Introduction

The fashion industry has recently seen a drastic increase in the turnover of its collections over the past decades, going from 2 collections a year in 2000 to up to 24 collections a year today for international retailers such as Zara (ADEME 2022). This new business strategy, called “fast fashion,” relies on accelerating changes in fashion trends to guarantee a constant need for customers to buy new clothes and transforming garments into disposables. The fashion industry produces over 100 billion clothing items a year, of which 85% will end up in landfills before the end of the year (UNEP 2018). This waste is mainly composed of polyester (54%) and cotton (22%) (Textile Exchange 2022).

Various microorganisms, such as fungi, are capable of biodegrading cellulose and other polymers. Soil-associated filamentous fungi have the natural capability to degrade lignocellulosic biomass through their vegetative part, the mycelium (Hawksworth and Lücking Reference Hawksworth and Lücking2017). Interestingly, mycelium is already being used in the fashion industry for the production of vegan leather-like materials (Gandia et al. Reference Gandia, van den Brandhof, Appels and Jones2021; Jones et al. Reference Jones, Gandia, John and Bismarck2021) and of various types of composite materials for packaging and object design (Elsacker et al. Reference Elsacker, Vandelook, Van Wylick, Ruytinx, De Laet and Peeters2020; Vandelook et al. Reference Vandelook, Elsacker, Van Wylick, De Laet and Peeters2021). Considering the dual role of mycelium as decomposer and material, an opportunity to rethink the linearity of the textile industry emerges: if textile waste could be used as the material input for mycelium-based fashion, it could transform the existing linear industry into a circular system.

Filamentous fungi secrete a wide range of lignocellulolytic enzymes for the catabolism of organic substrates (Rigobello and Ayres Reference Rigobello and Ayres2023). This pool of nonspecific enzymes includes enzymes highly efficient against both crystalline and amorphous cellulose. Cotton fibers are composed of 94% cellulose (Islam Shawn Reference Islam Shawn2014) and have been proven in the literature to be prone to enzymatic biodegradation when exposed to cellulases (Wang et al. Reference Wang, Egan and Salmon2023). The exploration of the use of mycelium for cotton biodegradation and mycelium-based composite materials making is promising: according to Egan and Salmon (Reference Egan and Salmon2022), “the microorganism penetrates into the lumen where it multiplies and eventually breaks down the fiber from the inside-out.” Taking this data into account, it is possible to hypothesize that filamentous fungi can metabolize cotton and other plant-based, as well as cellulose-rich textile waste. The Pleurotus ostreatus fungi is a common edible fungal strain reported to be able to break down complex polymers such as green polyethylene (Da Luz et al. Reference Da Luz, Paes, Ribeiro, Mendes and Kasuya2015) and to grow on oil-contaminated soil (Adewole and Olanrewaju Reference Adewole and Olanrewaju2017; Biomar Microbial Technologies 2019). These characteristics make it a good candidate for the biodegradation of natural and synthetic textile waste.

The use of textiles as a substrate for mycelium-based composites remains an underexplored domain but has recently started gaining greater interest. Saini et al. (Reference Saini, Kaur and Brar2023) qualitatively and quantitatively investigated mycelium growth on cotton fibers with the addition of supplementary nitrogen and glucose and the material properties of the composite arising thereof for packaging applications. In a similar way, Harper and Moody (Reference Harper and Moody2023) carried out experiments of fungal growth on textile with no supplements, and though no evidence of textile biodegradation could be concluded, very clear remediation of textile dye could be observed. Research from non-peered-reviewed isolated reports has been carried out on the specific case of processing textile waste as a feedstock for fungal fermentation, using denim and synthetic textile waste mixed with food waste with Trametes versicolor and Ganoderma lucidum (Dussault et al. Reference Dussault, Jaouich, Karam and Vermeersch2016, Reference Dussault, Mayer, Jaouich and Karam2017), and conceptual research projects suggested mycelium textile recycling factories as a potential textile recycling solution (Cai Reference Cai2017). Interestingly, it became a source of inspiration for design, aesthetic and artistic perspectives, with the ability – but also the raw concept – of fungi to biodegrade textiles instigating in artists and designers the generation of new design patterns and textures (Akpa Reference Akpa2017; Carole Collet 2019; Helena Elston Studio 2018). In these works, the design approach is focused on the added value of mycelium aesthetics on textile rather than textile biodegradation.

