1. Introduction

The modelling of complex fluids, synthetic or biological, is in general a challenging task due to the multiscale nature of the flow, leading to complex behaviours such as flow-induced phase separation, shear-thinning/thickening and viscoelasticity. Usual approaches involve the solution of a macroscopic balance of momentum, along with constitutive equations that relate the dependency of the stresses and velocity fields due to microscopically originated features. However, limitations of these approaches arise when the constitutive equations are not known a priori. Moreover, the existence of large relaxation times at the microscale results in a non-trivial interplay with macroscopic flow features, requiring a detailed description of the entire stress history. In this context, heterogeneous multiscale methods (HMMs) (Ee et al. Reference Ee, Engquist, Li, Ren and Vanden-Eijnden2007) that combine numerical algorithms to resolve separately macro- and microscales, appear as powerful tools to model the behaviour of fluids across scales. In HMMs, microscales are localized and solved on parts of the domain to obtain microscopically derived properties that are used to close the macroscale problem (Ren & Weinan Reference Ren and Weinan2005). This methodology offers the advantage of capturing microscopic effects at the macroscopic length scales, with a lower cost than solving the full microscale problem in the whole domain. In HMMs, the derived microscales properties can enter into the macroscales representations either through constitutive relationships or microscopic stresses information without a priori assumption of the constitutive relationships. The latest is an important advantage of HMMs for the modelling of complex fluids. For an extended review on HMMs, the reader is referred to the work of Ee et al. (Reference Ee, Engquist, Li, Ren and Vanden-Eijnden2007). One of the key benefits of having a constitutive equation for stress is the ability to generalize fluid behaviour in the macroscopic domain without the need for explicit microscopic simulations. Such constitutive relations have been formulated for various non-Newtonian fluids (Bird et al. Reference Bird, Curtiss, Amstrong and Ole1987). However, many complex systems lack an a priori constitutive relationship, which necessitates system-specific approximations. In this context, using microscopically informed stress for the momentum equation provides a more systematic approach to bypass the need for unknown constitutive models. The primary assumption with this strategy is that the adopted methodology used for the microscales should be capable of reproducing the physical system. Consequently, the microscales will typically require preliminary characterization.

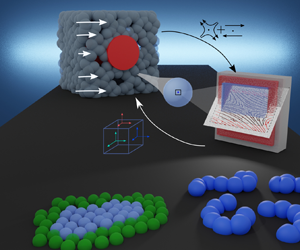

Depending on the type of discretization (Eulerian or Lagrangian) used for macro- and microscales, the HMMs are classified as Eulerian/Eulerian (EE), Lagrangian/Lagrangian (LL), Eulerian/Lagrangian (EL) and Lagrangian/Eulerian (LE); see figure 1(a). A large part of the existent HMMs relies on EE and EL schemes (Ee et al. Reference Ee, Engquist, Li, Ren and Vanden-Eijnden2007), where the macroscale dynamics is resolved on a fixed grid (using a variety of methods such as finite elements, finite volumes, lattice Boltzmann, to name a few), and microscale simulations (e.g. molecular dynamics (Alexiadis et al. Reference Alexiadis, Lockerby, Borg and Reese2013; Borg, Lockerby & Reese Reference Borg, Lockerby and Reese2015; Tedeschi et al. Reference Tedeschi, Giusteri, Yelash, Lukácová-Medvid'ová, Tedeschi, Giusteri, Yelash and Lukácová-Medvid'ová2021), coarse-graining methods, stochastic methods, etc.) are associated with grid points, where microscopic properties are derived. For viscoelastic fluids modelling, Laso and Öttinger introduced a pioneering approach known as CONNFFESSIT (Laso & Öttinger Reference Laso and Öttinger1993) (calculation of non-Newtonian flow: finite element and stochastic simulation technique), combining finite elements at the macroscale and stochastic particle simulations of polymer dynamics at the microscale.

Figure 1. Scheme of different HMM approaches. Eulerian–Eulerian (EE), Eulerian–Lagrangian (EL) and Lagrangian–Lagrangian (LL). The evolution of the stress tensor depends on the effective relaxation times at the microscales ![]() $\lambda '$. Systems with

$\lambda '$. Systems with ![]() $\lambda ' \ll \bar {\lambda }$ (green) are accurately computed at the microscopic scales, whereas for

$\lambda ' \ll \bar {\lambda }$ (green) are accurately computed at the microscopic scales, whereas for ![]() $\lambda ' \leq \bar {\lambda }$ (blue), larger microscale simulations are required to capture memory effects as the macro scales evolve. LL approaches facilitate the carrying of the stress information during the time integration at macroscales.

$\lambda ' \leq \bar {\lambda }$ (blue), larger microscale simulations are required to capture memory effects as the macro scales evolve. LL approaches facilitate the carrying of the stress information during the time integration at macroscales.

The EE and EL approaches are generally appropriate for fluids with microstructural relaxation times (![]() ${\lambda }'$) that are sufficiently small compared to the macroscopic ones (

${\lambda }'$) that are sufficiently small compared to the macroscopic ones (![]() ${\lambda }$) (Ren & Weinan Reference Ren and Weinan2005; Yasuda & Yamamoto Reference Yasuda and Yamamoto2008, Reference Yasuda and Yamamoto2014). As shown in figure 1(b), for multiscale problems with significant time scale separation, where

${\lambda }$) (Ren & Weinan Reference Ren and Weinan2005; Yasuda & Yamamoto Reference Yasuda and Yamamoto2008, Reference Yasuda and Yamamoto2014). As shown in figure 1(b), for multiscale problems with significant time scale separation, where ![]() ${\lambda }' \ll {\lambda }$ (or

${\lambda }' \ll {\lambda }$ (or ![]() $Wi = {\lambda }'/ {\lambda } \ll 1$, where

$Wi = {\lambda }'/ {\lambda } \ll 1$, where ![]() $Wi$ is the Weissenberg number), a quasi-steady state can be achieved for the microscopic stresses, regardless of the flow history. This approach has been employed in atomistic-continuum simulations of simple fluids using molecular dynamics with an Eulerian grid-based calculation of the flow field (Ren & Weinan Reference Ren and Weinan2005). In simple fluids, the local stress depends point-wise in time on the velocity gradient, and therefore, the initial conditions for the microstructure can be chosen arbitrarily at each time step. The average stress is then calculated using the Irving–Kirkwood approximation, provided that local stationarity is achieved within the same time step.

$Wi$ is the Weissenberg number), a quasi-steady state can be achieved for the microscopic stresses, regardless of the flow history. This approach has been employed in atomistic-continuum simulations of simple fluids using molecular dynamics with an Eulerian grid-based calculation of the flow field (Ren & Weinan Reference Ren and Weinan2005). In simple fluids, the local stress depends point-wise in time on the velocity gradient, and therefore, the initial conditions for the microstructure can be chosen arbitrarily at each time step. The average stress is then calculated using the Irving–Kirkwood approximation, provided that local stationarity is achieved within the same time step.

However, this approach cannot be extended to complex fluids with finite memory, when ![]() ${\lambda } \lesssim {\lambda }'$ (

${\lambda } \lesssim {\lambda }'$ (![]() $Wi>1$). As shown in figure 1(b), the stresses and microstructure heavily depend on flow history, and relaxation times are likely to be comparable to, or even exceed, the macroscopic time step. The direct use of EL or EE schemes to generate an initial microstructural configuration in a fixed fluid cell is fundamentally and technically limited due to two reasons. First, it is not known beforehand where the fluid comes from and what its flow history was, and second, even if this information were available, it would require additional constitutive and numerical features capable of accounting for complex spatio/temporal variations.

$Wi>1$). As shown in figure 1(b), the stresses and microstructure heavily depend on flow history, and relaxation times are likely to be comparable to, or even exceed, the macroscopic time step. The direct use of EL or EE schemes to generate an initial microstructural configuration in a fixed fluid cell is fundamentally and technically limited due to two reasons. First, it is not known beforehand where the fluid comes from and what its flow history was, and second, even if this information were available, it would require additional constitutive and numerical features capable of accounting for complex spatio/temporal variations.

Alternative techniques to address these issues include spatial/temporal homogenization methods and backward-tracking Lagrangian particles combined with Eulerian grids to capture memory effects in the fluid (Phillips & Williams Reference Phillips and Williams1999; Wapperom, Keunings & Legat Reference Wapperom, Keunings and Legat2000; Ingelsten et al. Reference Ingelsten, Mark, Kadar and Edelvik2021). However, fluid memory can be very long in polymer systems, suspensions, etc., precluding simple linear backward approximations. Regarding the second issue, one alternative is to incorporate continuum configuration fields that can be discretized and advected from the macroscales (Ottinger, van den Brule & Hulsen Reference Öttinger, van den Brule and Hulsen1997). However, it would be extremely challenging to know a priori those fields for general multiphysics problems (i.e. non-polymeric), as well as the numerical generation of microscopic configurations consistent with the history of the fluid.

