1. Introduction

Granular aggregates of various geometric configurations like size, shape or surface roughness are prone to segregation when sheared, shaken or vibrated, which is called particle segregation. This can be found in nature, industries and even our daily life, e.g. wet snow avalanche (Bartelt & McArdell Reference Bartelt and McArdell2009), debris flow (Iverson Reference Iverson1997), pharmaceutical and chemical processes (Khakhar, McCarthy & Ottino Reference Khakhar, McCarthy and Ottino1997; Ottino & Khakhar Reference Ottino and Khakhar2000; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015b), and the so-called ‘Brazil nut effect’ in our kitchens (Rosato et al. Reference Rosato, Strandburg, Prinz and Swendsen1987; Gajjar et al. Reference Gajjar, Johnson, Carr, Chrispeels, Gray and Withers2021). In some cases, this effect is desirable by segregation or classification (Jiang et al. Reference Jiang, Wu, Hu, Fu, Chen and Wang2021). However, in many other processes aiming for a homogeneous blend, the resulting non-uniformity is usually undesirable and should be eliminated . To this end, it is of practical significance to have better understanding of the de-mixing process (Trewhela, Gray & Ancey Reference Trewhela, Gray and Ancey2021b; Xu et al. Reference Xu, Yoshinaga, Tsunazawa and Tokoro2021).

Many factors are deemed responsible for particle segregation, including convection (Ehrichs et al. Reference Ehrichs, Jaeger, Karczmar, Knight, Kuperman and Nagel1995), fluidization (Schröter et al. Reference Schröter, Ulrich, Kreft, Swift and Swinney2006), clustering (Mullin Reference Mullin2000), and gravity-driven segregation. Among these, the last is recognized as the most dominant mechanism (Yang et al. Reference Yang, Zheng, Bai and Yu2021). The gravity-driven segregation is subject to the variance in the density or grain size. The former is intuitive and easily understandable, i.e. the particles with smaller density float to the top, while the heavier particles sink to the bottom due to the buoyancy effect. In contrast, the size-driven segregation is less straightforward and involves two processes. The first phase is termed kinetic sieving (Drahun & Bridgwater Reference Drahun and Bridgwater1983). At this stage, the large particles will relocate under shearing and give rise to some gaps, through which the small grains can penetrate downwards easily. Subsequently, all particles are leveraged to its adjacent layer due to the imbalance in contact forces on an individual grain. This process is named squeeze expulsion and believed to be size-insensitive (Savage & Lun Reference Savage and Lun1988). As time marches, the fine particles cluster at the bottom of the granular body, while the large ones tend to appear at the top, leading to the final inhomogeneous particle configuration. Due to its dominant role in particle segregation, the size-driven mechanism has attracted much attention. A comprehensive review on particle segregation in dense granular flows was provided recently by Gray (Reference Gray2018), which is highly recommended for readers interested in this topic.

Gray & Thornton (Reference Gray and Thornton2005) proposed a continuum-transport-based theoretical framework for the segregation-driven shallow granular free-surface flow. This approach starts from the mass and momentum conservation equations for each constituent, and introduces the percolation velocity using the interaction drag between phases. Later, Gray & Chugunov (Reference Gray and Chugunov2006) extended this theory to include the diffusion effect. This model is applied widely, and is capable of predicting qualitatively or quantitatively the results from experiments or simulations in various configurations, such as plug (Thornton, Gray & Hogg Reference Thornton, Gray and Hogg2006), annular shear (May et al. Reference May, Golick, Phillips, Shearer and Daniels2010) and chute (Wiederseiner et al. Reference Wiederseiner, Andreini, Épely-Chauvin, Moser, Monnereau, Gray and Ancey2011). However, as an analytical method, it needs some presumptions of the flow kinematics for simplification, limiting its applicability to the specific flow configurations. Another approach on this topic goes to the particle scale simulation using discrete models such as the discrete element method (DEM) (Brandao et al. Reference Brandao, Lima, Santos, Duarte and Barrozo2020). The DEM captures each particle trajectory in simulation, thus providing microscopic insight into the problem. For example, Thornton et al. (Reference Thornton, Weinhart, Luding and Bokhove2012) studied the relation between the segregation Péclet number (ratio of the segregation velocity to diffusion) and the particle-size ratio in a bidisperse mixture. Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018) investigated the effect of the confining pressure on segregation of granular material. The DEM is also used to determine some macroscopic quantities for the continuum models (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017). Despite the insight of such DEM simulations for the size-driven particle migration, however, the notorious high computation cost limits the applicability of the DEM to small-scale granular flow modelling. Thus it is of urgency to develop a generic method based on fundamental flow dynamics without the limitation of the system configuration and problem scale.

Continuum-model-based numerical methods are often used in computational fluid dynamics and computational solid mechanics for large-scale problems ascribed to their outstanding calculation efficiency. In the field of polydisperse granular simulation, two theoretical frameworks can be found. One is based on the mixture theory, which takes multisized granular media as spatially overlapped continua specified with different particle sizes, and introduces the source term such as the drag force in the momentum conservation equations to mimic the interplay between different constituents. Within this framework, Huang, Kao & Kuo (Reference Huang, Kao and Kuo2013) studied the solid–solid–gas three-phase particle segregation in a rotating drum using the Eulerian continuum approach. The other framework, adopted in this study, regards the particle aggregates as a single-phase system with varying concentration of constituents, and brings in the convective–diffusive transport equation governing the evolution of the concentration. More works have been conducted with the latter method, as the transport equation has been well studied in the multidisperse granular flow problem (Liu, Gonzalez & Wassgren Reference Liu, Gonzalez and Wassgren2018; Yang et al. Reference Yang, Zheng, Bai and Yu2021). For instance, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) implemented two-way coupling of segregation–diffusion–advection equations with partially regularized incompressible ![]() $\mu (I)$ rheology, and investigated numerically the inclined slope flow and square rotating drum in OpenFOAM. However, it is found that most of these studies adopt hybrid grid-based numerical methods, such as the combination of the Eulerian finite-element method (FEM) and the finite difference method, with the former updating the velocity information, whereas the latter solves the transport equation. Consequently, several drawbacks are inherent in such procedures due to the nature of the Eulerian grids, including (1) the difficulty in obtaining the temporal evolution of the field variables on a fixed particle, (2) the high computational cost and inaccuracy in tracking the free surface of the granular flow, and (3) cumbersomeness to treat irregular or complex geometries. Also, the mixed numerical methods have often complex formulations and are difficult to implement. To overcome these disadvantages, we present a mesh-free solver based on the smoothed particle hydrodynamics (SPH) in the current study.

$\mu (I)$ rheology, and investigated numerically the inclined slope flow and square rotating drum in OpenFOAM. However, it is found that most of these studies adopt hybrid grid-based numerical methods, such as the combination of the Eulerian finite-element method (FEM) and the finite difference method, with the former updating the velocity information, whereas the latter solves the transport equation. Consequently, several drawbacks are inherent in such procedures due to the nature of the Eulerian grids, including (1) the difficulty in obtaining the temporal evolution of the field variables on a fixed particle, (2) the high computational cost and inaccuracy in tracking the free surface of the granular flow, and (3) cumbersomeness to treat irregular or complex geometries. Also, the mixed numerical methods have often complex formulations and are difficult to implement. To overcome these disadvantages, we present a mesh-free solver based on the smoothed particle hydrodynamics (SPH) in the current study.

The SPH method is a Lagrangian particle-based mesh-free method that is suitable for problems involving large deformation and free-surface flows like the granular flow to be discussed in this study, because (1) it can avoid the instability caused by the large deformation or grid distortion in the conventional grid-based methods, and (2) no effort is needed to track the free surface thanks to the inherent property as a Lagrangian method. Initially, SPH was invented to solve problems in astrophysics in the 1970s (Gingold & Monaghan Reference Gingold and Monaghan1977; Lucy Reference Lucy1977). After almost half a century of development, it has been used in various walks of science and engineering, including cardiovascular medicine (Zhang et al. Reference Zhang, Wang, Rezavand, Wu and Hu2021), porous media flow (Peng et al. Reference Peng, Xu, Wu, Yu and Wang2017), high-explosive explosion (Liu et al. Reference Liu, Liu, Zong and Lam2003), the food industry (Harrison et al. Reference Harrison, Eyres, Cleary, Sinnott, Delahunty and Lundin2014), and geohazard prediction (Fourtakas & Rogers Reference Fourtakas and Rogers2016). In the past decades, SPH is also widely used in simulating the granular avalanche and debris flow. Despite the success of this method in multiple disciplines, the explicit time integration scheme adopted in SPH leads to low computation efficiency, in particular when it comes to large-scale three-dimensional problems. Fortunately, the locality property of this method makes it quite suitable for parallel computation. In this study, the GPU acceleration solution empowered by an NVIDIA generic graphic card will be adopted due to its better accessibility, availability and affordability compared with CPU clusters that are usually used in supercomputers.

In the remainder of this paper, the mathematical framework of the size-driven particle segregation will be developed, followed by the introduction of the constitutive model for the granular aggregates, in § 2. Then a brief introduction to the SPH formulation will be given in § 3. Section 4 describes the proposed hybrid continuum surface reaction scheme, which is necessary for realizing the inhomogeneous Neumann boundary condition for each granular constituent. In § 5, the developed solver is examined with the shear box experiment conducted by Van der Vaart et al. (Reference Van der Vaart, Gajjar, Épely-Chauvin, Andreini, Gray and Ancey2015). In § 6, the proposed SPH model is applied to investigate the segregation dynamics in a rotating drum filled with a bidisperse-sized granular assembly. Finally, some conclusions are summarized in § 7 to close the study.

