The existence of sharp objects created by humankind dates back millenia in the archeological record. Utensils, weapons, and other blades have been a part of human history and are essential in many aspects of our lives today. Although the specific requirements for sharp objects are varied, the overall material design is constant: achieving high sharpness and hardness. However, even the hardened stainless steel in a razor blade, coated with a diamond-containing material to make it even harder, loses its functionality when cutting a much softer material such as human hair just a few times. Kitchen knives, also, get dull when cutting soft substances such as cheese or potatoes. It is common to resharpen knives to make them fully functional again, which leads to the general conception that wear mechanisms are responsible for the performance degradation of sharp metallic edges. Essentially, a sharp edge wears to a more round shape, and the sharp edge can be restored by applying an abrasive at the proper angle (honing). A recent study by Gianluca Roscioli, Seyedeh Mohadeseh Taheri-Mousavi, and Cemal Cem Tasan showed that simple wear is not the only mechanism by which metal edges become dull when cutting hair; but rather an entirely different mechanism is largely responsible for this phenomenon.

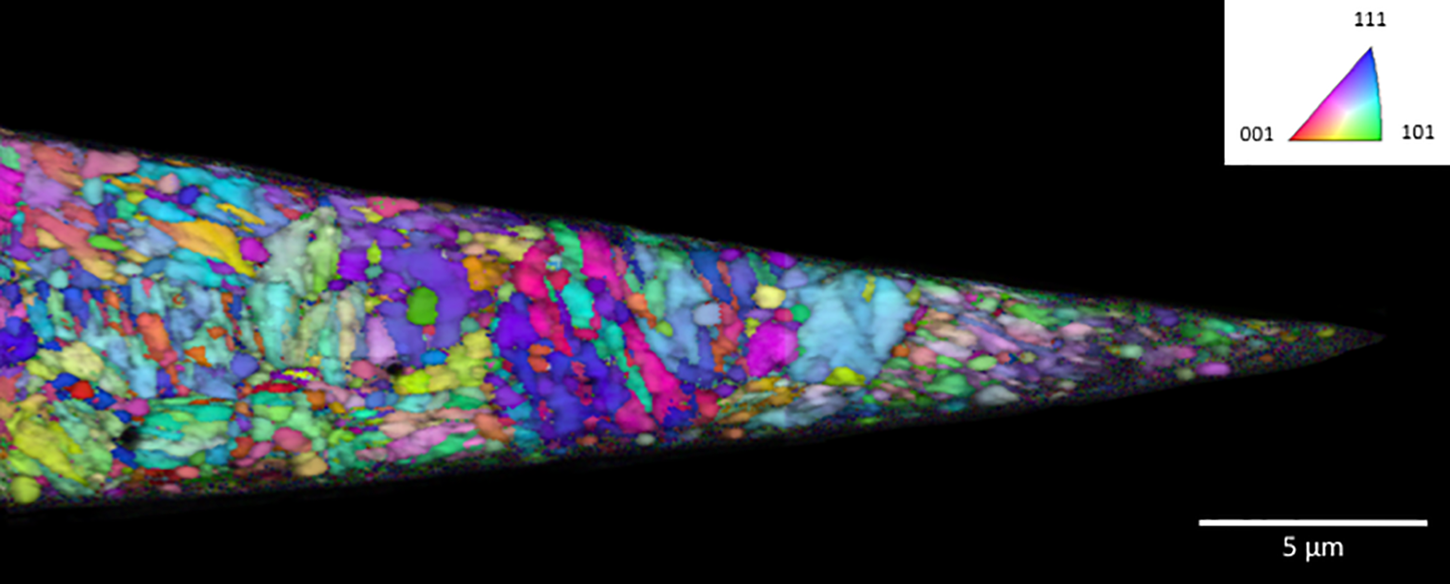

Although wear does occur during hair cutting, the failure mechanisms are more complex for two reasons. First, the structure of steel and hair are very different. Steel has heterogeneous internal features (Figure 1) that result in high hardness but a nonuniform micromechanical response. Hair is softer by more than an order of magnitude. Hair has an outer cuticle enclosing softer material with a hollow center. The different structure of hair results in a mechanical response in the steel that depends on several factors that contribute to deformation of the steel. Second, a hair is flexible resulting in different volumes of the hair interacting with the steel during different stages of cutting, which contributes to deformation of both materials.

Figure 1: Cross section of a razor blade. Electron backscatter diffraction inverse pole figure map of a cross section of a commercial razor blade. The blade shows a lath martensitic microstructure, with no preferential orientation, and a deformed surface layer due to the honing process on both sides of the sharp edge. The deformed layers merge at the tip of the razor blade in a region with higher grain boundary density.

The first step was to examine disposable razor blades by scanning electron microscopy (SEM). Roscioli et al. quantified the blade wear rate along the sharp edge during hair cutting using image analysis. The level of wear was low. However, they observed chips along the sharp edge. Certain features of the fracture surface of the chips indicated that the edge deformed before fracture. To better understand the development of this failure process, they performed SEM tests using a microdeformation stage with customized clamps that could hold a blade on one side and a single or multiple hair(s) on the other. Running in situ SEM tests enabled investigation of the underlying damage mechanisms. When the blade was perpendicular to the hair, the blade did not deform or chip. By contrast, creating a more realistic condition by tilting the blade created an out-of-plane force component and, in turn, led to plastic deformation and chipping. They also discovered that the chips most commonly appeared when the edge encountered the outer cuticle of the hair shaft. For example, one single hair could produce two chips in the blade, each of them corresponding to an edge of the hair.

Roscioli et al. performed several additional analyses, including simulations, that led them to the conclusion that haircutting causes structural failure at the edge of the blade when the hair was pushed into a (relatively) softer region bordered by a harder region within the steel. The stress on this boundary initiated a series of events that resulted in a fracture of the blade (chipping). Therefore, chipping occurs before other proposed failure modes due to wear effects or brittleness of the hard coatings.

It was apparent that the mechanism of chipping was revealed only by in situ observation during the cutting process. Static SEM analysis would not have told the whole story. The dynamic imaging of a hair interacting with the razor's edge in this elegant study was the key to demonstrating deformation of the steel and subsequent chipping. These and other insights suggested that more homogeneous microstructures for cutting tools could allow for more durable sharp edges. The ability to produce more efficient and longer-lasting sharp edges would have a favorable environmental impact by extending material functional duration. This, in turn, could motivate further investigations that would reduce waste and improve our environment.