1. Introduction

Bubble collapse near solid boundaries involves high speeds, high energy densities and very small time and length scales. This intense and fast energy release is the origin of the destructive potential of bubble cavitation, well known to be detrimental to the material surface. In fact, apart from the negative effect on hydraulic turbines and other applications in power engineering (Stripling & Acosta Reference Stripling and Acosta1962), cavitation can be exploited in many contexts, such as industrial cleaning processes (Brems et al. Reference Brems, Hauptmann, Camerotto, Pacco, Kim, Xu, Wostyn, Mertens and De Gendt2013), nanomaterials synthesis (Xu, Zeiger & Suslick Reference Xu, Zeiger and Suslick2013), kidney stones fragmentation in shock wave lithotripsy, (Zhong Reference Zhong2013), root canal treatment in dentistry (Robinson et al. Reference Robinson, Macedo, Verhaagen, Versluis, Cooper, Van der Sluis and Walmsley2018), ophthalmic surgery (Vogel et al. Reference Vogel, Hentschel, Holzfuss and Lauterborn1986) and drug permeability enhancement of overall tissues or cell membranes (Coussios & Roy Reference Coussios and Roy2008; Brennen Reference Brennen2015; Peruzzi et al. Reference Peruzzi, Sinibaldi, Silvani, Ruocco and Casciola2018; Silvani et al. Reference Silvani, Scognamiglio, Caprini, Marino, Chinappi, Sinibaldi, Peruzzi, Kiani and Casciola2019). The implosion of small bubbles is relevant also for botany, for example in the spore dispersal of ferns (Noblin et al. Reference Noblin, Rojas, Westbrook, Llorens, Argentina and Dumais2012; Scognamiglio et al. Reference Scognamiglio, Magaletti, Izmaylov, Gallo, Casciola and Noblin2018) or for the embolism of plant xylems under drought (Vincent et al. Reference Vincent, Marmottant, Quinto-Su and Ohl2012; Ponomarenko et al. Reference Ponomarenko, Vincent, Pietriga, Cochard, Badel and Marmottant2014). In most of these applications, the bubbles are relatively small, typically micrometre size. Despite their size, which may lead one to think that inertial effects are negligible, the damaging potential of micrometre-sized bubbles is, in fact, unexpectedly large.

From the experimental side, much work accumulated starting from the pioneering experiments carried out in Lauterborn's group using millimetre-sized laser-induced bubbles (Lauterborn & Bolle Reference Lauterborn and Bolle1975) that inspired much successive work (Occhicone et al. Reference Occhicone, Sinibaldi, Danz, Casciola and Michelotti2019; Sinibaldi et al. Reference Sinibaldi, Occhicone, Alves Pereira, Caprini, Marino, Michelotti and Casciola2019; Bokman et al. Reference Bokman, Biasiori-Poulanges, Meyer and Supponen2023). High-speed visualisations showed complex dynamics where the imploding bubble loses its spherical symmetry, due to the wall that inhibits the motion of the proximal part of the bubble, at the same time increasing the speed of the distal part. As a consequence, a strong water jet pierces the bubble, changing its topology from a spheroid into a toroid, while at the same time a complex system of compression waves is launched into the liquid. The combined action of the jet and the shock wave violently stresses the wall material inducing its damage in the form of pitting.

Different surfaces have been investigated in the past, including rigid walls (Tomita & Shima Reference Tomita and Shima1986; Zhang, Duncan & Chahine Reference Zhang, Duncan and Chahine1993; Brujan et al. Reference Brujan, Keen, Vogel and Blake2002; Johnsen & Colonius Reference Johnsen and Colonius2009; Gonzalez-Avila, Denner & Ohl Reference Gonzalez-Avila, Denner and Ohl2021; Saini et al. Reference Saini, Tanne, Arrigoni, Zaleski and Fuster2022), elastic solids (Brujan et al. Reference Brujan, Nahen, Schmidt and Vogel2001), soft tissues (Kodama & Takayama Reference Kodama and Takayama1998), porous plates (Andrews, Rivas & Peters Reference Andrews, Rivas and Peters2023) and free liquid–gas interfaces (Robinson et al. Reference Robinson, Blake, Kodama, Shima and Tomita2001). Plastic deformation has also been addressed in a number of papers, see e.g. Philipp & Lauterborn (Reference Philipp and Lauterborn1998), Dular, Delgosha & Petkovšek (Reference Dular, Delgosha and Petkovšek2013) and Dular et al. (Reference Dular, Požar, Zevnik and Petkovšek2019), where the shape and size of the indentations were measured accurately.

Concerning numerical simulations, several works that coupled the dynamics of the fluid–solid system emerged in recent years (Chahine & Hsiao Reference Chahine and Hsiao2015; Cao et al. Reference Cao, Wang, Coutier-Delgosha and Wang2021). In most of these cases, the focus was on relatively large, macroscopic bubbles, where the relevant physics is essentially described by the inviscid Euler equation for the only liquid phase (Johnsen & Colonius Reference Johnsen and Colonius2009; Rasthofer et al. Reference Rasthofer, Wermelinger, Karnakov, Šukys and Koumoutsakos2019).

With the advent of microtechnologies, experiments are now pushed to the submillimetre range (Ohl & Ikink Reference Ohl and Ikink2003; Tho, Manasseh & Ooi Reference Tho, Manasseh and Ooi2007; Wu et al. Reference Wu, Zheng, Li, Ohl, Yu and Li2021; Pfeiffer et al. Reference Pfeiffer, Shahrooz, Tortora, Casciola, Holman, Salomir, Meloni and Ohl2022; Gutiérrez-Hernández et al. Reference Gutiérrez-Hernández, Reese, Ohl and Quinto-Su2023). Significant effort is currently aimed at understanding how the material surface is affected by the collapsing bubble, particularly concerning clinical and biophysical applications (Miller, Pislaru & Greenleaf Reference Miller, Pislaru and Greenleaf2002; Adhikari, Goliaei & Berkowitz Reference Adhikari, Goliaei and Berkowitz2016; Mancia et al. Reference Mancia, Vlaisavljevich, Yousefi, Rodriguez, Ziemlewicz, Lee, Henann, Franck, Xu and Johnsen2019; Barney et al. Reference Barney2020), and industrial cleaning processes (Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018; Zeng, An & Ohl Reference Zeng, An and Ohl2022; Reese, Ohl & Ohl Reference Reese, Ohl and Ohl2023; Mnich et al. Reference Mnich, Reuter, Denner and Ohl2024). It is the purpose of the present paper to discuss the response of the material surface to the implosion of such small vapour bubbles, where surface tension, viscosity and phase change are intermingled, calling for a comprehensive model encompassing all the phenomenologies occurring along bubble collapse (Magaletti, Marino & Casciola Reference Magaletti, Marino and Casciola2015; Magaletti et al. Reference Magaletti, Gallo, Marino and Casciola2016). The bubble is assumed to be already present in the liquid, with no regard to the nucleation process that led to the bubble formation, see Gallo, Magaletti & Casciola (Reference Gallo, Magaletti and Casciola2018, Reference Gallo, Magaletti and Casciola2021), Gallo et al. (Reference Gallo, Magaletti, Cocco and Casciola2020, Reference Gallo, Magaletti, Georgoulas, Marengo, De Coninck and Casciola2023) and Magaletti, Gallo & Casciola (Reference Magaletti, Gallo and Casciola2021) for details on nucleation in the context of this kind of model. The wall is assumed flat and the analysis will concern the deformation of the solid, assumed as an elastoplastic material. Given the small size of the bubble, and the need to simultaneously account for the liquid compressibility, the dynamic response of the bubble gaseous phase, the phase change taking place in the vapour and the topology modification occurring during the collapse, the model of choice is a phase-field method (Anderson, McFadden & Wheeler Reference Anderson, McFadden and Wheeler1998; Jamet Reference Jamet2001; Magaletti et al. Reference Magaletti, Picano, Chinappi, Marino and Casciola2013; Hu, Wang & Gomez Reference Hu, Wang and Gomez2023) described in terms of mass density and accounting for surface tension through distributed capillary stresses, as originally introduced by van der Waals (Reference van der Waals1893, Reference van der Waals1979). The solid is basically described by the linear elasticity equations (Gurtin Reference Gurtin1982) on account of the expected small deformation of the solid. Indeed, the scope of the present paper is limited to relatively stiff materials which are hardly deformed, leaving for future investigations the case of softer materials, such as hydrogels (Guvendiren & Burdick Reference Guvendiren and Burdick2012; Liu, Toh & Ng Reference Liu, Toh and Ng2015; Drozdov & de Claville Christiansen Reference Drozdov and de Claville Christiansen2018) or tissues and cell membranes (Bottacchiari et al. Reference Bottacchiari, Gallo, Bussoletti and Casciola2022). As we show, despite the relatively large stiffness leading to small deformations, the state of tension undergone by the solid under the pressure field of the collapsing bubble is rather large and may easily exceed the yield stress of many materials (Abbondanza, Gallo & Casciola Reference Abbondanza, Gallo and Casciola2023a).

At variance with most applications of elastoplastic materials in structural engineering, the load exerted on the solid is highly non-stationary, inducing a complex response where elastic wave propagation is combined with unsteady plastic deformation (Von Kármán & Duwez Reference Von Kármán and Duwez1950). Moreover, due to the presence of the fluid–solid interface subject to the bubble pressure load propagating at a fast speed, the system of elastic waves turns out to be rather rich. As is well known, linear elastic solids support the propagation of two substantially different kinds of (bulk) waves: longitudinal, or compression, waves, travelling at the speed ![]() $c_{L} = \sqrt {(K+4/3G)/\rho _s}$, where

$c_{L} = \sqrt {(K+4/3G)/\rho _s}$, where ![]() $K$ and

$K$ and ![]() $G$ are the bulk and the shear moduli, respectively, with

$G$ are the bulk and the shear moduli, respectively, with ![]() $\rho _s$ the solid mass density; and transversal, or shear, waves with speed

$\rho _s$ the solid mass density; and transversal, or shear, waves with speed ![]() $c_{T} = \sqrt {G/\rho _s}$ (Graff Reference Graff2012). In load-free conditions, the interface propagates additional waves, confined to a narrow surface layer, studied by Lord Rayleigh (Reference Rayleigh1885) and Love (Reference Love1911), respectively. These two kinds of waves have two orthogonal polarisations, with the Rayleigh waves oscillating in the plane formed by the propagation direction (parallel to the undeformed surface) and the normal to the surface, whereas Love waves are shear waves oscillating along the surface and orthogonal to the propagation direction. An axisymmetric bubble collapse cannot induce Love waves and among the two possible polarisations of the (bulk) transverse waves, only the one oscillating in the axial plane is allowed.

