1 Introduction

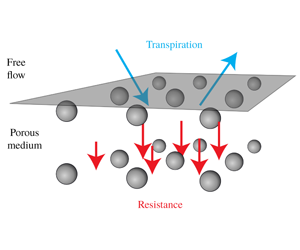

The physical behaviour of a number of fluid systems is dramatically modified by the presence of a small-scale surface roughness. For example, in wetting (figure 1a) – that is, when a liquid in contact with a solid reaches a balance of surface tensions – the resulting apparent contact angle ![]() $\unicode[STIX]{x1D703}$ is very sensitive to the details of the surface texture (Wenzel Reference Wenzel1936; Quéré Reference Quéré2008). At high Reynolds numbers (of order 1000 and above), the pressure loss in turbulent pipes is a function of the wall roughness (figure 1b) (Nikuradse Reference Nikuradse1950; Jiménez Reference Jiménez2004). Yet another example is the transport phenomena involving porous media, where the exchange of mass, momentum, energy and other passive scalars between a free flowing fluid and a porous medium depends very much on the roughness at the interface between the two domains (figure 1c).

$\unicode[STIX]{x1D703}$ is very sensitive to the details of the surface texture (Wenzel Reference Wenzel1936; Quéré Reference Quéré2008). At high Reynolds numbers (of order 1000 and above), the pressure loss in turbulent pipes is a function of the wall roughness (figure 1b) (Nikuradse Reference Nikuradse1950; Jiménez Reference Jiménez2004). Yet another example is the transport phenomena involving porous media, where the exchange of mass, momentum, energy and other passive scalars between a free flowing fluid and a porous medium depends very much on the roughness at the interface between the two domains (figure 1c).

Figure 1. Examples of problems that are sensitive to surface properties. Droplet spreading over a rough surface (a), friction drag of turbulent flow on a rough surface (b) and particle transport through the interface with a rough porous material (c).

Engineers take advantage of the sensitivity to the surface texture to modify large-scale flow features and to enhance the transport phenomena. Efficiency of heat exchangers (Mehendale, Jacobi & Shah Reference Mehendale, Jacobi and Shah2000; Agyenim et al. Reference Agyenim, Hewitt, Eames and Smyth2010) is highly dependent on the surface texture. In scaffold design for bone regeneration, the cell growth on the implant (a porous biomaterial such as a calcium phosphate cement) depends on the interaction between the surrounding liquid and the surface texture of the implant (Dalby et al. Reference Dalby, Gadegaard, Tare, Andar, Riehle, Herzyk, Wilkinson and Oreffo2007; Perez & Mestres Reference Perez and Mestres2016). The performance of fuel cells depends on the ability of gas flow to efficiently transport the water vapour away from the cathode, a thin porous medium (Prat Reference Prat2002; Haghighi & Kirchner Reference Haghighi and Kirchner2017). Turbulent skin friction on wings or turbine blades can be reduced by using riblets, which are able to push quasi-streamwise vortices away from the wall (Walsh & Lindemann Reference Walsh and Lindemann1984).

The design of the surface texture in the examples mentioned above is based on a trial and error procedure that may require a tremendous amount of effort, time and expensive surface manufacturing equipment. The formulation presented in this paper provides a framework for modelling the interaction between free flows and various textured and porous surfaces. Our modelling approach provides a direct relationship between the microscopic geometrical details of a complex surface and the associated macroscopic transport of mass and momentum. Thus it has the potential to replace the trial and error procedure in the design phase.

Due to the multiscale nature of the problems described above, fully resolved numerical investigations – of both the complex surface and the free flow above it – are practically impossible to perform in applied settings. Effective approaches are actively pursued to circumvent this difficulty. In this way, one can capture the averaged effect of the microscale features on the macroscopic processes, and hence avoid resolving microscopic geometric details. Some recent examples of effective modelling applied to drying, cell growth, heat exchange and flow modelling can be found in works by Mosthaf, Helmig & Or (Reference Mosthaf, Helmig and Or2014), Vaca-González et al. (Reference Vaca-González, Moncayo-Donoso, Guevara, Hata, Shefelbine and Garzón-Alvarado2018), Laloui, Nuth & Vulliet (Reference Laloui, Nuth and Vulliet2006), Wang et al. (Reference Wang, Zhang, Xiao, Jin and Li2018) and Zampogna et al. (Reference Zampogna, Lācis, Bagheri and Bottaro2019a). The main challenge for effective models describing fluid–surface interaction is the specification of a boundary condition at an artificially created interface between the free-fluid region and the complex surface. Despite the recent advancements, we still lack interface conditions that capture the dominant physical features associated with complex anisotropic surfaces.

Figure 2. Schematics of the slip length ![]() $L$ (a), the transpiration length

$L$ (a), the transpiration length ![]() $M$ (b) and the resistance coefficient

$M$ (b) and the resistance coefficient ![]() $f$ (c).

$f$ (c).

Before highlighting the main ingredients of our model, we make a brief account of the current state-of-the-art of effective boundary conditions of textured and porous surfaces. A two-dimensional configuration is sufficient for this purpose. The streamwise and wall-normal coordinates are denoted by ![]() $x$ and

$x$ and ![]() $z$, where the effective boundary conditions are imposed at a planar interface at coordinate

$z$, where the effective boundary conditions are imposed at a planar interface at coordinate ![]() $z=z_{i}$. For rigid textured surfaces with a characteristic size

$z=z_{i}$. For rigid textured surfaces with a characteristic size ![]() $\ell$, one may impose the slip velocity condition (Navier Reference Navier1823) as an effective boundary condition,

$\ell$, one may impose the slip velocity condition (Navier Reference Navier1823) as an effective boundary condition,

Here, ![]() $u_{x}$ is the tangential velocity component at the interface,

$u_{x}$ is the tangential velocity component at the interface, ![]() $u_{z}$ is the wall-normal velocity component at the interface and

$u_{z}$ is the wall-normal velocity component at the interface and ![]() $L\sim \ell$ is the slip length. Geometrically – as shown in figure 2(a) – the slip length in its simplest possible representation (i.e. assuming no variation in the

$L\sim \ell$ is the slip length. Geometrically – as shown in figure 2(a) – the slip length in its simplest possible representation (i.e. assuming no variation in the ![]() $x$ direction) is the distance that the velocity profile has to be linearly extrapolated to reach zero value. There has been extensive development of the slip boundary condition for textured and porous surfaces (Saffman Reference Saffman1971; Sahraoui & Kaviany Reference Sahraoui and Kaviany1992; Miksis & Davis Reference Miksis and Davis1994; Sarkar & Prosperetti Reference Sarkar and Prosperetti1996; Gupte & Advani Reference Gupte and Advani1997; Jäger & Mikelić Reference Jäger and Mikelić2001; Stroock et al. Reference Stroock, Dertinger, Whitesides and Ajdari2002; Bolanos & Vernescu Reference Bolanos and Vernescu2017). In the existing approaches, the interface normal (transpiration) velocity is typically set either to zero

$x$ direction) is the distance that the velocity profile has to be linearly extrapolated to reach zero value. There has been extensive development of the slip boundary condition for textured and porous surfaces (Saffman Reference Saffman1971; Sahraoui & Kaviany Reference Sahraoui and Kaviany1992; Miksis & Davis Reference Miksis and Davis1994; Sarkar & Prosperetti Reference Sarkar and Prosperetti1996; Gupte & Advani Reference Gupte and Advani1997; Jäger & Mikelić Reference Jäger and Mikelić2001; Stroock et al. Reference Stroock, Dertinger, Whitesides and Ajdari2002; Bolanos & Vernescu Reference Bolanos and Vernescu2017). In the existing approaches, the interface normal (transpiration) velocity is typically set either to zero ![]() $u_{z}=0$ (for textured surfaces) or to the interior flow

$u_{z}=0$ (for textured surfaces) or to the interior flow ![]() $u_{z}=u_{z}^{-}$ (for porous surfaces) due to mass conservation arguments or as the leading-order boundary condition (Mohammadi & Floryan Reference Mohammadi and Floryan2013; Lācis & Bagheri Reference Lācis and Bagheri2016; Jiménez Bolaños & Vernescu Reference Jiménez Bolaños and Vernescu2017).

$u_{z}=u_{z}^{-}$ (for porous surfaces) due to mass conservation arguments or as the leading-order boundary condition (Mohammadi & Floryan Reference Mohammadi and Floryan2013; Lācis & Bagheri Reference Lācis and Bagheri2016; Jiménez Bolaños & Vernescu Reference Jiménez Bolaños and Vernescu2017).

