Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Nguyen, Tri N. M.

Guo, Yichen

Qin, Shuyu

Frew, Kylie S.

Xu, Ruijuan

and

Agar, Joshua C.

2021.

Symmetry-aware recursive image similarity exploration for materials microscopy.

npj Computational Materials,

Vol. 7,

Issue. 1,

2022.

Principles of Electron Optics, Volume 4.

p.

2489.

Basak, Shibabrata

Dzieciol, Krzysztof

Durmus, Yasin Emre

Tempel, Hermann

Kungl, Hans

George, Chandramohan

Mayer, Joachim

and

Eichel, Rüdiger-A.

2022.

Characterizing battery materials and electrodes via in situ/operando transmission electron microscopy.

Chemical Physics Reviews,

Vol. 3,

Issue. 3,

Sytwu, Katherine

Rangel DaCosta, Luis

Groschner, Catherine

and

Scott, Mary C

2022.

Maximizing Neural Net Generalizability and Transfer Learning Success for Transmission Electron Microscopy Image Analysis in the Face of Small Experimental Datasets.

Microscopy and Microanalysis,

Vol. 28,

Issue. S1,

p.

3124.

Bell, Cameron G.

Treder, Kevin P.

Kim, Judy S.

Schuster, Manfred E.

Kirkland, Angus I.

and

Slater, Thomas J. A.

2022.

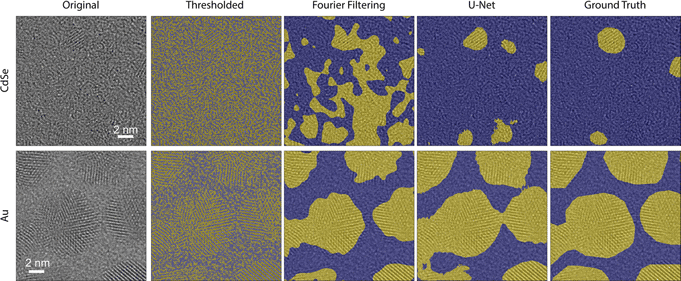

Trainable segmentation for transmission electron microscope images of inorganic nanoparticles.

Journal of Microscopy,

Vol. 288,

Issue. 3,

p.

169.

Jacobs, Ryan

2022.

Deep learning object detection in materials science: Current state and future directions.

Computational Materials Science,

Vol. 211,

Issue. ,

p.

111527.

Sytwu, Katherine

Groschner, Catherine

and

Scott, Mary C

2022.

Understanding the Influence of Receptive Field and Network Complexity in Neural Network-Guided TEM Image Analysis.

Microscopy and Microanalysis,

Vol. 28,

Issue. 6,

p.

1896.

Alrfou, Khaled

Kordijazi, Amir

Rohatgi, Pradeep

and

Zhao, Tian

2022.

Synergy of unsupervised and supervised machine learning methods for the segmentation of the graphite particles in the microstructure of ductile iron.

Materials Today Communications,

Vol. 30,

Issue. ,

p.

103174.

Rickert, Carolin A.

and

Lieleg, Oliver

2022.

Machine learning approaches for biomolecular, biophysical, and biomaterials research.

Biophysics Reviews,

Vol. 3,

Issue. 2,

Lewis, Nicholas R.

Jin, Yicheng

Tang, Xiuyu

Shah, Vidit

Doty, Christina

Matthews, Bethany E.

Akers, Sarah

and

Spurgeon, Steven R.

2022.

Forecasting of in situ electron energy loss spectroscopy.

npj Computational Materials,

Vol. 8,

Issue. 1,

Moreno-Hernandez, Ivan A.

Crook, Michelle F.

Jamali, Vida

and

Alivisatos, A. Paul

2022.

Recent advances in the study of colloidal nanocrystals enabled by in situ liquid-phase transmission electron microscopy.

MRS Bulletin,

Vol. 47,

Issue. 3,

p.

305.

Lu, Shizhao

Montz, Brian

Emrick, Todd

and

Jayaraman, Arthi

2022.

Semi-supervised machine learning workflow for analysis of nanowire morphologies from transmission electron microscopy images.

Digital Discovery,

Vol. 1,

Issue. 6,

p.

816.

Williamson, Emily M.

Ghrist, Aaron M.

Karadaghi, Lanja R.

Smock, Sara R.

Barim, Gözde

and

Brutchey, Richard L.

2022.

Creating ground truth for nanocrystal morphology: a fully automated pipeline for unbiased transmission electron microscopy analysis.

Nanoscale,

Vol. 14,

Issue. 41,

p.

15327.

Bruefach, Alexandra

Ophus, Colin

and

Scott, Mary C

2022.

Analysis of Interpretable Data Representations for 4D-STEM Using Unsupervised Learning.

Microscopy and Microanalysis,

Vol. 28,

Issue. 6,

p.

1998.

Jacobs, Ryan

Patki, Priyam

Lynch, Matthew J.

Chen, Steven

Morgan, Dane

and

Field, Kevin G.

2023.

Materials swelling revealed through automated semantic segmentation of cavities in electron microscopy images.

Scientific Reports,

Vol. 13,

Issue. 1,

Bárcena‐González, Guillermo

Hernández‐Robles, Andrei

Mayoral, Álvaro

Martinez, Lidia

Huttel, Yves

Galindo, Pedro L.

and

Ponce, Arturo

2023.

Unsupervised Learning for the Segmentation of Small Crystalline Particles at the Atomic Level.

Crystal Research and Technology,

Vol. 58,

Issue. 3,

Kaphle, Amrit

Jayarathna, Sandun

Moktan, Hem

Aliru, Maureen

Raghuram, Subhiksha

Krishnan, Sunil

and

Cho, Sang Hyun

2023.

Deep Learning-Based TEM Image Analysis for Fully Automated Detection of Gold Nanoparticles Internalized Within Tumor Cell.

Microscopy and Microanalysis,

Vol. 29,

Issue. 4,

p.

1474.

Zhang, Pinyang

and

Chen, Changzheng

2023.

A Two-Stage Framework for Time-Frequency Analysis and Fault Diagnosis of Planetary Gearboxes.

Applied Sciences,

Vol. 13,

Issue. 8,

p.

5202.

Gumbiowski, Nina

Loza, Kateryna

Heggen, Marc

and

Epple, Matthias

2023.

Automated analysis of transmission electron micrographs of metallic nanoparticles by machine learning.

Nanoscale Advances,

Vol. 5,

Issue. 8,

p.

2318.

Qamar, Saqib

Öberg, Rasmus

Malyshev, Dmitry

and

Andersson, Magnus

2023.

A hybrid CNN-Random Forest algorithm for bacterial spore segmentation and classification in TEM images.

Scientific Reports,

Vol. 13,

Issue. 1,