1. Introduction

Parallel compressible streams are at the heart of many applications, the most classic example being jet engines with a high-speed core and a slower surrounding jet. Examples of internal flows with multiple streams include ejectors or (sc)ramjets. Such heterogeneous flows are referred to as compound flows. This study investigates the choking of internal compound flows.

Recently, Lamberts et al. (Reference Lamberts, Chatelain, Bourgeois and Bartosiewicz2018) observed that compound flows could choke upstream of the geometrical throat, in contrast to the classic downstream displacement of the sonic section due to friction. By numerically increasing the wall roughness, Kracik & Dvorak (Reference Kracik and Dvorak2023) showed that friction has this effect on compound flows as well. Lamberts et al. (Reference Lamberts, Chatelain, Bourgeois and Bartosiewicz2018) attributed the upstream shift to non-isentropic effects, but the inherent cause remained unknown. While both Lamberts et al. (Reference Lamberts, Chatelain, Bourgeois and Bartosiewicz2018) and Kracik & Dvorak (Reference Kracik and Dvorak2023) addressed this problem through axisymmetric Reynolds-averaged Navier–Stokes (RANS) simulations, to the best of the authors’ knowledge, no theoretical analysis of the sonic section displacement has been provided.

The first theoretical treatment of compound flows was proposed by Pearson, Holiday & Smith (Reference Pearson, Holiday and Smith1958). These authors introduced the idea of splitting the domain into parallel one-dimensional (1-D) streams bounded by dividing streamlines and walls. The position of these streamlines can be identified by solving mass, momentum and energy conservation in each stream, together with a force balance at the dividing streamlines. The authors assumed adiabatic and isentropic conditions for the compound flow. Hence, only a pressure force is exerted between the streams, and the force balance requires equal static pressure for the entire cross-section. This formulation leads to a closed system of equations linking the evolution of mass, momentum and energy in each stream to the evolution of the respective cross-sections and streamwise pressure distribution. Pearson et al. (Reference Pearson, Holiday and Smith1958) state that the assumption of equal pressure is reasonable if the curvature of the streamlines remains limited.

Through some manipulations of the conservation equations, Bernstein, Heiser & Hevenor (Reference Bernstein, Heiser and Hevenor1967) showed that a single equation can be obtained for the uniform static pressure. Similarly to a single 1-D stream (see e.g. Shapiro Reference Shapiro1953), this equation is singular with a division of zero by zero if the flow is choked. The major result of the study by Pearson et al. (Reference Pearson, Holiday and Smith1958) lies in the fact that a compound flow can be choked with a combination of subsonic and supersonic streams. They showed that information cannot travel upstream in the subsonic streams due to the assumption of uniform static pressure. The derivation by Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967) confirms the findings of Pearson et al. (Reference Pearson, Holiday and Smith1958) identifying the compound choking from the singularity of the pressure equation. The same compound choking condition was found by Hoge & Segars (Reference Hoge and Segars1965) by minimising the impulse function defined in Chapter 4 of Shapiro (Reference Shapiro1953). An alternative approach by Agnone (Reference Agnone1971) identifies the compound choking from the singularity of the governing equations, written in a matrix form, while Fage (Reference Fage1976) defines it through the so-called ‘elasticity of the fluid boundary’ between the streams. Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967) gave the name ‘compound flow theory’, which we also adopt. These works did not consider exchanges between the streams; hence, the flow remained isentropic.

Later work investigated the effect of forces on the compound flow. Hoge & Segars (Reference Hoge and Segars1965) explored the effects of friction between the streams and the walls, assuming isentropic and adiabatic conditions but without deriving an explicit model to account for their impact on the flow. These authors postulated that the exchange of momentum between the streams would have a minimal impact on the compound choking mechanism. A more explicit approach is presented by Clark (Reference Clark1995), Papamoschou (Reference Papamoschou1996) and Grazzini, Mazzelli & Milazzo (Reference Grazzini, Mazzelli and Milazzo2016), who used the correlation proposed by Papamoschou (Reference Papamoschou1993) to compute the shear stress between the streams. The authors used the resulting compound flow equations with momentum exchange in a 1-D ejector model but did not investigate the choking mechanism. Earlier work by Otis (Reference Otis1976) treats the mixing and choking of a compound flow for constant-area ducts. An important conclusion of that work is that additional effects such as forces or heat exchange do not affect the choking condition as derived in the original compound theory. To the best of the author's knowledge, a general treatment of compound choking with momentum exchange in variable area ducts has not yet been proposed in the literature.

This work proposes such an extension and investigates the effect of friction between the streams and the walls on the choking mechanism. It is analytically shown that the sonic section moves upstream or downstream depending on the relative magnitude of the interstream and wall friction. The analysis is similar to ‘generalised 1-D flow’ (Shapiro Reference Shapiro1953, Chapter 8), which describes quasi-1-D compressible flow of a single stream with any combination of area change, friction, heat exchange and/or mass injection. Similarly, the isentropic compound flow theory, which only includes area change, is generalised in this work by including momentum exchanges. Our contribution is both theoretical and numerical: (i) we propose a simple theoretical model that captures the position of the sonic section, and (ii) we propose a quasi-third-order approximation of the pressure gradient in the vicinity of the sonic section to circumvent the numerical issues near the singular sonic point.

The governing equations are derived in § 2 and converted into an explicit system of ordinary differential equations (ODEs). Section 3 goes into more detail on the singularity of the equation for the static pressure at the sonic section. The numerical solution of the model is discussed in § 4. Numerical test cases are presented in § 5, to compare the results with the 1-D predictions in § 6. Section 7 closes the paper with conclusions and perspectives.

2. Model definition

The governing equations are derived in their general form in § 2.1. Section 2.2 introduces the treatment of the friction forces in the equation governing the streamwise pressure gradient. The corresponding choking mechanism is analysed in § 2.3.

2.1. Governing equations

Consider an internal flow consisting of two parallel streams (cf. figure 1) of the same ideal gas. The theory can be extended to any number of streams, but this generalisation is left for future work. The streams are modelled as uniform 1-D streams, i.e. in terms of cross-stream averaged quantities. The main assumption for compound-compressible flows is that the static pressure is uniform in all cross-sections, hence

where ![]() $p$ denotes the static pressure,

$p$ denotes the static pressure, ![]() $x$ is the axial coordinate and the subscripts

$x$ is the axial coordinate and the subscripts ![]() $p$ and

$p$ and ![]() $s$ refer to the primary and secondary stream. The distribution of the cross-sections

$s$ refer to the primary and secondary stream. The distribution of the cross-sections ![]() $A_i(x)$, with

$A_i(x)$, with ![]() $i \in [p,s]$, is initially unknown and should be calculated. These are subject to a geometrical constraint imposed by the cross-section of the channel

$i \in [p,s]$, is initially unknown and should be calculated. These are subject to a geometrical constraint imposed by the cross-section of the channel ![]() $A(x)$:

$A(x)$:

The governing equations consist of the conservation of mass, momentum and energy in each stream. For a steady, quasi-1-D flow, these read as follows:

where ![]() $\rho$ denotes the density,

$\rho$ denotes the density, ![]() $u$ denotes the axial velocity,

$u$ denotes the axial velocity, ![]() $F_i$ is the net force per unit length exerted on stream

$F_i$ is the net force per unit length exerted on stream ![]() $i$ and

$i$ and ![]() $h_t$ denotes the total enthalpy. The force

$h_t$ denotes the total enthalpy. The force ![]() $F_i$ accounts for the friction between the streams and at the wall, and is defined in § 2.2. The equations imply that the streams do not exchange mass and that the separating line between the streams is the dividing streamline. Heat exchange is not considered.

$F_i$ accounts for the friction between the streams and at the wall, and is defined in § 2.2. The equations imply that the streams do not exchange mass and that the separating line between the streams is the dividing streamline. Heat exchange is not considered.

Figure 1. The considered axisymmetric nozzle has a contour ![]() $A(x)$ and contains two streams, which have the same total temperature

$A(x)$ and contains two streams, which have the same total temperature ![]() $T_t$, but can have a different total pressure

$T_t$, but can have a different total pressure ![]() $p_t$. They exchange momentum through a friction force

$p_t$. They exchange momentum through a friction force ![]() $F_{ps}$ at the dividing streamline and a wall friction force

$F_{ps}$ at the dividing streamline and a wall friction force ![]() $F_w$. The static pressure

$F_w$. The static pressure ![]() $p$ is assumed to be uniform in each cross-section. The solution consists of the streamwise distribution of the flow variables

$p$ is assumed to be uniform in each cross-section. The solution consists of the streamwise distribution of the flow variables ![]() $p$,

$p$, ![]() $p_{t,p}$,

$p_{t,p}$, ![]() $p_{t,s}$,

$p_{t,s}$, ![]() $T_{t,p}$,

$T_{t,p}$, ![]() $T_{t,s}$ and the individual cross-sections

$T_{t,s}$ and the individual cross-sections ![]() $A_p$ and

$A_p$ and ![]() $A_s$.

$A_s$.

