1. Introduction

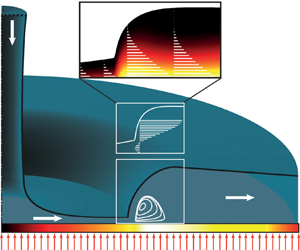

Free-surface liquid jet impingement is a practical cooling method in a wide range of technical applications. The design of jet-impingement cooling systems requires a good knowledge of the flow field on the target surface. Such a flow is schematically shown in figure 1, where the liquid spreads out from the stagnation region in a thin radial film and undergoes a sudden increase in the film height, called circular hydraulic jump (CHJ), at the jump radius, ![]() $r_{j}$. The CHJs pose a major challenge in the analysis of jet impingement problems, because they exhibit different flow structures depending on the strength of the jump. Based on the interface curvature and the flow structure in the jump region, the following classification of CHJs can be inferred from the literature (see also figure 1):

$r_{j}$. The CHJs pose a major challenge in the analysis of jet impingement problems, because they exhibit different flow structures depending on the strength of the jump. Based on the interface curvature and the flow structure in the jump region, the following classification of CHJs can be inferred from the literature (see also figure 1):

Figure 1. Schematic illustration of a circular jet impinging vertically upon a horizontal plate subjected to a constant heat flux (CHF) ![]() $( \dot {q} )$. Various flow structures, type 0 to type IIb, can occur depending on the strength of the jump. Finally the jump can also become unstable with air entrainment.

$( \dot {q} )$. Various flow structures, type 0 to type IIb, can occur depending on the strength of the jump. Finally the jump can also become unstable with air entrainment.

(i) type 0 – CHJ without any reversal flow in the jump region (Liu & Lienhard Reference Liu and Lienhard1993; Ellegaard et al. Reference Ellegaard, Hansen, Haaning and Bohr1996);

(ii) type Ia – CHJ with a single separation bubble on the wall (Ellegaard et al. Reference Ellegaard, Hansen, Haaning and Bohr1996);

(iii) type Ib – CHJ with a single roller underneath the interface (Askarizadeh et al. Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020, Reference Askarizadeh, Ehrenpreis, Kneer and Rohlfs2021);

(iv) type IIa – CHJ with a roller underneath the interface and a separation bubble directly afterwards on the wall (Liu & Lienhard Reference Liu and Lienhard1993; Ellegaard et al. Reference Ellegaard, Hansen, Haaning and Bohr1996);

(v) type IIb – double CHJ containing both a roller and a separation bubble (Liu & Lienhard Reference Liu and Lienhard1993; Bush, Aristoff & Hosoi Reference Bush, Aristoff and Hosoi2006; Askarizadeh et al. Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020);

(vi) the unstable CHJ with air entrainment (Liu & Lienhard Reference Liu and Lienhard1993; Ellegaard et al. Reference Ellegaard, Hansen, Haaning and Bohr1996).

Unfortunately, there is currently no comprehensive theory that characterises all types of CHJs and reflects the flow structure in the jump region. A typical approach in the investigation of CHJs is to reduce the Navier–Stokes equations to boundary layer equations (BLEs), since the radial thin film flow has a very small height compared with the radial dimensions. The main difference in comparison with regular BLEs is that an additional equation to determine the height of the film is required. Furthermore, this height determines the pressure term in the radial momentum equation. Such BLEs for thin film flows were numerically solved by Higuera (Reference Higuera1994) and de Vita et al. (Reference de Vita, Lagrée, Chibbaro and Popinet2020) for two-dimensional planar flows and also for radially spreading axisymmetric flows (Higuera Reference Higuera1997). The latter is of interest in this study.

A common approach to analytically describe the axisymmetric jump problem, is to find descriptions for the flow before and after the jump and to connect these by a discontinuous change of the flow variables at the jump position (Watson Reference Watson1964; Bohr, Dimon & Putkaradze Reference Bohr, Dimon and Putkaradze1993). However, such an approach is not able to reproduce the internal structure of CHJs. In this context, Bohr, Putkaradze & Watanabe (Reference Bohr, Putkaradze and Watanabe1997) introduced an averaging theory (AT) in which a third-order polynomial is assumed for the radial velocity profile over the film height, whose coefficients depend on the radius. The coefficients are determined using the boundary conditions (BCs), evaluation of the radial momentum equation on the plate and the radial momentum equation integrated over the height of the film. The chosen order of the polynomial together with the conditions for determining the coefficients lead to a non-self-similar velocity profile along the radius. The hereby achieved flexibility of the velocity profile results in a model which is able to render the flow structures ahead, in and after the jump region of the type Ia (Bohr et al. Reference Bohr, Putkaradze and Watanabe1997; Watanabe, Putkaradze & Bohr Reference Watanabe, Putkaradze and Bohr2003).

Being able to describe the flow field in the jump region, the introduced AT (Bohr et al. Reference Bohr, Putkaradze and Watanabe1997) can be used to study heat transfer in CHJs of type Ia. So far, jet impingement heat transfer has been thoroughly studied from the stagnation point (Liu, Gabour & Lienhard Reference Liu, Gabour and Lienhard1993; Rohlfs et al. Reference Rohlfs, Ehrenpreis, Haustein and Kneer2014) up to the jump position (Liu & Lienhard Reference Liu and Lienhard1989; Liu, Lienhard & Lombara Reference Liu, Lienhard and Lombara1991) and corresponding correlations for determining the heat transfer coefficient have been proposed. However, theoretical analysis of the heat transfer problem in the jump region has not yet been reported. In addition, relevant numerical (Sung, Choi & Yoo Reference Sung, Choi and Yoo1999; Askarizadeh et al. Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020) and experimental (Ishigai et al. Reference Ishigai, Nakanishi, Mizuno and Imamura1977; Stevens Reference Stevens1988) studies on heat transfer in the jump region are seldom in the literature. The complicated flow physics in the jump region, the lack of a comprehensive theory to determine the flow structure of CHJs, and a possible laminar to turbulent transition through the jump (Ishigai et al. Reference Ishigai, Nakanishi, Mizuno and Imamura1977) can be pointed out as reasons for the little available information on heat transfer in the jump region. In this regard, the AT introduced by Bohr et al. (Reference Bohr, Putkaradze and Watanabe1997) is further developed in this study to describe heat transfer in CHJs of type Ia. The extended AT, called AT for heat transfer (ATHT), is then compared with fully resolved numerical simulations (FRNSs) to show the applicability of the model to predict the temperature field in the jump region.

2. Problem statement

This section briefly presents the conservation equations describing the flow and heat transfer in radial thin film flows. The governing equations are simplified by applying boundary layer (BL) assumptions and physical constraints inherent to thin-layer film flows. This set of simplified equations together with the BCs will be used in the following section to develop a model for determining the flow and temperature fields.

2.1. Conservation equations

For an axisymmetric, incompressible, steady state thin film flow with constant fluid properties, the governing equations can be written in cylindrical coordinates as follows:

where the tilde signifies dimensional variables; ![]() $\tilde {r}$ and

$\tilde {r}$ and ![]() $\tilde {z}$ represent the radial and axial coordinates, respectively;

$\tilde {z}$ represent the radial and axial coordinates, respectively; ![]() ${\boldsymbol {v}} = \tilde {u} \hat {e}_{r} + \tilde {w} \hat {e}_{z}$ is the velocity field with

${\boldsymbol {v}} = \tilde {u} \hat {e}_{r} + \tilde {w} \hat {e}_{z}$ is the velocity field with ![]() $\hat {e}_{r}$ and

$\hat {e}_{r}$ and ![]() $\hat {e}_{z}$ as unit vectors;

$\hat {e}_{z}$ as unit vectors; ![]() $\rho$ stands for the density;

$\rho$ stands for the density; ![]() $\nu$ is the kinematic viscosity;

$\nu$ is the kinematic viscosity; ![]() $g$ depicts the gravitational acceleration;

$g$ depicts the gravitational acceleration; ![]() $p$ indicates the pressure.

$p$ indicates the pressure.

The thermal energy conservation equation can be expressed as follows (Schlichting & Gersten Reference Schlichting and Gersten2006):

\begin{equation} \tilde{u}

\frac{\partial \tilde{T}}{\partial \tilde{r}} + \tilde{w}

\frac{\partial \tilde{T}}{\partial \tilde{z}} =

\frac{k}{\rho c_{p}} \left( \frac{\partial^{2}

\tilde{T}}{\partial \tilde{r}^{2}} + \frac{1}{\tilde{r}}

\frac{\partial \tilde{T}}{\partial \tilde{r}} +

\frac{\partial^{2} \tilde{T}}{\partial \tilde{z}^{2}}

\right) + \frac{\tilde{\epsilon}}{\rho c_{p}},

\end{equation}

\begin{equation} \tilde{u}

\frac{\partial \tilde{T}}{\partial \tilde{r}} + \tilde{w}

\frac{\partial \tilde{T}}{\partial \tilde{z}} =

\frac{k}{\rho c_{p}} \left( \frac{\partial^{2}

\tilde{T}}{\partial \tilde{r}^{2}} + \frac{1}{\tilde{r}}

\frac{\partial \tilde{T}}{\partial \tilde{r}} +

\frac{\partial^{2} \tilde{T}}{\partial \tilde{z}^{2}}

\right) + \frac{\tilde{\epsilon}}{\rho c_{p}},

\end{equation}

where ![]() $\tilde {T}$ is the temperature,

$\tilde {T}$ is the temperature, ![]() $c_{p}$ the specific thermal capacity,

$c_{p}$ the specific thermal capacity, ![]() $k$ the thermal conductivity and

$k$ the thermal conductivity and ![]() $\epsilon$ the viscous dissipation term, which can be represented by

