Article contents

Synthesis of submicrometer-sized TiC particles in aluminum melt at low melting temperature

Published online by Cambridge University Press: 27 March 2014

Abstract

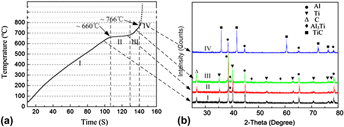

This research discussed how to synthesize submicrometer-sized TiC particulate reinforcement in the molten aluminum melt at low temperature via combustion synthesis by using in situ casting technique. A high temperature preheating treatment of Al–Ti–C pellets was carried out, by which the thermal explosion reaction of the pellets could take place in the pure aluminum melt at 750 °C. The synthesizing temperature of TiC particles was reduced by at least 150 °C compared with the conventional methods. In situ formed TiC particles were spherical in shape and were smaller than 1 µm in size due to the low melting temperature. The emergence of liquid aluminum phase led to the generation and accumulation of plenty of heat in the pellet in a short time due to the reactive diffusion of Al(l)–Ti(s). The formation mechanism of the submicrometer-sized TiC particles in the molten aluminum at low temperature was discussed in this research.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2014

References

REFERENCES

- 6

- Cited by