work[23].

This growth in the group meant there was a critical mass of academics broadly interested in similar scientific areas utilizing high-power lasers (Simon Hooker, Justin Wark, Steve Rose, Gianluca Gregori, Tony Bell and Peter Norreys). This has led to a number of synergies, for example Simon and Gianluca have recently established new high-power laser laboratories in the basement of the Denys Wilkinson Building in Oxford. The new laboratories house several high-power lasers, including a 15 TW Ti:sapphire laser system, and provide experimental facilities for the flourishing High Energy Density Science Group in Oxford Physics.

The Oxford Centre for High Energy Density Science (OxCHEDS) was established in 2013 as a distinct entity. Links made with AWE over many years were formalized at this time, and the AWE-funded institute provides welcome support for students and academics and promotes scientific collaboration between Oxford and AWE. As well as using the Orion laser at AWE, the Oxford group have been leading users of international laser facilities including those at the CLF, as well as Omega at Laboratory for Laser Energetics (LLE) in Rochester, and the NIF at LLNL. Such is the success of the High Power Laser Group that many of its members have won one of the most prestigious prizes in plasma physics: the American Physical Society John Dawson Award for Excellence in Plasma Physics has been won by Peter Norreys (2006), Simon Hooker (2010), Justin Wark and Sam Vinko (2015), and Gianluca Gregori (2019 and 2020).

In keeping with the above history of both creating and exploiting lasers with shorter and shorter wavelength, it was logical for the group at Oxford to play a lead role in the exploitation of fourth-generation light sources: XFELs that can operate at hard X-ray energies, with femtosecond pulse durations, have full spatial coherence and peak spectral brightness over a billion times greater than any synchrotron. Justin Wark was a member of the Science Advisory Committee at Stanford when LCLS (Linac Coherent Light Source) first ‘lased’ in 2009[24], and his work with Sam Vinko (then a DPhil student) in 2010 comprised the first interrogation of how intense X-ray radiation (at intensities that had hitherto been the province of optical lasers) interacted with solid targets[Reference Vinko, Ciricosta, Cho, Engelhorn, Chung, Brown, Burian, Chalupsky, Falcone, Graves, Hájkova, Higginbotham, Juha, Krzywinski, Lee, Messerschmidt, Murphy, Ping, Scherz, Schlotter, Toleikis, Turner, Vysin, Wang, Wu, Zastrau, Zhu, Lee, Heimann, Nagler and Wark25].

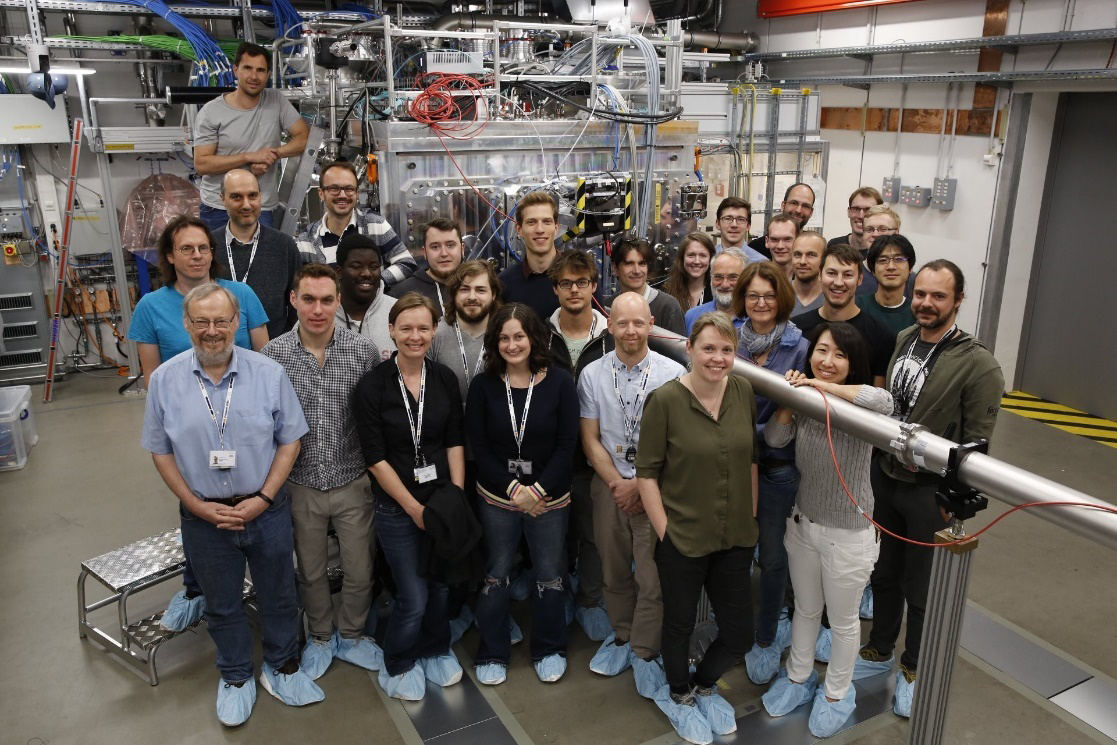

Oxford has pushed hard for UK involvement in the European XFEL in Hamburg, Germany[26]. Gianluca Gregori led the first user commissioning experiment on the MEC (Matter in Extreme Conditions) end station in May 2019[Reference Descamps, Ofori-Okai, Appel, Cerantola, Comley, Eggert, Fletcher, Gericke, Göde, Humphries, Karnbach, Lazicki, Loetzsch, McGonegle, Palmer, Plueckthun, Preston, Redmer, Senesky, Strohm, Uschmann, White, Wollenweber, Monaco, Wark, Hastings, Zastrau, Gregori, Glenzer and McBride27]. The experimental team are shown in Figure 4 in the MEC end station. Justin Wark also secured funding from the Science and Technology Facilities Council (STFC) and Engineering and Physical Sciences Research Council (EPSRC) to place a 100 J, 10 Hz, diode-pumped nanosecond laser at the Euro-XFEL, which was developed by the CLF. It is currently being commissioned in the MEC end station.

Figure 4 The experimental team in the Oxford-led first HED experiment on the Euro-XFEL in May 2019.

Much of this expansion into exploiting lasers at the shortest wavelength has been aided by the appointment of Sam Vinko as a Royal Society University Research Fellow in 2014, and then as a University Lecturer in 2020, continuing the long tradition of Oxford physics in the exploitation of lasers of shorter and shorter wavelength.

2.2 Imperial College London

Today, Imperial College London hosts the largest concentration of university based laser science in the UK, including extensive theoretical and experimental programmes in attoscience, high-power CPA and optical parametric chirped pulse amplification (OPCPA) laser development and high-average-power solid-state, fibre laser and diode pumped systems. Work spans multiple research groups including Quantum Optics and Laser Spectroscopy (QOLS)[28], Photonics[29] and Plasma Physics[30]. Fundamental laser science and ultra-fast laser physics is primarily concentrated in QOLS and the Extreme Light Consortium[31], while the Photonics Group works on more applied laser technologies, for example self-organizing (holographic) lasers, space-qualified diode-pumped solid-state systems for remote sensing, high-power and mid-infrared (mid-IR) fibre lasers[32] and mobile femtosecond medical and biophotonic imaging systems[33]. Members of the Plasma Physics Group are also extensive users of both UK and major international laser facilities such as RAL and Orion for experiments in areas including ion and electron acceleration and betatron X-ray imaging and also build and operate a number of in house multi-terawatt systems including Cerberus, a large multi-beam OPCPA system linked to the MAGPIE Z-Pinch[34].

Early history

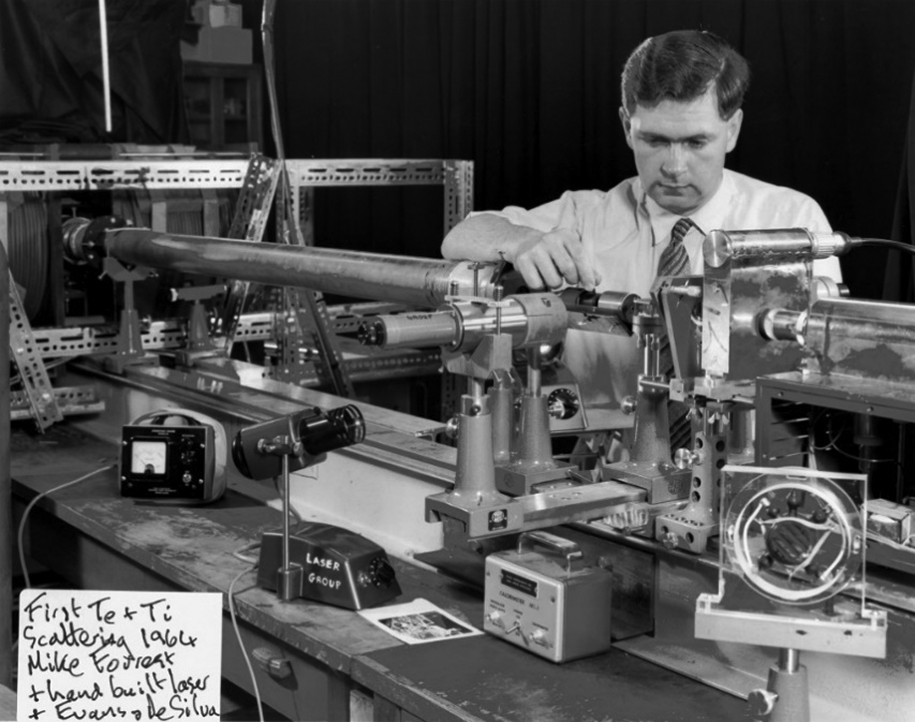

High-power laser research began at Imperial from 1962 with the aim of developing a home-built ruby system by Mike Key (later Director of CLF) as part of his PhD project in the Plasma Physics Group, following a conversation over coffee with Malcolm Haines, then a young lecturer. After three years of development the system was linked to a small theta pinch in 1965 for Thompson scattering experiments[Reference Key35] to diagnose magnetized plasma conditions. Dan Bradley also joined Imperial at this time as a lecturer in the Instrument Technology Group (J. D. McGee’s group, later named Applied Physics). He began to collaborate with UKAEA Culham, who had one of the first commercial ruby lasers in the country: the Triton Instruments LS-4, which was a Q-switched system, which Dan used for work related to scanning Fabry–Pérot and image tubes (both for storage and image enhancement). Dan and Mike left Imperial in 1964 along with the ruby laser system (later retrofitted with Nd:glass), moving first to Holloway where Dan was appointed Reader, and then on to QUB where Mike was appointed to a lectureship and Dan took up a chair in 1966, with only the development of a home built HeNe laser and a pulsed CO2 system for probing plasmas continuing at Imperial.