But is it feasible to develop a biological process for the upcycling of textile waste and revalorize it into a textile-like product using waste streams only? This paper is a qualitative exploration of the use of mycelium for the biodegradation of textile and food waste, assessing its ability to digest different types of waste and produce composite mycelium materials textiles out of it. The goal is not only to offer a new, more sustainable, biodegradable alternative to current leathers but also to enter the field of regenerative design with the bioremediation of the accumulating waste to make a new valuable product out of it. This study evaluates the growth of Pleurotus ostreatus on various mixes of denim textile waste, synthetic textile waste, food waste and coffee grounds, and a post-processing technique suitable for the fabrication of flexible composite mycelium material is subsequently described.

Methods

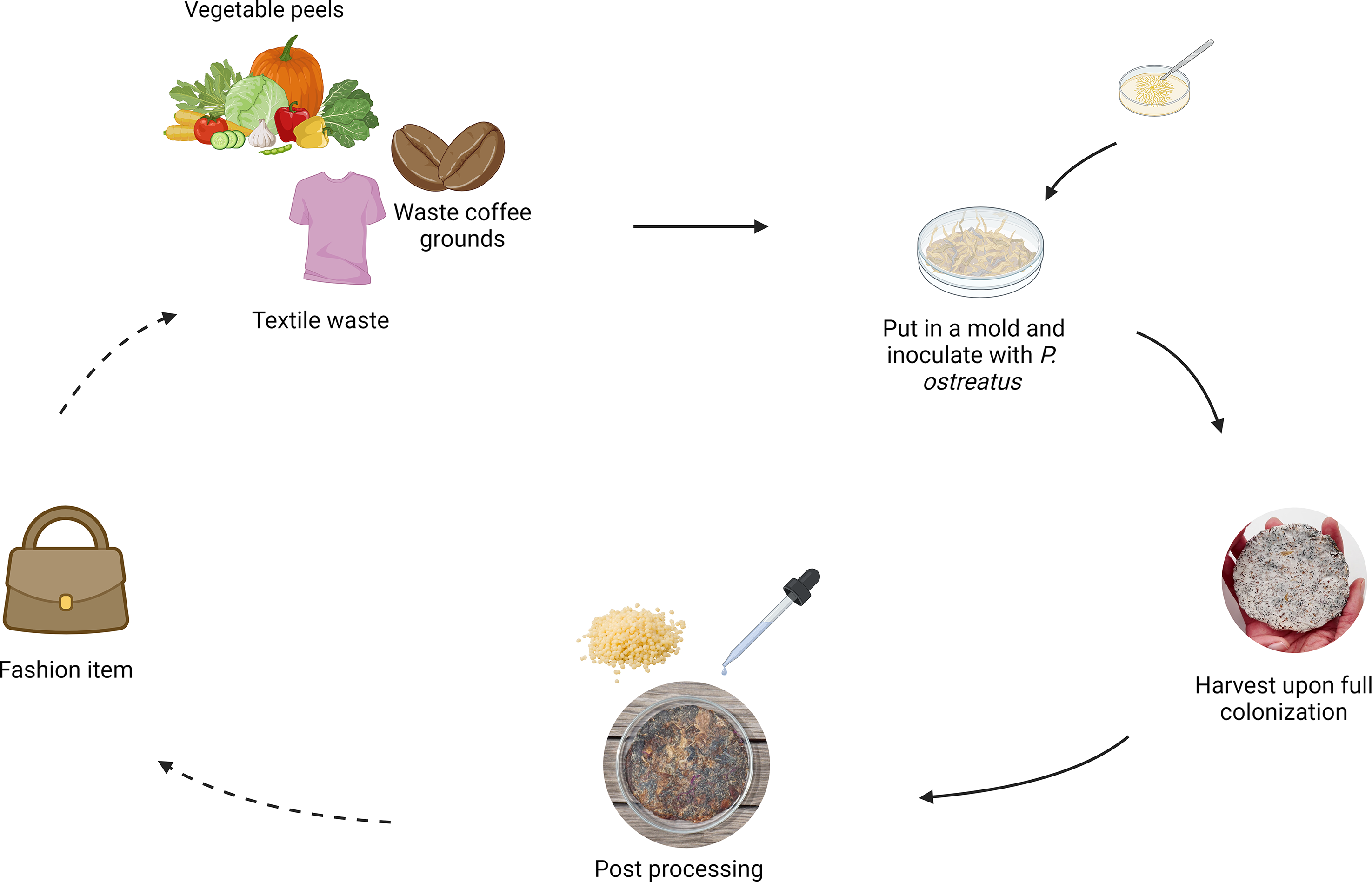

Figure 1 summarizes the process followed in this paper and described in the methods section.

