1. Introduction

The controlled production of tiny fluid entities such as drops, bubbles, emulsions and capsules has been extensively investigated over the last three decades because of its enormous relevance for a great variety of applications (Christopher & Anna Reference Christopher and Anna2007). In tip streaming (Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020) the dispersed phase is directed by some external actuation of either an electrical (Taylor Reference Taylor1964) or hydrodynamic nature (Suryo & Basaran Reference Suryo and Basaran2006) towards the tip of a suspended droplet (Eggleton, Tsai & Stebe Reference Eggleton, Tsai and Stebe2001) or fluid meniscus lifted above a fluid film (Cohen et al. Reference Cohen, Li, Hougland, Mrksich and Nagel2001) or attached to a feeding capillary (Zhang Reference Zhang2004). This tip emits quasi-monodisperse collections of drops/bubbles/emulsions either directly or through the breakage of a very thin jet. These fluid entities are smaller or even much smaller than any characteristic length of the microfluidic device. Tip streaming is frequently an elusive phenomenon, only found under particular conditions, which results from a delicate balance between the forces driving and opposing the flow (Montanero & Gañán-Calvo Reference Montanero and Gañán-Calvo2020).

Tip streaming can be produced by the hydrodynamic focusing caused by an outer stream moving faster than the dispersed phase when crossing a discharge orifice or tube. In this case, the drop of hydrostatic pressure and/or the viscous traction exerted by the outer stream collaborate in gently shaping a steady tapering meniscus to form a fluid converging ‘nozzle’. Tiny droplets can be directly ejected at the end of this fluid nozzle. Under certain conditions, the outer stream also sweeps away the capillary waves responsible for the breakup of the emitted fluid thread, thus allowing the formation of a thin jet (Huerre & Monkewitz Reference Huerre and Monkewitz1990). The jet eventually breaks up owing to the capillary instability (Rayleigh Reference Rayleigh1878), giving rise to a collection of droplets with an acceptable degree of monodispersity. Tip streaming is technologically advantageous even if that jet does not form because the droplets formed in the tip of the meniscus are still smaller than the characteristic length of the microfluidic device and exhibit a very high degree of monodispersity.

Several microfluidic configurations have been proposed to implement the hydrodynamic focusing principle in liquid–liquid systems. Figure 1 shows the main geometrical parameters governing the focusing effect. Table 1 shows the choices for those parameters leading to the different configurations: flow focusing (Gañán-Calvo & Riesco-Chueca Reference Gañán-Calvo and Riesco-Chueca2006), confined flow focusing (Cabezas et al. Reference Cabezas, Rubio, Rebollo-Muñoz, Herrada and Montanero2021), selective withdrawal (Cohen et al. Reference Cohen, Li, Hougland, Mrksich and Nagel2001), confined selective withdrawal (Evangelio, Campo-Cortés & Gordillo Reference Evangelio, Campo-Cortés and Gordillo2016), Raydrop (Dewandre et al. Reference Dewandre, Rivero-Rodriguez, Vitry, Sobac and Scheid2020), counter flow focusing (Utada et al. Reference Utada, Lorenceau, Link, Kaplan, Stone and Weitz2005) and opposed flow focusing (Dong et al. Reference Dong, Meissner, Faers, Eggers, Seddon and Royall2018). The focusing orifice/tube can be cylindrical or can have a converging shape, as indicated in the figure. The distance ![]() $\hat {H}$ between the feeding capillary and the focusing orifice is a control parameter in all the configurations, which affects the flow stability and, therefore, the minimum size of the emitted droplets. We have coined the term ‘stretched flow focusing’ to refer to one of the two configurations studied in the present work. As can be observed, this geometry is a hybrid between flow focusing and confined selective withdrawal, in which the focusing effect is produced by a very long orifice or a very thick tube.

$\hat {H}$ between the feeding capillary and the focusing orifice is a control parameter in all the configurations, which affects the flow stability and, therefore, the minimum size of the emitted droplets. We have coined the term ‘stretched flow focusing’ to refer to one of the two configurations studied in the present work. As can be observed, this geometry is a hybrid between flow focusing and confined selective withdrawal, in which the focusing effect is produced by a very long orifice or a very thick tube.

Figure 1. Microfluidic configurations based on the hydrodynamic flow focusing principle. The dashed line represents the nozzle used in confined flow focusing and counter flow focusing.

Table 1. Parameter relations corresponding to the microfluidic configurations which implement the hydrodynamic flow focusing principle. The last column indicates the shape of the focusing orifice.

Flow focusing (Gañán-Calvo & Riesco-Chueca Reference Gañán-Calvo and Riesco-Chueca2006) and confined selective withdrawal (Evangelio, Campo-Cortés & Gordillo Reference Evangelio, Campo-Cortés and Gordillo2015; Evangelio et al. Reference Evangelio, Campo-Cortés and Gordillo2016; Muñoz-Sánchez et al. Reference Muñoz-Sánchez, Silva, Pinho, Vega and Lima2016; He et al. Reference He, Campo-Cortés, Goral, López-León and Gordillo2019) are similar techniques to produce several microfluidic entities based on the hydrodynamic focusing principle. As shown in figure 1, the only difference between them is the shape of the discharge orifice located in front of the feeding capillary. While flow focusing uses an orifice located in a plate, the focusing effect in confined selective withdrawal is produced by a discharge tube. The applications of the axisymmetric liquid–liquid flow focusing configuration include the fabrication of flow cytometers (Lee et al. Reference Lee, Hung, Ke, Huang, Hwei and Lai2001), encapsulation and release of different actives (Takeuchi et al. Reference Takeuchi, Garstecki, Weibel and Whitesides2005; Utada et al. Reference Utada, Lorenceau, Link, Kaplan, Stone and Weitz2005; Sun et al. Reference Sun, Shum, Holtze and Weitz2010; Nabavi, Vladisavljevic & Manovic Reference Nabavi, Vladisavljevic and Manovic2017), and production of monodisperse cell-encapsulating microgel beads (Tsuda, Morimoto & Takeuchi Reference Tsuda, Morimoto and Takeuchi2010) and biodegradable poly(lactic acid) particles (Vladisavljevic et al. Reference Vladisavljevic, Henry, Duncanson, Shum and Weitz2012). Other applications are the fabrication of multiple emulsions as microreactors or fine templates for synthesizing advanced particles (Wang, Wang & Han Reference Wang, Wang and Han2011), single-step fabrication of multicompartment Janus microcapsules (Wu et al. Reference Wu, Yang, Liu, Xu, Zhu, Si and Xu2017), pesticide-loaded microcapsules (Zhong et al. Reference Zhong, Yang, Wu, Wang, Cheng, Dwivedi, Zhu, Si and Xu2020), as well as the production of polydimethylsiloxane (PDMS) microcapsules with tunable elastic properties (do Nascimento et al. Reference do Nascimento, Avendaño, Mehl, Moura, Carvalho and Duncanson2017) and multicompartment polymeric microcapsules (Wu et al. Reference Wu, Yang, Yang, Huang, Liu, Zhu, Si and Xu2018; Zhu et al. Reference Zhu, Wu, Han, Xu, Zhong, Yuan, Dwivedi, Si and Xu2018). The confined selective withdrawal geometry has been used to produce bubbles (Evangelio et al. Reference Evangelio, Campo-Cortés and Gordillo2015), emulsions (Evangelio et al. Reference Evangelio, Campo-Cortés and Gordillo2016), double emulsions and nematic shells (He et al. Reference He, Campo-Cortés, Goral, López-León and Gordillo2019), as well as micro-sized PDMS particles (Muñoz-Sánchez et al. Reference Muñoz-Sánchez, Silva, Pinho, Vega and Lima2016). Dewandre et al. (Reference Dewandre, Rivero-Rodriguez, Vitry, Sobac and Scheid2020) have recently engineered a new device, called Raydrop, with a vanishing disperse flow rate, and in which dripping to jetting transition was found as a function of the outer flow rate.

Both in flow focusing (Gañán-Calvo & Riesco-Chueca Reference Gañán-Calvo and Riesco-Chueca2006) and confined selective withdrawal (Evangelio et al. Reference Evangelio, Campo-Cortés and Gordillo2016), the size of the droplets produced via tip streaming critically depends on the ratio between the flow rates at which the inner (dispersed) and outer (continuous) phases are injected/withdrawn. In fact, the smallest droplets are always produced when the disperse-phase flow rate takes its smallest value compatible with the tip streaming stability (the so-called minimum flow rate stability limit) (Cabezas et al. Reference Cabezas, Rubio, Rebollo-Muñoz, Herrada and Montanero2021). This stability limit, in turn, is expected to depend on the specific geometry used to produce the hydrodynamic focusing. The role played by the geometrical parameters in the stability of the tapering meniscus is not well understood yet. Some studies have considered this problem in the gas–liquid flow focusing configuration (Vega et al. Reference Vega, Montanero, Herrada and Gañán-Calvo2010; Mu et al. Reference Mu, Qiao, Guo, Yang, Wu and Si2021). In the liquid–liquid case the results reduce to those of the experimental analysis by Evangelio et al. (Reference Evangelio, Campo-Cortés and Gordillo2016). In this paper we will study the influence of the hydrodynamic focusing geometry on both the tip streaming stability and size of the produced emulsions. Special attention will be paid to the distance ![]() $\hat {H}$ between the feeding capillary and the discharge orifice/tube, which is probably the main control parameter of the microfluidic device. Another important aspect of the focusing geometry is the outer flow around the discharge orifice/tube. Pan, Nunes & Stone (Reference Pan, Nunes and Stone2020) have recently shown how the outer flow upstream of the tube's orifice affects the ratio of the two phases being withdrawn in selective withdrawal. In this work we will consider and compare both the flow focusing and confined selective withdrawal configurations.