PhD student Malcolm White along with Bucker Dangor (one of the founders of the field of laser particle acceleration) built a megawatt class CO2 system comprising an oscillator and three amplifiers (with parts from the local ‘corner store’ Harrods)[Reference White and Dangor36]. This system was used to make the first ever experimental measurement of the thermal conductivity in a laser heated plasma and compare it with the theoretical prediction[Reference White, Kilkenny and Dangor37]. Bucker also built a HeNe laser in 1964/1965 based on a system designed and built by the Baldock research laboratory associated with the Royal Navy before systems of this type became commercially available, using a laser tube blown by Oscar, the resident physics glass technician.

The pace accelerated markedly when Dan Bradley returned to Imperial in 1973, taking up a chair in laser physics, and bringing with him a vibrant group of staff, postdocs and PhD students including Geoff New (a future head of the Laser Optics and Spectroscopy (LASP) Group), Henry Hutchinson (later Director of the Blackett Laser Consortium and then the CLF at RAL), Roy Taylor, Paul Ewart and Wilson Sibbett. Roy and Wilson have since been appointed Fellows of the Royal Society, highlighting what an extraordinary team Dan Bradley was building at this time. Other individuals such as Bill Toner and Alan Cairns were involved in Dan’s team with theoretical support from Geoff New (one of the pioneers of the OPCPA technique), and Malcolm Haines who was to become Head of Plasma Physics at Imperial and one of the UK’s most prominent theoretical plasma physicists. Dan Bradley was Head of the Physics Department at Imperial from 1976 to 1980.

In the early 1970s Dan Bradley and Malcolm Haines played a key role in establishing the CLF at RAL. Members of the Plasma Physics Group such as Joe Kilkenny were early users of the new Nd:glass system at RAL, which was later named VULCAN.

Dan and his team continued to work on passively, actively and hybridly mode-locked continuous wave (CW) dye lasers, with the former delivering the first reliable source of pulses of a few hundred femtoseconds[Reference Ruddock and Bradley38]. At various times throughout the 1970s Dan’s group held the record for the shortest pulses generated by a laser. They also linked lasers to innovative electro-optic systems such as streak cameras, developing the synchroscan streak camera[Reference Adams, Sibbett and Bradley39], which was to revolutionize real-time, ultra-fast diagnostics. This was coupled to a what was for its time a substantial 100 mJ, 5 ps Nd:silicate picosecond pulse seeded chain with four amplifier stages. This allowed for the characterization of VUV streak cameras using the sixth and tenth harmonics (i.e., third and fifth harmonics of the second harmonic in neon or xenon). The shortest harmonic generated was the 28th order (the 7th order of the 4th harmonic) in a system shown in Figure 5. Work to extend streak camera operation into the soft and hard X-ray ranges for use in laser fusion research[Reference Stradling, Studebaker, Cavailler, Launspach and Planes40] was also conducted in the Plasma Group with Joe Kilkenny, Jonathan Hares and Anthony Dymoke-Bradshaw developing systems which were then commercialized very effectively by Kentech Instruments[41].

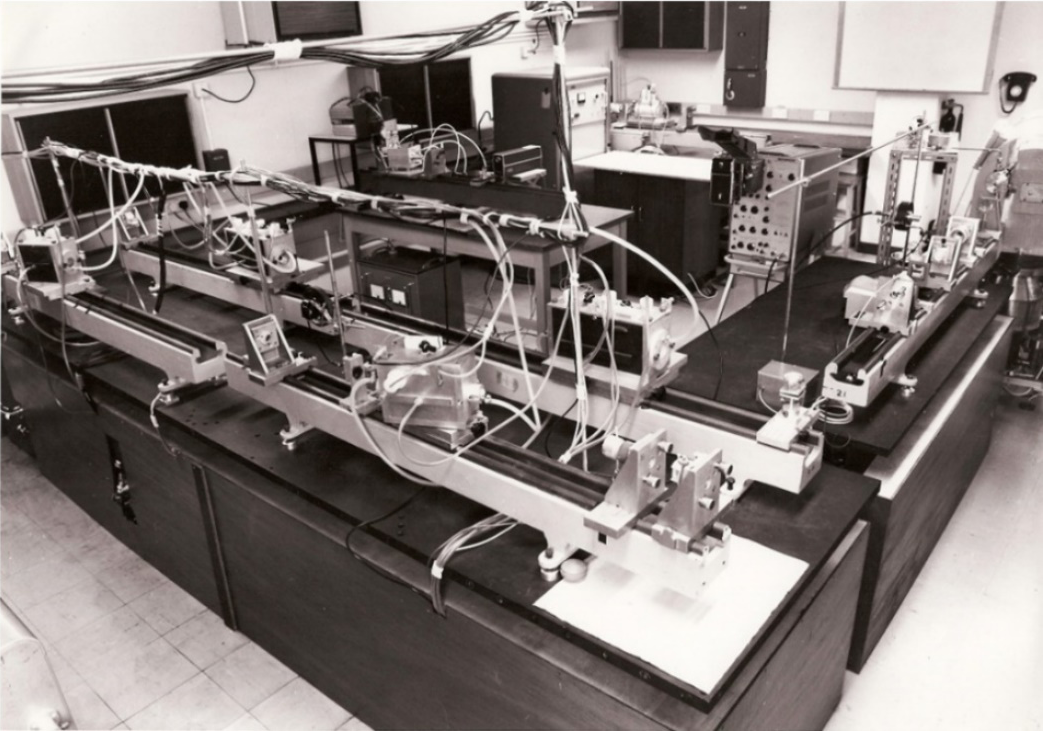

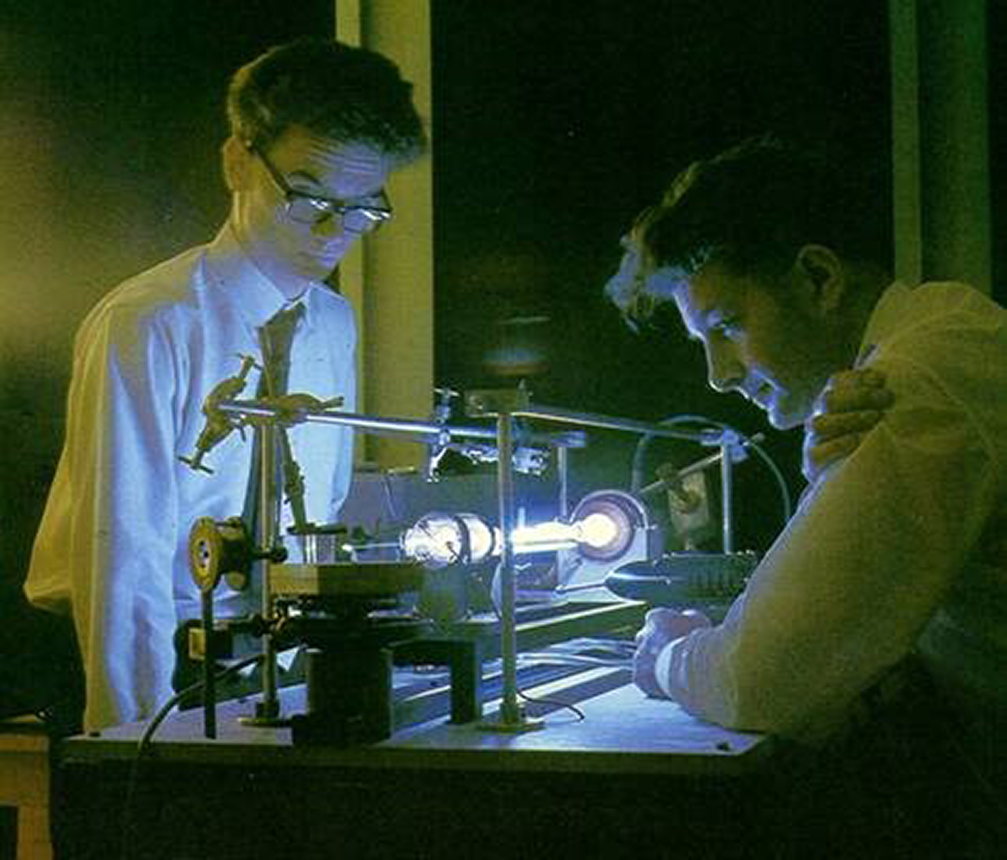

Figure 5 An early ~100 mJ, 5 ps flashlamp-pumped Nd silicate glass laser built by Roy Taylor at Imperial to investigate high harmonic generation (HHG; 2nd, 4th, 28th in Ne or He). (Picture courtesy of Imperial College London.)

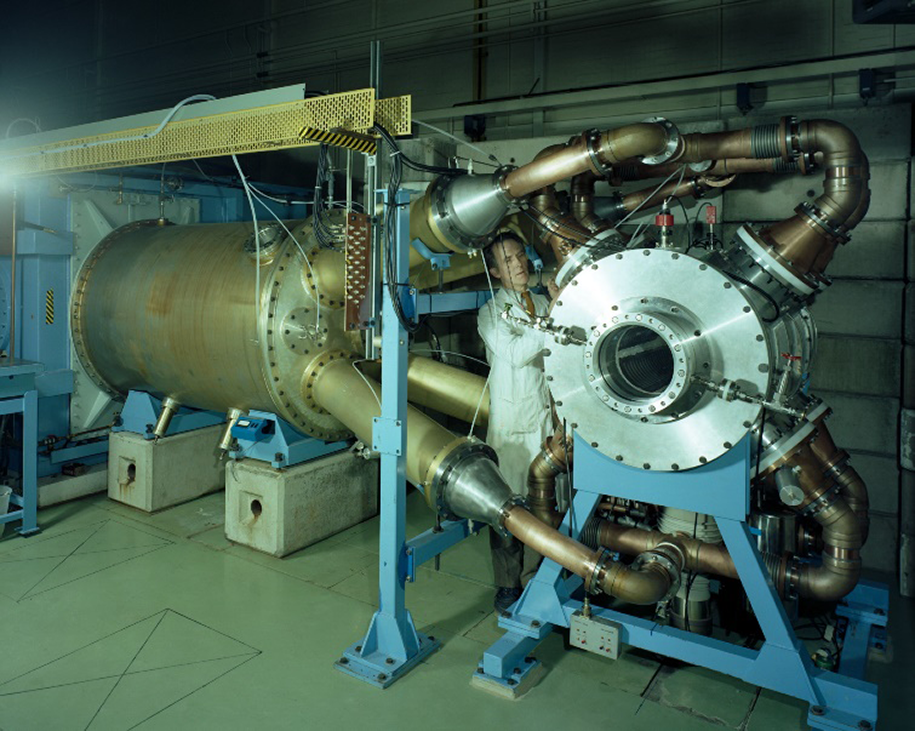

Gigawatt pulsed dye laser systems operating at the few millijoule, few picosecond level[Reference Adrain, Arthurs, Bradley, Roddie and Taylor42] were also developed by Roy Taylor, with a flashlamp pumped dye laser system in 1974 (R6G/RB mode locked with DODCI/DQOCI (3,3’-diethyloxadicarbocyanine iodide/1,3’-diethyl-4,2-quinolyloxacarbocyanine iodide)) driving third and fifth harmonics and four wave mixing in alkali vapours and inert gases for tunable VUV generation, along with an expanding research programme in increasingly larger and larger aperture e-beam pumped excimer gas lasers for VUV generation[Reference Bradley, Hull, Hutchinson and McGeoch43]. An early excimer laser developed by the group is shown in Figure 6.