2. Mathematical framework

The bidisperse granular assembly consists of three domains, i.e. the space occupied by the large grains (L), the small ones (S), and the interstitial fluid (F), as shown in figure 1. The volume fractions for each constituent are ![]() $\phi ^{L}$,

$\phi ^{L}$, ![]() $\phi ^{S}$ and

$\phi ^{S}$ and ![]() $\phi ^{F}$, with the superscript denoting the corresponding phase. In this study, the interstitial fluid is air, and its effect on the particle-size segregation is ignored. Since the concern lies in the evolution of the local grain distribution, the following volumetric concentration is introduced as an indicator to reflect the particle-size segregation:

$\phi ^{F}$, with the superscript denoting the corresponding phase. In this study, the interstitial fluid is air, and its effect on the particle-size segregation is ignored. Since the concern lies in the evolution of the local grain distribution, the following volumetric concentration is introduced as an indicator to reflect the particle-size segregation:

where ![]() $X={\rm L}, {\rm S}$, representing the specific grain size. The volume concentration is

$X={\rm L}, {\rm S}$, representing the specific grain size. The volume concentration is ![]() $C^{X}\in [0,1]$, and the two extremes

$C^{X}\in [0,1]$, and the two extremes ![]() $C^{X}=0$ or 1 denote the full segregation. Based on the above concentration definition, the following constraint holds everywhere of the calculation domain:

$C^{X}=0$ or 1 denote the full segregation. Based on the above concentration definition, the following constraint holds everywhere of the calculation domain:

Figure 1. Schematic diagram of a bidisperse granular assembly, in which L, S and F refer to large grains, small grains, and interstitial fluid, respectively.

2.1. Granular flow model

Within the framework of continuum mechanics, the governing equations dictating a granular flow include the mass conservation

and the linear momentum conservation

Here, ![]() ${\rm d}(\ \cdot\ )/{\rm d} t=\partial (\ \cdot\ )/\partial t+\boldsymbol u\boldsymbol {\cdot }\boldsymbol {\nabla }(\ \cdot\ )$ is the material derivative,

${\rm d}(\ \cdot\ )/{\rm d} t=\partial (\ \cdot\ )/\partial t+\boldsymbol u\boldsymbol {\cdot }\boldsymbol {\nabla }(\ \cdot\ )$ is the material derivative, ![]() $\rho$ represents the bulk density;

$\rho$ represents the bulk density; ![]() $\boldsymbol u$ is the velocity vector;

$\boldsymbol u$ is the velocity vector; ![]() $\boldsymbol \sigma$ denotes the stress tensor; and

$\boldsymbol \sigma$ denotes the stress tensor; and ![]() $\boldsymbol g$ refers to gravity, which is the most common external body force in granular flows. In this work, the granular mass is assumed incompressible, i.e. the bulk density

$\boldsymbol g$ refers to gravity, which is the most common external body force in granular flows. In this work, the granular mass is assumed incompressible, i.e. the bulk density ![]() $\rho$ remains constant, so (2.3) can be deactivated.

$\rho$ remains constant, so (2.3) can be deactivated.

Often, granular flow is considered within hydrodynamics by Navier–Stokes equations, in which the non-Newtonian viscosity is deployed to describe the behaviour of granular material (Gilberg & Steiner Reference Gilberg and Steiner2020). However, such a model is incompatible with the solid-like behaviours of the granular mass in the quasi-static state (Yang et al. Reference Yang, Zheng, Bai and Yu2021). Therefore, we use a regularized ![]() $\mu (I)$-rheology-based elastoplastic model in this study (Zhu, Peng & Wu Reference Zhu, Peng and Wu2022a). Details will be presented in § 2.3.

$\mu (I)$-rheology-based elastoplastic model in this study (Zhu, Peng & Wu Reference Zhu, Peng and Wu2022a). Details will be presented in § 2.3.

2.2. Segregation–diffusion model

To close the governing equations for the segregation dynamics of a bidisperse system, we need the so-called segregation–diffusion equation proposed by Gray & Chugunov (Reference Gray and Chugunov2006), which is formulated initially in the Eulerian framework. In this work, we first propose the following Lagrangian description:

In this equation, ![]() $\boldsymbol {\nabla }_{g}$ denotes the gradient along the direction of gravity;

$\boldsymbol {\nabla }_{g}$ denotes the gradient along the direction of gravity;

denotes the segregation flux, with ![]() $V$ the segregation velocity, and

$V$ the segregation velocity, and ![]() $F$ the segregation function, whose specific expression will be given subsequently; and

$F$ the segregation function, whose specific expression will be given subsequently; and ![]() $D\,\boldsymbol {\nabla } C^{S}$ is the diffusion flux, with

$D\,\boldsymbol {\nabla } C^{S}$ is the diffusion flux, with ![]() $D$ the diffusivity. The segregation velocity

$D$ the diffusivity. The segregation velocity ![]() $V$ and diffusivity

$V$ and diffusivity ![]() $D$ have similar scaling relations with the shear rate magnitude

$D$ have similar scaling relations with the shear rate magnitude ![]() $\dot \gamma$ and average grain diameter

$\dot \gamma$ and average grain diameter ![]() $d_{avg}$ such that (Savage & Dai Reference Savage and Dai1993; Hajra & Khakhar Reference Hajra and Khakhar2002)

$d_{avg}$ such that (Savage & Dai Reference Savage and Dai1993; Hajra & Khakhar Reference Hajra and Khakhar2002)

Here, ![]() $\chi _{D}$ and

$\chi _{D}$ and ![]() $\chi _{V}$ are material coefficients;

$\chi _{V}$ are material coefficients; ![]() $\dot \gamma =\sqrt {2\dot {\boldsymbol e}:\dot {\boldsymbol e}}$ (with

$\dot \gamma =\sqrt {2\dot {\boldsymbol e}:\dot {\boldsymbol e}}$ (with ![]() $:$ denoting the tensor inner product), where

$:$ denoting the tensor inner product), where ![]() $\dot {\boldsymbol e}=\dot {\boldsymbol \varepsilon }-\dot \varepsilon _v\boldsymbol{\mathsf{I}}$ represents the deviatoric strain rate, with

$\dot {\boldsymbol e}=\dot {\boldsymbol \varepsilon }-\dot \varepsilon _v\boldsymbol{\mathsf{I}}$ represents the deviatoric strain rate, with ![]() $\dot {\boldsymbol \varepsilon }=0.5(\boldsymbol u\,\boldsymbol {\nabla }+\boldsymbol {\nabla }\boldsymbol u)$ and

$\dot {\boldsymbol \varepsilon }=0.5(\boldsymbol u\,\boldsymbol {\nabla }+\boldsymbol {\nabla }\boldsymbol u)$ and ![]() $\dot \varepsilon _v=\textrm {tr}(\dot {\boldsymbol \varepsilon })/3$ (with

$\dot \varepsilon _v=\textrm {tr}(\dot {\boldsymbol \varepsilon })/3$ (with ![]() $\textrm {tr}(\ \cdot\ )$ denoting the trace), and

$\textrm {tr}(\ \cdot\ )$ denoting the trace), and ![]() $\boldsymbol{\mathsf{I}}$ is the identity tensor:

$\boldsymbol{\mathsf{I}}$ is the identity tensor: ![]() $d_{avg}=d^{S}C^{S}+d^{L}C^{L}$ with

$d_{avg}=d^{S}C^{S}+d^{L}C^{L}$ with ![]() $d$ referring to the grain diameter. It should be noted that (2.7a,b) are indeed simplified, as both segregation velocity and diffusivity are found to rely on many other factors, such as frictional coefficient, inertial number, lithostatic pressure and grain radius ratio (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019; Bancroft & Johnson Reference Bancroft and Johnson2021; Trewhela, Ancey & Gray Reference Trewhela, Ancey and Gray2021a). Also, in some studies,

$d$ referring to the grain diameter. It should be noted that (2.7a,b) are indeed simplified, as both segregation velocity and diffusivity are found to rely on many other factors, such as frictional coefficient, inertial number, lithostatic pressure and grain radius ratio (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019; Bancroft & Johnson Reference Bancroft and Johnson2021; Trewhela, Ancey & Gray Reference Trewhela, Ancey and Gray2021a). Also, in some studies, ![]() $V$ and

$V$ and ![]() $D$ are taken as constants, resulting in consistent agreement with experimental data (Van der Vaart et al. Reference Van der Vaart, Gajjar, Épely-Chauvin, Andreini, Gray and Ancey2015; Yang et al. Reference Yang, Zheng, Bai and Yu2021). Therefore, the effect of using constant or functional forms of

$D$ are taken as constants, resulting in consistent agreement with experimental data (Van der Vaart et al. Reference Van der Vaart, Gajjar, Épely-Chauvin, Andreini, Gray and Ancey2015; Yang et al. Reference Yang, Zheng, Bai and Yu2021). Therefore, the effect of using constant or functional forms of ![]() $V$ and

$V$ and ![]() $D$ will be discussed in § 5. From (2.5), we can identify three factors that influence the temporal evolution of the local concentration of the small-size grain on a material point. The first term on the right-hand side of (2.5) reflects the contribution from the volume change, while the second accounts for the particle-size segregation, and the last for diffusive remixing. As mentioned above, this study is restricted to the incompressible granular flow, so that the first term on the right-hand side in (2.5) can be disregarded. Since the unity condition, i.e. (2.2), holds everywhere, and only

$D$ will be discussed in § 5. From (2.5), we can identify three factors that influence the temporal evolution of the local concentration of the small-size grain on a material point. The first term on the right-hand side of (2.5) reflects the contribution from the volume change, while the second accounts for the particle-size segregation, and the last for diffusive remixing. As mentioned above, this study is restricted to the incompressible granular flow, so that the first term on the right-hand side in (2.5) can be disregarded. Since the unity condition, i.e. (2.2), holds everywhere, and only ![]() $C^{S}$ is utilized in the rest of the paper, the superscript is omitted for brevity.

$C^{S}$ is utilized in the rest of the paper, the superscript is omitted for brevity.