$\hat {H}$ between the feeding capillary and the discharge orifice/tube, which is probably the main control parameter of the microfluidic device. Another important aspect of the focusing geometry is the outer flow around the discharge orifice/tube. Pan, Nunes & Stone (Reference Pan, Nunes and Stone2020) have recently shown how the outer flow upstream of the tube's orifice affects the ratio of the two phases being withdrawn in selective withdrawal. In this work we will consider and compare both the flow focusing and confined selective withdrawal configurations.

Soluble surfactants play a fundamental role in many microfluidic applications (Anna Reference Anna2016). In hydrodynamic focusing the dispersed phase is injected or withdrawn from a reservoir at equilibrium with uniform monomer and micelle concentrations. Those concentrations are convected by the incompressible fluid particles, and they remain constant throughout most of the dispersed phase domain. The interface with the continuous phase constitutes a source/sink of surfactant molecules during the system evolution, and, therefore, spatial variations of surfactant concentration arise in the sublayer next to that surface. The adsorption/desorption kinetics and/or diffusion within the sublayer essentially govern the transfer of surfactant molecules from the bulk to the fresh interface created during the atomization. In hydrodynamic focusing the surfactant molecules adsorbed on the interface are convected towards the tip of the tapering liquid meniscus/film/droplet. The surface convection driven by the focusing stream can overcome the opposite Marangoni convection caused by the surface tension gradient. This results in the accumulation of surfactant molecules in the meniscus/film/droplet tip, which lowers the surface tension in that region, thus facilitating the tip streaming phenomenon. The effects of soluble surfactants on the tip streaming produced by hydrodynamic focusing have been studied in suspended droplets (De Bruijn Reference De Bruijn1993; Eggleton et al. Reference Eggleton, Tsai and Stebe2001) and bubbles (Booty & Siegel Reference Booty and Siegel2005) subject to extensional and shear flows, two-dimensional flow focusing (Anna, Bontoux & Stone Reference Anna, Bontoux and Stone2003; Lee, Walker & Anna Reference Lee, Walker and Anna2011) and selective withdrawal (Cohen Reference Cohen2004). To the best of our knowledge, this aspect of the problem has not yet being considered either in axisymmetric flow focusing or in confined selective withdrawal. In this paper we will examine the effect of soluble surfactants on both the stability of tip streaming and the size of the resulting droplets.

The calculation of the linear global modes (Theofilis Reference Theofilis2011) is an adequate tool to describe the instability mechanisms which limit the appearance of tip streaming. In this calculation one assumes that a long jet steadily tapers from the liquid meniscus and interrogates this basic flow about its response to small-amplitude perturbations (Sauter & Buggisch Reference Sauter and Buggisch2005; Tammisola, Lundell & Soderberg Reference Tammisola, Lundell and Soderberg2012; Gordillo, Sevilla & Campo-Cortés Reference Gordillo, Sevilla and Campo-Cortés2014; Cruz-Mazo et al. Reference Cruz-Mazo, Herrada, Gañán-Calvo and Montanero2017). If the largest growth rate of the eigenfrequency spectrum is positive, the jetting regime is unstable. In this case, one may analyse the interface perturbation amplitude of the eigenfunction responsible for the instability. If the amplitude almost vanishes in the tapering meniscus, the system is assumed to adopt a tip streaming mode, in which the droplets are produced right in front of the steady meniscus. On the contrary, if the amplitude is noticeable on the meniscus surface then we conclude that tip streaming does not occur. In this case, the growth of the unstable mode leads either to the interruption of the ejection or to self-sustained oscillations depending on the role played by the nonlinear terms. This paper will theoretically analyse the destabilizing mechanism when the dispersed phase flow rate is reduced just below the minimum flow rate stability limit. We will compare the predictions obtained from the global stability analysis with the experimental observations. The stability analysis will allow us to gain insight into the physical mechanisms responsible for the instability of the tip streaming in confined selective withdrawal.

2. Formulation of the problem

Consider the hydrodynamic focusing configuration sketched in figure 2. A liquid (the dispersed phase) of density ![]() $\rho _i$ and viscosity

$\rho _i$ and viscosity ![]() $\mu _i$ is injected through a feeding capillary of radius

$\mu _i$ is injected through a feeding capillary of radius ![]() $\hat {R}_c$ at a constant flow rate

$\hat {R}_c$ at a constant flow rate ![]() $Q_i$. The outer bath (the continuous phase) is another liquid of density

$Q_i$. The outer bath (the continuous phase) is another liquid of density ![]() $\rho _o$ and viscosity

$\rho _o$ and viscosity ![]() $\mu _o$ immiscible with the former. The dimensions of this bath are much larger than the rest of the lengths involved in the problem. The surface tension of the liquid–liquid interface in the absence of surfactant is

$\mu _o$ immiscible with the former. The dimensions of this bath are much larger than the rest of the lengths involved in the problem. The surface tension of the liquid–liquid interface in the absence of surfactant is ![]() $\gamma _0$. The two liquids are sucked at a constant flow rate

$\gamma _0$. The two liquids are sucked at a constant flow rate ![]() $Q_s$ through a discharge tube of diameter

$Q_s$ through a discharge tube of diameter ![]() $D$ and thickness

$D$ and thickness ![]() $e$ placed at a distance

$e$ placed at a distance ![]() ${\hat H}$ from the feeding capillary. The discharge tube is very long in terms of

${\hat H}$ from the feeding capillary. The discharge tube is very long in terms of ![]() $D$, and, therefore, its length has little influence on both the stability of the tapering meniscus and the size of the emitted droplets. The above configuration corresponds to stretched flow focusing and confined selective withdrawal for

$D$, and, therefore, its length has little influence on both the stability of the tapering meniscus and the size of the emitted droplets. The above configuration corresponds to stretched flow focusing and confined selective withdrawal for ![]() $e\gg D$ and

$e\gg D$ and ![]() $e\lesssim D$, respectively. As explained below, monodisperse collections of droplets of diameter

$e\lesssim D$, respectively. As explained below, monodisperse collections of droplets of diameter ![]() $\hat {d}$ are produced in the tip streaming modes of these configurations. When surfactants are added to one of the liquid phases, the formulation of the problem must be completed with the parameters characterizing the bulk diffusion of surfactant molecules, the adsorption–desorption kinetics at the interface and the dependency of surface tension upon the surface surfactant concentration. We do not introduce these parameters because this aspect of the problem will not be studied theoretically.

$\hat {d}$ are produced in the tip streaming modes of these configurations. When surfactants are added to one of the liquid phases, the formulation of the problem must be completed with the parameters characterizing the bulk diffusion of surfactant molecules, the adsorption–desorption kinetics at the interface and the dependency of surface tension upon the surface surfactant concentration. We do not introduce these parameters because this aspect of the problem will not be studied theoretically.

Figure 2. Sketch of the fluid configuration.

In the absence of surfactant, the problem can be formulated in terms of dimensionless geometrical parameters ![]() $R_c=\hat {R}_c/D$,

$R_c=\hat {R}_c/D$, ![]() $H=\hat {H}/D$ and

$H=\hat {H}/D$ and ![]() $\varepsilon =e/D$, the density and viscosity ratios

$\varepsilon =e/D$, the density and viscosity ratios ![]() $\rho =\rho _i/\rho _o$ and

$\rho =\rho _i/\rho _o$ and ![]() $\mu =\mu _i/\mu _o$, the Reynolds and capillary numbers,

$\mu =\mu _i/\mu _o$, the Reynolds and capillary numbers,

where ![]() $U=4 Q_s/({\rm \pi} D^{2})$ is the mean velocity in the discharge tube, and the flow rate ratio

$U=4 Q_s/({\rm \pi} D^{2})$ is the mean velocity in the discharge tube, and the flow rate ratio ![]() $Q=Q_i/Q_s$. As mentioned above, we consider experimental realizations in which

$Q=Q_i/Q_s$. As mentioned above, we consider experimental realizations in which ![]() $\varepsilon \gg 1$ and

$\varepsilon \gg 1$ and ![]() $\varepsilon \lesssim 1$, which corresponds to the stretched flow focusing and confined selective withdrawal configurations, respectively.

$\varepsilon \lesssim 1$, which corresponds to the stretched flow focusing and confined selective withdrawal configurations, respectively.

In the absence of surfactant, the mode adopted by the system, the droplet diameter ![]() $d=\hat {d}/D$ and the droplet production frequency

$d=\hat {d}/D$ and the droplet production frequency ![]() $f=\hat {f}D/U=3Q/(2d^{3})$ depend on the set of governing parameters

$f=\hat {f}D/U=3Q/(2d^{3})$ depend on the set of governing parameters ![]() $\{\varepsilon$,

$\{\varepsilon$, ![]() $R_c$,

$R_c$, ![]() $H$;

$H$; ![]() $\rho$,

$\rho$, ![]() $\mu$,

$\mu$, ![]() $\mbox {Re}$,

$\mbox {Re}$, ![]() $\mbox {Ca}$,

$\mbox {Ca}$, ![]() $Q\}$. The density ratio

$Q\}$. The density ratio ![]() $\rho$ takes values around unity in most liquid–liquid systems, and, therefore, it can be ruled out from the analysis. The dimensionless parameters

$\rho$ takes values around unity in most liquid–liquid systems, and, therefore, it can be ruled out from the analysis. The dimensionless parameters ![]() $\mu$,

$\mu$, ![]() $\mbox {Re}$ and

$\mbox {Re}$ and ![]() $\mbox {Ca}$ vary when the outer viscosity changes in our experiments and simulations. To simplify the description of our results, we will categorize the simulations and experiments in terms of the outer viscosity or the viscosity ratio instead of the above-mentioned dimensionless numbers.