Theoretical work also continued, with Bradley and New publishing a seminal invited review paper of the field[Reference Bradley and New44], the first work to give a comprehensive coverage to the physics of short pulse measurement. Geoff New went on to become a leading theoretician in the field of non-linear optics modelling a number of experiments within the Sprite and TITANIA programmes at RAL and with Ian Ross and others at RAL, developing the theoretical underpinnings of the OPCPA technique now employed by many high-power systems worldwide[Reference Ross, Matousek, New and Osvay45]. In parallel with laser development work at Imperial, members of the then Spectroscopy Group including Dave Burgess and Anne Thorne saw the potential of lasers as powerful probes of excited states and began to exploit lasers for experiments in plasma spectroscopy from the early 1970s onwards[Reference Burgess and Skinner46]. Other members of the Spectroscopy Group at the time included Hans Bachor and Ken Baldwin, later leaders of laser development in Australia along with Jinx Cooper who went on to leadership roles at JILA in Colorado.

Figure 6 Dan Bradley and Henry Hutchinson’s excimer laser in the basement of the Huxley building, Imperial College London. (Picture courtesy of Imperial College London.)

In the early 1980s members of the Plasma Physics Group became major users of the UK’s high-power laser facilities at the CLF. For example, Oswald Willi and his team, investigated early X-ray laser schemes, detailed later in the section on the X-ray Laser Consortium. Oswald’s team also worked on plasma instabilities and thermal transport[Reference Willi, Kiehn, Edwards, Barrow, Smith, Wark and Turcu47] related to laser fusion and in 1989 led the first interaction experiments using the Sprite laser at RAL. Sprite was also used to test ideas for creating ‘low-temperature’ laser plasmas that could be used for recombination X-ray laser schemes by Bucker Dangor in collaboration with Mike Key and Justin Wark[Reference Offenberger, Blyth, Dangor, Djaoui, Key, Najmudin and Wark48]. A large cohort of PhD students were also trained by Oswald, Bucker and others at this time, with many moving on to prominent roles elsewhere, for example John Edwards (associate director for inertial confinement fusion at NIF), Mike Dunne (Director of LCLS) and Marco Borghesi (Professor and Head of Group at QUB).

Work led by Bucker Dangor at this time also sought to use the VULCAN laser as a driver for an electron acceleration scheme using a ‘beat-wave’. This required co-propagating two synchronized and slightly different wavelength pulses through VULCAN, a major technical challenge at the time given the inherent bandwidth limitations of Nd:glass. The CLF adapted the 100 ps oscillator system on VULCAN, led by Colin Danson, to produce two wavelengths 1053 and 1064 nm in Nd:YLF and Nd:YAG and then used a mix of Nd:phosphate and silicate glass in the amplifier chain to give high-energy synchronized pulses at both wavelengths[Reference Dangor, Afshar-Rad, Cole, Danson, Dymoke-Bradshaw, Dyson, Edwards, Evans, Garvey and Mitchell49]. However, the beat-wave acceleration scheme itself was extremely challenging to operate as it required exquisite matching between the laser and plasma conditions and was eventually superseded by single-pulse techniques.

Blackett Laboratory Laser Consortium (BLLC) and early CPA lasers in the UK

With the first demonstration of the elegant CPA technique to circumvent non-linear optical damage in a high-power laser in 1985 by Strickland and Mourou[Reference Strickland and Mourou50] it became clear that there were important opportunities to extend high-power laser science and exploit this new technique in areas including high-field atomic physics and laser plasma experiments. A collaboration between leading theoretical and experimental physicists from the LASP and Plasma Physics Groups at Imperial led by Peter Knight, Henry Hutchinson, Keith Burnett, Oswald Willi, Dave Burgess and J.-P. Connerade with then Postdocs Roland Smith and Jon Marangos set out to develop a Nd:glass-based 1 J, 1 ps table-top terawatt (T3) laser at Imperial. This system initially used a 10 ps actively mode-locked Nd:YLF oscillator, pulse stretching and bandwidth generation in 2 km of optical fibre and then regenerative and multi-pass amplification in Nd:glass. It was the first CPA laser of its kind operational in Europe and is shown in Figure 7. Early successes driven by this system focused on high harmonic generation (HHG) and included the first temporal[Reference Faldon, Hutchinson, Marangos, Muffet, Smith, Tisch and Wahlstrom51], spatial[Reference Tisch, Smith, Ciarroca, Muffet, Marangos and Hutchinson52] and coherence measurements[Reference Ditmire, Gumbrell, Smith, Tisch, Meyerhofer and Hutchinson53] of high-order harmonics, work that now underpins the field of attoscience.

Figure 7 The UK’s first table-top terawatt (TReference Gould3) system, a 1 J, 1 ps TReference Gould3 laser developed at Imperial College by the Laser Consortium, circa 1998. This was the first operational T3 CPA laser system in Europe, built by PhD student Mary Falden and then Postdoc Roland Smith. (Picture courtesy of Imperial College London.)

The T3 system operated for over a decade, being upgraded a number of times to shorter-pulse and higher-energy operation by Roland Smith, with larger gold holographic compressor gratings and a Martinez-style stretcher in place of the original optical fibre. It was then used for much of the formative work on high-intensity laser interactions with atomic clusters[Reference Ditmire, Smith, Tisch and Hutchinson54, Reference Ditmire, Smith, Marjoribanks, Kulcsar and Hutchinson55] key aspects of which were driven by then Postdoc Todd Ditmire (now Professor at University of Austin at Texas), EPSRC Research Fellow John Tisch (now Professor and Head of the QOLS Group at Imperial) and Roland Smith. This work exploited the unique ability of clusters to couple to intense few picoseconds laser pulses through a dynamic plasma resonance[Reference Ditmire, Smith, Tisch and Hutchinson54, Reference Ditmire, Tisch, Springate, Mason, Hay, Marangos, Smith and Hutchinson56, Reference Springate, Hay, Tisch, Mason, Ditmire, Hutchinson and Marangos57] and was fundamental in launching the field of laser–cluster interaction physics, which led to later successes such as a demonstration of table-top thermonuclear fusion at LLNL using the Falcon laser[Reference Zweiback, Smith, Cowan, Hays, Wharton, Yanovsky and Ditmire58] in collaboration with scientists from Imperial.

The Blackett Laboratory Laser Consortium (BLLC), funded by grants from ESPRC, MoD and Imperial College, was initially under the directorship of Henry Hutchinson, and later Jon Marangos after Henry moved to RAL as the director of CLF. Techniques and diagnostics developed on the original Nd:glass CPA laser (for example, high-dynamic-range third-order autocorrelation[Reference Luan, Hutchinson, Smith, Zhou and Meas59] and fibre-mode locked oscillators for use as the front end of a picosecond CPA laser[Reference Mercer, Chang, Danson, Edward, Hutchinson and Miller60]) were instrumental in helping the CLF and other laboratories in Europe implement the CPA technique more effectively on larger-scale systems such as VULCAN. Imperial also collaborated with the CLF on the first CPA target experiments at RAL which observed plasma and MeV particle jet collimation[Reference Bell, Beg, Chang, Dangor, Danson, Edwards, Fews, Hutchinson, Luan, Lee, Norreys, Smith, Taday and Zhou61]. The higher energies and higher intensities produced by VULCAN enabled a series of high-profile collaborative experiments led by Imperial’s Bucker Dangor, including the first demonstration of self-injection from wakefield accelerators[Reference Modena, Najmudin, Dangor, Clayton, Marsh, Joshi, Malka, Darrow, Danson, Neely and Walsh62], the production of energetic jets of protons and heavy ions[Reference Clark, Krushelnick, Davies, Zepf, Tatarakis, Beg, Machacek, Norreys, Santala, Watts and Dangor63, Reference Clark, Krushelnick, Zepf, Beg, Tatarakis, Machacek, Santala, Watts, Norreys and Dangor64] and the production of solid harmonics up to the XUV[Reference Norreys, Zepf, Moustaizis, Fews, Zhang, Lee, Bakarezos, Danson, Dyson, Gibbon, Loukakos, Neely, Walsh, Wark and Dangor22].

The glass laser at Imperial also helped other groups establish their own high-power laser activities. Claes-Göran Wahlström who became Director of the Lund Laser Centre, Sweden, spent a year at Imperial working on the glass system before Lund began work on its own CPA program, while Simon Hooker, now Professor at Oxford, was able to conduct some of his first laser guiding experiments on this system at Imperial[Reference Hooker, Spence and Smith65].

