Article contents

Microstructure and Catalytic Activity of Al13Fe4 and Al13Co4 Melt-Spun Alloys

Published online by Cambridge University Press: 28 July 2021

Abstract

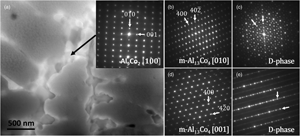

Rapidly solidified alloys with a nominal composition of Al76.5Fe23.5 and Al75.8Co24.2 (in at%), corresponding to the Al13Fe4 and Al13Co4 phases, were produced by a melt spinning technique. The microstructure and phase composition of the as-spun and heat-treated ribbons were examined by X-ray diffraction, scanning and transmission electron microscopy. The as-spun ribbons consisted of columnar grains with an average size of 1–2 μm, which increased by a factor of 2 after applied heat treatment. The Al13Fe4 as-spun ribbon comprised of two phases: grains of the Al13Fe4 phase surrounded by solid solution of Al, transformed into a single monoclinic Al13Fe4 phase after annealing. The as-spun Al13Co4 ribbons had a multiphase structure. A decagonal quasicrystalline D-phase, the monoclinic M-Al13Co4 phase, and the Al9Co2 phase were identified in their microstructure. After the heat treatment, the mixture of the orthorhombic O-Al13Co4 phase and grains of monoclinic Y-Al13Co4 were observed. The investigations of catalytic properties were performed for the phenylacetylene hydrogenation reaction using pulverized ribbons in the initial state and after annealing. The degree of conversion was in the range of 8–27% and increased with the increasing reaction temperature. The highest selectivity to styrene was obtained for the Al13Fe4 alloy in the as-spun state.

Keywords

- Type

- The XVIIth International Conference on Electron Microscopy (EM2020)

- Information

- Copyright

- Copyright © The Author(s), 2021. Published by Cambridge University Press on behalf of the Microscopy Society of America

References

- 7

- Cited by