1. Introduction

Shear flows are an extremely common occurrence in nature and technology. A simple example would be the fluid motion between two differentially moving parallel plates. More complex examples abound: from wind currents in the atmosphere at different speeds (Pedlosky Reference Pedlosky1987; Newman, Terry & Ware Reference Newman, Terry and Ware2007), to flow inside an industrial centrifugal reactor (Schrimpf et al. Reference Schrimpf, Esteban, Warmeling, Färber, Behr and Vorholt2021). A primary shear flow field generally involves adjacent fluid layers that move at different speeds. Under certain conditions, the primary flow can be hydrodynamically unstable and any perturbation will lead to a complex three-dimensional flow, where secondary structures can arise that are superimposed on the primary stream (Orszag & Patera Reference Orszag and Patera1983). Notable laminar secondary structures are found in the arteries in its curves and branches (Ku et al. Reference Ku1997). On the other hand, turbulent secondary structures are commonly found in geophysical and astrophysical occurrences, such as atmospheric convection cells responsible for the water cycle (Agee Reference Agee1984; Atkinson & Wu Zhang Reference Atkinson and Wu Zhang1996). They also exist in centrifugal reactors (Schrimpf et al. Reference Schrimpf, Esteban, Warmeling, Färber, Behr and Vorholt2021) and rotating reverse osmosis filtration devices (Lee & Lueptow Reference Lee and Lueptow2001a,Reference Lee and Lueptowb).

Secondary flows are a crucial component of the global properties of a system because they account for a major portion of the mass and momentum transport. Hence, the ability to affect or control these secondary structures could lead to affecting global transport properties or even the frictional losses in a system. The scientific interest behind this possibility has led to many attempts at secondary flow control (Qi et al. Reference Qi, Zou, Wang, Cao and Liu2012; Bakhuis et al. Reference Bakhuis, Ostilla-Mónico, van der Poel, Verzicco and Lohse2018, Reference Bakhuis, Ezeta, Berghout, Bullee, Tai, Chung, Verzicco, Lohse, Huisman and Sun2020; Naim & Baig Reference Naim and Baig2019). A natural place to start this investigation is to simplify the flow as much as possible to canonical models. One of the most frequently studied canonical models for shear flows and its secondary structure is Taylor–Couette flow (TCF) and its Taylor rolls, respectively.

Taylor–Couette flow (Donnelly Reference Donnelly1991; Grossmann, Lohse & Sun Reference Grossmann, Lohse and Sun2016) is the movement of the fluid between two concentric cylinders that rotate independently. A secondary flow called a Taylor roll forms if the flow is centrifugally (or Rayleigh) unstable, i.e. if the angular momentum of the inner cylinder is larger than that of the outer cylinder. At low Reynolds numbers, these are axisymmetric and laminar (Taylor Reference Taylor1923). As the Reynolds number increases, they go through a series of instabilities where they transition to increasingly turbulent states: first to wavy Taylor vortex flow, then to temporally modulated turbulent Taylor rolls and finally to turbulent Taylor rolls (Andereck, Liu & Swinney Reference Andereck, Liu and Swinney1986). As large Reynolds numbers are reached (![]() $Re\sim {O}(10^5)$), turbulent Taylor rolls wash away in certain regions of parameter space, and where they remain, their main driver is the combination of shear and solid body rotation (Lathrop, Fineberg & Swinney Reference Lathrop, Fineberg and Swinney1992b; Huisman et al. Reference Huisman, van der Veen, Sun and Lohse2014; Sacco, Verzicco & Ostilla-Mónico Reference Sacco, Verzicco and Ostilla-Mónico2019).

$Re\sim {O}(10^5)$), turbulent Taylor rolls wash away in certain regions of parameter space, and where they remain, their main driver is the combination of shear and solid body rotation (Lathrop, Fineberg & Swinney Reference Lathrop, Fineberg and Swinney1992b; Huisman et al. Reference Huisman, van der Veen, Sun and Lohse2014; Sacco, Verzicco & Ostilla-Mónico Reference Sacco, Verzicco and Ostilla-Mónico2019).

Taylor rolls are a particularly interesting example of a secondary flow because of their robustness in the turbulent regime (Zhu et al. Reference Zhu, Ostilla-Mónico, Verzicco and Lohse2016; Ostilla-Mónico et al. Reference Ostilla-Mónico, Zhu, Spandan, Verzicco and Lohse2017), and the possibility that multiple stable solutions (‘roll states’ with different roll sizes) can occur for the same boundary conditions (Coles Reference Coles1965; Huisman et al. Reference Huisman, van der Veen, Sun and Lohse2014; Martínez-Arias et al. Reference Martínez-Arias, Peixinho, Crumeyrolle and Mutabazi2014; Wen et al. Reference Wen, Zhang, Ren, Bao, Dini, Xi and Hu2020). Furthermore, Taylor rolls are commonly used in engineering applications to affect mixing properties (Lee & Lueptow Reference Lee and Lueptow2001a,Reference Lee and Lueptowb; Schrimpf et al. Reference Schrimpf, Esteban, Warmeling, Färber, Behr and Vorholt2021) and represent a large portion of the momentum transport across the cylinder gap (Brauckmann & Eckhardt Reference Brauckmann and Eckhardt2013; Ostilla-Mónico et al. Reference Ostilla-Mónico, Verzicco, Grossmann and Lohse2016b). By successfully modifying robust Taylor rolls, we can demonstrate a general capacity to modify secondary flows. The findings here can also be applied directly to TCF or TCF-like systems in engineering, such as centrifugal mixers or bioreactors.

A successful approach to affect turbulent secondary structures is to force an additional secondary flow at a different wavelength from the existing structures. This would generate a mismatch that interferes with existing or ‘natural’ secondary flows and weakens them (Bakhuis et al. Reference Bakhuis, Ostilla-Mónico, van der Poel, Verzicco and Lohse2018; Jeganathan, Alba & Ostilla-Mónico Reference Jeganathan, Alba and Ostilla-Mónico2021). In the current study we will attempt to induce Prandtl secondary flows of the second kind (Nikitin, Popelenskaya & Stroh Reference Nikitin, Popelenskaya and Stroh2021), which are turbulent secondary flows that arise to compensate for imbalances (mainly in the mean Reynolds stresses) through turbulent pulsations and can be found, for example, in turbulent rectangular pipes (Hoagland Reference Hoagland1962). The advantage of using this method is that this interference can be achieved through selective surface treating without substantially modifying an existing geometry. For example, patterns of heterogeneous roughness induce swirling motions in regions between high- and low-momentum pathways (Nugroho, Hutchins & Monty Reference Nugroho, Hutchins and Monty2013; Barros & Christensen Reference Barros and Christensen2014; Willingham et al. Reference Willingham, Anderson, Christensen and Barros2014; Anderson et al. Reference Anderson, Barros, Christensen and Awasthi2015). This swirling motion leads to secondary flows that are generated and sustained due to spanwise gradients in the Reynolds stress components, which cause an imbalance between the production and dissipation of turbulent kinetic energy that necessitates secondary advective velocities to balance (Anderson et al. Reference Anderson, Barros, Christensen and Awasthi2015). In a similar spirit, a recent study has showed that heterogeneous axially spaced roughness (equivalent to spanwise roughness in a plane geometry) is a plausible mechanism to control secondary flows in TCF (Bakhuis et al. Reference Bakhuis, Ezeta, Berghout, Bullee, Tai, Chung, Verzicco, Lohse, Huisman and Sun2020). Through a combined use of experiments and simulations, this study has reported that certain distributions of roughness induce a new, spatially fixed secondary flow that is absent from the base flow, and this effect has resulted in a large change in flow properties.

However, using roughness modifications to affect a system generally results in an increase in overall drag and causes energy losses in real-world applications. An alternative to using roughness, which increases local shear stress, is to attempt to induce the same types of secondary flow by using hydrophobic surfaces, which reduces local stress compared with untreated surfaces. This would induce similar stress imbalances and generate Prandtl secondary flows (Türk et al. Reference Türk, Daschiel, Stroh, Hasegawa and Frohnapfel2014). Idealized stress-free boundary inhomogeneities in TCF have been simulated in previous studies (Naim & Baig Reference Naim and Baig2019; Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021), which have reported a substantial modification of secondary flows when using axial (spanwise) boundary heterogeneity, with the effects persisting up to Reynolds numbers of the order of ![]() $Re\sim {O}(10^4)$. The effects are greatest when the axial heterogeneity is distributed in a pattern with a characteristic wavelength of half the wavelength of the natural structure (a single Taylor roll), causing a weakening interference between the two secondary flows (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021).

$Re\sim {O}(10^4)$. The effects are greatest when the axial heterogeneity is distributed in a pattern with a characteristic wavelength of half the wavelength of the natural structure (a single Taylor roll), causing a weakening interference between the two secondary flows (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021).