We proceed to consider the segregation function in (2.5). The following quadratic segregation function is used in a number of studies (Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray & Thornton Reference Gray and Thornton2005; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014):

Equation (2.8) is also named the symmetric flux function as it is symmetric about ![]() $C=0.5$, where both large and small grains have equal but opposite segregation flux. Despite its success in modelling segregation, the quadratic form may sometimes deviate from reality. For instance, Golick & Daniels (Reference Golick and Daniels2009) observed that the downward penetration of a small grain through a bidisperse matrix in an annular ring shear cell is faster than the rising of a large grain through the same matrix. Likewise, the percolation rate is observed noticeably lower for a large intruder migrating through a dissimilar granular matrix in a shear box than for a small intruder (Trewhela et al. Reference Trewhela, Ancey and Gray2021a). Based on the experimental observation, Gajjar & Gray (Reference Gajjar and Gray2014) proposed the asymmetric flux model

$C=0.5$, where both large and small grains have equal but opposite segregation flux. Despite its success in modelling segregation, the quadratic form may sometimes deviate from reality. For instance, Golick & Daniels (Reference Golick and Daniels2009) observed that the downward penetration of a small grain through a bidisperse matrix in an annular ring shear cell is faster than the rising of a large grain through the same matrix. Likewise, the percolation rate is observed noticeably lower for a large intruder migrating through a dissimilar granular matrix in a shear box than for a small intruder (Trewhela et al. Reference Trewhela, Ancey and Gray2021a). Based on the experimental observation, Gajjar & Gray (Reference Gajjar and Gray2014) proposed the asymmetric flux model

where the parameter ![]() $\kappa \in [0,1)$ controls the degree of asymmetry. The constant

$\kappa \in [0,1)$ controls the degree of asymmetry. The constant ![]() $A$ is chosen to ensure that the maximum flux is the same as for the symmetric flux function. Two sets of parameters

$A$ is chosen to ensure that the maximum flux is the same as for the symmetric flux function. Two sets of parameters ![]() $A$ and

$A$ and ![]() $\kappa$ (i.e.

$\kappa$ (i.e. ![]() $A=1.0$,

$A=1.0$, ![]() $\kappa =0$ and

$\kappa =0$ and ![]() $A=1.6$,

$A=1.6$, ![]() $\kappa =0.89$) are utilized in this study, and the corresponding segregation functions are demonstrated schematically in figure 2. Notice that (2.9) reduces to (2.8) in the case

$\kappa =0.89$) are utilized in this study, and the corresponding segregation functions are demonstrated schematically in figure 2. Notice that (2.9) reduces to (2.8) in the case ![]() $A=1$ and

$A=1$ and ![]() $\kappa =0$. Also, in the case of asymmetric segregation flux, the cubic relation between

$\kappa =0$. Also, in the case of asymmetric segregation flux, the cubic relation between ![]() $F$ and

$F$ and ![]() $C$ can lead to remarkable errors if (2.9) is substituted directly into (2.5) within the SPH framework. This is due to the complexity of high order between the segregation flux

$C$ can lead to remarkable errors if (2.9) is substituted directly into (2.5) within the SPH framework. This is due to the complexity of high order between the segregation flux ![]() $Q$ and coordinates. A detailed explanation is presented in Appendix A. For a better approximation, we modify the segregation–diffusion equation as

$Q$ and coordinates. A detailed explanation is presented in Appendix A. For a better approximation, we modify the segregation–diffusion equation as

in which ![]() $\mathcal {F}={\partial F}/{\partial C}=A( 3\kappa C^2-2( 1+\kappa )C+1 )$.

$\mathcal {F}={\partial F}/{\partial C}=A( 3\kappa C^2-2( 1+\kappa )C+1 )$.

Figure 2. Quadratic and cubic segregation functions.

2.3. Regularized  $\mu (I)$-rheology-based elastoplastic model

$\mu (I)$-rheology-based elastoplastic model

In this subsection, the regularized ![]() $\mu (I)$-rheology-based elastoplastic model with Drucker–Prager yield surface, first put forward in Zhu et al. (Reference Zhu, Peng and Wu2022a), is introduced briefly for the sake of self-containment. This model is featured with the pressure-dependent yield function written as

$\mu (I)$-rheology-based elastoplastic model with Drucker–Prager yield surface, first put forward in Zhu et al. (Reference Zhu, Peng and Wu2022a), is introduced briefly for the sake of self-containment. This model is featured with the pressure-dependent yield function written as

where ![]() $p={\rm tr}(\boldsymbol \sigma )/3$ is the hydrostatic pressure;

$p={\rm tr}(\boldsymbol \sigma )/3$ is the hydrostatic pressure; ![]() $J_2 = 0.5\boldsymbol s:\boldsymbol s$ represents the second invariant of the deviatoric stress

$J_2 = 0.5\boldsymbol s:\boldsymbol s$ represents the second invariant of the deviatoric stress ![]() $\boldsymbol s=\boldsymbol \sigma -p\boldsymbol{\mathsf{I}}$; and

$\boldsymbol s=\boldsymbol \sigma -p\boldsymbol{\mathsf{I}}$; and ![]() $k_\mu$ is the constitutive parameter related to the Mohr–Coulomb model through

$k_\mu$ is the constitutive parameter related to the Mohr–Coulomb model through

in which ![]() $\mu$ is the frictional coefficient. In the standard Drucker–Prager model,

$\mu$ is the frictional coefficient. In the standard Drucker–Prager model, ![]() $\mu$ is constant, which is valid for granular materials in quasi-static state. However, under the fast-shear condition, the frictional coefficient is found to be dependent on the local pressure level and shear rate magnitude with the so-called

$\mu$ is constant, which is valid for granular materials in quasi-static state. However, under the fast-shear condition, the frictional coefficient is found to be dependent on the local pressure level and shear rate magnitude with the so-called ![]() $\mu (I)$ relation (Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006)

$\mu (I)$ relation (Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006)

Here, ![]() $I= {\dot \gamma } d_{avg}/\sqrt {p/\rho _s}$ is the so-called inertial number;

$I= {\dot \gamma } d_{avg}/\sqrt {p/\rho _s}$ is the so-called inertial number; ![]() $\mu _s$ and

$\mu _s$ and ![]() $\mu _d$ denote the static and dynamic frictional coefficients, bounding the lower and upper limits; and

$\mu _d$ denote the static and dynamic frictional coefficients, bounding the lower and upper limits; and ![]() $I_0$ is a material parameter. Equations (2.11)–(2.13) are the major ingredients of the

$I_0$ is a material parameter. Equations (2.11)–(2.13) are the major ingredients of the ![]() $\mu (I )$ rheology-based elastoplastic model for granular materials.

$\mu (I )$ rheology-based elastoplastic model for granular materials.

However, (2.13) contains the potential numerical singularity in the case of zero shear rate, ![]() ${\dot \gamma }=0$. Also, the

${\dot \gamma }=0$. Also, the ![]() $\mu (I)$ relation is found to be well-posed for intermediate inertial numbers, but ill-posed for both low and high inertial numbers, which could result in a resolution-dependent simulation result or numerical instability (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015). For restoring the well-posedness, the

$\mu (I)$ relation is found to be well-posed for intermediate inertial numbers, but ill-posed for both low and high inertial numbers, which could result in a resolution-dependent simulation result or numerical instability (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015). For restoring the well-posedness, the ![]() $\mu (I)$ relation should be modified, or some regularization techniques such as non-local theory should be utilized (Dsouza & Nott Reference Dsouza and Nott2020). In this study, the following regularized

$\mu (I)$ relation should be modified, or some regularization techniques such as non-local theory should be utilized (Dsouza & Nott Reference Dsouza and Nott2020). In this study, the following regularized ![]() $\mu (I )$ relation based on the penalty scheme is adopted (Zhu et al. Reference Zhu, Peng and Wu2022a):

$\mu (I )$ relation based on the penalty scheme is adopted (Zhu et al. Reference Zhu, Peng and Wu2022a):

\begin{equation} \mu(I) =\mu_s + \frac{(\mu_d-\mu_s ) {\dot \gamma}}{I_0\sqrt{p/(\rho_s d_{avg}^2 ) }+\sqrt{ {\dot \gamma}^2+\lambda^2 }}, \end{equation}

\begin{equation} \mu(I) =\mu_s + \frac{(\mu_d-\mu_s ) {\dot \gamma}}{I_0\sqrt{p/(\rho_s d_{avg}^2 ) }+\sqrt{ {\dot \gamma}^2+\lambda^2 }}, \end{equation}

where ![]() $\lambda$ is the regularization parameter, and

$\lambda$ is the regularization parameter, and ![]() $\lambda =0.001$ is taken in this study following the suggestion in Zhu et al. (Reference Zhu, Peng and Wu2022a). The non-associated flow rule is employed in this study with the potential function

$\lambda =0.001$ is taken in this study following the suggestion in Zhu et al. (Reference Zhu, Peng and Wu2022a). The non-associated flow rule is employed in this study with the potential function

which is consistent with the incompressible flow assumption. As a result, the final stress rate could be given explicitly as

In this equation, ![]() $\dot {\boldsymbol \omega }=0.5(\boldsymbol u\,\boldsymbol {\nabla }-\boldsymbol {\nabla }\boldsymbol u)$ is the spin tensor. The first and second terms in (2.16) come from the Jaumann stress rate, which ensures the objectivity of the constructed constitutive equation;

$\dot {\boldsymbol \omega }=0.5(\boldsymbol u\,\boldsymbol {\nabla }-\boldsymbol {\nabla }\boldsymbol u)$ is the spin tensor. The first and second terms in (2.16) come from the Jaumann stress rate, which ensures the objectivity of the constructed constitutive equation; ![]() $\dot {\boldsymbol {e}}$ and

$\dot {\boldsymbol {e}}$ and ![]() $\dot \varepsilon _v$ are the deviatoric and volumetric strains, respectively, in which

$\dot \varepsilon _v$ are the deviatoric and volumetric strains, respectively, in which ![]() $\dot {\boldsymbol {e}}=\dot {\boldsymbol {\varepsilon }}-\dot \varepsilon _v\boldsymbol{\mathsf{I}}$, with the strain rate

$\dot {\boldsymbol {e}}=\dot {\boldsymbol {\varepsilon }}-\dot \varepsilon _v\boldsymbol{\mathsf{I}}$, with the strain rate ![]() $\dot {\boldsymbol {\varepsilon }}=0.5(\boldsymbol u\,\boldsymbol {\nabla }+\boldsymbol {\nabla }\boldsymbol u)$ and

$\dot {\boldsymbol {\varepsilon }}=0.5(\boldsymbol u\,\boldsymbol {\nabla }+\boldsymbol {\nabla }\boldsymbol u)$ and ![]() $\dot \varepsilon _v = {\rm tr}(\dot {\boldsymbol {\varepsilon }})/3$. Also,

$\dot \varepsilon _v = {\rm tr}(\dot {\boldsymbol {\varepsilon }})/3$. Also, ![]() $G$ and

$G$ and ![]() $K$ are the shear and bulk moduli, respectively;

$K$ are the shear and bulk moduli, respectively; ![]() $\boldsymbol {s}=\boldsymbol {\sigma }-p\boldsymbol{\mathsf{I}}$, denoting the deviatoric stress; and

$\boldsymbol {s}=\boldsymbol {\sigma }-p\boldsymbol{\mathsf{I}}$, denoting the deviatoric stress; and ![]() $\dot {\lambda }$ is the plastic multiplier, which can be written as

$\dot {\lambda }$ is the plastic multiplier, which can be written as

A brief introduction to the derivation of (2.16) within the elasto-perfect plastic theoretical framework is provided in Appendix B, where more details are accessible.