For systems with larger microstructural relaxation times (![]() ${\lambda } \lesssim {\lambda }'$), the particular restrictions of EE and EL can be circumvented using fully Lagrangian, LL, schemes (Ee et al. Reference Ee, Engquist, Li, Ren and Vanden-Eijnden2007), and a proper sampling procedure for the microstructure. Indeed, LL schemes have been successfully used to model elastic effect and history-dependent flows (Murashima & Taniguchi Reference Murashima and Taniguchi2010; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020; Morii & Kawakatsu Reference Morii and Kawakatsu2021) at large Weissenberg numbers. As illustrated in figure 1(b), LL schemes directly track the material points at the macroscale retaining their strain and strain-rate variation, thus naturally handling history-dependent fluids. A variety of LL methodologies have emerged over the last decade, adopting mainly smoothed particle hydrodynamics (SPH) discretizations at the macroscales and combination of different microscopic models (Ellero, Español & Flekkoy Reference Ellero, Español and Flekkoy2003; Murashima & Taniguchi Reference Murashima and Taniguchi2010; Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016; Xu & Yu Reference Xu and Yu2016; Sato & Taniguchi Reference Sato and Taniguchi2017; Zhao et al. Reference Zhao, Li, Caswell, Ouyang and Karniadakis2018; Sato, Harada & Taniguchi Reference Sato, Harada and Taniguchi2019; Giessen et al. Reference Giessen2020; Schieber & Hütter Reference Schieber and Hütter2020; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020; Morii & Kawakatsu Reference Morii and Kawakatsu2021). At the microscales, the stress evolution of polymeric solutions and entanglements have been accounted for using Brownian dynamic (Xu & Yu Reference Xu and Yu2016), active learning (Zhao et al. Reference Zhao, Li, Caswell, Ouyang and Karniadakis2018; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020) and slip-link models (Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016; Sato & Taniguchi Reference Sato and Taniguchi2017; Sato et al. Reference Sato, Harada and Taniguchi2019). In these LL schemes, it is considered that microscales only account for the polymer contribution to the stress, whereas the fluid is modelled uniquely from the macroscopic discretization (Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016). Its effect (i.e. velocity gradient tensor) enters the Langevin-type dynamics for stochastic micro-realizations implicitly as a single parameter, and not directly as a boundary condition for the full microsystem.

${\lambda } \lesssim {\lambda }'$), the particular restrictions of EE and EL can be circumvented using fully Lagrangian, LL, schemes (Ee et al. Reference Ee, Engquist, Li, Ren and Vanden-Eijnden2007), and a proper sampling procedure for the microstructure. Indeed, LL schemes have been successfully used to model elastic effect and history-dependent flows (Murashima & Taniguchi Reference Murashima and Taniguchi2010; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020; Morii & Kawakatsu Reference Morii and Kawakatsu2021) at large Weissenberg numbers. As illustrated in figure 1(b), LL schemes directly track the material points at the macroscale retaining their strain and strain-rate variation, thus naturally handling history-dependent fluids. A variety of LL methodologies have emerged over the last decade, adopting mainly smoothed particle hydrodynamics (SPH) discretizations at the macroscales and combination of different microscopic models (Ellero, Español & Flekkoy Reference Ellero, Español and Flekkoy2003; Murashima & Taniguchi Reference Murashima and Taniguchi2010; Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016; Xu & Yu Reference Xu and Yu2016; Sato & Taniguchi Reference Sato and Taniguchi2017; Zhao et al. Reference Zhao, Li, Caswell, Ouyang and Karniadakis2018; Sato, Harada & Taniguchi Reference Sato, Harada and Taniguchi2019; Giessen et al. Reference Giessen2020; Schieber & Hütter Reference Schieber and Hütter2020; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020; Morii & Kawakatsu Reference Morii and Kawakatsu2021). At the microscales, the stress evolution of polymeric solutions and entanglements have been accounted for using Brownian dynamic (Xu & Yu Reference Xu and Yu2016), active learning (Zhao et al. Reference Zhao, Li, Caswell, Ouyang and Karniadakis2018; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020) and slip-link models (Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016; Sato & Taniguchi Reference Sato and Taniguchi2017; Sato et al. Reference Sato, Harada and Taniguchi2019). In these LL schemes, it is considered that microscales only account for the polymer contribution to the stress, whereas the fluid is modelled uniquely from the macroscopic discretization (Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016). Its effect (i.e. velocity gradient tensor) enters the Langevin-type dynamics for stochastic micro-realizations implicitly as a single parameter, and not directly as a boundary condition for the full microsystem.

In fact, one important issue limiting the applicability of HMM methods to more detailed descriptions of complex fluids is precisely the proper imposition of microscale constraints that are consistent with the macroscale kinematics and the calculation of microscopic information required by the macro state (Ee et al. Reference Ee, Engquist, Li, Ren and Vanden-Eijnden2007). When using particle-based micro-models with explicit solvent description (e.g. molecular dynamics, dissipative particle dynamics, discrete element method, SDPD), the construction of this constrained microscale solver represents often the most cumbersome technical step. For LL schemes, due to the history-dependent evolution of the flow and the existence of non-trivial flow configurations, the microscales can be subjected to arbitrary series of deformations that are usually difficult to handle with traditional periodic boundary conditions (BCs). To avoid these limitations, existent LL schemes have been restricted to the use of microscopic simulators that do not depend on the ‘physical’ boundary conditions (Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016; Sato & Taniguchi Reference Sato and Taniguchi2017; Sato et al. Reference Sato, Harada and Taniguchi2019; Morii & Kawakatsu Reference Morii and Kawakatsu2021). This includes, for example, the case of Brownian dynamics for statistically independent polymers, such as dilute polymer solutions or polymer melts in mean field approximation, or where geometries that reproduce simple flow configurations are utilized (Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020) (i.e. simple shear or uniaxial deformation). More general micro–macro couplings (e.g. full particle-based model of polymeric dispersions, colloid suspensions, emulsions, etc.) involving detailed microsystems models undergoing arbitrary flow deformations are beyond the capabilities of the current frameworks.

Another important assumption in some of the existent microsolvers is that the microscopic states of all polymers are in equilibrium and that the coils do not have translational degrees of freedom, but only rotational and extensional ones (Morii & Kawakatsu Reference Morii and Kawakatsu2021). Regarding microscopic BCs approaches using simple flow configurations, they are suitable to account for translational effects and often provide information sufficient to characterize simple fluids. However, since complex fluids can possess microscopic structures that are influenced by different flow configurations, geometries, time scales and deformation rates, it has been evidenced that to correctly model non-Newtonian fluids (Tedeschi et al. Reference Tedeschi, Giusteri, Yelash, Lukácová-Medvid'ová, Tedeschi, Giusteri, Yelash and Lukácová-Medvid'ová2021), it is necessary to determine the full stress contribution from the microscopic solver.

In this manuscript, we propose a generalized fully Lagrangian HMM (LHMM) using smoothed dissipative particle dynamics (Español & Revenga Reference Español and Revenga2003; Ellero & Español Reference Ellero and Español2018) (SDPD), suitable to model general complex fluids (e.g. colloids, polymer, microstructures in suspensions) while using the same fluid description across scales. Among the different computational methods successfully used to model Newtonian and non-Newtonian fluids at continuum and microscales, SDPD has emerged as a suitable tool to simulate complex fluids (Kulkarni et al. Reference Kulkarni, Fu, Shell and Leal2013; Müller, Fedosov & Gompper Reference Müller, Fedosov and Gompper2014; Ellero & Español Reference Ellero and Español2018). The main strengths of SDPD are: (i) it consistently discretizes the fluctuating Navier–Stokes equations allowing the direct specification of transport properties such as viscosity of the fluid; (ii) SDPD is compliant with the general equation for non-equilibrium reversible–irreversible coupling (GENERIC) (Öttinger Reference Öttinger2005) and therefore, it discretely satisfies the first and second laws of thermodynamics, and fluctuation–dissipation theorem (FDT); (iii) at macroscopic scales, SDPD converges to the well-known continuum method smoothed particle hydrodynamics (SPH) as the characteristic size of the discretized particle increases (Vázquez-Quesada, Ellero & Español Reference Vázquez-Quesada, Ellero and Español2009; Ellero & Español Reference Ellero and Español2018). For an extended review of SDPD, the reader is referred to the publication of Ellero & Español (Reference Ellero and Español2018).

Since SDPD offers a natural physical link between different scales, we construct an HMM that uses SDPD to solve both macro- and microscales. This approach ensures the compatibility of the different representations by construction and physical consistency across scales. At the microscales, we adopt the recently proposed BC methodology (Moreno & Ellero Reference Moreno and Ellero2021) that allows the acquisition of the full microscopic stress contributions for arbitrary flow configurations. This allows to carry out micro-computations under general mixed flow conditions. While it is true that CONNFFESSIT (Laso & Öttinger Reference Laso and Öttinger1993) and other EL methodologies are also capable of handling mixed flow features, those features are not included in current LL methodologies with fully explicit solvent descriptions. Furthermore, in the context of LL, our approach exploits the versatility of SDPD to model a variety of microscopic physical systems beyond polymeric systems. Our LHMM scheme's strength lies in its unique combination of aspects that other methods only partially account for. We can summarize the main features of the proposed LHHM framework as follows.

(i) Model history-dependent flows by construction.

(ii) Significant spatio-temporal gains in simulations compared with fully resolved microscale simulations.

(iii) Thermodynamic-consistent discretization of the fluctuating Navier–Stokes equations in both macro- and microscales (deterministic–stochastic) providing a direct link to physical parameters.

(iv) GENERIC compliant at both macro and micro levels.

(v) Multiphysics – polymers, colloids, suspensions, multiphasic systems. No constitutive models for closure are required.

(vi) Complex-flow configurations are allowed and can be handled at the microscales.

In the following sections, first, a general description of HMM is introduced along with the governing balance equations, then, the proposed fully Lagrangian approach and the particle-based discretization are presented. Finally, without loss of generality, we streamline the validation of the methodology focusing on two-dimensional simulations of complex flows with memory. At the microscales, we adopt generic, yet complex, polymeric and multiphase flows to showcase the flexibility of the method.