$c_{T} = \sqrt {G/\rho _s}$ (Graff Reference Graff2012). In load-free conditions, the interface propagates additional waves, confined to a narrow surface layer, studied by Lord Rayleigh (Reference Rayleigh1885) and Love (Reference Love1911), respectively. These two kinds of waves have two orthogonal polarisations, with the Rayleigh waves oscillating in the plane formed by the propagation direction (parallel to the undeformed surface) and the normal to the surface, whereas Love waves are shear waves oscillating along the surface and orthogonal to the propagation direction. An axisymmetric bubble collapse cannot induce Love waves and among the two possible polarisations of the (bulk) transverse waves, only the one oscillating in the axial plane is allowed.

The moving load adds even more features to the whole picture. Let us consider, for the sake of definiteness, the effect on the solid of a strong compression wave in the liquid on top of the liquid–solid interface. Such a wave will emanate radially from the region of bubble collapse, such that, under axisymmetry, its trace on the liquid–solid interface consists of an expanding circumference centred at the bubble's centre projection onto the surface. Being the fastest signal travelling in the liquid, outside this circumference the load applied to the solid vanishes altogether. Different cases may arise, depending on the relative speed of the liquid compression (load) wave and the longitudinal and the transverse elastic waves (also the additional parameter given by the speed of the Rayleigh wave should be taken into account, which is however very close to ![]() $c_{T}$). Without entering into detail here, the interaction of the loading wave with the surface produces an elastic wave locked to external disturbance. Moreover, the interaction of the longitudinal elastic (bulk) wave with the liquid–solid surface generates a further wavefront, the so-called head, or von Schmidt, wave (Von Schmidt Reference Von Schmidt1938). As we show, the amplitude of this interacting system of wavefronts is eventually modulated by the energy dissipation due to the plasticisation of the material taking place where the stress overcomes the material strength. Plasticity is a realm in itself. Here we stick to one of the most popular models, the so-called rate-independent classical plasticity model (Lubliner Reference Lubliner2008).

$c_{T}$). Without entering into detail here, the interaction of the loading wave with the surface produces an elastic wave locked to external disturbance. Moreover, the interaction of the longitudinal elastic (bulk) wave with the liquid–solid surface generates a further wavefront, the so-called head, or von Schmidt, wave (Von Schmidt Reference Von Schmidt1938). As we show, the amplitude of this interacting system of wavefronts is eventually modulated by the energy dissipation due to the plasticisation of the material taking place where the stress overcomes the material strength. Plasticity is a realm in itself. Here we stick to one of the most popular models, the so-called rate-independent classical plasticity model (Lubliner Reference Lubliner2008).

The outline of the paper is as follows. Section 2 discusses the fluid–structure interaction and the approximation derived under the assumption of a stiff solid. Section 3 summarises the diffuse interface model, introducing the capillary distributed stress that complements the standard Navier–Stokes equations (mass, momentum and energy conservation) and illustrates the equation of state to account for the phase change. Section 4, for the convenience of unfamiliar readers, provides an account of the basic concepts of plasticity theory and elastoplastic waves. Section 5 presents a short description of the numerical methods adopted in the simulations. The main results concerning the dynamics of the collapsing bubble are reported in § 6 whereas the solid wall and related elastoplastic waves are addressed in § 7. Finally, conclusions are drawn in § 8 together with a discussion of perspectives and future research directions.

2. Fluid–solid interaction

The solid response to a bubble collapse is a typical example of fluid–structure interaction. Due to the nature of the solid material, it possesses certain peculiarities which are worth exploiting in the simulation. In fact, fluid and solid are coupled through the boundary conditions at the interface ![]() $\mathcal {I}$ which, assuming no overhangs, is described by the equation

$\mathcal {I}$ which, assuming no overhangs, is described by the equation ![]() $z = h(x,y,t)$, where

$z = h(x,y,t)$, where ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ are the three Cartesian coordinates of a point

$z$ are the three Cartesian coordinates of a point ![]() $\boldsymbol {x}$, with

$\boldsymbol {x}$, with ![]() $z = 0$ the undeformed (planar) interface.

$z = 0$ the undeformed (planar) interface.

The fluid occupies the domain ![]() $\varOmega _f = \{\boldsymbol {x} \in \mathbb {R}^3: z > h(x,y) \}$, whereas the solid is confined to the complementary region

$\varOmega _f = \{\boldsymbol {x} \in \mathbb {R}^3: z > h(x,y) \}$, whereas the solid is confined to the complementary region ![]() $\varOmega _s = \{\boldsymbol {x} \in \mathbb {R}^3: z < h(x,y) \}$. The fluid is described in terms of the mass density

$\varOmega _s = \{\boldsymbol {x} \in \mathbb {R}^3: z < h(x,y) \}$. The fluid is described in terms of the mass density ![]() $\rho (\boldsymbol {x},t)$, the velocity

$\rho (\boldsymbol {x},t)$, the velocity ![]() $\boldsymbol {u}(\boldsymbol {x},t)$ and the energy density

$\boldsymbol {u}(\boldsymbol {x},t)$ and the energy density ![]() $E(\boldsymbol {x},t)$ fields which obey the fundamental conservation laws.

$E(\boldsymbol {x},t)$ fields which obey the fundamental conservation laws.

The solid is described by the density field ![]() $\rho _s(\boldsymbol {X},t)$, the displacement field

$\rho _s(\boldsymbol {X},t)$, the displacement field ![]() $\boldsymbol {r}(\boldsymbol {X},t)$ and the energy density. Under isothermal conditions, the energy evolution is ignored in favour of the constant temperature assumption, thus rendering the Helmholtz free energy density

$\boldsymbol {r}(\boldsymbol {X},t)$ and the energy density. Under isothermal conditions, the energy evolution is ignored in favour of the constant temperature assumption, thus rendering the Helmholtz free energy density ![]() $\hat f_{S}$ the thermodynamic potential of choice. Here,

$\hat f_{S}$ the thermodynamic potential of choice. Here, ![]() $\boldsymbol {X}$ is the Lagrangian coordinate providing the initial position of the solid continuum points such that

$\boldsymbol {X}$ is the Lagrangian coordinate providing the initial position of the solid continuum points such that ![]() $\boldsymbol {x} = \boldsymbol {X}+\boldsymbol {r}$. As is well known (Gurtin Reference Gurtin1982),

$\boldsymbol {x} = \boldsymbol {X}+\boldsymbol {r}$. As is well known (Gurtin Reference Gurtin1982), ![]() $\rho _s(\boldsymbol {X},t) = \rho _0(\boldsymbol {X} )$, while the displacement field obeys momentum conservation.

$\rho _s(\boldsymbol {X},t) = \rho _0(\boldsymbol {X} )$, while the displacement field obeys momentum conservation.

Apart from the initial state, the equations require boundary conditions that can be specified in terms of the fields or their (generalised) normal derivatives (i.e. traction vector and heat flux) at the boundary. In the present case, the domains change in time (free-boundary problem), and one should require the continuity of displacements and normal derivatives. This information is sufficient to determine the fields at the current time, in particular the velocity ![]() $\boldsymbol {u}_{\mathcal {I}} = {\dot {\boldsymbol {r}}}_{\mathcal {I}}$ which allows the interface to be updated according to the equation

$\boldsymbol {u}_{\mathcal {I}} = {\dot {\boldsymbol {r}}}_{\mathcal {I}}$ which allows the interface to be updated according to the equation ![]() $h_t = {\dot z} - ( {\dot x} h_x + {\dot y} h_y )$.

$h_t = {\dot z} - ( {\dot x} h_x + {\dot y} h_y )$.

The specificity of the current problem is that the solid is stiff, meaning that its deformation (hence, also the interface displacement) is small under a finite intensity load, ![]() $|\boldsymbol {r} | = O(\epsilon ) \ll 1$, where

$|\boldsymbol {r} | = O(\epsilon ) \ll 1$, where ![]() $\epsilon$ is a small parameter. In the simulations described in the following, this condition is accomplished by having a solid-to-liquid impedance ratio

$\epsilon$ is a small parameter. In the simulations described in the following, this condition is accomplished by having a solid-to-liquid impedance ratio ![]() $Z_s/Z_l>10.5$, such that the solid–liquid interface can be considered rigid. This assumption allows linearising the entire system of equations with respect to the solid displacement while keeping finite all the other relevant quantities, in particular, the fluid velocity

$Z_s/Z_l>10.5$, such that the solid–liquid interface can be considered rigid. This assumption allows linearising the entire system of equations with respect to the solid displacement while keeping finite all the other relevant quantities, in particular, the fluid velocity ![]() $\boldsymbol {u}$ and the stress distribution in the solid.

$\boldsymbol {u}$ and the stress distribution in the solid.

Linearisation of the solid's equations requires the stress tensor to be linearised with respect to the displacement field. Nevertheless, also in its linearised form, the stress in the solid is still large, implying that the material may yield under the load. The final result is a linear elastic model with plasticity occurring where the yield strength of the material is locally exceeded.

We stress that, from the point of view of the fluid, the system at order zero in ![]() $\epsilon$ still retains its original nonlinearity. To this order, the interface is flat and the no-slip condition applies in the form

$\epsilon$ still retains its original nonlinearity. To this order, the interface is flat and the no-slip condition applies in the form ![]() $\boldsymbol {u}_{\mathcal {I}} = 0$. In other words, the fluid motion decouples from the solid. As a consequence, the solid occupies its undeformed domain and experiences the load exerted by the fluid. Clearly, the solid displacement dictates the deformation of the interface. In principle, one may want to carry over this procedure to evaluate the effect on the fluid of the order one interface displacement. Although doable, this would be uninfluential if the first-order solution for the solid is sufficient.