2.4. One-step return-mapping algorithm

With the specific yield criterion and potential function introduced above, and the generic plasticity theory, one can update the stress state provided that the strain rate is given. Here, a variety of schemes exist, but we consider only the so-called one-step return-mapping algorithm due to its accuracy and efficiency (de Borst Reference de Borst1993; Zhu et al. Reference Zhu, Peng and Wu2022a), which originates from the features of the Drucker–Prager-model-based elasto-perfect plasticity (de Borst Reference de Borst1991; Zhu, Peng & Wu Reference Zhu, Peng and Wu2021). Details for the algorithm are presented in Appendix C.

3. SPH formulation

3.1. SPH approximation

Two key steps are involved in the SPH approximation to an arbitrary field function ![]() $f(\boldsymbol x)$, i.e. the kernel approximation and the particle approximation. The former step starts from the identity

$f(\boldsymbol x)$, i.e. the kernel approximation and the particle approximation. The former step starts from the identity

in which ![]() $\varOmega$ is the integral domain containing

$\varOmega$ is the integral domain containing ![]() $\boldsymbol x$, and

$\boldsymbol x$, and ![]() $\delta (\boldsymbol x-{\boldsymbol x}^\prime )$ represents the Dirac delta function. If we replace

$\delta (\boldsymbol x-{\boldsymbol x}^\prime )$ represents the Dirac delta function. If we replace ![]() $\delta (\boldsymbol x-{\boldsymbol x^\prime })$ with a smoothing kernel function, then (3.1) can be rewritten as

$\delta (\boldsymbol x-{\boldsymbol x^\prime })$ with a smoothing kernel function, then (3.1) can be rewritten as

In the kernel function ![]() $W(\boldsymbol x-{\boldsymbol x}^\prime,h)$,

$W(\boldsymbol x-{\boldsymbol x}^\prime,h)$, ![]() $h$ is the smoothing length defining the influence domain of a particle. Some requirements or properties for the kernel function should be satisfied for a better performance, including the unity, compact support and positivity (for more details, see Liu & Liu Reference Liu and Liu2003, Reference Liu and Liu2010). Various kernel functions have been used in the literature, such as the Gaussian kernel (Gingold & Monaghan Reference Gingold and Monaghan1977), the cubic B-spline function (Monaghan & Lattanzio Reference Monaghan and Lattanzio1985), the higher-order (quartic and quintic) splines (Morris Reference Morris1996), and the Wenland function class (Wendland Reference Wendland1995). Among them, the Wendland C2 kernel is employed in this study due to its computational convenience and the capability to prevent pairing instability (Dehnen & Hossam Reference Dehnen and Hossam2012), which reads

$h$ is the smoothing length defining the influence domain of a particle. Some requirements or properties for the kernel function should be satisfied for a better performance, including the unity, compact support and positivity (for more details, see Liu & Liu Reference Liu and Liu2003, Reference Liu and Liu2010). Various kernel functions have been used in the literature, such as the Gaussian kernel (Gingold & Monaghan Reference Gingold and Monaghan1977), the cubic B-spline function (Monaghan & Lattanzio Reference Monaghan and Lattanzio1985), the higher-order (quartic and quintic) splines (Morris Reference Morris1996), and the Wenland function class (Wendland Reference Wendland1995). Among them, the Wendland C2 kernel is employed in this study due to its computational convenience and the capability to prevent pairing instability (Dehnen & Hossam Reference Dehnen and Hossam2012), which reads

\begin{equation} W=\alpha_d\begin{cases} (1-q/2)^4(2q+1), & 0\leq{q}\leq2,\\ 0, & q>2, \end{cases} \end{equation}

\begin{equation} W=\alpha_d\begin{cases} (1-q/2)^4(2q+1), & 0\leq{q}\leq2,\\ 0, & q>2, \end{cases} \end{equation} where ![]() $\alpha _d$ is a constant, taking the value

$\alpha _d$ is a constant, taking the value ![]() ${7}/{(4{\rm \pi} h^2)}$ in two dimensions, and

${7}/{(4{\rm \pi} h^2)}$ in two dimensions, and ![]() ${21}/{(16{\rm \pi} h^3)}$ in three dimensions, and

${21}/{(16{\rm \pi} h^3)}$ in three dimensions, and ![]() $q=r/h$ is the non-dimensional distance between points

$q=r/h$ is the non-dimensional distance between points ![]() $\boldsymbol x$ and

$\boldsymbol x$ and ![]() $\boldsymbol x^\prime$, with

$\boldsymbol x^\prime$, with ![]() $r=\| \boldsymbol x- \boldsymbol x^\prime \|$.

$r=\| \boldsymbol x- \boldsymbol x^\prime \|$.

When the field function in (3.2) is replaced by its spatial derivative, we can get the following expression by using integration by parts:

where ![]() $\boldsymbol {\nabla }_{\boldsymbol {x}}$ represents the gradient with respect to

$\boldsymbol {\nabla }_{\boldsymbol {x}}$ represents the gradient with respect to ![]() $\boldsymbol x$. The kernel approximation of the diffusion term in (2.5) has the expression

$\boldsymbol x$. The kernel approximation of the diffusion term in (2.5) has the expression

Details of the mathematical deduction of this equation are presented in Appendix D. Hitherto, we have constructed the integral representations of the field function, its derivative, and the diffusion term in the governing equations. The second step is to conduct the particle approximation, at which stage discrete particles will be used to replace the continuous domain, and the integral representations will be converted as summations over all the particles in the support domain such that

$$\begin{gather} f(\boldsymbol{x}_i) \doteq\sum_{j=1}^{n}f(\boldsymbol{x}_j)\,W_{ij}m_j/\rho_j, \end{gather}$$

$$\begin{gather} f(\boldsymbol{x}_i) \doteq\sum_{j=1}^{n}f(\boldsymbol{x}_j)\,W_{ij}m_j/\rho_j, \end{gather}$$ $$\begin{gather}\boldsymbol{\nabla}{f(\boldsymbol{x}_i)} \doteq\sum_{j=1}^{n}f(\boldsymbol{x}_j)\,\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j, \end{gather}$$

$$\begin{gather}\boldsymbol{\nabla}{f(\boldsymbol{x}_i)} \doteq\sum_{j=1}^{n}f(\boldsymbol{x}_j)\,\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j, \end{gather}$$ $$\begin{gather}\{ \boldsymbol{\nabla}(g(\boldsymbol x)\,\boldsymbol{\nabla} f(\boldsymbol x))\} _i=\sum_{j=1}^{n}[g(\boldsymbol x_i)+g(\boldsymbol x_j)][\,f(\boldsymbol x_i)-f(\boldsymbol x_j)]\,\frac{\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+\eta^2}\boldsymbol{\cdot}\boldsymbol{\nabla}_i{ W_{ij}}m_j/\rho_j, \end{gather}$$

$$\begin{gather}\{ \boldsymbol{\nabla}(g(\boldsymbol x)\,\boldsymbol{\nabla} f(\boldsymbol x))\} _i=\sum_{j=1}^{n}[g(\boldsymbol x_i)+g(\boldsymbol x_j)][\,f(\boldsymbol x_i)-f(\boldsymbol x_j)]\,\frac{\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+\eta^2}\boldsymbol{\cdot}\boldsymbol{\nabla}_i{ W_{ij}}m_j/\rho_j, \end{gather}$$

where the subscripts ![]() $i$ and

$i$ and ![]() $j$ denote the target particle and the neighbouring particles in the support domain;

$j$ denote the target particle and the neighbouring particles in the support domain; ![]() $n$ means the total particle number within the support domain of particle

$n$ means the total particle number within the support domain of particle ![]() $i$;

$i$; ![]() $\boldsymbol x_{ij}=\boldsymbol x_i-\boldsymbol x_j$;

$\boldsymbol x_{ij}=\boldsymbol x_i-\boldsymbol x_j$; ![]() $\eta =0.1h$ acts as a clipping constant to keep the denominator non-zero;

$\eta =0.1h$ acts as a clipping constant to keep the denominator non-zero; ![]() $W_{ij}$ is short for

$W_{ij}$ is short for ![]() $W(\boldsymbol x_{ij},h)$; and

$W(\boldsymbol x_{ij},h)$; and ![]() $\boldsymbol {\nabla }_i{W_{ij}}$ short for

$\boldsymbol {\nabla }_i{W_{ij}}$ short for ![]() $\boldsymbol {\nabla }_{\boldsymbol {x}_i}W(\boldsymbol x_{ij},h)$.

$\boldsymbol {\nabla }_{\boldsymbol {x}_i}W(\boldsymbol x_{ij},h)$.