$\epsilon$ the viscous dissipation term, which can be represented by

\begin{equation} \frac{\tilde{\epsilon}}{\rho} = \nu \left\lbrace 2 \left[ \left( \frac{\partial \tilde{u}}{\partial \tilde{r}} \right)^{2} + \left( \frac{\tilde{u}}{ \tilde{r}} \right)^{2} + \left( \frac{\partial \tilde{w}}{\partial \tilde{z}} \right)^{2} \right] + \left( \frac{\partial \tilde{u}}{\partial \tilde{z}} + \frac{\partial \tilde{w}}{\partial \tilde{r}} \right)^{2} \right\rbrace. \end{equation}

\begin{equation} \frac{\tilde{\epsilon}}{\rho} = \nu \left\lbrace 2 \left[ \left( \frac{\partial \tilde{u}}{\partial \tilde{r}} \right)^{2} + \left( \frac{\tilde{u}}{ \tilde{r}} \right)^{2} + \left( \frac{\partial \tilde{w}}{\partial \tilde{z}} \right)^{2} \right] + \left( \frac{\partial \tilde{u}}{\partial \tilde{z}} + \frac{\partial \tilde{w}}{\partial \tilde{r}} \right)^{2} \right\rbrace. \end{equation}2.2. Boundary layer equations for radial thin film flows

The thin film thickness, compared with the radial dimension of the flow, suggests that (2.1)–(2.5) can be simplified to BLEs. Detailed information on the simplification by means of dimensional analysis can be found in Watanabe et al. (Reference Watanabe, Putkaradze and Bohr2003). The simplified equations describing the flow are

where all variables are non-dimensionalised using the following characteristic scales introduced by Bohr et al. (Reference Bohr, Dimon and Putkaradze1993):

\begin{equation} \left.\begin{gathered} r_{*} = \left( \frac{q^{5}}{\nu^{3} g} \right)^{{1}/{8}}, \quad z_{*} = \left( \frac{q \nu}{g} \right)^{{1}/{4}}, \quad u_{*} = \left( q \nu g^{3} \right)^{{1}/{8}}, \\ w_{*} = \left( \frac{\nu^{3} g}{q} \right)^{{1}/{4}}, \quad p_{*} = \rho\!\left( q \nu g^{3} \right)^{{1}/{4}}. \end{gathered}\right\}\end{equation}

\begin{equation} \left.\begin{gathered} r_{*} = \left( \frac{q^{5}}{\nu^{3} g} \right)^{{1}/{8}}, \quad z_{*} = \left( \frac{q \nu}{g} \right)^{{1}/{4}}, \quad u_{*} = \left( q \nu g^{3} \right)^{{1}/{8}}, \\ w_{*} = \left( \frac{\nu^{3} g}{q} \right)^{{1}/{4}}, \quad p_{*} = \rho\!\left( q \nu g^{3} \right)^{{1}/{4}}. \end{gathered}\right\}\end{equation}

In (2.6), ![]() $h$ denotes the film height non-dimensionalised using the characteristic vertical length scale

$h$ denotes the film height non-dimensionalised using the characteristic vertical length scale ![]() $z_*$, and in (2.7)

$z_*$, and in (2.7) ![]() $q$ is defined as

$q$ is defined as ![]() $q = Q / ( 2 {\rm \pi})$, where

$q = Q / ( 2 {\rm \pi})$, where ![]() $Q$ indicates the volume flux of the film. Note that

$Q$ indicates the volume flux of the film. Note that ![]() $q$ should not be confused with

$q$ should not be confused with ![]() $\dot {q}$, which denotes the heat flux imposed on the plate.

$\dot {q}$, which denotes the heat flux imposed on the plate.

To simplify the heat transfer equation, (2.4), a dimensionless temperature needs to be introduced. In this study, two classical thermal BCs are investigated: (i) a constant heat flux (CHF) ![]() $( \dot {q} )$, and (ii) a constant plate temperature (CPT)

$( \dot {q} )$, and (ii) a constant plate temperature (CPT) ![]() $( T_0 )$. For the case of a CHF, the dimensionless temperature reads

$( T_0 )$. For the case of a CHF, the dimensionless temperature reads

and for the case of a CPT,

In both cases ![]() $T_{{f}}$ is the reference temperature signifying the liquid temperature before heat transfer from the plate to the liquid takes place. Additionally, a Reynolds number is defined as

$T_{{f}}$ is the reference temperature signifying the liquid temperature before heat transfer from the plate to the liquid takes place. Additionally, a Reynolds number is defined as ![]() ${{Re} = (u_{*} z_{*} ) / \nu }$. The thermal energy equation can then be reformulated as follows:

${{Re} = (u_{*} z_{*} ) / \nu }$. The thermal energy equation can then be reformulated as follows:

where ![]() ${Pr} = \nu / a$ denotes the Prandtl number and

${Pr} = \nu / a$ denotes the Prandtl number and ![]() $a = k / (\rho c_p )$ signifies the thermal diffusion coefficient. The last term in (2.10) is the dimensionless dissipation of kinetic energy that can be written as

$a = k / (\rho c_p )$ signifies the thermal diffusion coefficient. The last term in (2.10) is the dimensionless dissipation of kinetic energy that can be written as

\begin{equation} \frac{r_*}{\rho c_{p} \theta_* u_*} \tilde{\epsilon} = \frac{{Ec}}{{Re}^{2}} \left\lbrace 2 \left[ \left( \frac{\partial u}{\partial r} \right)^{2} + \left( \frac{u}{ r} \right)^{2} + \left( \frac{\partial w}{\partial z} \right)^{2} \right] + \left( {Re} \frac{\partial u}{\partial z} + \frac{1}{{Re}} \frac{\partial w}{\partial r} \right)^{2} \right\rbrace, \end{equation}

\begin{equation} \frac{r_*}{\rho c_{p} \theta_* u_*} \tilde{\epsilon} = \frac{{Ec}}{{Re}^{2}} \left\lbrace 2 \left[ \left( \frac{\partial u}{\partial r} \right)^{2} + \left( \frac{u}{ r} \right)^{2} + \left( \frac{\partial w}{\partial z} \right)^{2} \right] + \left( {Re} \frac{\partial u}{\partial z} + \frac{1}{{Re}} \frac{\partial w}{\partial r} \right)^{2} \right\rbrace, \end{equation}

where ![]() ${Ec} = u_{*}^{2} / (c_{p} \theta _{*})$ is the Eckert number. Equations (2.6a) and (2.6b) are based on the assumption that the Reynolds number is large, which will be used here as well. Furthermore, the assumption of a high heat flux transferred from the plate leads to a small Eckert number, so that dissipation can be neglected, resulting in the following simplified dimensionless energy equation:

${Ec} = u_{*}^{2} / (c_{p} \theta _{*})$ is the Eckert number. Equations (2.6a) and (2.6b) are based on the assumption that the Reynolds number is large, which will be used here as well. Furthermore, the assumption of a high heat flux transferred from the plate leads to a small Eckert number, so that dissipation can be neglected, resulting in the following simplified dimensionless energy equation:

Note that due to the assumed constant thermophysical properties, ((2.2), (2.3) and consequently (2.6)) are independent of temperature. Hence, the predicted flow field is not affected by temperature. In reality, an influence of the inhomogeneous temperature field through, for example, buoyancy forces originated by the temperature dependency of the density, might influence the flow field. Typically, the Boussinesq approximation is used to evaluate the buoyancy effect. This approximation adds an additional force to the otherwise unchanged terms in the momentum equations (Schlichting & Gersten Reference Schlichting and Gersten2006). For the simplified set of equations treated in this study, this means that the equation for the pressure resulting from (2.3) ![]() $\partial p / \partial y = -1$ must be extended as follows:

$\partial p / \partial y = -1$ must be extended as follows:

where ![]() $\beta$ represents the thermal expansion coefficient. Since the non-dimensional temperature is of the order of unity,

$\beta$ represents the thermal expansion coefficient. Since the non-dimensional temperature is of the order of unity, ![]() $\beta \theta _* \ll 1$ needs to hold for buoyancy effects to be negligible.

$\beta \theta _* \ll 1$ needs to hold for buoyancy effects to be negligible.

2.3. Boundary conditions

To fully describe the problem, BCs need to be specified. For the flow field, the no-slip condition holds on the plate surface, the shear stress disappears on the interface, and the flux conservation must hold at any radius. These conditions can be expressed as follows:

For the temperature field, the temperature gradient is assumed to vanish on the free surface due to the small conductivity of the gas phase in comparison with the liquid phase. This assumption might be inaccurate for lower Prandtl numbers, because the thermal BL thickness may meet the free surface and the temperature gradient at the interface may become important. However, as the results show, the proposed ATHT works well for low Prandtl numbers where the thermal BL thickness has already reached the free surface before the jump. The deviations in the temperature field predicted by ATHT compared with numerical simulations are at sufficiently high Prandtl numbers (discussed in § 4.2). Thus, the assumption of a negligible temperature gradient at the interface does not lead to observed deviations. In addition, two classical thermal BCs for the plate are considered: (i) a CHF and (ii) a CPT. The dimensionless form of these conditions is

3. Solution method

This section presents the AT introduced by Bohr et al. (Reference Bohr, Putkaradze and Watanabe1997) to approximate the solution of the flow field described by the set of (2.6) and the BCs (2.14). Then, the AT is further developed to approximate the solution of (2.12) with the BCs (2.15) and to describe heat transfer. Developing such an AT implies assuming a profile for the quantities that shall be described, i.e. velocity and temperature. This profile has to be chosen so that it fulfils the BCs and the BLEs at specific positions along the film height, while still containing an unknown parameter. This parameter is finally determined by imposing that equations derived by integrating the BLEs along the film height are satisfied. The described methodology fits into the category of integral methods for the approximate solution of BLEs first introduced by von Kármán (Reference von Kármán1921) and Pohlhausen (Reference Pohlhausen1921).