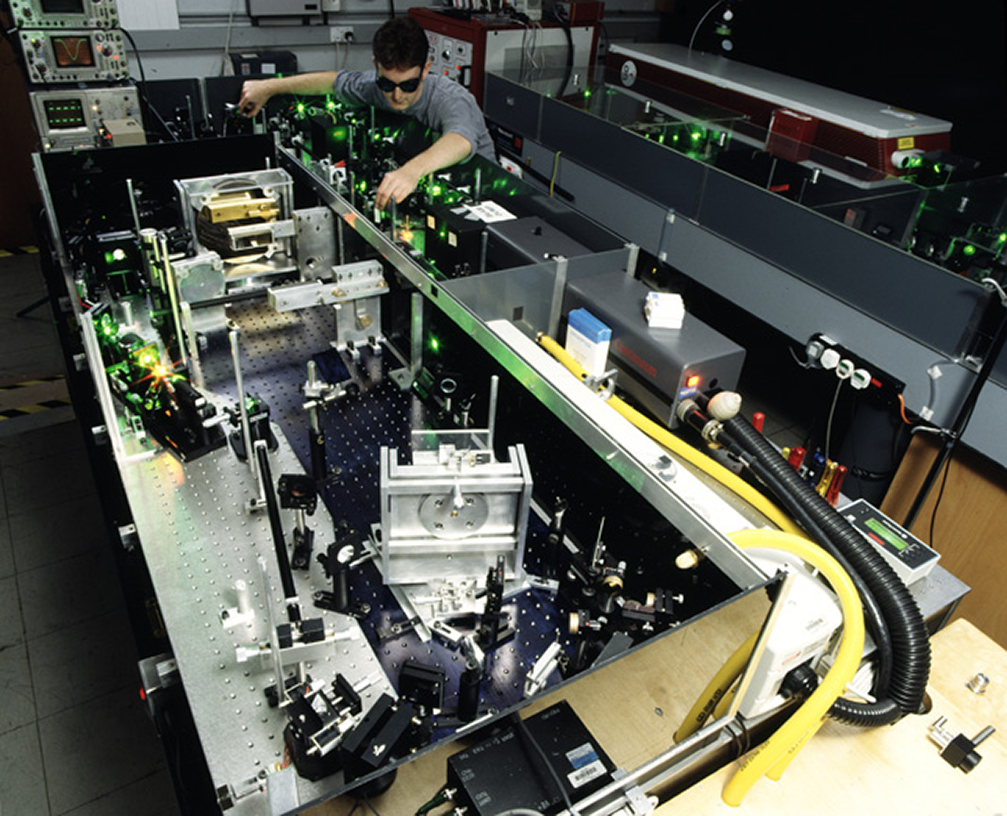

The BLLC also worked on shorter-pulse high-power systems, initially on sub-100 fs colliding pulse mode locked dye lasers operating in the visible seeding an amplifier chain pumped with excimers during the early 1990s, while Roy Taylor and colleagues continued to make pioneering advances in ultra-fast seed sources, including the first self-mode locking of Ti:sapphire below 50 fs[Reference Rizvi, French and Taylor66]. However, the difficulty of scaling dye laser systems to high energy and the general hazards of working with toxic chemicals and flammable solvents prompted development of a high-energy Ti:sapphire system from the mid-1990s onwards. A 150 fs, 150 mJ Ti:sapphire CPA laser system was developed by a team including Mike Mason (now Director of Engineering, Coherent UK) and John Tisch, shown in Figure 8, and used as a platform for an extensive series of investigations into processes such as energetic cluster explosions[Reference Shao, Ditmire, Tisch, Springate, Marangos and Hutchinson67], HHG with molecular gases[Reference Fraser, Hutchinson, Marangos, Shao, Tisch and Castillejo68], high-field interactions with fullerenes[Reference Hay, Springate, Mason, Tisch, Castillejo and Marangos69] and pioneered experimental techniques that permit the study of strong field interactions with controllably aligned molecules[Reference Velotta, Hay, Mason, Castillejo and Marangos70]. Alongside these technical and scientific developments, the BLLC also trained a large cohort of PhD students, many of whom moved on to roles in industry and both UK and international laboratories.

Figure 8 Imperial College’s terawatt 150 fs, 150 mJ Ti:sapphire CPA system circa 2000 being adjusted by the then PhD student Mike Mason. (Picture courtesy of Imperial College London.)

In the last decade, under Jon Marangos’ direction, the focus of the BLLC moved to the problem of generating and harnessing attosecond light pulses for probing ultra-fast processes such as electron dynamics and ionization in a single molecule. By this time, Ti:sapphire lasers operating at kilohertz repetition rates and tens of millijoules energies below 30 fs had become a commercial reality and the BLLC exploited a number of these systems as the front-end for innovative hollow-fibre bandwidth generation and pulse compression (HFPC) systems with much of the development led by John Tisch (now Professor and Head of the QOLS Group at Imperial). These hybrid systems were able to routinely deliver multi-millijoule pulses with world-leading durations below 4 fs[Reference Witting, Frank, Arrell, Okell, Marangos and Tisch71] and then drive sub-200 as soft X-ray pulses for experiments in surface science[Reference Okell, Witting, Fabris, Arrell, Hengster, Ibrahimkutty, Seiler, Barthelmess, Stankov, Lei, Sonnefraud, Rahmani, Uphues, Maier, Marangos and Tisch72], ultra-fast molecular rearrangement[Reference Baker, Robinson, Haworth, Teng, Smith, Chirila, Lein, Tisch and Marangos73] and molecular dynamics[Reference Torres, Siegel, Brugnera, Procino, Underwood, Altucci, Velotta, Springate, Froud, Turcu, Patchkovskii, Ivanov, Smirnova and Marangos74]. The BLLC became the primary centre for attoscience in the UK, but the tradition of spinning out core expertise and technologies to UK national laboratories continued, with an Imperial HFPC system being installed at RAL to enable the Astra Artemis system to deliver sub-femtosecond pulses for use by the wider scientific community.

Work also continued on higher-energy in-house systems, with the development of Cerberus, a large multi-beam OPCPA/Nd:glass laser by a collaboration between the QOLS and Plasma Physics groups led by Roland Smith and Sergey Lebedev. Construction of Cerberus began in 2008, and a unique feature of this system and its initial scientific driver was the ability to deliver light to both standalone target areas and the megaamp, megavolt Z-Pinch MAGPIE allowing it to drive fully quantitative plasma diagnostics including two-dimensional Faraday rotation imaging of magnetic fields[Reference Swadling, Lebedev, Hall, Patankar, Stewart, Smith, Harvey-Thompson, Burdiak, de Grouchy, Skidmore, Suttle, Suzuki-Vidal, Bland, Kwek, Pickworth, Bennett, Hare, Rozmus and Yuan75] and multi-point Thomson scattering[Reference Harvey-Thompson, Lebedev, Patankar, Bland, Burdiak, Chittenden, Colaitis, De Grouchy, Doyle, Hall, Khoory, Hohenberger, Pickworth, Suzuki-Vidal, Smith, Skidmore, Suttle and Swadling76]. This capability is currently only rivalled by the much larger Z-Beamlet and Z-Facility at the Sandia National Laboratory, USA. Cerberus includes a number of 50 mm diameter Nd:glass rod amplifiers donated by AWE following the shutdown of the HELEN laser, allowing long-pulse operation at energies beyond ~30 J. The short pulse arm is currently limited to ~5 J, 500 fs, 10 TW operation as a result of B-integral in the compressor, however in 2021 a new vacuum compressor and a series of additional larger aperture OPA gain stages will be commissioned, which will allow Cerberus to deliver >20 J, 50 TW shots on target.

The front-end architecture of Cerberus is by a combination of design and ‘convergent evolution’ very similar to that of the Orion laser at AWE, allowing this system to be used for proof of principle laser and diagnostic development for Orion. It has also been used to develop new plasma diagnostic systems such as multi-wavelength imaging interferometry[Reference Patankar, Gumbrell, Robinson, Lowe, Giltrap, Price, Stuart, Kemshall, Fyrth, Luis, Skidmore and Smith77] and high-brightness broad-band light sources[Reference Floyd, Gumbrell, Fyrth, Luis, Skidmore, Patankar, Giltrap and Smith78] for Orion, a facility also accessed by members of the Plasma Physics Group for experiments in areas such as radiative astrophysical shock studies[Reference Suzuki-Vidal, Clayson, Stehlé, Swadling, Foster, Skidmore, Graham, Burdiak, Lebedev, Chaulagain, Singh, Gumbrell, Patankar, Spindloe, Larour, Kozlova, Rodriguez, Gil, Espinosa, Velarde and Danson79].

The strong Iλ 2 scaling of ponderomotive energy with laser wavelength, and the success of >1.5 μm lasers in driving HHG to shorter wavelengths highlighted the attraction of mid-IR laser systems for extreme optical physics. In 2016 Imperial began work on a new high-energy mid-IR laser Chimera co-funded by Defence and Science Technology Laboratory (DSTL), EPSRC and the US Air Force Office of Scientific Research (AFOSR) as part of the first of a series of multi-national UK–US MURI projects. Chimera is a multi-beam mid-IR laser with an 800 nm, 7 fs Ti:sapphire front end, seeding a high-energy Nd:YLF pump chain, an 800 nm OPCPA stage which then generates 2–4.5 μm light by difference frequency generation with over 1 μm of bandwidth. A series of OPA gain stages then amplify 3.7 and 1.6 μm pulses, with a target performance of >50 mJ, 30 fs at 3.7 μm and higher energies at 1.6 μm. The system is currently operational at ~7 mJ and being scaled up towards its final target energy. The MURI project also funds mid-IR laser development and its exploitation for ultra-fast science[Reference Johnson, Austin, Wood, Brahms, Gregory, Holzner, Jarosch, Larsen, Parker, Strüber, Ye, Tisch and Marangos80, Reference Johnson, Miseikis, Wood, Austin, Brahms, Jarosch, Struber, Ye and Marangos81] by extending the wavelength shifting and HFPC capabilities of lower energy, but higher repetition rate kilohertz systems operated by the Extreme Light Consortium.

