Published online by Cambridge University Press: 02 May 2017

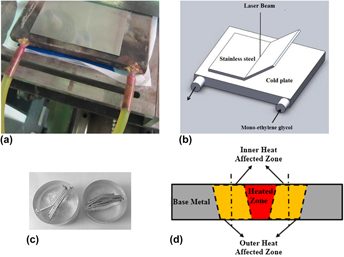

Sheets made of 316 stainless steel (100 × 100 × 1 mm3) were irradiated by laser at 1, 5, 10, and 15 passes under natural and forced cooling. Results showed that the deflection angle increased with the number of radiation passes. The bending angle after 15 passes of exposure under forced cooling was 5° higher than under natural cooling. The grain size under natural cooling increased from approximately 23–35 μm. By contrast, under forced cooling, the grain size decreased from approximately 37–27 μm. The sample hardness declined under natural cooling from approximately 212–200 HV. By contrast, sample hardness increased from approximately 216–233 HV under forced cooling. Polarization results show that the breakdown potential versus the number of lasing passes increased from −0.14 to −0.08 V under natural cooling and −0.16 to −0.06 V under forced cooling.

Contributing Editor: Jürgen Eckert