3.2. The SPH discretization of governing equations

By applying (3.6)–(3.8), one can obtain the SPH formulation for the momentum conservation equation as

\begin{equation} \frac{{\rm d}\boldsymbol u_i}{{\rm d}t}=\sum_{j=1}^{n}m_j\left( \frac{\boldsymbol\sigma_i}{\rho_i^2}+\frac{\boldsymbol\sigma_j}{\rho_j^2}+\varPi_{ij}\right)\boldsymbol{\nabla}_i W_{ij} +\boldsymbol g. \end{equation}

\begin{equation} \frac{{\rm d}\boldsymbol u_i}{{\rm d}t}=\sum_{j=1}^{n}m_j\left( \frac{\boldsymbol\sigma_i}{\rho_i^2}+\frac{\boldsymbol\sigma_j}{\rho_j^2}+\varPi_{ij}\right)\boldsymbol{\nabla}_i W_{ij} +\boldsymbol g. \end{equation}

In (3.9), ![]() $\varPi _{ij}$ denotes the artificial viscosity, which is a common stabilization scheme in the SPH theory to damp out unphysical numerical oscillations. In this study, the formulation proposed by Monaghan (Reference Monaghan1992) is adopted, reading

$\varPi _{ij}$ denotes the artificial viscosity, which is a common stabilization scheme in the SPH theory to damp out unphysical numerical oscillations. In this study, the formulation proposed by Monaghan (Reference Monaghan1992) is adopted, reading

\begin{equation} \varPi_{ij}=\begin{cases} \dfrac{\alpha_{\varPi}{c_{s}}h}{{\bar\rho}_{ij}}\,\dfrac{\boldsymbol{u}_{ij}\boldsymbol{\cdot}\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+0.01h^2}, & \boldsymbol{u}_{ij}\boldsymbol{\cdot}\boldsymbol{x}_{ij}<0,\\ 0, & \boldsymbol{u}_{ij}\boldsymbol{\cdot}\boldsymbol{x}_{ij}\geq0, \end{cases} \end{equation}

\begin{equation} \varPi_{ij}=\begin{cases} \dfrac{\alpha_{\varPi}{c_{s}}h}{{\bar\rho}_{ij}}\,\dfrac{\boldsymbol{u}_{ij}\boldsymbol{\cdot}\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+0.01h^2}, & \boldsymbol{u}_{ij}\boldsymbol{\cdot}\boldsymbol{x}_{ij}<0,\\ 0, & \boldsymbol{u}_{ij}\boldsymbol{\cdot}\boldsymbol{x}_{ij}\geq0, \end{cases} \end{equation}

in which ![]() $\alpha _{\varPi }$ is a constant coefficient, taken as 0.1 in this study (Bui et al. Reference Bui, Fukagawa, Sako and Ohno2008);

$\alpha _{\varPi }$ is a constant coefficient, taken as 0.1 in this study (Bui et al. Reference Bui, Fukagawa, Sako and Ohno2008); ![]() $c_{s}$ is the sound velocity;

$c_{s}$ is the sound velocity; ![]() $\bar \rho _{ij}=0.5( \rho _i+\rho _j)$ is the average density of particles

$\bar \rho _{ij}=0.5( \rho _i+\rho _j)$ is the average density of particles ![]() $i$ and

$i$ and ![]() $j$; and

$j$; and ![]() $\boldsymbol u_{ij}=\boldsymbol u_i-\boldsymbol u_j$. The specific terms related to stress in (3.9) come from the identity

$\boldsymbol u_{ij}=\boldsymbol u_i-\boldsymbol u_j$. The specific terms related to stress in (3.9) come from the identity

The pairwise SPH form of the momentum equation, i.e. (3.9), ensures the action–reaction principle and is stable in the calculation, thus gaining high popularity. Note that SPH suffers from the short-length-scale-noise problem, which could lead to unrealistic stress perturbations (Nguyen et al. Reference Nguyen, Nguyen, Bui, Nguyen and Fukagawa2000; Monaghan Reference Monaghan2012). To regularize the stress field, the Shepard filter scheme is adopted every so many steps (![]() $N_{step} = 30$ in this study) to reproduce the linear variation of stress fields, reading

$N_{step} = 30$ in this study) to reproduce the linear variation of stress fields, reading

Likewise, the SPH formulation for the segregation–diffusion equation should be written as

\begin{align} \frac{{\rm d}C}{{\rm d}t}&=-\sum_{j=1}^{n}\frac{m_j}{\rho_j}\,( V_i\mathcal{F}_{i}C_{ij}+F_{i}V_{ij})\,\frac{\boldsymbol g}{\| \boldsymbol g\|}\boldsymbol{\cdot}\boldsymbol{\nabla}_i W_{ij}\nonumber\\ &\quad +\sum_{j=1}^{n}\frac{m_j}{\rho_j}\,(D_i+D_j)C_{ij}\,\frac{\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+\eta^2}\boldsymbol{\cdot}\boldsymbol{\nabla}_i{ W_{ij}}, \end{align}

\begin{align} \frac{{\rm d}C}{{\rm d}t}&=-\sum_{j=1}^{n}\frac{m_j}{\rho_j}\,( V_i\mathcal{F}_{i}C_{ij}+F_{i}V_{ij})\,\frac{\boldsymbol g}{\| \boldsymbol g\|}\boldsymbol{\cdot}\boldsymbol{\nabla}_i W_{ij}\nonumber\\ &\quad +\sum_{j=1}^{n}\frac{m_j}{\rho_j}\,(D_i+D_j)C_{ij}\,\frac{\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+\eta^2}\boldsymbol{\cdot}\boldsymbol{\nabla}_i{ W_{ij}}, \end{align}

where ![]() $C_{ij}=C_i-C_j$ and

$C_{ij}=C_i-C_j$ and ![]() $V_{ij}=V_i-V_j$. A similar process for the strain rate tensor and spin tensor gives

$V_{ij}=V_i-V_j$. A similar process for the strain rate tensor and spin tensor gives

$$\begin{gather} \dot{\boldsymbol\varepsilon}=\dfrac{1}{2}\left( \sum_{j=1}^{n}\boldsymbol u_{ij}\otimes\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j+\sum_{j=1}^{n}\boldsymbol{\nabla}_i{W_{ij}}\otimes\boldsymbol u_{ij}m_j/\rho_j\right) \!, \end{gather}$$

$$\begin{gather} \dot{\boldsymbol\varepsilon}=\dfrac{1}{2}\left( \sum_{j=1}^{n}\boldsymbol u_{ij}\otimes\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j+\sum_{j=1}^{n}\boldsymbol{\nabla}_i{W_{ij}}\otimes\boldsymbol u_{ij}m_j/\rho_j\right) \!, \end{gather}$$ $$\begin{gather}\dot{\boldsymbol \omega}=\dfrac{1}{2}\left( \sum_{j=1}^{n}\boldsymbol u_{ij}\otimes\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j-\sum_{j=1}^{n}\boldsymbol{\nabla}_i{W_{ij}}\otimes\boldsymbol u_{ij}m_j/\rho_j\right) \!, \end{gather}$$

$$\begin{gather}\dot{\boldsymbol \omega}=\dfrac{1}{2}\left( \sum_{j=1}^{n}\boldsymbol u_{ij}\otimes\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j-\sum_{j=1}^{n}\boldsymbol{\nabla}_i{W_{ij}}\otimes\boldsymbol u_{ij}m_j/\rho_j\right) \!, \end{gather}$$

where ![]() $\boldsymbol u_{ij}=\boldsymbol u_i-\boldsymbol u_j$. The inclusion of

$\boldsymbol u_{ij}=\boldsymbol u_i-\boldsymbol u_j$. The inclusion of ![]() $\boldsymbol u_i$ is because of the identity

$\boldsymbol u_i$ is because of the identity

\begin{equation} \sum_{j=1}^{n}\boldsymbol u_{i}\otimes\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j=\boldsymbol 0. \end{equation}

\begin{equation} \sum_{j=1}^{n}\boldsymbol u_{i}\otimes\boldsymbol{\nabla}_i{W_{ij}m_j}/\rho_j=\boldsymbol 0. \end{equation}

One benefit of the adoption of the velocity difference ![]() $\boldsymbol u_{ij}$ in (3.14)–(3.15) is the restoration of

$\boldsymbol u_{ij}$ in (3.14)–(3.15) is the restoration of ![]() $O(h)$ convergence on the free surface (Colagrossi, Antuono & Le Touzé Reference Colagrossi, Antuono and Le Touzé2009).

$O(h)$ convergence on the free surface (Colagrossi, Antuono & Le Touzé Reference Colagrossi, Antuono and Le Touzé2009).

3.3. Time stepping

The SPH forms of the governing equations are solved numerically using explicit time integration schemes. In this work, we employ a second-order predictor–corrector integrator (Zhu et al. Reference Zhu, Peng and Wu2022a). At the predictor step, the physical variables at the midpoint of the calculation step are evaluated with

in which ![]() $X$ goes through position

$X$ goes through position ![]() $\boldsymbol x$, velocity

$\boldsymbol x$, velocity ![]() $\boldsymbol v$, stress

$\boldsymbol v$, stress ![]() $\boldsymbol \sigma$ and concentration

$\boldsymbol \sigma$ and concentration ![]() $C$, and

$C$, and ![]() $\varGamma ={\rm d}X/{\rm d}t$ is the material time derivative of

$\varGamma ={\rm d}X/{\rm d}t$ is the material time derivative of ![]() $X$. At the corrector step, the final value at the end of the calculation step is obtained with

$X$. At the corrector step, the final value at the end of the calculation step is obtained with

Here, ![]() $\varGamma ^{n+0.5}$ is determined with

$\varGamma ^{n+0.5}$ is determined with ![]() $X^{n+0.5}$ from the predictor step. Note that the time step

$X^{n+0.5}$ from the predictor step. Note that the time step ![]() $\Delta t$ used in the time integration is limited by the CFL condition

$\Delta t$ used in the time integration is limited by the CFL condition

where ![]() $\chi _{CFL}$ is the CFL coefficient, taken as 0.1 in this study, and

$\chi _{CFL}$ is the CFL coefficient, taken as 0.1 in this study, and ![]() $a_{max}$ denotes the maximum acceleration among all material particles.