Scientists from Imperial continue to be highly active at RAL and Orion in the UK and at other leading laser facilities worldwide, with for example Stuart Mangles and Zulfikar Najmudin leading prominent activities in gigaelectronvolt electron acceleration[Reference Mangles, Murphy, Najmudin, Thomas, Collier, Dangor, Divall, Foster, Gallacher, Hooker, Jaroszynski, Langley, Mori, Norreys, Tsung, Viskup, Walton and Krushelnick82, Reference Kneip, Nagel, Martins, Mangles, Bellei, Chekhlov, Clarke, Delerue, Divall, Doucas, Ertel, Fiuza, Fonseca, Foster, Hawkes, Hooker, Krushelnick, Mori, Palmer, Phuoc, Rajeev, Schreiber, Streeter, Urner, Vieira, Silva and Najmudin83], multi-megaelectronvolt ion acceleration[Reference Palmer, Dover, Pogorelsky, Babzien, Dudnikova, Ispiriyan, Polyanskiy, Schreiber, Shkolnikov, Yakimenko and Najmudin84, Reference Willingale, Mangles, Nilson, Clarke, Dangor, Kaluza, Karsch, Lancaster, Mori, Najmudin, Schreiber, Thomas, Wei and Krushelnick85] and betatron radiation imaging experiments[Reference Kneip, McGuffey, Martins, Martins, Bellei, Chvykov, Dollar, Fonseca, Huntington, Kalintchenko, Maksimchuk, Mangles, Matsuoka, Nagel, Palmer, Schreiber, Phuoc, Thomas, Yanovsky, Silva, Krushelnick and Najmudin86, Reference Cole, Symes, Lopes, Wood, Poder, Alatabi, Botchway, Foster, Gratton, Johnson, Kamperidis, Kononenko, De Lazzari, Palmer, Rusby, Sanderson, Sandholzer, Sarri, Szoke-Kovacs, Teboul, Thompson, Warwick, Westerberg, Hill, Norris, Mangles and Najmudin87] at large facilities. During his time as Director of the CLF, Henry Hutchinson initiated the development of the Astra laser at the RAL. Astra was then used in the first demonstration of monoenergetic electron beams from a laser accelerator[Reference Johnson, Austin, Wood, Brahms, Gregory, Holzner, Jarosch, Larsen, Parker, Strüber, Ye, Tisch and Marangos80], by a team led by Krushelnick, Dangor and Najmudin. Astra and its successor Astra Gemini have continued to drive major advances in the field of laser-driven plasma accelerators, many of these proposed and lead by Imperial academics. To support their work at national facilities, the Plasma Group operates a home-built >100 mJ, 30 fs Ti:sapphire laser for small-scale acceleration experiments and diagnostic development, complementing Cerberus, Chimera and three ultra-fast laser systems operated by the Extreme Light Consortium, an evolution of the original BLLC.

2.3 QUB

After short periods of his early career at Imperial College and Royal Holloway College, Dan Bradley was appointed Head of the Physics Department at QUB in 1966. Mike Key moved with him, and Geoff New joined the group from Oxford in 1967. Dan Bradley was very successful in attracting funding, and this allowed him to build the department into one of the world’s leading laser research centres. Dan’s team circa 1969 is shown in Figure 9.

Figure 9 Dan Bradley’s group at QUB circa 1969. (Picture courtesy of QUB.)

By 1970, QUB was at the leading edge of UK laser research, particularly in the generation of picosecond pulses in Q-switched and mode-locked Nd:glass lasers, and later in dye lasers. The two-photon fluorescence technique for pulse-width measurement was developed at that time and shown to be capable of sub-picosecond resolution[Reference Bradley, Liddy, Sibbett and Sleat88]. Pioneering work in the theory of mode-locking in CW dye lasers was also carried out during this period[Reference Arthurs, Bradley and Roddie89].

At the same time, Dan Bradley teamed up with Brian Bates to establish a space research group of international standing in the field of high-resolution solar spectroscopy. Yet another important research focus involved the development of a picosecond resolution optical streak camera. Dan Bradley and Bill Sleat established a link with a small UK consultancy company, and this became Electro-Photonics Ltd (EPL), which exploited the laser developments at QUB. EPL was best known for the flashlamp pumped model 33 dye laser, which became a standard research tool for many laboratories. The company also produced an optical streak camera with 15 ps resolution. EPL was absorbed into Hadland Photonics Ltd in 1976.

By the early 1970s, Mike Key had established a Nd:glass system which was quite impressive for the time. It had three oscillators (mode-locked Nd:YAG and Nd:glass plus Q-switched glass) which could be selected to feed the same amplifier chain with different duration pulses. The chain incorporated home built and commercial amplifiers, eventually culminating in a 38 mm diameter Korad rod amplifier. Even then, just over a decade from invention of the laser, the laser was able to provide 30 J/6 ns, 3 J/100 ps or 100 mJ/10 ps pulses for a range of experimental interactions. Beam quality and self-focusing damage was always a problem, but the chain included home-built apodized apertures, spatial filtering, Faraday rotators, a laser-triggered spark gap and double-pass amplifier geometries.

In 1973, with political tension high in Northern Ireland, Dan Bradley took up a chair back at Imperial College. Several members of his group left with him including Geoff New, Henry Hutchinson, Paul Ewart, Wilson Sibbett and Roy Taylor. In the same year, Mike Key went on sabbatical to MPI Munich and, soon after his return to QUB, was seconded to RAL.

During his final undergraduate year at QUB in 1970 Ciaran Lewis opted for a final year project topic ‘X-ray lasers’ inspired by the popular scientific press. His supervisor was Mike Key which led to him joining his research group in 1971 to start a PhD to explore options for shorter than visible wavelength laser devices. It turned out Mike Key already had a student, Bernard Rogers, working on a fast discharge VUV hydrogen laser and Ciaran worked alongside him at the start. Ciaran was one of the principal researchers in the UK X-ray Laser Consortium working closely with groups across the UK. The work of the Consortium is detailed in a separate section of this review. Ciaran Lewis was Head of Laser Interaction and Optoelectronic and later Plasma and Laser Interaction Physics Research Divisions (LIORD and PLIP) in QUB between 1989 and 2005. He was Acting Director of the International Research Centre for Experimental Physics (IRCEP, see below) in 2005 and Deputy Director of the re-structured Centre for Plasma Physics (CPP) from establishment in 2006 until his retirement in 2015.

It was the earlier optical streak camera development that led to the demonstration of an X-ray streak camera at QUB. Their glass workshops simply cut the end of an optical camera, fitted an O-ring seal around the open end used grazing incidence onto a suitable cathode. The first streak was of a carbon resonance line spectrum ~3–4 nm using grating dispersion and soon after an aluminium resonance line streak ~1 nm using crystal dispersion.

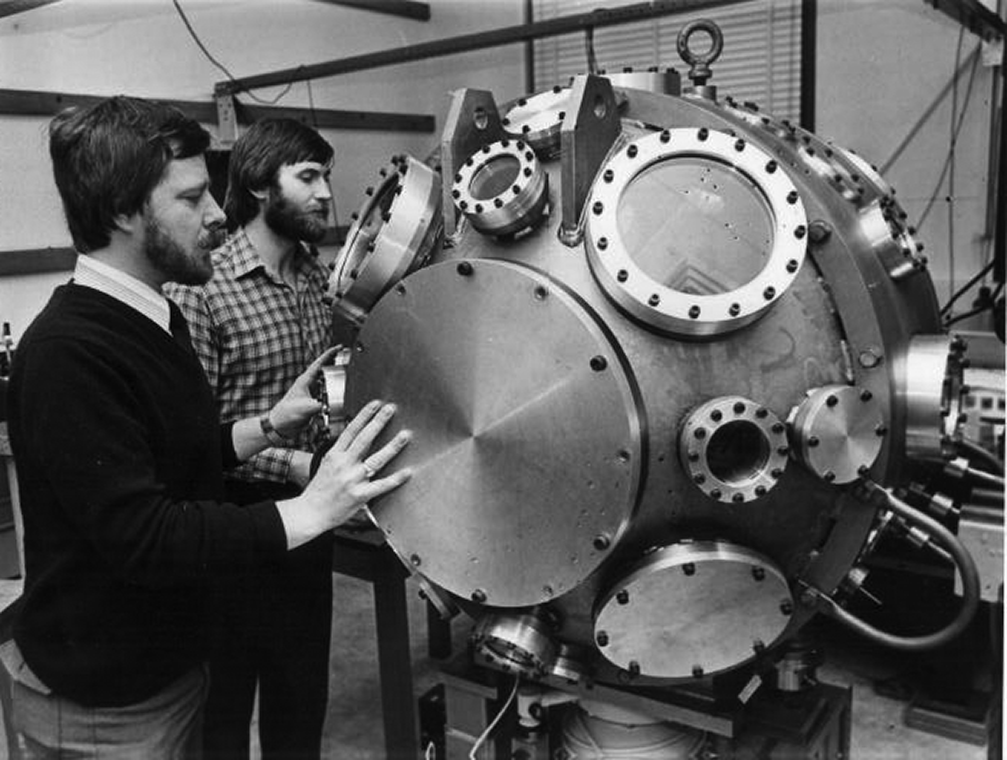

The QUB glass laser developed slowly after the arrival of access to the CLF at RAL in the late 1970s but stayed below ~10–50 GW capability. The case for a central facility was based on the premise that several strong university groups should not be competing for the same money to build parallel small laser systems at home institutions. But QUB benefitted by upgrades to VULCAN at the CLF through donations of old target chambers, such as from its TA2 and TAW target areas. Figure 10 shows Ciaran Lewis and his first PhD student, Peter Cunningham, at QUB in the mid-1980s with the old TA2 chamber installed in a customized room next to the Nd:glass laser system. Peter later went to University of Natal, Durban, South Africa, to work with Professor Max Michaelis.

Figure 10 Ciaran Lewis and his first PhD student, Peter Cunningham, at QUB in the mid-1980s with the TA2 target chamber recycled from the CLF. (Picture courtesy of QUB.)

As the CLF lasers grew it became clear that the advantage of university home-based smaller lasers to train students and test ideas was becoming increasingly important to increase the scientific efficiency of experiments at the CLF. An opportunity arose towards the end of the 1990s to address this problem. An EPSRC Support Programme for University Research (SPUR) initiative was launched and QUB, led by Ken Bell (Head of School of Mathematics and Physics) and aided by Ciaran Lewis specifically on major laser aspects, prepared an application to procure a facility infrastructure to support a range of activities. The bid for £9.3 million was successfully funded (and partly privately supported by Atlantic Philanthropies) and the extension/refurbishment to the old Physics building culminated in the official opening of the IRCEP building in June 2005 and the formation of new research centres, including the CPP[90].

With IRCEP laboratory space available, a successful grant application to EPSRC enabled the purchase and installation of a custom-built laser, known as TARANIS (Terawatt Apparatus for Relativistic and Non-linear Interaction Science). This capital project was co-funded with support from QUB and industrial sponsorship. The new laser system produced its first significant scientific output in 2008. The TARANIS laser[Reference Dzelzainis, Nersisyan, Riley, Romagnani, Ahmed, Bigongiari, Borghesi, Doria, Dromey, Makita, White, Kar, Marlow, Ramakrishna, Sarri, Zaka-Ul-Islam, Zepf and Lewis91] is a Nd:glass system that can deliver up to 30 J in a nanosecond pulse and ∼10 J in <1 ps. The laser is a hybrid Ti:sapphire–Nd:glass system using CPA. The laser front-end consists of a Ti:sapphire oscillator, an all-reflective folded stretcher and a Ti:sapphire regenerative amplifier. Amplification to multi-terawatt levels is achieved in a multi-stage flashlamp pumped Nd:phosphate glass rod chain with two rods of 9 mm and two of 25 mm diameter. The third stage consists of two parallel 50 mm diameter rods for amplification of two separate pulses up to peak energies of ~30 J per pulse at a repetition rate of one shot every 10 minutes. The pulses from the glass rod chain can be recompressed in two double-pass grating compressors each one with two 210 mm × 400 mm × 50 mm, 1740 lines/mm gold-coated diffraction gratings. A minimum pulse duration of 560 fs can be achieved, with ~60% energy transmission through the compressors. Long (~1 ns) pulses can be obtained by bypassing the compressors. Experiments are carried out in a dedicated target chamber, shown in Figure 11. For experiments requiring two beams, combinations of nanosecond–nanosecond, picosecond–picosecond or nanosecond–picosecond pulse durations can be selected.

