This project investigates plastic fingerprint impressions on artefacts from a Late Roman ceramics workshop at Beit Nattif in present day Israel (Figure 1). The workshop was active around AD 300, and produced figurines and oil lamps. The remains of the workshop were found in the early twentieth century, and it was subsequently excavated and partly published by Dimitri Baramki (Baramki Reference Baramki1936). The recovered material represents the largest ceramic assemblage from a figurine and oil-lamp workshop in the southern Levant; and it is an important reference for the typology and chronology of oil lamps and figurines in the region.

Figure 1. Map showing the location of the Beit Nattif site.

Baramki encountered two adjacent Roman cisterns into which the material was deposited as workshop waste. In total, fragments of approximately 700 lamps and figurines were recovered (Figure 2). Although the composition of the material from the two cisterns differs slightly, the cisterns themselves share structural similarities, and are therefore dated roughly to the same time. A study of all the figurines has recently been published (Lichtenberger Reference Lichtenberger2016). A petrographic study of some of the figurines and oil lamps suggests that they were produced using clay from the same geological formation (Cohen-Weinberger & Lichtenberger Reference Cohen-Weinberger and Lichtenberger2016). The production of oil lamps and figurines in the same workshop is common in this region (Lichtenberger Reference Lichtenberger2016: 6). As the Beit Nattif material stems from one workshop, and probably one production phase, a study of the fingerprints of this closed context is promising for understanding the workshop's organisation.

Figure 2. Female figurine from Beit Nattif (after Lichtenberger Reference Lichtenberger2016: 57 no. 63).

Approximately 20 per cent of the figurines and oil lamps display clear traces of fingerprints, known formally as friction ridge detail (FRD), on their internal surfaces. The figurines and the oil lamps were mould-made; the fingerprints therefore resulted from the production process, during which the clay was pressed into the moulds. The impression detail was preserved during firing. Fingerprints left in a matrix such as clay, and which result in a three-dimensional impression, are known as plastic fingerprints (Cowger Reference Cowger1992).

The fingerprints are the focus of the current project, and their investigation has provided insights regarding workshop organisation, the workers that were involved in the production process, the relationship between the production of figurines and oil lamps, and specific characteristics of the two cisterns. The fingerprints were studied and documented during a one-week operation in September 2017 at the Rockefeller Museum in Jerusalem, where the material is stored.

Clay fragments were initially assessed for the presence of FRD. This was accomplished by manually examining all surfaces using directed oblique lighting (Jägerbrand Reference Jägerbrand2007). Fragments were sorted into ‘high potential’, ‘low potential’ and ‘negative’ piles. High potential is defined as FRD containing a sufficient number of visible characteristics (e.g. ridge endings, bifurcations) to facilitate a comparison with other fragments. These characteristics may result in a ‘match’, meaning that both fragments of FRD came from a single source. Low potential is defined as FRD that is present, but with factors that make its use problematic. This could be the result of obscured detail, insufficient detail or a problematic angle for photography. The negative fragments were those on which no FRD was present.