Figure 1. Experimental design followed in this article.

Strain and culture conditions

The Pleurotus ostreatus strain was a kind gift from the personal collection of the SBiotica biodesign hub in Barcelona. Synthetic and denim textile waste was provided by Fab Lab Barcelona Fabricademy Node, Institute for Advanced Architecture of Catalonia (IAAC), issued from textile scraps. Synthetic textile waste was mainly composed of synthetic polyester textiles. Food waste was obtained by recycling vegetable peels (carrots, cucumbers, zucchini, onions and broccoli) from domestic waste. Spent coffee grounds were obtained from domestic waste of the Marcilla brand (Figure 2).

Figure 2. Left to right: vegetable peels, denim textile waste, coffee grounds and synthetic textile waste.

Waste substrate preparation

Table 1 features the list of the different waste combinations tested and how they were prepared.

Table 1. Types of waste tested and preparation protocol

From those wastes, six waste mixes were prepared, numbered from 1 to 6: (1) denim textile waste, (2) denim and coffee grounds (30 g denim textile waste, 10 g dry coffee grounds), (3) denim, coffee grounds and mixed food waste (30 g denim textile waste, 70 g food waste and 5 g dry coffee grounds), (4) synthetic textile waste, (5) synthetic textile waste and coffee grounds (30 g synthetic textile waste, 10 g dry coffee grounds) and (6) synthetic textile waste, coffee grounds and mixed food waste (30 g synthetic textile waste, 70 g food waste and 5 g dry coffee grounds).

Mixes were poured into 10 cm Ø glass petri dishes until the dish was full and sterilized for 2.5 hours in a pressure cooker (121°C, high pressure).

Growth conditions

Once sterilized and cooled to room temperature, each petri dish was inoculated with 1 cm2 of P. ostreatus grown on malt agar. All experiments were carried out in technical duplicates. Petri dishes were grown for up to 40 days at 27°C in darkness, and humidity was kept above 90%. Samples displaying uniform, dense and consistent growth were selected for the post-processing phase, to transform them into a composite material. These samples were heat pressed, terminating the mycelium growth. The remaining samples were considered inappropriate for further investigation and were autoclaved in a pressure cooker for 1hr and discarded.

Image analysis

Growth results analysis was made using the free open-source ImageJ software. For each picture, the image scale was determined with the internal diameter of the petri dish as a reference for a length of 9 cm. Area measurement was done manually using the freehand selection and measurement tools, as the threshold tool could not be used because of the lack of normalization of the images (no consistent background and light reflection). The qualitative variable “dense hyphae” was also assessed for “presence” or “absence” for each picture. Dense hyphae were considered “present” in pictures where a white, non-see-through zone could be identified.

Qualitative results were classified into the four following categories: no growth, growth, strong growth and very strong growth. These categories were determined through three different criteria: colonization area on day 7, colonization area on day 21 or day 25 depending on the sample and presence or absence of dense hyphae on day 7, day 21 or day 25.

“No growth” label was attributed to samples with colonization percentages on day 21 (or 25) inferior to 50%, which is equivalent to an area of colonization on day 21 of 3180 mm2.

“Growth” was attributed to samples with colonization percentages on day 21 (or 25) superior to 50% which is equivalent to a colonization area on day 21 (or 25) superior to 3180 mm2.

“Strong growth” was attributed to samples with a colonization percentage superior to 75% (colonization area on day 21 or 25 superior to 4770 mm2) and displaying dense hyphae on day 21 (or 25).

“Very strong growth” was attributed to samples with a colonization percentage superior to 75% (colonization area on day 21 or 25 superior to 4770 mm2) and displaying dense hyphae from day 7 onward.