A drawback of these numerical studies is that idealized stress-free boundaries are impossible to achieve in engineering applications, thus the potential for real-world applications is uncertain. In this paper we set out to investigate whether this is experimentally feasible, i.e. whether it is possible to control secondary flows using the types of stress-reducing surfaces available in a laboratory setting. To do this, we will use a highly accessible superhydrophobic (SHP) coating (Jeevahan et al. Reference Jeevahan, Chandrasekaran, Britto Joseph, Durairaj and Mageshwaran2018) and assess its effects on TCF. Superhydrophobic coatings, unlike the stress-free limits attainable in computer simulations, have a finite-slip length and are often heavily tested for their durability (Xue et al. Reference Xue, Guo, Zhang, Ma and Jia2015; Wang et al. Reference Wang, Chen, Han, Fan, Liu and Wang2016). Recent efforts (Lambley, Schutzius & Poulikakos Reference Lambley, Schutzius and Poulikakos2020; Wang et al. Reference Wang2020) show that it is indeed possible to achieve durable SHP surfaces that can withstand extreme conditions, paving the way for studies such as the present one.

The use of SHP surfaces for flow control has not been well explored, especially in the turbulent regime. However, there are some indications that they could be effective, such as reports that SHP surfaces can delay the onset of vortex shedding in flow over a cylinder, and also increase the shedding frequency of the Kármán vortex, causing premature vortex roll up (Muralidhar et al. Reference Muralidhar, Ferrer, Daniello and Rothstein2011; Kim, Kim & Park Reference Kim, Kim and Park2015). Another study has pointed out the existence of a large number of coherent structures and a change in the vortex shedding pattern in the near wake of an SHP cylinder (Sooraj et al. Reference Sooraj, Ramagya, Khan, Sharma and Agrawal2020). In addition to affecting secondary structures, the major impact of introducing stress-free or finite-slip boundary conditions is drag reduction. Indeed, our recent TCF simulations in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021) reported torque reductions of up to 32 % when using (ideal) axial patterns of 50/50 no-slip/stress-free heterogeneity. In the laboratory, drag reduction through the use of SHP surfaces has been achieved in channel flow experiments (Watanabe, Udagawa & Udagawa Reference Watanabe, Udagawa and Udagawa1999; Cheng & Giordano Reference Cheng and Giordano2002; Tretheway & Meinhart Reference Tretheway and Meinhart2002; Ou, Perot & Rothstein Reference Ou, Perot and Rothstein2004). Taylor–Couette flow studies also report a maximum drag reduction of up to 80 % using chemically generated SHP surfaces (Srinivasan et al. Reference Srinivasan, Kleingartner, Gilbert, Cohen, Milne and McKinley2015; Hu et al. Reference Hu2017; Rajappan & McKinley Reference Rajappan and McKinley2020), and up to 90 % using stress reduction limits generated by the Leidenfrost effect (Saranadhi et al. Reference Saranadhi, Chen, Kleingartner, Srinivasan, Cohen and McKinley2016; Ayan, Entezari & Chini Reference Ayan, Entezari and Chini2019). However, we emphasize that a pure focus on drag reduction is not our main interest because through the application of SHP treatments, we expect to see a reduction in drag in the majority of cases, provided the surface is sufficiently hydrophobic and durable (Daniello, Waterhouse & Rothstein Reference Daniello, Waterhouse and Rothstein2009), as seen, for example, in ship hulls (Dong et al. Reference Dong, Cheng, Zhang, Wei and Shi2013; Hwang et al. Reference Hwang, Patir, Page, Lu, Allan and Parkin2017). We focus mainly on how the secondary structures are affected by these surface treatments, while making sure that the possible energy losses do not substantially increase.

To keep the parameter space simple, we apply SHP surface treatments only to the inner cylinder and focus on the resulting flow organization and torque for a TCF system with pure inner cylinder rotation. We study a Reynolds number of the order of ![]() $Re\sim {O}(10^4)$, where the flow is turbulent and the Taylor rolls persist. The parameter space is further restricted to only axial (spanwise) pattern wavelengths that are large enough to have an impact on large-scale structures, rather than small pattern wavelengths that do not have a significant effect on the flow (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021) and are more difficult to construct.

$Re\sim {O}(10^4)$, where the flow is turbulent and the Taylor rolls persist. The parameter space is further restricted to only axial (spanwise) pattern wavelengths that are large enough to have an impact on large-scale structures, rather than small pattern wavelengths that do not have a significant effect on the flow (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021) and are more difficult to construct.

2. Experiments

2.1. Experimental methods

A schematic of the experimental set-up is shown in figure 1(a). The dimensional and dimensionless parameters are consistently denoted with and without a hat symbol, ![]() $\hat {}$, respectively, throughout this paper. The Taylor–Couette experimental set-up is built using an aluminum inner cylinder of radius,

$\hat {}$, respectively, throughout this paper. The Taylor–Couette experimental set-up is built using an aluminum inner cylinder of radius, ![]() $\hat r_i=76.2$ mm, and an acrylic outer cylinder of radius,

$\hat r_i=76.2$ mm, and an acrylic outer cylinder of radius, ![]() $\hat r_o=92.1$ mm, leaving a gap width of

$\hat r_o=92.1$ mm, leaving a gap width of ![]() $\hat d=\hat r_o-\hat r_i=15.9$ mm. The length of the cylinders is

$\hat d=\hat r_o-\hat r_i=15.9$ mm. The length of the cylinders is ![]() $\hat l=614.7$ mm. The resulting dimensionless geometric parameters are the radius ratio,

$\hat l=614.7$ mm. The resulting dimensionless geometric parameters are the radius ratio, ![]() $\eta =\hat r_i/\hat r_o=0.83$, and the aspect ratio,

$\eta =\hat r_i/\hat r_o=0.83$, and the aspect ratio, ![]() $\varGamma _z=\hat {l}/\hat {d}=38.7$. The outer cylinder is fixed, and the inner cylinder is rotated at a rotational velocity,

$\varGamma _z=\hat {l}/\hat {d}=38.7$. The outer cylinder is fixed, and the inner cylinder is rotated at a rotational velocity, ![]() $\hat \omega _i$, driven by a brushless DC motor (IKA Eurostar 200 mixer). The shear driving strength can be expressed as a Reynolds number of the inner cylinder,

$\hat \omega _i$, driven by a brushless DC motor (IKA Eurostar 200 mixer). The shear driving strength can be expressed as a Reynolds number of the inner cylinder, ![]() $Re_i=\hat r_i \hat \omega _i \hat d/\hat {\nu }$, where

$Re_i=\hat r_i \hat \omega _i \hat d/\hat {\nu }$, where ![]() $\hat \nu$ is the kinematic viscosity of the working fluid.

$\hat \nu$ is the kinematic viscosity of the working fluid.

Figure 1. (a) Schematic of experimental set-up. (b,c) Scanning electron microscope images of the untreated aluminum surface (blue region in the schematic) and the SHP surface (yellow region in the schematic), respectively. (d) Flat and (e) stepped SHP modifications on the inner cylinder. Scanning electron microscope images of (f) the freshly coated SHP surface and (g) SHP surface sheared at the highest studied shear rate of ![]() $\hat {\dot {\varGamma }}=600$ s

$\hat {\dot {\varGamma }}=600$ s![]() $^{-1}$ for 90 min. The insets in (f) and (g) depict the contact angle of a

$^{-1}$ for 90 min. The insets in (f) and (g) depict the contact angle of a ![]() $5\ \mathrm {\mu }$L deionized water droplet on the corresponding surfaces. (h) Dimensional slip length (

$5\ \mathrm {\mu }$L deionized water droplet on the corresponding surfaces. (h) Dimensional slip length (![]() $\blacktriangle$, green) of the SHP coating measured using the rheometer at various tip shear rates. The right-hand

$\blacktriangle$, green) of the SHP coating measured using the rheometer at various tip shear rates. The right-hand ![]() $y$ axis shows the slip length non-dimensionalized by the cylinder gap width,

$y$ axis shows the slip length non-dimensionalized by the cylinder gap width, ![]() $\hat d$, from the experiments. The dotted green line shows the average slip length

$\hat d$, from the experiments. The dotted green line shows the average slip length ![]() $b=0.023$ of all tip shear rates. The error bars show the average of slip lengths measured during three separate instances (Srinivasan et al. Reference Srinivasan, Choi, Park, Chhatre, Cohen and McKinley2013). The blue region shows the zone of uncertainty caused by the onset of turbulence in rheometry tests; see Appendix A.

$b=0.023$ of all tip shear rates. The error bars show the average of slip lengths measured during three separate instances (Srinivasan et al. Reference Srinivasan, Choi, Park, Chhatre, Cohen and McKinley2013). The blue region shows the zone of uncertainty caused by the onset of turbulence in rheometry tests; see Appendix A.

As shown in figure 1(a), there is a small gap between the inner cylinder and the end caps at the top and bottom. The end caps are stationary, and this would mean a discontinuity in velocity between the inner cylinder and end caps. To minimize torque losses, the system is filled in a way such that the fluid only fills the gap up to the top surface of the inner cylinder. This means that only the space between the inner cylinder and the bottom end cap contains liquid. The gap between the inner cylinder and the cylinder's top cap contains air. With this set-up we estimate that 20–30 % of the measured torque results from the end caps and other system losses.