Configurations with porous surfaces require additional boundary conditions. If the bulk of the surface (i.e. interior of the porous material) is governed by the Darcy–Brinkmann equation, which is typical for works considering the method of volume averaging (Whitaker Reference Whitaker1998), stress jump conditions are often derived (Ochoa-Tapia & Whitaker Reference Ochoa-Tapia and Whitaker1995; Valdés-Parada et al. Reference Valdés-Parada, Alvarez-Ramírez, Goyeau and Ochoa-Tapia2009, Reference Valdés-Parada, Aguilar-Madera, Ochoa-Tapia and Goyeau2013). In the current work, however, we consider only Darcy’s law within the bulk of the porous surface. Consequently, a condition for the Darcy pressure or the pore pressure ![]() $p^{-}$ is needed. The pressure continuity

$p^{-}$ is needed. The pressure continuity ![]() $p=p^{-}$, where

$p=p^{-}$, where ![]() $p$ is the free-fluid pressure, has been a common choice in the past (Ene & Sanchez-Palencia Reference Ene and Sanchez-Palencia1975; Levy & Sanchez-Palencia Reference Levy and Sanchez-Palencia1975; Hou et al. Reference Hou, Holmes, Lai and Mow1989; Lācis & Bagheri Reference Lācis and Bagheri2016). The most notable recent theoretical and numerical developments (Marciniak-Czochra & Mikelić Reference Marciniak-Czochra and Mikelić2012; Carraro et al. Reference Carraro, Goll, Marciniak-Czochra and Mikelić2013; Carraro, Marušić-Paloka & Mikelić Reference Carraro, Marušić-Paloka and Mikelić2018) have resulted in the pressure jump condition

$p$ is the free-fluid pressure, has been a common choice in the past (Ene & Sanchez-Palencia Reference Ene and Sanchez-Palencia1975; Levy & Sanchez-Palencia Reference Levy and Sanchez-Palencia1975; Hou et al. Reference Hou, Holmes, Lai and Mow1989; Lācis & Bagheri Reference Lācis and Bagheri2016). The most notable recent theoretical and numerical developments (Marciniak-Czochra & Mikelić Reference Marciniak-Czochra and Mikelić2012; Carraro et al. Reference Carraro, Goll, Marciniak-Czochra and Mikelić2013; Carraro, Marušić-Paloka & Mikelić Reference Carraro, Marušić-Paloka and Mikelić2018) have resulted in the pressure jump condition

Here, ![]() $\unicode[STIX]{x1D707}$ is the fluid dynamic viscosity and

$\unicode[STIX]{x1D707}$ is the fluid dynamic viscosity and ![]() $C_{\unicode[STIX]{x03C0}}$ is a stabilisation parameter derived from matching boundary layer solutions with exterior solutions. The coefficient

$C_{\unicode[STIX]{x03C0}}$ is a stabilisation parameter derived from matching boundary layer solutions with exterior solutions. The coefficient ![]() $C_{\unicode[STIX]{x03C0}}$ is non-zero only for anisotropic porous surfaces. The pressure interface condition – as well as the velocity interface condition – for porous media has been a subject of many investigations and is still debated (Beavers & Joseph Reference Beavers and Joseph1967; Mikelić & Jäger Reference Mikelić and Jäger2000; Han, Ganatos & Weinbaum Reference Han, Ganatos and Weinbaum2005; Le Bars & Grae Worster Reference Le Bars and Grae Worster2006; Jäger & Mikelić Reference Jäger and Mikelić2009; Carraro et al. Reference Carraro, Goll, Marciniak-Czochra and Mikelić2015, Reference Carraro, Marušić-Paloka and Mikelić2018; Rosti, Cortelezzi & Quadrio Reference Rosti, Cortelezzi and Quadrio2015; Lācis & Bagheri Reference Lācis and Bagheri2016; Zampogna & Bottaro Reference Zampogna and Bottaro2016; Angot, Goyeau & Ochoa-Tapia Reference Angot, Goyeau and Ochoa-Tapia2017; Zampogna, Magnaudet & Bottaro Reference Zampogna, Magnaudet and Bottaro2019b).

$C_{\unicode[STIX]{x03C0}}$ is non-zero only for anisotropic porous surfaces. The pressure interface condition – as well as the velocity interface condition – for porous media has been a subject of many investigations and is still debated (Beavers & Joseph Reference Beavers and Joseph1967; Mikelić & Jäger Reference Mikelić and Jäger2000; Han, Ganatos & Weinbaum Reference Han, Ganatos and Weinbaum2005; Le Bars & Grae Worster Reference Le Bars and Grae Worster2006; Jäger & Mikelić Reference Jäger and Mikelić2009; Carraro et al. Reference Carraro, Goll, Marciniak-Czochra and Mikelić2015, Reference Carraro, Marušić-Paloka and Mikelić2018; Rosti, Cortelezzi & Quadrio Reference Rosti, Cortelezzi and Quadrio2015; Lācis & Bagheri Reference Lācis and Bagheri2016; Zampogna & Bottaro Reference Zampogna and Bottaro2016; Angot, Goyeau & Ochoa-Tapia Reference Angot, Goyeau and Ochoa-Tapia2017; Zampogna, Magnaudet & Bottaro Reference Zampogna, Magnaudet and Bottaro2019b).

In this work, we extend the above conditions with new terms for the wall-normal velocity condition and the pressure condition. Our proposed set of boundary conditions is called the transpiration-resistance (TR) model, and it is applicable to any textured or porous surface consisting of regular repeating geometric entities. The TR model captures the transport of interface tangential momentum as well as the transport of mass and interface normal momentum. It is a homogenised boundary condition, valid for configurations with a scale separation ![]() $\unicode[STIX]{x1D716}=\ell /H\ll 1$, where

$\unicode[STIX]{x1D716}=\ell /H\ll 1$, where ![]() $H$ is the characteristic length scale of the free fluid. It consists of the slip boundary condition (1.1) for the interface tangential velocity. The wall-normal velocity in the TR model is

$H$ is the characteristic length scale of the free fluid. It consists of the slip boundary condition (1.1) for the interface tangential velocity. The wall-normal velocity in the TR model is

The first term is the seepage Darcy velocity, given by ![]() $u_{z}^{-}=(K/\unicode[STIX]{x1D707})\unicode[STIX]{x2202}_{z}p^{-}$, where

$u_{z}^{-}=(K/\unicode[STIX]{x1D707})\unicode[STIX]{x2202}_{z}p^{-}$, where ![]() $K$ is the interior permeability. The second term quantifies how much a surface texture allows exchange of mass with the surrounding fluid due to a streamwise variation of the slip velocity. Using continuity, the above condition for textured surfaces (where

$K$ is the interior permeability. The second term quantifies how much a surface texture allows exchange of mass with the surrounding fluid due to a streamwise variation of the slip velocity. Using continuity, the above condition for textured surfaces (where ![]() $u_{z}^{-}=0$) can be written as

$u_{z}^{-}=0$) can be written as ![]() $u_{z}=M\unicode[STIX]{x2202}_{z}u_{z}$. Geometrically (figure 2b), the transpiration length

$u_{z}=M\unicode[STIX]{x2202}_{z}u_{z}$. Geometrically (figure 2b), the transpiration length ![]() $M$ is thus the distance below the interface for which a non-zero transpiration velocity

$M$ is thus the distance below the interface for which a non-zero transpiration velocity ![]() $u_{z}$ can exist. This depth is obtained from a linear extrapolation of the wall-normal component of the outer flow,

$u_{z}$ can exist. This depth is obtained from a linear extrapolation of the wall-normal component of the outer flow, ![]() $u_{z}$. For a porous surface, the TR model provides the pressure condition,

$u_{z}$. For a porous surface, the TR model provides the pressure condition,

Here, the left-hand side is the normal stress of the outside free flow on the interface plane, and the right-hand side is the normal stress from the porous material. The resistance coefficient ![]() $f$ quantifies the friction force that the Darcy seepage velocity generates while passing through the interface (figure 2c).

$f$ quantifies the friction force that the Darcy seepage velocity generates while passing through the interface (figure 2c).

Three assumptions underlie the proposed TR model.

- (A1)

Creeping flow assumption

$Re<1$, which allows us to solve a given flow problem near the interface with the help of linear decomposition.

$Re<1$, which allows us to solve a given flow problem near the interface with the help of linear decomposition.- (A2)

Scale separation assumption

$\unicode[STIX]{x1D716}\ll 1$, which leads to constant macroscopic flow field variables (velocities, pressures and all macroscopic gradients of these fields) over the characteristic length

$\unicode[STIX]{x1D716}\ll 1$, which leads to constant macroscopic flow field variables (velocities, pressures and all macroscopic gradients of these fields) over the characteristic length  $\ell$ of the surface.

$\ell$ of the surface.- (A3)

The surface is homogeneous i.e. it consists of repeating geometric entities or elements, which allows us to consider only a single structure to determine surface properties.