3.1. Averaged flow equations

Integrating the momentum BLE over the film height leads to the following averaged equation:

\begin{equation} \frac{1}{h r} \frac{\mathrm{d}}{\mathrm{d} r} \left( r \int_{0}^{h} u^{2} \,\mathrm{d}z \right) =-\frac{\mathrm{d}h}{\mathrm{d}r} - \frac{1}{h} \left. \frac{\partial u}{\partial z} \right|_{z = 0}. \end{equation}

\begin{equation} \frac{1}{h r} \frac{\mathrm{d}}{\mathrm{d} r} \left( r \int_{0}^{h} u^{2} \,\mathrm{d}z \right) =-\frac{\mathrm{d}h}{\mathrm{d}r} - \frac{1}{h} \left. \frac{\partial u}{\partial z} \right|_{z = 0}. \end{equation}

Furthermore, introducing the average radial velocity ![]() ${v}(r) = h^{-1} \int _{0}^{h} u(r , z) \, \textrm {d}z$ allows us to represent the flux conservation equation, which can be interpreted as the averaged mass conservation equation, and the averaged momentum equation as

${v}(r) = h^{-1} \int _{0}^{h} u(r , z) \, \textrm {d}z$ allows us to represent the flux conservation equation, which can be interpreted as the averaged mass conservation equation, and the averaged momentum equation as

where ![]() $G$ is the ratio of radial momentum fluxes resulting from

$G$ is the ratio of radial momentum fluxes resulting from ![]() $u(r , z)$ and its average over the flow height,

$u(r , z)$ and its average over the flow height, ![]() ${v}(r)$, respectively. In order to derive a model capable of reproducing CHJs including a separation bubble, the radial velocity is assumed to be a polynomial of the form

${v}(r)$, respectively. In order to derive a model capable of reproducing CHJs including a separation bubble, the radial velocity is assumed to be a polynomial of the form

Equation (2.14) provides three conditions for determining the coefficients of the above polynomial, leaving one undetermined coefficient. This coefficient is chosen to be the so-called shape parameter, ![]() $\lambda (r)$, introduced by Bohr et al. (Reference Bohr, Putkaradze and Watanabe1997). The radial velocity profile then takes the following form:

$\lambda (r)$, introduced by Bohr et al. (Reference Bohr, Putkaradze and Watanabe1997). The radial velocity profile then takes the following form:

To fully describe the velocity field, ![]() $h(r)$ and

$h(r)$ and ![]() $\lambda (r)$ must be determined. An ordinary differential equation (ODE) for

$\lambda (r)$ must be determined. An ordinary differential equation (ODE) for ![]() $h(r)$ can be obtained by evaluating the momentum BLE (2.6b) on the plate surface while using the velocity profile (3.6). This results in

$h(r)$ can be obtained by evaluating the momentum BLE (2.6b) on the plate surface while using the velocity profile (3.6). This results in

Note that ![]() $G$ is only a function of

$G$ is only a function of ![]() $\lambda$ for the velocity profile (3.6),

$\lambda$ for the velocity profile (3.6), ![]() $G = 1/105 \lambda ^{2} - 1/15 \lambda + 6/5$. Applying this to (3.3), replacing

$G = 1/105 \lambda ^{2} - 1/15 \lambda + 6/5$. Applying this to (3.3), replacing ![]() ${v}$ through (3.2) with

${v}$ through (3.2) with ![]() $(hr)^{-1}$, and inserting the ODE (3.7) as well as the velocity profile (3.6) in (3.3) gives the following relation for

$(hr)^{-1}$, and inserting the ODE (3.7) as well as the velocity profile (3.6) in (3.3) gives the following relation for ![]() $\lambda (r)$:

$\lambda (r)$:

\begin{equation} \frac{\mathrm{d} \lambda}{\mathrm{d} r} = \frac{1}{\displaystyle\dfrac{\mathrm{d}G}{\mathrm{d}\lambda}} \left[ \frac{4 \lambda r}{h} + G \frac{h^{4} - (5 \lambda +3)}{r h^{4}} \right]\!. \end{equation}

\begin{equation} \frac{\mathrm{d} \lambda}{\mathrm{d} r} = \frac{1}{\displaystyle\dfrac{\mathrm{d}G}{\mathrm{d}\lambda}} \left[ \frac{4 \lambda r}{h} + G \frac{h^{4} - (5 \lambda +3)}{r h^{4}} \right]\!. \end{equation}3.2. Averaged energy equations

Similar to the AT for the flow, instead of solving the thermal BL equation, (2.12), the integral of this equation over the film height will be used, which reads

\begin{equation} \int_{0}^{h} \left( u \frac{\partial \theta}{\partial r} + w \frac{\partial \theta}{\partial z} = \frac{1}{{Pr}} \frac{\partial^{2} \theta}{\partial z^{2}} \right) \mathrm{d}z \Rightarrow \frac{1}{r} \frac{\mathrm{d}}{\mathrm{d}r} \left( r \int_{0}^{h} u \theta \, \mathrm{d}z \right) =-\frac{1}{{Pr}} \left. \frac{\partial \theta}{\partial z}\right|_{z = 0}. \end{equation}

\begin{equation} \int_{0}^{h} \left( u \frac{\partial \theta}{\partial r} + w \frac{\partial \theta}{\partial z} = \frac{1}{{Pr}} \frac{\partial^{2} \theta}{\partial z^{2}} \right) \mathrm{d}z \Rightarrow \frac{1}{r} \frac{\mathrm{d}}{\mathrm{d}r} \left( r \int_{0}^{h} u \theta \, \mathrm{d}z \right) =-\frac{1}{{Pr}} \left. \frac{\partial \theta}{\partial z}\right|_{z = 0}. \end{equation}

Note that (3.2) and the kinematic condition at the free surface, ![]() $\textrm {d}h/\textrm {d}r = ( u/w )_{z=h}$ are employed to derive (3.9). The kinematic condition is a condition the flow field needs to fulfil. However, it does not need to be imposed in the hydrodynamic problem as it holds if (2.14c) holds. Introducing an average temperature as

$\textrm {d}h/\textrm {d}r = ( u/w )_{z=h}$ are employed to derive (3.9). The kinematic condition is a condition the flow field needs to fulfil. However, it does not need to be imposed in the hydrodynamic problem as it holds if (2.14c) holds. Introducing an average temperature as

equation (3.9) results in

For the case of a CHF, (2.15b) can be directly inserted into (3.11), which results in the right-hand side of (3.11) being just ![]() $1/{Pr}$. Therefore, (3.11) can be integrated from

$1/{Pr}$. Therefore, (3.11) can be integrated from ![]() $0$ to

$0$ to ![]() $r$ leading to the following equation:

$r$ leading to the following equation:

Interestingly, the resulting equation for a CHF (3.12) is an algebraic equation, while for the case of a CPT the ODE (3.11) needs to be used. Therefore, an additional initial condition (IC) is required when dealing with a CPT. This difference results from the possibility of integrating (3.11) when the heat flux, which is related to the temperature gradient at the plate, is known along the entire radial domain. Physically interpreted, the amount of heat transported with the flow is known for all radial positions. If a CPT is assumed, this information, however, is unknown and an IC, which then fixes the amount of heat transported with the flow at the initial radius of the investigated domain of integration, becomes necessary.

For the selection of the radial velocity profile, the AT assumes that the viscous BL has already reached the film surface (Bohr et al. Reference Bohr, Putkaradze and Watanabe1997; Watanabe et al. Reference Watanabe, Putkaradze and Bohr2003). This is supported by the study of Watson (Reference Watson1964), where an analytic model of the viscous BL growth was used to show that the BL reaches the film surface relatively close to the stagnation region. Such an assumption cannot be made for modelling the temperature as the thickness of the thermal BL with respect to that of the viscous BL depends on the Prandtl number. Therefore, cases when the thermal BL ![]() $\delta _T$ is equal to the film height (thermally developed/fully diffused) and when

$\delta _T$ is equal to the film height (thermally developed/fully diffused) and when ![]() $\delta _T$ is smaller than the film height (thermally developing) are separately treated in the following sections. As in the description of the flow, polynomials are used to describe the temperature profile along the height.

$\delta _T$ is smaller than the film height (thermally developing) are separately treated in the following sections. As in the description of the flow, polynomials are used to describe the temperature profile along the height.

3.2.1. Fully developed thermal boundary layer ( $\delta _T = h$)

$\delta _T = h$)

For this case the temperature profile reads

where ![]() $\eta$ has been defined in (3.5a,b). The BCs given in (2.15) and the evaluation of the thermal BLE (2.12) on the plate surface, showing

$\eta$ has been defined in (3.5a,b). The BCs given in (2.15) and the evaluation of the thermal BLE (2.12) on the plate surface, showing ![]() $A_{2}(r) = 0$, provide three conditions to determine five coefficients of the temperature profile given in (3.13). The two undetermined coefficients are then represented by the free-surface temperature

$A_{2}(r) = 0$, provide three conditions to determine five coefficients of the temperature profile given in (3.13). The two undetermined coefficients are then represented by the free-surface temperature ![]() $( \theta |_{z = h} = \theta _{{s}} )$ and the plate temperature

$( \theta |_{z = h} = \theta _{{s}} )$ and the plate temperature ![]() $( \theta |_{z = 0} = \theta _{0} )$, in case of a CHF, or by the free-surface temperature

$( \theta |_{z = 0} = \theta _{0} )$, in case of a CHF, or by the free-surface temperature ![]() $( \theta |_{z = h} = \theta _{{s}} )$ and the dimensionless plate heat flux

$( \theta |_{z = h} = \theta _{{s}} )$ and the dimensionless plate heat flux ![]() $( \partial \theta / \partial z |_{z=0} = -\dot {q}(r) )$. The temperature profile can be expressed, depending on the BC imposed at the plate, a CHF or a CPT, as follows:

$( \partial \theta / \partial z |_{z=0} = -\dot {q}(r) )$. The temperature profile can be expressed, depending on the BC imposed at the plate, a CHF or a CPT, as follows:

\begin{equation} \left.\begin{gathered} \mathrm{CHF} \quad\theta = \theta_0 \left( 1 - 4 \eta^{3} + 3 \eta^{4} \right) - h \left( 2 \eta^{4} - 3 \eta^{3} + \eta \right) + \theta_{{s}} \left( 4 \eta^{3} - 3 \eta^{4} \right), \\ \mathrm{CPT} \quad\theta = \left( 1 - 4 \eta^{3} + 3 \eta^{4} \right) - h \dot{q}(r) \left( 2 \eta^{4} - 3 \eta^{3} + \eta \right) + \theta_{{s}} \left( 4 \eta^{3} - 3 \eta^{4} \right)\!. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \mathrm{CHF} \quad\theta = \theta_0 \left( 1 - 4 \eta^{3} + 3 \eta^{4} \right) - h \left( 2 \eta^{4} - 3 \eta^{3} + \eta \right) + \theta_{{s}} \left( 4 \eta^{3} - 3 \eta^{4} \right), \\ \mathrm{CPT} \quad\theta = \left( 1 - 4 \eta^{3} + 3 \eta^{4} \right) - h \dot{q}(r) \left( 2 \eta^{4} - 3 \eta^{3} + \eta \right) + \theta_{{s}} \left( 4 \eta^{3} - 3 \eta^{4} \right)\!. \end{gathered}\right\} \end{equation}Substituting the respective temperature profile (3.14) together with the velocity profile (3.6) in (3.11) or (3.12) results in

for a CHF or

for a CPT, where

In both cases, CHF and CPT, the functions ![]() ${N}(\lambda )$ and

${N}(\lambda )$ and ![]() ${M}(\lambda )$ are determined as

${M}(\lambda )$ are determined as

\begin{align} \left.\begin{gathered} \begin{array}{l} {M}(\lambda) = \displaystyle\int\nolimits_{0}^{1} f(r , \eta) \left( 3\eta^{4} - 4\eta^{3} \right) \mathrm{d}\eta \\[10pt] \quad\quad\enspace= \dfrac{1}{30} \lambda - \dfrac{19}{35}, \end{array} \quad \begin{array}{l} {N}(\lambda) = \displaystyle\int\nolimits_{0}^{1} f(r , \eta) \left( 2\eta^{4} - 3\eta^{3} + \eta \right) \mathrm{d}\eta \\[10pt] \quad\quad\!\enspace= \dfrac{1}{168} \lambda + \dfrac{41}{280}. \end{array} \end{gathered}\right\} \end{align}

\begin{align} \left.\begin{gathered} \begin{array}{l} {M}(\lambda) = \displaystyle\int\nolimits_{0}^{1} f(r , \eta) \left( 3\eta^{4} - 4\eta^{3} \right) \mathrm{d}\eta \\[10pt] \quad\quad\enspace= \dfrac{1}{30} \lambda - \dfrac{19}{35}, \end{array} \quad \begin{array}{l} {N}(\lambda) = \displaystyle\int\nolimits_{0}^{1} f(r , \eta) \left( 2\eta^{4} - 3\eta^{3} + \eta \right) \mathrm{d}\eta \\[10pt] \quad\quad\!\enspace= \dfrac{1}{168} \lambda + \dfrac{41}{280}. \end{array} \end{gathered}\right\} \end{align}To close the system of equations, evaluation of the thermal BLE, (2.12), at the free surface is used, as follows:

\begin{equation} u\frac{\mathrm{d}\theta_{{s}}}{\mathrm{d}r} = \frac{1}{{Pr}\,h^2} \left. \frac{\partial^2 \theta}{\partial \eta^2}\right|_{\eta = 1}. \end{equation}

\begin{equation} u\frac{\mathrm{d}\theta_{{s}}}{\mathrm{d}r} = \frac{1}{{Pr}\,h^2} \left. \frac{\partial^2 \theta}{\partial \eta^2}\right|_{\eta = 1}. \end{equation}Inserting the velocity profile (3.5a,b) and the respective temperature profile (3.14) into the above equation leads to

\begin{equation} \left.\begin{gathered} \mathrm{CHF} \quad\displaystyle\frac{\mathrm{d} \theta_{{s}}}{\mathrm{d} r} = \displaystyle\frac{6 r}{{Pr} \, h \, f (r , \eta = 1)} [ 2 ( \theta_{0} - \theta_{{s}} ) - h ], \\ \mathrm{CPT} \quad\displaystyle\frac{\mathrm{d} \theta_{{s}}}{\mathrm{d} r} = \displaystyle\frac{6 r}{{Pr} \, h \, f (r , \eta = 1)} [ 2 ( 1 - \theta_{{s}} ) - \dot{q}(r) h ]. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \mathrm{CHF} \quad\displaystyle\frac{\mathrm{d} \theta_{{s}}}{\mathrm{d} r} = \displaystyle\frac{6 r}{{Pr} \, h \, f (r , \eta = 1)} [ 2 ( \theta_{0} - \theta_{{s}} ) - h ], \\ \mathrm{CPT} \quad\displaystyle\frac{\mathrm{d} \theta_{{s}}}{\mathrm{d} r} = \displaystyle\frac{6 r}{{Pr} \, h \, f (r , \eta = 1)} [ 2 ( 1 - \theta_{{s}} ) - \dot{q}(r) h ]. \end{gathered}\right\} \end{equation}3.2.2. Developing thermal boundary layer ( $\delta _T < h$)

$\delta _T < h$)

For this case, a temperature profile of the form

is assumed, where ![]() $\eta _T = z/\delta _T$. As the thermal BL thickness is smaller than the height of the film, the partial derivative

$\eta _T = z/\delta _T$. As the thermal BL thickness is smaller than the height of the film, the partial derivative ![]() $\partial \theta / \partial z$ already vanishes at the height

$\partial \theta / \partial z$ already vanishes at the height ![]() $z = \delta _T$. Furthermore, the thermal BLE (2.12) is evaluated at

$z = \delta _T$. Furthermore, the thermal BLE (2.12) is evaluated at ![]() $z = \delta _T$. Consequently, the two following equations hold:

$z = \delta _T$. Consequently, the two following equations hold:

The above conditions together with the respective condition at the plate (2.15b,c), evaluation of the thermal BLE (2.12) on the plate, and ![]() $\theta |_{z=\delta _T} = 0$ allow the determination of all but one coefficient in (3.21):

$\theta |_{z=\delta _T} = 0$ allow the determination of all but one coefficient in (3.21):

\begin{equation} \left.\begin{gathered} \mathrm{CHF} \quad\theta = \delta_T( \tfrac{1}{2} - \eta_T + \eta_T^3 - \tfrac{1}{2} \eta_T^4 ), \\ \mathrm{CPT} \quad\theta = 1 - 2\eta_T + 2\eta_T^3 - \eta_T^4. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \mathrm{CHF} \quad\theta = \delta_T( \tfrac{1}{2} - \eta_T + \eta_T^3 - \tfrac{1}{2} \eta_T^4 ), \\ \mathrm{CPT} \quad\theta = 1 - 2\eta_T + 2\eta_T^3 - \eta_T^4. \end{gathered}\right\} \end{equation} Introducing ![]() $\varPhi = \delta _T / h$, using

$\varPhi = \delta _T / h$, using ![]() $\eta = \varPhi \eta _T$ and inserting the velocity profile, (3.6), and the temperature profile for a CHF, (3.23), into (3.12) results in

$\eta = \varPhi \eta _T$ and inserting the velocity profile, (3.6), and the temperature profile for a CHF, (3.23), into (3.12) results in

where

\begin{align} \varGamma(\varPhi,\lambda) &= \varPhi^2 \int_{0}^{1} f( r, \eta_T ) \left( \frac{1}{2} - \eta_T + \eta_T^3 - \frac{1}{2} \eta_T^4 \right) \mathrm{d}\eta_T \nonumber\\ &= \frac{\lambda + 3}{30} \varPhi^3 - \frac{5\lambda + 3}{168} \varPhi^4 + \frac{\lambda}{140} \varPhi^5. \end{align}

\begin{align} \varGamma(\varPhi,\lambda) &= \varPhi^2 \int_{0}^{1} f( r, \eta_T ) \left( \frac{1}{2} - \eta_T + \eta_T^3 - \frac{1}{2} \eta_T^4 \right) \mathrm{d}\eta_T \nonumber\\ &= \frac{\lambda + 3}{30} \varPhi^3 - \frac{5\lambda + 3}{168} \varPhi^4 + \frac{\lambda}{140} \varPhi^5. \end{align}For the case of a CPT, the velocity profile, (3.6), and the respective temperature profile, (3.23), are inserted into (3.11), leading to

\begin{align} \frac{\mathrm{d}\varPhi}{\mathrm{d}r} = \frac{1}{\displaystyle\dfrac{\partial \xi(\varPhi,\lambda)}{\partial \varPhi}} \left[ \frac{2r}{\varPhi h \,{Pr}} - \frac{\partial\xi(\varPhi,\lambda)}{\partial \lambda} \frac{\mathrm{d} \lambda}{\mathrm{d}r} \right] \quad \mathrm{with} \ \xi(\varPhi,\lambda) = \frac{\lambda + 3}{15} \varPhi^{2} - \frac{5\lambda +3}{84} \varPhi^{3} + \frac{\lambda}{70} \varPhi^{4}. \end{align}

\begin{align} \frac{\mathrm{d}\varPhi}{\mathrm{d}r} = \frac{1}{\displaystyle\dfrac{\partial \xi(\varPhi,\lambda)}{\partial \varPhi}} \left[ \frac{2r}{\varPhi h \,{Pr}} - \frac{\partial\xi(\varPhi,\lambda)}{\partial \lambda} \frac{\mathrm{d} \lambda}{\mathrm{d}r} \right] \quad \mathrm{with} \ \xi(\varPhi,\lambda) = \frac{\lambda + 3}{15} \varPhi^{2} - \frac{5\lambda +3}{84} \varPhi^{3} + \frac{\lambda}{70} \varPhi^{4}. \end{align}Note, the reason for using a fourth-order instead of a third-order polynomial for the determination of the temperature field has been discussed in Appendix A.