2. Heterogeneous multiscale methods

In general, for HMMs, we can define the macroscopic problem considering a domain ![]() $\varOmega \subset \mathcal {R}^D$ (with dimension

$\varOmega \subset \mathcal {R}^D$ (with dimension ![]() $D=2,3$) with a boundary

$D=2,3$) with a boundary ![]() $\partial \varOmega = \varGamma _{\mathcal {D}} \cup \varGamma _{\mathcal {N}}$, where

$\partial \varOmega = \varGamma _{\mathcal {D}} \cup \varGamma _{\mathcal {N}}$, where ![]() $\varGamma _{\mathcal {D}}$ and

$\varGamma _{\mathcal {D}}$ and ![]() $\varGamma _{\mathcal {N}}$ correspond to boundary regions where Dirichlet and Neumann boundary conditions are applied, respectively. The mass and momentum balance of the system for an incompressible fluid with constant density

$\varGamma _{\mathcal {N}}$ correspond to boundary regions where Dirichlet and Neumann boundary conditions are applied, respectively. The mass and momentum balance of the system for an incompressible fluid with constant density ![]() $\rho$ can be expressed as

$\rho$ can be expressed as

\begin{equation} \left. \begin{aligned} \boldsymbol{\nabla} \boldsymbol{\cdot} {\boldsymbol{v}} & = 0, \quad \text{in} \ \varOmega \times (0,T),\\ \rho \frac{\text{d} {\boldsymbol{v}}}{\text{d} t} - \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol\tau({\boldsymbol{v}},p) & = f ,\quad \text{in} \ \varOmega \times (0,T),\\ {\boldsymbol{v}} & = g, \quad \text{on} \ \varGamma_{\mathcal{D}} \times (0,T), \\ {\boldsymbol{v}}(0) & = {\boldsymbol{v}}_0, \quad \text{in} \ \varOmega \times \{0\}, \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} \boldsymbol{\nabla} \boldsymbol{\cdot} {\boldsymbol{v}} & = 0, \quad \text{in} \ \varOmega \times (0,T),\\ \rho \frac{\text{d} {\boldsymbol{v}}}{\text{d} t} - \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol\tau({\boldsymbol{v}},p) & = f ,\quad \text{in} \ \varOmega \times (0,T),\\ {\boldsymbol{v}} & = g, \quad \text{on} \ \varGamma_{\mathcal{D}} \times (0,T), \\ {\boldsymbol{v}}(0) & = {\boldsymbol{v}}_0, \quad \text{in} \ \varOmega \times \{0\}, \end{aligned} \right\} \end{equation}

where the total stress tensor is given by ![]() ${\boldsymbol \tau } = -p{\boldsymbol I} + \boldsymbol {\pi }$, with

${\boldsymbol \tau } = -p{\boldsymbol I} + \boldsymbol {\pi }$, with ![]() $p$ being the pressure and

$p$ being the pressure and ![]() $\boldsymbol {\pi }$ the viscous stress. For incompressible Newtonian fluids, the viscous stress is a linear function of the strain rate (

$\boldsymbol {\pi }$ the viscous stress. For incompressible Newtonian fluids, the viscous stress is a linear function of the strain rate (![]() $\boldsymbol {\pi }=\eta (\boldsymbol {\nabla }{\boldsymbol v} + \boldsymbol {\nabla }{\boldsymbol v}^T)$, with

$\boldsymbol {\pi }=\eta (\boldsymbol {\nabla }{\boldsymbol v} + \boldsymbol {\nabla }{\boldsymbol v}^T)$, with ![]() $\eta$ being the viscosity) and the flow can be totally described using (2.1). For non-Newtonian fluids such as colloidal and polymeric systems, this linear behaviour does not hold and other relationships are required (Bird et al. Reference Bird, Curtiss, Amstrong and Ole1987). Additionally, for microfluidics, where complex flow patterns and thermal effects may arise, the use of Dirichlet boundary conditions,

$\eta$ being the viscosity) and the flow can be totally described using (2.1). For non-Newtonian fluids such as colloidal and polymeric systems, this linear behaviour does not hold and other relationships are required (Bird et al. Reference Bird, Curtiss, Amstrong and Ole1987). Additionally, for microfluidics, where complex flow patterns and thermal effects may arise, the use of Dirichlet boundary conditions, ![]() ${\boldsymbol {v}} = g$ on

${\boldsymbol {v}} = g$ on ![]() $\varGamma _{\mathcal {D}} \times (0,T)$, may not accurately model such microscopic effects, requiring more elaborated considerations for the boundary conditions.

$\varGamma _{\mathcal {D}} \times (0,T)$, may not accurately model such microscopic effects, requiring more elaborated considerations for the boundary conditions.

2.1. Lagrangian heterogeneous multiscale method (LHMM)

We propose an LL-type of methodology, as depicted in figure 1, discretizing both macro- and microscales with a particle-based representation of the system. We distinguish macroscale parameters and variables if they are derived from microscales calculations using the upper bar (i.e. ![]() $\bar {X}$), whereas microscale variables are denoted using a prime (i.e.

$\bar {X}$), whereas microscale variables are denoted using a prime (i.e. ![]() $X'$). We use the subindices

$X'$). We use the subindices ![]() $x,y$ and

$x,y$ and ![]() $z$ to indicate the coordinate axis. If we express the macroscopic viscous stress determined from a representative microscopic domain

$z$ to indicate the coordinate axis. If we express the macroscopic viscous stress determined from a representative microscopic domain ![]() $\varOmega '$ in terms of hydrodynamic, non-hydrodynamic and kinetic contributions as

$\varOmega '$ in terms of hydrodynamic, non-hydrodynamic and kinetic contributions as ![]() ${\bar {\boldsymbol {\pi }}}={\bar {\boldsymbol {\pi }}}_{h}+{\bar {\boldsymbol {\pi }}}_{m}+{\bar {\boldsymbol {\pi }}}_{k}$, the ensemble average stress at the microscales leads to

${\bar {\boldsymbol {\pi }}}={\bar {\boldsymbol {\pi }}}_{h}+{\bar {\boldsymbol {\pi }}}_{m}+{\bar {\boldsymbol {\pi }}}_{k}$, the ensemble average stress at the microscales leads to

\begin{align} \langle \bar{\boldsymbol{\pi}} \rangle (\boldsymbol x) &= \frac{1}{\varOmega'} \int_{\varOmega'}{\boldsymbol{\pi}'} \,\text{d} \varOmega', \nonumber\\ &= \frac{1}{\varOmega'} \left(\int_{\varOmega'} {\boldsymbol{\pi}}_h' \,\text{d} \varOmega' + \int_{\varOmega'} {\boldsymbol{\pi}}_m' \,\text{d} \varOmega' + \int_{\varOmega'} {\boldsymbol{\pi}}_k' \,\text{d} \varOmega' \right), \end{align}

\begin{align} \langle \bar{\boldsymbol{\pi}} \rangle (\boldsymbol x) &= \frac{1}{\varOmega'} \int_{\varOmega'}{\boldsymbol{\pi}'} \,\text{d} \varOmega', \nonumber\\ &= \frac{1}{\varOmega'} \left(\int_{\varOmega'} {\boldsymbol{\pi}}_h' \,\text{d} \varOmega' + \int_{\varOmega'} {\boldsymbol{\pi}}_m' \,\text{d} \varOmega' + \int_{\varOmega'} {\boldsymbol{\pi}}_k' \,\text{d} \varOmega' \right), \end{align}

where ![]() ${\boldsymbol {\pi }}_h'$ accounts for the hydrodynamic contributions to the stress and

${\boldsymbol {\pi }}_h'$ accounts for the hydrodynamic contributions to the stress and ![]() ${\boldsymbol {\pi }}_m'$ corresponds to the non-hydrodynamics effects (presence of colloids, polymers, walls, etc). The

${\boldsymbol {\pi }}_m'$ corresponds to the non-hydrodynamics effects (presence of colloids, polymers, walls, etc). The ![]() $\langle \boldsymbol {\cdot }\rangle$ denotes the averaging over the microscopic domain. However, the

$\langle \boldsymbol {\cdot }\rangle$ denotes the averaging over the microscopic domain. However, the ![]() $\bar {\boldsymbol {\pi }}$ corresponds to a macroscopic field. For a Newtonian (ideal) solvent, the stress is given by

$\bar {\boldsymbol {\pi }}$ corresponds to a macroscopic field. For a Newtonian (ideal) solvent, the stress is given by ![]() $\langle \bar {\boldsymbol {\pi }}_o\rangle = <2\eta \bar {\boldsymbol {d}}> = \langle \bar {\boldsymbol {\pi }}_h\rangle$ (

$\langle \bar {\boldsymbol {\pi }}_o\rangle = <2\eta \bar {\boldsymbol {d}}> = \langle \bar {\boldsymbol {\pi }}_h\rangle$ (![]() $\bar {\boldsymbol {d}}$ being the rate-of-strain tensor computed from microscopic information). Additionally, if this Newtonian solvent stress contributes homogeneously over the whole domain at all scales, it is reasonable to consider that

$\bar {\boldsymbol {d}}$ being the rate-of-strain tensor computed from microscopic information). Additionally, if this Newtonian solvent stress contributes homogeneously over the whole domain at all scales, it is reasonable to consider that ![]() ${\boldsymbol {\pi }}_o = 2 \eta \boldsymbol {d} =\langle \bar {\boldsymbol {\pi }}_o\rangle$. (Notice that the overbar notation of

${\boldsymbol {\pi }}_o = 2 \eta \boldsymbol {d} =\langle \bar {\boldsymbol {\pi }}_o\rangle$. (Notice that the overbar notation of ![]() $\boldsymbol {d}$ is omitted since is not a multiscale contribution, in contrast to

$\boldsymbol {d}$ is omitted since is not a multiscale contribution, in contrast to ![]() $\bar {\boldsymbol {d}}$ that is a macroscopic rate of strain determined from microscopic variables.) We can now introduce a hybrid macro–micro formulation given by

$\bar {\boldsymbol {d}}$ that is a macroscopic rate of strain determined from microscopic variables.) We can now introduce a hybrid macro–micro formulation given by

\begin{equation}

\langle{\bar{\boldsymbol{\pi}}}_{h}\rangle (\boldsymbol x)

= \underbrace{\epsilon 2 \eta

\boldsymbol{d}}_{\textit{macro}} +

\underbrace{\frac{1}{\varOmega'} \int_{\varOmega'}

(1-\epsilon) {\boldsymbol{\pi}}_h' \,\text{d}

\varOmega'}_{\textit{micro}}.