To achieve the SHP surfaces required to construct TCF experiments, we use a commercial two-step coating called Ultra-Ever Dry, UltraTech International, as used in a previous TCF study by Hu et al. (Reference Hu2017). The first step requires spraying a chemical called ‘bottom coat’ followed by the ‘top coat’ in the second step. The bottom coat is not SHP, but once it cures, it facilitates the self-assembly and bonding characteristic of the microstructures responsible for the superhydrophobicity found in the ‘top coat’. Microscope images comparing the uncoated and SHP surfaces are shown in figures 1(b) and 1(c), respectively. We can clearly see that the SHP-treated surface has air-trapping microstructures that cause superhydrophobicity that are largely absent on the uncoated surface. There are two ways by which one may apply the SHP coating on the inner cylinder in TCF experiments. In the first method the treated surfaces are made by sandblasting the inner cylinder, followed by spraying the coatings. This method leaves a nearly flat surface on the inner cylinder as shown in figure 1(d). Therefore, we refer to this treatment as ‘flat SHP’. In the second method we spray the SHP coating on abrasive tapes of 80 grit size, achieving a combined thickness of tape and coating of ![]() $0.58$ mm. These are fixed on the inner cylinder using an adhesive backing. This leaves a step-like structure on the system as shown in figure 1(e). We accordingly refer to this treatment as ‘stepped SHP’. Superhydrophobic patterns are applied to the inner cylinder in an axially periodic manner, as shown in figure 1(a). This is achieved by masking portions of the inner cylinder during the coating process.

$0.58$ mm. These are fixed on the inner cylinder using an adhesive backing. This leaves a step-like structure on the system as shown in figure 1(e). We accordingly refer to this treatment as ‘stepped SHP’. Superhydrophobic patterns are applied to the inner cylinder in an axially periodic manner, as shown in figure 1(a). This is achieved by masking portions of the inner cylinder during the coating process.

We define the dimensionless SHP pattern wavelength as ![]() $\lambda _z= 2\hat s_z/\hat d$, with

$\lambda _z= 2\hat s_z/\hat d$, with ![]() $\hat s_z$ being the dimensional axial width of the coating. We will explore three pattern sizes:

$\hat s_z$ being the dimensional axial width of the coating. We will explore three pattern sizes: ![]() $\lambda _z=1.2$,

$\lambda _z=1.2$, ![]() $\lambda _z=2.4$ and

$\lambda _z=2.4$ and ![]() $\lambda _z=4.8$. We have chosen these three values because of several reasons: (i) they serve to divide the cylinder equally, (ii) they roughly correspond to the values of

$\lambda _z=4.8$. We have chosen these three values because of several reasons: (i) they serve to divide the cylinder equally, (ii) they roughly correspond to the values of ![]() $\lambda _z$ studied in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021) (

$\lambda _z$ studied in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021) (![]() $1.17$ and

$1.17$ and ![]() $2.33$), and (iii) they roughly correspond to one-half, one or twice the Taylor roll wavelength one can expect at these Reynolds numbers. This last point is important as it can serve to experimentally test the prediction from Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), where we found that

$2.33$), and (iii) they roughly correspond to one-half, one or twice the Taylor roll wavelength one can expect at these Reynolds numbers. This last point is important as it can serve to experimentally test the prediction from Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), where we found that ![]() $\lambda _z=\frac {1}{2}\lambda _{TR}$ was the most effective wavelength in disrupting the turbulent Taylor rolls. We note that with this choice, we cannot distinguish whether

$\lambda _z=\frac {1}{2}\lambda _{TR}$ was the most effective wavelength in disrupting the turbulent Taylor rolls. We note that with this choice, we cannot distinguish whether ![]() $\lambda _z=1.2$,

$\lambda _z=1.2$, ![]() $\lambda _z=1.3$ or

$\lambda _z=1.3$ or ![]() $\lambda =1.4$ would be the best fit for this (or any) Taylor–Couette system, but instead focus on giving a proof of concept that axial heterogeneities with wavelengths similar to half the roll size can disrupt turbulent Taylor rolls in an experiment, and that they work better than axial heterogeneities at wavelengths comparable to a single or double roll size. Finally, as mentioned in the introduction, we did not study patterns with wavelengths smaller than

$\lambda =1.4$ would be the best fit for this (or any) Taylor–Couette system, but instead focus on giving a proof of concept that axial heterogeneities with wavelengths similar to half the roll size can disrupt turbulent Taylor rolls in an experiment, and that they work better than axial heterogeneities at wavelengths comparable to a single or double roll size. Finally, as mentioned in the introduction, we did not study patterns with wavelengths smaller than ![]() $\approx \frac {1}{2}\lambda _{TR}$, as we do not expect them to affect the rolls substantially (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021).

$\approx \frac {1}{2}\lambda _{TR}$, as we do not expect them to affect the rolls substantially (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021).

To depict the SHP microstructures more clearly, we show the microscopic image of a freshly coated SHP surface in figure 1(f). These microstructures display superhydrophobicity by creating a low surface energy (Jeevahan et al. Reference Jeevahan, Chandrasekaran, Britto Joseph, Durairaj and Mageshwaran2018) and causing the droplet contact angle to be as high as ![]() $\varTheta =160^\circ \pm 2^\circ$, as shown in the insert of figure 1(f). To demonstrate the durability of this coating, we present a microscopic image of a water droplet and its contact angle with an SHP surface that has been sheared for 90 min at a shear rate of

$\varTheta =160^\circ \pm 2^\circ$, as shown in the insert of figure 1(f). To demonstrate the durability of this coating, we present a microscopic image of a water droplet and its contact angle with an SHP surface that has been sheared for 90 min at a shear rate of ![]() $\hat {\dot {\varGamma }}=600$ s

$\hat {\dot {\varGamma }}=600$ s![]() $^{-1}$ in figure 1(g). We use this shear rate and duration as they correspond to the highest

$^{-1}$ in figure 1(g). We use this shear rate and duration as they correspond to the highest ![]() $Re_i$ in this study,

$Re_i$ in this study, ![]() $Re_i=2\times 10^4$, and to the time frame of the TCF experiments. The sheared surface still retains its SHP microstructures and a high contact angle of

$Re_i=2\times 10^4$, and to the time frame of the TCF experiments. The sheared surface still retains its SHP microstructures and a high contact angle of ![]() $\varTheta =158^\circ$, giving us confidence in the ability of the coating to withstand TCF experiments. To study the stress-reducing characteristics of SHP surface, we use the method detailed in Srinivasan et al. (Reference Srinivasan, Choi, Park, Chhatre, Cohen and McKinley2013). The experimental slip length at different tip shear rates

$\varTheta =158^\circ$, giving us confidence in the ability of the coating to withstand TCF experiments. To study the stress-reducing characteristics of SHP surface, we use the method detailed in Srinivasan et al. (Reference Srinivasan, Choi, Park, Chhatre, Cohen and McKinley2013). The experimental slip length at different tip shear rates ![]() $2\ {\rm s}^{-1}<\hat {\dot {\varGamma }}<600\ {\rm s}^{-1}$ is derived from rheometer (HR-3 Discovery hybrid model, TA Instruments) measurements presented in figure 1(h). The average slip length across all the shear rates is found to be

$2\ {\rm s}^{-1}<\hat {\dot {\varGamma }}<600\ {\rm s}^{-1}$ is derived from rheometer (HR-3 Discovery hybrid model, TA Instruments) measurements presented in figure 1(h). The average slip length across all the shear rates is found to be ![]() $\hat b=360 \pm 12\ \mathrm {\mu }$m. This corresponds to

$\hat b=360 \pm 12\ \mathrm {\mu }$m. This corresponds to ![]() $b=\hat {b}/\hat {d}=0.023$ in dimensionless terms. Further details of the characterization of the SHP surface are provided in Appendices A and B.

$b=\hat {b}/\hat {d}=0.023$ in dimensionless terms. Further details of the characterization of the SHP surface are provided in Appendices A and B.

Once the SHP surfaces are fixed to the inner cylinders of different axial patterns, we start a series of TCF experiments. The gap between the inner and outer cylinders is filled with deionized water, which is seeded with ![]() $50\ \mathrm {\mu }$m polyamide seeding particle at 0.2 g L

$50\ \mathrm {\mu }$m polyamide seeding particle at 0.2 g L![]() $^{-1}$ to obtain particle image velocity (PIV) data (Buchhave Reference Buchhave1992). The working fluid is isolated between the cylinders using various rotary and static rubber seals. Temperature fluctuations are recorded using an Omega HH308 thermometer, revealing that they are within

$^{-1}$ to obtain particle image velocity (PIV) data (Buchhave Reference Buchhave1992). The working fluid is isolated between the cylinders using various rotary and static rubber seals. Temperature fluctuations are recorded using an Omega HH308 thermometer, revealing that they are within ![]() $0.1$ K during the PIV experiments. LaVision Nd:YAG laser (

$0.1$ K during the PIV experiments. LaVision Nd:YAG laser (![]() $532$ nm) is used to generate a vertical laser sheet of thickness

$532$ nm) is used to generate a vertical laser sheet of thickness ![]() $2$ mm that illuminates the gap between the cylinders. To reduce light refraction errors from the curved acrylic outer cylinder, we have placed the TCF cell inside a cuboidal external chamber. The cuboidal chamber is made from acrylic and filled with water that has a refractive index close to that of acrylic, creating a fish tank (Moisés et al. Reference Moisés, Naccache, Alba and Frigaard2016).

$2$ mm that illuminates the gap between the cylinders. To reduce light refraction errors from the curved acrylic outer cylinder, we have placed the TCF cell inside a cuboidal external chamber. The cuboidal chamber is made from acrylic and filled with water that has a refractive index close to that of acrylic, creating a fish tank (Moisés et al. Reference Moisés, Naccache, Alba and Frigaard2016).