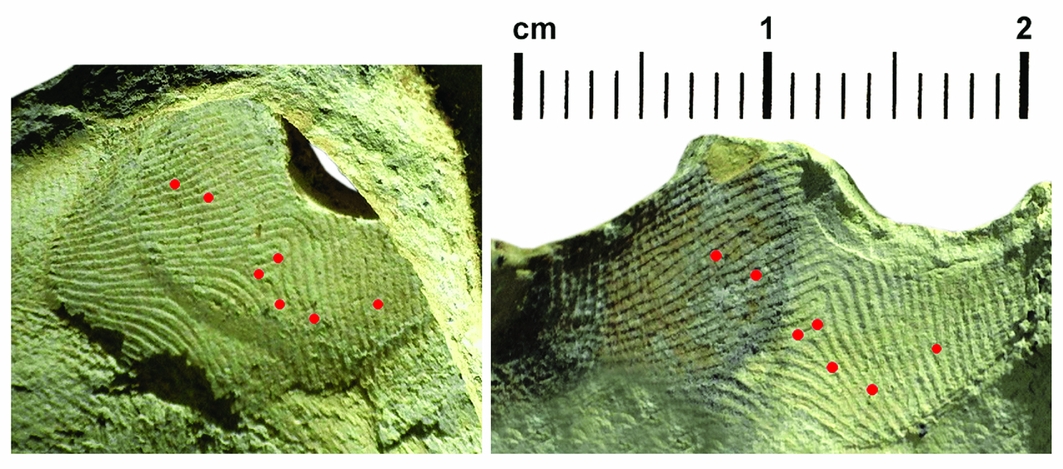

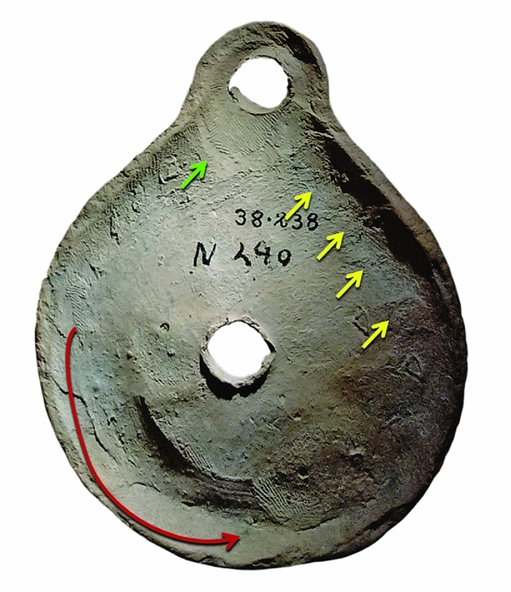

A thorough study of the fingerprints is underway, but an early finding points to one particular individual producing the oil lamps. During the initial sorting, it became apparent that a single fingerprint impression was present on multiple objects. This impression was of the ‘plain arch’ pattern, and it consistently appeared in the lower left quadrant of the lamp spout (Holder et al. Reference Holder, Robinson and Laub2011). Several of these impressions are of such quality that a comparison of ridge characteristics could be done on the spot. Figure 3 shows the ridge characteristics in agreement, confirming that the arches are from the same source (i.e. that they ‘match’ and represent the individual who manufactured these lamps). Figure 4 shows a selection of the lamps bearing the arch impression. Figure 4a shows the top of these lamps bearing their decorative elements; 4b shows their underside at the position of the lamp spout. In every case where the arch is present, it is located in the exact same position and in the same orientation. Other impressions on the underside of the lamp lid indicate the method by which the object was manufactured. The clay was pressed into the mould with pressure focused along the rim of the lid. Working counter-clockwise, the clay was smeared along the left side of the mould and then firmly pressed in a series of punctuating motions along the right side of the object. Figure 5 shows the finger impressions that serve as tool marks in the manufacturing process. FRD along the rim is in agreement with the singular arch impression, demonstrating that the same finger, most probably an index finger, was used. The counter-clockwise motion suggests that the mould was held in the left hand and the pressing action was made with the right hand. These accompanying manufacturing marks are consistent across all lamp fragments containing the arch impression, suggesting that the maker employed a well-practised methodology.

Figure 3. Ridge characteristics in agreement between oil lamps N 251 (left) and N 273 (right); the red dots represent the minutiae points that are in agreement; photograph by Kimberlee Moran.

Figure 4. Top left to top right: oil lamps N 240, N 241 and N 250; bottom left to bottom right: oil lamps N 251, N 253 and N 273.

Figure 5. Details of production process: the red arrow indicates the downwards counter-clockwise smearing of the clay within the mould. The yellow arrows indicate the punctuating impressions. The green arrow points to the arch fingerprint. The impression is left in the same location and orientation on all the lamps that contain it.

Most of the oil lamps produced by this individual were recovered from cistern 1. There is, however, a singular lamp match from cistern 2. In addition to the lamps, one figurine fragment has what initially appears to be the same arch impression. It seems that the ‘arch-maker’ was also involved in the production of figurines. This confirms what had always been assumed for Beit Nattif—namely, that the production of figurines and oil lamps took place in the same workshop. The presence of the same fingerprint on both lamps and figurines suggests that both types of material were made by the same individual. Furthermore, it is clear that there is some limited overlap between the material of cistern 1 and that of cistern 2, although it seems that the majority of each results from slightly different production phases.

Tracing the ‘arch’ fingerprint helps not only to reconstruct the specific production process of an object and the organisation of a workshop, but also contributes to tracing individual innovations. Most of the oil lamps with the ‘arch’-fingerprint were of a typical Beit Nattif type: a large disc top made from buff clay (Sussman Reference Sussman2017: 11–12). One object that was produced by the arch-maker, however, had a much smaller round mirror and red slip (Figure 6; see also Sussman Reference Sussman2017: 352–53, no. 1146). This is a unique lamp that seems to belong to an experimentation phase. It merges the round disc with the red slip and the smaller size from another type of lamp that was produced in the workshop. This experimental type, however, was not continued.

Figure 6. Lamp from Beit Nattif (Rockefeller Museum, Jerusalem, N 418). This unique lamp seems to belong to an experimentation phase. It merges styles from other lamps produced in the workshop.

Studying fingerprints allows us to come as close as possible to the past individual and to the dynamics of the way that they worked. An in-depth study of the Beit Nattif material currently being undertaken by the authors will further illuminate the workshop's organisation and the individuals working there.

Acknowledgements

The authors would like to thank the Israel Antiquities Authority in Jerusalem and the colleagues working in the Rockefeller Museum for the opportunity to study the Beit Nattif material. We especially would like to thank Alegre Savariego for her continuous help. We also would like to thank the University of Münster and Rutgers University-Camden for supporting this research, and Robert Dylka for improving the images.