Post-processing

According to Vandelook et al. (Reference Vandelook, Elsacker, Van Wylick, De Laet and Peeters2021), the post-processing of mycelium skins includes heat pressing, plasticizing and coating. An optional step of deacetylation followed by crosslinking is possible before plasticizing. The overall information available about the process is usually very vague so an empirical approach of trial and error was employed to evaluate the most suitable process for these preliminary small-scale experiments. Fresh mycelium composite was first heat pressed three times for 20 sec at 150°C for the triple purpose of killing the fungus, increasing the density and promoting heat-induced crosslinking of molecular bonds in the mycelium material (Vandelook et al. Reference Vandelook, Elsacker, Van Wylick, De Laet and Peeters2021). Then, the pressed composite was dipped in a 30% glycerol bath for 12 hours for plasticizing purposes and finally dried at 35°C for 8 hours in a dehydrator. The plasticizing step serves the purpose of preventing the mycelium part of the material from completely drying and becoming brittle. Once dried, the composite was coated with melted soy wax and heat pressed three times for 20 sec at 150°C to make the coating uniform. This process potentially provides a protective waterproof layer to the biocomposite.

One of the samples was color dyed prior to the coating step using Indian ink.

Qualitative evaluation

A qualitative evaluation survey involving 12 participants was conducted to get peers’ feedback on the material and understand their impressions of the final post-processed samples. Participants were selected among IAAC students, staff and visitors and were asked in person to take part in the survey. Questions included participant’s gender, age group and whether they had a design background or not. The participants were first given the non-dyed prototype and asked the following questions without knowing what the material was made from:

-

- What does this material remind you of?

-

- How does it feel like (touch, texture, flexibility, thickness…)?

-

- What does it smell like?

-

- Is it pleasant, neutral or unpleasant?

Then, the participants were shown the black painted sample and given the exact composition and process for the making of both samples. The participants were finally asked for their comments on the dyed vs non-dyed material, if they had preferences and comments. The complete list of questions and answers can be found in Supplementary data 1.

Results and analysis

Growth results

Table 2 presents the results of the growth experiments on the various waste types. Samples where dense hyphae could be observed are highlighted in green. Average growth curves with their respective standard deviation can be found in Supplementary Data 2. As replicate 2 did not grow for condition 6, only the results from the second replicate were considered for further analysis. Figure 3 features images of the different conditions on day 7. Growth pictures of each condition for day 0, day 7, day 21/25 and further can be found in Supplementary Data 3.

Table 2. Growth results. Numbers refer to the compositions described in §Methods–Waste substrates preparation, colored cells correspond to samples where dense hyphae could be observed

Figure 3. Pleurotus ostreatus growth on the different mixes on day 7. Numbers refer to the composition described in §Methods–Waste substrates preparation.

P. ostreatus mycelium grew on all the combinations of food waste (vegetable peels and coffee grounds) and textile waste (synthetic textile and denim textile) and even grew on denim textile waste only, suggesting effective biodegradation and metabolization, thus classifying it as a promising strain for cellulose-based textiles biodegradation and recycling processes. Basidiomycetes such as P. ostreatus are known for possessing a very versatile extracellular catabolic system for the enzymatic degradation of cellulosic substrate and of dyes (Peralta et al. Reference Peralta, Polacchine Da Silva, Carvalho, Côrrea, Kato, Augusto, Seixas and Bracht2017; Rigobello and Ayres Reference Rigobello and Ayres2023; Sen et al. Reference Sen, Raut, Bandyopadhyay and Raut2016). These results show the fungus acquired nutrients from the denim textile waste and thus degraded it. However, further research is required to define what components from the dyes or the fibers or both were the source of nutrients used by the fungus.

P. ostreatus also grew on mixes involving synthetic textile waste and food waste, but not on synthetic textile waste alone. In this case, biodegradation could not be observed, but growth on mixes containing synthetic textile waste and food waste blends shows the synthetic nature of the fibers does not prevent P. ostreatus from acquiring nutrients from the organic waste. It does thus suggest these synthetic fibers could be incorporated into composite materials with this species. Therefore, the result is not about the biodegradation and metabolization of textile waste but rather its upcycling into a new function.

For the first three setups where growth was observed on natural fibers, the mycelium seemed to only partially degrade the fibers, leading to a composite made of the mycelium and the remaining of its substrate. Provided the flexible nature of the substrate (as opposed to woodchips generating solid mycelium composites), the textile waste and food waste mycelium composite is flexible.

Mixes including coffee grounds and food waste (n°3 and n°6) led to very strong growth with the formation of denser hyphae earlier in the growth process, potentially making it interesting for materials applications. However, samples containing synthetic textile waste (n°6) attained their maximum growth around day 30, while samples containing denim textile waste (n°3) continued growing and led to complete colonization of every free spot of the petri dish after 45 days, forming a strong and thick “composite pancake” (Figure 4). The mycelium did not entirely degrade the fibers and only partially digested it, leading to a flexible composite made of the mycelium, textile fibers and food waste, making it interesting for material applications.