\end{equation}

\begin{equation}

\langle{\bar{\boldsymbol{\pi}}}_{h}\rangle (\boldsymbol x)

= \underbrace{\epsilon 2 \eta

\boldsymbol{d}}_{\textit{macro}} +

\underbrace{\frac{1}{\varOmega'} \int_{\varOmega'}

(1-\epsilon) {\boldsymbol{\pi}}_h' \,\text{d}

\varOmega'}_{\textit{micro}}.

\end{equation}

This scheme is a generalized framework that allows us to incorporate ideal hydrodynamics interactions of the fluid from both scales. The weighting parameter ![]() $\epsilon$ conveniently provides numerical stability to the method, whereas naturally accounting for spatial inhomogeneities of the stresses. According to (2.3), if

$\epsilon$ conveniently provides numerical stability to the method, whereas naturally accounting for spatial inhomogeneities of the stresses. According to (2.3), if ![]() $\epsilon =1$, the ideal hydrodynamic contributions are fully accounted for from the macroscale level, and microscales only contribute to non-hydrodynamic interactions. In contrast, if

$\epsilon =1$, the ideal hydrodynamic contributions are fully accounted for from the macroscale level, and microscales only contribute to non-hydrodynamic interactions. In contrast, if ![]() $\epsilon =0$, the viscous stresses used to solve the macroscale problem are totally computed by the micro-representation, and it implicitly accounts for all stress contributions (hydro- and non-hydrodynamic) across scales. The balance between the origin of the Newtonian contribution to the stress, whether from macro- or microscales, can be controlled by the parameter

$\epsilon =0$, the viscous stresses used to solve the macroscale problem are totally computed by the micro-representation, and it implicitly accounts for all stress contributions (hydro- and non-hydrodynamic) across scales. The balance between the origin of the Newtonian contribution to the stress, whether from macro- or microscales, can be controlled by the parameter ![]() $\epsilon$. Traditionally, Newtonian contributions have only been modelled from macroscales (

$\epsilon$. Traditionally, Newtonian contributions have only been modelled from macroscales (![]() $\epsilon =1$) as in previous work by other researchers (Murashima & Taniguchi Reference Murashima and Taniguchi2010; Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016; Xu & Yu Reference Xu and Yu2016; Sato & Taniguchi Reference Sato and Taniguchi2017; Zhao et al. Reference Zhao, Li, Caswell, Ouyang and Karniadakis2018; Sato et al. Reference Sato, Harada and Taniguchi2019; Schieber & Hütter Reference Schieber and Hütter2020; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020; Morii & Kawakatsu Reference Morii and Kawakatsu2021). Microscopic simulations have generally been used to reproduce only the complex microstructural features without incorporating the Newtonian contributions. In contrast, our proposed framework uses the SDPD method at both scales, which consistently discretizes the Navier–Stokes equation. As a result, our method is theoretically capable of retrieving the ideal solvent stress contribution from microscales as well. Although this would not be needed for dispersed systems in Newtonian media undergoing affine deformations, it could be relevant in most complex cases considering non-Newtonian materials (Einarsson, Yang & Shaqfeh Reference Einarsson, Yang and Shaqfeh2018) or non-affine polymer deformations (Simavilla, Espanol & Ellero Reference Simavilla, Espanol and Ellero2023).

$\epsilon =1$) as in previous work by other researchers (Murashima & Taniguchi Reference Murashima and Taniguchi2010; Feng et al. Reference Feng, Andreev, Pilyugina and Schieber2016; Xu & Yu Reference Xu and Yu2016; Sato & Taniguchi Reference Sato and Taniguchi2017; Zhao et al. Reference Zhao, Li, Caswell, Ouyang and Karniadakis2018; Sato et al. Reference Sato, Harada and Taniguchi2019; Schieber & Hütter Reference Schieber and Hütter2020; Seryo et al. Reference Seryo, Sato, Molina and Taniguchi2020; Morii & Kawakatsu Reference Morii and Kawakatsu2021). Microscopic simulations have generally been used to reproduce only the complex microstructural features without incorporating the Newtonian contributions. In contrast, our proposed framework uses the SDPD method at both scales, which consistently discretizes the Navier–Stokes equation. As a result, our method is theoretically capable of retrieving the ideal solvent stress contribution from microscales as well. Although this would not be needed for dispersed systems in Newtonian media undergoing affine deformations, it could be relevant in most complex cases considering non-Newtonian materials (Einarsson, Yang & Shaqfeh Reference Einarsson, Yang and Shaqfeh2018) or non-affine polymer deformations (Simavilla, Espanol & Ellero Reference Simavilla, Espanol and Ellero2023).

A major limitation associated with using only microscopic simulations to determine both hydrodynamic and non-hydrodynamic contributions (![]() $\epsilon =0$) can be related to the numerical stability of the method. The computation of the stress involves spatial and temporal averaging over the microscopic realization, and the thermal fluctuations on the ideal stress can be amplified, leading to instability of the entire macro–micro scheme. Therefore, it seems reasonable to consider always a non-vanishing contribution of the Newtonian solvent in the macro description. In the results section, we compare the stability and accuracy of (2.3) for different values of

$\epsilon =0$) can be related to the numerical stability of the method. The computation of the stress involves spatial and temporal averaging over the microscopic realization, and the thermal fluctuations on the ideal stress can be amplified, leading to instability of the entire macro–micro scheme. Therefore, it seems reasonable to consider always a non-vanishing contribution of the Newtonian solvent in the macro description. In the results section, we compare the stability and accuracy of (2.3) for different values of ![]() $\epsilon$ for different simple and complex fluids. An additional feature of this macro–micro scheme is that it allows for further generalization of the framework to simulate microscopic stresses at arbitrary locations of the macro domain, whereas other regions are modelled using the standard Newtonian discretization. Given (2.2) and (2.3), we can now express

$\epsilon$ for different simple and complex fluids. An additional feature of this macro–micro scheme is that it allows for further generalization of the framework to simulate microscopic stresses at arbitrary locations of the macro domain, whereas other regions are modelled using the standard Newtonian discretization. Given (2.2) and (2.3), we can now express ![]() $\boldsymbol {\tau }$ in (2.1) as

$\boldsymbol {\tau }$ in (2.1) as

\begin{equation} \boldsymbol \tau

={-}p{\boldsymbol I} +

\left(\underbrace{\epsilon{\boldsymbol{\pi}_o}}_{\textit{macroscopic}}

+ \underbrace{\left[(1-\epsilon)\bar{\boldsymbol{\pi}}_h

+\bar{\boldsymbol{\pi}}_m +

\bar{\boldsymbol{\pi}}_k\right]}_{\textit{microscopic

}}\right). \end{equation}

\begin{equation} \boldsymbol \tau

={-}p{\boldsymbol I} +

\left(\underbrace{\epsilon{\boldsymbol{\pi}_o}}_{\textit{macroscopic}}

+ \underbrace{\left[(1-\epsilon)\bar{\boldsymbol{\pi}}_h

+\bar{\boldsymbol{\pi}}_m +

\bar{\boldsymbol{\pi}}_k\right]}_{\textit{microscopic

}}\right). \end{equation}

We remark that hydrodynamic contributions for non-Newtonian solvents combine both ideal and non-ideal interactions, ![]() $\langle \bar {\boldsymbol {\pi }}_h\rangle =\langle \bar {\boldsymbol {\pi }}_o\rangle +\langle \bar {\boldsymbol {\pi }}_h|_{{non\textrm {-}ideal}}\rangle$. Whereas the ideal effects are expected to occur in the fluid at all scales, the non-ideal interactions are only evident at microscales by the disruption of the flow field due to the presence of any microstructures. In Appendix B, we present a general LHMM description suitable for Newtonian and non-Newtonian macroscopic matrix descriptions. Here, we evaluate our LHMM scheme using (2.4). In § 2.4, we describe the methodology used to estimate the different components of these stresses. Considering the representation of fluid in a Lagrangian framework (Español & Revenga Reference Español and Revenga2003) and the previous decomposition (2.4), the divergence of the total stress in (2.1) takes the form

$\langle \bar {\boldsymbol {\pi }}_h\rangle =\langle \bar {\boldsymbol {\pi }}_o\rangle +\langle \bar {\boldsymbol {\pi }}_h|_{{non\textrm {-}ideal}}\rangle$. Whereas the ideal effects are expected to occur in the fluid at all scales, the non-ideal interactions are only evident at microscales by the disruption of the flow field due to the presence of any microstructures. In Appendix B, we present a general LHMM description suitable for Newtonian and non-Newtonian macroscopic matrix descriptions. Here, we evaluate our LHMM scheme using (2.4). In § 2.4, we describe the methodology used to estimate the different components of these stresses. Considering the representation of fluid in a Lagrangian framework (Español & Revenga Reference Español and Revenga2003) and the previous decomposition (2.4), the divergence of the total stress in (2.1) takes the form

where ![]() $D$ is the dimension, and

$D$ is the dimension, and ![]() ${\eta }$ and

${\eta }$ and ![]() ${\zeta }$ are the shear and bulk viscosities, respectively. It is worth noting that although the continuity equation assumes exact incompressibility, the SDPD and SPH models adopted in this work are based on a standard quasi-incompressible approach where the artificial sound speed is tuned to keep compressibility effects below a few percent. As a results, compressible terms in the continuity and momentum equations are considered whereas the magnitude of the bulk viscosity is chosen to remove the velocity divergence formally from the momentum equation. Previous studies have also discussed the importance of these numerical aspects in SDPD discretizations (Colagrossi et al. Reference Colagrossi, Durante, Avalos and Souto-Iglesias2017).