$\mbox {Ca}$ vary when the outer viscosity changes in our experiments and simulations. To simplify the description of our results, we will categorize the simulations and experiments in terms of the outer viscosity or the viscosity ratio instead of the above-mentioned dimensionless numbers.

We distinguish the following flow modes: (i) jetting via tip streaming in which a jet is extruded from the tip of a steady liquid meniscus hanging on the feeding capillary (mode I), (ii) dripping via tip streaming (microdripping) in which droplets are periodically produced right in front of the tip of a steady meniscus (mode II), and (iii) unstable ejection in which the meniscus emits trains of droplets (modes IIIa and IIIb). As can be seen, and to simplify the analysis, experimental realizations are identified as modes I, II or III regardless of the size of the emitted jet or droplets. figure 3 shows examples of all these modes. As can be observed, only modes I and II lead to monodisperse collections of droplets.

Figure 3. Flow regimes: mode I (jetting), mode II (microdripping), modes IIIa and IIIb (intermittent ejection of drops trains).

3. Experimental method

The experimental set-up is sketched in figure 4. The focused (inner) and focusing (outer) liquids are withdrawn through a glass discharge tube (A) inserted into a transparent cell (B) across its bottom. The focused liquid is supplied through a sharpened steel capillary (C) around 300 ![]() $\mathrm {\mu }$m in inner diameter located in front of the discharge tube around 200 (450)

$\mathrm {\mu }$m in inner diameter located in front of the discharge tube around 200 (450) ![]() $\mathrm {\mu }$m in inner (outer) diameter by using a high-precision orientation–translation system. The outer cell square section is 10 mm in width, more than 15 times the feeding capillary outer diameter (600

$\mathrm {\mu }$m in inner (outer) diameter by using a high-precision orientation–translation system. The outer cell square section is 10 mm in width, more than 15 times the feeding capillary outer diameter (600 ![]() $\mathrm {\mu }$m). The cell is filled with the focusing liquid to form a reservoir open to the atmosphere. We withdraw the liquids with a syringe pump (KD Scientific Legato 210) (D). The dispersed phase is injected with another syringe pump (KD Scientific, KDS120) (E). The focusing liquid withdrawn from the cell is continuously replaced to keep the free surface level approximately constant.

$\mathrm {\mu }$m). The cell is filled with the focusing liquid to form a reservoir open to the atmosphere. We withdraw the liquids with a syringe pump (KD Scientific Legato 210) (D). The dispersed phase is injected with another syringe pump (KD Scientific, KDS120) (E). The focusing liquid withdrawn from the cell is continuously replaced to keep the free surface level approximately constant.

Figure 4. Experimental set-up: glass discharge tube (A), transparent cell (B), steel capillary (C), syringe pumps (D,E), high-speed CMOS camera (F) and optical fibre (G).

We chose to suck the focusing liquid instead of pumping it (Evangelio et al. Reference Evangelio, Campo-Cortés and Gordillo2016) because this procedure allows for conveniently varying the control parameter ![]() $\hat {H}$. However, the maximum value of the withdrawn flow rate

$\hat {H}$. However, the maximum value of the withdrawn flow rate ![]() $Q_s$ is limited by the maximum pressure drop of 1 bar across the discharge circuit. This limitation is minimized by reducing the length of that circuit. The alternative to this configuration is to close and seal the liquid bath so that we can impose an arbitrarily large positive gauge pressure to pump the outer liquid (Evangelio et al. Reference Evangelio, Campo-Cortés and Gordillo2016). This method has no limitation in terms of the pressure gradient driving the flow. However, it requires dissembling, re-assembling, re-aligning and re-sealing the experimental cell every time we change the distance

$Q_s$ is limited by the maximum pressure drop of 1 bar across the discharge circuit. This limitation is minimized by reducing the length of that circuit. The alternative to this configuration is to close and seal the liquid bath so that we can impose an arbitrarily large positive gauge pressure to pump the outer liquid (Evangelio et al. Reference Evangelio, Campo-Cortés and Gordillo2016). This method has no limitation in terms of the pressure gradient driving the flow. However, it requires dissembling, re-assembling, re-aligning and re-sealing the experimental cell every time we change the distance ![]() $\hat {H}$.

$\hat {H}$.

Digital images of the fluid configuration were acquired using a high-speed CMOS camera (Photron, Fastcam SA5) (F), which allowed us to acquire images at ![]() $10^{4}$ f.p.s. with an exposure time of 6.944

$10^{4}$ f.p.s. with an exposure time of 6.944 ![]() $\mathrm {\mu }$s. The camera was equipped with optical lenses with a magnification ranging from 1.92 to 4.71

$\mathrm {\mu }$s. The camera was equipped with optical lenses with a magnification ranging from 1.92 to 4.71 ![]() $\mathrm {\mu }$m pixel

$\mathrm {\mu }$m pixel![]() $^{-1}$. The camera could be displaced horizontally and vertically using a triaxial translation stage to focus the interface. The fluid configuration was illuminated from the backside by cool white light provided by an optical fibre (G) connected to a light source. We also acquired images using an auxiliary CCD camera (not shown in figure 4) with an optical axis perpendicular to that of the CMOS camera to check that the capillaries were correctly aligned. All these elements were mounted on an optical table with a pneumatic anti-vibration isolation system, which prevents errors in determining the stability limits caused by finite-amplitude vibrations coming from the building.

$^{-1}$. The camera could be displaced horizontally and vertically using a triaxial translation stage to focus the interface. The fluid configuration was illuminated from the backside by cool white light provided by an optical fibre (G) connected to a light source. We also acquired images using an auxiliary CCD camera (not shown in figure 4) with an optical axis perpendicular to that of the CMOS camera to check that the capillaries were correctly aligned. All these elements were mounted on an optical table with a pneumatic anti-vibration isolation system, which prevents errors in determining the stability limits caused by finite-amplitude vibrations coming from the building.

We used distilled water as inner liquid and two silicone oils as outer (focusing) streams. Their properties are shown in table 2. The surface tension of the water–silicone oil interface was measured with the theoretical image fitting analysis (TIFA) method (Ferrera, Montanero & Cabezas Reference Ferrera, Montanero and Cabezas2007), while the density and viscosity were taken from the manufacturer's specifications.

Table 2. Properties of the working liquids at 25 ![]() $^{\circ }$C.

$^{\circ }$C. ![]() $\gamma$ is the interfacial tension of the interface between distilled water and the corresponding liquid.

$\gamma$ is the interfacial tension of the interface between distilled water and the corresponding liquid.

In each experimental run we fixed the flow rate ![]() $Q_s$ at which the two liquids were suctioned. For 10-cSt silicone oil, we started the experiment by setting a dispersed phase flow rate

$Q_s$ at which the two liquids were suctioned. For 10-cSt silicone oil, we started the experiment by setting a dispersed phase flow rate ![]() $Q_i$ sufficiently high to establish the steady jetting regime (mode I). Then, this flow rate was progressively reduced until the meniscus became unstable (mode III). The images allowed us to determine whether microdripping (mode II) was established during the experimental run. For 100-cSt silicone oil, the outer flow rate was not sufficiently high to produce steady jetting. We started the experiment by setting a flow rate

$Q_i$ sufficiently high to establish the steady jetting regime (mode I). Then, this flow rate was progressively reduced until the meniscus became unstable (mode III). The images allowed us to determine whether microdripping (mode II) was established during the experimental run. For 100-cSt silicone oil, the outer flow rate was not sufficiently high to produce steady jetting. We started the experiment by setting a flow rate ![]() $Q_i$ sufficiently high to establish the microdrippng mode. Then,

$Q_i$ sufficiently high to establish the microdrippng mode. Then, ![]() $Q_i$ was progressively reduced until the meniscus became unstable. In all the experiments the diameter

$Q_i$ was progressively reduced until the meniscus became unstable. In all the experiments the diameter ![]() $d$ of the ejected droplets was determined with pixel resolution. We verified that the optical distortion caused by the cell and discharge tube was negligible. To this end, we checked that there was good agreement between the droplet diameter measured from the image and that calculated from the inner flow rate and the frequency at which the drops were ejected.

$d$ of the ejected droplets was determined with pixel resolution. We verified that the optical distortion caused by the cell and discharge tube was negligible. To this end, we checked that there was good agreement between the droplet diameter measured from the image and that calculated from the inner flow rate and the frequency at which the drops were ejected.