This system of equations can be converted to an explicit system of ODEs for numerical integration. The derivation can be found in classic textbooks; for example in Chapter 8 of Shapiro (Reference Shapiro1953). The equations in terms of the static pressure ![]() $p$, the total pressure

$p$, the total pressure ![]() $p_t$ and the total temperature

$p_t$ and the total temperature ![]() $T_t$ read as follows:

$T_t$ read as follows:

having introduced the ratio of specific heats ![]() $\gamma$ and the Mach numbers

$\gamma$ and the Mach numbers ![]() $\textit {Ma}_i$,

$\textit {Ma}_i$,

where ![]() $R$ denotes the specific gas constant. Equations (2.6)–(2.8) do not form a closed system of equations because the cross-sections

$R$ denotes the specific gas constant. Equations (2.6)–(2.8) do not form a closed system of equations because the cross-sections ![]() $A_i(x)$ are unknown (as opposed to a single stream where

$A_i(x)$ are unknown (as opposed to a single stream where ![]() $A_i = A$). Nonetheless, their sum should equal the known channel's cross-section

$A_i = A$). Nonetheless, their sum should equal the known channel's cross-section ![]() $A(x)$ (2.2). The derivative

$A(x)$ (2.2). The derivative ![]() ${\rm d}A/{{\rm d}\kern0.7pt x}$ can be computed from the channel's profile, so the unknown terms

${\rm d}A/{{\rm d}\kern0.7pt x}$ can be computed from the channel's profile, so the unknown terms ![]() ${\rm d}A_i/{{\rm d}\kern0.7pt x}$ can be eliminated from the system by summing over the streams

${\rm d}A_i/{{\rm d}\kern0.7pt x}$ can be eliminated from the system by summing over the streams ![]() $i$. The gradient of the cross-section

$i$. The gradient of the cross-section ![]() $A_i$ is first isolated from (2.6),

$A_i$ is first isolated from (2.6),

where the index for the pressure is omitted because of (2.1). Note that (2.10) can be integrated to compute the cross-section of a single stream if the pressure gradient is known. Summing over the streams ![]() $i$ gives

$i$ gives

\begin{equation} \sum_{i\in[p,s]} \frac{{\rm d}A_i}{{\rm d}\kern0.7pt x} = \frac{{\rm d}A}{{\rm d}\kern0.7pt x} = \sum_{i\in[p,s]} \left[A_i\frac{1-\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}\right]\frac{1}{p} \frac{{\rm d}p}{{\rm d}\kern0.7pt x} - \sum_{i\in[p,s]}\left[\frac{1 + \left(\gamma - 1\right)\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}\right] \frac{F_i}{p}. \end{equation}

\begin{equation} \sum_{i\in[p,s]} \frac{{\rm d}A_i}{{\rm d}\kern0.7pt x} = \frac{{\rm d}A}{{\rm d}\kern0.7pt x} = \sum_{i\in[p,s]} \left[A_i\frac{1-\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}\right]\frac{1}{p} \frac{{\rm d}p}{{\rm d}\kern0.7pt x} - \sum_{i\in[p,s]}\left[\frac{1 + \left(\gamma - 1\right)\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}\right] \frac{F_i}{p}. \end{equation}The pressure gradient is the only remaining unknown, for which an explicit equation is obtained from (2.11),

\begin{equation} \frac{1}{p} \frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \dfrac{1}{\beta}\left( \dfrac{{\rm d}A}{{\rm d}\kern0.7pt x} + \sum_{i\in[p,s]}\left[\dfrac{1 + \left(\gamma - 1\right)\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}\right] \dfrac{F_i}{p}\right), \end{equation}

\begin{equation} \frac{1}{p} \frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \dfrac{1}{\beta}\left( \dfrac{{\rm d}A}{{\rm d}\kern0.7pt x} + \sum_{i\in[p,s]}\left[\dfrac{1 + \left(\gamma - 1\right)\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}\right] \dfrac{F_i}{p}\right), \end{equation}

where ![]() $\beta$ denotes the compound choking indicator,

$\beta$ denotes the compound choking indicator,

\begin{equation} \beta = \sum_{i\in[p,s]} A_i\dfrac{1-\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}. \end{equation}

\begin{equation} \beta = \sum_{i\in[p,s]} A_i\dfrac{1-\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2}. \end{equation} Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967) showed that ![]() $\beta > 0$ corresponds to a compound-subsonic flow,

$\beta > 0$ corresponds to a compound-subsonic flow, ![]() $\beta =0$ to a compound-sonic flow and

$\beta =0$ to a compound-sonic flow and ![]() $\beta < 0$ to a compound-supersonic flow. As a result, the pressure gradient and the area gradient of a compound-subsonic flow share the same sign in the absence of forces, leading to an expansion in a convergent channel and a compression in a divergent channel. Recently, Metsue et al. (Reference Metsue, Debroeyer, Poncet and Bartosiewicz2021) extended the compound choking condition to real gases and showed that the condition

$\beta < 0$ to a compound-supersonic flow. As a result, the pressure gradient and the area gradient of a compound-subsonic flow share the same sign in the absence of forces, leading to an expansion in a convergent channel and a compression in a divergent channel. Recently, Metsue et al. (Reference Metsue, Debroeyer, Poncet and Bartosiewicz2021) extended the compound choking condition to real gases and showed that the condition ![]() $\beta =0$ corresponds to the maximal combined mass flow rate.

$\beta =0$ corresponds to the maximal combined mass flow rate.

A convenient variable to identify the compound flow regime is the so-called equivalent Mach number ![]() $\textit {Ma}_{eq}$, introduced by Hedges & Hill (Reference Hedges and Hill1974),

$\textit {Ma}_{eq}$, introduced by Hedges & Hill (Reference Hedges and Hill1974),

\begin{equation} \textit{Ma}_{eq} = \left(\gamma \frac{\beta}{A}+1\right)^{-{1}/{2}}. \end{equation}

\begin{equation} \textit{Ma}_{eq} = \left(\gamma \frac{\beta}{A}+1\right)^{-{1}/{2}}. \end{equation} This equals one for a compound choked flow. Section 2.3 analyses choking in more detail. It is important to note that the forces do not affect ![]() $\beta$ and hence the compound choking criterion, as pointed out by Otis (Reference Otis1976). Moreover, as shown by Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967), compound waves can no longer travel upstream of a location

$\beta$ and hence the compound choking criterion, as pointed out by Otis (Reference Otis1976). Moreover, as shown by Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967), compound waves can no longer travel upstream of a location ![]() $x$ if

$x$ if ![]() $\beta (x) \leqslant 0$, which constitutes the fundamental principle of choking as in the case of a single stream.

$\beta (x) \leqslant 0$, which constitutes the fundamental principle of choking as in the case of a single stream.

Equations (2.7), (2.8), (2.10) and (2.12) form a closed system for the (uniform) static pressure ![]() $p$ and the total pressure

$p$ and the total pressure ![]() $p_{t,i}$, the total temperature

$p_{t,i}$, the total temperature ![]() $T_{t,i}$ and the cross-section

$T_{t,i}$ and the cross-section ![]() $A_i$ in each stream. These variables fully define the state of the flow and other variables can easily be calculated from them using classic gas dynamic relations. The explicit nature of the equations facilitates numerical integration with a shooting method. More details on the numerical solution are provided in § 4.

$A_i$ in each stream. These variables fully define the state of the flow and other variables can easily be calculated from them using classic gas dynamic relations. The explicit nature of the equations facilitates numerical integration with a shooting method. More details on the numerical solution are provided in § 4.

2.2. Model closure

The compound flow is assumed to be axisymmetric, with the primary stream surrounded by the secondary stream. Planar flows are left as technical extensions for future studies. Hence, wall friction acts only on the secondary stream. A friction coefficient ![]() $f_w$ is defined such that the friction force per unit length

$f_w$ is defined such that the friction force per unit length ![]() $F_w$ equals

$F_w$ equals

where ![]() $l_w$ denotes the wetted perimeter of the cross-section. In a circular duct,

$l_w$ denotes the wetted perimeter of the cross-section. In a circular duct, ![]() $l_w$ is related to the cross-section

$l_w$ is related to the cross-section ![]() $A$ as follows:

$A$ as follows:

where ![]() $r$ denotes the radius of the total cross-section

$r$ denotes the radius of the total cross-section ![]() $A$. Similarly, the friction between the streams is defined as (Papamoschou Reference Papamoschou1993)

$A$. Similarly, the friction between the streams is defined as (Papamoschou Reference Papamoschou1993)

where ![]() $f_{ps}$ denotes a friction coefficient and

$f_{ps}$ denotes a friction coefficient and ![]() $l_{ps}$ denotes the perimeter of the primary stream,

$l_{ps}$ denotes the perimeter of the primary stream,

The friction force between the streams opposes the stream with the highest velocity and is defined to be positive by (2.17) if ![]() $u_p > u_s$. Therefore,

$u_p > u_s$. Therefore, ![]() $F_{ps}$ opposes the primary stream, while the secondary stream is entrained by the interstream friction and decelerated by the wall friction,

$F_{ps}$ opposes the primary stream, while the secondary stream is entrained by the interstream friction and decelerated by the wall friction,

Two approaches were used in this work for both coefficients ![]() $f_w$ and

$f_w$ and ![]() $f_{ps}$ and tested to the RANS simulations in § 6.1.

$f_{ps}$ and tested to the RANS simulations in § 6.1.