The system is started up by accelerating the inner cylinder at 0.279 rad s![]() $^{-2}$ to reach the desired revolutions per minute. For most cases, this achieves a reliable number of rolls, as we detail below. Before starting the PIV measurements, we wait five minutes at a given

$^{-2}$ to reach the desired revolutions per minute. For most cases, this achieves a reliable number of rolls, as we detail below. Before starting the PIV measurements, we wait five minutes at a given ![]() $Re_i$ so that the flow achieves a statistically stationary state. After this period, we use a high-speed camera (Phantom VEO 710) to record 6000 PIV images (

$Re_i$ so that the flow achieves a statistically stationary state. After this period, we use a high-speed camera (Phantom VEO 710) to record 6000 PIV images (![]() $1280 \times 504$ pixels) of the fully developed Taylor rolls at

$1280 \times 504$ pixels) of the fully developed Taylor rolls at ![]() $2000$ fps for a time period of 3 s. We selected this fps after an extensive parametric study to achieve high-resolution images. The 3 s time period corresponds to

$2000$ fps for a time period of 3 s. We selected this fps after an extensive parametric study to achieve high-resolution images. The 3 s time period corresponds to ![]() $\approx 300$ eddy turnover times of Taylor rolls,

$\approx 300$ eddy turnover times of Taylor rolls, ![]() $\hat {t}_e = \hat {d}/(\hat {r}_i\hat {\omega }_i)$, which is long enough to study their properties, while the initial wait of five minutes corresponds to

$\hat {t}_e = \hat {d}/(\hat {r}_i\hat {\omega }_i)$, which is long enough to study their properties, while the initial wait of five minutes corresponds to ![]() $\approx 3 \times 10^5$ large-eddy turnover times, more than enough to achieve a statistically stationary state (Ostilla-Mónico et al. Reference Ostilla-Mónico, Verzicco, Grossmann and Lohse2016b). The camera is fitted with a K2 DistaMax long-distance microscope to achieve a 4.4x zoom factor. The PIV images are post processed in MATLAB's open-source PIVlab software (Thielicke & Sonntag Reference Thielicke and Sonntag2021) using multi-step interrogation windows ranging from

$\approx 3 \times 10^5$ large-eddy turnover times, more than enough to achieve a statistically stationary state (Ostilla-Mónico et al. Reference Ostilla-Mónico, Verzicco, Grossmann and Lohse2016b). The camera is fitted with a K2 DistaMax long-distance microscope to achieve a 4.4x zoom factor. The PIV images are post processed in MATLAB's open-source PIVlab software (Thielicke & Sonntag Reference Thielicke and Sonntag2021) using multi-step interrogation windows ranging from ![]() $64 \times 64$ to

$64 \times 64$ to ![]() $32 \times 32$ pixels. We then obtain the instantaneous radial,

$32 \times 32$ pixels. We then obtain the instantaneous radial, ![]() $\hat {u}_r$, and axial,

$\hat {u}_r$, and axial, ![]() $\hat {u}_z$, velocity components of the flow. Torque,

$\hat {u}_z$, velocity components of the flow. Torque, ![]() $\hat T$, is measured for

$\hat T$, is measured for ![]() $600$ s at a rate of

$600$ s at a rate of ![]() $1000$ Hz using an inline rotary ultra-precision torque sensor (Himmelstein MCRT 48801 V[25-0]CFZ). The torque sensor is attached to the driving shaft that connects the motor to the TCF cell. In Appendix C we compare velocity and torque data obtained from our experiment to other experiments and simulations. We use low internal clearance P5 high-precision deep groove SKF ball bearings to reduce the effects of frictional force on the rotary seals, centrifugal forces and the buoyancy of the rotating inner cylinder on the measured torque. The temperature of water is measured during the torque measurement experiments, and the corresponding viscosities and densities are used in the Reynolds number calculations. The density and viscosity of the working fluids at different temperatures are measured using a hand-held density meter (DMA Basic 35) and a rheometer (HR-3 Discovery hybrid model, TA Instruments), respectively.

$1000$ Hz using an inline rotary ultra-precision torque sensor (Himmelstein MCRT 48801 V[25-0]CFZ). The torque sensor is attached to the driving shaft that connects the motor to the TCF cell. In Appendix C we compare velocity and torque data obtained from our experiment to other experiments and simulations. We use low internal clearance P5 high-precision deep groove SKF ball bearings to reduce the effects of frictional force on the rotary seals, centrifugal forces and the buoyancy of the rotating inner cylinder on the measured torque. The temperature of water is measured during the torque measurement experiments, and the corresponding viscosities and densities are used in the Reynolds number calculations. The density and viscosity of the working fluids at different temperatures are measured using a hand-held density meter (DMA Basic 35) and a rheometer (HR-3 Discovery hybrid model, TA Instruments), respectively.

2.2. Experimental results

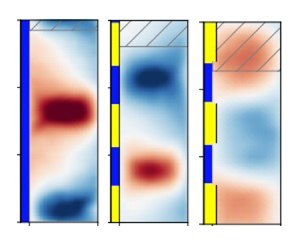

To visualize the classic no-slip turbulent TCF, we present the temporally averaged dimensionless radial velocity ![]() $\langle u_r \rangle _t$ of the flow field at

$\langle u_r \rangle _t$ of the flow field at ![]() $Re_i=10^4$ in figure 2(a) and the corresponding PIV experiment in supplementary movie M1 available at https://doi.org/10.1017/jfm.2023.606. The

$Re_i=10^4$ in figure 2(a) and the corresponding PIV experiment in supplementary movie M1 available at https://doi.org/10.1017/jfm.2023.606. The ![]() $x$ and

$x$ and ![]() $y$ axes are non-dimensionalized by gap width,

$y$ axes are non-dimensionalized by gap width, ![]() $\hat d$, with

$\hat d$, with ![]() $r=0$ corresponding to the inner cylinder and

$r=0$ corresponding to the inner cylinder and ![]() $r=1$ the outer cylinder. The average radial velocity

$r=1$ the outer cylinder. The average radial velocity ![]() $\langle \hat u_r \rangle _t$ is non-dimensionalized using the rotational velocity

$\langle \hat u_r \rangle _t$ is non-dimensionalized using the rotational velocity ![]() $\widehat {r_i} \hat \omega _i$ of the inner cylinder to obtain the dimensionless velocity presented in figure 2. The effect of different wavelengths of the SHP pattern on the turbulent TCF flow field for both flat and stepped patterns is shown in figure 2(b–h) at

$\widehat {r_i} \hat \omega _i$ of the inner cylinder to obtain the dimensionless velocity presented in figure 2. The effect of different wavelengths of the SHP pattern on the turbulent TCF flow field for both flat and stepped patterns is shown in figure 2(b–h) at ![]() $Re_i=10^4$. For the flat patterns, it is apparent that the size of the rolls formed in the system changes across different patterns, something we can attribute to the Taylor–Couette system having a range of possible solutions reflected as changing roll wavelengths (Huisman et al. Reference Huisman, van der Veen, Sun and Lohse2014; Martínez-Arias et al. Reference Martínez-Arias, Peixinho, Crumeyrolle and Mutabazi2014). This finding is consistent with Bakhuis et al. (Reference Bakhuis, Ezeta, Berghout, Bullee, Tai, Chung, Verzicco, Lohse, Huisman and Sun2020), who has used axially varying roughness to control a TCF and has observed different roll sizes in their system.

$Re_i=10^4$. For the flat patterns, it is apparent that the size of the rolls formed in the system changes across different patterns, something we can attribute to the Taylor–Couette system having a range of possible solutions reflected as changing roll wavelengths (Huisman et al. Reference Huisman, van der Veen, Sun and Lohse2014; Martínez-Arias et al. Reference Martínez-Arias, Peixinho, Crumeyrolle and Mutabazi2014). This finding is consistent with Bakhuis et al. (Reference Bakhuis, Ezeta, Berghout, Bullee, Tai, Chung, Verzicco, Lohse, Huisman and Sun2020), who has used axially varying roughness to control a TCF and has observed different roll sizes in their system.

Figure 2. Temporally averaged radial velocity results ![]() $\langle u_r \rangle _t$ from experiments at

$\langle u_r \rangle _t$ from experiments at ![]() $Re_i=10^4$. (a–d) No-slip turbulent TCF; flat SHP patterns with wavelengths

$Re_i=10^4$. (a–d) No-slip turbulent TCF; flat SHP patterns with wavelengths ![]() $\lambda _z=1.2$,

$\lambda _z=1.2$, ![]() $\lambda _z=2.4$ and

$\lambda _z=2.4$ and ![]() $\lambda _z=4.8$. (e–h) At

$\lambda _z=4.8$. (e–h) At ![]() $Re_i=10^4$, stepped pattern with no SHP coating with wavelength

$Re_i=10^4$, stepped pattern with no SHP coating with wavelength ![]() $\lambda _z=1.2$; stepped SHP patterns with wavelengths

$\lambda _z=1.2$; stepped SHP patterns with wavelengths ![]() $\lambda _z=1.2$,

$\lambda _z=1.2$, ![]() $\lambda _z=2.4$ and

$\lambda _z=2.4$ and ![]() $\lambda _z=4.8$. The areas striped in grey represent the limits of one roll pair, as measured through the autocorrelation.