4. Governing equations and numerical method

In this work we calculate the base flow and its eigenmodes in the absence of surfactant to explain some of the effects observed in the experiments. In this section we present the governing equations and the numerical method used to conduct the above-mentioned calculation. Here, all the variables are made dimensionless with the diameter ![]() $D$ of the discharge tube, the mean velocity

$D$ of the discharge tube, the mean velocity ![]() $U=4Q_s/({\rm \pi} D^{2})$ in that tube and the focusing liquid viscosity

$U=4Q_s/({\rm \pi} D^{2})$ in that tube and the focusing liquid viscosity ![]() $\mu _o$. The dimensionless, axisymmetric, incompressible Navier–Stokes equations for the velocity

$\mu _o$. The dimensionless, axisymmetric, incompressible Navier–Stokes equations for the velocity ![]() $\boldsymbol {v}^{(k)}(r,z;t)$ and pressure

$\boldsymbol {v}^{(k)}(r,z;t)$ and pressure ![]() $p^{(k)}(r,z;t)$ fields are

$p^{(k)}(r,z;t)$ fields are

where ![]() $t$ is the time,

$t$ is the time, ![]() $r$ (

$r$ (![]() $z$) is the radial (axial) coordinate,

$z$) is the radial (axial) coordinate, ![]() $u^{(k)}$ (

$u^{(k)}$ (![]() $w^{(k)}$) is the radial (axial) velocity component and

$w^{(k)}$) is the radial (axial) velocity component and ![]() $\delta _{ij}$ is the Kronecker delta. In the above equations and henceforth, the superscripts

$\delta _{ij}$ is the Kronecker delta. In the above equations and henceforth, the superscripts ![]() $k=i$ and

$k=i$ and ![]() $o$ refer to the inner (disperse) and outer (continuous) phases, respectively. In addition, the subscripts

$o$ refer to the inner (disperse) and outer (continuous) phases, respectively. In addition, the subscripts ![]() $t$,

$t$, ![]() $r$ and

$r$ and ![]() $z$ denote the partial derivatives with respect to the corresponding variables. The action of the gravitational field has been neglected due to the smallness of the fluid configuration.

$z$ denote the partial derivatives with respect to the corresponding variables. The action of the gravitational field has been neglected due to the smallness of the fluid configuration.

The kinematic compatibility and the velocity field continuity at the interface ![]() $r=F(z,t)$ yields

$r=F(z,t)$ yields

The equilibrium of both tangential and normal stresses on that surface leads to

$$\begin{gather} p^{(i)}+\mbox{Ca}^{{-}1}\frac{FF_{zz}-1-F_z^{2}}{F(1+F_z^{2})^{3/2}}-\frac{2\mu[u^{(i)}_r-F_z(w^{(i)}_r+u^{(i)}_z)+F_z^{2}w^{(i)}_z]}{1+F_z^{2}} \nonumber\\= p^{(o)}-\frac{2u[u^{(o)}_r-F_z(w^{(o)}_r+u^{(o)}_z)+F_z^{2}w^{(o)}_z]}{1+F_z^{2}}. \end{gather}$$

$$\begin{gather} p^{(i)}+\mbox{Ca}^{{-}1}\frac{FF_{zz}-1-F_z^{2}}{F(1+F_z^{2})^{3/2}}-\frac{2\mu[u^{(i)}_r-F_z(w^{(i)}_r+u^{(i)}_z)+F_z^{2}w^{(i)}_z]}{1+F_z^{2}} \nonumber\\= p^{(o)}-\frac{2u[u^{(o)}_r-F_z(w^{(o)}_r+u^{(o)}_z)+F_z^{2}w^{(o)}_z]}{1+F_z^{2}}. \end{gather}$$ We integrate the Navier–Stokes equations in the numerical domain sketched in figure 5. The red lines correspond to the contours of the feeding capillary and discharge tube used in the experiments of confined selective withdrawal, while the blue and black lines have been added to close the numerical domain. The cylindrical shape of the outer cylinder has a negligible influence on the results given the large distance between the cylinder wall and the interface. The discharge tube length is equal to ![]() $2H$, and the feeding capillary length is

$2H$, and the feeding capillary length is ![]() $H$. The feeding capillary end is assumed to be infinitely thin to facilitate the numerical calculations, which may constitute a significant difference with respect to the experiments. The edge of the discharge tube has been rounded to eliminate numerical singularities associated with the vertex.

$H$. The feeding capillary end is assumed to be infinitely thin to facilitate the numerical calculations, which may constitute a significant difference with respect to the experiments. The edge of the discharge tube has been rounded to eliminate numerical singularities associated with the vertex.

Figure 5. Sketch of the computational domain.

We impose a parabolic velocity distribution at the inlet section of the feeding capillary. A uniform velocity profile is prescribed on the lateral surface of the outer cylinder. The constant pressure and ![]() $F_z=0$ conditions are imposed at the outlet section (the pressure in the inner phase equals the pressure in the outer phase plus the capillary pressure). The non-slip boundary condition is prescribed at the solid walls (red and blue lines in figure 5). The anchorage condition of the triple contact line,

$F_z=0$ conditions are imposed at the outlet section (the pressure in the inner phase equals the pressure in the outer phase plus the capillary pressure). The non-slip boundary condition is prescribed at the solid walls (red and blue lines in figure 5). The anchorage condition of the triple contact line, ![]() $F=1$, is prescribed at the edge of the feeding capillary. We impose the standard regularity conditions

$F=1$, is prescribed at the edge of the feeding capillary. We impose the standard regularity conditions ![]() $u^{(i)}=w^{(i)}_r =0$ at the symmetry axis.

$u^{(i)}=w^{(i)}_r =0$ at the symmetry axis.

To calculate the linear global modes, we assume the temporal dependence

\begin{equation} \left. \begin{aligned} U(r,z;t) & =U_0(r,z)+\delta U(r,z)\, {\rm e}^{-{\rm i}\omega t} \quad (\delta U\ll U), \\ F(z;t) & =F_0(z)+\delta F(z)\, {\rm e}^{-{\rm i}\omega t} (\delta F\ll F_0), \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} U(r,z;t) & =U_0(r,z)+\delta U(r,z)\, {\rm e}^{-{\rm i}\omega t} \quad (\delta U\ll U), \\ F(z;t) & =F_0(z)+\delta F(z)\, {\rm e}^{-{\rm i}\omega t} (\delta F\ll F_0), \end{aligned} \right\} \end{equation}

where ![]() $U(r,z;t)$ represents the velocity and pressure fields,

$U(r,z;t)$ represents the velocity and pressure fields, ![]() $U_0(r,z)$ and

$U_0(r,z)$ and ![]() $\delta U(r,z)$ stand for the base flow (steady) solution and the spatial dependence of the eigenmode, respectively, while

$\delta U(r,z)$ stand for the base flow (steady) solution and the spatial dependence of the eigenmode, respectively, while ![]() $\omega =\omega _r+\textrm {i}\omega _i$ is the eigenfrequency characterizing the perturbation evolution. Special attention will be paid to the perturbation amplitude

$\omega =\omega _r+\textrm {i}\omega _i$ is the eigenfrequency characterizing the perturbation evolution. Special attention will be paid to the perturbation amplitude ![]() $\delta F(z)$ of the interface position

$\delta F(z)$ of the interface position ![]() $F(z;t)$ around the base flow solution

$F(z;t)$ around the base flow solution ![]() $F_0(z)$. If the growth rate

$F_0(z)$. If the growth rate ![]() $\omega _i$ of the dominant mode (i.e. that with the largest

$\omega _i$ of the dominant mode (i.e. that with the largest ![]() $\omega _i$) is positive then the base flow is asymptotically unstable under small-amplitude perturbations (Theofilis Reference Theofilis2011). In this work we will determine the critical value of the flow rate ratio

$\omega _i$) is positive then the base flow is asymptotically unstable under small-amplitude perturbations (Theofilis Reference Theofilis2011). In this work we will determine the critical value of the flow rate ratio ![]() $Q$ for which the base becomes asymptotically unstable as a function of the rest of the governing parameters.

$Q$ for which the base becomes asymptotically unstable as a function of the rest of the governing parameters.

The growth of the linear perturbations makes the system enter into the nonlinear regime. The nonlinear terms of the Navier–Stokes equations and interface boundary conditions may stabilize the system. In this case, self-sustained oscillations, continuously fed by the growth of unstable infinitesimal perturbations, can be observed. Otherwise, the linear instability of the jetting (mode I) base flow is assumed to lead either to the microdripping mode (mode II) or intermittent liquid ejection (mode III). The outcome adopted by the system cannot be predicted from the linear stability analysis.

The governing equations are integrated with the numerical method proposed by Herrada & Montanero (Reference Herrada and Montanero2016). In this method the inner and outer fluid domains are mapped onto fixed numerical domains through a non-singular mapping with a quasi-elliptic transformation (Dimakopoulos & Tsamopoulos Reference Dimakopoulos and Tsamopoulos2003). The equations expressed in terms of ![]() $t$ and the transformed spatial coordinates are discretized in the mapped radial direction with Chebyshev spectral collocation points (Khorrami, Malik & Ash Reference Khorrami, Malik and Ash1989). Fourth-order finite differences with equally spaced points are used to discretize the mapped axial direction.

$t$ and the transformed spatial coordinates are discretized in the mapped radial direction with Chebyshev spectral collocation points (Khorrami, Malik & Ash Reference Khorrami, Malik and Ash1989). Fourth-order finite differences with equally spaced points are used to discretize the mapped axial direction.