3.3. Numerical solution of the AT

The simplified hydrodynamic problem described by the ODEs (3.7) and (3.8) can be solved as a boundary value problem, prescribing ![]() $h_{{i}}$ and

$h_{{i}}$ and ![]() $h_{{end}}$ at two different radii

$h_{{end}}$ at two different radii ![]() $r_{i}$ and

$r_{i}$ and ![]() $r_{{end}}$ before and after the jump, respectively. A thorough analysis of the equations and the solution properties can be found in Watanabe et al. (Reference Watanabe, Putkaradze and Bohr2003). In order to cope with the stiffness of the system of equations, a relaxation method (Press et al. Reference Press, Teukolsky, Vetterling and Flannery2007) is used in this study, which was first successfully applied to type Ia CHJs by Nielsen (Reference Nielsen2015). Details on this method can be found in Press et al. (Reference Press, Teukolsky, Vetterling and Flannery2007). An exemplary visualisation of the resulting flow is shown in figure 2, where a recirculation bubble is formed on the plate surface in the jump region in a clockwise direction.

$r_{{end}}$ before and after the jump, respectively. A thorough analysis of the equations and the solution properties can be found in Watanabe et al. (Reference Watanabe, Putkaradze and Bohr2003). In order to cope with the stiffness of the system of equations, a relaxation method (Press et al. Reference Press, Teukolsky, Vetterling and Flannery2007) is used in this study, which was first successfully applied to type Ia CHJs by Nielsen (Reference Nielsen2015). Details on this method can be found in Press et al. (Reference Press, Teukolsky, Vetterling and Flannery2007). An exemplary visualisation of the resulting flow is shown in figure 2, where a recirculation bubble is formed on the plate surface in the jump region in a clockwise direction.

Figure 2. Streamlines in the region of the hydraulic jump determined by the AT. The working fluid is water: ![]() $\rho =998.2 \ \mathrm {kg}\ \mathrm {m}^{-3}$;

$\rho =998.2 \ \mathrm {kg}\ \mathrm {m}^{-3}$; ![]() $\mu = 10.03 \times 10^{-4} \ \mathrm {kg}\ (\mathrm {ms})^{-1}$;

$\mu = 10.03 \times 10^{-4} \ \mathrm {kg}\ (\mathrm {ms})^{-1}$; ![]() $c_p = 4182 \ \mathrm {J}\ (\mathrm {kg}\ \mathrm {K})^{-1}$;

$c_p = 4182 \ \mathrm {J}\ (\mathrm {kg}\ \mathrm {K})^{-1}$; ![]() ${Pr}=6.991$. The volume flow rate is

${Pr}=6.991$. The volume flow rate is ![]() $Q = 15 \ \mathrm {ml}\ \mathrm {s}^{-1}$.

$Q = 15 \ \mathrm {ml}\ \mathrm {s}^{-1}$.

Once ![]() $h(r)$ and

$h(r)$ and ![]() $\lambda (r)$ are known, the results can be used to solve the heat transfer problem. If a CHF is prescribed as the BC at the plate, this means that (3.15) and (3.20) or (3.24) shall be solved depending on whether the thermal BL thickness has reached the flow height. If a CPT is imposed, a solution of (3.16) and (3.20) or (3.26) will be required.

$\lambda (r)$ are known, the results can be used to solve the heat transfer problem. If a CHF is prescribed as the BC at the plate, this means that (3.15) and (3.20) or (3.24) shall be solved depending on whether the thermal BL thickness has reached the flow height. If a CPT is imposed, a solution of (3.16) and (3.20) or (3.26) will be required.

As it is initially not known which region of the flow field can be described by which equations, values for ![]() $\varPhi$ are determined on the entire domain using (3.24) or (3.26). Solving (3.24) implies determining the roots of a fifth-order polynomial and the only physically relevant ones are those located between

$\varPhi$ are determined on the entire domain using (3.24) or (3.26). Solving (3.24) implies determining the roots of a fifth-order polynomial and the only physically relevant ones are those located between ![]() $0$ and

$0$ and ![]() $1$. Depending on the values of

$1$. Depending on the values of ![]() $\lambda$,

$\lambda$, ![]() $h$ and

$h$ and ![]() $r$ there will either be a single one or none in this interval. Solving (3.26) means solving a first-order ODE, therefore, an IC is required. For the investigations presented in the next section of this study,

$r$ there will either be a single one or none in this interval. Solving (3.26) means solving a first-order ODE, therefore, an IC is required. For the investigations presented in the next section of this study, ![]() $\varPhi (r_{{i}})$ was chosen by fixing the Nusselt number at

$\varPhi (r_{{i}})$ was chosen by fixing the Nusselt number at ![]() $r_{{i}}$.

$r_{{i}}$.

After determining ![]() $\varPhi$, the first radius is determined, to which

$\varPhi$, the first radius is determined, to which ![]() $\varPhi > 1$ applies. Thenceforward, the set of (3.15) and (3.20) is used, starting with an IC

$\varPhi > 1$ applies. Thenceforward, the set of (3.15) and (3.20) is used, starting with an IC ![]() $\theta _{{s}} = 0$. For the case of a CPT, an additional IC for

$\theta _{{s}} = 0$. For the case of a CPT, an additional IC for ![]() $\dot {q}(r)$ is needed. For this, the equality of the temperature profiles determined with (3.23) and (3.14) is used. This equality is guaranteed where the thermal BL meets the free surface. The resulting condition is

$\dot {q}(r)$ is needed. For this, the equality of the temperature profiles determined with (3.23) and (3.14) is used. This equality is guaranteed where the thermal BL meets the free surface. The resulting condition is ![]() $\dot {q}(r) = 2/h$.

$\dot {q}(r) = 2/h$.

If ![]() $\varPhi > 1$ already applies for

$\varPhi > 1$ already applies for ![]() $r_{{i}}$, it means that the thermal BL has reached the film surface before

$r_{{i}}$, it means that the thermal BL has reached the film surface before ![]() $r_{{i}}$. Consequently, (3.15) and (3.20) or (3.16 and (3.20), depending on the thermal BC, are solved from

$r_{{i}}$. Consequently, (3.15) and (3.20) or (3.16 and (3.20), depending on the thermal BC, are solved from ![]() $r_{{i}}$ onwards.

$r_{{i}}$ onwards.

To carry out the solution, the initial value of ![]() $\theta _{{s}}$ and, if necessary, that of

$\theta _{{s}}$ and, if necessary, that of ![]() $\dot {q}(r)$ must still be determined. For the case of a CHF condition, this can be done, for example, by solving (3.7), (3.8) and (3.24) in the direction of decreasing

$\dot {q}(r)$ must still be determined. For the case of a CHF condition, this can be done, for example, by solving (3.7), (3.8) and (3.24) in the direction of decreasing ![]() $r$ until the radius

$r$ until the radius ![]() $r_T$ is found, for which the thermal BL reaches the film height. Equations (3.15) and (3.20) can then be solved from this new initial radius onwards using the initial condition

$r_T$ is found, for which the thermal BL reaches the film height. Equations (3.15) and (3.20) can then be solved from this new initial radius onwards using the initial condition ![]() $\theta _{{s}} = 0$.

$\theta _{{s}} = 0$.

Note that ![]() $r_T$ decreases if the Prandtl number decreases. For

$r_T$ decreases if the Prandtl number decreases. For ![]() ${Pr} \lesssim 1$, the thermal BL will eventually reach the film surface before the viscous BL does. In such a case, the assumption of a fully viscous BL is not valid around

${Pr} \lesssim 1$, the thermal BL will eventually reach the film surface before the viscous BL does. In such a case, the assumption of a fully viscous BL is not valid around ![]() $r_T$. It is therefore reasonable that this approach will not be valid for very small Prandtl numbers. Moreover, this approach cannot be used for the case of a CPT as the equation determining

$r_T$. It is therefore reasonable that this approach will not be valid for very small Prandtl numbers. Moreover, this approach cannot be used for the case of a CPT as the equation determining ![]() $\varPhi$, (3.26), is not an algebraic equation and an initial value for

$\varPhi$, (3.26), is not an algebraic equation and an initial value for ![]() $\theta _{{s}}$ as well as

$\theta _{{s}}$ as well as ![]() $\dot {q}(r)$ needs to be chosen.

$\dot {q}(r)$ needs to be chosen.

The entire process to compute the parameters describing the temperature field, i.e. ![]() $\delta _T$,

$\delta _T$, ![]() $\theta _0$ and

$\theta _0$ and ![]() $\theta _{{s}}$, is shown in the flowchart provided in figure 3. The algorithm for solving the AT for heat transfer was implemented in MATLAB and is freely accessible under the link given in the Supplementary data.

$\theta _{{s}}$, is shown in the flowchart provided in figure 3. The algorithm for solving the AT for heat transfer was implemented in MATLAB and is freely accessible under the link given in the Supplementary data.

Figure 3. Flowchart of the solution method for the heat transfer problem.

4. Results

In the following, the results of the ATHT are compared with the available studies on the heat transfer in CHJs with a separation bubble. Validation of the original AT introduced by Bohr et al. (Reference Bohr, Putkaradze and Watanabe1997) with the numerical study of Higuera (Reference Higuera1997), experimental study of Duchesne, Lebon & Limat (Reference Duchesne, Lebon and Limat2014) and also with analytical approaches for upstream and downstream regions of the jump is presented in Appendix B.

4.1. Evaluation of the ATHT: comparison with Sung et al. (Reference Sung, Choi and Yoo1999)

The first comparison is with the numerical results presented by Sung et al. (Reference Sung, Choi and Yoo1999), where the simulated region starts at a radius of ![]() $r_{{i}} = 10$ mm before the jump and ends after the jump at a radius of

$r_{{i}} = 10$ mm before the jump and ends after the jump at a radius of ![]() $r_{{end}} = 100$ mm. Sung et al. studied four cases with different volume flow rates. The height at the starting radius

$r_{{end}} = 100$ mm. Sung et al. studied four cases with different volume flow rates. The height at the starting radius ![]() $r_{{i}}$ is equal for all cases.

$r_{{i}}$ is equal for all cases.