$\lambda _z=4.8$. The areas striped in grey represent the limits of one roll pair, as measured through the autocorrelation.

To set the boundary of a pair of rolls and quantify the roll strength, we first calculate the roll (pair) wavelength ![]() $\lambda _{TR}$. This is given by twice the roll size determined from the axial autocorrelation of the radial velocity at the mid-gap, and in turn this is given by the (axial) distance to the first local minimum of the autocorrelation (Ostilla-Mónico, Verzicco & Lohse Reference Ostilla-Mónico, Verzicco and Lohse2015). Figure 3(a) shows how the different treatments affect

$\lambda _{TR}$. This is given by twice the roll size determined from the axial autocorrelation of the radial velocity at the mid-gap, and in turn this is given by the (axial) distance to the first local minimum of the autocorrelation (Ostilla-Mónico, Verzicco & Lohse Reference Ostilla-Mónico, Verzicco and Lohse2015). Figure 3(a) shows how the different treatments affect ![]() $\lambda _{TR}$, quantifying the previous visual intuition: the roll wavelength

$\lambda _{TR}$, quantifying the previous visual intuition: the roll wavelength ![]() $\lambda _{TR}$ varies by

$\lambda _{TR}$ varies by ![]() $\pm$20–30 % with respect to the no-slip reference case as the underlying pattern wavelength

$\pm$20–30 % with respect to the no-slip reference case as the underlying pattern wavelength ![]() $\lambda _z$ is changed.

$\lambda _z$ is changed.

Figure 3. (a) Roll wavelength ![]() $\lambda _{TR}$ obtained from autocorrelations for various flat

$\lambda _{TR}$ obtained from autocorrelations for various flat ![]() $\triangledown$ (red) and stepped

$\triangledown$ (red) and stepped ![]() $\square$ (blue) SHP pattern wavelengths at

$\square$ (blue) SHP pattern wavelengths at ![]() $Re_i=10^4$. (b) Roll strength

$Re_i=10^4$. (b) Roll strength ![]() $\sigma _r$ for the same cases. The black horizontal lines represent the reference no-slip roll wavelength

$\sigma _r$ for the same cases. The black horizontal lines represent the reference no-slip roll wavelength ![]() $\lambda _{TR}=2.85$ and roll strength

$\lambda _{TR}=2.85$ and roll strength ![]() $\sigma _r=6.02\times 10^{-2}$, respectively. The

$\sigma _r=6.02\times 10^{-2}$, respectively. The ![]() $\rhd$ (green) symbol represents a different roll state obtained for a flat pattern during experiments, and the

$\rhd$ (green) symbol represents a different roll state obtained for a flat pattern during experiments, and the ![]() $\circ$ (magenta) represents the stepped experiment with no treatment.

$\circ$ (magenta) represents the stepped experiment with no treatment.

In addition to the changes in roll size, we can also observe our intended effect: Taylor rolls are slightly affected for ![]() $\lambda _z=1.2$ as seen in figure 2(b), especially when compared with other pattern wavelengths (figures 2c and 2d) and no-slip TCF (figure 2a). To quantify this, we define the roll strength,

$\lambda _z=1.2$ as seen in figure 2(b), especially when compared with other pattern wavelengths (figures 2c and 2d) and no-slip TCF (figure 2a). To quantify this, we define the roll strength, ![]() $\sigma _r$, using the standard deviation of the average radial velocity

$\sigma _r$, using the standard deviation of the average radial velocity ![]() $\langle u_r\rangle _{t}$ along the axial direction in the mid-gap,

$\langle u_r\rangle _{t}$ along the axial direction in the mid-gap, ![]() $r=0.5$. We note that this definition is different from what is used, for example, in Sacco et al. (Reference Sacco, Verzicco and Ostilla-Mónico2019), where the roll strength is defined using the amplitude of Fourier modes. However, Fourier-based approaches are not suitable for comparisons in this study due to large deviations in the roll shape discussed later. Some care must be taken when comparing

$r=0.5$. We note that this definition is different from what is used, for example, in Sacco et al. (Reference Sacco, Verzicco and Ostilla-Mónico2019), where the roll strength is defined using the amplitude of Fourier modes. However, Fourier-based approaches are not suitable for comparisons in this study due to large deviations in the roll shape discussed later. Some care must be taken when comparing ![]() $\sigma _r$ for rolls with a different

$\sigma _r$ for rolls with a different ![]() $\lambda _{TR}$, as we can expect different values of

$\lambda _{TR}$, as we can expect different values of ![]() $\sigma _r$ for different sized rolls, as the roll footprint varies as the roll wavelength changes (c.f. Ostilla-Mónico, Lohse & Verzicco (Reference Ostilla-Mónico, Lohse and Verzicco2016a) and Appendix C).

$\sigma _r$ for different sized rolls, as the roll footprint varies as the roll wavelength changes (c.f. Ostilla-Mónico, Lohse & Verzicco (Reference Ostilla-Mónico, Lohse and Verzicco2016a) and Appendix C).

Figure 3(b) shows the roll strength ![]() $\sigma _r$ for all treatments at

$\sigma _r$ for all treatments at ![]() $Re_i=10^4$. We first observe that the roll strength corresponding to the pattern wavelength

$Re_i=10^4$. We first observe that the roll strength corresponding to the pattern wavelength ![]() $\lambda _z=1.2$ is lower than that of the no-slip TCF. The axial signature of the roll is weakened (as shown in figure 2b), and this is reflected as a smaller value of

$\lambda _z=1.2$ is lower than that of the no-slip TCF. The axial signature of the roll is weakened (as shown in figure 2b), and this is reflected as a smaller value of ![]() $\sigma _r$. The wavelength of this particular SHP pattern is almost equal to the size of a single large-scale structure in the flow (or half the roll wavelength). This matches our earlier numerical observations from Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), which also showed dramatic effects on the large-scale structures of TCF when the wavelength of the ideal free-slip pattern is equal to the size of a single structure or half the roll wavelength. Physically, this weakening is caused by the axial heterogeneity, which would generate a secondary flow in a shear flow if none are present (Anderson et al. Reference Anderson, Barros, Christensen and Awasthi2015). However, as there already is a secondary flow with a different wavelength, this heterogeneity instead induces a mismatch that interferes with the existing structures, and, as a result, weakens them.

$\sigma _r$. The wavelength of this particular SHP pattern is almost equal to the size of a single large-scale structure in the flow (or half the roll wavelength). This matches our earlier numerical observations from Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), which also showed dramatic effects on the large-scale structures of TCF when the wavelength of the ideal free-slip pattern is equal to the size of a single structure or half the roll wavelength. Physically, this weakening is caused by the axial heterogeneity, which would generate a secondary flow in a shear flow if none are present (Anderson et al. Reference Anderson, Barros, Christensen and Awasthi2015). However, as there already is a secondary flow with a different wavelength, this heterogeneity instead induces a mismatch that interferes with the existing structures, and, as a result, weakens them.

We now turn to the cases with ![]() $\lambda _z=2.4$ and

$\lambda _z=2.4$ and ![]() $\lambda _z=4.8$. Because secondary flows have changed size in response to heterogeneity, as seen in figure 3(a) (

$\lambda _z=4.8$. Because secondary flows have changed size in response to heterogeneity, as seen in figure 3(a) (![]() $\triangledown$, red symbols), the flow statistics will be affected (Ostilla-Mónico et al. Reference Ostilla-Mónico, Verzicco and Lohse2015). Hence, the change in

$\triangledown$, red symbols), the flow statistics will be affected (Ostilla-Mónico et al. Reference Ostilla-Mónico, Verzicco and Lohse2015). Hence, the change in ![]() $\sigma _r$ can potentially be attributed to changes in the roll as well as to the effect of superhydrophobicity (c.f. Appendix C). In the case of

$\sigma _r$ can potentially be attributed to changes in the roll as well as to the effect of superhydrophobicity (c.f. Appendix C). In the case of ![]() $\lambda _z=2.4$, the value of

$\lambda _z=2.4$, the value of ![]() $\sigma _r$ is higher than the value for the no-slip case, yet

$\sigma _r$ is higher than the value for the no-slip case, yet ![]() $\lambda _{TR}$ is also smaller, so no conclusions can be drawn. The case with

$\lambda _{TR}$ is also smaller, so no conclusions can be drawn. The case with ![]() $\lambda _z=4.8$ shows a slightly lower value of

$\lambda _z=4.8$ shows a slightly lower value of ![]() $\sigma _r$ than the baseline case, but

$\sigma _r$ than the baseline case, but ![]() $\lambda _{TR}$ is slightly higher, again preventing us from drawing clear conclusions and distinguishing the effect of roll weakening through the SHP treatment from the effects of variation in the roll itself. In summary, while we can see that the treatment with

$\lambda _{TR}$ is slightly higher, again preventing us from drawing clear conclusions and distinguishing the effect of roll weakening through the SHP treatment from the effects of variation in the roll itself. In summary, while we can see that the treatment with ![]() $\lambda =1.2$ is somewhat effective, as

$\lambda =1.2$ is somewhat effective, as ![]() $\sigma _r$ is lower with a smaller value of

$\sigma _r$ is lower with a smaller value of ![]() $\lambda _{TR}$, we cannot point out an optimum flat SHP wavelength as in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), at which the Taylor rolls could be weakened, or distinguish the effects of different

$\lambda _{TR}$, we cannot point out an optimum flat SHP wavelength as in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), at which the Taylor rolls could be weakened, or distinguish the effects of different ![]() $\lambda _z$.