The accurate calculation of the dominant mode eigenvalue at the marginal stability demands very fine meshes, probably due to the complex base flow arising at the stability limit. In fact, and as will be shown in § 6, large velocity gradients can be found next to the interface. The resulting viscous forces affect the focusing stability and, therefore, must be accurately calculated to determine the critical conditions. It is worth noting that the minimum jet diameter was 6 ![]() $\mathrm {\mu }$m, around 50 times smaller than the inner diameter of the feeding capillary. We tried different grid configurations with different numbers of domains. The configuration shown in figure 6 was the only one producing good convergence. In this sense, the simulation is not a straightforward extension of that recently used for the confined flow focusing configuration (Cabezas et al. Reference Cabezas, Rubio, Rebollo-Muñoz, Herrada and Montanero2021). We verified that the results did not significantly depend on the mesh size. For instance, for

$\mathrm {\mu }$m, around 50 times smaller than the inner diameter of the feeding capillary. We tried different grid configurations with different numbers of domains. The configuration shown in figure 6 was the only one producing good convergence. In this sense, the simulation is not a straightforward extension of that recently used for the confined flow focusing configuration (Cabezas et al. Reference Cabezas, Rubio, Rebollo-Muñoz, Herrada and Montanero2021). We verified that the results did not significantly depend on the mesh size. For instance, for ![]() $\{\varepsilon =0.59$,

$\{\varepsilon =0.59$, ![]() $R_c=1.69$,

$R_c=1.69$, ![]() $H=1.66$;

$H=1.66$; ![]() $\rho =1.07$,

$\rho =1.07$, ![]() $\mu =0.107$;

$\mu =0.107$; ![]() $\mbox {Re}=11.8$,

$\mbox {Re}=11.8$, ![]() $\mbox {Ca}=0.15$,

$\mbox {Ca}=0.15$, ![]() $Q=0.059\}$, an increase of 40 % in the number of points produced errors in the critical flow rate ratio below 5 %. In each simulation the outer domain radius is selected so that the meniscus interface remains in the grid's cyan domain of figure 6. That value ranged from 4 to 7.5 times that of feeding capillary. We verified that the solution did not significantly depend on this choice. We also verified that the minimum flow rate ratio and the jet diameter did not depend on the cut-off length of the numerical domain. More precisely, a variation of 50 % of the discharge tube length produced a difference smaller than 0.5 % and 1.5 % in the minimum flow rate and the jet diameter, respectively.

$Q=0.059\}$, an increase of 40 % in the number of points produced errors in the critical flow rate ratio below 5 %. In each simulation the outer domain radius is selected so that the meniscus interface remains in the grid's cyan domain of figure 6. That value ranged from 4 to 7.5 times that of feeding capillary. We verified that the solution did not significantly depend on this choice. We also verified that the minimum flow rate ratio and the jet diameter did not depend on the cut-off length of the numerical domain. More precisely, a variation of 50 % of the discharge tube length produced a difference smaller than 0.5 % and 1.5 % in the minimum flow rate and the jet diameter, respectively.

Figure 6. Details of the grid used in the simulations. The grid consists of four blocks corresponding to the inner liquid (red) and the outer stream (cyan, green and magenta). Panel (b) shows details of the grid around the edge of the discharge tube.

5. Experimental results

This section presents experimental results on the stability of confined selective withdrawal and the diameter of the produced droplets in tip streaming realizations. We consider as a tip streaming realization that in which a steady liquid meniscus periodically emits droplets, regardless of whether a jet is formed in the discharge tube (mode I, jetting) or the droplets are ejected from the meniscus tip (mode II, microdripping). In our experiments with ![]() $\mu =0.1$ (10-cSt silicone oil), tip streaming ejections were produced via the jetting and microdripping regimes. However, the jetting regime was not observed for

$\mu =0.1$ (10-cSt silicone oil), tip streaming ejections were produced via the jetting and microdripping regimes. However, the jetting regime was not observed for ![]() $\mu =0.01$ (100-cSt silicone oil) due to the limited speed of the jet in the discharge tube, which makes the jet absolutely unstable (Huerre & Monkewitz Reference Huerre and Monkewitz1990).

$\mu =0.01$ (100-cSt silicone oil) due to the limited speed of the jet in the discharge tube, which makes the jet absolutely unstable (Huerre & Monkewitz Reference Huerre and Monkewitz1990).

In the jetting regime the droplet diameter can be estimated from that of the precursor jet by considering the wavelength of the most unstable capillary mode (Tomotika Reference Tomotika1936). In turn, the jet diameter can be estimated from continuity arguments in terms of the flow rate ratio. The dependence of the droplet diameter on the flow rate ratio in the microdripping mode is analysed for ![]() $\mu =0.01$ in figure 7. The power law that best fits the experimental data is

$\mu =0.01$ in figure 7. The power law that best fits the experimental data is ![]() $d=1.14\, Q^{0.45}$. As can be observed, the experimental results are also accurately fitted by the law

$d=1.14\, Q^{0.45}$. As can be observed, the experimental results are also accurately fitted by the law ![]() $d=1.35\, Q^{1/2}$, which leads to the production frequency

$d=1.35\, Q^{1/2}$, which leads to the production frequency ![]() $f=0.61 Q^{-1/2}$. Interestingly, the reduction of the flow rate ratio in the microdripping mode does not affect the shape of the tapering meniscus (figure 8). The meniscus tip sharpens as

$f=0.61 Q^{-1/2}$. Interestingly, the reduction of the flow rate ratio in the microdripping mode does not affect the shape of the tapering meniscus (figure 8). The meniscus tip sharpens as ![]() $Q$ decreases, which lowers the size of the droplets ejected in that region. The scaling law reported here is the same as that obtained by Evangelio et al. (Reference Evangelio, Campo-Cortés and Gordillo2016) for both the microdripping (short jets) and jetting (long jets) modes. In that work, the authors rationalize their experimental observations using arguments based on mass conservation. The collection of produced droplets exhibits a high degree of monodispersity. The standard deviation of the drop diameter is below 10 % in all the cases.

$Q$ decreases, which lowers the size of the droplets ejected in that region. The scaling law reported here is the same as that obtained by Evangelio et al. (Reference Evangelio, Campo-Cortés and Gordillo2016) for both the microdripping (short jets) and jetting (long jets) modes. In that work, the authors rationalize their experimental observations using arguments based on mass conservation. The collection of produced droplets exhibits a high degree of monodispersity. The standard deviation of the drop diameter is below 10 % in all the cases.

Figure 7. Drop diameter ![]() $d$ vs the flow rate ratio

$d$ vs the flow rate ratio ![]() $Q$ in the absence of surfactant for

$Q$ in the absence of surfactant for ![]() $\varepsilon =0.52$,

$\varepsilon =0.52$, ![]() $R_c=1.7$,

$R_c=1.7$, ![]() $H=2.9$,

$H=2.9$, ![]() $\rho =1.03$,

$\rho =1.03$, ![]() $\mu =0.010$,

$\mu =0.010$, ![]() $\mbox {Re}=0.40$ and

$\mbox {Re}=0.40$ and ![]() $Ca=0.53$. The symbols and the solid line correspond to the experimental results and the scaling law

$Ca=0.53$. The symbols and the solid line correspond to the experimental results and the scaling law ![]() $d=1.35\, Q^{1/2}$, respectively.

$d=1.35\, Q^{1/2}$, respectively.

Figure 8. Images acquired for (a) ![]() $Q=0.042$ and (b)

$Q=0.042$ and (b) ![]() $Q=0.001$. The rest of the governing parameters are the same as those in figure 7. The yellow line in the image (b) is the meniscus contour in case (a).

$Q=0.001$. The rest of the governing parameters are the same as those in figure 7. The yellow line in the image (b) is the meniscus contour in case (a).

In this work we pay special attention to the influence on the flow stability and droplet diameter of two factors of the problem not systematically studied in previous works: (i) the geometry of the microfluidic configuration through the parameters ![]() $H$ and

$H$ and ![]() $\varepsilon$, and (ii) the role played by the surfactant monolayer formed on the interface when a soluble surfactant is added to the inner liquid.

$\varepsilon$, and (ii) the role played by the surfactant monolayer formed on the interface when a soluble surfactant is added to the inner liquid.