Figure 4 shows the comparison of the flow heights (figure 4a) and the Nusselt number profiles for both thermal BCs, a CHF (figure 4b) and a CPT (figure 4c). The film heights in figure 4(a) before and after the jump as well as the jump location are well captured by the AT. However, the sudden increase in the film height predicted by the AT is steeper than that of the numerical simulations. In addition, the small decrease in the film height just before the jump in the numerical results, called capillary ripple, cannot be captured by the AT. These differences can be ascribed to the neglect of surface tension in the AT.

Figure 4. Comparison of the heights (a) and the Nusselt number profiles (b) predicted by the AT to the results presented by Sung et al. (Reference Sung, Choi and Yoo1999). The working fluid in all cases is water: ![]() $\rho =998.2 \ \mathrm {kg}\ \mathrm {m}^{-3}$;

$\rho =998.2 \ \mathrm {kg}\ \mathrm {m}^{-3}$; ![]() $\mu = 10.03 \times 10^{-4} \ \mathrm {kg}\ (\mathrm {ms})^{-1}$;

$\mu = 10.03 \times 10^{-4} \ \mathrm {kg}\ (\mathrm {ms})^{-1}$; ![]() $c_p = 4182 \ \mathrm {J}\ (\mathrm {kg}\ \mathrm {K})^{-1}$;

$c_p = 4182 \ \mathrm {J}\ (\mathrm {kg}\ \mathrm {K})^{-1}$; ![]() ${Pr} = 6.991$. Results for four different volume fluxes

${Pr} = 6.991$. Results for four different volume fluxes ![]() $Q = 15$, 20, 25 and

$Q = 15$, 20, 25 and ![]() $30 \ \mathrm {ml}\ \mathrm {s}^{-1}$ are shown. The solutions were initialised at a radius of

$30 \ \mathrm {ml}\ \mathrm {s}^{-1}$ are shown. The solutions were initialised at a radius of ![]() $r_{{i}} = 10\ \mathrm {mm}$ with an initial height of

$r_{{i}} = 10\ \mathrm {mm}$ with an initial height of ![]() $h_{{i}} = 0.2 \ \mathrm {mm}$ and constant temperature and radial velocity across the film height. Accordingly, the range of the entrance Reynolds numbers is

$h_{{i}} = 0.2 \ \mathrm {mm}$ and constant temperature and radial velocity across the film height. Accordingly, the range of the entrance Reynolds numbers is ![]() ${Re}_{h_{{i}}} = Q/(2 {\rm \pi}r_{{i}} \nu ) \approx 237.59\unicode{x2013} 475.18$. For the AT, apart from the initial height, the final heights were fixed at a radius of

${Re}_{h_{{i}}} = Q/(2 {\rm \pi}r_{{i}} \nu ) \approx 237.59\unicode{x2013} 475.18$. For the AT, apart from the initial height, the final heights were fixed at a radius of ![]() $r_{{end}} = 100 \ \mathrm {mm}$ for the four different cases in the order of increasing volume flux as

$r_{{end}} = 100 \ \mathrm {mm}$ for the four different cases in the order of increasing volume flux as ![]() $h_{{end}} = 1.55\ \mathrm {mm}$,

$h_{{end}} = 1.55\ \mathrm {mm}$, ![]() $1.60 \ \mathrm {mm}$,

$1.60 \ \mathrm {mm}$, ![]() $1.63 \ \mathrm {mm}$ and

$1.63 \ \mathrm {mm}$ and ![]() $1.68 \ \mathrm {mm}$, respectively. Sung et al. (Reference Sung, Choi and Yoo1999) used the definition of

$1.68 \ \mathrm {mm}$, respectively. Sung et al. (Reference Sung, Choi and Yoo1999) used the definition of ![]() ${Nu}_{h_{{i}}} = q_{w} h_{{i}} /[ ( T_0 - T_{{i}} ) k ]$ for the Nusselt number, where

${Nu}_{h_{{i}}} = q_{w} h_{{i}} /[ ( T_0 - T_{{i}} ) k ]$ for the Nusselt number, where ![]() $T_{{i}}$ is the temperature across the film height at

$T_{{i}}$ is the temperature across the film height at ![]() $r_{{i}}$. According to the notations in this study, the equivalent definition for the Nusselt number reads

$r_{{i}}$. According to the notations in this study, the equivalent definition for the Nusselt number reads ![]() ${Nu}_{h_{{i}}} = h_{{i}}/(\theta _0 )$, with

${Nu}_{h_{{i}}} = h_{{i}}/(\theta _0 )$, with ![]() $h_{{i}}$ denoting the non-dimensional height at

$h_{{i}}$ denoting the non-dimensional height at ![]() $r_{{i}}$. Note that the ICs for the temperature field determined by the ATHT in the order of increasing volume flow rate for the case of a CPT are

$r_{{i}}$. Note that the ICs for the temperature field determined by the ATHT in the order of increasing volume flow rate for the case of a CPT are ![]() ${Nu} = 5.12$,

${Nu} = 5.12$, ![]() $5.44$,

$5.44$, ![]() $5.53$ and

$5.53$ and ![]() $6.11$, respectively. These hold for a radius of

$6.11$, respectively. These hold for a radius of ![]() $r = 10.8\ \mathrm {mm}$, because the Nusselt number at the initial radius,

$r = 10.8\ \mathrm {mm}$, because the Nusselt number at the initial radius, ![]() $r_{{i}}$, was not exactly extractable from the original work by Sung et al. (Reference Sung, Choi and Yoo1999).

$r_{{i}}$, was not exactly extractable from the original work by Sung et al. (Reference Sung, Choi and Yoo1999).

Figures 4(b) and 4(c) present the Nusselt number profiles over the entire radial range for a CHF imposed on the plate and a CPT, respectively. The Nusselt number curves are well predicted for both cases by the ATHT with related deviations from the numerical results of the same order as the deviations seen for the height profiles.

Note that the Nusselt number curves bend upwards close to the initial radius ![]() $r_{{i}}$ (see figure 4b). This is because Sung et al. imposed a constant temperature along the height at

$r_{{i}}$ (see figure 4b). This is because Sung et al. imposed a constant temperature along the height at ![]() $r_{{i}}$ and used this temperature as the reference temperature for calculating the heat transfer coefficient. It means that the Nusselt numbers tend to infinity if

$r_{{i}}$ and used this temperature as the reference temperature for calculating the heat transfer coefficient. It means that the Nusselt numbers tend to infinity if ![]() $r \rightarrow r_{{i}}$ and it can be interpreted as if the heat transfer between the plate and the flow starts at radius

$r \rightarrow r_{{i}}$ and it can be interpreted as if the heat transfer between the plate and the flow starts at radius ![]() $r_{{i}}$. The same behaviour is reproduced with the ATHT for the CHF condition by replacing (3.12) with

$r_{{i}}$. The same behaviour is reproduced with the ATHT for the CHF condition by replacing (3.12) with ![]() $\vartheta = ( r^2 - r_{{i}}^2) / (2\,{Pr})$. For the case of a CPT, the Nusselt number at the first data point is used as IC so no adaptation was necessary.

$\vartheta = ( r^2 - r_{{i}}^2) / (2\,{Pr})$. For the case of a CPT, the Nusselt number at the first data point is used as IC so no adaptation was necessary.

Figure 4(c) shows that the Nusselt number drops slightly below zero for the two cases with lower volume flow rates, i.e. ![]() $15$ ml s

$15$ ml s![]() $^{-1}$ and

$^{-1}$ and ![]() $20$ ml s

$20$ ml s![]() $^{-1}$ (see the first two profiles from the left side in the inset of figure 4c). The reason is the following: when a constant temperature is considered as the thermal BC, the Nusselt number is proportional to the heat transmitted from the plate to the fluid. A negative Nusselt number, therefore, means that heat is being transmitted from the fluid to the plate. This behaviour should not happen in this case because the inlet temperature of the flow is lower than the plate temperature. Such errors can be attributed to the solution method that only satisfies the averaged conservation equations but cannot guarantee physical values in the entire domain. However, the Nusselt number profiles presented by Sung et al. (Reference Sung, Choi and Yoo1999) are otherwise well captured.

$^{-1}$ (see the first two profiles from the left side in the inset of figure 4c). The reason is the following: when a constant temperature is considered as the thermal BC, the Nusselt number is proportional to the heat transmitted from the plate to the fluid. A negative Nusselt number, therefore, means that heat is being transmitted from the fluid to the plate. This behaviour should not happen in this case because the inlet temperature of the flow is lower than the plate temperature. Such errors can be attributed to the solution method that only satisfies the averaged conservation equations but cannot guarantee physical values in the entire domain. However, the Nusselt number profiles presented by Sung et al. (Reference Sung, Choi and Yoo1999) are otherwise well captured.

4.2. Evaluation of the ATHT: comparison with Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020)

The second comparison is with the numerical study by Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020), who analysed several CHJs with different internal structures (type Ia to IIb, see also figure 1).

Figure 5 shows the variation of the flow height ![]() $h(r)$ and that of the shape parameter

$h(r)$ and that of the shape parameter ![]() $\lambda (r)$ with radius (figure 5a) and also those of the Nusselt number profiles (figure 5b,c) for a CHJ of type Ia together with the results obtained applying the ATHT. Nusselt number profiles are presented for different Prandtl numbers,

$\lambda (r)$ with radius (figure 5a) and also those of the Nusselt number profiles (figure 5b,c) for a CHJ of type Ia together with the results obtained applying the ATHT. Nusselt number profiles are presented for different Prandtl numbers, ![]() ${Pr} = 7$, 50, 100 and

${Pr} = 7$, 50, 100 and ![]() $164$, and these for the two thermal BCs, CHF (figure 5b) and CPT (figure 5c).

$164$, and these for the two thermal BCs, CHF (figure 5b) and CPT (figure 5c).