The first approach was to leverage known correlations for similar flow configurations. The formula of Van Driest (Reference Van Driest1951) for the local wall friction coefficient ![]() $f_w$ under a turbulent boundary layer in a compressible flow gives

$f_w$ under a turbulent boundary layer in a compressible flow gives

where

with the dynamic viscosity ![]() $\mu$ computed with the law of Sutherland (Reference Sutherland1893), a reference viscosity

$\mu$ computed with the law of Sutherland (Reference Sutherland1893), a reference viscosity ![]() $\mu _{ref}$ of

$\mu _{ref}$ of ![]() $1.716 \times 10^{-5}$ Pa s at

$1.716 \times 10^{-5}$ Pa s at ![]() $T_{ref} = 273.2$ K, and

$T_{ref} = 273.2$ K, and ![]() $S = 110.4$ K. For the interstream friction coefficient

$S = 110.4$ K. For the interstream friction coefficient ![]() $f_{ps}$, the formula of Papamoschou (Reference Papamoschou1993) gives

$f_{ps}$, the formula of Papamoschou (Reference Papamoschou1993) gives

\begin{equation} f_{ps} = 0.013 \dfrac{(1 + u_s/u_p) (1 + \sqrt{\rho_s / \rho_p})}{1 + (u_s/u_p) \sqrt{\rho_s / \rho_p}} \left(0.25 + 0.75 \exp({-}3 \textit{Ma}_c^2)\right), \end{equation}

\begin{equation} f_{ps} = 0.013 \dfrac{(1 + u_s/u_p) (1 + \sqrt{\rho_s / \rho_p})}{1 + (u_s/u_p) \sqrt{\rho_s / \rho_p}} \left(0.25 + 0.75 \exp({-}3 \textit{Ma}_c^2)\right), \end{equation}

with all quantities evaluated locally and the local convective Mach number ![]() $\textit {Ma}_c$ is defined as follows:

$\textit {Ma}_c$ is defined as follows:

The second approach was to infer these coefficients from the RANS results using an inverse method. In this setting, both coefficients ![]() $f_w$ and

$f_w$ and ![]() $f_{ps}$ are assumed to be constant and are determined by an optimiser which seeks to minimise the

$f_{ps}$ are assumed to be constant and are determined by an optimiser which seeks to minimise the ![]() $l_2$ norm of the discrepancy between the proposed model and the results of RANS simulations. This approach is expected to be more accurate due to the calibration, provided that the assumption of constant coefficient is adequate. On the other hand, these coefficients are not expected to generalise well outside the reference data, while the correlations (2.20) and (2.22) make the model self-sufficient and closed.

$l_2$ norm of the discrepancy between the proposed model and the results of RANS simulations. This approach is expected to be more accurate due to the calibration, provided that the assumption of constant coefficient is adequate. On the other hand, these coefficients are not expected to generalise well outside the reference data, while the correlations (2.20) and (2.22) make the model self-sufficient and closed.

2.3. Choking mechanism

Substituting the forces ![]() $F_p$ and

$F_p$ and ![]() $F_s$ as defined in the section above in (2.12) leads to a rational equation for the static pressure gradient,

$F_s$ as defined in the section above in (2.12) leads to a rational equation for the static pressure gradient,

with ![]() $\beta$ defined in (2.13) and the numerator,

$\beta$ defined in (2.13) and the numerator,

where

$$\begin{gather} N_{ps} = \dfrac{f_{ps}l_{ps}}{2}\frac{\textit{Ma}_p^2 - \textit{Ma}_s^2}{\gamma \textit{Ma}_p^2 \textit{Ma}_s^2} \dfrac{\rho_p+\rho_s}{2} \left(u_p - u_s\right) \left|u_p - u_s\right| \dfrac{1}{p}, \end{gather}$$

$$\begin{gather} N_{ps} = \dfrac{f_{ps}l_{ps}}{2}\frac{\textit{Ma}_p^2 - \textit{Ma}_s^2}{\gamma \textit{Ma}_p^2 \textit{Ma}_s^2} \dfrac{\rho_p+\rho_s}{2} \left(u_p - u_s\right) \left|u_p - u_s\right| \dfrac{1}{p}, \end{gather}$$ The term ![]() $N_w$ stems from wall friction (

$N_w$ stems from wall friction ( ![]() $f_w$) and is negative by definition. The term

$f_w$) and is negative by definition. The term ![]() $N_{ps}$ is due to friction between the streams and it is positive unless the terms

$N_{ps}$ is due to friction between the streams and it is positive unless the terms ![]() $\textit {Ma}_p^2-\textit {Ma}_s^2$ and

$\textit {Ma}_p^2-\textit {Ma}_s^2$ and ![]() $u_p-u_s$ have a different sign. In the natural case

$u_p-u_s$ have a different sign. In the natural case ![]() $u_p>u_s$, this is possible only if

$u_p>u_s$, this is possible only if ![]() $T_p/T_s \geqslant u^2_p/u^2_s$. This scenario is not encountered in Lamberts et al. (Reference Lamberts, Chatelain, Bourgeois and Bartosiewicz2018) and Kracik & Dvorak (Reference Kracik and Dvorak2023) and thus not discussed further. Therefore, the interstream friction has a positive contribution to the numerator

$T_p/T_s \geqslant u^2_p/u^2_s$. This scenario is not encountered in Lamberts et al. (Reference Lamberts, Chatelain, Bourgeois and Bartosiewicz2018) and Kracik & Dvorak (Reference Kracik and Dvorak2023) and thus not discussed further. Therefore, the interstream friction has a positive contribution to the numerator ![]() $N$ in (2.24) in the considered conditions and the wall friction has a negative contribution. This leads to some fundamental implications.

$N$ in (2.24) in the considered conditions and the wall friction has a negative contribution. This leads to some fundamental implications.

A compound-subsonic flow (![]() $\beta > 0$) expands in a convergent section (

$\beta > 0$) expands in a convergent section (![]() ${\rm d}A/{{\rm d}\kern0.7pt x} < 0$) and under the action of wall friction (as in a classic Fanno flow). Conversely, it recovers pressure in a divergent section and under the action of interstream friction. This force opposes the stream with the highest velocity, seeking to equalise velocities between streams. Consequently, momentum exchange between the streams promotes flow uniformity and results in a net increase in static pressure. The opposite is true for a compound-supersonic flow.

${\rm d}A/{{\rm d}\kern0.7pt x} < 0$) and under the action of wall friction (as in a classic Fanno flow). Conversely, it recovers pressure in a divergent section and under the action of interstream friction. This force opposes the stream with the highest velocity, seeking to equalise velocities between streams. Consequently, momentum exchange between the streams promotes flow uniformity and results in a net increase in static pressure. The opposite is true for a compound-supersonic flow.

Equation (2.24) is singular in the sonic section (![]() $\beta = 0$), similarly to a single stream where the denominator equals

$\beta = 0$), similarly to a single stream where the denominator equals ![]() $1 - \textit {Ma}^2$ (cf. Shapiro Reference Shapiro1953; Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). Nevertheless, classic nozzle flows and compound flows expand continuously through the sonic section, meaning that their pressure gradient is finite at

$1 - \textit {Ma}^2$ (cf. Shapiro Reference Shapiro1953; Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). Nevertheless, classic nozzle flows and compound flows expand continuously through the sonic section, meaning that their pressure gradient is finite at ![]() $\beta =0$. This is possible according to (2.24) only if both the numerator

$\beta =0$. This is possible according to (2.24) only if both the numerator ![]() $N$ and the denominator

$N$ and the denominator ![]() $\beta$ tend to zero, leading to an indeterminate form with a finite value. This observation is corroborated by (2.11), which simplifies to

$\beta$ tend to zero, leading to an indeterminate form with a finite value. This observation is corroborated by (2.11), which simplifies to ![]() $N=0$ if

$N=0$ if ![]() $\beta =0$. In isentropic conditions (

$\beta =0$. In isentropic conditions ( ![]() $f_{ps} = f_w = 0$), a compound flow becomes sonic at the throat (

$f_{ps} = f_w = 0$), a compound flow becomes sonic at the throat (![]() ${\rm d}A/{{\rm d}\kern0.7pt x} = 0$), as shown by Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967). In non-isentropic conditions, the relative magnitudes of

${\rm d}A/{{\rm d}\kern0.7pt x} = 0$), as shown by Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967). In non-isentropic conditions, the relative magnitudes of ![]() $N_{ps}$ and

$N_{ps}$ and ![]() $N_w$ in (2.25) determine the position of the sonic section.

$N_w$ in (2.25) determine the position of the sonic section.

Wall friction has a negative contribution to the numerator. Therefore, in the absence of interstream friction ( ![]() $f_{ps}=0$), one must have

$f_{ps}=0$), one must have ![]() ${\rm d}A/{{\rm d}\kern0.7pt x}>0$ to respect

${\rm d}A/{{\rm d}\kern0.7pt x}>0$ to respect ![]() $N=0$. This implies that the sonic section is located in a divergent section, hence downstream of the throat. The wall friction has the same effect on a nozzle flow with a single stream (Shapiro Reference Shapiro1953; Beans Reference Beans1970; Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). Likewise, in the absence of wall friction (

$N=0$. This implies that the sonic section is located in a divergent section, hence downstream of the throat. The wall friction has the same effect on a nozzle flow with a single stream (Shapiro Reference Shapiro1953; Beans Reference Beans1970; Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). Likewise, in the absence of wall friction ( ![]() $f_w=0$), one must have

$f_w=0$), one must have ![]() ${\rm d}A/{{\rm d}\kern0.7pt x} < 0$ to respect

${\rm d}A/{{\rm d}\kern0.7pt x} < 0$ to respect ![]() $N=0$. This implies that the interstream friction pushes the sonic section upstream of the throat. This analysis offers a plausible explanation for the observed displacement of the sonic section by Lamberts et al. (Reference Lamberts, Chatelain, Bourgeois and Bartosiewicz2018) and Kracik & Dvorak (Reference Kracik and Dvorak2023). The interplay between both forces is investigated further in § 6.