$a_{max}$ denotes the maximum acceleration among all material particles.

3.4. Numerical implementations

The proposed SPH model is developed based on our in-house code LOQUAT, an open-source SPH solver (Peng et al. Reference Peng, Wang, Wu, Yu, Wang and Chen2019). In each calculation step, four subroutines are executed serially, including (1) nearest neighbouring particle searching, (2) boundary treatment, (3) particle interaction, and (4) time integration. Boundary treatment refers to the fulfilment of specific boundary conditions, which will be illustrated in detail in § 4. Particle interaction in this work means that the SPH approximation of the material time derivative of velocity and concentration from the support domain, i.e. (3.9) and (3.13). The introduction to time integration was presented in the previous subsection. Here, we focus mainly on the illustration of the first subroutine.

An SPH particle interacts only with its nearest neighbouring particles (NNP) located within the influence domain, so the prerequisite of SPH computations is identifying these particles. This process is referred to as nearest neighbouring particle searching (NNPS) in the literature. A naive strategy is to conduct the calculation of all pairwise distances between particles ![]() $i$ and

$i$ and ![]() $j$. Particle

$j$. Particle ![]() $j$ is found to belong to the support domain of particle

$j$ is found to belong to the support domain of particle ![]() $i$ provided that the distance is less than

$i$ provided that the distance is less than ![]() $2h$. However, this method would be prohibitively expensive for large-scale problems, as the computational burden of such an operation is of order

$2h$. However, this method would be prohibitively expensive for large-scale problems, as the computational burden of such an operation is of order ![]() $O(N^2)$. Therefore, various alternatives have been proposed to improve search efficiency. Typical examples include the Verlet neighbour list, cell-linked list and tree searching algorithms (Liu & Liu Reference Liu and Liu2003; Viccione, Bovolin & Carratelli Reference Viccione, Bovolin and Carratelli2008).

$O(N^2)$. Therefore, various alternatives have been proposed to improve search efficiency. Typical examples include the Verlet neighbour list, cell-linked list and tree searching algorithms (Liu & Liu Reference Liu and Liu2003; Viccione, Bovolin & Carratelli Reference Viccione, Bovolin and Carratelli2008).

Among all the approaches, this study adopts the cell-linked list scheme to advance NNPS. The first step in implementing this algorithm is to cover the whole calculation domain with a virtual square lattice mesh whose length is equal to ![]() $2h$, as shown in figure 3. Each cell is indexed by

$2h$, as shown in figure 3. Each cell is indexed by ![]() $\alpha$,

$\alpha$, ![]() $\beta$ and

$\beta$ and ![]() $\gamma$ according to its position. With this background grid, all SPH particles can be binned into the corresponding cells. From figure 3, we can find that the support domain is encircled by the neighbour cells so that NNPS can be confined to the

$\gamma$ according to its position. With this background grid, all SPH particles can be binned into the corresponding cells. From figure 3, we can find that the support domain is encircled by the neighbour cells so that NNPS can be confined to the ![]() $M$ particles from these cells. As a result, the neighbour search operation is scaled down to the order

$M$ particles from these cells. As a result, the neighbour search operation is scaled down to the order ![]() $O(MN)$. The cell-linked list scheme needs to store all particles in each cell, which is memory-consuming. Green (Reference Green2010) proposed a modification by sorting all the particles according to their associated cell index, thus only the beginning and ending particle indexes are necessary for each cell. This modified cell-linked list not only consumes less memory, but also has a high data accessing rate since all information is stockpiled in memory serially.

$O(MN)$. The cell-linked list scheme needs to store all particles in each cell, which is memory-consuming. Green (Reference Green2010) proposed a modification by sorting all the particles according to their associated cell index, thus only the beginning and ending particle indexes are necessary for each cell. This modified cell-linked list not only consumes less memory, but also has a high data accessing rate since all information is stockpiled in memory serially.

Figure 3. Sketch of the virtual square lattice mesh.

4. Boundary conditions

4.1. Kinematic and dynamic boundary condition

A proper formulation of boundary conditions for SPH is crucially important to achieve physically meaningful and quantitatively correct results (Adami, Hu & Adams Reference Adami, Hu and Adams2012). However, the implementation of boundary conditions in SPH is far from trivial and is often regarded as a major weakness compared to the FEM, thus identified as one of the grand challenges (Vacondio et al. Reference Vacondio, Altomare, De Leffe, Hu, Le Touzé, Lind, Marongiu, Marrone, Rogers and Souto-Iglesias2021). For instance, in a rotating drum, two boundary conditions are concerned, i.e. a free surface and rigid wall boundary, as shown in figure 4. One distinct advantage of the SPH method is the intrinsic fulfilment of the kinematic and dynamic boundary conditions on the free surfaces (Colagrossi et al. Reference Colagrossi, Antuono and Le Touzé2009; Lyu & Sun Reference Lyu and Sun2022).

Figure 4. Sketch of a granular flow with a free surface and rigid wall boundary.

On the rigid wall boundaries, the dummy particle scheme, initially proposed for fluid flow (Adami et al. Reference Adami, Hu and Adams2012), and later modified for geomaterials (Peng et al. Reference Peng, Wang, Wu, Yu, Wang and Chen2019; Zhan et al. Reference Zhan, Peng, Zhang and Wu2019; Zhu et al. Reference Zhu, Peng, Wu and Wang2022b), is employed for modelling the rigid wall boundary due to its accuracy and efficiency for regular boundary geometries (Valizadeh & Monaghan Reference Valizadeh and Monaghan2015). As shown in figure 5, at the beginning of the simulation, several layers of dummy particles (depending on the ratio of smoothing length to the initial particle spacing, i.e. ![]() $h/\Delta r$) are arranged outside the calculation domain. The fictitious particles participate in the interaction if they are located in the support domain of the material particles. However, unlike the internal particles, whose field variables are updated according to the governing equations, the necessary information of the dummy particles is extrapolated from those material particles close to the boundary (named boundary particles, hereafter). For a non-slip boundary condition, the following extrapolation scheme is applied:

$h/\Delta r$) are arranged outside the calculation domain. The fictitious particles participate in the interaction if they are located in the support domain of the material particles. However, unlike the internal particles, whose field variables are updated according to the governing equations, the necessary information of the dummy particles is extrapolated from those material particles close to the boundary (named boundary particles, hereafter). For a non-slip boundary condition, the following extrapolation scheme is applied:

\begin{equation} \boldsymbol u_d=2\boldsymbol u_w-\frac{\displaystyle\sum_{m=1}^{n}\boldsymbol u_mW_{dm}V_m}{\displaystyle\sum_{m=1}^{n}W_{dm}V_m}, \end{equation}

\begin{equation} \boldsymbol u_d=2\boldsymbol u_w-\frac{\displaystyle\sum_{m=1}^{n}\boldsymbol u_mW_{dm}V_m}{\displaystyle\sum_{m=1}^{n}W_{dm}V_m}, \end{equation}

where the subscripts ![]() $d$ and

$d$ and ![]() $m$ refer to dummy and material, respectively, and

$m$ refer to dummy and material, respectively, and ![]() $\boldsymbol u_w$ represents the prescribed velocity of the rigid wall. In the scenario of a free-slip boundary, the procedure remains the same with (4.1) for the normal component of the velocity vector, while the tangential part is modified as follows:

$\boldsymbol u_w$ represents the prescribed velocity of the rigid wall. In the scenario of a free-slip boundary, the procedure remains the same with (4.1) for the normal component of the velocity vector, while the tangential part is modified as follows:

\begin{equation} \left.\begin{array}{c} u_d^{n}=2 u_w^{n}-\dfrac{\displaystyle\sum_{m=1}^{n} u_m^{n}W_{dm}V_m}{\displaystyle\sum_{m=1}^{n}W_{dm}V_m},\\ u_d^\tau=\dfrac{\displaystyle\sum_{m=1}^{n} u_m^{\tau}W_{dm}V_m}{\displaystyle\sum_{m=1}^{n}W_{dm}V_m}, \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c} u_d^{n}=2 u_w^{n}-\dfrac{\displaystyle\sum_{m=1}^{n} u_m^{n}W_{dm}V_m}{\displaystyle\sum_{m=1}^{n}W_{dm}V_m},\\ u_d^\tau=\dfrac{\displaystyle\sum_{m=1}^{n} u_m^{\tau}W_{dm}V_m}{\displaystyle\sum_{m=1}^{n}W_{dm}V_m}, \end{array}\right\} \end{equation}

where the superscripts ![]() $n$ and

$n$ and ![]() $\tau$ represent the normal and tangential directions. To avoid the particle penetration through the rigid wall, the dummy particles are assigned the following stress (Adami et al. Reference Adami, Hu and Adams2012; Peng et al. Reference Peng, Wang, Wu, Yu, Wang and Chen2019):

$\tau$ represent the normal and tangential directions. To avoid the particle penetration through the rigid wall, the dummy particles are assigned the following stress (Adami et al. Reference Adami, Hu and Adams2012; Peng et al. Reference Peng, Wang, Wu, Yu, Wang and Chen2019):

\begin{equation} \boldsymbol \sigma_d = \dfrac{\displaystyle\sum_{m=1}^{n}\boldsymbol\sigma_mW_{dm}V_m+\boldsymbol{\mathsf{I}} \circ\sum_{m=1}^{n}m_m\boldsymbol g\otimes\boldsymbol r_{dm}W_{dm}}{\displaystyle\sum_{j=1}^{n}W_{dm}V_m}, \end{equation}

\begin{equation} \boldsymbol \sigma_d = \dfrac{\displaystyle\sum_{m=1}^{n}\boldsymbol\sigma_mW_{dm}V_m+\boldsymbol{\mathsf{I}} \circ\sum_{m=1}^{n}m_m\boldsymbol g\otimes\boldsymbol r_{dm}W_{dm}}{\displaystyle\sum_{j=1}^{n}W_{dm}V_m}, \end{equation}

in which ![]() $\circ$ denotes the Hadamard product, and

$\circ$ denotes the Hadamard product, and ![]() $\boldsymbol r_{dm}=\boldsymbol r_d - \boldsymbol r_m$.