${\zeta }$ are the shear and bulk viscosities, respectively. It is worth noting that although the continuity equation assumes exact incompressibility, the SDPD and SPH models adopted in this work are based on a standard quasi-incompressible approach where the artificial sound speed is tuned to keep compressibility effects below a few percent. As a results, compressible terms in the continuity and momentum equations are considered whereas the magnitude of the bulk viscosity is chosen to remove the velocity divergence formally from the momentum equation. Previous studies have also discussed the importance of these numerical aspects in SDPD discretizations (Colagrossi et al. Reference Colagrossi, Durante, Avalos and Souto-Iglesias2017).

In general, since we aim to incorporate hydrodynamics interactions of the fluid in both scales, a critical requirement for the microscales solver is the capability to model both simple and complex fluids. Here, we model both macro- and microscales using SDPD, discretizing the fluctuating momentum equation as a set of ![]() $N$ interacting particles with position

$N$ interacting particles with position ![]() ${\boldsymbol r}_i$ and velocity

${\boldsymbol r}_i$ and velocity ![]() ${\boldsymbol {v}}_i$. The system is constituted by particles with a volume

${\boldsymbol {v}}_i$. The system is constituted by particles with a volume ![]() $\mathcal {V}_i$, such that

$\mathcal {V}_i$, such that ![]() ${1}/{\mathcal {V}_i} = d_i = \sum _j W(r_{ij},h)$, with

${1}/{\mathcal {V}_i} = d_i = \sum _j W(r_{ij},h)$, with ![]() $d_i$ being the number density of particles,

$d_i$ being the number density of particles, ![]() $r_{ij} = |{\boldsymbol r}_i-{\boldsymbol r}_j|$, and

$r_{ij} = |{\boldsymbol r}_i-{\boldsymbol r}_j|$, and ![]() $W(r_{ij},h)$ an interpolant kernel with finite support

$W(r_{ij},h)$ an interpolant kernel with finite support ![]() $h$ and normalized to one. Additionally, to discretize the balance equations, a positive function

$h$ and normalized to one. Additionally, to discretize the balance equations, a positive function ![]() $F_{ij}$ is introduced such that

$F_{ij}$ is introduced such that ![]() $F_{ij} = -\boldsymbol {\nabla } W(r_{ij},h)/r_{ij}$, where the gradient of the kernel function is expressed as

$F_{ij} = -\boldsymbol {\nabla } W(r_{ij},h)/r_{ij}$, where the gradient of the kernel function is expressed as ![]() $\boldsymbol {\nabla } W(r_{ij},h) = \partial W(r_{ij},h) / \partial r_{ij} \ \boldsymbol {e}_{ij}$. From now, when describing each scale, we identify the discrete particles at microscales with the subindices

$\boldsymbol {\nabla } W(r_{ij},h) = \partial W(r_{ij},h) / \partial r_{ij} \ \boldsymbol {e}_{ij}$. From now, when describing each scale, we identify the discrete particles at microscales with the subindices ![]() $i$ and

$i$ and ![]() $j$, whereas those at macroscales with

$j$, whereas those at macroscales with ![]() $I$ and

$I$ and ![]() $J$.

$J$.

For the interpolant function at both scales, we adopt the Lucy kernel (Español & Revenga Reference Español and Revenga2003) typically used in SPH and SDPD:

\begin{equation} W(r) = \begin{cases} \dfrac{w_0}{h^D}\left(1+\dfrac{3r}{h}\right)\left(1-\dfrac{r}{h}\right)^3, & r/h<1,\\ 0, & r/h>1, \end{cases} \end{equation}

\begin{equation} W(r) = \begin{cases} \dfrac{w_0}{h^D}\left(1+\dfrac{3r}{h}\right)\left(1-\dfrac{r}{h}\right)^3, & r/h<1,\\ 0, & r/h>1, \end{cases} \end{equation}

where ![]() $w_0=5/{\rm \pi}$ or

$w_0=5/{\rm \pi}$ or ![]() $w_0=105/16{\rm \pi}$ for two or three dimensions, respectively.

$w_0=105/16{\rm \pi}$ for two or three dimensions, respectively.

2.2. Macroscales

At the macroscales, when the volume ![]() ${\mathcal {V}}_I$ of the discretizing particle approach continuum scales and thermal fluctuations are negligible, SDPD is equivalent to the smoothed particle hydrodynamics method (Vázquez-Quesada et al. Reference Vázquez-Quesada, Ellero and Español2009). For this scale, the geometry and type of flow prescribe the boundary condition at

${\mathcal {V}}_I$ of the discretizing particle approach continuum scales and thermal fluctuations are negligible, SDPD is equivalent to the smoothed particle hydrodynamics method (Vázquez-Quesada et al. Reference Vázquez-Quesada, Ellero and Español2009). For this scale, the geometry and type of flow prescribe the boundary condition at ![]() $\partial \varOmega$. The SDPD discretized equations for (2.1), describing the particle's position, density and momentum for a fluid without external forces, are expressed as (Español & Revenga Reference Español and Revenga2003)

$\partial \varOmega$. The SDPD discretized equations for (2.1), describing the particle's position, density and momentum for a fluid without external forces, are expressed as (Español & Revenga Reference Español and Revenga2003)

where ![]() ${\boldsymbol {r}}_{IJ} = {\boldsymbol r}_I - {\boldsymbol r}_J$,

${\boldsymbol {r}}_{IJ} = {\boldsymbol r}_I - {\boldsymbol r}_J$, ![]() ${\boldsymbol {v}}_{IJ} = {\boldsymbol {v}}_I - {\boldsymbol {v}}_J$ and

${\boldsymbol {v}}_{IJ} = {\boldsymbol {v}}_I - {\boldsymbol {v}}_J$ and ![]() ${\boldsymbol e}_{IJ}= {\boldsymbol {r}}_{IJ}/{r}_{IJ}$. In (2.8),

${\boldsymbol e}_{IJ}= {\boldsymbol {r}}_{IJ}/{r}_{IJ}$. In (2.8), ![]() ${F}_{IJ}$ is expressed in terms of the macroscales indicating its correspondence with a interpolation kernel with finite support

${F}_{IJ}$ is expressed in terms of the macroscales indicating its correspondence with a interpolation kernel with finite support ![]() $\bar {h}$. Additionally,

$\bar {h}$. Additionally, ![]() $a$ and

$a$ and ![]() $b$ are friction coefficients related to the shear

$b$ are friction coefficients related to the shear ![]() ${\eta }$ and bulk

${\eta }$ and bulk ![]() ${\zeta }$ viscosities of the fluid through

${\zeta }$ viscosities of the fluid through ![]() $a={(D+2){\eta }}/{D}-{\zeta }$ and

$a={(D+2){\eta }}/{D}-{\zeta }$ and ![]() $b = (D+2)({\zeta }+{\eta }/{D})$ (for

$b = (D+2)({\zeta }+{\eta }/{D})$ (for ![]() $D=2,3$).

$D=2,3$).

The term ![]() ${p}$ is the density-dependent pressure. We adopt the Tait equation of state, given by

${p}$ is the density-dependent pressure. We adopt the Tait equation of state, given by ![]() $p_i = {c^2\rho _0}/{7}[ ({\rho _i}/{\rho _0})^{7}-1]+p_b$, where

$p_i = {c^2\rho _0}/{7}[ ({\rho _i}/{\rho _0})^{7}-1]+p_b$, where ![]() $c$ is the speed of sound on the fluid and

$c$ is the speed of sound on the fluid and ![]() $\rho _0$ is the reference density. The term

$\rho _0$ is the reference density. The term ![]() $c^2\rho _0/7$ corresponds to the reference pressure of the system, given by

$c^2\rho _0/7$ corresponds to the reference pressure of the system, given by ![]() $c^2 = \partial p/ \partial \rho |_{\rho =\rho _0}$. The parameter

$c^2 = \partial p/ \partial \rho |_{\rho =\rho _0}$. The parameter ![]() $p_b$ is a background pressure that provides numerical stability by keeping the pressure of the system always positive.

$p_b$ is a background pressure that provides numerical stability by keeping the pressure of the system always positive.

The microscopically informed tensor ![]() $\bar {\boldsymbol {\pi }}_{IJ}$ is given by

$\bar {\boldsymbol {\pi }}_{IJ}$ is given by

The terms ![]() $(\bar {\boldsymbol {\pi }}_{I})_h$,

$(\bar {\boldsymbol {\pi }}_{I})_h$, ![]() $(\bar {\boldsymbol {\pi }}_{I})_m$ and

$(\bar {\boldsymbol {\pi }}_{I})_m$ and ![]() $(\bar {\boldsymbol {\pi }}_{I})_k$ are obtained from the microscale. Their representation is detailed in § 2.4.

$(\bar {\boldsymbol {\pi }}_{I})_k$ are obtained from the microscale. Their representation is detailed in § 2.4.