Under these assumptions, the slip length, the transpiration length and the resistance coefficients are properties of the surface texture only, and can be computed by solving five fundamental Stokes problems. For a given texture, the knowledge of these effective coefficients provides important information on the diffusive/advective transport into the material as well as the ability of the solid skeleton to resist an externally imposed shear stress. The TR model is based on conditions derived from a formal multi-scale expansion (MSE) in the small parameter ![]() $\unicode[STIX]{x1D716}$ (Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2019). By including higher-order terms for the transpiration velocity and for the pressure, we will show using numerical simulations that the error of the TR model is close to

$\unicode[STIX]{x1D716}$ (Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2019). By including higher-order terms for the transpiration velocity and for the pressure, we will show using numerical simulations that the error of the TR model is close to ![]() $O(\unicode[STIX]{x1D716}^{2})$.

$O(\unicode[STIX]{x1D716}^{2})$.

This paper is organised as follows. In §§ 2 and 3, we describe and validate the TR model for textured surfaces and porous surfaces, respectively. In § 4, we show using the turbulent channel flow that the transpiration velocity in the TR model – despite being a higher-order term from an asymptotic viewpoint – is essential from a physical viewpoint. In § 5, the TR model is discussed in the context of formal multi-scale expansion and, finally, we provide conclusions in § 6.

2 A model for textured surfaces

In this section, we present the TR model for three-dimensional (3-D) textured surfaces in contact with a free flowing fluid, assuming (A1)–(A3). First, we explain the boundary condition for the interface tangential velocity (the slip condition) and show how to obtain the associated slip length tensor. Second, we introduce the transpiration velocity condition and demonstrate how to determine the transpiration length tensor by making use of mass conservation. Next, we compute the slip and transpiration tensors and validate the model against geometry-resolved direct numerical simulations. Finally, the effect of the interface location on the accuracy of the TR model is discussed.

2.1 Tangential interface velocity and slip length

The tangential velocity condition in the TR model is provided by the standard slip condition, which for 3-D textured surfaces is

where ![]() $\unicode[STIX]{x1D749}=\unicode[STIX]{x1D707}(\unicode[STIX]{x2202}_{z}u_{x}+\unicode[STIX]{x2202}_{x}u_{z},\unicode[STIX]{x2202}_{z}u_{y}+\unicode[STIX]{x2202}_{y}u_{z})$ and

$\unicode[STIX]{x1D749}=\unicode[STIX]{x1D707}(\unicode[STIX]{x2202}_{z}u_{x}+\unicode[STIX]{x2202}_{x}u_{z},\unicode[STIX]{x2202}_{z}u_{y}+\unicode[STIX]{x2202}_{y}u_{z})$ and ![]() $\unicode[STIX]{x1D647}=(\unicode[STIX]{x1D613}_{xx},\unicode[STIX]{x1D613}_{xy};\unicode[STIX]{x1D613}_{xy},\unicode[STIX]{x1D613}_{yy})$ is the symmetric positive definite (Kamrin & Stone Reference Kamrin and Stone2011) surface slip length tensor. Here,

$\unicode[STIX]{x1D647}=(\unicode[STIX]{x1D613}_{xx},\unicode[STIX]{x1D613}_{xy};\unicode[STIX]{x1D613}_{xy},\unicode[STIX]{x1D613}_{yy})$ is the symmetric positive definite (Kamrin & Stone Reference Kamrin and Stone2011) surface slip length tensor. Here, ![]() $\boldsymbol{u}_{t}$ is the tangential velocity vector, and the subscript

$\boldsymbol{u}_{t}$ is the tangential velocity vector, and the subscript ![]() $t$ is used interchangeably with the

$t$ is used interchangeably with the ![]() $x$ and

$x$ and ![]() $y$ components.

$y$ components.

Figure 3. (a) Shows a flow domain with a generic free flow. The flat interface with the vertical coordinate ![]() $z_{i}$ above the surface texture is depicted using a transparent plane. The red rectangle is the interface cell. (b) Shows the interface cell with a bottom coordinate

$z_{i}$ above the surface texture is depicted using a transparent plane. The red rectangle is the interface cell. (b) Shows the interface cell with a bottom coordinate ![]() $\hat{z}_{b}(x,y)$ – describing the surface texture – and a top coordinate

$\hat{z}_{b}(x,y)$ – describing the surface texture – and a top coordinate ![]() $\hat{z}_{t}$. The tangential shear stress is decomposed in unit forcing terms along the

$\hat{z}_{t}$. The tangential shear stress is decomposed in unit forcing terms along the ![]() $x$ (c) and the

$x$ (c) and the ![]() $y$ (d) axes.

$y$ (d) axes.

We consider a patterned wall and a vortical flow over it, as illustrated in figure 3(a). The scale separation assumption (A2) allows us to introduce two different spatial coordinates: ![]() $x_{i}$ and

$x_{i}$ and ![]() $\hat{x}_{i}$. The former is used to describe spatial variations over large length scales (

$\hat{x}_{i}$. The former is used to describe spatial variations over large length scales (![]() $x_{i}\sim H$). The latter is used to describe microscopic variations over much smaller roughness scale (

$x_{i}\sim H$). The latter is used to describe microscopic variations over much smaller roughness scale (![]() $\hat{x}_{i}\sim \ell$). The effective boundary condition (2.1) is a macroscopic condition; the microscopic features of the texture are embedded in an averaged sense in the slip length tensor

$\hat{x}_{i}\sim \ell$). The effective boundary condition (2.1) is a macroscopic condition; the microscopic features of the texture are embedded in an averaged sense in the slip length tensor ![]() $\unicode[STIX]{x1D647}$.

$\unicode[STIX]{x1D647}$.

To determine ![]() $\unicode[STIX]{x1D647}$, we consider a small volume near the surface of the texture with a cross-section

$\unicode[STIX]{x1D647}$, we consider a small volume near the surface of the texture with a cross-section ![]() $\ell \times \ell$. This volume contains a representative surface structure, see figure 3(a,b). Within this interface cell, the scale separation assumption (A2) allows us to treat the shear stress from the free fluid

$\ell \times \ell$. This volume contains a representative surface structure, see figure 3(a,b). Within this interface cell, the scale separation assumption (A2) allows us to treat the shear stress from the free fluid ![]() $\unicode[STIX]{x1D749}$ as a spatially constant external parameter. Due to the creeping flow assumption (A1), the equations governing the flow response to the free-fluid shear stress are the Stokes equations,

$\unicode[STIX]{x1D749}$ as a spatially constant external parameter. Due to the creeping flow assumption (A1), the equations governing the flow response to the free-fluid shear stress are the Stokes equations,

where ![]() $\unicode[STIX]{x1D6FF}$ is the Dirac delta function with

$\unicode[STIX]{x1D6FF}$ is the Dirac delta function with ![]() $\hat{z}$ as an argument and consequently it has the unit of inverse metres (m

$\hat{z}$ as an argument and consequently it has the unit of inverse metres (m![]() $^{-1}$). This set of equations is equivalent to a two-domain description satisfying velocity continuity and stress jump at the interface (appendix B). Additionally, equations (2.2)–(2.3) are the same as previously used and derived by Luchini, Manzo & Pozzi (Reference Luchini, Manzo and Pozzi1991), Kamrin, Bazant & Stone (Reference Kamrin, Bazant and Stone2010) and Luchini (Reference Luchini2013). The imposed boundary conditions are no slip and no penetration on the solid structure (

$^{-1}$). This set of equations is equivalent to a two-domain description satisfying velocity continuity and stress jump at the interface (appendix B). Additionally, equations (2.2)–(2.3) are the same as previously used and derived by Luchini, Manzo & Pozzi (Reference Luchini, Manzo and Pozzi1991), Kamrin, Bazant & Stone (Reference Kamrin, Bazant and Stone2010) and Luchini (Reference Luchini2013). The imposed boundary conditions are no slip and no penetration on the solid structure (![]() $\boldsymbol{u}=0$ on

$\boldsymbol{u}=0$ on ![]() $\hat{z}=\hat{z}_{b}$). We impose periodic conditions at the vertical faces of the interface cell (due to the assumption (A3)). At the top surface of the cell, we impose a zero-stress condition (

$\hat{z}=\hat{z}_{b}$). We impose periodic conditions at the vertical faces of the interface cell (due to the assumption (A3)). At the top surface of the cell, we impose a zero-stress condition (![]() $\unicode[STIX]{x1D72E}\boldsymbol{\cdot }\boldsymbol{n}=0$ on

$\unicode[STIX]{x1D72E}\boldsymbol{\cdot }\boldsymbol{n}=0$ on ![]() $\hat{z}=\hat{z}_{t}$) to keep the shear stress at the interface as the only driving force of the problem.

$\hat{z}=\hat{z}_{t}$) to keep the shear stress at the interface as the only driving force of the problem.