$N=0$. This implies that the interstream friction pushes the sonic section upstream of the throat. This analysis offers a plausible explanation for the observed displacement of the sonic section by Lamberts et al. (Reference Lamberts, Chatelain, Bourgeois and Bartosiewicz2018) and Kracik & Dvorak (Reference Kracik and Dvorak2023). The interplay between both forces is investigated further in § 6.

The indeterminate pressure gradient can be computed by applying l'Hôpital's rule on (2.24) (cf. Bernstein et al. Reference Bernstein, Heiser and Hevenor1967; Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022),

where the superscript ![]() $*$ refers to the sonic section. The derivatives

$*$ refers to the sonic section. The derivatives ![]() ${\rm d}N/{{\rm d}\kern0.7pt x}$ and

${\rm d}N/{{\rm d}\kern0.7pt x}$ and ![]() ${\rm d}\beta /{{\rm d}\kern0.7pt x}$ give rise to the derivatives of Mach numbers

${\rm d}\beta /{{\rm d}\kern0.7pt x}$ give rise to the derivatives of Mach numbers ![]() $\textit {Ma}_i$, cross-sections

$\textit {Ma}_i$, cross-sections ![]() $A_i$, forces

$A_i$, forces ![]() $F_i$ and the static pressure

$F_i$ and the static pressure ![]() $p$ (see (2.25) and (2.13)), and these can be all related to the local pressure gradient. The relevant equations are presented in Appendix A.

$p$ (see (2.25) and (2.13)), and these can be all related to the local pressure gradient. The relevant equations are presented in Appendix A.

For example, the gradient of ![]() $\beta$ is given by

$\beta$ is given by

\begin{equation} \dfrac{{\rm d}\beta}{{\rm d}\kern0.7pt x} = \sum_{i\in[p,s]} \left(\dfrac{{\rm d}A_i}{{\rm d}\kern0.7pt x}\dfrac{1-\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2} - \dfrac{A_i}{\gamma \textit{Ma}_i^4}\dfrac{{\rm d}\textit{Ma}_i^2}{{\rm d}\kern0.7pt x}\right). \end{equation}

\begin{equation} \dfrac{{\rm d}\beta}{{\rm d}\kern0.7pt x} = \sum_{i\in[p,s]} \left(\dfrac{{\rm d}A_i}{{\rm d}\kern0.7pt x}\dfrac{1-\textit{Ma}_i^2}{\gamma \textit{Ma}_i^2} - \dfrac{A_i}{\gamma \textit{Ma}_i^4}\dfrac{{\rm d}\textit{Ma}_i^2}{{\rm d}\kern0.7pt x}\right). \end{equation} Writing the Mach numbers ![]() $\textit {Ma}_i$ as a function of the total and the static pressure,

$\textit {Ma}_i$ as a function of the total and the static pressure,

\begin{equation} \textit{Ma}_i^2 = \frac{2}{\gamma-1}\left(\left(\frac{p_{t,i}}{p}\right)^{(\gamma-1)/{\gamma}}-1\right), \end{equation}

\begin{equation} \textit{Ma}_i^2 = \frac{2}{\gamma-1}\left(\left(\frac{p_{t,i}}{p}\right)^{(\gamma-1)/{\gamma}}-1\right), \end{equation}

the derivatives ![]() ${\rm d}\textit {Ma}_i^2/{{\rm d}\kern0.7pt x}$ in (2.29) can be substituted by the gradients of the static and total pressures. The resulting expression for the gradient of

${\rm d}\textit {Ma}_i^2/{{\rm d}\kern0.7pt x}$ in (2.29) can be substituted by the gradients of the static and total pressures. The resulting expression for the gradient of ![]() $\beta$ thus contains first derivatives of the static pressure, the cross-sections

$\beta$ thus contains first derivatives of the static pressure, the cross-sections ![]() $A_i$ and the total pressures

$A_i$ and the total pressures ![]() $p_{t,i}$. The latter two can be substituted using (2.7) and (2.10), which contain the static pressure gradient. The resulting expression for the gradient of

$p_{t,i}$. The latter two can be substituted using (2.7) and (2.10), which contain the static pressure gradient. The resulting expression for the gradient of ![]() $\beta$ is linear with respect to the static pressure gradient, with nonlinear coefficients depending on the Mach numbers, forces and static pressure,

$\beta$ is linear with respect to the static pressure gradient, with nonlinear coefficients depending on the Mach numbers, forces and static pressure,

The analytical expressions of ![]() $c_{\beta 0}$ and

$c_{\beta 0}$ and ![]() $c_{\beta 1}$ are given by (A26) and (A27). The same approach leads to a similar linear equation for the derivative of the numerator (see (A21)). These equations are derived for constant friction coefficients, i.e. the correlations (2.20) and (2.22) are not explicitly differentiated. This approximation is deemed acceptable since the distribution of

$c_{\beta 1}$ are given by (A26) and (A27). The same approach leads to a similar linear equation for the derivative of the numerator (see (A21)). These equations are derived for constant friction coefficients, i.e. the correlations (2.20) and (2.22) are not explicitly differentiated. This approximation is deemed acceptable since the distribution of ![]() $f_w$ and

$f_w$ and ![]() $f_{ps}$ are relatively flat, as later shown in § 6. The result is an implicit equation for the static pressure gradient in the sonic section,

$f_{ps}$ are relatively flat, as later shown in § 6. The result is an implicit equation for the static pressure gradient in the sonic section,

\begin{equation} \left(\frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)^* = \dfrac{c_{N0}^* \left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)^* + c_{N1}^*}{c_{\beta0}^*\left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)^* + c_{\beta1}^*}. \end{equation}

\begin{equation} \left(\frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)^* = \dfrac{c_{N0}^* \left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)^* + c_{N1}^*}{c_{\beta0}^*\left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)^* + c_{\beta1}^*}. \end{equation} Rearranging the equation above leads to the quadratic equation (A28) for the static pressure gradient. The two roots correspond to the subsonic and the supersonic solution downstream of the sonic point (cf. Shapiro Reference Shapiro1953). For an isentropic compound flow, the derivative of the numerator corresponds to the second derivative of the cross-section ![]() ${\rm d}^2A/{{\rm d}\kern0.7pt x}^2$ (

${\rm d}^2A/{{\rm d}\kern0.7pt x}^2$ ( ![]() $f_{ps}=f_w=0$), leading to the tractable expression reported by Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967). The additional terms introduced by the friction forces preclude such a concise expression, which is why the coefficients and their analytical expressions are reported in Appendix A. Note, however, that these equations are exact and analytical.

$f_{ps}=f_w=0$), leading to the tractable expression reported by Bernstein et al. (Reference Bernstein, Heiser and Hevenor1967). The additional terms introduced by the friction forces preclude such a concise expression, which is why the coefficients and their analytical expressions are reported in Appendix A. Note, however, that these equations are exact and analytical.

3. Approximations to circumvent the singularity at the sonic section

The pressure gradient can be computed in any section using (2.32) if the flow is compound-sonic or by using (2.24) otherwise. However, (2.24) is numerically ill-conditioned near the sonic section. Therefore, approximations of the pressure gradient near the sonic section help stabilising the numerical integration. In this section, such approximations are developed analytically.

L’Hôpital's rule used in § 2.3 arises from a Taylor series expansion of the numerator and the denominator around the sonic section ![]() $x^*$, which is then evaluated at the sonic section

$x^*$, which is then evaluated at the sonic section ![]() $x^*$ itself. More generally, these expansions lead to the following equation in

$x^*$ itself. More generally, these expansions lead to the following equation in ![]() $x$, which is still exact,

$x$, which is still exact,

\begin{equation} \frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \frac{N}{\beta} = \frac{N^* + (x-x^*) \dfrac{{\rm d}N}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*)^2 \dfrac{{\rm d}^2N}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^3 \dfrac{{\rm d}^3N}{{{\rm d}\kern0.7pt x}^3}^* + \dots}{\beta^* + (x-x^*) \dfrac{{\rm d}\beta}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*)^2 \dfrac{{\rm d}^2\beta}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^3 \dfrac{{\rm d}^3\beta}{{{\rm d}\kern0.7pt x}^3}^* + \dots}. \end{equation}

\begin{equation} \frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \frac{N}{\beta} = \frac{N^* + (x-x^*) \dfrac{{\rm d}N}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*)^2 \dfrac{{\rm d}^2N}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^3 \dfrac{{\rm d}^3N}{{{\rm d}\kern0.7pt x}^3}^* + \dots}{\beta^* + (x-x^*) \dfrac{{\rm d}\beta}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*)^2 \dfrac{{\rm d}^2\beta}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^3 \dfrac{{\rm d}^3\beta}{{{\rm d}\kern0.7pt x}^3}^* + \dots}. \end{equation} Since ![]() $N^* = \beta ^* = 0$, the equation above simplifies to the following expression:

$N^* = \beta ^* = 0$, the equation above simplifies to the following expression:

\begin{equation} \frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \frac{N}{\beta} = \frac{\dfrac{{\rm d}N}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*) \dfrac{{\rm d}^2N}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^2 \dfrac{{\rm d}^3N}{{{\rm d}\kern0.7pt x}^3}^* + \dots}{\dfrac{{\rm d}\beta}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*) \dfrac{{\rm d}^2\beta}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^2 \dfrac{{\rm d}^3\beta}{{{\rm d}\kern0.7pt x}^3}^* + \dots}. \end{equation}

\begin{equation} \frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \frac{N}{\beta} = \frac{\dfrac{{\rm d}N}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*) \dfrac{{\rm d}^2N}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^2 \dfrac{{\rm d}^3N}{{{\rm d}\kern0.7pt x}^3}^* + \dots}{\dfrac{{\rm d}\beta}{{\rm d}\kern0.7pt x}^* + \dfrac{1}{2} (x-x^*) \dfrac{{\rm d}^2\beta}{{{\rm d}\kern0.7pt x}^2}^* + \dfrac{1}{6} (x-x^*)^2 \dfrac{{\rm d}^3\beta}{{{\rm d}\kern0.7pt x}^3}^* + \dots}. \end{equation}Truncating the Taylor series leads to approximations of arbitrary order in space. The first-order approximation only retains the first derivatives, which are constant since they are evaluated at the sonic section. Hence, the pressure gradient in the vicinity of the sonic section is approximated as a constant, equal to its value in the sonic section. Note that the resulting expression is identical to (2.28) and thus leads to the quadratic (2.32) in § 2.3.

Higher accuracy is obtained by retaining higher-order derivatives. The analytical expressions for the second derivatives are given by (B32) and (B42). The derivation could continue up to the third derivative, but to avoid overly cumbersome expressions, this work proceeds with a third-order approximation by numerically differentiating the analytical second derivatives.

Numerically, one has to decide when to switch from the direct equation (2.24) to the approximation (3.2). This can be achieved by imposing a tolerance on ![]() $\beta$ (or

$\beta$ (or ![]() $\textit {Ma}_{eq}$), e.g. using the approximation when

$\textit {Ma}_{eq}$), e.g. using the approximation when ![]() $-\epsilon < \beta < \epsilon$, with

$-\epsilon < \beta < \epsilon$, with ![]() $\epsilon$ an arbitrary small positive number (cf. Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). An alternative condition is based on an estimate of the truncation error in the Taylor series, which can be estimated as the magnitude of the first term after the truncation. The resulting truncation errors on the numerator and the denominator, denoted by

$\epsilon$ an arbitrary small positive number (cf. Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). An alternative condition is based on an estimate of the truncation error in the Taylor series, which can be estimated as the magnitude of the first term after the truncation. The resulting truncation errors on the numerator and the denominator, denoted by ![]() $\delta N$ and

$\delta N$ and ![]() $\delta \beta$, can be propagated to the pressure gradient as follows:

$\delta \beta$, can be propagated to the pressure gradient as follows:

\begin{equation} \delta \left(\frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x}\right) = \sqrt{\left(\frac{1}{\beta}\right)^2\left(\delta N\right)^2 + \left(-\frac{N}{\beta^2}\right)^2\left(\delta \beta\right)^2}. \end{equation}

\begin{equation} \delta \left(\frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x}\right) = \sqrt{\left(\frac{1}{\beta}\right)^2\left(\delta N\right)^2 + \left(-\frac{N}{\beta^2}\right)^2\left(\delta \beta\right)^2}. \end{equation}

Equation (3.3) is analytically available for the first-order approximation using the second derivatives for ![]() $\delta N$ and

$\delta N$ and ![]() $\delta \beta$ (cf. Appendix B). The second-order approximation requires third derivatives to estimate its error, which can be computed with finite differences (as in the quasi-third-order approximation). The switch from the direct equation (2.24) to the approximation (3.2) is based on the relative error on the static pressure gradient,

$\delta \beta$ (cf. Appendix B). The second-order approximation requires third derivatives to estimate its error, which can be computed with finite differences (as in the quasi-third-order approximation). The switch from the direct equation (2.24) to the approximation (3.2) is based on the relative error on the static pressure gradient,

\begin{equation} \frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \begin{cases} \textrm{(3.2)} & \textrm{if } \dfrac{\delta \left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)}{\left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)} \leqslant 5\,\% , \\[10pt] \textrm{(2.24)} & \textrm{otherwise.} \end{cases} \end{equation}

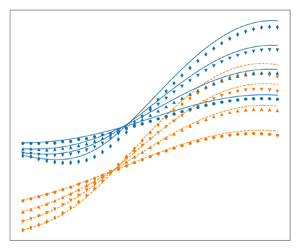

\begin{equation} \frac{1}{p}\frac{{\rm d}p}{{\rm d}\kern0.7pt x} = \begin{cases} \textrm{(3.2)} & \textrm{if } \dfrac{\delta \left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)}{\left(\dfrac{1}{p}\dfrac{{\rm d}p}{{\rm d}\kern0.7pt x}\right)} \leqslant 5\,\% , \\[10pt] \textrm{(2.24)} & \textrm{otherwise.} \end{cases} \end{equation}Examples of the distribution of the pressure gradient using the approximations of increasing order are shown in figure 2. The higher-order approximations are more accurate in a wider region around the sonic section. The estimated truncation error for the quasi-third-order approximation is not shown. The compound equations have been integrated using the blended equation (3.4) for the pressure. More details on the numerical integration are provided in § 4. The blended function (3.4) matches the direct equation (2.24) at the inlet and switches to the approximation (3.2) as the truncation error, computed with (3.3), drops below 5 %. The flow then passes through the sonic section using the approximation (3.2), effectively avoiding the indeterminate form (2.28) of the direct equation. Downstream, the direct equation is integrated when the threshold on the truncation error is exceeded again.

Figure 2. The pressure gradient computed directly with (2.24), with the approximation (3.2) (truncated after the first, second and third derivatives) and with the blended function (3.4), the shaded region indicates the truncation error estimated by (3.3), which is unavailable for the quasi-third-order approximation: (a) first order; (b) first order (zoom); (c) second order; (d) second order (zoom); (e) quasi-third-order; ( f) quasi-third-order (zoom).

In this study, the quasi-third-order approximation is used with a backward second-order finite difference formula, with a threshold of 5 % on the second-order approximation, since the fourth derivatives needed for the truncation error are not available.

4. Numerical solution

The governing equations (2.7), (2.8), (2.10), (2.24), with the approximation (3.2) near the sonic point, form a system of ODEs in function of the axial coordinate ![]() $x$, which can thus be integrated in space. The fourth-order Runge–Kutta method is used in this study, which is readily available in Python with the ‘solve_ivp’ function in SciPy (https://docs.scipy.org/doc/scipy/reference/generated/scipy.integrate.solve_ivp.html). In this study, the mesh consists of 100 equally distributed points, which has been found sufficient to accurately respect the conservation equations.

$x$, which can thus be integrated in space. The fourth-order Runge–Kutta method is used in this study, which is readily available in Python with the ‘solve_ivp’ function in SciPy (https://docs.scipy.org/doc/scipy/reference/generated/scipy.integrate.solve_ivp.html). In this study, the mesh consists of 100 equally distributed points, which has been found sufficient to accurately respect the conservation equations.

The boundary conditions consist of the total pressures ![]() $p_{t,p}, p_{t,s}$, total temperatures

$p_{t,p}, p_{t,s}$, total temperatures ![]() $T_{t,p}, T_{t,s}$ and the cross-sections

$T_{t,p}, T_{t,s}$ and the cross-sections ![]() $A_{p}, A_{s}$ at the inlet (

$A_{p}, A_{s}$ at the inlet (![]() $x=0$) and of the static pressure

$x=0$) and of the static pressure ![]() $p_b$ at the outlet (

$p_b$ at the outlet (![]() $x=L$), as indicated in figure 1. The distribution of the channel's cross-section

$x=L$), as indicated in figure 1. The distribution of the channel's cross-section ![]() $A(x)$ is prescribed. Integrating the system of ODEs requires an ‘initial’ condition at the inlet or at any point from which the integration proceeds forward in

$A(x)$ is prescribed. Integrating the system of ODEs requires an ‘initial’ condition at the inlet or at any point from which the integration proceeds forward in ![]() $x$. In a single stream computation, the sonic condition

$x$. In a single stream computation, the sonic condition ![]() $N^*=0$ is used to identify the sonic section and split the integration for the Mach number from the inlet to the sonic section and from the sonic section to the outlet (as proposed by Beans (Reference Beans1970) and Restrepo & Simões-Moreira (Reference Restrepo and Simões-Moreira2022)).

$N^*=0$ is used to identify the sonic section and split the integration for the Mach number from the inlet to the sonic section and from the sonic section to the outlet (as proposed by Beans (Reference Beans1970) and Restrepo & Simões-Moreira (Reference Restrepo and Simões-Moreira2022)).