Figure 11 The TARANIS target chamber at the CPP, QUB. (Picture courtesy of QUB.)

At present, 2020, the QUB contribution to UK laser science remains strong, with a long history going back to the arrival of Dan Bradley and Mike Key in 1966. The group has made significant contributions to high-power laser development and has established one of the strongest plasma physics groups in the UK through the CPP currently led by Professor Marco Borghesi. CPP researchers have provided particularly important scientific contributions in areas such as ion acceleration[Reference Scullion, Doria, Romagnani, Sgattoni, Naughton, Symes, McKenna, Macchi, Zepf, Kar and Borghesi92, Reference Kar, Ahmed, Prasad, Cerchez, Brauckmann, Aurand, Cantono, Hadjisolomou, Lewis, Macchi, Nersisyan, Robinson, Schroer, Swantusch, Zepf, Willi and Borghesi93] and applications[Reference Dromey, Coughlan, Senje, Taylor, Kuschel, Villagomez-Bernabe, Stefanuik, Nersisyan, Stella, Kohanoff, Borghesi, Currell, Riley, Jung, Wahlström, Lewis and Zepf94, Reference Doria, Kakolee, Kar, Litt, Fiorini, Ahmed, Green, Jeynes, Kavanagh, Kirby, Kirkby, Lewis, Merchant, Nersisyan, Prasad, Prise, Schettino, Zepf and Borghesi95] (with QUB leadership of important UK-wide initiatives, such as the LIBRA[Reference Borghesi, Kar, Prasad, Kakolee, Quinn, Ahmed, Sarri, Ramakrishna, Qiao, Geissler, Ter-Avetisyan, Zepf, Schettino, Stevens, Tolley, Ward, Green, Foster, Spindloe, Gallegos, Robinson, Neely, Carroll, Tresca, Yuan, Quinn, McKenna, Dover, Palmer, Schreiber, Najmudin, Sari, Kraft, Merchant, Jeynes, Kirkby, Fiorini, Kirby and Green96] and A-SAIL[97] consortia), high-field physics[Reference Ahmed, Dieckmann, Romagnani, Doria, Sarri, Cerchez, Ianni, Kourakis, Giesecke, Notley, Prasad, Quinn, Willi and Borghesi98, Reference Warwick, Dzelzainis, Dieckmann, Schumaker, Doria, Romagnani, Poder, Cole, Alejo, Yeung, Krushelnick, Mangles, Najmudin, Reville, Samarin, Symes, Thomas, Borghesi and Sarr99], warm dense matter[Reference Saiz, Gregori, Khattak, Kohanoff, Sahoo, Naz, Bandyopadhyay, Notley, Weber and Riley100], laboratory astrophysics[Reference Sarri, Poder, Cole, Schumaker, Piazza, Reville, Dzelzainis, Doria, Gizzi, Grittani, Kar, Keitel, Krushelnick, Kuschel, Mangles, Najmudin, Shukla, Silva, Symes, Thomas, Vargas, Vieira and Zepf101], HEDP[Reference Sarri, Macchi, Cecchetti, Kar, Liseykina, Yang, Dieckmann, Fuchs, Galimberti, Gizzi, Jung, Kourakis, Osterholz, Pegoraro, Robinson, Romagnani, Willi and Borghesi102, Reference Romagnani, Robinson, Clarke, Doria, Lancia, Nazarov, Notley, Pipahl, Quinn, Ramakrishna, Wilson, Fuchs, Willi and Borghesi103], HHG[Reference Dromey, Adams, Hörlein, Nomura, Rykovanov, Carroll, Foster, Kar, Markey, McKenna, Neely, Geissler, Tsakiris and Zepf104] and attosecond science[Reference Yeung, Rykovanov, Bierbach, Li, Eckner, Kuschel, Woldegeorgis, Rödel, Sävert, Paulus, Coughlan, Dromey and Zepf105]. QUB has also made significant contributions to the management of the CLF with Mike Key and Henry Hutchinson (both CLF Directors), Fergus O’Neill and David Neely.

2.4 University of Southampton

Work on lasers started at University of Southampton very soon after Maiman’s 1960 demonstration of the first laser. Alec Gambling initiated the work at Southampton’s Electronics Department, recruiting Bob Smith, and the first research student Dilip Bhawalkar in 1962, with three more students in 1963, which included Dave Hanna. Amongst the interests of this Laser Group was the development of lasers with sufficient power to produce a variety of non-linear optical phenomena. Of these, optical parametric oscillators (OPOs) represented a particularly enticing goal with their promise of tuning over a very broad spectral range, a feature that still eluded the lasers of that era. At the same time Alec Gambling’s Optical Fibre Group, targeted the use of lasers for optical communications, with the development of optical fibres as an essential prerequisite, and brilliantly fulfilled by Dave Payne, who joined as a research student in 1966.

In 1971 the laser group suffered a major set-back when a massive fire totally destroyed the ‘laser hut’. The group bounced back with newly constructed facilities.

Both groups progressed prolifically, but largely independently and by 1984, the Laser Group migrated, under the leadership of Dave Hanna, to the Physics Department, shown in Figure 12. As fate would have it, the two groups, once separated physically found reason to start close collaboration, over a shared interest in optical fibre lasers. The effectiveness of this collaboration was a significant element in the successful bid for an Interdisciplinary Research Centre grant from EPSRC, which enabled the two groups to be physically reunited in 1989, within the Optoelectronics Research Centre (ORC), with new premises and extensive fabrication facilities. Alec Gambling was the Director of the ORC, with the two Daves as Deputy Directors. In due course, when Alec retired, Dave Payne took on the role of Director.

Figure 12 Dave Hanna in the early days of the ORC at Southampton. (Picture courtesy of the University of Southampton.)

The research of the Laser Group is described in detail from 1963 to 2001 in a review by Dave Hanna marking his 60th birthday[Reference Hanna106]. The early goal of constructing an OPO made stringent demands both on laser power (or, more correctly, laser beam brightness) and on a non-linear medium having sufficient non-linearity and robustness against laser-induced damage. Research students Harvey Rutt and then Barry Luther-Davies, using a proustite crystal and a Q-switched Nd laser as pump, obtained a spectacular OPO performance with a tuning range of nearly three octaves for this OPO[Reference Hanna, Luther-Davies and Smith107]. Some useful lessons obtained from this work were the importance of using a laser pump in a highly controlled way, with maximum brightness, i.e., single transverse and longitudinal mode. This care over mode control has remained a key aspect of laser developments in the ORC as it is fundamental to achieving the best performance from a limited available power.

Further refinements came later with the use of a telescope within the laser resonator to allow a larger mode diameter within the laser medium, and hence more single mode power. Then, moving to mode-locked operation of the pump laser, combined with synchronous pumping of the OPO resonator (SPOPO), the average pump-power requirement for the OPO was significantly reduced. By using the technique of additive-pulse-mode-locking (APM) the pulse duration could be further reduced to the sub-picosecond regime, thus, further reducing the mean pump power needed. Typically, by this stage in laser developments, it was becoming common practice to use diode lasers as pumps for the main laser and APM operation to provide a CW mode-locked pulse train.

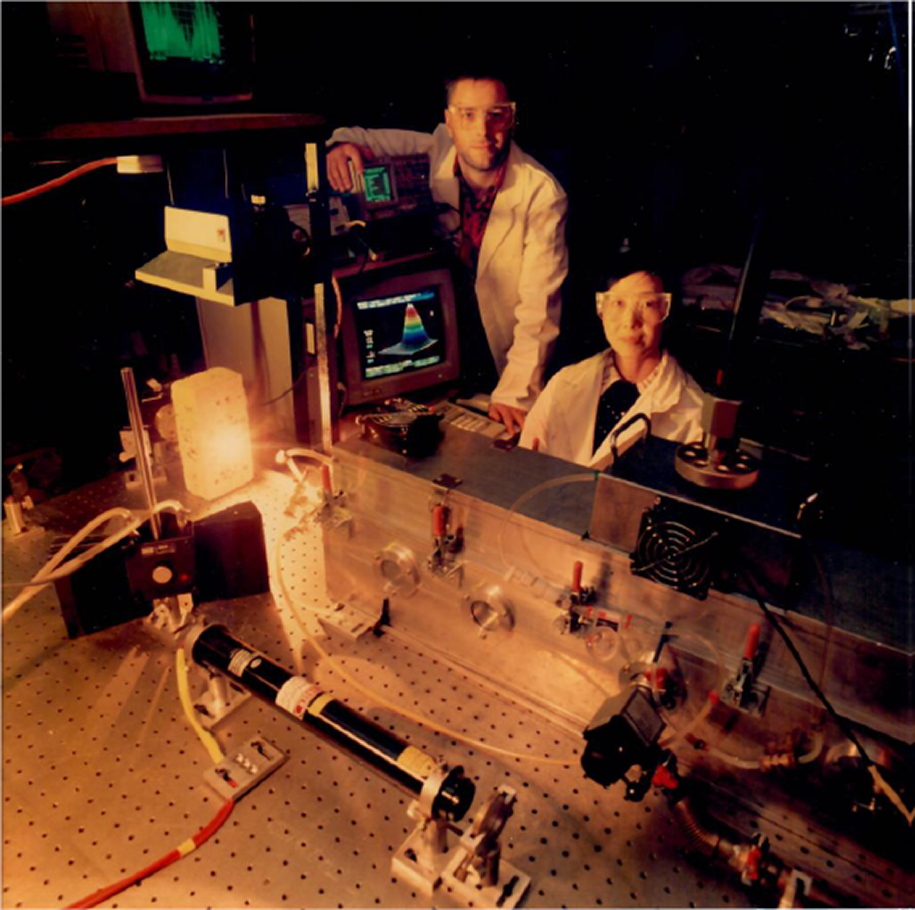

An early example of the usefulness of the latter approach was the construction of a diode-pumped APM Nd:LMA laser at Southampton by John Barr and colleagues, shown in Figure 13. This was delivered to RAL in 1992 to serve as master oscillator for VULCAN, which then had the distinction of being, at 35 TW, the world’s most powerful laser in operation at the time[Reference Phillips, Chang, Danson, Barr, Hughes, Edwards and Hanna108].