The linearity assumption (A1) allows us to write the solution as a product between a response operator ![]() $\hat{\unicode[STIX]{x1D64D}}_{\unicode[STIX]{x1D70F}}$ and the free-fluid shear stress,

$\hat{\unicode[STIX]{x1D64D}}_{\unicode[STIX]{x1D70F}}$ and the free-fluid shear stress,

This can be expanded as

Thus the velocity fields ![]() $\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}x)}$ and

$\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}x)}$ and ![]() $\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}y)}$ are solutions of the following two fundamental problems,

$\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}y)}$ are solutions of the following two fundamental problems,

The fundamental problems are forced in the ![]() $x$ and

$x$ and ![]() $y$ directions, respectively, with unit shear at the plane

$y$ directions, respectively, with unit shear at the plane ![]() $z_{i}$. The boundary conditions are the same as for equations (2.2)–(2.3). The fundamental problems are named with two capital letters FP complemented with two small letters denoting the forcing direction. For example, equation (FPsx) reads ‘Fundamental Problem forced by shear in

$z_{i}$. The boundary conditions are the same as for equations (2.2)–(2.3). The fundamental problems are named with two capital letters FP complemented with two small letters denoting the forcing direction. For example, equation (FPsx) reads ‘Fundamental Problem forced by shear in ![]() $\boldsymbol{x}$-direction’.

$\boldsymbol{x}$-direction’.

Taking the surface average of expression (2.5b) at the interface, we obtain

No average is carried out for the free-fluid shear stress, because it is constant within the interface cell (A2). The surface average of an arbitrary quantity ![]() $\hat{a}$ is defined as

$\hat{a}$ is defined as

By comparing the surface-averaged velocity in the interface cell (2.7) with the slip boundary condition (2.1), we observe that the components of the slip length tensor can be obtained as

In terms of the response operator, the slip tensor becomes ![]() $\unicode[STIX]{x1D647}=\unicode[STIX]{x1D707}\langle \hat{\unicode[STIX]{x1D64D}}_{\unicode[STIX]{x1D70F}}\rangle _{i}$. Note that the dimension of the vector fields

$\unicode[STIX]{x1D647}=\unicode[STIX]{x1D707}\langle \hat{\unicode[STIX]{x1D64D}}_{\unicode[STIX]{x1D70F}}\rangle _{i}$. Note that the dimension of the vector fields ![]() $\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}x)}$ and

$\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}x)}$ and ![]() $\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}y)}$ is the same as for velocity per shear, which gives a unit of metres (m). The units of the different fields introduced throughout the paper are summarised in table 2.

$\hat{\boldsymbol{u}}^{(\unicode[STIX]{x1D70F}y)}$ is the same as for velocity per shear, which gives a unit of metres (m). The units of the different fields introduced throughout the paper are summarised in table 2.

2.2 Interface normal velocity and transpiration length

We begin with a simple motivation for the transpiration velocity based on the principle of mass conservation. We consider a two-dimensional rough surface and define a control volume (CV) below the interface ![]() $z=z_{i}$ as shown in figure 4. We assume that there is a slip velocity variation from

$z=z_{i}$ as shown in figure 4. We assume that there is a slip velocity variation from ![]() $u_{x,1}$ at the left side of the CV to

$u_{x,1}$ at the left side of the CV to ![]() $u_{x,2}$ at the right side of the CV. The mass fluxes at the left and the right boundaries of the CV are proportional to the slip velocities at the interface (a direct consequence of (A1)). Consequently, mass conservation requires a non-zero transpiration velocity

$u_{x,2}$ at the right side of the CV. The mass fluxes at the left and the right boundaries of the CV are proportional to the slip velocities at the interface (a direct consequence of (A1)). Consequently, mass conservation requires a non-zero transpiration velocity ![]() $u_{z}$ at the interface. If the slip velocity is increasing

$u_{z}$ at the interface. If the slip velocity is increasing ![]() $u_{x,2}>u_{x,1}$, the generated transpiration velocity is, therefore, negative.

$u_{x,2}>u_{x,1}$, the generated transpiration velocity is, therefore, negative.

Figure 4. Illustration of the transpiration velocity as a consequence from mass conservation owing to the variation of slip velocity along the interface. Control volume (CV) below the interface (![]() $\hat{z}=\hat{z}_{i}$) is denoted with a shaded (blue) region. The quantities

$\hat{z}=\hat{z}_{i}$) is denoted with a shaded (blue) region. The quantities ![]() $u_{x,1}$ and

$u_{x,1}$ and ![]() $u_{x,2}$ denote slip velocities at the left and the right boundaries of the CV, respectively.

$u_{x,2}$ denote slip velocities at the left and the right boundaries of the CV, respectively.

More generally, the interface normal velocity condition in the TR model for a 3-D textured surface is provided by a linear law relating the normal velocity with the tangential variation of slip velocity,

where ![]() $\unicode[STIX]{x1D648}=(\unicode[STIX]{x1D614}_{xx},\unicode[STIX]{x1D614}_{xy};\unicode[STIX]{x1D614}_{xy},\unicode[STIX]{x1D614}_{yy})$ is the transpiration length tensor – exhibiting the same symmetry properties as the slip length tensor – and

$\unicode[STIX]{x1D648}=(\unicode[STIX]{x1D614}_{xx},\unicode[STIX]{x1D614}_{xy};\unicode[STIX]{x1D614}_{xy},\unicode[STIX]{x1D614}_{yy})$ is the transpiration length tensor – exhibiting the same symmetry properties as the slip length tensor – and ![]() $\unicode[STIX]{x1D735}_{2}=(\unicode[STIX]{x2202}_{x},\unicode[STIX]{x2202}_{y})$ is gradient operator containing the two tangential directions. The double dot product between two second-rank tensors

$\unicode[STIX]{x1D735}_{2}=(\unicode[STIX]{x2202}_{x},\unicode[STIX]{x2202}_{y})$ is gradient operator containing the two tangential directions. The double dot product between two second-rank tensors ![]() $\unicode[STIX]{x1D63C}$ and

$\unicode[STIX]{x1D63C}$ and ![]() $\unicode[STIX]{x1D63D}$ is defined as

$\unicode[STIX]{x1D63D}$ is defined as ![]() $\unicode[STIX]{x1D63C}\boldsymbol{ : }\unicode[STIX]{x1D63D}=\unicode[STIX]{x1D608}_{ij}\unicode[STIX]{x1D609}_{ij}$, where summation over repeating indices is implied. We use the normal

$\unicode[STIX]{x1D63C}\boldsymbol{ : }\unicode[STIX]{x1D63D}=\unicode[STIX]{x1D608}_{ij}\unicode[STIX]{x1D609}_{ij}$, where summation over repeating indices is implied. We use the normal ![]() $n$ subscript interchangeably with the

$n$ subscript interchangeably with the ![]() $z$ component. The proposed expression, motivated by the conservation of mass, also emerges from a formal multi-scale expansion (see § 5, appendix A and Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2019). A similar multi-scale expansion has been recently used by Bottaro (Reference Bottaro2019) to confirm the present transpiration velocity condition.

$z$ component. The proposed expression, motivated by the conservation of mass, also emerges from a formal multi-scale expansion (see § 5, appendix A and Sudhakar et al. Reference Sudhakar, Lācis, Pasche and Bagheri2019). A similar multi-scale expansion has been recently used by Bottaro (Reference Bottaro2019) to confirm the present transpiration velocity condition.

To determine ![]() $\unicode[STIX]{x1D648}$, we make use of mass conservation in a 3-D setting. We define a CV with size

$\unicode[STIX]{x1D648}$, we make use of mass conservation in a 3-D setting. We define a CV with size ![]() $(x_{2}-x_{1})\times (y_{2}-y_{1})\times (\hat{z}_{i}-\hat{z}_{b})$ over a number of texture elements as shown in figure 5. By definition, no flux goes through the impermeable bottom surface. Therefore mass conservation requires

$(x_{2}-x_{1})\times (y_{2}-y_{1})\times (\hat{z}_{i}-\hat{z}_{b})$ over a number of texture elements as shown in figure 5. By definition, no flux goes through the impermeable bottom surface. Therefore mass conservation requires

where ![]() $Q_{i}$ is the volumetric flux through faces of the CV (figure 5). The flux through the vertical faces (

$Q_{i}$ is the volumetric flux through faces of the CV (figure 5). The flux through the vertical faces (![]() $i=1,\ldots ,4$) of the CV can be evaluated as

$i=1,\ldots ,4$) of the CV can be evaluated as

where ![]() $\boldsymbol{u}$ is the effective velocity field at the CV face,

$\boldsymbol{u}$ is the effective velocity field at the CV face, ![]() $\boldsymbol{n}$ is the unit normal vector of the surface and

$\boldsymbol{n}$ is the unit normal vector of the surface and ![]() $s$ is either

$s$ is either ![]() $x$ or

$x$ or ![]() $y$, depending on the orientation of the surface. Note that the integral in the wall-normal direction is carried out over the microscale

$y$, depending on the orientation of the surface. Note that the integral in the wall-normal direction is carried out over the microscale ![]() $\hat{z}$, because macroscopically the textured surface is infinitesimal and variation in depth does not exist.