Figure 5. Comparison of the height profile (a) and the Nusselt number profiles in the case of a CHF (b) and in the case of a CPT (c) predicted by the AT with that of the FRNS following Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020). The working fluid is ethylene–glycol (antifreeze) mixed with water with a kinematic viscosity of ![]() $\nu = 10^{-5}\ \mathrm {m}^2\ \mathrm {s}^{-1}$ and a volume flow rate of

$\nu = 10^{-5}\ \mathrm {m}^2\ \mathrm {s}^{-1}$ and a volume flow rate of ![]() $Q = 30 \ \mathrm {ml}\ \mathrm {s}^{-1}$ emerges from a nozzle with a diameter of

$Q = 30 \ \mathrm {ml}\ \mathrm {s}^{-1}$ emerges from a nozzle with a diameter of ![]() $d = 5 \ \mathrm {mm}$. The entrance Reynolds number of the jet is

$d = 5 \ \mathrm {mm}$. The entrance Reynolds number of the jet is ![]() ${Re}_d= 4Q/{\rm \pi} \,d \nu \approx 764$ and the Prandtl number is

${Re}_d= 4Q/{\rm \pi} \,d \nu \approx 764$ and the Prandtl number is ![]() ${Pr} \approx 164$. Comparisons were carried out for four Pr numbers:

${Pr} \approx 164$. Comparisons were carried out for four Pr numbers: ![]() $Pr = 7$, 50, 100 and 164. For the AT, the BCs are

$Pr = 7$, 50, 100 and 164. For the AT, the BCs are ![]() $h_{{i}} = 0.60 \ \mathrm {mm}$ at

$h_{{i}} = 0.60 \ \mathrm {mm}$ at ![]() $r_{{i}} = 5 \ \mathrm {mm}$ and

$r_{{i}} = 5 \ \mathrm {mm}$ and ![]() $h_{{end}} = 3.1 \ \mathrm {mm}$ at

$h_{{end}} = 3.1 \ \mathrm {mm}$ at ![]() $r_{{end}} = 40 \ \mathrm {mm}$. Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020) used the definition of

$r_{{end}} = 40 \ \mathrm {mm}$. Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020) used the definition of ![]() ${Nu}_d = \dot {q}(r) {\cdot } d/[ ( T_0 - T_f ) k ]$ for the Nusselt number, where the inlet diameter of the jet (

${Nu}_d = \dot {q}(r) {\cdot } d/[ ( T_0 - T_f ) k ]$ for the Nusselt number, where the inlet diameter of the jet (![]() $d = 5 \ \mathrm {mm}$) was used as characteristic length. The equivalent definition with the notation used in this study is

$d = 5 \ \mathrm {mm}$) was used as characteristic length. The equivalent definition with the notation used in this study is ![]() ${Nu}_d = d/(\theta _0 z^{*} )$. Figure 5(a) also shows the variation of the shape parameter, which indicates sudden changes of the radial velocity profile in the jump region. This is used in § 4.3.2 to describe the convective effects in the jump region. The abscissa and ordinate are made dimensionless applying the nozzle diameter. The ICs for the temperature field determined by the ATHT in the order of increasing Prandtl number for the case of a CPT are

${Nu}_d = d/(\theta _0 z^{*} )$. Figure 5(a) also shows the variation of the shape parameter, which indicates sudden changes of the radial velocity profile in the jump region. This is used in § 4.3.2 to describe the convective effects in the jump region. The abscissa and ordinate are made dimensionless applying the nozzle diameter. The ICs for the temperature field determined by the ATHT in the order of increasing Prandtl number for the case of a CPT are ![]() ${Nu} = 22.35$,

${Nu} = 22.35$, ![]() $43.33$,

$43.33$, ![]() $54.70$ and

$54.70$ and ![]() $64.63$, respectively. These hold for a radial position of

$64.63$, respectively. These hold for a radial position of ![]() $r/d = 2$. This point was chosen because the flow field predicted by the FRNS for

$r/d = 2$. This point was chosen because the flow field predicted by the FRNS for ![]() $r/d < 2$ is still influenced by the stagnation zone.

$r/d < 2$ is still influenced by the stagnation zone.

The Nusselt number profile for ![]() ${Pr} = 164$ determined by FRNS is also to be found in Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020). Note that all the results obtained by FRNS have been calculated again in this study, including the case of a CPT that was not treated by Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020). Following Askarizadeh et al., numerical simulations have been carried out in this study by solving the Navier–Stokes equations under the assumption of a laminar, incompressible, immiscible two-phase flow using the SMICFoam (smooth interface compression) solver (Rohlfs, Figueiredo & Pischke Reference Rohlfs, Figueiredo and Pischke2020). This solver was developed to fix the shortcomings of the standard interFoam solver of the open field operation and manipulation (OpenFOAM) library in the presence of sudden changes in the pressure field and in the interface. See Appendix C for more details on the numerical solution.

${Pr} = 164$ determined by FRNS is also to be found in Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020). Note that all the results obtained by FRNS have been calculated again in this study, including the case of a CPT that was not treated by Askarizadeh et al. (Reference Askarizadeh, Ahmadikia, Ehrenpreis, Kneer, Pishevar and Rohlfs2020). Following Askarizadeh et al., numerical simulations have been carried out in this study by solving the Navier–Stokes equations under the assumption of a laminar, incompressible, immiscible two-phase flow using the SMICFoam (smooth interface compression) solver (Rohlfs, Figueiredo & Pischke Reference Rohlfs, Figueiredo and Pischke2020). This solver was developed to fix the shortcomings of the standard interFoam solver of the open field operation and manipulation (OpenFOAM) library in the presence of sudden changes in the pressure field and in the interface. See Appendix C for more details on the numerical solution.

Figure 5(a) shows that the height profile is well captured by the AT, suggesting that the flow field should also have been well captured. A more detailed comparison of the predicted flow fields will be given in § 4.3.1. Concerning the heat transfer characteristics in the jump region, figures 5(b) and 5(c) show that the ATHT is capable of correctly predicting the Nusselt number for ![]() ${Pr} = 7$. However, for higher Prandtl numbers, e.g.

${Pr} = 7$. However, for higher Prandtl numbers, e.g. ![]() ${Pr} = 164$, the ATHT underestimates the Nusselt number from the beginning of the jump onwards, while correctly predicts the Nusselt number before the jump. This holds true regardless of the imposed BC.

${Pr} = 164$, the ATHT underestimates the Nusselt number from the beginning of the jump onwards, while correctly predicts the Nusselt number before the jump. This holds true regardless of the imposed BC.

For the case of a CHF, figure 5(b) indicates that the Nusselt number predicted by the ATHT increases again in the final segment of the jump region for the two higher Prandtl numbers, ![]() ${Pr} = 100$ and

${Pr} = 100$ and ![]() $164$. Such an increase is not seen for the two lower Prandtl numbers. This is because of the existence of a threshold value for the Prandtl number (

$164$. Such an increase is not seen for the two lower Prandtl numbers. This is because of the existence of a threshold value for the Prandtl number (![]() ${Pr_{th}}$), above which the thermal BL predicted by the ATHT does not reach the film surface throughout the flow field and there is no transition from a region described by (3.24) to a region described by (3.15) and (3.20).

${Pr_{th}}$), above which the thermal BL predicted by the ATHT does not reach the film surface throughout the flow field and there is no transition from a region described by (3.24) to a region described by (3.15) and (3.20).

For the presented cases in figure 5(b), the threshold Prandtl number is ![]() ${Pr_{th}} \approx 52$. Figure 6(a) indicates that for a Prandtl number slightly lower than

${Pr_{th}} \approx 52$. Figure 6(a) indicates that for a Prandtl number slightly lower than ![]() ${Pr_{th}}$, the thermal BL reaches the free surface, while it stays below the free surface throughout the flow field for higher Prandtl numbers than

${Pr_{th}}$, the thermal BL reaches the free surface, while it stays below the free surface throughout the flow field for higher Prandtl numbers than ![]() ${Pr_{th}}$. Figure 6(b) shows that the Nusselt number profiles signify the same qualitative difference shown in figure 5(b) for

${Pr_{th}}$. Figure 6(b) shows that the Nusselt number profiles signify the same qualitative difference shown in figure 5(b) for ![]() ${Pr} = 7$ and 164, i.e. the different behaviour of the ATHT in the prediction of the Nusselt number depending on the Prandtl number. Although the two Prandtl numbers are close to each other, the resulting Nusselt number curves in the jump region differ from each other, since different sets of equations must be solved for determining the temperature field. Concluding, there exists a discontinuous behaviour of the solution with respect to the Prandtl number, because different sets of equations are needed to determine the temperature field.

${Pr} = 7$ and 164, i.e. the different behaviour of the ATHT in the prediction of the Nusselt number depending on the Prandtl number. Although the two Prandtl numbers are close to each other, the resulting Nusselt number curves in the jump region differ from each other, since different sets of equations must be solved for determining the temperature field. Concluding, there exists a discontinuous behaviour of the solution with respect to the Prandtl number, because different sets of equations are needed to determine the temperature field.

Figure 6. Comparison of the thermal BLs (a) and Nusselt number profiles (b) predicted by the ATHT for two Prandtl numbers slightly higher and lower than ![]() ${Pr_{th}} = 52$. The flow conditions are the same as in figure 5. The abscissa and ordinate are made dimensionless applying the diameter of the nozzle (

${Pr_{th}} = 52$. The flow conditions are the same as in figure 5. The abscissa and ordinate are made dimensionless applying the diameter of the nozzle (![]() $d = 5 \ \mathrm {mm}$), from which the jet emerges.

$d = 5 \ \mathrm {mm}$), from which the jet emerges.

For the case of a CPT (figure 5c), discontinuity in the solution procedure was not observed. In fact, the ATHT predicts the thermal BL to reach the surface before the jump or in the jump region for all cases shown. Increasing the Prandtl number further, a threshold Prandtl number can also be found for the case of a CPT.

4.3. Physical insights into the ATHT

To further analyse the accuracy of the ATHT and understand the differences compared with the FRNS, four additional investigations are carried out. First, the flow structure obtained by the two methods will be compared. Second, the predicted temperature field will be compared for different Prandtl numbers. Third, the flow field predicted by the FRNS is used as input for the ATHT to study the temperature field while avoiding possible inaccuracies in the prediction of the flow field properties by the AT. Finally, the thermal BLE (2.12) will be used to investigate the influence of the Prandtl number on the temperature field and the applicability of the AT.