Figure 4. P. ostreatus grown on denim textile waste, food waste and coffee grounds on day 45. Live composite material before post-processing.

Post-processing into a material sample

Provided the soft nature of the substrate, the textile waste and food waste mycelium composite grown on mix n°3 is also malleable (Figure 4). Post-processing methods have previously been described for pure mycelium leather, but not for composite flexible materials. In this paper, a similar approach to pure mycelium materials was explored through the empirical method of trial and error. Heat pressing live mycelium composite three times for 20 sec at 150°C led to the termination of the fungal growth and to increasing its density. During this step, the mycelium part of the composite also changed colors from white to light brown. The plasticization process allowed the composite to change from a brittle to a flexible texture, and the wax coating gave it a protective layer as well as smoothened the surface for a more enjoyable touch (Figure 5).

Figure 5. Sample n°3 through different stages of post-processing. Left: fresh sample before heat pressing. Middle: sample after heat pressing. Right: sample after plasticizing and wax coating.

Adequate post-processing using bio-sourced and biodegradable plasticizer and coating led to a flexible composite material. Two prototypes were generated: a non-dyed and a dyed one (Figure 6).

Figure 6. P. ostreatus grown on denim textile waste, food waste and coffee grounds after post-processing.

Final material sample evaluation

Designers have been growing interest to use biological materials in everyday design. Their unique look, novelty and environmental friendliness make them a topic of interest in the design world; however, studies show that their perception by the wider public differs. In a survey conducted by Sayuti et al. (Reference Sayuti, Sommer and Ahmed-Kristensen2022), the concepts of insects, fungi, algae and bacteria were perceived rather negatively by the wider public as these materials are rarely used in designs or are still in a conceptual or experimental stage. Designer’s perception of biological materials tends to be more positively connotated due to them being more familiar to it. It is thus important when developing new material samples to evaluate the audience’s response to their looks with and without prior information of their composition.

The aim of the survey described in the methods section was to see how a design-related audience would perceive the material and what should be improved for further material development. A complete list of answers is available in Supplementary Data 1. Participants’ answers were generally heterogeneous.

Participants predominantly associated the material with neutral elements and objects. Among the identified objects were natural elements such as “cork,” “pressed flowers,” “leather” and “peach skin.” Additionally, there were associations with biomaterials, including references to “mycelium pavilion,” “kombucha leather” and “live organisms.” Food-related comparisons were also noted, such as “dried meat” and “roti bread,” as well as synthetic materials commonly used in architecture like “insulation material,” “plastic,” “textile” and “asphalt.” However, some responses had negative connotations, with participants likening the material to “wound crusts” and “dry chewing gum,” possibly due to its composite nature.

Regarding the tactile properties of the material, descriptors such as “fragile” and “brittle” were frequently mentioned. More neutral descriptions of the texture included terms like “mix of textures,” “irregular,” “natural,” “water repellent,” “very soft,” “sticky,” “non-porous,” “imperfect” and “smooth.”

Concerning the olfactory properties of the sample, most participants noted that the material had a natural scent, with comparisons to “spice,” “biomaterials,” “tea,” “coffee,” “mushrooms” and “woody” aromas. Some likened the scent to materials derived from natural sources, such as “leather” and “the inside of a cardboard box.” The smell was unanimously described as neutral, neither “pleasant” nor “unpleasant.”

Most participants enjoyed the more natural look of the composite with no dyes applied, and the neutral smell and the pleasant texture are important assets. However, post-processing of the composite should still be more extensively explored to bring new properties and new esthetics to it. One main outcome of the survey is that the composite leather looks fragile and is not flexible enough, which are crucial mechanical criteria for commercialization and usability standards of a material for textile applications. The issue of flexibility could be targeted by investigating alternative plasticizing processes. In the same way, the fragility and brittleness issues can be targeted by optimizing the growth of the mycelium and finding a better way to structure the fibers prior to inoculation, for instance by felting them which could increase tearing resistance.

The results are encouraging considering that these samples are the outcome of a 3-month research in a biolaboratory with very basic equipment. The information that could be extracted from this perception survey is guiding the next research steps toward the improvement of the growth conditions for obtaining a more solid and less fragile composite.