$\boldsymbol r_{dm}=\boldsymbol r_d - \boldsymbol r_m$.

Figure 5. Dummy particle scheme for the rigid wall boundary.

4.2. Inhomogeneous Neumann boundary condition

The above section presents the procedure for achieving the kinematic and dynamic boundary conditions. We proceed to show strategies on how to realize the concentration-related boundary conditions.

Provided that there is no concentration flux of small particles across the boundary, the mathematical expression can be written as follows (Gray & Chugunov Reference Gray and Chugunov2006):

in which ![]() $\boldsymbol n$ denotes the normal vector on

$\boldsymbol n$ denotes the normal vector on ![]() $\partial \varOmega$ pointing towards

$\partial \varOmega$ pointing towards ![]() $\varOmega$. Equation (4.4) reveals that the segregation and diffusion fluxes have identical magnitude but opposite direction along the normal of the boundary. After some mathematical manipulations, an inhomogeneous Neumann boundary condition about

$\varOmega$. Equation (4.4) reveals that the segregation and diffusion fluxes have identical magnitude but opposite direction along the normal of the boundary. After some mathematical manipulations, an inhomogeneous Neumann boundary condition about ![]() $C$ can be reached as follows:

$C$ can be reached as follows:

Here, ![]() $V$ and

$V$ and ![]() $F$ denote the segregation velocity and segregation functions (cf. (2.6)).

$F$ denote the segregation velocity and segregation functions (cf. (2.6)).

4.2.1. Continuum surface reaction scheme for solid boundaries

It is challenging to enforce the inhomogeneous Neumann boundary condition within the SPH framework directly. Following the spirit of the continuum surface reaction (CSR) method (Ryan, Tartakovsky & Amon Reference Ryan, Tartakovsky and Amon2010), the inhomogeneous Neumann boundary condition can be replaced by the homogeneous Neumann boundary condition and a volumetric source term added into the segregation–diffusion equation (Wang et al. Reference Wang, Hu, Zhang and Pan2019), reading

The implementation of the homogeneous Neumann boundary condition in SPH can be enforced by assuming that the virtual and concerned material particles have identical concentrations, i.e. ![]() $C_j=C_i$ (Wang et al. Reference Wang, Hu, Zhang and Pan2019), which is achieved intrinsically with the SPH form of the Laplace operator adopted in (3.13). The last term on the right-hand side of (4.7), i.e.

$C_j=C_i$ (Wang et al. Reference Wang, Hu, Zhang and Pan2019), which is achieved intrinsically with the SPH form of the Laplace operator adopted in (3.13). The last term on the right-hand side of (4.7), i.e. ![]() $q$, is the volumetric source term, which is related to

$q$, is the volumetric source term, which is related to ![]() $f(C)$ through the expression

$f(C)$ through the expression

where the integral domain ![]() $\varOmega _{s}$ (as seen in figure 5) denotes the missing support truncated by the boundary. The SPH approximation to (4.8) is

$\varOmega _{s}$ (as seen in figure 5) denotes the missing support truncated by the boundary. The SPH approximation to (4.8) is

Here, the normal vectors at points ![]() $i$ and

$i$ and ![]() $j$, i.e.

$j$, i.e. ![]() $\boldsymbol n_i$ and

$\boldsymbol n_i$ and ![]() $\boldsymbol n_j$, are evaluated with

$\boldsymbol n_j$, are evaluated with

\begin{equation} \boldsymbol n_i=\dfrac{\displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}(c_i-c_j)\,\boldsymbol{\nabla}_iW_{ij}V_j}{\left| \displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}(c_i-c_j)\,\boldsymbol{\nabla}_iW_{ij}V_j\right| }, \end{equation}

\begin{equation} \boldsymbol n_i=\dfrac{\displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}(c_i-c_j)\,\boldsymbol{\nabla}_iW_{ij}V_j}{\left| \displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}(c_i-c_j)\,\boldsymbol{\nabla}_iW_{ij}V_j\right| }, \end{equation}

where ![]() $c$ represents a colour function whose value is 0 for the material particles, and 1 for the fictitious particles. However, the CSR scheme introduced above is found only with first-order accuracy, thus errors could arise near the boundary (Pan et al. Reference Pan, Kim, Perego, Tartakovsky and Parks2017). To remedy this, a degenerate function

$c$ represents a colour function whose value is 0 for the material particles, and 1 for the fictitious particles. However, the CSR scheme introduced above is found only with first-order accuracy, thus errors could arise near the boundary (Pan et al. Reference Pan, Kim, Perego, Tartakovsky and Parks2017). To remedy this, a degenerate function ![]() $\psi _d$ is introduced, and the segregation–diffusion equation is modified as (Wang et al. Reference Wang, Hu, Zhang and Pan2019)

$\psi _d$ is introduced, and the segregation–diffusion equation is modified as (Wang et al. Reference Wang, Hu, Zhang and Pan2019)

where ![]() $\psi _d$ can be specified with

$\psi _d$ can be specified with

\begin{equation} \psi_d(\boldsymbol x)=\begin{cases} 1, & \boldsymbol x\in\varOmega,\\ 0, & \boldsymbol x\in\partial\varOmega,\\ -1, & \boldsymbol x\in\varOmega_{s}. \end{cases} \end{equation}

\begin{equation} \psi_d(\boldsymbol x)=\begin{cases} 1, & \boldsymbol x\in\varOmega,\\ 0, & \boldsymbol x\in\partial\varOmega,\\ -1, & \boldsymbol x\in\varOmega_{s}. \end{cases} \end{equation}The corresponding SPH form of the Laplace operator in (4.11) can be given as

\begin{equation} {\boldsymbol{\nabla}(\psi_dD\,\boldsymbol{\nabla} C )}=\sum_{j=1}^{n}\dfrac{m_j}{\rho_j}\,(\tilde\psi_{di}D_i+\tilde\psi_{dj}D_j)C_{ij}\,\dfrac{\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+\eta^2}\boldsymbol{\cdot}\boldsymbol{\nabla}_i{ W_{ij}}, \end{equation}

\begin{equation} {\boldsymbol{\nabla}(\psi_dD\,\boldsymbol{\nabla} C )}=\sum_{j=1}^{n}\dfrac{m_j}{\rho_j}\,(\tilde\psi_{di}D_i+\tilde\psi_{dj}D_j)C_{ij}\,\dfrac{\boldsymbol{x}_{ij}}{\| \boldsymbol{x}_{ij}\| ^2+\eta^2}\boldsymbol{\cdot}\boldsymbol{\nabla}_i{ W_{ij}}, \end{equation}

where ![]() $\tilde \psi _{d}$ represents the smoothed counterpart of

$\tilde \psi _{d}$ represents the smoothed counterpart of ![]() $\psi _{d}$, defined as

$\psi _{d}$, defined as

\begin{equation} \tilde\psi_{di}=\dfrac{\displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}\psi_{dj}W_{ij}V_j}{\displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}W_{ij}V_j}. \end{equation}

\begin{equation} \tilde\psi_{di}=\dfrac{\displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}\psi_{dj}W_{ij}V_j}{\displaystyle\sum_{j\in\varOmega\cup\varOmega_{s}}W_{ij}V_j}. \end{equation}4.2.2. Hybrid CSR scheme

The conventional CSR (CCSR) scheme introduced above evaluates physical fields based on the missing support domain, e.g. (4.9) and (4.10). This can be achieved trivially on the rigid wall boundary, i.e. ![]() $\partial \varOmega _{W}$, where the missing support domain is supplemented by the fictitious particles. However, the implementation on the dynamic free surface will be troublesome, particularly when the geometry is irregular. To fulfil (4.6) on the free surface, we put forward a modified CSR (MCSR) scheme that can avoid introducing additional fictitious particles because the SPH approximation to the volumetric source term (

$\partial \varOmega _{W}$, where the missing support domain is supplemented by the fictitious particles. However, the implementation on the dynamic free surface will be troublesome, particularly when the geometry is irregular. To fulfil (4.6) on the free surface, we put forward a modified CSR (MCSR) scheme that can avoid introducing additional fictitious particles because the SPH approximation to the volumetric source term (![]() $q$) and degenerate function (

$q$) and degenerate function (![]() $\tilde \psi _{d}$) is carried out using the material particles.

$\tilde \psi _{d}$) is carried out using the material particles.

This new variant has the same boundary condition and governing equation as (4.6) and (4.11), but with the following kernel approximation to the volumetric source term:

Correspondingly, the SPH approximation to ![]() $q$ is

$q$ is

Here, ![]() $\boldsymbol n_i$ is evaluated with

$\boldsymbol n_i$ is evaluated with

\begin{equation} \boldsymbol

n_i=\begin{cases}

\dfrac{\displaystyle\sum_{j\in\varOmega}\boldsymbol{\nabla}_iW_{ij}V_j}{\displaystyle\left|

\sum_{j\in\varOmega}\boldsymbol{\nabla}_iW_{ij}V_j\right|},

& i\in\varOmega_{F},\\

\dfrac{\displaystyle\sum_{j\in\varOmega_{F}}\boldsymbol{\nabla}_iW_{ij}V_j}{\displaystyle\left|

\sum_{j\in\varOmega_{F}}\boldsymbol{\nabla}_iW_{ij}V_j\right|

}, & i\in\varOmega_{f}. \end{cases}

\end{equation}

\begin{equation} \boldsymbol

n_i=\begin{cases}

\dfrac{\displaystyle\sum_{j\in\varOmega}\boldsymbol{\nabla}_iW_{ij}V_j}{\displaystyle\left|

\sum_{j\in\varOmega}\boldsymbol{\nabla}_iW_{ij}V_j\right|},

& i\in\varOmega_{F},\\

\dfrac{\displaystyle\sum_{j\in\varOmega_{F}}\boldsymbol{\nabla}_iW_{ij}V_j}{\displaystyle\left|

\sum_{j\in\varOmega_{F}}\boldsymbol{\nabla}_iW_{ij}V_j\right|

}, & i\in\varOmega_{f}. \end{cases}

\end{equation} In this equation, ![]() $\varOmega _{F}$ denotes the subset consisting of free surface particles, and

$\varOmega _{F}$ denotes the subset consisting of free surface particles, and ![]() $\varOmega _{f}$ indicates the particles in the vicinity of the free surface, as shown in figure 4. The procedure to identify these particles will now be presented. The smoothed degenerate function has the expression

$\varOmega _{f}$ indicates the particles in the vicinity of the free surface, as shown in figure 4. The procedure to identify these particles will now be presented. The smoothed degenerate function has the expression

Note that the volumetric source term should vanish (i.e. ![]() $q_{i}=0$) for the material particles with full support domain (i.e.