5.1. Influence of the feeding capillary-to-discharge tube distance

figure 9 shows the minimum value of the flow rate ratio, ![]() $Q_{{min}}$, as a function of the capillary number

$Q_{{min}}$, as a function of the capillary number ![]() $\mbox {Ca}$ for the smallest value of the viscosity ratio

$\mbox {Ca}$ for the smallest value of the viscosity ratio ![]() $\mu =0.01$ considered in our experiments. We conducted the experiments for three values of the distance

$\mu =0.01$ considered in our experiments. We conducted the experiments for three values of the distance ![]() $H$ between the feeding capillary and the discharge tube. For flow rate ratios larger than

$H$ between the feeding capillary and the discharge tube. For flow rate ratios larger than ![]() $Q_{{min}}$, the system adopts the microdripping regime (mode II), while unsteady ejection (mode III) is produced otherwise. The force driving the inner liquid ejection increases with the capillary number, stabilizing the tapering meniscus and increasing the range of

$Q_{{min}}$, the system adopts the microdripping regime (mode II), while unsteady ejection (mode III) is produced otherwise. The force driving the inner liquid ejection increases with the capillary number, stabilizing the tapering meniscus and increasing the range of ![]() $Q$ for which microdripping is obtained. There is a significant influence of the distance

$Q$ for which microdripping is obtained. There is a significant influence of the distance ![]() $H$ on the system stability for small values of

$H$ on the system stability for small values of ![]() $\mbox {Ca}$. However, this distance becomes irrelevant as the capillary number increases. In fact, the microdripping mode destabilizes for

$\mbox {Ca}$. However, this distance becomes irrelevant as the capillary number increases. In fact, the microdripping mode destabilizes for ![]() $Q\lesssim 10^{-3}$ regardless of the

$Q\lesssim 10^{-3}$ regardless of the ![]() $\mbox {Ca}$ and

$\mbox {Ca}$ and ![]() $H$ values. Unfortunately, and due to the limitations of our experimental set-up, we could not analyse the system stability for

$H$ values. Unfortunately, and due to the limitations of our experimental set-up, we could not analyse the system stability for ![]() $\mbox {Ca}\gtrsim 0.63$. As

$\mbox {Ca}\gtrsim 0.63$. As ![]() $H$ decreases, the stress exerted by the outer stream on the inner liquid increases, which stabilizes the liquid ejection in most cases. However, the dependence of

$H$ decreases, the stress exerted by the outer stream on the inner liquid increases, which stabilizes the liquid ejection in most cases. However, the dependence of ![]() $Q_{{min}}$ on

$Q_{{min}}$ on ![]() $H$ is non-monotonic for some values of

$H$ is non-monotonic for some values of ![]() $\mbox {Ca}$.

$\mbox {Ca}$.

Figure 9. Minimum value of the flow rate ratio, ![]() $Q_{{min}}$, vs the capillary number,

$Q_{{min}}$, vs the capillary number, ![]() $\mbox {Ca}$, in the absence of surfactant for

$\mbox {Ca}$, in the absence of surfactant for ![]() $\varepsilon =0.64$,

$\varepsilon =0.64$, ![]() $R_c=1.75$,

$R_c=1.75$, ![]() $\rho =1.03$,

$\rho =1.03$, ![]() $\mu =0.010$, and different values of the distance

$\mu =0.010$, and different values of the distance ![]() $H$ between the feeding capillary and the discharge tube. The Reynolds number took values smaller than 0.5.

$H$ between the feeding capillary and the discharge tube. The Reynolds number took values smaller than 0.5.

The role played by ![]() $H$ in the meniscus stability for a fixed value of

$H$ in the meniscus stability for a fixed value of ![]() $\mbox {Ca}$ is analysed in figure 10. As mentioned above, this parameter becomes irrelevant for the largest value of

$\mbox {Ca}$ is analysed in figure 10. As mentioned above, this parameter becomes irrelevant for the largest value of ![]() $\mbox {Ca}$ considered in our experiments. For

$\mbox {Ca}$ considered in our experiments. For ![]() $\mbox {Ca}=0.22$, the meniscus stabilizes as

$\mbox {Ca}=0.22$, the meniscus stabilizes as ![]() $H$ decreases. However, the diameter of droplets ejected in the microdripping mode depends only slightly on

$H$ decreases. However, the diameter of droplets ejected in the microdripping mode depends only slightly on ![]() $Q$ at the stability limit. Therefore, the distance

$Q$ at the stability limit. Therefore, the distance ![]() $H$ considerably affects the ejection frequency but not the droplet diameter. This is a reminiscence of the behaviour in quasi-static dripping, which takes place for a small disperse flow rate. For

$H$ considerably affects the ejection frequency but not the droplet diameter. This is a reminiscence of the behaviour in quasi-static dripping, which takes place for a small disperse flow rate. For ![]() $H\simeq 0.5$ and

$H\simeq 0.5$ and ![]() $\mbox {Ca}=0.63$, we observe an instability mechanism consisting in the depinning of the triple contact line from the edge of the feeding capillary. In this case, the contact line climbs on the inner wall of the feeding capillary and remains still at a certain distance from the capillary end. This phenomenon is associated with the large extensional stress exerted by the viscous outer stream for small

$\mbox {Ca}=0.63$, we observe an instability mechanism consisting in the depinning of the triple contact line from the edge of the feeding capillary. In this case, the contact line climbs on the inner wall of the feeding capillary and remains still at a certain distance from the capillary end. This phenomenon is associated with the large extensional stress exerted by the viscous outer stream for small ![]() $H$, and has also been observed in similar configurations, such as gaseous flow focusing of viscoelastic jets (Ponce-Torres et al. Reference Ponce-Torres, Montanero, Vega and Gañán-Calvo2016). For

$H$, and has also been observed in similar configurations, such as gaseous flow focusing of viscoelastic jets (Ponce-Torres et al. Reference Ponce-Torres, Montanero, Vega and Gañán-Calvo2016). For ![]() $H\gtrsim 4.5$ and

$H\gtrsim 4.5$ and ![]() $\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary. This occurs because the contact angle reaches the threshold value leading to the contact line depinning at the outer edge of the feeding capillary end. When the triple contact line is depinned, the system behaviour downstream is essentially the same as that taking place with pinned contact lines: if the flow rate ratio is greater/smaller than the critical one, then mode II/III is obtained. The tapering meniscus became unstable for

$\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary. This occurs because the contact angle reaches the threshold value leading to the contact line depinning at the outer edge of the feeding capillary end. When the triple contact line is depinned, the system behaviour downstream is essentially the same as that taking place with pinned contact lines: if the flow rate ratio is greater/smaller than the critical one, then mode II/III is obtained. The tapering meniscus became unstable for ![]() $H\lesssim 2$ and

$H\lesssim 2$ and ![]() $\mbox {Ca}=0.22$. As can be observed in figure 10, the sharp decrease of

$\mbox {Ca}=0.22$. As can be observed in figure 10, the sharp decrease of ![]() $Q_{{min}}$ when

$Q_{{min}}$ when ![]() $\mbox {Ca}$ is increased translates into a reduction of one order of magnitude of the droplet diameter

$\mbox {Ca}$ is increased translates into a reduction of one order of magnitude of the droplet diameter ![]() $d_{{min}}$ at the stability limit.

$d_{{min}}$ at the stability limit.

Figure 10. Minimum value of the flow rate ratio, ![]() $Q_{{min}}$ (a), and the corresponding droplet diameter,

$Q_{{min}}$ (a), and the corresponding droplet diameter, ![]() $d_{{min}}$ (b), vs the distance

$d_{{min}}$ (b), vs the distance ![]() $H$ between the feeding capillary and the discharge tube in the absence of surfactant for

$H$ between the feeding capillary and the discharge tube in the absence of surfactant for ![]() $\varepsilon =0.64$,

$\varepsilon =0.64$, ![]() $R_c=1.85$,

$R_c=1.85$, ![]() $\rho =1.03$,

$\rho =1.03$, ![]() $\mu =0.010$, and different values of

$\mu =0.010$, and different values of ![]() $\mbox {Ca}$ and

$\mbox {Ca}$ and ![]() $\mbox {Re}$. For

$\mbox {Re}$. For ![]() $H\simeq 0.5$ and

$H\simeq 0.5$ and ![]() $\mbox {Ca}=0.63$, the triple contact line climbs on the inner wall of the feeding capillary (open symbols). For

$\mbox {Ca}=0.63$, the triple contact line climbs on the inner wall of the feeding capillary (open symbols). For ![]() $H\gtrsim 4.5$ and

$H\gtrsim 4.5$ and ![]() $\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary (open symbols). The dashed line is a guide to the eye.

$\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary (open symbols). The dashed line is a guide to the eye.

When the outer liquid viscosity ![]() $\mu _o$ is reduced, the suction flow rate

$\mu _o$ is reduced, the suction flow rate ![]() $Q_s$ must be increased to produce tip streaming. As a consequence, the outer liquid speed in the discharge tube increases, and so does the velocity of the liquid thread ejected by the meniscus tip. This allows the system to sweep away the capillary waves growing on the thread surface (convective instability) (Huerre & Monkewitz Reference Huerre and Monkewitz1990), and the jetting regime (mode I) can be produced. Thus, for

$Q_s$ must be increased to produce tip streaming. As a consequence, the outer liquid speed in the discharge tube increases, and so does the velocity of the liquid thread ejected by the meniscus tip. This allows the system to sweep away the capillary waves growing on the thread surface (convective instability) (Huerre & Monkewitz Reference Huerre and Monkewitz1990), and the jetting regime (mode I) can be produced. Thus, for ![]() $\mu =0.107$ and

$\mu =0.107$ and ![]() $Q>Q_{{min}}$, steady jetting was found in most of our experiments, while (as mentioned above) microdripping was always obtained for

$Q>Q_{{min}}$, steady jetting was found in most of our experiments, while (as mentioned above) microdripping was always obtained for ![]() $\mu =0.010$. This occurred due to the limited outer flow rate produced by our experimental set-up for the high outer viscosity case. In fact, for a given suction flow rate, the jetting regime is more likely to occur for higher outer viscosity.

$\mu =0.010$. This occurred due to the limited outer flow rate produced by our experimental set-up for the high outer viscosity case. In fact, for a given suction flow rate, the jetting regime is more likely to occur for higher outer viscosity.