$\lambda _z$.

Furthermore, there is the possibility that the system could have roll states with a different number of rolls for the same ![]() $\lambda _z$. In Taylor–Couette experiments the formation of different roll states is achieved through control of the cylinder acceleration and phase space trajectory (Coles Reference Coles1965; Huisman et al. Reference Huisman, van der Veen, Sun and Lohse2014; Wen et al. Reference Wen, Zhang, Ren, Bao, Dini, Xi and Hu2020). In our experiment we do not observe multiplicity of roll states in most cases: with the acceleration profile detailed in the methods section, as well as other acceleration profiles, we reliably obtain a Taylor roll wavelength of

$\lambda _z$. In Taylor–Couette experiments the formation of different roll states is achieved through control of the cylinder acceleration and phase space trajectory (Coles Reference Coles1965; Huisman et al. Reference Huisman, van der Veen, Sun and Lohse2014; Wen et al. Reference Wen, Zhang, Ren, Bao, Dini, Xi and Hu2020). In our experiment we do not observe multiplicity of roll states in most cases: with the acceleration profile detailed in the methods section, as well as other acceleration profiles, we reliably obtain a Taylor roll wavelength of ![]() $\lambda _{TR}=2.85$ for the no-slip TCF. On the other hand, for the special case of a

$\lambda _{TR}=2.85$ for the no-slip TCF. On the other hand, for the special case of a ![]() $\lambda _z=1.2$ flat SHP pattern, we can achieve states with different

$\lambda _z=1.2$ flat SHP pattern, we can achieve states with different ![]() $\lambda _{TR}$ even when the system was started up with a similar acceleration profile for the cylinders. In figure 3 we have included an additional data point (

$\lambda _{TR}$ even when the system was started up with a similar acceleration profile for the cylinders. In figure 3 we have included an additional data point (![]() $\rhd$ green marker) that denotes another experimentally accessible state, seen more rarely than the roll state shown in figure 2(b). This state, with a

$\rhd$ green marker) that denotes another experimentally accessible state, seen more rarely than the roll state shown in figure 2(b). This state, with a ![]() $\lambda _{TR}=2.27$ wavelength, has a larger value for

$\lambda _{TR}=2.27$ wavelength, has a larger value for ![]() $\sigma _r$ when compared with the other experimentally realizable roll state, again showcasing the trend that smaller values of

$\sigma _r$ when compared with the other experimentally realizable roll state, again showcasing the trend that smaller values of ![]() $\lambda _{TR}$ tend to lead to larger values of

$\lambda _{TR}$ tend to lead to larger values of ![]() $\sigma _r$. This means that to fairly assess the treatment, one must fix the roll size, such that the roll modification is not simply a matter of the system finding it easier to access different roll states when the flat SHP pattern is present. Furthermore, to make the treatment weaken the roll in a reproducible manner, one must fix the roll size, which can be a challenging task.

$\sigma _r$. This means that to fairly assess the treatment, one must fix the roll size, such that the roll modification is not simply a matter of the system finding it easier to access different roll states when the flat SHP pattern is present. Furthermore, to make the treatment weaken the roll in a reproducible manner, one must fix the roll size, which can be a challenging task.

Now, we turn to the stepped SHP patterns. Since the stepped SHP pattern is formed due to a combination of the step feature caused by the abrasive adhesive tape and the SHP coating, it is important to assess whether the steps themselves affect the flow. To show the effect of steps, we have used uncoated smooth filler tape whose thickness is the same height as the stepped SHP surface and pattern wavelength of ![]() $\lambda _z=1.2$ and presented the temporally averaged velocity in figure 2(e) for

$\lambda _z=1.2$ and presented the temporally averaged velocity in figure 2(e) for ![]() $Re_i=10^4$. Although there is some disturbance caused by the steps in the flow, large-scale structures that can be identified as Taylor rolls still remain. The data are represented as

$Re_i=10^4$. Although there is some disturbance caused by the steps in the flow, large-scale structures that can be identified as Taylor rolls still remain. The data are represented as ![]() $\circ$ (magenta) in figure 3. The roll wavelength is

$\circ$ (magenta) in figure 3. The roll wavelength is ![]() $\lambda _{TR}=2.95$, very different from the applied

$\lambda _{TR}=2.95$, very different from the applied ![]() $\lambda _z$, and larger than the no-slip wavelength. The associated value of

$\lambda _z$, and larger than the no-slip wavelength. The associated value of ![]() $\sigma _r$ is smaller than that of the no-slip case. However, due to the increased roll wavelength, it cannot be linked to a weakening of the roll.

$\sigma _r$ is smaller than that of the no-slip case. However, due to the increased roll wavelength, it cannot be linked to a weakening of the roll.

Having checked this, figure 2(f–h) show the effect of different stepped SHP pattern wavelengths. First, we observe that, unlike flat SHP, the roll size is now fairly constant: ![]() $\lambda _{TR} \approx 2.3$ as shown in figure 3(a) (

$\lambda _{TR} \approx 2.3$ as shown in figure 3(a) (![]() $\square$, blue symbols), as intended. We hypothesize that the combination of steps with SHP coating reduces the number of possible solutions and helps to fix the roll size. Since the rolls are now comparable across different pattern wavelengths, any observed change in roll strength can be attributed only to the SHP pattern inhomogeneity and not to the size of the formed roll. Furthermore, fixing the roll size increases the chances of affecting them by using precise SHP pattern wavelengths determined by theoretical and numerical methods. The success of this approach is evident from looking at the resulting velocity field for the stepped SHP pattern wavelength of

$\square$, blue symbols), as intended. We hypothesize that the combination of steps with SHP coating reduces the number of possible solutions and helps to fix the roll size. Since the rolls are now comparable across different pattern wavelengths, any observed change in roll strength can be attributed only to the SHP pattern inhomogeneity and not to the size of the formed roll. Furthermore, fixing the roll size increases the chances of affecting them by using precise SHP pattern wavelengths determined by theoretical and numerical methods. The success of this approach is evident from looking at the resulting velocity field for the stepped SHP pattern wavelength of ![]() $\lambda _z=1.2$ in figure 2(f). We again quantify this effect using the roll strength

$\lambda _z=1.2$ in figure 2(f). We again quantify this effect using the roll strength ![]() $\sigma _r$, and show the results in figure 3(b) (

$\sigma _r$, and show the results in figure 3(b) (![]() $\square$, blue symbols). Unlike the flat SHP pattern, we observe a distinct trend of increasing the roll strength with pattern wavelength due to the fixed roll size in the system. We also note the roll strength is the lowest for the stepped SHP

$\square$, blue symbols). Unlike the flat SHP pattern, we observe a distinct trend of increasing the roll strength with pattern wavelength due to the fixed roll size in the system. We also note the roll strength is the lowest for the stepped SHP ![]() $\lambda _z=1.2$ case, which corresponds to the heavily altered roll state observed in figure 2(f). Therefore, once the roll sizes are fixed, the SHP pattern with

$\lambda _z=1.2$ case, which corresponds to the heavily altered roll state observed in figure 2(f). Therefore, once the roll sizes are fixed, the SHP pattern with ![]() $\lambda _z=1.2$ is revealed to substantially weaken Taylor rolls, which corresponds to the heterogeneity wavelengths of about half the size of the Taylor roll, as in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021). We note that when applying the stepped coating, we reliably obtain the same roll size in the experiments, unlike for the flat treatment, ensuring the reproducibility of the roll modification and that the variations in

$\lambda _z=1.2$ is revealed to substantially weaken Taylor rolls, which corresponds to the heterogeneity wavelengths of about half the size of the Taylor roll, as in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021). We note that when applying the stepped coating, we reliably obtain the same roll size in the experiments, unlike for the flat treatment, ensuring the reproducibility of the roll modification and that the variations in ![]() $\sigma _r$ can be linked to a roll weakening.

$\sigma _r$ can be linked to a roll weakening.

We emphasize that these experiments show that theoretical results can be achieved in a real-world laboratory setting using commercially available treatments. This is further demonstrated by supplementary movie M2. This result should, however, not be taken to mean that a priori, ![]() $\lambda _z=1.2$ is better than say

$\lambda _z=1.2$ is better than say ![]() $1.3$ or

$1.3$ or ![]() $1.4$ in disrupting the existing structures, but that treatments with a wavelength equal to approximately half the natural size of the rolls disrupt the rolls better than those with larger wavelengths.

$1.4$ in disrupting the existing structures, but that treatments with a wavelength equal to approximately half the natural size of the rolls disrupt the rolls better than those with larger wavelengths.