$\hat{z}$, because macroscopically the textured surface is infinitesimal and variation in depth does not exist.

Figure 5. Control volume for deriving the transpiration length tensor ![]() $\unicode[STIX]{x1D648}$. All the possible volumetric fluxes are indicated with thick arrows.

$\unicode[STIX]{x1D648}$. All the possible volumetric fluxes are indicated with thick arrows.

Next, we use equation (2.8) in conjunction with the solution of fundamental problems (FPsx), (FPsy) to rewrite equation (2.12) as

$$\begin{eqnarray}\displaystyle Q_{i} & = & \displaystyle \int _{\hat{z}_{b}}^{\hat{z}_{i}}\int _{s_{1}}^{s_{2}}\boldsymbol{u}\boldsymbol{\cdot }\boldsymbol{n}\,\text{d}\hat{z}\,\text{d}s=\int _{\hat{z}_{b}}^{\hat{z}_{i}}\int _{s_{1}}^{s_{2}}\langle \hat{\boldsymbol{u}}\rangle _{s}(x,y,\hat{z})\boldsymbol{\cdot }\boldsymbol{n}\,\text{d}\hat{z}\,\text{d}s\nonumber\\ \displaystyle & = & \displaystyle \int _{\hat{z}_{b}}^{\hat{z}_{i}}\int _{s_{1}}^{s_{2}}[\langle \hat{\unicode[STIX]{x1D64D}}_{\unicode[STIX]{x1D70F}}\rangle _{s}(\hat{z})\boldsymbol{\cdot }\unicode[STIX]{x1D749}(x,y)]\boldsymbol{\cdot }\boldsymbol{n}\,\text{d}\hat{z}\,\text{d}s=\left(\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\int _{s_{1}}^{s_{2}}\unicode[STIX]{x1D749}\,\text{d}s\right)\boldsymbol{\cdot }\boldsymbol{n},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle Q_{i} & = & \displaystyle \int _{\hat{z}_{b}}^{\hat{z}_{i}}\int _{s_{1}}^{s_{2}}\boldsymbol{u}\boldsymbol{\cdot }\boldsymbol{n}\,\text{d}\hat{z}\,\text{d}s=\int _{\hat{z}_{b}}^{\hat{z}_{i}}\int _{s_{1}}^{s_{2}}\langle \hat{\boldsymbol{u}}\rangle _{s}(x,y,\hat{z})\boldsymbol{\cdot }\boldsymbol{n}\,\text{d}\hat{z}\,\text{d}s\nonumber\\ \displaystyle & = & \displaystyle \int _{\hat{z}_{b}}^{\hat{z}_{i}}\int _{s_{1}}^{s_{2}}[\langle \hat{\unicode[STIX]{x1D64D}}_{\unicode[STIX]{x1D70F}}\rangle _{s}(\hat{z})\boldsymbol{\cdot }\unicode[STIX]{x1D749}(x,y)]\boldsymbol{\cdot }\boldsymbol{n}\,\text{d}\hat{z}\,\text{d}s=\left(\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\int _{s_{1}}^{s_{2}}\unicode[STIX]{x1D749}\,\text{d}s\right)\boldsymbol{\cdot }\boldsymbol{n},\end{eqnarray}$$ where we have defined the response tensor ![]() $\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}$ as

$\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}$ as

The flux through the top wall is expressed as

Inserting the expressions for the fluxes through the CV faces into the mass conservation identity (2.11) we obtain

$$\begin{eqnarray}\displaystyle \int _{x_{1}}^{x_{2}}\int _{y_{1}}^{y_{2}}u_{z}\,\text{d}x\,\text{d}y & = & \displaystyle -\left(\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\int _{y_{1}}^{y_{2}}[\unicode[STIX]{x1D749}(x_{2},y)-\unicode[STIX]{x1D749}(x_{1},y)]\,\text{d}y\right)\boldsymbol{\cdot }\boldsymbol{e}_{x}\nonumber\\ \displaystyle & & \displaystyle -\left(\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\int _{x_{1}}^{x_{2}}[\unicode[STIX]{x1D749}(x,y_{2})-\unicode[STIX]{x1D749}(x,y_{1})]\,\text{d}x\right)\boldsymbol{\cdot }\boldsymbol{e}_{y}.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \int _{x_{1}}^{x_{2}}\int _{y_{1}}^{y_{2}}u_{z}\,\text{d}x\,\text{d}y & = & \displaystyle -\left(\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\int _{y_{1}}^{y_{2}}[\unicode[STIX]{x1D749}(x_{2},y)-\unicode[STIX]{x1D749}(x_{1},y)]\,\text{d}y\right)\boldsymbol{\cdot }\boldsymbol{e}_{x}\nonumber\\ \displaystyle & & \displaystyle -\left(\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\int _{x_{1}}^{x_{2}}[\unicode[STIX]{x1D749}(x,y_{2})-\unicode[STIX]{x1D749}(x,y_{1})]\,\text{d}x\right)\boldsymbol{\cdot }\boldsymbol{e}_{y}.\end{eqnarray}$$To proceed towards the effective boundary condition (2.10), we take an infinitesimal CV limit, which gives us

were we have ![]() $\unicode[STIX]{x0394}y=y_{2}-y_{1}$,

$\unicode[STIX]{x0394}y=y_{2}-y_{1}$, ![]() $\unicode[STIX]{x0394}x=x_{2}-x_{1}$ and

$\unicode[STIX]{x0394}x=x_{2}-x_{1}$ and ![]() $x_{1}=x$ and

$x_{1}=x$ and ![]() $y_{1}=y$. Dividing both sides by

$y_{1}=y$. Dividing both sides by ![]() $\unicode[STIX]{x0394}x\unicode[STIX]{x0394}y$ and using the definition of a derivative, we obtain

$\unicode[STIX]{x0394}x\unicode[STIX]{x0394}y$ and using the definition of a derivative, we obtain

This expression can be rewritten using double dot product as

To obtain the transpiration length tensor, we express the tangential shear stress from (2.1) and insert the result into (2.19). Comparing the final result with (2.10) yields

Recall that the tensor ![]() $\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}$ can be obtained as a post-processing step from the fundamental problems (FPsx), (FPsy) using the volume integral (2.14).

$\unicode[STIX]{x1D64D}_{\unicode[STIX]{x1D70F}}$ can be obtained as a post-processing step from the fundamental problems (FPsx), (FPsy) using the volume integral (2.14).

It is interesting to note that the velocity conditions (2.1), (2.10) can be written in a more compact form,

$$\begin{eqnarray}\left(\begin{array}{@{}c@{}}u_{x}\\ u_{y}\\ u_{z}\end{array}\right)=\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D613}_{xx} & 0 & 0\\ 0 & \unicode[STIX]{x1D613}_{xx} & 0\\ 0 & 0 & \unicode[STIX]{x1D614}_{xx}\end{array}\right)\boldsymbol{\cdot }\left(\begin{array}{@{}c@{}}\unicode[STIX]{x2202}_{z}u_{x}+\unicode[STIX]{x2202}_{x}u_{z}\\ \unicode[STIX]{x2202}_{z}u_{y}+\unicode[STIX]{x2202}_{y}u_{z}\\ \unicode[STIX]{x2202}_{z}u_{z}\end{array}\right),\end{eqnarray}$$

$$\begin{eqnarray}\left(\begin{array}{@{}c@{}}u_{x}\\ u_{y}\\ u_{z}\end{array}\right)=\left(\begin{array}{@{}ccc@{}}\unicode[STIX]{x1D613}_{xx} & 0 & 0\\ 0 & \unicode[STIX]{x1D613}_{xx} & 0\\ 0 & 0 & \unicode[STIX]{x1D614}_{xx}\end{array}\right)\boldsymbol{\cdot }\left(\begin{array}{@{}c@{}}\unicode[STIX]{x2202}_{z}u_{x}+\unicode[STIX]{x2202}_{x}u_{z}\\ \unicode[STIX]{x2202}_{z}u_{y}+\unicode[STIX]{x2202}_{y}u_{z}\\ \unicode[STIX]{x2202}_{z}u_{z}\end{array}\right),\end{eqnarray}$$ valid for an incompressible flow over isotropic geometries or for incompressible two-dimensional flows. The upper left ![]() $2\times 2$ block corresponds to the slip length tensor

$2\times 2$ block corresponds to the slip length tensor ![]() $\unicode[STIX]{x1D647}$ introduced before, while the lower right element

$\unicode[STIX]{x1D647}$ introduced before, while the lower right element ![]() $\unicode[STIX]{x1D614}_{xx}$ is the first term of the transpiration length tensor

$\unicode[STIX]{x1D614}_{xx}$ is the first term of the transpiration length tensor ![]() $\unicode[STIX]{x1D648}$. The equivalence with the previous formulation is obtained using the continuity equation, i.e.