To fix the capillary and Reynolds numbers, one must fix the outer viscosity and total (suction) flow rate. Then, one must change the inner viscosity and inner flow rate so that the dependency of the critical flow rate ratio on the viscosity ratio can be analysed. The inner viscosity cannot be significantly reduced below that of water. Therefore, the only possibility is to use a viscous outer bath (e.g. 100 cSt silicone oil) and inner liquids with viscosities in the range, say, 1–10 cSt. In this case, the system is so viscous that the jetting regime cannot be produced with our experimental configuration, as explained above. For this reason, we considered water as the inner liquid and changed the bath viscosity. Unfortunately, this implies that the Reynolds and capillary numbers cannot be fixed simultaneously.

The comparison between the minimum flow rates measured for ![]() $\mu =0.010$ and 0.107 (figure 11) shows that there is a significant interval of

$\mu =0.010$ and 0.107 (figure 11) shows that there is a significant interval of ![]() $H$ within which the outer viscosity hardly affects the stability limit (it must be noted that the Reynolds and capillary numbers did not take the same values for the two cases). However, the droplet diameter was considerably smaller in the lesser viscous case because those droplets were produced in the jetting regime.

$H$ within which the outer viscosity hardly affects the stability limit (it must be noted that the Reynolds and capillary numbers did not take the same values for the two cases). However, the droplet diameter was considerably smaller in the lesser viscous case because those droplets were produced in the jetting regime.

Figure 11. Minimum value of the flow rate ratio, ![]() $Q_{{min}}$ (a), and the corresponding droplet diameter,

$Q_{{min}}$ (a), and the corresponding droplet diameter, ![]() $d_{{min}}$ (b), vs the distance

$d_{{min}}$ (b), vs the distance ![]() $H$ between the feeding capillary and the discharge tube in the absence of surfactant for

$H$ between the feeding capillary and the discharge tube in the absence of surfactant for ![]() $\varepsilon =0.62$ and

$\varepsilon =0.62$ and ![]() $R_c=1.7$. The black symbols correspond to

$R_c=1.7$. The black symbols correspond to ![]() $\rho =1.03$,

$\rho =1.03$, ![]() $\mu =0.010$,

$\mu =0.010$, ![]() $\mbox {Ca}=0.22$ and

$\mbox {Ca}=0.22$ and ![]() $\mbox {Re}=0.15$, while the blue symbols correspond to

$\mbox {Re}=0.15$, while the blue symbols correspond to ![]() $\rho =1.07$,

$\rho =1.07$, ![]() $\mu =0.107$,

$\mu =0.107$, ![]() $\mbox {Ca}=0.15$ and

$\mbox {Ca}=0.15$ and ![]() $\mbox {Re}=12$. For

$\mbox {Re}=12$. For ![]() $H\lesssim 0.7$ and

$H\lesssim 0.7$ and ![]() $\mbox {Ca}=0.15$, the triple contact line climbs on the inner wall of the feeding capillary (open symbols). For

$\mbox {Ca}=0.15$, the triple contact line climbs on the inner wall of the feeding capillary (open symbols). For ![]() $H\gtrsim 4.5$ and

$H\gtrsim 4.5$ and ![]() $\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary (open symbols). The dashed line is a guide to the eye.

$\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary (open symbols). The dashed line is a guide to the eye.

5.2. Confined selective withdrawal vs stretched flow focusing

In confined selective withdrawal a tube with a thickness smaller than or similar to the tube diameter (![]() $\varepsilon \lesssim 1$) is placed in front of the feeding capillary to focus the inner liquid current and to collect the jet/droplets ejected by the tapering meniscus. When the tube thickness is much larger than the diameter (

$\varepsilon \lesssim 1$) is placed in front of the feeding capillary to focus the inner liquid current and to collect the jet/droplets ejected by the tapering meniscus. When the tube thickness is much larger than the diameter (![]() $\varepsilon \gg 1$), the outer flow streamlines considerably change in the focusing region, which may significantly affect the outcome of the process. We conducted experiments with a very thick discharge tube to investigate this possible effect. As mentioned in the introduction, we have coined the expression ‘stretched flow focusing’ to refer to this configuration, which can be regarded as a hybrid between confined selective withdrawal and flow focusing.

$\varepsilon \gg 1$), the outer flow streamlines considerably change in the focusing region, which may significantly affect the outcome of the process. We conducted experiments with a very thick discharge tube to investigate this possible effect. As mentioned in the introduction, we have coined the expression ‘stretched flow focusing’ to refer to this configuration, which can be regarded as a hybrid between confined selective withdrawal and flow focusing.

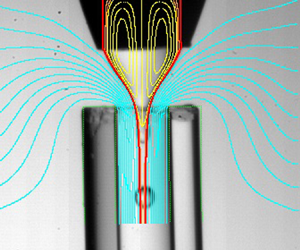

figure 12 shows the minimum value of the flow rate ratio and the corresponding droplet diameter obtained for ![]() $\mu =0.01$ with both the confined selective withdrawal and stretched flow focusing configurations. As can be observed, confined selective withdrawal considerably enhances the stability of the microdripping mode by reducing the minimum value of the flow rate ratio and by enlarging the interval of

$\mu =0.01$ with both the confined selective withdrawal and stretched flow focusing configurations. As can be observed, confined selective withdrawal considerably enhances the stability of the microdripping mode by reducing the minimum value of the flow rate ratio and by enlarging the interval of ![]() $H$ within which microdripping is produced. In fact, stable ejection was obtained with stretched flow focusing only for

$H$ within which microdripping is produced. In fact, stable ejection was obtained with stretched flow focusing only for ![]() $2\lesssim H\lesssim 3$ when the capillary number was reduced to 0.22. For

$2\lesssim H\lesssim 3$ when the capillary number was reduced to 0.22. For ![]() $\mbox {Ca}=0.63$ and

$\mbox {Ca}=0.63$ and ![]() $H\lesssim 1$, the meniscus became unstable in the stretched flow focusing configuration. The decrease of

$H\lesssim 1$, the meniscus became unstable in the stretched flow focusing configuration. The decrease of ![]() $Q_{{min}}$ achieved by confined selective withdrawal entails a significant reduction of the minimum value of the droplet diameter (figure 12b). The comparison between the images (a) and (b) in figure 13 shows that the upwards flow of the outer liquid around the discharge tube reduces the volume of the tapering meniscus and stretches the liquid thread formed at its tip. This effect seems to be responsible for the meniscus stabilization in confined selective withdrawal and allows one to reduce the droplet diameter by lowering the inner flow rate (figure 13c).

$Q_{{min}}$ achieved by confined selective withdrawal entails a significant reduction of the minimum value of the droplet diameter (figure 12b). The comparison between the images (a) and (b) in figure 13 shows that the upwards flow of the outer liquid around the discharge tube reduces the volume of the tapering meniscus and stretches the liquid thread formed at its tip. This effect seems to be responsible for the meniscus stabilization in confined selective withdrawal and allows one to reduce the droplet diameter by lowering the inner flow rate (figure 13c).

Figure 12. Minimum value of the flow rate ratio, ![]() $Q_{{min}}$ (a), and the corresponding droplet diameter,

$Q_{{min}}$ (a), and the corresponding droplet diameter, ![]() $d_{{min}}$ (b), vs the distance

$d_{{min}}$ (b), vs the distance ![]() $H$ between the feeding capillary and the discharge tube in the absence of surfactant for

$H$ between the feeding capillary and the discharge tube in the absence of surfactant for ![]() $\varepsilon =0.64$ (confined selective withdrawal) (squares) and

$\varepsilon =0.64$ (confined selective withdrawal) (squares) and ![]() $\varepsilon =22.2$ (stretched flow focusing) (triangles). The black and red symbols correspond to (

$\varepsilon =22.2$ (stretched flow focusing) (triangles). The black and red symbols correspond to (![]() $Ca=0.63$,

$Ca=0.63$, ![]() $Re=0.41$) and (

$Re=0.41$) and (![]() $\mbox {Ca}=0.22$,

$\mbox {Ca}=0.22$, ![]() $Re=0.15$), respectively. The rest of the governing parameters are

$Re=0.15$), respectively. The rest of the governing parameters are ![]() $R_c=1.8$,

$R_c=1.8$, ![]() $\rho =1.03$ and

$\rho =1.03$ and ![]() $\mu =0.010$. For

$\mu =0.010$. For ![]() $H\lesssim 0.5$ and

$H\lesssim 0.5$ and ![]() $\mbox {Ca}=0.63$, the triple contact line climbs on the inner wall of the feeding capillary in the confined selective withdrawal configuration. For

$\mbox {Ca}=0.63$, the triple contact line climbs on the inner wall of the feeding capillary in the confined selective withdrawal configuration. For ![]() $H\gtrsim 4.5$ and

$H\gtrsim 4.5$ and ![]() $\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary in the confined selective withdrawal configuration.

$\mbox {Ca}=0.22$, the triple contact line climbs on the outer wall of the feeding capillary in the confined selective withdrawal configuration.

Figure 13. Images of the ejection mode in the absence of surfactant for (![]() $\varepsilon =10.6$,

$\varepsilon =10.6$, ![]() $Q=Q_{{min}}=0.021$) (a), (

$Q=Q_{{min}}=0.021$) (a), (![]() $\varepsilon =0.64$,

$\varepsilon =0.64$, ![]() $Q=0.021$) (b) and (

$Q=0.021$) (b) and (![]() $\varepsilon =0.64$,

$\varepsilon =0.64$, ![]() $Q=0.012$) (c). The rest of the governing parameters are

$Q=0.012$) (c). The rest of the governing parameters are ![]() $R_c=1.9$,

$R_c=1.9$, ![]() $H=3.3$,

$H=3.3$, ![]() $\rho =1.03$,

$\rho =1.03$, ![]() $\mu =0.010$,

$\mu =0.010$, ![]() $Re=0.41$ and

$Re=0.41$ and ![]() $\mbox {Ca}=0.63$.