Conclusions

This work introduces a new method of upcycling a mix of textile and food waste using Pleurotus ostreatus mycelium for the biodegradation and aggregation of fibers in a new composite leather-like material. Biodegradation of fibers was qualitatively investigated and showed P. ostreatus mycelium grew strong on all combinations of synthetic or denim textiles mixed with additives (food and coffee wastes) and even grew on denim textile waste only. While quantitative degradation assessment methods used in previous studies (Saini et al., Reference Saini, Kaur and Brar2023; Harper & Moody, Reference Harper and Moody2023; Dussault et al., Reference Dussault, Jaouich, Karam and Vermeersch2016, Reference Dussault, Mayer, Jaouich and Karam2017) were not applied, this result indicates effective biodegradation, suggesting P. ostreatus as a promising strain for recycling cellulose-based textiles. Qualitative analysis of growth behavior on the different combinations of substrates enabled straightforward identification of the best conditions for the intended revalorization purpose: adding coffee grounds and food waste allowed the mycelium to have more nutrients and to grow very strong, leading to a thick, flexible composite material suitable for post-processing, highlighting the potential of this approach for sustainable material innovation. Adequate and 100% natural post-processing protocols were established during this research. The final resulting product is a sustainable composite mycelium material sample that can be incorporated into a circular fashion model. The benefits of this process can be seen in the promotion of the circularity of waste fabrics and the transformation of post-consumer waste to a novel material that can lead to new circular business opportunities. Additionally, the simplicity of the setup and the basic equipment needed give this technique the potential to fit in a distributed design and manufacturing scenario.

While this simple setup is a great asset for upscaling and distributed manufacturing purposes, further research is required for optimizing the characteristics of this novel material, improving the best samples and refining the growth protocol to obtain a stronger material. An interesting perspective to explore would be to « train » the mycelium to grow on textile substrates and eventually make it capable of digesting textile waste more efficiently as it has been previously been explored by independent researchers on cigarette subs (Radical Mycology 2014). It would also be of interest to investigate the impact of the size of the fibers on their biodegradability and see if shredding the textile waste into smaller particles eases the enzymatic degradation, allowing for better growth of the mycelium. Another avenue to explore would be to exploit the use of fibers that are not being fully degraded and are still present in the final material to find an entanglement method such as felting to strengthen the composite. This would allow for the development of a performative composite that would comply with industry standards and open the doors to upscaling for the making of recyclable garments, accessories and shoes.

Supplementary material

The supplementary material for this article can be found at https://doi.org/10.1017/btd.2024.26.

Data availability statement

The data that support the findings of this study are available within the article and its supplementary materials and openly available on the webpage of the project at https://class.textile-academy.org/2022/annah-sangosanya/FinalProject/08_FinalOutcome/.

Acknowledgments

We would like to thank the IAAC FabLab BCN team, Maud Bausier and IAAC alumna Jessica Kate Dias for their help and guidance during the trimester of research. We would also like to thank Prof. Jane Scott for suggesting us to publish this work in this journal and for proofreading and correcting the first version of the paper, and we thank Prof. Eveline Peeters and Dr. Elise Vanden Elsacker for helping with the reviewing and corrections.

This project was awarded the Lenzing Young Scientist Award 2022 in the category of textile recycling, the crQlr awards 2022 MMGH fashion prize and fungi prize and nominated for the Green Concept Award 2023 in the Fashion category.

Graphical abstract and Figure 1 were created with BioRender.com.

Author contribution

This research is part of Annah-Ololade’s final postgraduate project at Fabricademy, Textile & Technology Academy, FabLab Barcelona (IAAC), “The Pure Hyphae Project.” This research was supervised by Mrs Anastasia Pistofidou, thesis mentor and director of Fabricademy Global. The contribution of the second author includes supervision of the project and resources gathering for equipment and external help. It also includes guidance and help in the conceptualization of the study, in project administration and in article reviewing. Remaining work including project conceptualization, methodology, investigation, formal analysis, writing of the original draft, review and editing was performed by first author.

Funding statement

This research received no specific grant from any funding agency, commercial or not-for-profit sectors.

Competing interests

None.

Ethics statement

Study participants provided oral informed consent to participate in this research. Ethical approval was deemed unnecessary for the other aspects of the study.

Comments

No accompanying comment.