$\unicode[STIX]{x1D648}$. The equivalence with the previous formulation is obtained using the continuity equation, i.e. ![]() $\unicode[STIX]{x2202}_{z}u_{z}=-\unicode[STIX]{x2202}_{x}u_{x}-\unicode[STIX]{x2202}_{y}u_{y}$. The form (2.21) can be useful in practice, for example, if boundary conditions are imposed weakly in the finite element method. A similar set of boundary conditions – obtained by neglecting

$\unicode[STIX]{x2202}_{z}u_{z}=-\unicode[STIX]{x2202}_{x}u_{x}-\unicode[STIX]{x2202}_{y}u_{y}$. The form (2.21) can be useful in practice, for example, if boundary conditions are imposed weakly in the finite element method. A similar set of boundary conditions – obtained by neglecting ![]() $\unicode[STIX]{x2202}_{x}u_{z}$ and

$\unicode[STIX]{x2202}_{x}u_{z}$ and ![]() $\unicode[STIX]{x2202}_{y}u_{z}$ – has been numerically investigated by Gómez de Segura et al. (Reference Gómez de Segura, Fairhall, MacDonald, Chung and García-Mayoral2018). In their work, the focus was on elucidating the turbulent flow response to the boundary condition (2.21) where all the coefficients for the slip and the transpiration lengths could take different values; however, connection to a surface texture geometry has never been made.

$\unicode[STIX]{x2202}_{y}u_{z}$ – has been numerically investigated by Gómez de Segura et al. (Reference Gómez de Segura, Fairhall, MacDonald, Chung and García-Mayoral2018). In their work, the focus was on elucidating the turbulent flow response to the boundary condition (2.21) where all the coefficients for the slip and the transpiration lengths could take different values; however, connection to a surface texture geometry has never been made.

2.3 Numerical validation of velocity conditions

We consider a lid-driven cavity whose bottom surface is made of a texture with the characteristic length scale ![]() $\ell$ (figure 6a). The macroscopic length scale

$\ell$ (figure 6a). The macroscopic length scale ![]() $H$ corresponds to the cavity width and depth. The scale separation parameter is equal to

$H$ corresponds to the cavity width and depth. The scale separation parameter is equal to ![]() $\unicode[STIX]{x1D716}=\ell /H=0.1$. A no-slip condition is applied on all surfaces except the top wall, which moves with a prescribed velocity

$\unicode[STIX]{x1D716}=\ell /H=0.1$. A no-slip condition is applied on all surfaces except the top wall, which moves with a prescribed velocity ![]() $(U_{0},0)$. Details about the numerical solver can be found in § C.1.

$(U_{0},0)$. Details about the numerical solver can be found in § C.1.

Figure 6. Lid-driven cavity with a textured bottom. (a) Shows the computational domain used for the resolved simulations. The bottom surface consists of ten regular cavities. The domain for effective model simulation is shown in (b).

The moving upper wall generates a clockwise rotating vortex. This vortex imposes a negative shear on the rough surface. It also induces a downward mass flux at the right half of the cavity and an upward mass flux at the left half of the cavity. Near the textured surface, one can observe velocity fluctuations with a wavelength corresponding to the texture size ![]() $\ell$. To obtain macroscopic flow fields from geometry-resolving direct numerical simulation (DNS), we average out the microscale oscillations by creating an ensemble of

$\ell$. To obtain macroscopic flow fields from geometry-resolving direct numerical simulation (DNS), we average out the microscale oscillations by creating an ensemble of ![]() $50$ DNS simulations. The ensemble consists of configurations in which the textured surface at the bottom of the cavity is incrementally shifted in the

$50$ DNS simulations. The ensemble consists of configurations in which the textured surface at the bottom of the cavity is incrementally shifted in the ![]() $x$ direction. The shift between neighbouring simulations is

$x$ direction. The shift between neighbouring simulations is ![]() $\ell /50$. We believe that the ensemble average is the most appropriate way to obtain macroscopic variations due to the boundaries of the cavity. For periodic configurations, moving average or Fourier filtering could be equally accurate choices. The tangential and the transpiration velocities from the ensemble-averaged DNS along

$\ell /50$. We believe that the ensemble average is the most appropriate way to obtain macroscopic variations due to the boundaries of the cavity. For periodic configurations, moving average or Fourier filtering could be equally accurate choices. The tangential and the transpiration velocities from the ensemble-averaged DNS along ![]() $z=0.2\ell$ are shown with black lines in figures 7(a) and 7(b), respectively.

$z=0.2\ell$ are shown with black lines in figures 7(a) and 7(b), respectively.

Figure 7. Tangential (a) and normal (b) velocities along the interface between the flow in the lid-driven cavity and the rough bottom. Dashed vertical lines show the streamwise locations where the DNS and model predictions are compared in table 1.

For comparison, we set up an effective simulation of the problem with the domain and boundary conditions shown in figure 6(b). We observed that in this particular shear-driven flow configuration the ![]() $\unicode[STIX]{x2202}_{x}u_{z}$ term in the shear stress at the wall is very small compared to

$\unicode[STIX]{x2202}_{x}u_{z}$ term in the shear stress at the wall is very small compared to ![]() $\unicode[STIX]{x2202}_{z}u_{x}$. Therefore, in the effective simulation we neglect

$\unicode[STIX]{x2202}_{z}u_{x}$. Therefore, in the effective simulation we neglect ![]() $\unicode[STIX]{x2202}_{x}u_{z}$. We define the interface location at the previously selected coordinate

$\unicode[STIX]{x2202}_{x}u_{z}$. We define the interface location at the previously selected coordinate ![]() $z_{i}=0.2\ell$. The coefficients for the boundary conditions (2.1), (2.10) – the slip and the transpiration lengths – are computed as described in §§ 2.1 and 2.2, using a FreeFEM++ open-source code (Lācis & Bagheri Reference Lācis and Bagheri2016 --2019). At this specific interface location, we have

$z_{i}=0.2\ell$. The coefficients for the boundary conditions (2.1), (2.10) – the slip and the transpiration lengths – are computed as described in §§ 2.1 and 2.2, using a FreeFEM++ open-source code (Lācis & Bagheri Reference Lācis and Bagheri2016 --2019). At this specific interface location, we have ![]() $\unicode[STIX]{x1D613}_{xx}=0.218\ell$ and

$\unicode[STIX]{x1D613}_{xx}=0.218\ell$ and ![]() $\unicode[STIX]{x1D614}_{xx}=0.110\ell$. The velocities at

$\unicode[STIX]{x1D614}_{xx}=0.110\ell$. The velocities at ![]() $z=0.2\ell$ from the effective simulation are compared to the ensemble-averaged DNS in figure 7(a,b). It is clear that the effective boundary conditions accurately predict the ensemble average (or the macroscopic variation) of both velocity components.

$z=0.2\ell$ from the effective simulation are compared to the ensemble-averaged DNS in figure 7(a,b). It is clear that the effective boundary conditions accurately predict the ensemble average (or the macroscopic variation) of both velocity components.

Table 1. The slip length ![]() $\unicode[STIX]{x1D613}_{xx}$ and the transpiration length

$\unicode[STIX]{x1D613}_{xx}$ and the transpiration length ![]() $\unicode[STIX]{x1D614}_{xx}$ for a range of interface locations

$\unicode[STIX]{x1D614}_{xx}$ for a range of interface locations ![]() $z_{i}$ above the textured surface. The effective tangential velocity

$z_{i}$ above the textured surface. The effective tangential velocity ![]() $u_{x}$ is sampled at

$u_{x}$ is sampled at ![]() $(0.5H,z_{i})$. The effective transpiration velocity

$(0.5H,z_{i})$. The effective transpiration velocity ![]() $u_{z}$ is sampled at

$u_{z}$ is sampled at ![]() $(0.25H,z_{i})$. The model predictions are finally normalised using the ensemble averaged results from DNS

$(0.25H,z_{i})$. The model predictions are finally normalised using the ensemble averaged results from DNS ![]() $\bar{u}_{x}$ and

$\bar{u}_{x}$ and ![]() $\bar{u}_{z}$.

$\bar{u}_{z}$.