Figure 13 Dave Hughes, Research Fellow, and PhD student A. A. Majdabadi from Southampton commissioning the Nd:LMA oscillator on the VULCAN laser for ultra-short pulse operation. (Picture courtesy of STFC.)

Returning to OPOs, at this stage it was shown that a CW diode-pumped APM Nd:YLF laser could drive an SPOPO based on KTP as the non-linear medium[Reference McCarthy and Hanna109]. Further developments were also being made in non-linear materials, notably with periodically poled lithium niobate (PPLN), of which, high-quality material was fabricated in the ORC. With help from PPLN, CW mode-locked SPOPOs were now becoming practical devices, with modest power needs, representing a huge advance from the early OPOs. There are still various ways for further advances in device performance, with increasing diode-laser powers, and further sophistication of the SPOPO pulse-shaping and duration (see for example, Ref. [110]) using an optical fibre as the main element forming the feedback path of an SPOPO resonator. In addition, there are further major capabilities being offered from fibre lasers, notably their high-power performance, but also their broad spectral bandwidth, high gain and generally robust mode control. One can also consider a hybrid scheme involving diode pumping of a cladding-pumped fibre laser which then pumps a bulk laser[Reference Clarkson111], thus exploiting optimal features of each stage.

Optical fibre development for communications

In 1966, work on optical fibres began at Southampton to try to make long-distance light communication a practical reality. In early days of fibre lasers in the ORC an agreement was made to parcel out the work on various rare earths so that ORC staff did not end up competing amongst themselves. In this arrangement Anne Tropper and Dave Hanna chose to work together on Yb and Tm, on the general basis that Yb seemed to offer virgin territory, having been generally neglected hitherto as a bulk laser candidate, on account of its three-level character (which was of less relevance in a fibre laser). Another attractive feature was the fact that Yb had a very simple energy level structure, thus presenting an ideal system for careful examination of basic principles. Tm was chosen for its opposite quality of having rather crowded energy levels and therefore a degree of complexity that could have room for surprises. These choices were not disappointing and the first operations of an Yb fibre laser[Reference Hanna, Percival, Perry, Smart, Suni, Townsend and Tropper112], and of a Tm fibre laser[Reference Hanna, Percival, Perry, Smart, Suni, Townsend and Tropper113], were achieved by Tropper, Hanna and colleagues in 1988. This was followed up with various examinations of their laser performance and prospects, which clearly indicated future promise for high-power performance. Indeed, this is now well-established and ongoing work under Dave Payne at the ORC, and elsewhere, has led to greatly increased power levels.

Fibre research led by Alec Gambling with David Payne as his research student resulted in the development of extensive fibre manufacturing capabilities allowing them to create fibres with losses of just 1000 dB/km. At the time, this was an amazing result, but more was to come. Although some of the pioneering communications laboratories across the world had dismissed silica optical fibres as impractical, losses had been reduced to a few decibels per kilometre[Reference Luther-Davies, Payne and Gambling114, Reference Payne and Gambling115]. The development of specialized low-loss fibres using lower dopant levels was able to exploit longer interaction lengths[Reference Poole, Payne and Fermann116]. Another key piece to the puzzle was the invention of the first practical fibre optical amplifier to boost the intensity of light signals[Reference Mears, Reekie, Jauncey and Payne117]. This made long-distance optical communications practical, as many signals could be easily sent hundreds of miles without requiring electronic conversion. The effect was to make huge amounts of bandwidth available at low cost over very long distances. This was a major pre-requisite for the formation of the Internet as it is today. David Payne, shown in Figure 14, was elected as a Fellow of the Royal Society in 1992[118] and knighted in the 2013 New Year Honours for services to photonics research and applications.

Figure 14 Sir David Payne conducting research on optical fibres. (Picture courtesy of the University of Southampton.)

David’s research in this field has also led to the development of high-power lasers based on specialized optical fibres. These fibre lasers were ‘born’ out of research at Southampton’s ORC and have led to the development of highly efficient and highly practical fibre laser technology. In the 1990s the researchers explored the testing and identification of the critical rare earth ion dopants (ytterbium, erbium and thulium) and the core glass compositions required to generate and reliably sustain ultrahigh levels at near-IR wavelengths.

They developed large-mode-area core designs capable of handling high powers and high pulse energies. This key research provided access to the multi-kilowatt class, high brightness laser regime and was critical in the success of the spin-out company SPI Lasers UK Ltd[119]. SPI started out as a ‘telecomms’ company, not a high-power laser company at all. In the big telecomms recession most such start-ups died, but SPI reinvented itself successfully as a high-power fibre laser company. Southampton’s high-power fibre laser research has revolutionized areas of industrial material processing and enabled the development of specialist components for high-end industries such as aviation and defence. It has also been significant in the creation of an array of new medical devices, procedures and manufacturing technologies.

The ORC suffered a second major set-back in 2005 with another major fire. Following major rebuilding and reconstruction of facilities such as clean-rooms and fabrication suites, research has since forged ahead.

The Zepler Institute was established at the University of Southampton in 2013 and is the largest photonics and electronics institute in the UK. It has over 350 research staff and PhD students who use their expertise in optoelectronics, electronics, quantum technologies, physics and nanoscience to develop technologies and devices that tackle key societal challenges. It brings together leading researchers from across the University and enables innovation by providing access to one of the most comprehensive collections of nanoelectronics and photonics fabrication equipment in Europe. The institute has an interdisciplinary, industry-focused approach to research which has resulted in many successful spin-outs and the commercialization of products.

2.5 University of Hull

In 1962 the University of Hull opened a Department of Applied Physics which ran alongside, but independently of, the existing Physics Department. The founding Head Professor Jim Ring had as his main interest instrumentation for infrared astronomy. Far-IR lasers were seen as potential tools for testing instrumental performance. In 1965, with this in mind, Doug James a lecturer in applied physics, built the department’s first laser: a pulsed 337 μm HCN laser which could also operate at 28 μm using water vapour and 10.6 μm using CO2.

In 1967 Jim Ring moved to Imperial College. His successor to the Chair in Applied Physics was Professor Stuart Ramsden a spectroscopist who had worked at Harwell on Zeta and subsequently at the National Research Council in Ottawa, Canada, on laser-induced gas breakdown and related plasma studies. His appointment heralded a rapid growth in laser research in the department and he was instrumental in setting up a number of key groups supported by a first-class team of mechanical, electronic and research technicians.

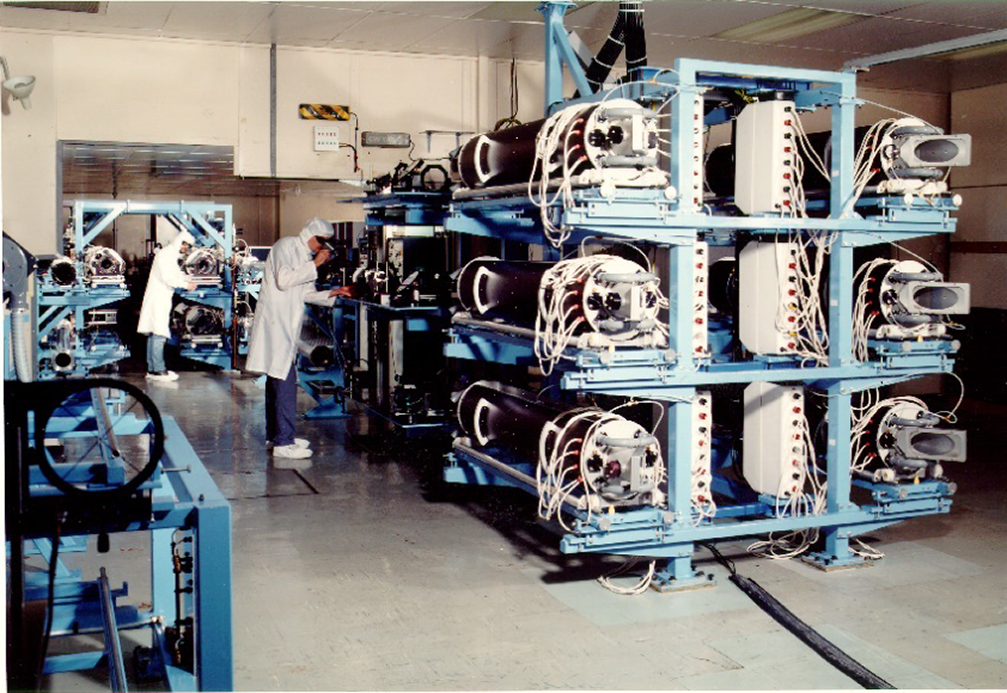

The Molecular Gas Laser Group, headed by Doug James, was developing high-power devices for plasma heating and materials processing. This centred on transversely excited atmospheric-pressure (TEA) and multi-atmospheric pressure CO2 lasers, pulsed HF/DF chemical lasers, and related optical resonator concepts[Reference Dyer, James and Ramsden120, Reference Hamilton, James and Ramsden121]. When, in the mid-1970s, Doug James moved to a post in Canada, Dr. Peter Dyer took over the group. The TEA CO2 laser work continued to evolve[Reference Dyer, Ramsden, Sayers and Skipper122], and investigations of the newly emerging discharge-excited excimer lasers commenced. The nanosecond UV excimer lasers were found to be excellent tools for micromachining various materials by ablation. During the 1980s and 1990s the group made significant contributions to basic studies of UV and VUV laser ablation of polymers, metal films and biological tissue. In collaboration with Drs. Oldershaw and Holbrook (Chemistry Department) and industrial partners, UV laser-induced photochemical processing was also pursued. Science Research Council (SRC) funding provided the group with a high-energy electron beam sustained excimer laser for use in large-scale chemical ‘processing’.