This is not a viable option for compound flows since the sonic state is not uniquely defined (as ![]() $\textit {Ma}=1$), but can consist of various combinations of cross-sections

$\textit {Ma}=1$), but can consist of various combinations of cross-sections ![]() $A_i$ and Mach numbers

$A_i$ and Mach numbers ![]() $\textit {Ma}_i$. The system state is available at the inlet except for the static pressure

$\textit {Ma}_i$. The system state is available at the inlet except for the static pressure ![]() $p(0)$. This was found with a shooting method until the boundary condition at the outlet was respected. Firstly, bounds for the inlet pressure are established, considering that

$p(0)$. This was found with a shooting method until the boundary condition at the outlet was respected. Firstly, bounds for the inlet pressure are established, considering that ![]() $p(0)$ cannot exceed the total pressure of any stream by definition, that is the upper bound of

$p(0)$ cannot exceed the total pressure of any stream by definition, that is the upper bound of ![]() $p(0)$ is

$p(0)$ is

The compound flow is assumed to be subsonic at the inlet (as in a classic nozzle flow), so the second limiting condition is a sonic flow at the inlet (![]() $\beta (0) = 0)$. Using (2.13) and (2.30), the sonic condition at the inlet leads to the lower bound

$\beta (0) = 0)$. Using (2.13) and (2.30), the sonic condition at the inlet leads to the lower bound ![]() $p_{min}$ for the static pressure at the inlet,

$p_{min}$ for the static pressure at the inlet,

\begin{equation} \beta(0) = 0 = \sum_{i\in[p,s]}\dfrac{A_{i}}{\gamma}\left(\left[\frac{2}{\gamma-1}\left(\left(\frac{p_{t,i}(0)}{p_{min}}\right)^{(\gamma-1)/{\gamma}}-1\right)\right]^{{-}1} - 1\right), \end{equation}

\begin{equation} \beta(0) = 0 = \sum_{i\in[p,s]}\dfrac{A_{i}}{\gamma}\left(\left[\frac{2}{\gamma-1}\left(\left(\frac{p_{t,i}(0)}{p_{min}}\right)^{(\gamma-1)/{\gamma}}-1\right)\right]^{{-}1} - 1\right), \end{equation}

where ![]() $p_{min}$ can be found iteratively. The bounds

$p_{min}$ can be found iteratively. The bounds ![]() $[p_{min}, p_{max}]$ allow us to find the correct inlet pressure

$[p_{min}, p_{max}]$ allow us to find the correct inlet pressure ![]() $p(0)$ with a bisection method, which iteratively restricts the bounds of the interval as depicted in figure 3. In each iteration, the governing equations are integrated using the mean of the current interval, after which either its bottom or top half is used in the next iteration. This update depends on whether the computed flow is choked.

$p(0)$ with a bisection method, which iteratively restricts the bounds of the interval as depicted in figure 3. In each iteration, the governing equations are integrated using the mean of the current interval, after which either its bottom or top half is used in the next iteration. This update depends on whether the computed flow is choked.

Figure 3. Flowchart of the numerical procedure to solve the compound nozzle flow. The static pressure ![]() $p(0)$ at the inlet is found with a bisection method. A subsonic solution is accepted if the computed back pressure

$p(0)$ at the inlet is found with a bisection method. A subsonic solution is accepted if the computed back pressure ![]() $p(L)$ matches the boundary condition

$p(L)$ matches the boundary condition ![]() $p_b$. A choked flow requires both

$p_b$. A choked flow requires both ![]() $\beta$ and the numerator

$\beta$ and the numerator ![]() $N$ to equal zero (see (2.28)). The approximation (3.2) is computed after convergence of the choked procedure, which is then repeated, replacing (2.24) by (3.4).

$N$ to equal zero (see (2.28)). The approximation (3.2) is computed after convergence of the choked procedure, which is then repeated, replacing (2.24) by (3.4).

In the subsonic case, the inlet pressure ![]() $p(0)$ and the computed outlet pressure

$p(0)$ and the computed outlet pressure ![]() $p(L)$ are positively correlated: a lower inlet pressure leads to a lower outlet pressure. If the computed back pressure is too low with respect to the boundary condition (

$p(L)$ are positively correlated: a lower inlet pressure leads to a lower outlet pressure. If the computed back pressure is too low with respect to the boundary condition (![]() $p(L) < p_b$), the inlet pressure should increase and the average pressure

$p(L) < p_b$), the inlet pressure should increase and the average pressure ![]() $p(0)$ becomes the new lower bound of the bracket in the next iteration. The opposite is true if

$p(0)$ becomes the new lower bound of the bracket in the next iteration. The opposite is true if ![]() $p(L) < p_b$. If the pressures

$p(L) < p_b$. If the pressures ![]() $p(L)$ and

$p(L)$ and ![]() $p_b$ match, the solution has been found and the flow is compound-subsonic.

$p_b$ match, the solution has been found and the flow is compound-subsonic.

If the computed flow becomes sonic (![]() $\beta (x) = 0$), the integration is stopped locally at the sonic point and the numerator

$\beta (x) = 0$), the integration is stopped locally at the sonic point and the numerator ![]() $N$ is computed with (2.25). If the condition

$N$ is computed with (2.25). If the condition ![]() $N=0$ is not respected (see (2.28)), the inlet pressure

$N=0$ is not respected (see (2.28)), the inlet pressure ![]() $p(0)$ must be updated. A negative numerator indicates that a subsonic flow tends to expand. If this occurs in the sonic section, the sonic point is reached too far upstream, and hence the inlet pressure should be increased. Considering, for example, an isentropic compound flow (

$p(0)$ must be updated. A negative numerator indicates that a subsonic flow tends to expand. If this occurs in the sonic section, the sonic point is reached too far upstream, and hence the inlet pressure should be increased. Considering, for example, an isentropic compound flow ( ![]() $f_{ps}=f_w=0$), where the numerator

$f_{ps}=f_w=0$), where the numerator ![]() $N$ is reduced to the gradient

$N$ is reduced to the gradient ![]() ${\rm d}A/{{\rm d}\kern0.7pt x}$, it is known that the flow becomes sonic at the throat (

${\rm d}A/{{\rm d}\kern0.7pt x}$, it is known that the flow becomes sonic at the throat (![]() ${\rm d}A/{{\rm d}\kern0.7pt x} = 0$). The case

${\rm d}A/{{\rm d}\kern0.7pt x} = 0$). The case ![]() $N= {\rm d}A/{{\rm d}\kern0.7pt x} < 0$ at the sonic section implies that the sonic point is reached in a convergent section; hence, the inlet pressure should be increased to avoid having a non-physical mass flow rate exceeding the choked one. The same argument holds for a non-isentropic flow.

$N= {\rm d}A/{{\rm d}\kern0.7pt x} < 0$ at the sonic section implies that the sonic point is reached in a convergent section; hence, the inlet pressure should be increased to avoid having a non-physical mass flow rate exceeding the choked one. The same argument holds for a non-isentropic flow.

If ![]() $N=0$, the flow is sonic in the correct section, and the approximation (3.4) can be computed with the desired order of accuracy. This slightly modifies the governing equations, so the choked solution also changes. Therefore, the procedure to find the inlet pressure

$N=0$, the flow is sonic in the correct section, and the approximation (3.4) can be computed with the desired order of accuracy. This slightly modifies the governing equations, so the choked solution also changes. Therefore, the procedure to find the inlet pressure ![]() $p(0)$ is repeated, replacing (2.24) with (3.4).

$p(0)$ is repeated, replacing (2.24) with (3.4).

The resulting choked solution is available from the inlet to the sonic section (![]() $\beta (x) = 0$). The governing equations are then integrated up to the outlet, using the positive root

$\beta (x) = 0$). The governing equations are then integrated up to the outlet, using the positive root ![]() $({\rm d}p/{{\rm d}\kern0.7pt x})^*$ of (2.32) to obtain the subsonic solution. The complete solution is thus subsonic throughout, except at the sonic point. This limiting case corresponds to the highest back pressure which chokes the flow, which is commonly referred to as the critical back pressure

$({\rm d}p/{{\rm d}\kern0.7pt x})^*$ of (2.32) to obtain the subsonic solution. The complete solution is thus subsonic throughout, except at the sonic point. This limiting case corresponds to the highest back pressure which chokes the flow, which is commonly referred to as the critical back pressure ![]() $p_b^*$ in ejector modelling. The final step checks whether the choked solution respects the boundary condition

$p_b^*$ in ejector modelling. The final step checks whether the choked solution respects the boundary condition ![]() $p_b$. The flow remains choked if the imposed back pressure

$p_b$. The flow remains choked if the imposed back pressure ![]() $p_b$ is lower than the critical value

$p_b$ is lower than the critical value ![]() $p_b^*$. Otherwise, the static pressure at the inlet should increase, leading to a subsonic solution.

$p_b^*$. Otherwise, the static pressure at the inlet should increase, leading to a subsonic solution.

The supersonic solution can be obtained with the negative root ![]() $({\rm d}p/{{\rm d}\kern0.7pt x})^*$ of (2.32). If the back pressure

$({\rm d}p/{{\rm d}\kern0.7pt x})^*$ of (2.32). If the back pressure ![]() $p_b$ lies between the pressures corresponding to the two continuous choked solutions, a shock appears in the diffuser as in the case of a nozzle flow with a single stream. The shock position can be found iteratively by imposing the computed back pressure

$p_b$ lies between the pressures corresponding to the two continuous choked solutions, a shock appears in the diffuser as in the case of a nozzle flow with a single stream. The shock position can be found iteratively by imposing the computed back pressure ![]() $p(L)$ to match

$p(L)$ to match ![]() $p_b$ (see e.g. Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). However, to the authors’ knowledge, a compound shock model has not been presented in the literature.

$p_b$ (see e.g. Restrepo & Simões-Moreira Reference Restrepo and Simões-Moreira2022). However, to the authors’ knowledge, a compound shock model has not been presented in the literature.