The results obtained using the TR model are reasonably accurate for different interface locations. To show this, we repeat the previous effective computation for a range of interface locations ![]() $z_{i}=(0.0,0.1,0.3,0.4,0.5)\ell$. For each interface coordinate, the effective coefficients

$z_{i}=(0.0,0.1,0.3,0.4,0.5)\ell$. For each interface coordinate, the effective coefficients ![]() $\unicode[STIX]{x1D613}_{xx}$ and

$\unicode[STIX]{x1D613}_{xx}$ and ![]() $\unicode[STIX]{x1D614}_{xx}$ are recomputed using the fundamental problems (FPsx)–(FPsy), see table 1. To quantitatively present the TR model predictions, we select two streamwise positions at the interface plane, shown with vertical dashed lines in figure 7. In table 1, we present the model predictions of

$\unicode[STIX]{x1D614}_{xx}$ are recomputed using the fundamental problems (FPsx)–(FPsy), see table 1. To quantitatively present the TR model predictions, we select two streamwise positions at the interface plane, shown with vertical dashed lines in figure 7. In table 1, we present the model predictions of ![]() $u_{x}$ sampled at point

$u_{x}$ sampled at point ![]() $(0.5H,z_{i})$ for all interface locations. As the interface moves upwards – further away from the solid structures – the value of the predicted slip velocity increases due to a larger distance over which the viscous friction can bring the velocity to the no-slip value at the wall. This effect is correctly captured by the model through the linear increase of the slip length

$(0.5H,z_{i})$ for all interface locations. As the interface moves upwards – further away from the solid structures – the value of the predicted slip velocity increases due to a larger distance over which the viscous friction can bring the velocity to the no-slip value at the wall. This effect is correctly captured by the model through the linear increase of the slip length ![]() $\unicode[STIX]{x1D613}_{xx}$ (table 1). In other words, the information about the interface location is provided to the effective model through the adjustment of the coefficients. The interface normal velocity component

$\unicode[STIX]{x1D613}_{xx}$ (table 1). In other words, the information about the interface location is provided to the effective model through the adjustment of the coefficients. The interface normal velocity component ![]() $u_{z}$ and transpiration length

$u_{z}$ and transpiration length ![]() $\unicode[STIX]{x1D614}_{xx}$ exhibit the same behaviour.

$\unicode[STIX]{x1D614}_{xx}$ exhibit the same behaviour.

In the last two columns of table 1, we present the ratio between model predictions and the ensemble-averaged DNS results. We observe that, for all interface locations, the relative error (![]() $1-u/\bar{u}$) is below

$1-u/\bar{u}$) is below ![]() $7\,\%$ for the slip velocity. The relative error for the transpiration velocity is below

$7\,\%$ for the slip velocity. The relative error for the transpiration velocity is below ![]() $14\,\%$. There is a trend of an increasing error as the interface is moved upwards, except for the interface location

$14\,\%$. There is a trend of an increasing error as the interface is moved upwards, except for the interface location ![]() $z_{i}=0$. Despite the trend of increasing error with interface location, the TR model has a remarkably good accuracy taking into account that the transpiration velocity varies over two orders of magnitude (see 5th column of table 1). It has to be mentioned that the convergence of the ensemble averaging for the interface location

$z_{i}=0$. Despite the trend of increasing error with interface location, the TR model has a remarkably good accuracy taking into account that the transpiration velocity varies over two orders of magnitude (see 5th column of table 1). It has to be mentioned that the convergence of the ensemble averaging for the interface location ![]() $z_{i}=0$ is very slow and we used

$z_{i}=0$ is very slow and we used ![]() $250$ simulations to obtain a smooth result. The shift of the textured wall between each simulation is then

$250$ simulations to obtain a smooth result. The shift of the textured wall between each simulation is then ![]() $\ell /250$. We have carried out similar numerical computations on equilateral triangular surface texture and obtained the same behaviour as reported above.

$\ell /250$. We have carried out similar numerical computations on equilateral triangular surface texture and obtained the same behaviour as reported above.

This investigation shows that it is possible to adjust the interface height over distances ![]() $O(\ell )$ without a significant loss of accuracy. A similar conclusion about the interface location has already been reached numerically by Lācis & Bagheri (Reference Lācis and Bagheri2016) and theoretically by Marciniak-Czochra & Mikelić (Reference Marciniak-Czochra and Mikelić2012) for the slip velocity alone. However, as a ‘rule-of-thumb’, we suggest placing the interface as close to the solid structure as possible without intersecting the solids.

$O(\ell )$ without a significant loss of accuracy. A similar conclusion about the interface location has already been reached numerically by Lācis & Bagheri (Reference Lācis and Bagheri2016) and theoretically by Marciniak-Czochra & Mikelić (Reference Marciniak-Czochra and Mikelić2012) for the slip velocity alone. However, as a ‘rule-of-thumb’, we suggest placing the interface as close to the solid structure as possible without intersecting the solids.

3 The TR model for porous surfaces

In this section, we extend the TR model to 3-D porous surfaces by augmenting the set of boundary conditions for the textured wall with a pressure condition. This is achieved by considering the transfer of normal momentum between the free flow region and the porous surface.

To determine the coefficients appearing in the interface boundary conditions, we will adopt a similar interface-cell approach as for the textured surface (see figure 8a,b). The bottom coordinate of the interface cell, ![]() $\hat{z}_{b}$, is chosen sufficiently deep such that it can be considered as part of the interior (Darcy) domain. As a rule-of-thumb, the interface cell should contain around four solid skeleton entities

$\hat{z}_{b}$, is chosen sufficiently deep such that it can be considered as part of the interior (Darcy) domain. As a rule-of-thumb, the interface cell should contain around four solid skeleton entities ![]() $\hat{z}_{b}\approx \hat{z}_{i}-4\ell$ and extend a similar distance in the free fluid

$\hat{z}_{b}\approx \hat{z}_{i}-4\ell$ and extend a similar distance in the free fluid ![]() $\hat{z}_{t}\approx \hat{z}_{i}+4\ell$. From the scale separation assumption (A2) it follows that, in the interface cell, the shear stress from the free fluid and the pore pressure gradient from the porous material are both constant.

$\hat{z}_{t}\approx \hat{z}_{i}+4\ell$. From the scale separation assumption (A2) it follows that, in the interface cell, the shear stress from the free fluid and the pore pressure gradient from the porous material are both constant.

Figure 8. (a) Illustrates a system consisting of a porous medium and a free fluid. The transparent plane is the interface. The solid red cuboid is the interface cell (a,b). (b–g) Shows the interface cell and the corresponding decomposition into five fundamental problems forced either with the shear at the interface (c,d) or the pore pressure gradient below the interface (e–g).

3.1 Velocity boundary conditions

For a porous surface, the tangential velocity boundary condition is identical to the textured surface, i.e. the slip condition (2.1). The interface normal velocity condition, on the other hand, becomes

where ![]() $u_{n}^{-}$ is the interface normal Darcy velocity, satisfying

$u_{n}^{-}$ is the interface normal Darcy velocity, satisfying

This term is induced by mass conservation between the free fluid and the porous domain.

The tensors ![]() $\unicode[STIX]{x1D648}$ and

$\unicode[STIX]{x1D648}$ and ![]() $\unicode[STIX]{x1D647}$ are determined by solving the fundamental problems (FPsx)–(FPsy). The only difference from the textured surface is that the solid structures within the interface cell represent the porous material. Consequently, all the elements in

$\unicode[STIX]{x1D647}$ are determined by solving the fundamental problems (FPsx)–(FPsy). The only difference from the textured surface is that the solid structures within the interface cell represent the porous material. Consequently, all the elements in ![]() $\unicode[STIX]{x1D647}$ and

$\unicode[STIX]{x1D647}$ and ![]() $\unicode[STIX]{x1D648}$ can be obtained through expressions (2.9) and (2.20), respectively. The interior permeability tensor (

$\unicode[STIX]{x1D648}$ can be obtained through expressions (2.9) and (2.20), respectively. The interior permeability tensor (![]() $\unicode[STIX]{x1D646}$) of the porous medium is computed through a set of Stokes equations in a bulk unit cell (Whitaker Reference Whitaker1998; Mei & Vernescu Reference Mei and Vernescu2010).

$\unicode[STIX]{x1D646}$) of the porous medium is computed through a set of Stokes equations in a bulk unit cell (Whitaker Reference Whitaker1998; Mei & Vernescu Reference Mei and Vernescu2010).

3.2 Pressure boundary condition

The pressure boundary condition for a general 3-D porous surface, obeying assumptions (A1)–(A3), is obtained through a balance between the normal free-fluid stress and the stress from the porous material, i.e.