$\boldsymbol {u}_{\mathcal {I}} = 0$. In other words, the fluid motion decouples from the solid. As a consequence, the solid occupies its undeformed domain and experiences the load exerted by the fluid. Clearly, the solid displacement dictates the deformation of the interface. In principle, one may want to carry over this procedure to evaluate the effect on the fluid of the order one interface displacement. Although doable, this would be uninfluential if the first-order solution for the solid is sufficient.

3. Diffuse interface model of a cavitation bubble

The dynamics of a cavitation bubble close to a solid surface is described by a diffuse interface model (Jamet et al. Reference Jamet, Lebaigue, Coutris and Delhaye2001; Magaletti et al. Reference Magaletti, Marino and Casciola2015) which, overall, involves the familiar mass, momentum and energy conservation equations,

with ![]() $\boldsymbol {T}(\boldsymbol {x},t)$ the stress tensor and

$\boldsymbol {T}(\boldsymbol {x},t)$ the stress tensor and ![]() $\boldsymbol {q}_f(\boldsymbol {x},t)$ the energy flux. The specificity comes from the constitutive equations (Magaletti et al. Reference Magaletti, Gallo, Marino and Casciola2016),

$\boldsymbol {q}_f(\boldsymbol {x},t)$ the energy flux. The specificity comes from the constitutive equations (Magaletti et al. Reference Magaletti, Gallo, Marino and Casciola2016),

\begin{gather}

\boldsymbol{T}={-}\left(p_0-\frac{\lambda}{2}|\boldsymbol{\nabla}\rho|^2

-\rho\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)\right)

\boldsymbol{I}\nonumber\\

-\lambda\boldsymbol{\nabla}\rho\otimes\boldsymbol{\nabla}\rho+\eta(\boldsymbol{\nabla}\boldsymbol{u}

+(\boldsymbol{\nabla}\boldsymbol{u})^{\rm

T})-\tilde{\eta}(\boldsymbol{\nabla}\boldsymbol{\cdot}

\boldsymbol{u})\boldsymbol{I},

\end{gather}

\begin{gather}

\boldsymbol{T}={-}\left(p_0-\frac{\lambda}{2}|\boldsymbol{\nabla}\rho|^2

-\rho\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)\right)

\boldsymbol{I}\nonumber\\

-\lambda\boldsymbol{\nabla}\rho\otimes\boldsymbol{\nabla}\rho+\eta(\boldsymbol{\nabla}\boldsymbol{u}

+(\boldsymbol{\nabla}\boldsymbol{u})^{\rm

T})-\tilde{\eta}(\boldsymbol{\nabla}\boldsymbol{\cdot}

\boldsymbol{u})\boldsymbol{I},

\end{gather}

which, aside from classical effects described by Newton's law of viscosity and Fourier's law of heat conduction, accounts for distributed capillary terms depending on the density gradient. Moreover, a suitable pressure field is derived from an equation of state able to describe the thermodynamics of the fluid in the liquid, vapour and supercritical states that all occur during bubble implosion. In the above equations, the capillary coefficient ![]() $\lambda (\theta )$ is a function of the temperature

$\lambda (\theta )$ is a function of the temperature ![]() $\theta$,

$\theta$, ![]() $\eta$ is the first dynamic viscosity coefficient,

$\eta$ is the first dynamic viscosity coefficient, ![]() $\tilde {\eta }$ (often taken to be

$\tilde {\eta }$ (often taken to be ![]() $\tilde {\eta }=-2/3\eta$) is the second dynamic viscosity coefficient and

$\tilde {\eta }=-2/3\eta$) is the second dynamic viscosity coefficient and ![]() $k$ is the thermal conductivity.

$k$ is the thermal conductivity.

Importantly, this system describes the transition from the high-density liquid to the low-density vapour, together with the change of the other thermodynamic and kinetic properties of the fluid. In the case of a vapour bubble in a liquid bulk, the fluid properties switch smoothly across a thin interfacial layer, a distributed form of liquid–vapour interface as originally envisaged by van der Waals (Reference van der Waals1893). Its thickness is determined by the fluid thermodynamics,

\begin{equation} \ell_{lv} = (\rho_l-\rho_v)\sqrt{\frac{\lambda/2}{{w}_0(\bar{\rho})- {w}_0(\rho_v)}} , \end{equation}

\begin{equation} \ell_{lv} = (\rho_l-\rho_v)\sqrt{\frac{\lambda/2}{{w}_0(\bar{\rho})- {w}_0(\rho_v)}} , \end{equation}

where ![]() ${\bar \rho }$ is the fluid density where the density gradient is maximal,

${\bar \rho }$ is the fluid density where the density gradient is maximal, ![]() $|{\rm d} \rho /{\rm d}{\kern0.8pt}x|_{max} = \sqrt {2(w_0({\bar \rho }) - w_0(\rho _v))/\lambda }$, and it is the seat of the strong density gradients that sum up to the (equilibrium) surface tension

$|{\rm d} \rho /{\rm d}{\kern0.8pt}x|_{max} = \sqrt {2(w_0({\bar \rho }) - w_0(\rho _v))/\lambda }$, and it is the seat of the strong density gradients that sum up to the (equilibrium) surface tension

\begin{equation} \sigma = \int_{-\infty}^{+\infty}\lambda\left(\frac{{\rm d}\rho}{{\rm d}{\kern0.8pt}x}\right)^2{\rm d}{\kern0.8pt}x = \int_{\rho_v}^{\rho_l}\sqrt{2\lambda ({w}_0(\rho) - {w}_0(\rho_v))}\,{\rm d}\rho, \end{equation}

\begin{equation} \sigma = \int_{-\infty}^{+\infty}\lambda\left(\frac{{\rm d}\rho}{{\rm d}{\kern0.8pt}x}\right)^2{\rm d}{\kern0.8pt}x = \int_{\rho_v}^{\rho_l}\sqrt{2\lambda ({w}_0(\rho) - {w}_0(\rho_v))}\,{\rm d}\rho, \end{equation}

where ![]() ${w}_0 = {f}_f^b - \rho \mu ^b_f$, with

${w}_0 = {f}_f^b - \rho \mu ^b_f$, with ![]() ${f}_f^b$ the fluid (bulk) Helmholtz free energy per unit volume and

${f}_f^b$ the fluid (bulk) Helmholtz free energy per unit volume and ![]() $\mu ^b_f = \partial {f}_f^b/\partial \rho$ the chemical potential, which under equilibrium (saturation) conditions is a function of the only temperature (

$\mu ^b_f = \partial {f}_f^b/\partial \rho$ the chemical potential, which under equilibrium (saturation) conditions is a function of the only temperature (![]() $\mu ^b_f = {\mu ^b_f}_{eq}$).

$\mu ^b_f = {\mu ^b_f}_{eq}$).

The system of equations (3.1), complemented with the constitutive relations (3.2)–(3.3), is closed by prescribing the appropriate thermodynamics potential that holds across the liquid–vapour transition. Here the van der Waals equation of state for the Helmholtz free energy is assumed, ![]() $f_f^b/p_c = -8/3 \rho _R \theta _R \{1 + \ln [(1 - \rho _R/3 )/(\rho _c \rho _R\varLambda ^3/m_p) ] \} - 3 \rho _R^2$, with the subscript

$f_f^b/p_c = -8/3 \rho _R \theta _R \{1 + \ln [(1 - \rho _R/3 )/(\rho _c \rho _R\varLambda ^3/m_p) ] \} - 3 \rho _R^2$, with the subscript ![]() $R$ denoting reduced quantities (e.g.

$R$ denoting reduced quantities (e.g. ![]() $\rho _R = \rho /\rho _c$),

$\rho _R = \rho /\rho _c$), ![]() $\varLambda = \sqrt {2\pi \hbar ^2/(m_p k_b \theta )}$ denoting the De Broglie thermal wavelength,

$\varLambda = \sqrt {2\pi \hbar ^2/(m_p k_b \theta )}$ denoting the De Broglie thermal wavelength, ![]() $m_p$ denoting the atom mass and the subscript

$m_p$ denoting the atom mass and the subscript ![]() $c$ denoting the critical state. Hence, the pressure is

$c$ denoting the critical state. Hence, the pressure is

Most of the boundary conditions are standard: in the present case, as discussed in § 2, no-slip and impermeability conditions and constant temperature hold on the flat solid wall. A little more information is needed concerning capillarity, which should account for the solid wettability and requires explicitly calling into play the Helmholtz free energy functional for a stratified fluid, which reads

where ![]() $f_w (\rho, \theta ) = - \cos \varTheta \int _{\rho _v}^\rho \sqrt {2 \lambda [w_0(\rho, \theta ) - w_0(\rho _v, \theta ) ]} \,{\rm d}\rho +\gamma _{sv}$ is the solid–fluid interfacial energy, with

$f_w (\rho, \theta ) = - \cos \varTheta \int _{\rho _v}^\rho \sqrt {2 \lambda [w_0(\rho, \theta ) - w_0(\rho _v, \theta ) ]} \,{\rm d}\rho +\gamma _{sv}$ is the solid–fluid interfacial energy, with ![]() $\varTheta$ Young's contact angle and

$\varTheta$ Young's contact angle and ![]() $\gamma _{sv}$ the surface energy for vapour in contact with the solid. In the free energy functional, the square density gradient term accounts for the excess energy of the interfacial layer and ultimately is the origin of the distributed capillary stresses. Minimising the free energy with respect to the density field provides two Euler–Lagrange equations. The first is the equation for equilibrium density, replaced here by the evolution equations illustrated before, whereas the second provides the boundary condition for the mass density (Gallo et al. Reference Gallo, Magaletti and Casciola2021),

$\gamma _{sv}$ the surface energy for vapour in contact with the solid. In the free energy functional, the square density gradient term accounts for the excess energy of the interfacial layer and ultimately is the origin of the distributed capillary stresses. Minimising the free energy with respect to the density field provides two Euler–Lagrange equations. The first is the equation for equilibrium density, replaced here by the evolution equations illustrated before, whereas the second provides the boundary condition for the mass density (Gallo et al. Reference Gallo, Magaletti and Casciola2021),

The flow is governed by three dimensionless parameters, the Cahn, Reynolds and Péclet numbers, taking the place of ![]() $\lambda$,

$\lambda$, ![]() $1/\eta$ and

$1/\eta$ and ![]() $1/k$, respectively, in (3.2) and (3.3), and defined as

$1/k$, respectively, in (3.2) and (3.3), and defined as

\begin{equation} Cn=\sqrt{\frac{\lambda\rho_c^2}{p_cR_0^2}},\quad Re=\frac{R_0\sqrt{p_c \rho_c}}{\eta}, \quad Pe= \frac{R_0\sqrt{p_c \rho_c}}{k} , \end{equation}

\begin{equation} Cn=\sqrt{\frac{\lambda\rho_c^2}{p_cR_0^2}},\quad Re=\frac{R_0\sqrt{p_c \rho_c}}{\eta}, \quad Pe= \frac{R_0\sqrt{p_c \rho_c}}{k} , \end{equation}

with ![]() $R_0$ the initial bubble radius.