2.3. Microscales

At microscales, the SDPD (Ellero & Español Reference Ellero and Español2018) equations contain both deterministic and stochastic contributions. The later accounts consistently for thermal fluctuations. The balance equations are then given by

where ![]() ${\boldsymbol {v}}'_{ij} = {\boldsymbol {v}}'_i - {\boldsymbol {v}}'_j$, and

${\boldsymbol {v}}'_{ij} = {\boldsymbol {v}}'_i - {\boldsymbol {v}}'_j$, and ![]() $a'$ and

$a'$ and ![]() $b'$ are friction coefficients related to the shear

$b'$ are friction coefficients related to the shear ![]() $\eta$ and bulk

$\eta$ and bulk ![]() $\zeta$ viscosities of the fluid through

$\zeta$ viscosities of the fluid through ![]() $a'={(D+2)\eta }/{D}-\zeta$ and

$a'={(D+2)\eta }/{D}-\zeta$ and ![]() $b' = (D+2)(\zeta +{\eta }/{D})$. Thermal fluctuations are consistently incorporated into the model through the stochastic contributions to the momentum equation by (2.12). Here,

$b' = (D+2)(\zeta +{\eta }/{D})$. Thermal fluctuations are consistently incorporated into the model through the stochastic contributions to the momentum equation by (2.12). Here, ![]() ${\boldsymbol {W}}_{ij}$ is a matrix of independent increments of a Wiener process for each pair

${\boldsymbol {W}}_{ij}$ is a matrix of independent increments of a Wiener process for each pair ![]() $i,j$ of particles and

$i,j$ of particles and ![]() ${\boldsymbol {\tilde {W}}}_{ij}$ is its traceless symmetric part, given by

${\boldsymbol {\tilde {W}}}_{ij}$ is its traceless symmetric part, given by

where the independent increments of the Wiener processes satisfy

To satisfy the fluctuation–dissipation balance, the amplitude of the thermal noises ![]() $A_{ij}$ and

$A_{ij}$ and ![]() $B_{ij}$ are related to the friction coefficients

$B_{ij}$ are related to the friction coefficients ![]() $a'$ and

$a'$ and ![]() $b'$ through

$b'$ through

$$\begin{gather} A_{ij} = \left[4k_BT a' \frac{{F}_{ij}'}{d_i d_j} \right]^{1/2}, \end{gather}$$

$$\begin{gather} A_{ij} = \left[4k_BT a' \frac{{F}_{ij}'}{d_i d_j} \right]^{1/2}, \end{gather}$$ $$\begin{gather}B_{ij} = \left[4k_BT\left(b' -a'\frac{D-2}{D}\right)\frac{{F}_{ij}'}{d_i d_j} \right]^{1/2}. \end{gather}$$

$$\begin{gather}B_{ij} = \left[4k_BT\left(b' -a'\frac{D-2}{D}\right)\frac{{F}_{ij}'}{d_i d_j} \right]^{1/2}. \end{gather}$$

We remark that in (2.12), the prime notation for the ![]() $A_{ij}$ and

$A_{ij}$ and ![]() $B_{ij}$ is omitted since thermal fluctuations are only accounted for microscales. The selection of these amplitudes in (2.15) and (2.16) for the noise terms, in the context of the fluctuation–dissipation theorem, leads to a dissipation which is exactly the same as that in the macroscopic discretization of SDPD. Furthermore, (2.15) and (2.16) ensure that the stochastic differential equation (2.11) produces a variables distribution in accordance with the Einstein distribution function and follows the GENERIC structure. For a detailed derivation of SDPD, the reader is referred to the work of Español & Revenga (Reference Español and Revenga2003).

$B_{ij}$ is omitted since thermal fluctuations are only accounted for microscales. The selection of these amplitudes in (2.15) and (2.16) for the noise terms, in the context of the fluctuation–dissipation theorem, leads to a dissipation which is exactly the same as that in the macroscopic discretization of SDPD. Furthermore, (2.15) and (2.16) ensure that the stochastic differential equation (2.11) produces a variables distribution in accordance with the Einstein distribution function and follows the GENERIC structure. For a detailed derivation of SDPD, the reader is referred to the work of Español & Revenga (Reference Español and Revenga2003).

At microscales, smoothed dissipative particle dynamics has been used to model complex fluids such as polymer or colloids (Ellero et al. Reference Ellero, Español and Flekkoy2003; Vázquez-Quesada et al. Reference Vázquez-Quesada, Ellero and Español2009; Moreno & Ellero Reference Moreno and Ellero2021; Simavilla & Ellero Reference Simavilla and Ellero2022) by using additional potentials (Litvinov et al. Reference Litvinov, Ellero, Hu and Adams2008) or constructing colloidal objects with adequate interaction potentials with the surrounding fluid (Vázquez-Quesada et al. Reference Vázquez-Quesada, Ellero and Español2009; Bian et al. Reference Bian, Litvinov, Qian, Ellero and Adams2012). Using this approach, (2.11) can be further enlarged to explicitly account for contributions due to connectivity potentials (i.e. FENE Litvinov et al. Reference Litvinov, Ellero, Hu and Adams2008), colloid–solvent interactions (Bian et al. Reference Bian, Litvinov, Qian, Ellero and Adams2012), colloid–colloid interactions (Vázquez-Quesada et al. Reference Vázquez-Quesada, Ellero and Español2009), blood flow (Moreno et al. Reference Moreno, Vignal, Li and Calo2013; Müller et al. Reference Müller, Fedosov and Gompper2014; Ye et al. Reference Ye, Shi, Phan-Thien and Lim2020), phase separation (Lei et al. Reference Lei, Baker, Wu, Schenter, Mundy and Tartakovsky2016) and coffee extraction (Mo et al. Reference Mo, Johnston, Navarini and Ellero2021).

2.4. Coupling

In the proposed LHMM, the transfer of information macro-to-micro occurs through the velocity field of the macroscales, ![]() ${\boldsymbol {v}}$, that defines the boundary conditions of the microscale subsystems. However, the micro-to-macro transfer occurs via the stress tensor,

${\boldsymbol {v}}$, that defines the boundary conditions of the microscale subsystems. However, the micro-to-macro transfer occurs via the stress tensor, ![]() $\bar {\boldsymbol {\pi }}$. If

$\bar {\boldsymbol {\pi }}$. If ![]() $\mathcal {N}$ denotes the number of microscopic subsystems generated to compute microscale-informed stresses, here we consider the most general case,

$\mathcal {N}$ denotes the number of microscopic subsystems generated to compute microscale-informed stresses, here we consider the most general case, ![]() $\mathcal {N} = \bar {N}$, such that one microscopic simulation is generated per each macroscopic particle. Of course, microscopic simulations contain a large number of microscopic degrees of freedom (e.g. polymers, colloids, droplets) on which the mean average is referred. In general, the total number of degrees of freedom (particles) required to describe a system using LHMM decreases compared with a fully resolved microscopic system when the length scale separation between scales increases (i.e. towards a continuum representation of the fluid), which offers significant advantages from a computational standpoint. In § 2.5, we further discuss those computational aspects. We present the general stages of the coupling in figure 2 and Algorithm 1 in Appendix A. The coupling strategy is accomplished in two alternating stages: (i) macro-to-micro and (ii) micro-to-macro. In the first stage, the velocity gradient at the macroscale is computed and used to prescribe the boundary conditions at the microscale. Microscale simulations are then conducted using (2.10) and (2.11). In the second stage, the ensemble and time average of the stress for each microscopic simulations is computed and passed to the macroscopic particles to solve (2.7) and (2.8). After updating positions and velocities of the macroscale particles, another coupling loop is started

$\mathcal {N} = \bar {N}$, such that one microscopic simulation is generated per each macroscopic particle. Of course, microscopic simulations contain a large number of microscopic degrees of freedom (e.g. polymers, colloids, droplets) on which the mean average is referred. In general, the total number of degrees of freedom (particles) required to describe a system using LHMM decreases compared with a fully resolved microscopic system when the length scale separation between scales increases (i.e. towards a continuum representation of the fluid), which offers significant advantages from a computational standpoint. In § 2.5, we further discuss those computational aspects. We present the general stages of the coupling in figure 2 and Algorithm 1 in Appendix A. The coupling strategy is accomplished in two alternating stages: (i) macro-to-micro and (ii) micro-to-macro. In the first stage, the velocity gradient at the macroscale is computed and used to prescribe the boundary conditions at the microscale. Microscale simulations are then conducted using (2.10) and (2.11). In the second stage, the ensemble and time average of the stress for each microscopic simulations is computed and passed to the macroscopic particles to solve (2.7) and (2.8). After updating positions and velocities of the macroscale particles, another coupling loop is started

Figure 2. (a) Schematic representation of the fully Lagrangian heterogeneous multiscale method proposed. (b) Algorithm and (c) parallelization.

2.4.1. Macro-to-micro

At the microscale, we use a generalized boundary condition scheme recently proposed (Moreno & Ellero Reference Moreno and Ellero2021) to non-trivial velocity fields (i.e. mixed shear and extensional) in periodic domains. We decompose the microscopic simulation domain in three regions: buffer, boundary condition (![]() $\varOmega _{bc}'$) and core (

$\varOmega _{bc}'$) and core (![]() $\varOmega '$), as shown in figure 2. The properties of the fluid, such as the stress tensor, are evaluated from the core region. In the boundary-condition region, the velocity of the particles is prescribed from a macroscopic velocity field

$\varOmega '$), as shown in figure 2. The properties of the fluid, such as the stress tensor, are evaluated from the core region. In the boundary-condition region, the velocity of the particles is prescribed from a macroscopic velocity field ![]() ${\boldsymbol {v}}$. The system is further stabilized and periodic boundary conditions are adopted owing to the buffer region. A detailed description of this domain decomposition approach can be found from Moreno & Ellero (Reference Moreno and Ellero2021). To reconstruct the velocity field

${\boldsymbol {v}}$. The system is further stabilized and periodic boundary conditions are adopted owing to the buffer region. A detailed description of this domain decomposition approach can be found from Moreno & Ellero (Reference Moreno and Ellero2021). To reconstruct the velocity field ![]() ${\boldsymbol {v}}$ at boundary regions

${\boldsymbol {v}}$ at boundary regions ![]() $\varOmega _{bc}'$, we use the velocity gradient

$\varOmega _{bc}'$, we use the velocity gradient ![]() $\boldsymbol {\nabla } {\boldsymbol {v}}_I$ at the macroscale

$\boldsymbol {\nabla } {\boldsymbol {v}}_I$ at the macroscale ![]() $I$th particle position. The macroscopic

$I$th particle position. The macroscopic ![]() $\boldsymbol {\nabla } {\boldsymbol {v}}_I$ can be approximated using the SDPD interpolation kernel, such that

$\boldsymbol {\nabla } {\boldsymbol {v}}_I$ can be approximated using the SDPD interpolation kernel, such that

This first-order approximation allows us to compute velocity gradients with a minimal computational cost during the macroscopic force calculation stage. In the results section, we validate the use of this approach. Other high-order alternatives to compute ![]() $\boldsymbol {\nabla } {\boldsymbol {v}}_I$ are also possible. However, it would require an additional spatial interpolation step (Zhang & Batra Reference Zhang and Batra2004). Using (2.17), the velocity

$\boldsymbol {\nabla } {\boldsymbol {v}}_I$ are also possible. However, it would require an additional spatial interpolation step (Zhang & Batra Reference Zhang and Batra2004). Using (2.17), the velocity ![]() ${\boldsymbol {v}}'_i$ of the microscale particles located at the boundary-condition region is then determined by

${\boldsymbol {v}}'_i$ of the microscale particles located at the boundary-condition region is then determined by

where the macroscopic velocity field is linearly interpolated taking the macroscopic particle centred at the origin of the box (see figure 2). The extent of the microscopic subsystems is given by the characteristic length ![]() $\varOmega '$. In general, we consider that all microscopic subsystems have the same size

$\varOmega '$. In general, we consider that all microscopic subsystems have the same size ![]() $\varOmega '$, however, different sizes can be used if the specific features of the flow require it.