We have checked the effect of increasing Reynolds numbers (and of larger physical shear experiments on our SHP treatment) by extending the analysis to a larger ![]() $Re_i= 2\times 10^4$. We visually show the weakened rolls corresponding to the treatment wavelength of

$Re_i= 2\times 10^4$. We visually show the weakened rolls corresponding to the treatment wavelength of ![]() $\lambda _z=1.2$ for both the flat and stepped SHP patterns at

$\lambda _z=1.2$ for both the flat and stepped SHP patterns at ![]() $Re_i=2 \times 10^4$ in figures 4(a) and 4(b), respectively. The results show a slight change compared with figures 2(b) and 2(f), corresponding to

$Re_i=2 \times 10^4$ in figures 4(a) and 4(b), respectively. The results show a slight change compared with figures 2(b) and 2(f), corresponding to ![]() $Re_i=10^4$. In addition, figure 4(c) shows the roll strength,

$Re_i=10^4$. In addition, figure 4(c) shows the roll strength, ![]() $\sigma _r$, as a function of

$\sigma _r$, as a function of ![]() $Re_i$ for the pattern wavelength of

$Re_i$ for the pattern wavelength of ![]() $\lambda _z=1.2$, providing a comparison between the no-slip TCF (

$\lambda _z=1.2$, providing a comparison between the no-slip TCF (![]() $\bullet$ black line), flat SHP (

$\bullet$ black line), flat SHP (![]() $\blacktriangledown$ red line), as well as stepped SHP surface (

$\blacktriangledown$ red line), as well as stepped SHP surface (![]() $\blacksquare$ blue line). We clearly see that both the flat and stepped

$\blacksquare$ blue line). We clearly see that both the flat and stepped ![]() $\lambda _z=1.2$ SHP patterns make Taylor rolls weaker across all

$\lambda _z=1.2$ SHP patterns make Taylor rolls weaker across all ![]() $Re_i$. As expected, the stepped

$Re_i$. As expected, the stepped ![]() $\lambda _z=1.2$ SHP pattern is better at weakening the rolls in the

$\lambda _z=1.2$ SHP pattern is better at weakening the rolls in the ![]() $Re_i$ range studied compared with the flat pattern due to its ability to fix the roll size. This is further corroborated in figure 4(d), which shows the normalized roll strength

$Re_i$ range studied compared with the flat pattern due to its ability to fix the roll size. This is further corroborated in figure 4(d), which shows the normalized roll strength ![]() $\sigma _r/\sigma _{r,0}$, where

$\sigma _r/\sigma _{r,0}$, where ![]() $\sigma _{r,0}$ is the reference from the no-slip data. It can be appreciated that the flat SHP case only causes a

$\sigma _{r,0}$ is the reference from the no-slip data. It can be appreciated that the flat SHP case only causes a ![]() $10\,\%$ reduction in

$10\,\%$ reduction in ![]() $\sigma _r$, while the stepped case results in a reduction of between 25–35 %.

$\sigma _r$, while the stepped case results in a reduction of between 25–35 %.

Figure 4. Reynolds number dependence. (a,b) Temporally averaged radial velocity at ![]() $Re_i=2\times 10^4$ for flat SHP (a) and stepped SHP (b) treatments with

$Re_i=2\times 10^4$ for flat SHP (a) and stepped SHP (b) treatments with ![]() $\lambda _z=1.2$. (c) Roll strength

$\lambda _z=1.2$. (c) Roll strength ![]() $\sigma _r$ for no-slip (

$\sigma _r$ for no-slip (![]() $\bullet$, black),

$\bullet$, black), ![]() $\lambda _z=1.2$ flat SHP (

$\lambda _z=1.2$ flat SHP (![]() $\blacktriangledown$, red) and

$\blacktriangledown$, red) and ![]() $\lambda _z=1.2$ stepped SHP (

$\lambda _z=1.2$ stepped SHP (![]() $\blacksquare$, blue) patterns, at different

$\blacksquare$, blue) patterns, at different ![]() $Re_i$. (d) Roll strength from treated cases divided by the roll strength for the no-slip reference case. (e) Dimensionless torque

$Re_i$. (d) Roll strength from treated cases divided by the roll strength for the no-slip reference case. (e) Dimensionless torque ![]() $G$ for the same cases. The error bars represent the standard error of the mean of the torque collected from the sensor for 60 000 eddy turnover times, which corresponds to 10 minutes.

$G$ for the same cases. The error bars represent the standard error of the mean of the torque collected from the sensor for 60 000 eddy turnover times, which corresponds to 10 minutes.

Finally, we compare the effects of the treatment wavelength ![]() $\lambda _z=1.2$ for flat and stepped SHP patterns on torque in figure 4(e). The mean torque is displayed as a dimensionless parameter,

$\lambda _z=1.2$ for flat and stepped SHP patterns on torque in figure 4(e). The mean torque is displayed as a dimensionless parameter, ![]() $G=\langle \hat T \rangle _t/(\hat \rho \hat l \hat \nu ^2)$, where

$G=\langle \hat T \rangle _t/(\hat \rho \hat l \hat \nu ^2)$, where ![]() $\langle \hat T \rangle _t$ is the time average of the discrete torque values,

$\langle \hat T \rangle _t$ is the time average of the discrete torque values, ![]() $\hat T$, measured by the torque sensor for 60 000 eddy turnover times (10 min in physical time), here

$\hat T$, measured by the torque sensor for 60 000 eddy turnover times (10 min in physical time), here ![]() $\hat l$ is the length of the inner cylinder, and

$\hat l$ is the length of the inner cylinder, and ![]() $\hat \rho$ and

$\hat \rho$ and ![]() $\hat \nu$ are the density and kinematic viscosity of the working fluid, respectively. The uncertainty in the mean torque is quantified through the standard error of the mean (Gul, Elsinga & Westerweel Reference Gul, Elsinga and Westerweel2018). The standard error of the mean is given by

$\hat \nu$ are the density and kinematic viscosity of the working fluid, respectively. The uncertainty in the mean torque is quantified through the standard error of the mean (Gul, Elsinga & Westerweel Reference Gul, Elsinga and Westerweel2018). The standard error of the mean is given by ![]() $\hat \epsilon _T=\hat \sigma _T/\sqrt {N}$, where

$\hat \epsilon _T=\hat \sigma _T/\sqrt {N}$, where ![]() $\hat \sigma _T$ is the standard deviation of the torque and

$\hat \sigma _T$ is the standard deviation of the torque and ![]() $N$ is the number of torque samples collected. For both the flat and stepped SHP patterns, we note that the mean torque on the inner cylinder is lower when compared with the regular no-slip TCF. This is a clear indication of the drag-reduction property of the SHP surfaces. They show relatively similar scaling laws

$N$ is the number of torque samples collected. For both the flat and stepped SHP patterns, we note that the mean torque on the inner cylinder is lower when compared with the regular no-slip TCF. This is a clear indication of the drag-reduction property of the SHP surfaces. They show relatively similar scaling laws ![]() $G \sim Re_i^\alpha$, even if the torque reductions are smaller than those in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), a point to which we will return below. We also note that the weakening of the rolls, as quantified through

$G \sim Re_i^\alpha$, even if the torque reductions are smaller than those in Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), a point to which we will return below. We also note that the weakening of the rolls, as quantified through ![]() $\sigma _r$, does not seem to be a good predictor of the torque decrease for the flat SHP case. While this is unlike what was seen in the simulations (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021), we again note that the experiments with flat SHP patterns tend to actually achieve a multiplicity of possible solutions, and this could be causing the erratic increases of

$\sigma _r$, does not seem to be a good predictor of the torque decrease for the flat SHP case. While this is unlike what was seen in the simulations (Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021), we again note that the experiments with flat SHP patterns tend to actually achieve a multiplicity of possible solutions, and this could be causing the erratic increases of ![]() $G$.

$G$.

3. Direct numerical simulations

3.1. Numerical methods

To further assess the potential applicability of SHP coatings, we have performed a series of direct numerical simulations (DNS) of a similar TCF system using a second-order energy-conserving finite-difference code regularly used in our research group to simulate such systems (van der Poel et al. Reference van der Poel, Ostilla-Mónico, Donners and Verzicco2015; Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021). Direct numerical simulations of TCF are performed in a rotating frame of reference by solving the non-dimensional incompressible Navier–Stokes equations

with the incompressibility condition

where ![]() $\boldsymbol {u}$ and

$\boldsymbol {u}$ and ![]() $p$ are the non-dimensional velocity and pressure, respectively;

$p$ are the non-dimensional velocity and pressure, respectively; ![]() $t$ is the non-dimensional time,

$t$ is the non-dimensional time, ![]() $Re_s$ is the shear Reynolds number defined below,

$Re_s$ is the shear Reynolds number defined below, ![]() $\boldsymbol {e}_z$ is the unit vector in the axial direction and

$\boldsymbol {e}_z$ is the unit vector in the axial direction and ![]() $R_\varOmega$ is the Coriolis parameter defined below.

$R_\varOmega$ is the Coriolis parameter defined below.

The rotating frame is chosen such that the velocities of both cylinders are equal and opposite, ![]() $\pm \hat U/2$ in dimensional terms. The equations are non-dimensionalized using this velocity

$\pm \hat U/2$ in dimensional terms. The equations are non-dimensionalized using this velocity ![]() $\hat U$ and the gap width

$\hat U$ and the gap width ![]() $\hat d$. This results in two non-dimensional control parameters, the shear Reynolds number

$\hat d$. This results in two non-dimensional control parameters, the shear Reynolds number ![]() $Re_s=\hat U \hat d/\hat \nu$ and the Coriolis parameter

$Re_s=\hat U \hat d/\hat \nu$ and the Coriolis parameter ![]() $R_\varOmega =2 \hat \varOmega \hat d/\hat U$, where

$R_\varOmega =2 \hat \varOmega \hat d/\hat U$, where ![]() $\hat \nu$ is the kinematic viscosity of the fluid and

$\hat \nu$ is the kinematic viscosity of the fluid and ![]() $\hat \varOmega$ is the dimensional rotational velocity of the rotating frame.