5. Validation test cases with axisymmetric simulations

The predictions of the 1-D theoretical model are compared with postprocessed axisymmetric RANS simulations of a compound nozzle in § 6. The numerical set-up of these two-dimensional (2-D) simulations is detailed in § 5.1, and the test cases are described in § 5.2.

5.1. Numerical set-up for the RANS validation

The computational domain is shown in figure 4. It consists of an axisymmetric convergent–divergent nozzle with two distinct inlets. The simulation was carried out with a wedge-shaped domain of five degrees and a single cell in the tangential direction. The contour of the upper wall was defined as a cosine between ![]() ${\rm \pi} /2$ and

${\rm \pi} /2$ and ![]() $2{\rm \pi}$ with appropriate scaling to reach the dimensions shown in figure 4:

$2{\rm \pi}$ with appropriate scaling to reach the dimensions shown in figure 4:

Figure 4. The computational domain consists of an axisymmetric convergent–divergent nozzle with two distinct inlets. The primary stream (index ![]() $p$) is surrounded by the secondary stream (index

$p$) is surrounded by the secondary stream (index ![]() $s$). The reference geometry is defined by

$s$). The reference geometry is defined by ![]() $L = 187.5$ mm,

$L = 187.5$ mm, ![]() $R_i = 9.5$ mm,

$R_i = 9.5$ mm, ![]() $R_{th} = 9.0$ mm,

$R_{th} = 9.0$ mm, ![]() $R_o = 10$ mm and

$R_o = 10$ mm and ![]() $R_p = 0.5 R_i$. The model validation considered various throat

$R_p = 0.5 R_i$. The model validation considered various throat ![]() $R_{th}$ and the primary inlet

$R_{th}$ and the primary inlet ![]() $R_p$ radii, as described in § 5.2, while keeping the same resolution at the wall. The coarse mesh is displayed for visibility.

$R_p$ radii, as described in § 5.2, while keeping the same resolution at the wall. The coarse mesh is displayed for visibility.

Hence, the radius at the inlet (![]() $x=0$) follows from the outlet radius

$x=0$) follows from the outlet radius ![]() $R_o$, the throat radius

$R_o$, the throat radius ![]() $R_{th}$ and the length

$R_{th}$ and the length ![]() $L$. The throat is located at one-third of the domain. The analysis of the sonic section displacement was focused on a test case with nozzle lengths of 187.5 mm, outlet radius

$L$. The throat is located at one-third of the domain. The analysis of the sonic section displacement was focused on a test case with nozzle lengths of 187.5 mm, outlet radius ![]() $R_o=10$ mm, inlet radius

$R_o=10$ mm, inlet radius ![]() $R_i = 9.5$ mm, throat radios

$R_i = 9.5$ mm, throat radios ![]() $R_{th} = 9$ mm and

$R_{th} = 9$ mm and ![]() $R_p = 0.5 R_i$. For the model validation, several other geometries were considered as reported in more details in § 5.2.

$R_p = 0.5 R_i$. For the model validation, several other geometries were considered as reported in more details in § 5.2.

The mesh was generated using Gmsh (https://gmsh.info/) coupled to Python to allow full control of the number of elements and of the refinement near the walls. The simulations were performed with an adapted version of the compressible transient solver rhoCentralFoam in OpenFOAM v9 (https://openfoam.org/version/9/) with the ![]() $k-\omega$ shear stress transport turbulence model of Menter (Reference Menter1993). The adapted solver does not solve for the tangential component of the velocity, which remains equal to zero (no swirl). The law of Sutherland (Reference Sutherland1893) is used to compute the viscosity. The simulations are wall-resolved as shown in § 5.2.

$k-\omega$ shear stress transport turbulence model of Menter (Reference Menter1993). The adapted solver does not solve for the tangential component of the velocity, which remains equal to zero (no swirl). The law of Sutherland (Reference Sutherland1893) is used to compute the viscosity. The simulations are wall-resolved as shown in § 5.2.

The boundary conditions at the inlets consist of the total pressure and total temperature. The primary inlet is chosen to be supersonic, so static pressure is also imposed. A wave transmissive boundary condition is imposed at the exit as the flow is supersonic. The wall is adiabatic and treated with a slip or no-slip condition, depending on the test case. The ‘wedge’ boundary condition is imposed on the sides of the wedge to inform OpenFOAM of the axisymmetry.

The resulting 2-D flow fields are postprocessed by identifying the dividing streamline between the streams and by averaging over the resulting cross-sections. The radial position ![]() $r_{d}$ of the dividing streamline is found at any point

$r_{d}$ of the dividing streamline is found at any point ![]() $x$ by integrating the axial mass flux,

$x$ by integrating the axial mass flux,

\begin{equation} \dot{m}_p(x) = \int_0^{r_{d}(x)} \rho(x,r) u(x,r) 2 {\rm \pi}r \, {\rm d}r \quad \mbox{and} \quad \dot{m}_s(x) = \int_{r_{d}(x)}^{R} \rho(x,r) u(x,r) 2 {\rm \pi}r \, {\rm d}r, \end{equation}

\begin{equation} \dot{m}_p(x) = \int_0^{r_{d}(x)} \rho(x,r) u(x,r) 2 {\rm \pi}r \, {\rm d}r \quad \mbox{and} \quad \dot{m}_s(x) = \int_{r_{d}(x)}^{R} \rho(x,r) u(x,r) 2 {\rm \pi}r \, {\rm d}r, \end{equation}

where ![]() $u$ denotes the axial component of the velocity vector. Knowing the radius

$u$ denotes the axial component of the velocity vector. Knowing the radius ![]() $r_d(0)$ of the dividing streamline at the primary inlet, the primary mass flow rate is calculated. The evolution of the dividing streamline at any position

$r_d(0)$ of the dividing streamline at the primary inlet, the primary mass flow rate is calculated. The evolution of the dividing streamline at any position ![]() $x$ follows from (5.2a,b). The second step consists of averaging the relevant flow variables across the ejector's section, i.e.

$x$ follows from (5.2a,b). The second step consists of averaging the relevant flow variables across the ejector's section, i.e.

for ![]() $i \in [p,s]$ and where

$i \in [p,s]$ and where ![]() $e_t = c_v T + u^2/2$ denotes the total specific internal energy and

$e_t = c_v T + u^2/2$ denotes the total specific internal energy and ![]() $c_v$ is the specific heat at constant volume. The density-averaged velocity and internal energy ensure that the 1-D mass flow rate and internal energy match their integrated 2-D counterpart. The averaged static temperature, static pressure and Mach number follow from (5.3)–(5.5) and the specific gas constant

$c_v$ is the specific heat at constant volume. The density-averaged velocity and internal energy ensure that the 1-D mass flow rate and internal energy match their integrated 2-D counterpart. The averaged static temperature, static pressure and Mach number follow from (5.3)–(5.5) and the specific gas constant ![]() $R$:

$R$:

\begin{equation} \hat{T}_{i} = \frac{1}{c_v} \left(\hat{e}_{t,i}-\frac{1}{2}\hat{u}_{i}^2\right), \quad \hat{p}_i = \hat{\rho}_i R \hat{T}_i \quad \mbox{and} \quad \widehat{\textit{Ma}}_{i} = \frac{\hat{u}_{i}}{\sqrt{\gamma R \hat{T}_{i}}}.\end{equation}

\begin{equation} \hat{T}_{i} = \frac{1}{c_v} \left(\hat{e}_{t,i}-\frac{1}{2}\hat{u}_{i}^2\right), \quad \hat{p}_i = \hat{\rho}_i R \hat{T}_i \quad \mbox{and} \quad \widehat{\textit{Ma}}_{i} = \frac{\hat{u}_{i}}{\sqrt{\gamma R \hat{T}_{i}}}.\end{equation}5.2. Selected test cases

Three simulations were carried out where the wall and interstream friction forces were numerically (de)-activated. The boundary conditions are listed in table 1. At both inlets, the turbulent mixing length was set equal to 7 % of the hydraulic diameter, as recommended by Versteeg (Reference Versteeg2007). The turbulence intensity was set to 1 %, as this value proved to best match the friction coefficients predicted by (2.22).

Table 1. Boundary conditions of the simulations presented in § 6. The primary inlet is supersonic with ![]() $\textit {Ma}_p=1.22$. They cover (i) an isentropic case, (ii) a case with friction between the streams but without wall friction and (ii) a case with both forces, respectively.

$\textit {Ma}_p=1.22$. They cover (i) an isentropic case, (ii) a case with friction between the streams but without wall friction and (ii) a case with both forces, respectively.

The first simulation is inviscid and thus serves as a reference for the original compound flow theory without momentum exchange. The second simulation is viscous with a slip condition at the wall: only friction forces between the streams are thus active in this case. Finally, wall friction is included in the third case by imposing a no-slip condition along the upper boundary. A mesh convergence study was carried out on the viscous simulation with the no-slip condition. The number of cells was doubled in each direction, leading to meshes with ![]() $400 \times 25$,

$400 \times 25$, ![]() $800 \times 52$ and

$800 \times 52$ and ![]() $1600 \times 106$ cells. The resulting distributions of

$1600 \times 106$ cells. The resulting distributions of ![]() $y^+$ near the wall and the Mach number at the centreline are shown for the three meshes in figure 5. The medium and fine meshes show good agreement and are both wall-resolved. The wall friction Reynolds number

$y^+$ near the wall and the Mach number at the centreline are shown for the three meshes in figure 5. The medium and fine meshes show good agreement and are both wall-resolved. The wall friction Reynolds number ![]() $Re_{\tau } = \rho u_{\tau } D_h / \mu$ equals

$Re_{\tau } = \rho u_{\tau } D_h / \mu$ equals ![]() $1.9\times 10^4$ at the inlet and

$1.9\times 10^4$ at the inlet and ![]() $5.3 \times 10^3$ at the outlet in case 3. The results on the fine mesh are used in the next section to profit from its higher resolution.