$\varOmega '$, however, different sizes can be used if the specific features of the flow require it.

2.4.2. Micro-to-macro

Given a macroscopic particle ![]() $I$, we determined its stress tensor,

$I$, we determined its stress tensor, ![]() $\bar {\boldsymbol {\pi }}_I$, from the microscales. Here, we adopt the Irving–Kirkwood (IK) methodology (Yang, Wu & Li Reference Yang, Wu and Li2012) such that the stress is given by

$\bar {\boldsymbol {\pi }}_I$, from the microscales. Here, we adopt the Irving–Kirkwood (IK) methodology (Yang, Wu & Li Reference Yang, Wu and Li2012) such that the stress is given by ![]() $\bar {\boldsymbol {\pi }}_I({\boldsymbol x'};t) = \bar {\boldsymbol {\pi }}_I^K ({\boldsymbol x'};t) + \bar {\boldsymbol {\pi }}_I^P ({\boldsymbol x'};t)$, where

$\bar {\boldsymbol {\pi }}_I({\boldsymbol x'};t) = \bar {\boldsymbol {\pi }}_I^K ({\boldsymbol x'};t) + \bar {\boldsymbol {\pi }}_I^P ({\boldsymbol x'};t)$, where ![]() $\bar {\boldsymbol {\pi }}_I^K ({\boldsymbol x'};t)$ and

$\bar {\boldsymbol {\pi }}_I^K ({\boldsymbol x'};t)$ and ![]() $\bar {\boldsymbol {\pi }}_I^P ({\boldsymbol x'};t)$ account for kinetic and potential contributions to the stress tensor, respectively. This potential contribution contains both hydrodynamic and non-hydrodynamic terms. We use the weighting function

$\bar {\boldsymbol {\pi }}_I^P ({\boldsymbol x'};t)$ account for kinetic and potential contributions to the stress tensor, respectively. This potential contribution contains both hydrodynamic and non-hydrodynamic terms. We use the weighting function ![]() $w_{IK}({\boldsymbol r'},{\boldsymbol x'})$ for the spatial averaging, whereas time averaging is conducted over a range on

$w_{IK}({\boldsymbol r'},{\boldsymbol x'})$ for the spatial averaging, whereas time averaging is conducted over a range on ![]() $N_t'$ microscopic time steps. Transient simulations require careful consideration of the desired level of accuracy. Ensemble averaging alone can lead to a high noise-to-signal ratio, producing spurious fluctuations in the macroscopic system. While running replicates of the microscale simulations can improve ensemble measurement, this incurs a significant overhead, making it impractical for use in the LHMM. To accurately estimate the stress, the IK approach requires spatial and temporal averaging. We propose a simple approximation of the measured stress at the end of the microscopic interval using the computed running average of the stress during that interval, which suffices if the stress magnitude does not significantly change during that interval. For a more precise estimation of the transient stress, a denoising stage can be performed at the end of each coupling loop (Zimmerman, Jones & Templeton Reference Zimmerman, Jones and Templeton2010; Zimon, Reese & Emerson Reference Zimon, Reese and Emerson2016). This involves smoothing and interpolating the measured signal within the interval of the microscopic simulation, followed by using the interpolated approximation to calculate the expected stress at the end of the microscale interval. This approach is particularly useful for systems where larger macroscopic time steps are desired or if the measured stress during the macroscopic interval can exhibit an overshoot.

$N_t'$ microscopic time steps. Transient simulations require careful consideration of the desired level of accuracy. Ensemble averaging alone can lead to a high noise-to-signal ratio, producing spurious fluctuations in the macroscopic system. While running replicates of the microscale simulations can improve ensemble measurement, this incurs a significant overhead, making it impractical for use in the LHMM. To accurately estimate the stress, the IK approach requires spatial and temporal averaging. We propose a simple approximation of the measured stress at the end of the microscopic interval using the computed running average of the stress during that interval, which suffices if the stress magnitude does not significantly change during that interval. For a more precise estimation of the transient stress, a denoising stage can be performed at the end of each coupling loop (Zimmerman, Jones & Templeton Reference Zimmerman, Jones and Templeton2010; Zimon, Reese & Emerson Reference Zimon, Reese and Emerson2016). This involves smoothing and interpolating the measured signal within the interval of the microscopic simulation, followed by using the interpolated approximation to calculate the expected stress at the end of the microscale interval. This approach is particularly useful for systems where larger macroscopic time steps are desired or if the measured stress during the macroscopic interval can exhibit an overshoot.

The kinetic part is then given by (Tadmor & Miller Reference Tadmor and Miller2011)

\begin{equation} \bar{\boldsymbol{\pi}}_I^K ({\boldsymbol x};t) ={-}\frac{1}{N_t'}\sum_{n=1}^{N_t'} \left[ \sum_{i} m_i \, w_{IK}({\boldsymbol r}_i(n)-{\boldsymbol x}){\vartriangle {\boldsymbol{v}}'_i(n)}\otimes {\vartriangle {\boldsymbol{v}}'_i(n)} \right], \end{equation}

\begin{equation} \bar{\boldsymbol{\pi}}_I^K ({\boldsymbol x};t) ={-}\frac{1}{N_t'}\sum_{n=1}^{N_t'} \left[ \sum_{i} m_i \, w_{IK}({\boldsymbol r}_i(n)-{\boldsymbol x}){\vartriangle {\boldsymbol{v}}'_i(n)}\otimes {\vartriangle {\boldsymbol{v}}'_i(n)} \right], \end{equation}

where ![]() $\vartriangle {\boldsymbol {v}}'_i(n) = {\boldsymbol {v}}'_i - \langle {\boldsymbol {v}}' ({\boldsymbol r}_i;n) \rangle$ is the relative velocity of the particle

$\vartriangle {\boldsymbol {v}}'_i(n) = {\boldsymbol {v}}'_i - \langle {\boldsymbol {v}}' ({\boldsymbol r}_i;n) \rangle$ is the relative velocity of the particle ![]() $i$ at time step

$i$ at time step ![]() $n$. In the IK approach, if

$n$. In the IK approach, if ![]() $\varphi _{ij}$ is the magnitude of the force between particles

$\varphi _{ij}$ is the magnitude of the force between particles ![]() $i$ and

$i$ and ![]() $j$, it is considered that the force term can be expressed in central force decomposition as

$j$, it is considered that the force term can be expressed in central force decomposition as

With this, the potential part of the stress tensor reads

\begin{equation} \bar{\boldsymbol{\pi}}_I^P ({\boldsymbol x},t) = \frac{1}{2N_t'}\sum_{n=1}^{N_t'} \left[\sum_{\substack{i,j \\ i\neq j}} {\boldsymbol f}_{ij}(n) \otimes {\boldsymbol r}_{ij}(n) \, \mathcal{B}({\boldsymbol x};{\boldsymbol r}_i(n),{\boldsymbol r}_j(n)) \right] ,\end{equation}

\begin{equation} \bar{\boldsymbol{\pi}}_I^P ({\boldsymbol x},t) = \frac{1}{2N_t'}\sum_{n=1}^{N_t'} \left[\sum_{\substack{i,j \\ i\neq j}} {\boldsymbol f}_{ij}(n) \otimes {\boldsymbol r}_{ij}(n) \, \mathcal{B}({\boldsymbol x};{\boldsymbol r}_i(n),{\boldsymbol r}_j(n)) \right] ,\end{equation}

where ![]() $\mathcal {B}({\boldsymbol x};{\boldsymbol r}_i(n),{\boldsymbol r}_j(n))$ is a bond function given by

$\mathcal {B}({\boldsymbol x};{\boldsymbol r}_i(n),{\boldsymbol r}_j(n))$ is a bond function given by ![]() $\mathcal {B}({\boldsymbol x; u,v}) = \int _{s=0}^1 w_{IK} ((1-s){\boldsymbol u}+s {\boldsymbol v}-\boldsymbol {x} ) \,\textrm {d} s$. The bond function is the integrated weight of the bond for a weighting function centred at

$\mathcal {B}({\boldsymbol x; u,v}) = \int _{s=0}^1 w_{IK} ((1-s){\boldsymbol u}+s {\boldsymbol v}-\boldsymbol {x} ) \,\textrm {d} s$. The bond function is the integrated weight of the bond for a weighting function centred at ![]() $\boldsymbol x$. If the weighting function

$\boldsymbol x$. If the weighting function ![]() $w_{IK}(\kern1pt \boldsymbol{y}-{\boldsymbol x})$ is taken as constant within a domain

$w_{IK}(\kern1pt \boldsymbol{y}-{\boldsymbol x})$ is taken as constant within a domain ![]() $\varOmega _a$ and zero elsewhere,

$\varOmega _a$ and zero elsewhere, ![]() $w_{IK} = 1/\textrm {Vol}(\varOmega _a)$ if

$w_{IK} = 1/\textrm {Vol}(\varOmega _a)$ if ![]() ${\boldsymbol y} \in \varOmega _a$. If additionally, the bond function

${\boldsymbol y} \in \varOmega _a$. If additionally, the bond function ![]() $\mathcal {B}$ is calculated only with bonds fully contained in

$\mathcal {B}$ is calculated only with bonds fully contained in ![]() $\varOmega _a$, we would have

$\varOmega _a$, we would have ![]() $\mathcal {B}({\boldsymbol x};{\boldsymbol r}_i,{\boldsymbol r}_j) = 1/\textrm {Vol}(\varOmega _a)$ for

$\mathcal {B}({\boldsymbol x};{\boldsymbol r}_i,{\boldsymbol r}_j) = 1/\textrm {Vol}(\varOmega _a)$ for ![]() $i-j \in \varOmega _a$. For more detailed descriptions and extended validation benchmarks, we refer the reader to the work of Moreno & Ellero (Reference Moreno and Ellero2021).