$\mbox {Ca}=0.63$.

figure 14 shows the results obtained when the outer viscosity is reduced (![]() $\mu =0.1$). In this case, the minimum flow rate ratio reached by the two configurations for large values of

$\mu =0.1$). In this case, the minimum flow rate ratio reached by the two configurations for large values of ![]() $H$ is practically the same, although the jet (and, therefore, the droplets) emitted by confined selective withdrawal is slightly thinner (figure 14b). The difference between the values of

$H$ is practically the same, although the jet (and, therefore, the droplets) emitted by confined selective withdrawal is slightly thinner (figure 14b). The difference between the values of ![]() $Q_{{min}}$ becomes noticeable as

$Q_{{min}}$ becomes noticeable as ![]() $H$ decreases. In fact, stretched flow focusing ceases to produce a stable ejection for

$H$ decreases. In fact, stretched flow focusing ceases to produce a stable ejection for ![]() $H\lesssim 1.3$, while confined selective withdrawal keeps running for smaller values of the capillary-to-orifice distance. This result may be expected because the tapering meniscus is ‘compressed’ between the feeding capillary and the discharge tube as

$H\lesssim 1.3$, while confined selective withdrawal keeps running for smaller values of the capillary-to-orifice distance. This result may be expected because the tapering meniscus is ‘compressed’ between the feeding capillary and the discharge tube as ![]() $H$ decreases in the two configurations. For this reason, the meniscus stability becomes more sensitive to variations of the outer flow in the focusing region.

$H$ decreases in the two configurations. For this reason, the meniscus stability becomes more sensitive to variations of the outer flow in the focusing region.

Figure 14. Minimum value of the flow rate ratio, ![]() $Q_{{min}}$ (a), and the corresponding droplet diameter,

$Q_{{min}}$ (a), and the corresponding droplet diameter, ![]() $d_{{min}}$ (b), vs the distance

$d_{{min}}$ (b), vs the distance ![]() $H$ between the feeding capillary and the discharge tube in the absence of surfactant for

$H$ between the feeding capillary and the discharge tube in the absence of surfactant for ![]() $\varepsilon =0.64$ (confined selective withdrawal) (squares) and

$\varepsilon =0.64$ (confined selective withdrawal) (squares) and ![]() $\varepsilon =10.6$ (stretched flow focusing) (triangles). The rest of the governing parameters are

$\varepsilon =10.6$ (stretched flow focusing) (triangles). The rest of the governing parameters are ![]() $R_c=1.8$,

$R_c=1.8$, ![]() $\rho =1.07$,

$\rho =1.07$, ![]() $\mu =0.107$,

$\mu =0.107$, ![]() $\mbox {Re}=11$ and

$\mbox {Re}=11$ and ![]() $\mbox {Ca}=0.15$. For

$\mbox {Ca}=0.15$. For ![]() $H\lesssim 0.7$, the triple contact line climbs on the inner wall of the feeding capillary in the confined selective withdrawal configuration.

$H\lesssim 0.7$, the triple contact line climbs on the inner wall of the feeding capillary in the confined selective withdrawal configuration.

We investigated the difference between the two configurations at the stability limit ![]() $Q=Q_{{min}}$ for a relatively large value of

$Q=Q_{{min}}$ for a relatively large value of ![]() $H$, for which the minimum flow rate is practically the same in the two cases (figure 15). Interestingly, the length of the jet emitted by confined selective withdrawal is considerably larger than that produced by stretched flow focusing even though the inner and outer flow rates are practically the same in the two cases. This comparison shows the role played by the shape of the outer flow next to the emission point. The difference between the two configurations becomes more noticeable when the value of

$H$, for which the minimum flow rate is practically the same in the two cases (figure 15). Interestingly, the length of the jet emitted by confined selective withdrawal is considerably larger than that produced by stretched flow focusing even though the inner and outer flow rates are practically the same in the two cases. This comparison shows the role played by the shape of the outer flow next to the emission point. The difference between the two configurations becomes more noticeable when the value of ![]() $H$ is decreased (figure 16). In this case, and as mentioned above, the inner flow rate in confined selective withdrawal can be reduced beyond the minimum value for stretched flow focusing, which significantly reduces the droplet diameter.

$H$ is decreased (figure 16). In this case, and as mentioned above, the inner flow rate in confined selective withdrawal can be reduced beyond the minimum value for stretched flow focusing, which significantly reduces the droplet diameter.

Figure 15. Images of the ejection mode in the absence of surfactant for (![]() $\varepsilon =10.6$,

$\varepsilon =10.6$, ![]() $R_c=1.93$,

$R_c=1.93$, ![]() $Re=10.3$) (a), (

$Re=10.3$) (a), (![]() $\varepsilon =0.60$,

$\varepsilon =0.60$, ![]() $R_c=1.66$,

$R_c=1.66$, ![]() $Re=11.8$) (b). The rest of the governing parameters are

$Re=11.8$) (b). The rest of the governing parameters are ![]() $H=3.3$,

$H=3.3$, ![]() $\rho =1.07$,

$\rho =1.07$, ![]() $\mu =0.107$,

$\mu =0.107$, ![]() $\mbox {Ca}=0.15$ and

$\mbox {Ca}=0.15$ and ![]() $Q=Q_{{min}}=0.1$.

$Q=Q_{{min}}=0.1$.

Figure 16. Images of the ejection mode in the absence of surfactant for (![]() $\varepsilon =10.6$,

$\varepsilon =10.6$, ![]() $R_c=1.68$,

$R_c=1.68$, ![]() $H=1.7$

$H=1.7$ ![]() $Re=10.3$,

$Re=10.3$, ![]() $Q=Q_{{min}}=0.051$) (a), (

$Q=Q_{{min}}=0.051$) (a), (![]() $\varepsilon =0.60$,

$\varepsilon =0.60$, ![]() $R_c=1.46$,

$R_c=1.46$, ![]() $H=1.43$,

$H=1.43$, ![]() $Re=11.8$,

$Re=11.8$, ![]() $Q=Q_{{min}}=0.029$) (b). The rest of the governing parameters are

$Q=Q_{{min}}=0.029$) (b). The rest of the governing parameters are ![]() $\rho =1.07$,

$\rho =1.07$, ![]() $\mu =0.107$ and

$\mu =0.107$ and ![]() $\mbox {Ca}=0.15$.

$\mbox {Ca}=0.15$.

5.3. Influence of the surfactant

In the last part of our experimental analysis, we pay attention to the role played by a surfactant monolayer in the confined selective withdrawal technique. Specifically, we examine the effect of sodium dodecyl sulfate (SDS) and TWEEN 80 on the microdripping stability and the droplet diameter in the viscous case ![]() $\mu =0.01$. Sodium dodecyl sulfate and TWEEN 80 are two commonly used surfactants in microfluidics. Sodium dodecyl sulfate and TWEEN 80 are ionic and non-ionic surfactants, respectively, characterized by different adsorption/desorption times. To the best of our knowledge, the adsorption times of SDS and TWEEN have not been reported for the interface considered in our experiments. The adsorption time of SDS and TWEEN is of the order of 100 ms and 1 s, respectively, for the air–water interface and the concentrations in our experiments (Qazi et al. Reference Qazi, Schlegel, Backus, Bonn, Bonn and Shahidzadeh2020). We determined the critical micelle concentration (CMC) from surface tension measurements and obtained

$\mu =0.01$. Sodium dodecyl sulfate and TWEEN 80 are two commonly used surfactants in microfluidics. Sodium dodecyl sulfate and TWEEN 80 are ionic and non-ionic surfactants, respectively, characterized by different adsorption/desorption times. To the best of our knowledge, the adsorption times of SDS and TWEEN have not been reported for the interface considered in our experiments. The adsorption time of SDS and TWEEN is of the order of 100 ms and 1 s, respectively, for the air–water interface and the concentrations in our experiments (Qazi et al. Reference Qazi, Schlegel, Backus, Bonn, Bonn and Shahidzadeh2020). We determined the critical micelle concentration (CMC) from surface tension measurements and obtained ![]() $0.0089\,\textrm {mol}\,\textrm {l}^{-1}$ and

$0.0089\,\textrm {mol}\,\textrm {l}^{-1}$ and ![]() $0.0012\,\textrm {mol}\,\textrm {l}^{-1}$ for SDS and TWEEN 80, respectively, in good agreement with the literature (Chou et al. Reference Chou, Krishnamurthy, Randolph, Carpenter and Manning2005; Motin, Hafiz-Mia & Nasimul-Islam Reference Motin, Hafiz-Mia and Nasimul-Islam2015). The concentrations were chosen close to or larger than the CMC to obtain appreciable effects on the stability while maintaining a standard capillary jet breaking. As can be observed in figure 17, SDS dissolved in the inner liquid at 0.8 CMC and TWEEN at 1.3 CMC, which correspond to the same concentration (0.2 % wt), produce similar effects even though the adsorption time of SDS is much shorter than that of TWEEN. When the TWEEN concentration is increased up to 3.4 CMC (0.5 % wt), a significant reduction of both the minimum flow rate ratio and the corresponding droplet diameter is obtained.