Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Li, Yifei

Cai, Zhipeng

Li, Kejian

Pan, Jiluan

Liu, Xia

Sun, Lingen

and

Wang, Peng

2018.

Investigation of local brittle zone in multipass welded joint of NiCrMoV steel with heavy section.

Journal of Materials Research,

Vol. 33,

Issue. 8,

p.

923.

Ding, Kai

Wang, Peng

Liu, Xia

Li, Xiaohong

Zhao, Bingge

and

Gao, Yulai

2018.

Formation of Lamellar Carbides in Alloy 617-HAZ and Their Role in the Impact Toughness of Alloy 617/9%Cr Dissimilar Welded Joint.

Journal of Materials Engineering and Performance,

Vol. 27,

Issue. 11,

p.

6027.

Xu, Ke

Wang, Xiongfei

Cui, Haichao

and

Lu, Fenggui

2019.

Investigation on LCF Behavior of Welded Joint at Different Temperatures for Bainite Steel.

Chinese Journal of Mechanical Engineering,

Vol. 32,

Issue. 1,

Ding, Kai

Qiao, Shangfei

Liu, Shuping

Zhao, Bingge

Huo, Xin

Li, Xiaohong

and

Gao, Yulai

2019.

Failure Transition Mechanism of Stress Rupture Performance of the Inconel 625/9 Pct Cr Steel Dissimilar Welded Joint.

Metallurgical and Materials Transactions A,

Vol. 50,

Issue. 10,

p.

4652.

Fang, Tao

Liu, Xia

Shao, Chendong

Cui, Haichao

and

Lu, Fenggui

2020.

Role of tempering cooling rate on impact toughness of 2CrMoV weld metal.

Journal of Materials Research,

Vol. 35,

Issue. 12,

p.

1612.

Ding, Kai

Zhao, Bingge

Zhang, Yuanheng

Wei, Tao

Wu, Guanzhi

Wang, Yuanfang

and

Gao, Yulai

2020.

Characterization of Minerals, Metals, and Materials 2020.

p.

291.

Ding, Kai

Zhao, Bingge

Huo, Xin

Fan, Manjie

Li, Xiaohong

Zhang, Yuanheng

Wei, Tao

Wu, Guanzhi

and

Gao, Yulai

2020.

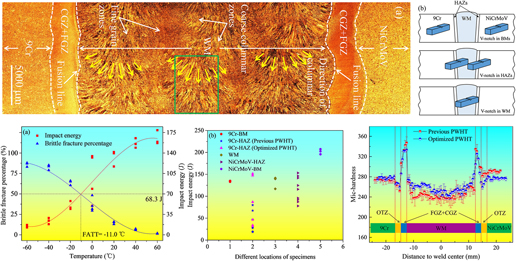

Role of the V-Notch Location in the Impact Toughness of 9 Pct Cr-CrMoV Dissimilar Welded Joints.

Metallurgical and Materials Transactions A,

Vol. 51,

Issue. 4,

p.

1699.

Zhang, Tianyi

Liu, Wei

Dong, Baojun

Wu, Yongjun

Yang, Weijian

Zhao, Yonggang

Fan, Yueming

and

Chen, Longjun

2022.

Determining on welding methods and parameters for the 3%Ni steel welded joints-insights into the corrosion resistance of the fusion zone.

Materials Chemistry and Physics,

Vol. 276,

Issue. ,

p.

125365.

Wang, Qi

Shao, Chendong

Cui, Haichao

Gao, Yuan

and

Lu, Fenggui

2022.

Effect of Carbon Migration on Interface Fatigue Crack Growth Behavior in 9Cr/CrMoV Dissimilar Welded Joint.

Acta Metallurgica Sinica (English Letters),

Vol. 35,

Issue. 5,

p.

714.

Li, Yao

Lu, Pengmin

Wang, Binhua

Hu, Xiaozhi

Li, Datao

and

Xiang, Qingyi

2022.

Evaluation of the fracture toughness of butt-welded joints using the boundary effect model.

Engineering Fracture Mechanics,

Vol. 274,

Issue. ,

p.

108777.

Ding, Kai

Fan, Manjie

He, Yi

Huo, Xin

Liu, Xia

Wei, Tao

Wu, Guanzhi

and

Gao, Yulai

2023.

Microstructure evolution and its effect on the stress rupture behavior of 9%Cr-CrMoV dissimilar welded joint.

Engineering Failure Analysis,

Vol. 146,

Issue. ,

p.

107071.

Zhang, Tianyi

Liu, Wei

Dong, Baojun

Yang, Weijian

Chen, Longjun

Sun, Yipu

Li, Hai

and

Zhang, Bo

2023.

Clarifying the effect of Cu element on the corrosion properties of Ni-Mo low alloy steel in marine environment.

Corrosion Science,

Vol. 216,

Issue. ,

p.

111107.

Li, Jiahui

Li, Yipeng

Liu, Dan

Ding, Yuming

Cui, Haichao

Tang, Xinhua

and

Lu, Fenggui

2024.

The Influence of Microstructure Evolution in Thick Plate 9%Ni Steel Submerged Arc Welding Joint on Fracture Toughness Properties.

Journal of Materials Engineering and Performance,

Vol. 33,

Issue. 19,

p.

10081.