$i-j \in \varOmega _a$. For more detailed descriptions and extended validation benchmarks, we refer the reader to the work of Moreno & Ellero (Reference Moreno and Ellero2021).

2.4.3. Time stepping

A critical aspect of heterogeneous multiscale methods is the time-stepping approach used to send information between scales (Ee, Ren & Vanden-Eijnden Reference Ee, Ren and Vanden-Eijnden2009; Lockerby et al. Reference Lockerby, Duque-Daza, Borg and Reese2013). From macroscales, we consider the time step is given by ![]() $\Delta {t}$, whereas the overall time scale

$\Delta {t}$, whereas the overall time scale ![]() $\lambda _{MM}$ of the system investigated is related to the operative conditions, such as the shear rate,

$\lambda _{MM}$ of the system investigated is related to the operative conditions, such as the shear rate, ![]() $\dot {\gamma }$. Thus, macroscopic scales define the extent of the overall simulations, requiring a minimum of

$\dot {\gamma }$. Thus, macroscopic scales define the extent of the overall simulations, requiring a minimum of ![]() $m$ steps (

$m$ steps (![]() $\lambda _{MM} = m\Delta {t}$). The time-stepping approach depends on the time-scale separation between macro- and microsystems. If we denote the characteristic relaxation time for each scale as

$\lambda _{MM} = m\Delta {t}$). The time-stepping approach depends on the time-scale separation between macro- and microsystems. If we denote the characteristic relaxation time for each scale as ![]() $\lambda$, systems with large time scale separation satisfy

$\lambda$, systems with large time scale separation satisfy ![]() ${\lambda }' \ll {\lambda }$, whereas for highly coupled scales,

${\lambda }' \ll {\lambda }$, whereas for highly coupled scales, ![]() ${\lambda }' \approx {\lambda }$. From microscales, the time step

${\lambda }' \approx {\lambda }$. From microscales, the time step ![]() $\Delta {t}'$ sets the condition to accurately resolve the stress evolution of the system. The relaxation of the microscales requires a minimal number of time steps

$\Delta {t}'$ sets the condition to accurately resolve the stress evolution of the system. The relaxation of the microscales requires a minimal number of time steps ![]() $n$, such that

$n$, such that ![]() ${\lambda }' = n \Delta {t}'$. In practice, microscopic simulations would use

${\lambda }' = n \Delta {t}'$. In practice, microscopic simulations would use ![]() $n$ large enough (

$n$ large enough (![]() ${\lambda }' < n \Delta {t}'$) to ensure the proper stabilization of the system and to reduce the noise-to-signal ratio.

${\lambda }' < n \Delta {t}'$) to ensure the proper stabilization of the system and to reduce the noise-to-signal ratio.

In multiscale methods, the relaxation time of the macro- and microsystems determines the ratio ![]() $\Delta {t}/ \Delta {t}'$. As the limit condition for the highest temporal resolution, we can consider the case of

$\Delta {t}/ \Delta {t}'$. As the limit condition for the highest temporal resolution, we can consider the case of ![]() $\Delta {t}/ \Delta {t}' = 1$. However, in practice, this would not correspond to a temporal multiscale method, but a fully microscopic description of the system. In those cases, the gain in performance for using HMM comes only from the spatial upscaling of the stress. Existent LL schemes (Yasuda & Yamamoto Reference Yasuda and Yamamoto2014; Sato & Taniguchi Reference Sato and Taniguchi2017; Sato et al. Reference Sato, Harada and Taniguchi2019) that use time steps in the same order for macro- and microsolvers are limited to problems with microscale temporal resolutions. Otherwise, in the case of stochastic microscale simulations (Morii & Kawakatsu Reference Morii and Kawakatsu2021), equilibration of the microscales is assumed through mean-field approximations. Due to these practical restrictions, different time-stepping approaches have been recently investigated (Ee et al. Reference Ee, Ren and Vanden-Eijnden2009; Lockerby et al. Reference Lockerby, Duque-Daza, Borg and Reese2013) to increase the temporal gain in HMMs and reach macroscopic time scales. Depending on the order of magnitude of

$\Delta {t}/ \Delta {t}' = 1$. However, in practice, this would not correspond to a temporal multiscale method, but a fully microscopic description of the system. In those cases, the gain in performance for using HMM comes only from the spatial upscaling of the stress. Existent LL schemes (Yasuda & Yamamoto Reference Yasuda and Yamamoto2014; Sato & Taniguchi Reference Sato and Taniguchi2017; Sato et al. Reference Sato, Harada and Taniguchi2019) that use time steps in the same order for macro- and microsolvers are limited to problems with microscale temporal resolutions. Otherwise, in the case of stochastic microscale simulations (Morii & Kawakatsu Reference Morii and Kawakatsu2021), equilibration of the microscales is assumed through mean-field approximations. Due to these practical restrictions, different time-stepping approaches have been recently investigated (Ee et al. Reference Ee, Ren and Vanden-Eijnden2009; Lockerby et al. Reference Lockerby, Duque-Daza, Borg and Reese2013) to increase the temporal gain in HMMs and reach macroscopic time scales. Depending on the order of magnitude of ![]() $\Delta {t}/ \Delta {t}'$, different time-stepping schemes can be used. In figure 3, we illustrate the basic sequence of time stepping: (a) scattering

$\Delta {t}/ \Delta {t}'$, different time-stepping schemes can be used. In figure 3, we illustrate the basic sequence of time stepping: (a) scattering ![]() $\boldsymbol {\nabla } {\boldsymbol {v}}_I$ on individual microscopic solvers; (b) solving microscales under arbitrary BC; (c) gathering

$\boldsymbol {\nabla } {\boldsymbol {v}}_I$ on individual microscopic solvers; (b) solving microscales under arbitrary BC; (c) gathering ![]() $\bar {\boldsymbol {\pi }}_I$ for macroscales; and (d) solving macroscales. The simplest time-stepping, typically referred as continuous coupling between scales (see figure 3), considers that microsolvers are evolved during

$\bar {\boldsymbol {\pi }}_I$ for macroscales; and (d) solving macroscales. The simplest time-stepping, typically referred as continuous coupling between scales (see figure 3), considers that microsolvers are evolved during ![]() $n\Delta {t}'$, whereas the time integration at macroscale occurs at

$n\Delta {t}'$, whereas the time integration at macroscale occurs at ![]() $\Delta {t} = n\Delta {t}'$. An alternative to achieve both spatial and temporal gain when using our LL schemes is the heterogeneous-coupling time stepping (Lockerby et al. Reference Lockerby, Duque-Daza, Borg and Reese2013) (as known as time burst), as presented in figure 3. In time-burst approaches, the macroscales are evolved using

$\Delta {t} = n\Delta {t}'$. An alternative to achieve both spatial and temporal gain when using our LL schemes is the heterogeneous-coupling time stepping (Lockerby et al. Reference Lockerby, Duque-Daza, Borg and Reese2013) (as known as time burst), as presented in figure 3. In time-burst approaches, the macroscales are evolved using ![]() $\Delta {t} = m \Delta {t}'$, where

$\Delta {t} = m \Delta {t}'$, where ![]() $m\gg n$. Therefore, microscale behaviour is extrapolated over larger periods. Compared with continuous coupling, the overall gain of heterogeneous time stepping is given by the ratio

$m\gg n$. Therefore, microscale behaviour is extrapolated over larger periods. Compared with continuous coupling, the overall gain of heterogeneous time stepping is given by the ratio ![]() $m/n$. In general, for highly coupled scales (

$m/n$. In general, for highly coupled scales (![]() ${\lambda }' \approx {\lambda }$), we would require

${\lambda }' \approx {\lambda }$), we would require ![]() $m \sim n$ to reach the continuous coupling. The EE and EL schemes with time-burst time stepping have been adopted for systems with large enough time scale separation (

$m \sim n$ to reach the continuous coupling. The EE and EL schemes with time-burst time stepping have been adopted for systems with large enough time scale separation (![]() ${\lambda }' \ll {\lambda }$). However, due to the incompatibility of a simple Eulerian description to capture memory effects, this approximation of constant microscopic stresses over a larger macroscopic time exhibit larger deviations as the microscale relaxation time increases. These limitations can be significantly relieved using LL schemes (Ee et al. Reference Ee, Ren and Vanden-Eijnden2009). Here, depending on the type of system and scale separation, we used both continuous and heterogeneous coupling in time.