Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Yurchenko, Nikita

Panina, Evgeniya

Zherebtsov, Sergey

Salishchev, Gennady

and

Stepanov, Nikita

2018.

Oxidation Behavior of Refractory AlNbTiVZr0.25 High-Entropy Alloy.

Materials,

Vol. 11,

Issue. 12,

p.

2526.

Kanyane, L. Rudolf.

Popoola, A. Patricia

and

Malatji, Nicholus

2019.

Influence of Sintering Temperature on Microhardness and Tribological Properties of Equi-Atomic Ti-Al- Mo-Si-W Multicomponent Alloy.

IOP Conference Series: Materials Science and Engineering,

Vol. 538,

Issue. 1,

p.

012009.

Waseem, Owais Ahmed

and

Ryu, Ho Jin

2019.

Toughening of a low-activation tungsten alloy using tungsten short fibers and particles reinforcement for fusion plasma-facing applications.

Nuclear Fusion,

Vol. 59,

Issue. 2,

p.

026007.

Kanyane, L.R.

Malatji, N.

Popoola, A.P.I

and

Fayomi, O.S.I

2019.

Synthesis of equi-atomic Ti-Al-Mo-Si-Ni high entropy alloy via spark plasma sintering technique: Evolution of microstructure, wear, corrosion and oxidation behaviour.

Results in Physics,

Vol. 14,

Issue. ,

p.

102465.

Kanyane, L.R.

Popoola, A.P.I.

Malatji, N.

and

Sibisi, P.N

2020.

Synthesis and characterization of TixAlSixMoW light-weight high entropy alloys.

Materials Today: Proceedings,

Vol. 28,

Issue. ,

p.

1231.

Kanyane, L. R.

Popoola, A. P. I.

Malatji, N.

and

Shongwe, M. B.

2020.

Synthesis and characterization of non-equiatomic Ti0.3AlMoSi0.3W0.1 high-entropy alloy fabricated via spark plasma sintering.

The International Journal of Advanced Manufacturing Technology,

Vol. 107,

Issue. 1-2,

p.

679.

Veselkov, Sergey

Samoilova, Olga

Shaburova, Nataliya

and

Trofimov, Evgeny

2021.

High-Temperature Oxidation of High-Entropic Alloys: A Review.

Materials,

Vol. 14,

Issue. 10,

p.

2595.

Yan, Yonggang

McGarrity, Kade A.

Delia, Daniel J.

Fekety, Curtis

and

Kun, Wang

2021.

The Oxidation-Resistance Mechanism of Wtanbtial Refractory High Entropy Alloy.

SSRN Electronic Journal ,

Kanyane, L. R.

Popoola, A.P.I

Malatji, N.

Mthisi, A

and

Fayomi, O.S.I

2021.

Oxidation and Corrosion properties of a Novel Al15Ti30Si30Mo15Ni10 High Entropy Alloy fabricated by Spark Plasma Sintering Technology.

IOP Conference Series: Materials Science and Engineering,

Vol. 1107,

Issue. 1,

p.

012233.

Yang, Xiaomeng

An, Zibing

Zhai, Yadi

Wang, Xin

Chen, Yanhui

Mao, Shengcheng

and

Han, Xiaodong

2021.

Effect of Al content on the thermal oxidation behaviour of AlHfMoNbTi high-entropy alloys analysed by in situ environmental TEM.

Corrosion Science,

Vol. 191,

Issue. ,

p.

109711.

Gorr, Bronislava

Schellert, Steven

Müller, Franz

Christ, Hans-Jürgen

Kauffmann, Alexander

and

Heilmaier, Martin

2021.

Current Status of Research on the Oxidation Behavior of Refractory High Entropy Alloys.

Advanced Engineering Materials,

Vol. 23,

Issue. 5,

El Garah, Mohamed

Achache, Sofiane

Michau, Alexandre

Schuster, Frederic

and

Sanchette, Frederic

2021.

AlTiTaZr(-N) Medium-Entropy Films Deposited by Magnetron Sputtering with a Combinatorial Approach.

Journal of Materials Engineering and Performance,

Vol. 30,

Issue. 6,

p.

4063.

Li, Weidong

Xie, Di

Li, Dongyue

Zhang, Yong

Gao, Yanfei

and

Liaw, Peter K.

2021.

Mechanical behavior of high-entropy alloys.

Progress in Materials Science,

Vol. 118,

Issue. ,

p.

100777.

Lu, Shuaidan

Li, Xiaoxiao

Liang, Xiaoyu

He, Jiahua

Shao, Wenting

Li, Kuanhe

and

Chen, Jian

2022.

Effect of Y additions on the oxidation behavior of vacuum arc melted refractory high-entropy alloy AlMo0.5NbTa0.5TiZr at elevated temperatures.

Vacuum,

Vol. 201,

Issue. ,

p.

111069.

Lo, Kai-Chi

Murakami, Hideyuki

Glatzel, Uwe

Yeh, Jien-Wei

Gorsse, Stéphane

and

Yeh, An-Chou

2022.

Elemental effects on the oxidation of refractory compositionally complex alloys.

International Journal of Refractory Metals and Hard Materials,

Vol. 108,

Issue. ,

p.

105918.

Yan, Yonggang

McGarrity, Kade A.

Delia, Daniel J.

Fekety, Curtis

and

Wang, Kun

2022.

The oxidation-resistance mechanism of WTaNbTiAl refractory high entropy alloy.

Corrosion Science,

Vol. 204,

Issue. ,

p.

110377.

Yi, Guoming

Ding, Yi

Cheng, Yanhai

Zhang, Ping

Wang, Xin

and

Liang, Xiubing

2022.

Development and oxidation behavior of high entropy silicide (NbMoTaWV)Si2 coatings on NbMoTaWV alloy.

Journal of Alloys and Compounds,

Vol. 916,

Issue. ,

p.

165384.

Yao, Hongwei

Qiao, Dongxu

Miao, Junwei

Wang, Jun

Guo, Enyu

and

Lu, Yiping

2022.

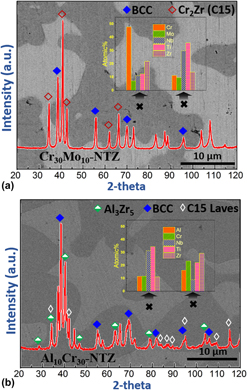

Criteria for laves-phase formation in refractory high-entropy alloys.

Philosophical Magazine Letters,

Vol. 102,

Issue. 5-6,

p.

161.

Lu, Shuaidan

Li, Xiaoxiao

Liang, Xiaoyu

Shao, Wenting

Yang, Wei

and

Chen, Jian

2022.

Effect of Al content on the oxidation behavior of refractory high-entropy alloy AlMo0.5NbTa0.5TiZr at elevated temperatures.

International Journal of Refractory Metals and Hard Materials,

Vol. 105,

Issue. ,

p.

105812.

Schellert, S.

Weber, M.

Christ, H.J.

Wiktor, C.

Butz, B.

Galetz, M.C.

Laube, S.

Kauffmann, A.

Heilmaier, M.

and

Gorr, B.

2023.

Formation of rutile (Cr,Ta,Ti)O2 oxides during oxidation of refractory high entropy alloys in Ta-Mo-Cr-Ti-Al system.

Corrosion Science,

Vol. 211,

Issue. ,

p.

110885.