$R_0$ the initial bubble radius.

3.1. Baroclinic vorticity production

The interface and, possibly, the strong compression waves generated by the bubble implosion, may activate the baroclinic mechanism of vorticity production. As usual, the vorticity equation follows by taking the curl of the momentum equation (B26), rewritten here explicitly

\begin{align} \frac{\partial \rho \boldsymbol{u}}{\partial t} + \boldsymbol{\nabla}\boldsymbol{\cdot}(\rho\boldsymbol{u}\otimes\boldsymbol{u}) &={-}\boldsymbol{\nabla}\left(p_0-\frac{\lambda}{2}|\boldsymbol{\nabla}\rho|^2 -\rho\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)\right)\nonumber\\ &\quad -\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho\otimes\boldsymbol{\nabla}\rho) +\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{\varSigma}, \end{align}

\begin{align} \frac{\partial \rho \boldsymbol{u}}{\partial t} + \boldsymbol{\nabla}\boldsymbol{\cdot}(\rho\boldsymbol{u}\otimes\boldsymbol{u}) &={-}\boldsymbol{\nabla}\left(p_0-\frac{\lambda}{2}|\boldsymbol{\nabla}\rho|^2 -\rho\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)\right)\nonumber\\ &\quad -\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho\otimes\boldsymbol{\nabla}\rho) +\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{\varSigma}, \end{align}

where ![]() $\boldsymbol \varSigma$ is the classical viscous part of the stress tensor. The first two terms on the right-hand side of (3.10) are manipulated to yield

$\boldsymbol \varSigma$ is the classical viscous part of the stress tensor. The first two terms on the right-hand side of (3.10) are manipulated to yield

\begin{align} &-\boldsymbol{\nabla}\left(p_0-\frac{\lambda}{2}|\boldsymbol{\nabla}\rho|^2 -\rho\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)\right) -\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho\otimes\boldsymbol{\nabla}\rho)\nonumber\\ &\quad ={-}\boldsymbol{\nabla} p_0 + \frac{1}{2}\frac{\partial \lambda}{\partial \theta}|\boldsymbol{\nabla}\rho|^2\boldsymbol{\nabla}\theta +\rho\boldsymbol{\nabla}[\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)]. \end{align}

\begin{align} &-\boldsymbol{\nabla}\left(p_0-\frac{\lambda}{2}|\boldsymbol{\nabla}\rho|^2 -\rho\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)\right) -\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho\otimes\boldsymbol{\nabla}\rho)\nonumber\\ &\quad ={-}\boldsymbol{\nabla} p_0 + \frac{1}{2}\frac{\partial \lambda}{\partial \theta}|\boldsymbol{\nabla}\rho|^2\boldsymbol{\nabla}\theta +\rho\boldsymbol{\nabla}[\boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)]. \end{align}

Expressing ![]() $p_0$ in terms of the bulk (fluid) Helmholtz free energy

$p_0$ in terms of the bulk (fluid) Helmholtz free energy ![]() $f_f^b(\rho,\theta )$ and chemical potential

$f_f^b(\rho,\theta )$ and chemical potential ![]() $\mu _f^b = \partial f_f^b/\partial \rho$ as

$\mu _f^b = \partial f_f^b/\partial \rho$ as ![]() $p_0 = \rho \mu _f^b - f_f^b$, its gradient takes the form

$p_0 = \rho \mu _f^b - f_f^b$, its gradient takes the form

where the bulk entropy density is ![]() $s_f^b=-\partial f_f^b/\partial \theta$. Substituting (3.12) in (3.11) and back into (3.10), we get

$s_f^b=-\partial f_f^b/\partial \theta$. Substituting (3.12) in (3.11) and back into (3.10), we get

\begin{align} \frac{\partial \rho \boldsymbol{u}}{\partial t} + \boldsymbol{\nabla}\boldsymbol{\cdot}(\rho\boldsymbol{u}\otimes\boldsymbol{u}) &={-} \rho\boldsymbol{\nabla}[\mu_f^b - \boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)]\nonumber\\ &\quad + \left({-}s_f^b + \frac{1}{2}\frac{\partial \lambda}{\partial \theta}|\boldsymbol{\nabla}\rho|^2\right)\boldsymbol{\nabla}\theta +\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{\varSigma}. \end{align}

\begin{align} \frac{\partial \rho \boldsymbol{u}}{\partial t} + \boldsymbol{\nabla}\boldsymbol{\cdot}(\rho\boldsymbol{u}\otimes\boldsymbol{u}) &={-} \rho\boldsymbol{\nabla}[\mu_f^b - \boldsymbol{\nabla}\boldsymbol{\cdot}(\lambda\boldsymbol{\nabla}\rho)]\nonumber\\ &\quad + \left({-}s_f^b + \frac{1}{2}\frac{\partial \lambda}{\partial \theta}|\boldsymbol{\nabla}\rho|^2\right)\boldsymbol{\nabla}\theta +\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{\varSigma}. \end{align}After noting that the terms in brackets on the right-hand side can be written in terms of generalised entropy and chemical potential,

where the total Helmholtz free energy of the system is ![]() $F[\rho,\theta ]=\int _{V} [f_f^b(\rho,\theta ) +\lambda /2|\boldsymbol {\nabla }\rho |^2]\,\text {d}V$ (van der Waals Reference van der Waals1979), and exploiting mass conservation, (3.13) reads

$F[\rho,\theta ]=\int _{V} [f_f^b(\rho,\theta ) +\lambda /2|\boldsymbol {\nabla }\rho |^2]\,\text {d}V$ (van der Waals Reference van der Waals1979), and exploiting mass conservation, (3.13) reads

Applying the curl operator to (3.15), recalling that ![]() ${\rm D}\boldsymbol {u}/{\rm D}t=\partial \boldsymbol {u}/\partial t+\boldsymbol {\nabla }(|\boldsymbol {u}|^2/2)+\boldsymbol {\zeta }\times \boldsymbol {u}$, the vorticity equation follows as

${\rm D}\boldsymbol {u}/{\rm D}t=\partial \boldsymbol {u}/\partial t+\boldsymbol {\nabla }(|\boldsymbol {u}|^2/2)+\boldsymbol {\zeta }\times \boldsymbol {u}$, the vorticity equation follows as

where the first term on the right-hand side describes the stretching and tilting of vorticity, and the second is a generalised baroclinic term, responsible for vorticity production. It was shown in Gallo et al. (Reference Gallo, Magaletti and Casciola2018) that a constant capillary coefficient can reproduce the temperature dependence of the surface tension for a Lennard-Jones fluid; see figure 1 for the Van der Waals case. In these conditions, the baroclinic term appearing in (B27) simplifies considerably, see § 3.1.

Figure 1. Surface tension ![]() $\sigma$ vs temperature

$\sigma$ vs temperature ![]() $\theta$ obtained from (3.5) with the Van der Waals equation of state. The capillary coefficient is kept constant corresponding to the dimensionless Cahn number

$\theta$ obtained from (3.5) with the Van der Waals equation of state. The capillary coefficient is kept constant corresponding to the dimensionless Cahn number ![]() $Cn = 1.1 \times 10^{-3}$, (3.9). In the graph,

$Cn = 1.1 \times 10^{-3}$, (3.9). In the graph, ![]() $p_c=22$ MPa,

$p_c=22$ MPa, ![]() $\theta _c=647$ K and

$\theta _c=647$ K and ![]() $R_0=10^{-6}$ m are the critical quantities and the reference radius used.

$R_0=10^{-6}$ m are the critical quantities and the reference radius used.

A discussion of the sharp interface limit for the vorticity equation, which recovers the well-established sharp interface formulations (Magnaudet & Mercier Reference Magnaudet and Mercier2020) (see also (Terrington, Hourigan & Thompson Reference Terrington, Hourigan and Thompson2020, Reference Terrington, Hourigan and Thompson2021, Reference Terrington, Hourigan and Thompson2022) for a detailed analysis of vorticity generation on interfaces) compared with the diffuse interface form discussed here, is provided in Appendix B.

4. Elastoplastic dynamics of the substrate

It is a common belief that elastoplastic models may look bewildering to the non-specialist (Antman & Szymczak Reference Antman and Szymczak1989). It may then be appropriate to simplify the discussion as much as possible to focus on key features. We henceforth assume that thermal effects can be neglected and we shall limit the analysis to materials with a rate-independent response. The first assumption is well-motivated given the small heat capacity of microbubbles as compared with the solid. Rate-independency, instead, is in principle questionable, due to the extremely fast time scales involved in the collapse. Nevertheless, we adopt a rate-independent model sufficiently rich to account for material hardening and to address the time-dependent elastoplastic response (Von Kármán & Duwez Reference Von Kármán and Duwez1950). In case it was required, the model, and the simulations thereof, can be readily extended in several respects to include thermal effects and rate-dependency, as we explain in Appendix A.

As discussed in § 2, for stiff materials the dynamics can be linearised with respect to the solid displacement. The formal procedure is highlighted in Appendix A which also provides a self-contained account of basic nonlinear plasticity elements. Here, as a necessary preliminary to elastoplastic wave dynamics, we begin the section with a concise summary of the equations, see Appendix A and (Antman Reference Antman2005; Lubliner Reference Lubliner2008) for further details.

