Published online by Cambridge University Press: 27 September 2011

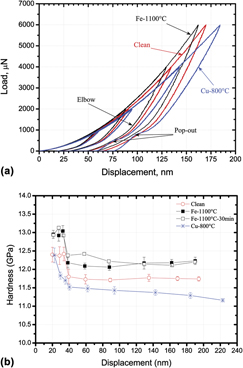

Nanoindentation was used to examine the impact of impurities and grain boundaries on the mechanical properties of a “model” (110)/(100) grain boundary (GB) interface prepared using direct silicon bonding via the hybrid orientation technique of (110) and (100) p-type silicon wafers. Remarkable differences were found between the mechanical behavior of Fe- and Cu-contaminated samples. The direct silicon bonded wafers contaminated with either Fe or Cu showed opposite effects on mechanical properties, with Fe enhancing the silicon hardness, while Cu contamination induces a gradual weakening. High-resolution transmission electron microscopy was used to verify that the abrupt hardness changes observed during increasing nanoindentation loading is attributed to local deformation induced by the GB interface, Cu precipitate colony induced dislocations, and the abrupt crystallographic orientation change across the GB. The resulting dislocation loop generation facilitated the deformation process during nanoindentation and therefore softened the material.