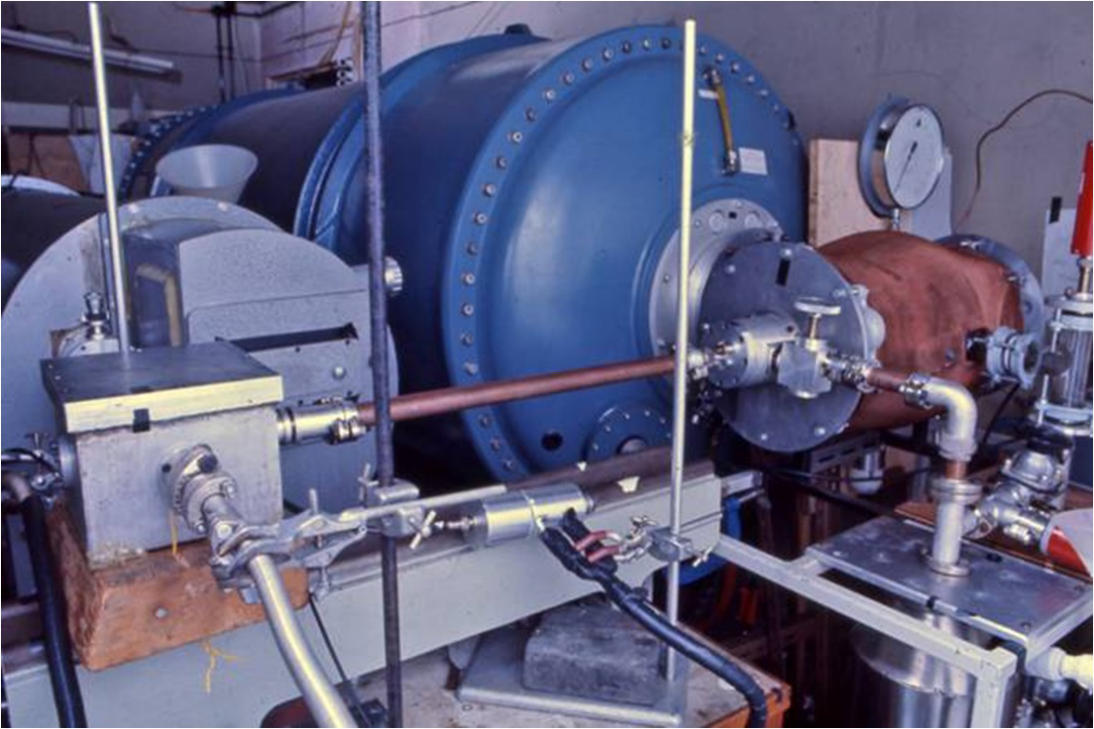

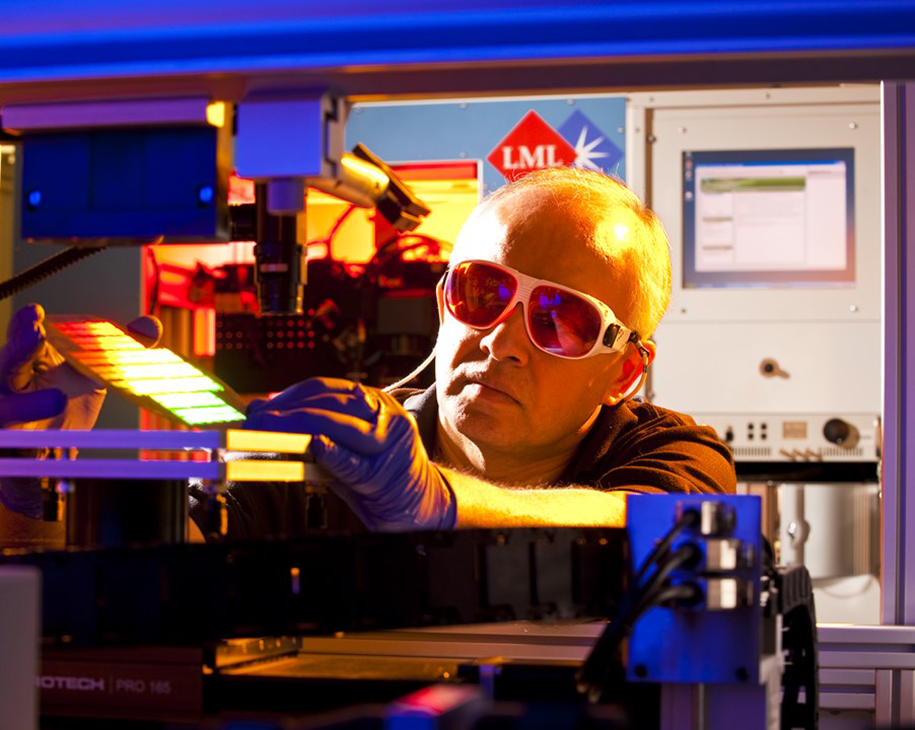

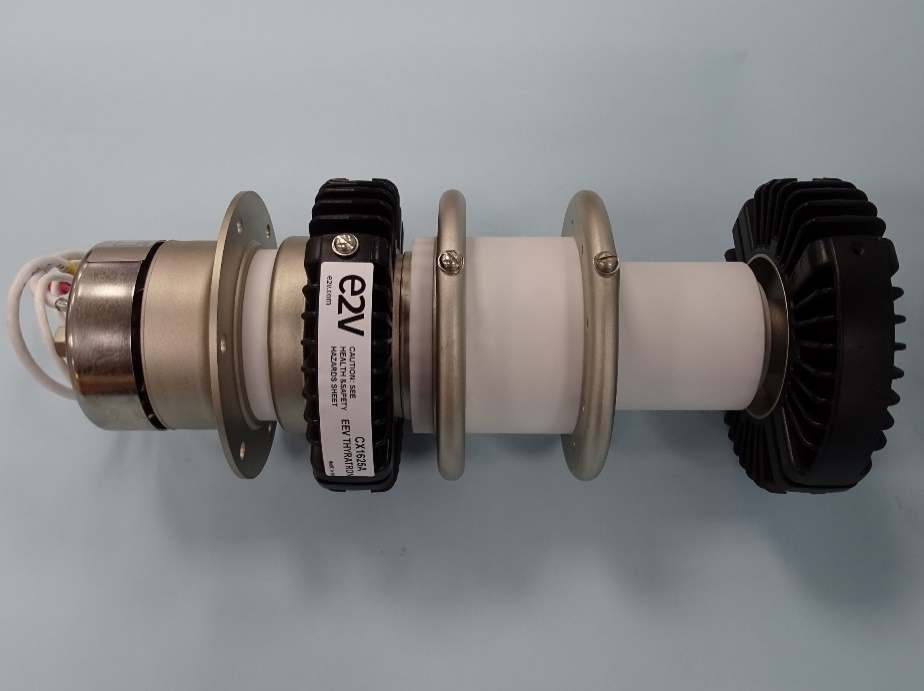

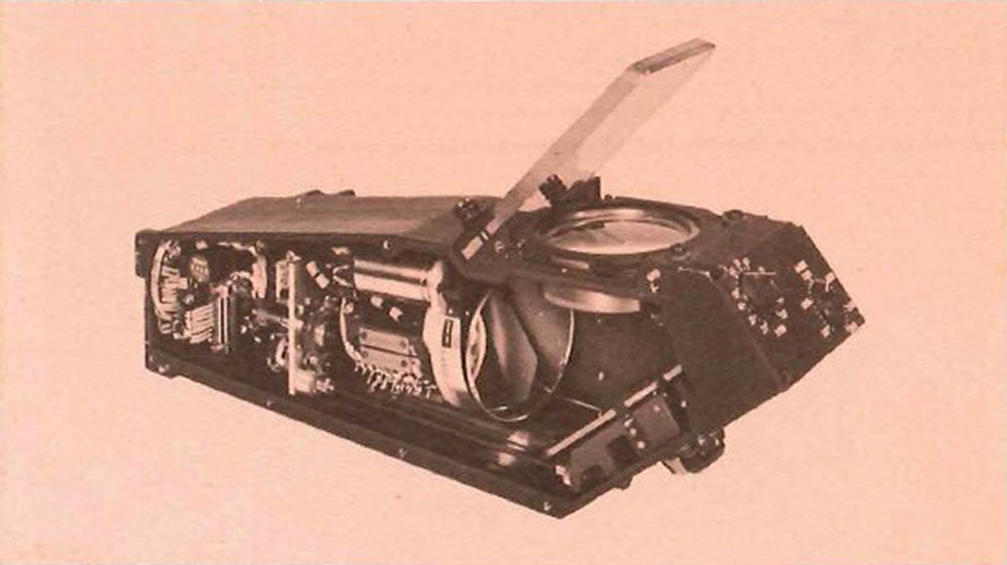

The activity was strengthened in 1980 when Dr. Howard Baker joined the department and set up research on mercury halide and TEA CO2 lasers, and pulse circuitry incorporating magnetic switching. A mercury bromide laser from this era is shown in Figure 15. With the appointments of Dr. Phillip Key (to the Exitech Lectureship in Lasers Applications) and Dr. David Sands in the 1990s, and later Dr. Howard Snelling and Dr. Chris Walton there was a further growth of applications work. This included: UV laser semiconductor processing; film deposition by UV laser ablation (e.g., high T c superconductors, magnetic films, liquid crystal); UV and VUV laser micromachining of glass substrates; Bragg grating fabrication in optical fibres; and fibre jacket stripping by ablation. Basic studies of matrix-assisted laser desorption ionization (MALDI) mechanisms for tissue analysis, and femtosecond laser two-photon excitation of sensitizers for photodynamic therapy (PDT) were also carried out.

Figure 15 Mercury bromide laser (University of Hull, Applied Physics Department, circa 1983).

Laser applications work continues in physics: Dr. Snelling has programmes on excimer and ultra-short-pulse Ti:sapphire and Nd:YLF lasers (e.g., for novel thin film fabrication, glass processing for free-form optics) and analysis/management of laser-generated ‘fume’; Dr. Walton is investigating UV lasers for processing silicon carbide and for nanostructure fabrication.

Laser–plasma interactions

Given Stuart Ramsden’s interests in laser-produced plasmas and thermonuclear fusion, the construction of solid-state lasers became an important departmental activity from the late 1960s onward. High-power Nd:glass and Nd:YAG devices were developed for laser–matter interaction studies, with Richard Dewhurst concentrating on picosecond and burst-mode laser oscillators for gas breakdown and plasma heating and Bob Hyde on developing laser amplifiers. In the 1980s Richard Dewhurst[Reference Dewhurst, Al-Obaidi, Ramsden, Hadland and Harris123] went on to exploit solid-state laser-generated plasmas for exciting high-frequency ultrasound waves in materials, applying this to a wide range of non-destructive testing techniques. He also developed novel laser-based sensing methods.