Once linearised based on the assumption ![]() $| r| = O( \epsilon )$, § 2, the solid displacement field can be expressed in the Eulerian frame as

$| r| = O( \epsilon )$, § 2, the solid displacement field can be expressed in the Eulerian frame as ![]() $\boldsymbol {r} = \boldsymbol {r}(\boldsymbol {x},t )$ which, to the required accuracy level, entails

$\boldsymbol {r} = \boldsymbol {r}(\boldsymbol {x},t )$ which, to the required accuracy level, entails ![]() $\rho _{S}(\boldsymbol {x},t) = \rho _0 + O( \epsilon )$, with

$\rho _{S}(\boldsymbol {x},t) = \rho _0 + O( \epsilon )$, with ![]() $\rho _0 = {\rm const.}$ for a homogeneous material. In the linearised theory, the (infinitesimal) strain reduces to

$\rho _0 = {\rm const.}$ for a homogeneous material. In the linearised theory, the (infinitesimal) strain reduces to

and possesses the peculiar property of being additively split into plastic and elastic parts, ![]() $\boldsymbol {\epsilon } = \boldsymbol {\epsilon }_p + \boldsymbol {\epsilon }_e$. With little surprise, the linearised momentum equation becomes

$\boldsymbol {\epsilon } = \boldsymbol {\epsilon }_p + \boldsymbol {\epsilon }_e$. With little surprise, the linearised momentum equation becomes

where ![]() $\boldsymbol {\sigma } = \boldsymbol {C}_e : \boldsymbol {\epsilon }_e$ is the (linearised) Cauchy stress, see Appendix A and, e.g. Gurtin, Fried & Anand (Reference Gurtin, Fried and Anand2010).

$\boldsymbol {\sigma } = \boldsymbol {C}_e : \boldsymbol {\epsilon }_e$ is the (linearised) Cauchy stress, see Appendix A and, e.g. Gurtin, Fried & Anand (Reference Gurtin, Fried and Anand2010).

We assume the material to be isotropic, implying that the stress–strain relation involving the elastic tensor ![]() $\boldsymbol {C}_e$ is entirely characterised by the Lamé constants,

$\boldsymbol {C}_e$ is entirely characterised by the Lamé constants, ![]() $\lambda _{S}$ and

$\lambda _{S}$ and ![]() $\mu _{S}$. When the material's distortional free energy density,

$\mu _{S}$. When the material's distortional free energy density, ![]() $f^e_{dev} = \boldsymbol {\sigma }_{dev}: \boldsymbol {\sigma }_{dev}/(4 \mu _{S})$, is on the verge of exceeding the critical value

$f^e_{dev} = \boldsymbol {\sigma }_{dev}: \boldsymbol {\sigma }_{dev}/(4 \mu _{S})$, is on the verge of exceeding the critical value ![]() $f^c_{dev} = \sigma _Y^2/(6 \mu _{S})$ that depends on the yield stress

$f^c_{dev} = \sigma _Y^2/(6 \mu _{S})$ that depends on the yield stress ![]() $\sigma _Y$, the material yields, the plastic strain accumulates and the material undergoes hardening. While all this is happening, the material will still remain in an admissible state, i.e.

$\sigma _Y$, the material yields, the plastic strain accumulates and the material undergoes hardening. While all this is happening, the material will still remain in an admissible state, i.e. ![]() $f^e_{dev} - f^c_{dev} \le 0$. This unilateral constraint acts only under plastic loading, i.e. when the two conditions (i) distortional free energy reaching the critical level,

$f^e_{dev} - f^c_{dev} \le 0$. This unilateral constraint acts only under plastic loading, i.e. when the two conditions (i) distortional free energy reaching the critical level, ![]() $|\boldsymbol {\sigma }_{dev}| = \sqrt {2/3} \sigma _Y$, and (ii) positive distortional stress power,

$|\boldsymbol {\sigma }_{dev}| = \sqrt {2/3} \sigma _Y$, and (ii) positive distortional stress power, ![]() $\boldsymbol {\sigma }_{dev} : \dot {\boldsymbol {\epsilon }} > 0$, are met.

$\boldsymbol {\sigma }_{dev} : \dot {\boldsymbol {\epsilon }} > 0$, are met.

The elastic strain, needed to evaluate the stress, is known from the total strain after the evolution equation for the plastic strain,

is solved, where ![]() $\hat {\boldsymbol {\sigma }}_{dev} = \boldsymbol {\sigma }_{dev}/|\boldsymbol {\sigma }_{dev}|$,

$\hat {\boldsymbol {\sigma }}_{dev} = \boldsymbol {\sigma }_{dev}/|\boldsymbol {\sigma }_{dev}|$, ![]() $D = [1 + K_{H}/(3\mu _{S} ) ]$ and the strain rate is

$D = [1 + K_{H}/(3\mu _{S} ) ]$ and the strain rate is ![]() $\dot {\boldsymbol {\epsilon }} = ( {\nabla _{\boldsymbol {x}} \dot {\boldsymbol {r}} + \nabla _{\boldsymbol {x}} \dot {\boldsymbol {r}}^T} )/2$. The symbol

$\dot {\boldsymbol {\epsilon }} = ( {\nabla _{\boldsymbol {x}} \dot {\boldsymbol {r}} + \nabla _{\boldsymbol {x}} \dot {\boldsymbol {r}}^T} )/2$. The symbol ![]() $\otimes$ denotes the tensor product and

$\otimes$ denotes the tensor product and ![]() $K_{H}$ is the hardening modulus (Lubliner Reference Lubliner1972). The yield stress dictates the hardening. It is constant except under plastic loading when

$K_{H}$ is the hardening modulus (Lubliner Reference Lubliner1972). The yield stress dictates the hardening. It is constant except under plastic loading when

Strictly speaking, the system of ((4.2)–(4.4)) suffice to determine the elastoplastic evolution, once appropriate material parameters, boundary conditions on the fluid–solid interface and radiation conditions for the outward-propagating waves are prescribed. The accumulated plastic deformation, ![]() $\alpha _p\propto \int _0^t |\dot {\boldsymbol {\epsilon }}_p | \,{\rm d}t$, is recovered from the yield stress,

$\alpha _p\propto \int _0^t |\dot {\boldsymbol {\epsilon }}_p | \,{\rm d}t$, is recovered from the yield stress, ![]() $\alpha _p = (\sigma _Y - \sigma _Y^0)/K_{H}$. The plastic dissipation differs from zero only under plastic loading where it is given by

$\alpha _p = (\sigma _Y - \sigma _Y^0)/K_{H}$. The plastic dissipation differs from zero only under plastic loading where it is given by ![]() $\sqrt {2/3} \sigma _Y^0 |\hat {\boldsymbol {\sigma }}_{dev} : \dot {\boldsymbol {\epsilon }}|/D$.

$\sqrt {2/3} \sigma _Y^0 |\hat {\boldsymbol {\sigma }}_{dev} : \dot {\boldsymbol {\epsilon }}|/D$.

Together with the capillary Navier–Stokes equations of § 3, this system is the basis for the simulations of the elastoplastic response to bubble collapse discussed in the forthcoming sections. Before proceeding, we take the chance to emphasise that all the relevant quantities are continuous across the plastic deformation boundary since they are linear in the distortional stress power that, together with the distortional free energy, demarcates the different regimes.

The elastoplastic dynamics is governed by the following dimensionless parameters:

where ![]() $c_{L}=\sqrt {(\lambda _{S}+2\mu _{S})/\rho _{S}}$ and

$c_{L}=\sqrt {(\lambda _{S}+2\mu _{S})/\rho _{S}}$ and ![]() $c_{T}=\sqrt {\mu _{S}/\rho _{S}}$.

$c_{T}=\sqrt {\mu _{S}/\rho _{S}}$.

4.1. Elastoplastic waves

Elastoplastic waves may develop within the material as a consequence of the loading exerted on the solid wall by the collapsing bubble. Considering for the moment the purely elastic case for which ![]() $\boldsymbol {\sigma }^e = \boldsymbol {C}_e : \boldsymbol {\epsilon }$, the Helmholtz decomposition for the displacement field

$\boldsymbol {\sigma }^e = \boldsymbol {C}_e : \boldsymbol {\epsilon }$, the Helmholtz decomposition for the displacement field ![]() $\boldsymbol r(\boldsymbol x, t)=\boldsymbol {\nabla }\phi +\boldsymbol {\nabla }\times \boldsymbol {A}$ (a vector in the

$\boldsymbol r(\boldsymbol x, t)=\boldsymbol {\nabla }\phi +\boldsymbol {\nabla }\times \boldsymbol {A}$ (a vector in the ![]() $r$–

$r$–![]() $z$ plane by axisymmetry) decouples (4.2) into two separate equations for the scalar,

$z$ plane by axisymmetry) decouples (4.2) into two separate equations for the scalar, ![]() $\phi$, and the vector potential,

$\phi$, and the vector potential, ![]() $\boldsymbol {A} = \psi \hat {\boldsymbol {e}}_z \times \hat {\boldsymbol {e}}_r$ (

$\boldsymbol {A} = \psi \hat {\boldsymbol {e}}_z \times \hat {\boldsymbol {e}}_r$ (![]() $\psi$ is the analogous of the Stokes stream function),

$\psi$ is the analogous of the Stokes stream function),

where ![]() $c_{L}$ and

$c_{L}$ and ![]() $c_{T}$ are identified as the longitudinal and transverse wave propagation speeds, respectively. Equations (4.6) and (4.7) are, in fact, wave equations for the divergence and (the only non-vanishing component of) the curl of the displacement field (

$c_{T}$ are identified as the longitudinal and transverse wave propagation speeds, respectively. Equations (4.6) and (4.7) are, in fact, wave equations for the divergence and (the only non-vanishing component of) the curl of the displacement field (![]() $\nabla ^2\phi =\boldsymbol {\nabla }\boldsymbol {\cdot }\boldsymbol {r},\ -\nabla ^2 \boldsymbol {A}=\boldsymbol {\nabla }\times \boldsymbol {r}$). These two fields, which in isolation would describe purely longitudinal and transverse waves, respectively, interact with the wall and the moving load to generate a complex wave field (figure 2). In fact, the boundary condition on the wall,

$\nabla ^2\phi =\boldsymbol {\nabla }\boldsymbol {\cdot }\boldsymbol {r},\ -\nabla ^2 \boldsymbol {A}=\boldsymbol {\nabla }\times \boldsymbol {r}$). These two fields, which in isolation would describe purely longitudinal and transverse waves, respectively, interact with the wall and the moving load to generate a complex wave field (figure 2). In fact, the boundary condition on the wall,

where ![]() $\sigma ^e_{zz}$ (

$\sigma ^e_{zz}$ (![]() $T_{zz}$) and

$T_{zz}$) and ![]() $\sigma ^e_{rz}$ (

$\sigma ^e_{rz}$ (![]() $T_{rz}$) are the normal and shear components of the elastic stress

$T_{rz}$) are the normal and shear components of the elastic stress ![]() $\boldsymbol {\sigma }^e$ (fluid stress

$\boldsymbol {\sigma }^e$ (fluid stress ![]() $\boldsymbol {T}$, § 3), respectively, once expressed in terms of scalar and vector potential (

$\boldsymbol {T}$, § 3), respectively, once expressed in terms of scalar and vector potential (![]() $r_r = \partial \phi /\partial r - \partial \psi /\partial z$,

$r_r = \partial \phi /\partial r - \partial \psi /\partial z$, ![]() $r_z = \partial \phi /\partial z + 1/r\, \partial (r \psi )/\partial r$) couple together the two fields.