$q_{i}=0$) for the material particles with full support domain (i.e. ![]() $\varOmega _{I}$ in figure 4). This is satisfied intrinsically within the CCSR scheme as the approximation to

$\varOmega _{I}$ in figure 4). This is satisfied intrinsically within the CCSR scheme as the approximation to ![]() $q$ is based on the fictitious particles. However, the MCSR scheme employs the material particles, so non-zero value always appears due to the distorted particle distribution, especially for a granular flow with large deformation. One effective strategy to mitigate this issue is to restrict the MCSR scheme to only those material particles in the vicinity of the free surface (i.e.

$q$ is based on the fictitious particles. However, the MCSR scheme employs the material particles, so non-zero value always appears due to the distorted particle distribution, especially for a granular flow with large deformation. One effective strategy to mitigate this issue is to restrict the MCSR scheme to only those material particles in the vicinity of the free surface (i.e. ![]() $\varOmega _{F}$ and

$\varOmega _{F}$ and ![]() $\varOmega _{f}$ in figure 4). To achieve this, the following boundary particle searching algorithm is proposed.

$\varOmega _{f}$ in figure 4). To achieve this, the following boundary particle searching algorithm is proposed.

Step 1, identifying the surface particles (i.e. ![]() $\varOmega _{F}$,

$\varOmega _{F}$, ![]() $\varOmega _{W}$ in figure 4). In this step, the surface detection scheme proposed by Marrone et al. (Reference Marrone, Colagrossi, Le Touzé and Graziani2010) is adopted with some optimization. In the optimized version, a rough-refining two-stage strategy is used to advance the searching. First, those non-empty virtual cells are divided into three categories. Type I is the outermost layer, featured with some empty neighbour cells. Type II is the second outermost layer, which are intermediate neighbour cells of Type I. The remaining cells, i.e. the interior ones, consist of Type III. Since the lattice mesh has length

$\varOmega _{W}$ in figure 4). In this step, the surface detection scheme proposed by Marrone et al. (Reference Marrone, Colagrossi, Le Touzé and Graziani2010) is adopted with some optimization. In the optimized version, a rough-refining two-stage strategy is used to advance the searching. First, those non-empty virtual cells are divided into three categories. Type I is the outermost layer, featured with some empty neighbour cells. Type II is the second outermost layer, which are intermediate neighbour cells of Type I. The remaining cells, i.e. the interior ones, consist of Type III. Since the lattice mesh has length ![]() $2h$, we can conclude that all the particles located in Type I cells could have truncated support. In comparison, particles in Type III cells have complete support. In this manner, Type II cells can be regarded as transitional regions, as some particles in Type II cells will have full support in

$2h$, we can conclude that all the particles located in Type I cells could have truncated support. In comparison, particles in Type III cells have complete support. In this manner, Type II cells can be regarded as transitional regions, as some particles in Type II cells will have full support in ![]() $\varOmega$, while the rest do not. Accordingly, we can reduce the further searching in the next stage to only those particles from Type I cells. Subsequently, the surface particles are detected from the potential candidates by searching the so-called ‘umbrella-shaped’ region, as sketched in figure 6. A concerned particle will be considered as a surface particle if the ‘umbrella-shaped’ region is particle-free, i.e.

$\varOmega$, while the rest do not. Accordingly, we can reduce the further searching in the next stage to only those particles from Type I cells. Subsequently, the surface particles are detected from the potential candidates by searching the so-called ‘umbrella-shaped’ region, as sketched in figure 6. A concerned particle will be considered as a surface particle if the ‘umbrella-shaped’ region is particle-free, i.e.

\begin{equation} \left.\begin{array}{c@{}} \nexists \,j\in\{ \boldsymbol x_j\,|\, |\boldsymbol x_{ij}|\geq\sqrt{2}h \text{ and } |\boldsymbol x_{jT}|< h \},\\ \nexists \,j\in\left\{ \boldsymbol x_j\,|\,|\boldsymbol x_{ij}|<\sqrt{2}h \text{ and } \boldsymbol x_{ij} \boldsymbol{\cdot}\boldsymbol x_{iT} >\dfrac{\sqrt{2}}{2}\,|\boldsymbol x_{ij} |\,h \right\}. \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c@{}} \nexists \,j\in\{ \boldsymbol x_j\,|\, |\boldsymbol x_{ij}|\geq\sqrt{2}h \text{ and } |\boldsymbol x_{jT}|< h \},\\ \nexists \,j\in\left\{ \boldsymbol x_j\,|\,|\boldsymbol x_{ij}|<\sqrt{2}h \text{ and } \boldsymbol x_{ij} \boldsymbol{\cdot}\boldsymbol x_{iT} >\dfrac{\sqrt{2}}{2}\,|\boldsymbol x_{ij} |\,h \right\}. \end{array}\right\} \end{equation}

Figure 6. Sketch of the boundary particle detection scheme.

Step 2, determining the surface vicinity particles (i.e. ![]() $\varOmega _f$,

$\varOmega _f$, ![]() $\varOmega _w$ in figure 4). One can observe from figure 6 that the surface vicinity particles come from Type I or II cells, thus the searching operation is also of a small amount compared to the total SPH particle number. In this work, an SPH particle is considered a free-surface vicinity particle (i.e.

$\varOmega _w$ in figure 4). One can observe from figure 6 that the surface vicinity particles come from Type I or II cells, thus the searching operation is also of a small amount compared to the total SPH particle number. In this work, an SPH particle is considered a free-surface vicinity particle (i.e. ![]() $\boldsymbol x_i\in \varOmega _{f}$) when the following condition is satisfied:

$\boldsymbol x_i\in \varOmega _{f}$) when the following condition is satisfied:

The identification of ![]() $\varOmega _{w}$ is based on its definition, i.e.

$\varOmega _{w}$ is based on its definition, i.e.

In practice, CCSR is used for particles in domains ![]() $\varOmega _{W}$ and

$\varOmega _{W}$ and ![]() $\varOmega _{w}$, while MCSR is used for those in domains

$\varOmega _{w}$, while MCSR is used for those in domains ![]() $\varOmega _{F}$ and

$\varOmega _{F}$ and ![]() $\varOmega _{f}$. This implementation scheme is named the hybrid continuum surface reaction (HCSR) method in this study. Note that the identification of

$\varOmega _{f}$. This implementation scheme is named the hybrid continuum surface reaction (HCSR) method in this study. Note that the identification of ![]() $\varOmega _{W}$ and

$\varOmega _{W}$ and ![]() $\varOmega _{w}$ is unnecessary within the framework of CCSR, but indispensable for obtaining accurate segregation flux at the boundary

$\varOmega _{w}$ is unnecessary within the framework of CCSR, but indispensable for obtaining accurate segregation flux at the boundary ![]() $\partial \varOmega$, which will be introduced in the next subsection for the whole boundary particles.

$\partial \varOmega$, which will be introduced in the next subsection for the whole boundary particles.

4.3. Accurate approximation to the segregation flux gradient

The SPH approximation of the segregation flux gradient adopted in (3.13) has ![]() $C^1$ consistency at the interior particles, but this level of accuracy is infeasible at the boundary particles due to the particle deficiency. The mirroring technique with antisymmetric extension of

$C^1$ consistency at the interior particles, but this level of accuracy is infeasible at the boundary particles due to the particle deficiency. The mirroring technique with antisymmetric extension of ![]() $C$ and

$C$ and ![]() $V$ can restore the

$V$ can restore the ![]() $C^1$ consistency close to the boundaries (Macia et al. Reference Macia, Antuono, González and Colagrossi2011). However, this method needs to introduce virtual particles around the boundary

$C^1$ consistency close to the boundaries (Macia et al. Reference Macia, Antuono, González and Colagrossi2011). However, this method needs to introduce virtual particles around the boundary ![]() $\partial \varOmega$, which is difficult for implementation when the boundary has an irregular shape, as discussed earlier. In this study, we employ the approach proposed by Liu & Liu (Reference Liu and Liu2011) to obtain the accurate approximation with

$\partial \varOmega$, which is difficult for implementation when the boundary has an irregular shape, as discussed earlier. In this study, we employ the approach proposed by Liu & Liu (Reference Liu and Liu2011) to obtain the accurate approximation with ![]() $C^1$ consistency for

$C^1$ consistency for ![]() $\boldsymbol {\nabla }_{g}C$ and

$\boldsymbol {\nabla }_{g}C$ and ![]() $\boldsymbol {\nabla }_{g}V$ in (2.10). Details can be found in Appendix B. This method needs only the information from material particles, thus avoiding introduction of fictitious particles. Note that this technique is restricted to boundary particles (

$\boldsymbol {\nabla }_{g}V$ in (2.10). Details can be found in Appendix B. This method needs only the information from material particles, thus avoiding introduction of fictitious particles. Note that this technique is restricted to boundary particles (![]() $\varOmega -\varOmega _{I}$). For the interior particles (

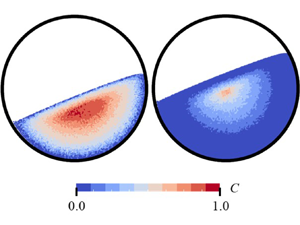

$\varOmega -\varOmega _{I}$). For the interior particles (![]() $\varOmega _{I}$), the standard SPH approximation, i.e. (3.13), is used for obtaining the segregation flux gradient.