$\hat \varOmega$ is the dimensional rotational velocity of the rotating frame.

The domain is taken to be axially periodic, with a periodicity length ![]() $\hat L_z$, which can be expressed non-dimensionally as an aspect ratio

$\hat L_z$, which can be expressed non-dimensionally as an aspect ratio ![]() $\varGamma _z=\hat L_z/\hat d$. Following Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), the domain is set to be axially periodic with a dimensionless axial periodicity length of

$\varGamma _z=\hat L_z/\hat d$. Following Jeganathan et al. (Reference Jeganathan, Alba and Ostilla-Mónico2021), the domain is set to be axially periodic with a dimensionless axial periodicity length of ![]() $\varGamma _z=\hat {L}_z/\hat {d}=2.33$. This fixes the wavelength of the roll pair

$\varGamma _z=\hat {L}_z/\hat {d}=2.33$. This fixes the wavelength of the roll pair ![]() $\lambda _{TR}=\varGamma _z$ and forces the domain to contain a single roll pair. The radius ratio

$\lambda _{TR}=\varGamma _z$ and forces the domain to contain a single roll pair. The radius ratio ![]() $\eta =\hat r_i/\hat r_o$ is fixed to

$\eta =\hat r_i/\hat r_o$ is fixed to ![]() $\eta =0.83$, where

$\eta =0.83$, where ![]() $\hat r_i$ and

$\hat r_i$ and ![]() $\hat r_o$ are the radius of the inner and outer cylinders, corresponding to the experiments. We also impose a rotational symmetry of order

$\hat r_o$ are the radius of the inner and outer cylinders, corresponding to the experiments. We also impose a rotational symmetry of order ![]() $n_{sym}=10$, corresponding to a streamwise periodicity length of around

$n_{sym}=10$, corresponding to a streamwise periodicity length of around ![]() $2{\rm \pi}$ half-gaps, large enough to obtain asymptotic torque and mean flow statistics (Ostilla-Mónico et al. Reference Ostilla-Mónico, Verzicco and Lohse2015; Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021).

$2{\rm \pi}$ half-gaps, large enough to obtain asymptotic torque and mean flow statistics (Ostilla-Mónico et al. Reference Ostilla-Mónico, Verzicco and Lohse2015; Jeganathan et al. Reference Jeganathan, Alba and Ostilla-Mónico2021).

Spatial discretization is performed using a second-order energy-conserving centred finite-difference scheme. Time is advanced using a low-storage third-order Runge–Kutta for the explicit terms and a second-order Crank-Nicholson scheme for the implicit treatment of the wall-normal viscous terms. More details of the algorithm can be found in previous studies Verzicco & Orlandi (Reference Verzicco and Orlandi1996), van der Poel et al. (Reference van der Poel, Ostilla-Mónico, Donners and Verzicco2015). The code has been heavily validated for the TCF problem (Ostilla-Mónico et al. Reference Ostilla-Mónico, van der Poel, Verzicco, Grossmann and Lohse2014). The spatial resolution used is ![]() $n_\theta \times n_r\times n_z = 384\times 512\times 768$ in the azimuthal, radial and axial directions, respectively, following Sacco et al. (Reference Sacco, Verzicco and Ostilla-Mónico2019).

$n_\theta \times n_r\times n_z = 384\times 512\times 768$ in the azimuthal, radial and axial directions, respectively, following Sacco et al. (Reference Sacco, Verzicco and Ostilla-Mónico2019).

In a classical TCF problem, the cylinders have a no-slip boundary condition, where the velocity of the fluid at the wall matches the velocity of the cylinder. However, in the present study we alternate no-slip and finite-slip boundary conditions at the wall. Finite-slip boundary conditions are expressed by the combination of (1) a no penetration (![]() $u_r=0$) and (2) the condition that the two velocity components tangential to the wall equal the slip length times their respective normal derivatives. In non-dimensional terms, this is expressed as

$u_r=0$) and (2) the condition that the two velocity components tangential to the wall equal the slip length times their respective normal derivatives. In non-dimensional terms, this is expressed as ![]() $u_{\theta }= b \partial _r u_\theta$ and

$u_{\theta }= b \partial _r u_\theta$ and ![]() $u_z= b \partial _r u_z$. We implement the finite-slip boundary condition by modifying the shear stress

$u_z= b \partial _r u_z$. We implement the finite-slip boundary condition by modifying the shear stress ![]() $\tau$ originating from the wall at the first point on the grid. This is done by modifying the viscous term, which is first approximated using a finite difference of shear stresses (

$\tau$ originating from the wall at the first point on the grid. This is done by modifying the viscous term, which is first approximated using a finite difference of shear stresses (![]() $[\tau ^+-\tau ^-]/{\rm \Delta} r$). Then, these shears are approximated using a finite difference of velocities,

$[\tau ^+-\tau ^-]/{\rm \Delta} r$). Then, these shears are approximated using a finite difference of velocities, ![]() $u_z$ or

$u_z$ or ![]() $u_\theta$, depending on the direction being considered. With some rearrangement, this results in a simple correction factor to the geometric factors that multiply the velocity difference. For example, the radial shear stress for

$u_\theta$, depending on the direction being considered. With some rearrangement, this results in a simple correction factor to the geometric factors that multiply the velocity difference. For example, the radial shear stress for ![]() $u_z$ at the first grid point is expressed with the following equation:

$u_z$ at the first grid point is expressed with the following equation:

Here ![]() $u_{z}(r_i)$ is the axial velocity at the inner cylinder,

$u_{z}(r_i)$ is the axial velocity at the inner cylinder, ![]() $u_{z}(r_1)$ is the axial velocity at the first grid point and

$u_{z}(r_1)$ is the axial velocity at the first grid point and ![]() $r_1$ the radial coordinate of the first grid point. In the case of no-slip,

$r_1$ the radial coordinate of the first grid point. In the case of no-slip, ![]() $u_{z}(r_i)$ is equal to the wall velocity (zero for the axial component), while in the case of finite slip,

$u_{z}(r_i)$ is equal to the wall velocity (zero for the axial component), while in the case of finite slip, ![]() $u_{z}(r_i)$ is equal to the slip velocity

$u_{z}(r_i)$ is equal to the slip velocity ![]() $u_{z,s}$. The slip velocity can be rewritten as

$u_{z,s}$. The slip velocity can be rewritten as ![]() $u_{z,s}=b \partial _r u_z(r_1) = b Re_s \tau ^-_{z,1}$. Expressed this way, it can be substituted back into (3.3) and the equation is now closed. The finite-difference approach of the code allows us to quickly change between no-slip, finite-slip and free-slip conditions by modifying the metric terms multiplying

$u_{z,s}=b \partial _r u_z(r_1) = b Re_s \tau ^-_{z,1}$. Expressed this way, it can be substituted back into (3.3) and the equation is now closed. The finite-difference approach of the code allows us to quickly change between no-slip, finite-slip and free-slip conditions by modifying the metric terms multiplying ![]() $\tau ^-_{z,1}$, and can allow for potential extensions of this work that consider a spatially or temporally dependent slip length.

$\tau ^-_{z,1}$, and can allow for potential extensions of this work that consider a spatially or temporally dependent slip length.

The alternating no-slip and finite-slip boundaries applied in the code have a pattern wavelength of ![]() $\lambda _z=\lambda _{TR}/2=1.17\approx 1.2$, similar to experiments. We simulate pure inner cylinder rotation with an inner cylinder Reynolds number of

$\lambda _z=\lambda _{TR}/2=1.17\approx 1.2$, similar to experiments. We simulate pure inner cylinder rotation with an inner cylinder Reynolds number of ![]() $Re_i=10^4$ to match the experiments by setting

$Re_i=10^4$ to match the experiments by setting ![]() $R_\varOmega =(1-\eta )=0.17$ and

$R_\varOmega =(1-\eta )=0.17$ and ![]() $Re_s=2/(1+\eta ) Re_i = 1.09\times 10^4$. We then vary the dimensionless slip length,

$Re_s=2/(1+\eta ) Re_i = 1.09\times 10^4$. We then vary the dimensionless slip length, ![]() $b=\hat b / \hat d$, to determine the minimum slip length required for our treatments to be effective in weakening the secondary flows. The simulations are initialized from a zero-velocity condition and, after a transient that usually takes around

$b=\hat b / \hat d$, to determine the minimum slip length required for our treatments to be effective in weakening the secondary flows. The simulations are initialized from a zero-velocity condition and, after a transient that usually takes around ![]() $200$ large-eddy turnover times (

$200$ large-eddy turnover times (![]() $\hat {d}/\hat {U}_i$), flow statistics are taken for around

$\hat {d}/\hat {U}_i$), flow statistics are taken for around ![]() $600$ large-eddy turnover times. This criteria ensures that the time-averaged torque at both cylinders is equal to within

$600$ large-eddy turnover times. This criteria ensures that the time-averaged torque at both cylinders is equal to within ![]() $1\,\%$.

$1\,\%$.

3.2. Numerical results