$r_z = \partial \phi /\partial z + 1/r\, \partial (r \psi )/\partial r$) couple together the two fields.

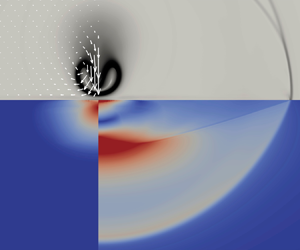

Figure 2. A compact, axisymmetric pressure disturbance is suddenly applied at time ![]() $t=0$ to the wall at the origin and spreads radially out. The elastic solid occupies the

$t=0$ to the wall at the origin and spreads radially out. The elastic solid occupies the ![]() $z < 0$ half-space and the sketch concerns the case with a disturbance velocity intermediate between the faster longitudinal waves and the slower transversal waves. The disturbance (green), by moving faster than the transverse waves, gives rise to a conical wavefront (green line, D). The longitudinal waves move faster and are enveloped by their hemispherical wavefront impulsively generated at time

$z < 0$ half-space and the sketch concerns the case with a disturbance velocity intermediate between the faster longitudinal waves and the slower transversal waves. The disturbance (green), by moving faster than the transverse waves, gives rise to a conical wavefront (green line, D). The longitudinal waves move faster and are enveloped by their hemispherical wavefront impulsively generated at time ![]() $t = 0$ (blue line, L). The interaction of the longitudinal wavefront with the unloaded wall (ahead of the disturbance) causes the head wave (purple line, H). Behind the disturbance, the transversal wavefront produced at time

$t = 0$ (blue line, L). The interaction of the longitudinal wavefront with the unloaded wall (ahead of the disturbance) causes the head wave (purple line, H). Behind the disturbance, the transversal wavefront produced at time ![]() $t=0$, moves slower than the disturbance and is represented by the red line (T), followed by the Rayleigh wave, just behind, which is confined to the surface layer (yellow line, R).

$t=0$, moves slower than the disturbance and is represented by the red line (T), followed by the Rayleigh wave, just behind, which is confined to the surface layer (yellow line, R).

The sketch of figure 2 illustrates the elastic wavefronts generated by an axisymmetric compact pressure load, ![]() $T_{zz} = f(r - v_D t)$,

$T_{zz} = f(r - v_D t)$, ![]() $T_{rz} = 0$, suddenly applied to the wall at time

$T_{rz} = 0$, suddenly applied to the wall at time ![]() $t =0$ which travels radially outwards with velocity

$t =0$ which travels radially outwards with velocity ![]() $v_D$ intermediate between the speed of the longitudinal and the transversal elastic waves. At

$v_D$ intermediate between the speed of the longitudinal and the transversal elastic waves. At ![]() $t=0$ longitudinal and transversal waves start being generated and are confined by hemispherical wavefronts whose configuration is depicted in the sketch at a later time

$t=0$ longitudinal and transversal waves start being generated and are confined by hemispherical wavefronts whose configuration is depicted in the sketch at a later time ![]() $t$ (blue and red circles, respectively). In the meanwhile, the disturbance moves and is found at time

$t$ (blue and red circles, respectively). In the meanwhile, the disturbance moves and is found at time ![]() $t$ somewhere between the traces on the wall of the longitudinal and transversal fronts. While the load moves, further waves are generated. Since it moves faster than the transversal wave system and slower than the longitudinal one, at variance with the latter, the former cannot be radiated ahead of the disturbance. It remains confined to a cone whose generatrix is shown by the green oblique straight line tangent to the red circle forming the angle

$t$ somewhere between the traces on the wall of the longitudinal and transversal fronts. While the load moves, further waves are generated. Since it moves faster than the transversal wave system and slower than the longitudinal one, at variance with the latter, the former cannot be radiated ahead of the disturbance. It remains confined to a cone whose generatrix is shown by the green oblique straight line tangent to the red circle forming the angle ![]() $\theta _{D}=\sin ^{-1}(c_{T}/v_{D})$ with the wall. The construction is the same as supersonic small disturbance theory in gas dynamics where one would talk of a Mach cone. Meanwhile, the longitudinal waves propagate ahead, where the wall is not yet perturbed by the pressure load. However, the field associated with the longitudinal waves alone cannot satisfy the load-free boundary conditions and, through the coupling implied by (4.8a), excites the transversal field. The corresponding wave system, being longitudinal waves supersonic with respect to transversal waves, must be confined within a second cone. This is called a head (or von Schmidt) (Von Schmidt Reference Von Schmidt1938) wave and is shown by the oblique straight line in purple, which originates at the trace on the wall of the longitudinal front, is tangent to the red circle, and forms with the wall the angle

$\theta _{D}=\sin ^{-1}(c_{T}/v_{D})$ with the wall. The construction is the same as supersonic small disturbance theory in gas dynamics where one would talk of a Mach cone. Meanwhile, the longitudinal waves propagate ahead, where the wall is not yet perturbed by the pressure load. However, the field associated with the longitudinal waves alone cannot satisfy the load-free boundary conditions and, through the coupling implied by (4.8a), excites the transversal field. The corresponding wave system, being longitudinal waves supersonic with respect to transversal waves, must be confined within a second cone. This is called a head (or von Schmidt) (Von Schmidt Reference Von Schmidt1938) wave and is shown by the oblique straight line in purple, which originates at the trace on the wall of the longitudinal front, is tangent to the red circle, and forms with the wall the angle ![]() $\theta _{H}=\sin ^{-1}(c_{T}/c_{L})$. Longitudinal and transverse systems are not the only free waves supported in this configuration. Actually, the unloaded wall sustains a third kind confined to the surface layer, the so-called Rayleigh waves. Their dispersion relationship, worked out as

$\theta _{H}=\sin ^{-1}(c_{T}/c_{L})$. Longitudinal and transverse systems are not the only free waves supported in this configuration. Actually, the unloaded wall sustains a third kind confined to the surface layer, the so-called Rayleigh waves. Their dispersion relationship, worked out as ![]() $(2-c_{R}^2/c_{T}^2)^2-4(1-c_{R}^2/c_{L}^2)^{1/2}(1-c_{R}^2/c_{T}^2)^{1/2}=0$ (Rayleigh Reference Rayleigh1885) and, for ductile metals, approximated by

$(2-c_{R}^2/c_{T}^2)^2-4(1-c_{R}^2/c_{L}^2)^{1/2}(1-c_{R}^2/c_{T}^2)^{1/2}=0$ (Rayleigh Reference Rayleigh1885) and, for ductile metals, approximated by ![]() $c_{R}=0.9194 c_{T}$ (Graff Reference Graff2012), shows that the Rayleigh wave is slower than all the others and localised in the region highlighted in yellow in the sketch. Other waves that could exist in principle (namely transverse wave and Love surface wave with polarisation normal to the axial plane shown in the sketch) are ruled out by the assumed symmetry of the problem. Once the general principle is laid down, it is easy to realise what to expect depending on the relative velocity of the load with respect to characteristic elastic speeds. Three cases are identified, (i)

$c_{R}=0.9194 c_{T}$ (Graff Reference Graff2012), shows that the Rayleigh wave is slower than all the others and localised in the region highlighted in yellow in the sketch. Other waves that could exist in principle (namely transverse wave and Love surface wave with polarisation normal to the axial plane shown in the sketch) are ruled out by the assumed symmetry of the problem. Once the general principle is laid down, it is easy to realise what to expect depending on the relative velocity of the load with respect to characteristic elastic speeds. Three cases are identified, (i) ![]() $v_{D}< c_{T}$, (ii)

$v_{D}< c_{T}$, (ii) ![]() $c_{L}>v_{D}>c_{T}$ and (iii)

$c_{L}>v_{D}>c_{T}$ and (iii) ![]() $v_{D}>c_{L}$, as discussed in a series of beautiful papers in the late 1960s (Gakenheimer & Miklowitz Reference Gakenheimer and Miklowitz1969; Gakenheimer Reference Gakenheimer1971); see also the book (Miklowitz Reference Miklowitz2012), where analytic function and integral transform theories are cleverly exploited.

$v_{D}>c_{L}$, as discussed in a series of beautiful papers in the late 1960s (Gakenheimer & Miklowitz Reference Gakenheimer and Miklowitz1969; Gakenheimer Reference Gakenheimer1971); see also the book (Miklowitz Reference Miklowitz2012), where analytic function and integral transform theories are cleverly exploited.

