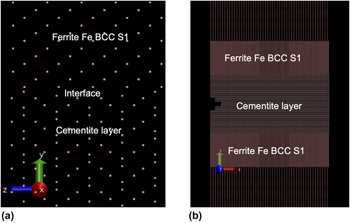

Nanoscale models are very small but involve multiple physics, multiscales, confinement, high rates, etc. These make the numerical simulation of intrinsic and extrinsic size effects difficult for the ferrite/cementite layered structure of carbon steel. In this work, a “new” simulation approach is proposed with “hypothesis” as the key to make the on-going simulation simple, physically sound, and the related atomistically based simulation productive. Using this refreshed approach, which is based on the traditional scientific philosophy, size effects that are related to interface structure and the layer thickness on failure due to thermomechanical coupling are investigated. Among interesting findings, it proves that the peak stress in the strain–stress curve as the characteristic parameter to describe the size effects on failure of thermomechanical coupling is not fully accurate, and a multiplication form of energy barrier with fast decaying function of thermal activation energy should be used in the size-dependent failure initiation criterion. This makes developing guidelines available for designing interface sizes at nanoscale.