$5.3 \times 10^3$ at the outlet in case 3. The results on the fine mesh are used in the next section to profit from its higher resolution.

Figure 5. The coarse, medium and fine mesh contain ![]() $400 \times 25$,

$400 \times 25$, ![]() $800 \times 52$ and

$800 \times 52$ and ![]() $1600 \times 106$ elements, respectively. The medium and fine meshes lead to a wall-resolved simulation and to good agreement for the Mach number at the centreline. The fine mesh is retained for the other simulations and the postprocessing. Here (a)

$1600 \times 106$ elements, respectively. The medium and fine meshes lead to a wall-resolved simulation and to good agreement for the Mach number at the centreline. The fine mesh is retained for the other simulations and the postprocessing. Here (a) ![]() $y^+$ of the first cell near the wall; (b) Mach number at the centreline.

$y^+$ of the first cell near the wall; (b) Mach number at the centreline.

A parametric study was carried out to validate the model in a wider range of conditions. The reference case is the viscous simulation with the no-slip condition at the wall (case 3 in table 1), as it is the most representative for practical applications. Three parameters were varied independently: (i) the total pressure at the secondary inlet between ![]() $p_{t,s} = 0.5$ and 3 bar; (ii) the radius of the throat between

$p_{t,s} = 0.5$ and 3 bar; (ii) the radius of the throat between ![]() $R_{th}/R_o = 0.6$ and 0.9; and (iii) the radius of the primary inlet between

$R_{th}/R_o = 0.6$ and 0.9; and (iii) the radius of the primary inlet between ![]() $R_p/R_i = 0.3$ and 0.7 (see figure 4). The correlations (2.20) and (2.22) were used in all cases, so the model was not tuned further.

$R_p/R_i = 0.3$ and 0.7 (see figure 4). The correlations (2.20) and (2.22) were used in all cases, so the model was not tuned further.

The resulting distributions of the static pressure and the Mach numbers depend on the geometry and the inlet conditions, so the static pressure imposed at the supersonic primary inlet changes too. However, the static pressure at the inlet corresponding to a choked flow without a shock train is initially unknown. The 1-D model proved to be a useful tool to compute this pressure, as it provides a cross-stream averaged description of a choked flow with a uniform static pressure profile. The 1-D model was thus run first, to provide the boundary conditions for the RANS simulations afterwards (see table 2). The primary stream is supersonic in most cases, except if ![]() $p_{t,s} \geqslant 2$ bar. In that case, only the total pressure and total temperature were imposed. The other boundary conditions remained identical to those in table 1.

$p_{t,s} \geqslant 2$ bar. In that case, only the total pressure and total temperature were imposed. The other boundary conditions remained identical to those in table 1.

Table 2. Boundary conditions for the parametric study. The primary static pressure ![]() $p_p$ was computed a priori with the 1-D model and served a posteriori as a boundary condition for the RANS simulations. The primary stream is subsonic at the inlet for

$p_p$ was computed a priori with the 1-D model and served a posteriori as a boundary condition for the RANS simulations. The primary stream is subsonic at the inlet for ![]() $p_{t,s} \geqslant 2$ bar, so the static pressure is not imposed.

$p_{t,s} \geqslant 2$ bar, so the static pressure is not imposed.

6. Results

The two approaches to close the model from § 2.2 are compared in § 6.1, followed by a validation of the model in various operating conditions and geometries in § 6.2. The effect of the friction forces on compound choking is illustrated in § 6.3. Compound choking is shown to be a plausibly more general flow blockage mechanism than individual streams reaching a unitary Mach number in § 6.4. This is demonstrated through a choked compound flow with a fully subsonic secondary stream, both with the 1-D model and with an axisymmetric RANS simulation.

6.1. Model closure

Before proceeding with the analysis of the investigated test cases, figure 6 showcases the impact of the friction coefficients at the wall and at the dividing streamline for the test case 3. Figures 6(a) and 6(b) show the streamwise evolution of the friction coefficients (i) obtained with the correlations (2.20) and (2.22), (ii) identified as constants by the inverse method as described in § 2.2 and (iii) extracted from the viscous RANS simulations as reference. The correlation (2.20) for the wall friction is adequate and follows the correct trend. The calibrated constant matches the reference on average. The friction between the streams is mostly underpredicted by correlation (2.22), as also observed by Grazzini et al. (Reference Grazzini, Mazzelli and Milazzo2016). This was found to be sensitive to the turbulent intensity at the inlets, which directly impacts the turbulent viscosity and hence the friction between the streams. Analysing this effect in further details is beyond the scope of the current work.

Figure 6. Comparison of the two approaches for determining the friction coefficients (see § 2.2). The model predicts the static pressure accurately with the correlations (2.20) and (2.22), and with the calibrated constants ( ![]() $f_w = 0.00377, f_{ps}=0.0355$). (a) Wall friction coefficient

$f_w = 0.00377, f_{ps}=0.0355$). (a) Wall friction coefficient ![]() $f_w$; (b) interstream friction coefficient

$f_w$; (b) interstream friction coefficient ![]() $f_{ps}$; (c) prediction of the static pressure with the correlations; (d) prediction of the static pressure with calibrated constants.

$f_{ps}$; (c) prediction of the static pressure with the correlations; (d) prediction of the static pressure with calibrated constants.

More importantly, the distribution of the static pressure is predicted accurately by the 1-D model in both cases, as shown in figures 6(c) and 6(d). The averaged static pressure is computed from the RANS simulations with (5.2a,b)–(5.6a–c) and is displayed with diamonds as the reference. For plotting purposes, the spacing in the markers is much larger than the mesh resolution.

It is worth noticing that the static pressure in the two streams oscillates near the inlet due to a weak shock train. This effect is not captured in the 1-D model because of the assumption of uniform static pressure. The agreement between the model and the RANS simulations shows that the correlations (2.20) and (2.22) are adequate for the purposes of this work. Moreover, the agreement between predictions with both constant and varying coefficients indicates a weak sensitivity to these parameters, justifying the exclusion of their derivatives in the approximation in § 3. All the results presented for the 1-D model in the remaining of this section were obtained with the correlations. This approach has the advantage of not requiring calibration since the model is fully closed when using (2.20) and (2.22).

6.2. Model validation

Figure 7 illustrates the distribution of the Mach numbers and the dividing streamlines for the different secondary inlet pressures (see table 2). The primary Mach number decreases significantly with increasing total pressure ![]() $p_{t,s}$, due to an increased static pressure at the inlet. Similarly, the secondary Mach number increases with increasing

$p_{t,s}$, due to an increased static pressure at the inlet. Similarly, the secondary Mach number increases with increasing ![]() $p_{t,s}$, but is less sensitive. When the total pressures are equal (uniform flow), the Mach numbers are equal in each stream at the inlet. Downstream, the secondary Mach number decreases relative to the primary due to wall friction, which is not fully counteracted by the weak shear force from the quasiuniform flow.

$p_{t,s}$, but is less sensitive. When the total pressures are equal (uniform flow), the Mach numbers are equal in each stream at the inlet. Downstream, the secondary Mach number decreases relative to the primary due to wall friction, which is not fully counteracted by the weak shear force from the quasiuniform flow.

Figure 7. Comparison of the model predictions and the postprocessed RANS simulations with varying total pressure ![]() $p_{t,s}$ at the secondary inlet and constant total pressure

$p_{t,s}$ at the secondary inlet and constant total pressure ![]() $p_{t,p} = 3$ bar at the primary inlet. The reference case is highlighted in bold. The geometry is identical to the reference case in § 5.1. The primary Mach number decreases with increasing

$p_{t,p} = 3$ bar at the primary inlet. The reference case is highlighted in bold. The geometry is identical to the reference case in § 5.1. The primary Mach number decreases with increasing ![]() $p_{t,s}$ due to a higher static pressure at the inlet and eventually becomes subsonic. The agreement degrades with a larger difference in inlet pressures. Here (a) Mach numbers; (b) dividing streamlines.

$p_{t,s}$ due to a higher static pressure at the inlet and eventually becomes subsonic. The agreement degrades with a larger difference in inlet pressures. Here (a) Mach numbers; (b) dividing streamlines.

The model agreement with RANS simulations worsens as the inlet pressure difference grows. Notably, in these cases, the primary Mach number and dividing streamline oscillate near the inlet, due to the formation of a mild shock train. The resulting oblique shocks introduce pressure losses that are not captured by the 1-D model, which assumes a uniform static pressure across the streams. Additionally, the maximal relative error of the model amounts to 10 %, which is comparable to the scatter of the data on which the correlation (2.22) is based (see Papamoschou Reference Papamoschou1993). Despite this, the overall agreement is satisfactory, especially considering that the model was not specifically calibrated for these conditions.

The throat radius ![]() $R_{th}$ was varied between 60 % and 90 % of the outlet radius