Let us now turn our attention to the elastoplastic case. For an elastoplastic material, Appendix A, (4.6) and (4.7) take the form

where the plastic deformation, time-dependent in general, ![]() $\boldsymbol {\epsilon }_p(\boldsymbol {x},t)$, follows by solving (4.3), where the strain rate in terms of the time derivative of the potentials is

$\boldsymbol {\epsilon }_p(\boldsymbol {x},t)$, follows by solving (4.3), where the strain rate in terms of the time derivative of the potentials is ![]() $\dot {\boldsymbol {\epsilon }} = \boldsymbol {\nabla } \otimes \boldsymbol {\nabla }{\dot \phi } + [ {\boldsymbol {\nabla } \otimes ( \boldsymbol {\nabla } \times \dot {\boldsymbol {A}}) + \boldsymbol {\nabla } \otimes (\boldsymbol {\nabla } \times \dot {\boldsymbol {A}})^{\rm T}}]/{2}$, with

$\dot {\boldsymbol {\epsilon }} = \boldsymbol {\nabla } \otimes \boldsymbol {\nabla }{\dot \phi } + [ {\boldsymbol {\nabla } \otimes ( \boldsymbol {\nabla } \times \dot {\boldsymbol {A}}) + \boldsymbol {\nabla } \otimes (\boldsymbol {\nabla } \times \dot {\boldsymbol {A}})^{\rm T}}]/{2}$, with ![]() ${\dot \phi }$ and

${\dot \phi }$ and ![]() $\dot {\boldsymbol {A}}$ the corresponding velocity potentials,

$\dot {\boldsymbol {A}}$ the corresponding velocity potentials, ![]() ${\boldsymbol v} = {\dot {\boldsymbol r}} = \boldsymbol {\nabla } {\dot \phi } + \boldsymbol {\nabla } \times \dot {\boldsymbol {A}}$. Equations (4.9), (4.10) involve wave operators on the left-hand side and memory terms on the right-hand side which come from the time-integration of (4.3). Note that the right-hand side of (4.3) is nonlinear in the fields, given the dependency of

${\boldsymbol v} = {\dot {\boldsymbol r}} = \boldsymbol {\nabla } {\dot \phi } + \boldsymbol {\nabla } \times \dot {\boldsymbol {A}}$. Equations (4.9), (4.10) involve wave operators on the left-hand side and memory terms on the right-hand side which come from the time-integration of (4.3). Note that the right-hand side of (4.3) is nonlinear in the fields, given the dependency of ![]() ${\boldsymbol \sigma }_{dev}$ on the solution.

${\boldsymbol \sigma }_{dev}$ on the solution.

To qualitatively describe the rich phenomenology implied by the elastoplastic model, we may consider two limiting conditions, one concerning a system remaining in the elastic range, ![]() $\dot {\boldsymbol {\epsilon }}_p = 0$, with preexistent plastic deformation, the other a system undergoing plastic loading,

$\dot {\boldsymbol {\epsilon }}_p = 0$, with preexistent plastic deformation, the other a system undergoing plastic loading, ![]() $\dot {\boldsymbol {\epsilon }}_p \ne 0$. In the first case, the plastic strain is time-independent,

$\dot {\boldsymbol {\epsilon }}_p \ne 0$. In the first case, the plastic strain is time-independent, ![]() ${\boldsymbol \epsilon }_p({\boldsymbol x})$, and the potentials can be split into time-independent and transient components,

${\boldsymbol \epsilon }_p({\boldsymbol x})$, and the potentials can be split into time-independent and transient components, ![]() $\phi = \phi ^p({\boldsymbol x}) + \phi _{w}^e({\boldsymbol x},t)$,

$\phi = \phi ^p({\boldsymbol x}) + \phi _{w}^e({\boldsymbol x},t)$, ![]() ${\boldsymbol A} = {\boldsymbol A}^p({\boldsymbol x}) + {\boldsymbol A}^e_w({\boldsymbol x},t)$, where the equations

${\boldsymbol A} = {\boldsymbol A}^p({\boldsymbol x}) + {\boldsymbol A}^e_w({\boldsymbol x},t)$, where the equations

completed with load-free boundary conditions account for the deformation induced in the solid by the preexistent plastic region with the residual stress given by ![]() $\boldsymbol {\sigma }_{R} = \boldsymbol {C}^e :({\boldsymbol \epsilon - \boldsymbol {\epsilon }_p})$. The transient contributions,

$\boldsymbol {\sigma }_{R} = \boldsymbol {C}^e :({\boldsymbol \epsilon - \boldsymbol {\epsilon }_p})$. The transient contributions, ![]() $\phi ^e_w$,

$\phi ^e_w$, ![]() ${\boldsymbol A}^e_w$, obey the very same equations and boundary conditions of the previously considered purely elastic case, implying that the wave propagation is not altered.

${\boldsymbol A}^e_w$, obey the very same equations and boundary conditions of the previously considered purely elastic case, implying that the wave propagation is not altered.

The second case can be addressed in the same spirit, after assuming, for the purpose of the present analysis, the plastic strain field ![]() ${\boldsymbol \epsilon }_p({\boldsymbol x},t)$ to be known. Now the splittings read

${\boldsymbol \epsilon }_p({\boldsymbol x},t)$ to be known. Now the splittings read ![]() $\phi =\phi ^p({\boldsymbol x},t) + \phi ^e_w({\boldsymbol x},t)$ and

$\phi =\phi ^p({\boldsymbol x},t) + \phi ^e_w({\boldsymbol x},t)$ and ![]() ${\boldsymbol A} ={\boldsymbol A}^p({\boldsymbol x},t) + {\boldsymbol A}^e_w({\boldsymbol x},t)$, where the elastic wave components behave as before and take care of the load at the interface, whereas the potentials

${\boldsymbol A} ={\boldsymbol A}^p({\boldsymbol x},t) + {\boldsymbol A}^e_w({\boldsymbol x},t)$, where the elastic wave components behave as before and take care of the load at the interface, whereas the potentials ![]() $\phi ^p$ and

$\phi ^p$ and ![]() ${\boldsymbol A}^p$ obey the forced wave equations

${\boldsymbol A}^p$ obey the forced wave equations

with load-free boundary conditions. The nature of the solutions to the above equations depends on the behaviour of the plastic strain field. In fact, it is known that, under suitable conditions, elastoplastic waves can develop (Antman & Szymczak Reference Antman and Szymczak1989; Lubliner Reference Lubliner2008). In this case, the potentials inherit the propagative nature of the plastic strain field plus a system of purely elastic waves. Combining the partial solutions together, we arrive at a displacement field that possesses wave characteristics, in part purely elastic and in part associated with the envisaged elastoplastic propagation.

5. Numerical methods

The Navier–Stokes equations with capillarity (3.1) with constitutive equations (3.2), (3.3), and the elastoplasticity equations (4.2), (4.3) are solved adopting the finite-element method, implemented using the deal.II library (Arndt et al. Reference Arndt2023).

Concerning the fluid, an auxiliary field ![]() $g=\nabla ^2\rho$ is added to take into account higher-order derivatives in the stress tensor (3.2). Piecewise linear shape functions have been selected for the spatial discretisation, and the fluid domain

$g=\nabla ^2\rho$ is added to take into account higher-order derivatives in the stress tensor (3.2). Piecewise linear shape functions have been selected for the spatial discretisation, and the fluid domain ![]() $\varOmega _f$ is subdivided in two regions with different spatial resolution. A finer grid is adopted around the bubble initial position and in proximity to the wall, extending radially to follow the propagation of the shock wave at the wall, whereas a coarser grid is used far from the bubble. The grid size in the former region is

$\varOmega _f$ is subdivided in two regions with different spatial resolution. A finer grid is adopted around the bubble initial position and in proximity to the wall, extending radially to follow the propagation of the shock wave at the wall, whereas a coarser grid is used far from the bubble. The grid size in the former region is ![]() $\varDelta =20R_0/2^{11}$, with

$\varDelta =20R_0/2^{11}$, with ![]() $R_0$ the initial bubble radius (

$R_0$ the initial bubble radius (![]() $20R_0$ being the domain extension in both directions), whereas in the latter the grid size is

$20R_0$ being the domain extension in both directions), whereas in the latter the grid size is ![]() $\varDelta =20R_0/2^{6}$. To properly resolve the gradients at the interface, at the shock wave fronts, and near the solid wall an automatic grid refinement based on the Kelly error estimator (Kelly et al. Reference Kelly, De SR Gago, Zienkiewicz and Babuska1983; Ainsworth & Oden Reference Ainsworth and Oden2011) is employed, using the density gradients as indicator and setting the minimum allowed grid size to

$\varDelta =20R_0/2^{6}$. To properly resolve the gradients at the interface, at the shock wave fronts, and near the solid wall an automatic grid refinement based on the Kelly error estimator (Kelly et al. Reference Kelly, De SR Gago, Zienkiewicz and Babuska1983; Ainsworth & Oden Reference Ainsworth and Oden2011) is employed, using the density gradients as indicator and setting the minimum allowed grid size to ![]() $\varDelta =20R_0/2^{15}$. For time discretisation, the second-order Crank–Nicolson scheme is adopted, with timestep

$\varDelta =20R_0/2^{15}$. For time discretisation, the second-order Crank–Nicolson scheme is adopted, with timestep ![]() $\Delta t$ in the range

$\Delta t$ in the range ![]() $10^{-5}$–

$10^{-5}$–![]() $10^{-3}\,t_{ref}$, depending on the collapse dynamics. System nonlinearities are treated with a Newton–Raphson iterative method.

$10^{-3}\,t_{ref}$, depending on the collapse dynamics. System nonlinearities are treated with a Newton–Raphson iterative method.

Regarding the elastoplastic solid, the domain ![]() $\varOmega _s$ (here the extension is reduced to

$\varOmega _s$ (here the extension is reduced to ![]() $10R_0$ in both directions, exploiting an absorbing layer to prevent spurious reflections, to focus on the local wave structure) is discretised with a uniform grid with grid size

$10R_0$ in both directions, exploiting an absorbing layer to prevent spurious reflections, to focus on the local wave structure) is discretised with a uniform grid with grid size ![]() $\varDelta =10R_0/2^{11}$. The second-order Newmark-beta method (Newmark Reference Newmark1959) is used for time discretisation with parameters

$\varDelta =10R_0/2^{11}$. The second-order Newmark-beta method (Newmark Reference Newmark1959) is used for time discretisation with parameters ![]() $\beta =0.49$ and

$\beta =0.49$ and ![]() $\gamma =0.9$, and timestep

$\gamma =0.9$, and timestep ![]() $\Delta t\leq 0.9\varDelta /\max (c_{L},v_{D})$, with

$\Delta t\leq 0.9\varDelta /\max (c_{L},v_{D})$, with ![]() $c_{L}$ and

$c_{L}$ and ![]() $v_{D}$ the longitudinal waves speed and the distrurbance speed at the wall, respectively. The nonlinearities arising due to plasticity effects are treated with the Newton–Raphson iterative method, and the local plastic equilibrium is ensured with a classical return mapping algorithm (Simo & Taylor Reference Simo and Taylor1985; Simo & Hughes Reference Simo and Hughes2006). As anticipated, viscous layers are used to dampen outward-propagating waves and avoid spurious reflections at the artificial boundaries.