4.3.1. Flow field and velocity profile in the jump region

To signify the differences between the flow fields in the jump region resulting from the AT and FRNS, figure 7 is shown in addition to figure 5(a), where the good agreement in the prediction of the height profile suggests that the flow field can also be captured well.

Figure 7. Comparison of the streamlines (a,c) and velocity profiles (b,d) in the jump region. Streamlines are plotted on the temperature field: FRNS (a); AT (b). Temperature field is presented for the case of ![]() ${Pr} = 164$, for which the AT does not properly capture the temperature field. Velocity profiles in the jump region and at the centre of the separation bubble obtained by the FRNS (c) and AT (d) signify the differences in the captured flow fields. The abscissa and ordinate are made dimensionless applying the nozzle diameter

${Pr} = 164$, for which the AT does not properly capture the temperature field. Velocity profiles in the jump region and at the centre of the separation bubble obtained by the FRNS (c) and AT (d) signify the differences in the captured flow fields. The abscissa and ordinate are made dimensionless applying the nozzle diameter ![]() $d = 5 \ {\mathrm {mm}}$, from which the jet emerges.

$d = 5 \ {\mathrm {mm}}$, from which the jet emerges.

Figures 7(a) and 7(c) show the streamlines plotted on the temperature field for ![]() ${Pr} = 164$ and for the case of a CHF BC. There is good agreement between the FRNS and AT in predicting the leading edge of the separation bubble. However, the separation bubble predicted by the AT is smaller and the kink in the height profile is closer to the leading edge of the separation bubble. This results in a smaller cross-sectional area above the separation bubble, through which the main flow must pass, and consequently in higher positive velocities over the separation bubble. Hence, negative velocities in the separation bubble must also be higher, because higher positive velocities make the separation bubble circulate faster (see figures 7b and 7d).

${Pr} = 164$ and for the case of a CHF BC. There is good agreement between the FRNS and AT in predicting the leading edge of the separation bubble. However, the separation bubble predicted by the AT is smaller and the kink in the height profile is closer to the leading edge of the separation bubble. This results in a smaller cross-sectional area above the separation bubble, through which the main flow must pass, and consequently in higher positive velocities over the separation bubble. Hence, negative velocities in the separation bubble must also be higher, because higher positive velocities make the separation bubble circulate faster (see figures 7b and 7d).

Comparing figures 5(b) and 7 shows that the strongest change in the Nusselt number takes place at the leading edge of the separation bubble. Thus, a good prediction of this leading edge is important to correctly predict the heat transfer characteristics in the jump region.

As a conclusion, the flow height is well captured (figure 5a), the separation bubble can be resolved in the jump region and the position of its leading edge is well determined (figure 7a,c) applying AT. However, there are dissimilarities between the flow field obtained in comparison with that of FRNS (figure 7a). This is in due to the neglect of surface tension effects and due to the assumed velocity profile in the AT. As the flow field is crucial to determining the temperature field, the dissimilarities in the flow fields can also lead to dissimilarities in the temperature fields.

4.3.2. Temperature field and temperature profile in the jump region

The temperature distribution in the jump region determined by ATHT is examined in more detail in this section by making comparisons with the one determined by FRNS for two different Prandtl numbers, ![]() ${Pr} = 7$ and

${Pr} = 7$ and ![]() $164$ (figure 8).

$164$ (figure 8).

Figure 8. Comparison of the temperature fields and profiles in the jump region obtained from the AT (a,b), and from the FRNS (c,d). The flow conditions are the same as those given in figure 5 for ![]() ${Pr} = 7$ and

${Pr} = 7$ and ![]() ${Pr} = 164$. The abscissa and ordinate are made dimensionless applying the nozzle diameter

${Pr} = 164$. The abscissa and ordinate are made dimensionless applying the nozzle diameter ![]() $d = 5 \ {\mathrm {mm}}$, from which the jet emerges. The temperature profiles resulted from the AT (a,b), regardless of the Prandtl number, are monotonically decreasing from the plate onwards, while those of the FRNS (c,d) exhibit a local maximum away from the plate for high Prandtl numbers. In the FRNS

$d = 5 \ {\mathrm {mm}}$, from which the jet emerges. The temperature profiles resulted from the AT (a,b), regardless of the Prandtl number, are monotonically decreasing from the plate onwards, while those of the FRNS (c,d) exhibit a local maximum away from the plate for high Prandtl numbers. In the FRNS ![]() $\delta _T$ is defined as the line where

$\delta _T$ is defined as the line where ![]() $\theta = 10^{-6}$ holds.

$\theta = 10^{-6}$ holds.

The temperature fields obtained by the FRNS exhibit significant differences in the jump region for low and high Prandtl numbers. For low Prandtl numbers (figure 8c), where the thermal BL thickness has already reached the free surface before the jump, the temperature profiles remain monotonically decreasing throughout the jump. However, the situation is different for high Prandtl numbers (figure 8d), where the thermal BL thickness does not reach the free surface across the jump. In this case, the temperature profiles in the jump region exhibit a local maximum away from the plate; an important feature not captured by the ATHT. After the jump, this maximum disappears and a monotonically decreasing profile is seen again. Such a maximum in the temperature profile occurs because of the following: first, the highest temperatures occur at the leading edge of the separation bubble due to the vanishing flow velocity in the radial direction; and second, the generated heat in this region is transported by the separated flow that circumvents the separation bubble leading to the local maximum in the temperature profile. For high Prandtl numbers, i.e. when the influence of diffusive heat transfer is low, this transported heat reaches a region over the separation bubble not affected by diffusive heat transfer from the plate. Furthermore, the higher the Prandtl number, the longer it takes for the transported heat to be transferred to adjacent streamlines.

In the ATHT, however, the selected temperature profile remains monotonically decreasing and concave over the entire flow regardless of the Prandtl number. This can also be deduced from the simple temperature profile (3.23). As a result, the ATHT captures the temperature field for ![]() ${Pr} = 7$ (figure 8a) but not completely for

${Pr} = 7$ (figure 8a) but not completely for ![]() ${Pr} = 164$ (figure 8b). Besides, the missing local maximum away from the plate that can be seen in the FRNS (figure 8d), the temperature is overestimated in the jump region, leading to the previously shown underestimation of the Nusselt number (figure 5b).

${Pr} = 164$ (figure 8b). Besides, the missing local maximum away from the plate that can be seen in the FRNS (figure 8d), the temperature is overestimated in the jump region, leading to the previously shown underestimation of the Nusselt number (figure 5b).

The behaviour of the thermal BL thickness also differs from the one predicted by the FRNS. First, the thermal BL reaches the free surface at smaller values of the radial coordinate in the ATHT than in the FRNS for small Pr numbers (figure 8a,c). This location is equal to ![]() $r/d \approx 3$ for AHAT and

$r/d \approx 3$ for AHAT and ![]() ${\approx }4$ for FRNS in this case. Second, for

${\approx }4$ for FRNS in this case. Second, for ![]() $Pr = 164$, the BL thickness shows a more pronounced increase at the leading edge of the separation bubble and decreases more strongly after the separation bubble in the ATHT than in the FRNS.

$Pr = 164$, the BL thickness shows a more pronounced increase at the leading edge of the separation bubble and decreases more strongly after the separation bubble in the ATHT than in the FRNS.

The overestimation of the plate temperature in the jump region as well as the curve of the thermal BL thickness in the ATHT (figure 8b) can be explained by the fact that the ATHT adopts the concave and monotonically decreasing profile (3.23), whose only variable is ![]() $\delta _T$, to satisfy the integral energy equation (3.12). As there is a backflow close to the plate and no local temperature maximum away from it in the ATHT, higher temperatures over the entire height are required to balance the negative heat flux, which means an increase in the thermal BL thickness. This phenomenon is further strengthened by overestimation of the velocities in the separation bubble shown in figure 7. Since there is no heat flux transported in the negative radial direction after the separation bubble, the predicted temperatures decrease again together with the thermal BL thickness. This decrease is much stronger than the one in the FRNS.

$\delta _T$, to satisfy the integral energy equation (3.12). As there is a backflow close to the plate and no local temperature maximum away from it in the ATHT, higher temperatures over the entire height are required to balance the negative heat flux, which means an increase in the thermal BL thickness. This phenomenon is further strengthened by overestimation of the velocities in the separation bubble shown in figure 7. Since there is no heat flux transported in the negative radial direction after the separation bubble, the predicted temperatures decrease again together with the thermal BL thickness. This decrease is much stronger than the one in the FRNS.

4.3.3. Averaging theory using the full Navier–Stokes velocity field

In order to rid the ATHT of the possible shortcomings in predicting the velocity field, which may lead to inaccuracies in predicting the temperature field, the heat transfer problem was studied with the ATHT using the flow field determined by the FRNS.

Figures 9(a) and 9(b) show the temperature fields obtained in this way for ![]() $Pr = 7$ and

$Pr = 7$ and ![]() $Pr = 164$, respectively. Compared with figure 8, the temperature field for

$Pr = 164$, respectively. Compared with figure 8, the temperature field for ![]() $Pr = 7$ is reasonably predicted by this approach. This is comprehensible as this case was already well predicted by the ATHT (see figure 5b as well).

$Pr = 7$ is reasonably predicted by this approach. This is comprehensible as this case was already well predicted by the ATHT (see figure 5b as well).

Figure 9. (a,b) Temperature fields and profiles determined by the ATHT using the flow field determined by the FRNS. (c,d) Nusselt number profiles for ![]() $Pr = 7$ and 164 determined by the FRNS, by the FRNS and ATHT (FRNS–ATHT), and by the ATHT alone. Nusselt number profiles over the entire radial range (c), and over the jump region (d).

$Pr = 7$ and 164 determined by the FRNS, by the FRNS and ATHT (FRNS–ATHT), and by the ATHT alone. Nusselt number profiles over the entire radial range (c), and over the jump region (d).