$v_{D}$ the longitudinal waves speed and the distrurbance speed at the wall, respectively. The nonlinearities arising due to plasticity effects are treated with the Newton–Raphson iterative method, and the local plastic equilibrium is ensured with a classical return mapping algorithm (Simo & Taylor Reference Simo and Taylor1985; Simo & Hughes Reference Simo and Hughes2006). As anticipated, viscous layers are used to dampen outward-propagating waves and avoid spurious reflections at the artificial boundaries.

The code was validated against finite-difference codes already used in a previous work (Magaletti et al. Reference Magaletti, Gallo, Marino and Casciola2016), and a convergence analysis has been carried out to ensure the results are grid-independent, by increasing the maximum resolution of the fluid grid in the interfacial region setting ![]() $\varDelta =20R_0/2^{16}$.

$\varDelta =20R_0/2^{16}$.

Additional details regarding the numerical methods are provided in the see supplementary material available at https://doi.org/10.1017/jfm.2024.925.

6. Bubble dynamics

In experiments on single bubbles, the bubble is usually generated by a spark or laser (Lauterborn & Bolle Reference Lauterborn and Bolle1975; Sinibaldi et al. Reference Sinibaldi, Occhicone, Alves Pereira, Caprini, Marino, Michelotti and Casciola2019), that is, it is formed due to intense electric fields that induce the dielectrics breakdown in the form of hot plasma. This leads to the localised vaporisation of the water and ultimately initiates the bubble. After its formation, the bubble expands up to a maximum radius, collapses back, rebounds and is finally reabsorbed. Although the energy deposition process can be simulated (Abbondanza, Gallo & Casciola Reference Abbondanza, Gallo and Casciola2023b), the cases analysed here consider instead a preexisting bubble of a given radius and let it collapse as a result of an overpressure in the liquid.

6.1. Simulation set-up

All the simulations are performed using cylindrical coordinates ![]() $r$,

$r$, ![]() $\theta$ and

$\theta$ and ![]() $z$, in the truncated domain

$z$, in the truncated domain ![]() $\varOmega _f=[0,\,R] \times [0, 2 \pi ]\times [0,\,H]$, assuming axisymmetry. On the solid wall, located at

$\varOmega _f=[0,\,R] \times [0, 2 \pi ]\times [0,\,H]$, assuming axisymmetry. On the solid wall, located at ![]() $z = 0$, the boundary conditions prescribe

$z = 0$, the boundary conditions prescribe

with ![]() $-\hat {\boldsymbol {e}}_z$ the outward normal at the adiabatic wall, where no-slip is assumed and the last equation determines the contact angle (3.8). The remaining part of the domain boundary is assumed sufficiently far from the bubble to allow the boundary conditions,

$-\hat {\boldsymbol {e}}_z$ the outward normal at the adiabatic wall, where no-slip is assumed and the last equation determines the contact angle (3.8). The remaining part of the domain boundary is assumed sufficiently far from the bubble to allow the boundary conditions,

The initial conditions are

$$\begin{gather} \rho(r,z,0)=\rho_v^{eq}+\frac{1}{2}\left(1+\tanh\left(\frac{\sqrt{r^2+(z-Z_c)^2}-R_0}{\ell}\right) (\rho_l-\rho_v^{eq})\right), \end{gather}$$

$$\begin{gather} \rho(r,z,0)=\rho_v^{eq}+\frac{1}{2}\left(1+\tanh\left(\frac{\sqrt{r^2+(z-Z_c)^2}-R_0}{\ell}\right) (\rho_l-\rho_v^{eq})\right), \end{gather}$$

with ![]() $\rho _v^{eq}$ and

$\rho _v^{eq}$ and ![]() $\rho _l$ the initial vapour and liquid density, respectively. The initial condition describes a still vapour bubble of radius

$\rho _l$ the initial vapour and liquid density, respectively. The initial condition describes a still vapour bubble of radius ![]() $R_0$, at the external liquid temperature

$R_0$, at the external liquid temperature ![]() $\theta _0$, with the centre on the symmetry axis and standoff distance

$\theta _0$, with the centre on the symmetry axis and standoff distance ![]() $Z_c$ with respect to the wall, see the sketch in figure 3(a). Here

$Z_c$ with respect to the wall, see the sketch in figure 3(a). Here ![]() $\ell \simeq \ell _{LV}$, (3.4), is the initial width of the liquid–vapour interface. As is well known (Debenedetti Reference Debenedetti2021), a bubble in an unbound domain cannot exist in a stable equilibrium state. In fact, the thermal, mechanical and chemical equilibria,

$\ell \simeq \ell _{LV}$, (3.4), is the initial width of the liquid–vapour interface. As is well known (Debenedetti Reference Debenedetti2021), a bubble in an unbound domain cannot exist in a stable equilibrium state. In fact, the thermal, mechanical and chemical equilibria,

lead to a critical bubble that would either spontaneously shrink (be reabsorbed into the liquid) or expand. Starting from the unstable state described by (6.6), the increase of the liquid density to ![]() $\rho _l > \rho _l^{eq}$ invariably leads to collapse of the bubble.

$\rho _l > \rho _l^{eq}$ invariably leads to collapse of the bubble.

Figure 3. (a) Initial two-dimensional cylindrical configuration in the fluid domain. The bubble is initially located on the axis, at height ![]() $Z_c$. The pressure in the liquid is

$Z_c$. The pressure in the liquid is ![]() $p_{L}$, whereas the pressure in the bubble is

$p_{L}$, whereas the pressure in the bubble is ![]() $p_{V}$. (b) Initial overpressure conditions in the liquid represented on a normalised

$p_{V}$. (b) Initial overpressure conditions in the liquid represented on a normalised ![]() $p$–

$p$–![]() $\rho$ plane, with the corresponding van der Waals equation of state at the initial temperature of the system. Colours correspond to the three different conditions explored, increasing overpressure from red to blue. The saturation pressure, very similar to the equilibrium pressure in these conditions, is represented with a dashed line. Here

$\rho$ plane, with the corresponding van der Waals equation of state at the initial temperature of the system. Colours correspond to the three different conditions explored, increasing overpressure from red to blue. The saturation pressure, very similar to the equilibrium pressure in these conditions, is represented with a dashed line. Here ![]() $p_c=22$ MPa and

$p_c=22$ MPa and ![]() $\rho _c=322$ kg m

$\rho _c=322$ kg m![]() $^{-3}$ are the critical pressure and density.

$^{-3}$ are the critical pressure and density.

Figure 4 shows the equilibrium liquid pressure at temperature ![]() $\theta _0$ as a function of the bubble radius. It is substantially independent of the bubble size as soon as the bubble radius is 10

$\theta _0$ as a function of the bubble radius. It is substantially independent of the bubble size as soon as the bubble radius is 10 ![]() $\mathrm {\mu }$m or larger. According to the Rayleigh–Plesset dynamics (Brennen Reference Brennen2014), in free space, the collapse time of a vapour bubble of radius

$\mathrm {\mu }$m or larger. According to the Rayleigh–Plesset dynamics (Brennen Reference Brennen2014), in free space, the collapse time of a vapour bubble of radius ![]() $R_0$ is approximately given by

$R_0$ is approximately given by

\begin{equation} T_c(R_0) = R_0 \sqrt{\frac{3 \rho_l}{2 (p_l - p_v^{eq})}} \int_{0}^1 {\rm d}{\kern0.8pt}x \sqrt{\frac{x^3}{1 - x^3 + \alpha (1-x^2)}}, \end{equation}

\begin{equation} T_c(R_0) = R_0 \sqrt{\frac{3 \rho_l}{2 (p_l - p_v^{eq})}} \int_{0}^1 {\rm d}{\kern0.8pt}x \sqrt{\frac{x^3}{1 - x^3 + \alpha (1-x^2)}}, \end{equation}

where ![]() $x = R/R_0$,

$x = R/R_0$, ![]() $\alpha (R_0) = 3 \sigma /[R_0(p_l - p_v^{eq})]$,

$\alpha (R_0) = 3 \sigma /[R_0(p_l - p_v^{eq})]$, ![]() $p_l = p_l^{eq}(1 + \beta )$ and

$p_l = p_l^{eq}(1 + \beta )$ and ![]() $\rho _l = \rho _l(\theta _0,p_l)$, with

$\rho _l = \rho _l(\theta _0,p_l)$, with ![]() $\beta = (p_l-p_l^{eq})/p_l^{eq}$ the overpressure parameter quantifying the liquid pressure increase over the equilibrium value given by (6.6). The approximation consists of assuming that the liquid state, that is pressure and density, is not affected by the bubble collapse and the vapour pressure remains at the equilibrium value. It is worth stressing that the above prediction accounts for the presence of surface tension which becomes significant for microbubbles. From the collapse time, one may define a typical collapse speed,

$\beta = (p_l-p_l^{eq})/p_l^{eq}$ the overpressure parameter quantifying the liquid pressure increase over the equilibrium value given by (6.6). The approximation consists of assuming that the liquid state, that is pressure and density, is not affected by the bubble collapse and the vapour pressure remains at the equilibrium value. It is worth stressing that the above prediction accounts for the presence of surface tension which becomes significant for microbubbles. From the collapse time, one may define a typical collapse speed, ![]() $V_c = R_0/T_c$ that is also found to be substantially independent of the bubble radius above

$V_c = R_0/T_c$ that is also found to be substantially independent of the bubble radius above ![]() $R_0 = 10$