The normal stress from the porous material consists of the pore pressure ![]() $p^{-}$ and two friction coefficients,

$p^{-}$ and two friction coefficients, ![]() $\boldsymbol{f}^{(1)}$ and

$\boldsymbol{f}^{(1)}$ and ![]() $\boldsymbol{f}^{(2)}$. The coefficient

$\boldsymbol{f}^{(2)}$. The coefficient ![]() $\boldsymbol{f}^{(1)}$ describes the interface normal resistance that the Darcy flow

$\boldsymbol{f}^{(1)}$ describes the interface normal resistance that the Darcy flow ![]() $\boldsymbol{u}^{-}$ must overcome to transport mass and momentum across and along the interface. The coefficient

$\boldsymbol{u}^{-}$ must overcome to transport mass and momentum across and along the interface. The coefficient ![]() $\boldsymbol{f}^{(2)}$ provides the interface normal force due to the slip velocity near the interface. It exists only for anisotropic and misaligned surface geometries, similarly to the stabilisation parameter (see (1.2)) derived by Marciniak-Czochra & Mikelić (Reference Marciniak-Czochra and Mikelić2012) and Carraro et al. (Reference Carraro, Marušić-Paloka and Mikelić2018). Misalignment in this context is a difference between the principal axes of the pore geometry and the coordinate axes.

$\boldsymbol{f}^{(2)}$ provides the interface normal force due to the slip velocity near the interface. It exists only for anisotropic and misaligned surface geometries, similarly to the stabilisation parameter (see (1.2)) derived by Marciniak-Czochra & Mikelić (Reference Marciniak-Czochra and Mikelić2012) and Carraro et al. (Reference Carraro, Marušić-Paloka and Mikelić2018). Misalignment in this context is a difference between the principal axes of the pore geometry and the coordinate axes.

The friction coefficients are again determined by considering the interface cell (figure 8b). The difference from the textured surface is the existence of the pore pressure resulting in an additional forcing term in the governing equations of the interface cell, yielding

Darcy’s law is valid only in the porous material, therefore the pressure gradient forcing is considered only below the interface. A 1-D Heaviside step function ![]() $H(\hat{z})$ is used to distinguish between regions above and below the interface. Boundary conditions for the interface cell are the same as for the equations (2.2)–(2.3) except at the bottom of the domain, where we impose the interior solution corresponding to the Darcy flow due to the same pressure gradient

$H(\hat{z})$ is used to distinguish between regions above and below the interface. Boundary conditions for the interface cell are the same as for the equations (2.2)–(2.3) except at the bottom of the domain, where we impose the interior solution corresponding to the Darcy flow due to the same pressure gradient ![]() $\unicode[STIX]{x1D735}p^{-}$ (Whitaker Reference Whitaker1998; Mei & Vernescu Reference Mei and Vernescu2010; Lācis & Bagheri Reference Lācis and Bagheri2016).

$\unicode[STIX]{x1D735}p^{-}$ (Whitaker Reference Whitaker1998; Mei & Vernescu Reference Mei and Vernescu2010; Lācis & Bagheri Reference Lācis and Bagheri2016).

Then, we use the linearity assumption (A1) and write the pressure as

Here, ![]() $\hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}$ and

$\hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}$ and ![]() $\hat{\boldsymbol{r}}_{p}$ are the response operators related to the shear stress

$\hat{\boldsymbol{r}}_{p}$ are the response operators related to the shear stress ![]() $\unicode[STIX]{x1D749}$ and the pressure gradient

$\unicode[STIX]{x1D749}$ and the pressure gradient ![]() $\unicode[STIX]{x1D735}p^{-}$, respectively. This expression is expanded as

$\unicode[STIX]{x1D735}p^{-}$, respectively. This expression is expanded as

$$\begin{eqnarray}\displaystyle \hat{p} & = & \displaystyle \hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }(\unicode[STIX]{x1D70F}_{x}\boldsymbol{e}_{x}+\unicode[STIX]{x1D70F}_{y}\boldsymbol{e}_{y})-\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }(\unicode[STIX]{x2202}_{x}p^{-}\boldsymbol{e}_{x}+\unicode[STIX]{x2202}_{y}p^{-}\boldsymbol{e}_{y}+\unicode[STIX]{x2202}_{z}p^{-}\boldsymbol{e}_{z})\nonumber\\ \displaystyle & = & \displaystyle (\hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\boldsymbol{e}_{x})\unicode[STIX]{x1D70F}_{x}+(\hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\boldsymbol{e}_{y})\unicode[STIX]{x1D70F}_{y}-(\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }\boldsymbol{e}_{x})\unicode[STIX]{x2202}_{x}p-(\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }\boldsymbol{e}_{y})\unicode[STIX]{x2202}_{y}p-(\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }\boldsymbol{e}_{z})\unicode[STIX]{x2202}_{z}p\nonumber\\ \displaystyle & = & \displaystyle \hat{p}^{(\unicode[STIX]{x1D70F}x)}\frac{\unicode[STIX]{x1D70F}_{x}}{\unicode[STIX]{x1D707}}+\hat{p}^{(\unicode[STIX]{x1D70F}y)}\frac{\unicode[STIX]{x1D70F}_{y}}{\unicode[STIX]{x1D707}}-\hat{p}^{(px)}\frac{\unicode[STIX]{x2202}_{x}p}{\unicode[STIX]{x1D707}}-\hat{p}^{(py)}\frac{\unicode[STIX]{x2202}_{y}p}{\unicode[STIX]{x1D707}}-\hat{p}^{(pz)}\frac{\unicode[STIX]{x2202}_{z}p}{\unicode[STIX]{x1D707}},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \hat{p} & = & \displaystyle \hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }(\unicode[STIX]{x1D70F}_{x}\boldsymbol{e}_{x}+\unicode[STIX]{x1D70F}_{y}\boldsymbol{e}_{y})-\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }(\unicode[STIX]{x2202}_{x}p^{-}\boldsymbol{e}_{x}+\unicode[STIX]{x2202}_{y}p^{-}\boldsymbol{e}_{y}+\unicode[STIX]{x2202}_{z}p^{-}\boldsymbol{e}_{z})\nonumber\\ \displaystyle & = & \displaystyle (\hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\boldsymbol{e}_{x})\unicode[STIX]{x1D70F}_{x}+(\hat{\boldsymbol{r}}_{\unicode[STIX]{x1D70F}}\boldsymbol{\cdot }\boldsymbol{e}_{y})\unicode[STIX]{x1D70F}_{y}-(\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }\boldsymbol{e}_{x})\unicode[STIX]{x2202}_{x}p-(\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }\boldsymbol{e}_{y})\unicode[STIX]{x2202}_{y}p-(\hat{\boldsymbol{r}}_{p}\boldsymbol{\cdot }\boldsymbol{e}_{z})\unicode[STIX]{x2202}_{z}p\nonumber\\ \displaystyle & = & \displaystyle \hat{p}^{(\unicode[STIX]{x1D70F}x)}\frac{\unicode[STIX]{x1D70F}_{x}}{\unicode[STIX]{x1D707}}+\hat{p}^{(\unicode[STIX]{x1D70F}y)}\frac{\unicode[STIX]{x1D70F}_{y}}{\unicode[STIX]{x1D707}}-\hat{p}^{(px)}\frac{\unicode[STIX]{x2202}_{x}p}{\unicode[STIX]{x1D707}}-\hat{p}^{(py)}\frac{\unicode[STIX]{x2202}_{y}p}{\unicode[STIX]{x1D707}}-\hat{p}^{(pz)}\frac{\unicode[STIX]{x2202}_{z}p}{\unicode[STIX]{x1D707}},\end{eqnarray}$$where we have defined

and

Note that ![]() $\hat{p}^{(\unicode[STIX]{x1D70F}x)}$ and

$\hat{p}^{(\unicode[STIX]{x1D70F}x)}$ and ![]() $\hat{p}^{(\unicode[STIX]{x1D70F}y)}$ are the pressure fields appearing in the fundamental problems (FPsx), (FPsy); they are the pressure responses to the interface shear forcing in the

$\hat{p}^{(\unicode[STIX]{x1D70F}y)}$ are the pressure fields appearing in the fundamental problems (FPsx), (FPsy); they are the pressure responses to the interface shear forcing in the ![]() $x$ and

$x$ and ![]() $y$ directions, respectively. Furthermore,

$y$ directions, respectively. Furthermore, ![]() $\hat{p}^{(px)}$,

$\hat{p}^{(px)}$, ![]() $\hat{p}^{(py)}$ and

$\hat{p}^{(py)}$ and ![]() $\hat{p}^{(pz)}$ are the pressure fields associated with the following three fundamental problems

$\hat{p}^{(pz)}$ are the pressure fields associated with the following three fundamental problems

These problems describe the response to the pressure gradient forcing along the three coordinates and have been previously derived by Lācis & Bagheri (Reference Lācis and Bagheri2016) using formal multi-scale expansion. Keep in mind that in (FPpx)–(FPpz) the fields ![]() $\hat{\boldsymbol{u}}^{(px)}$,

$\hat{\boldsymbol{u}}^{(px)}$, ![]() $\hat{\boldsymbol{u}}^{(py)}$ and

$\hat{\boldsymbol{u}}^{(py)}$ and ![]() $\hat{\boldsymbol{u}}^{(pz)}$ have units of m

$\hat{\boldsymbol{u}}^{(pz)}$ have units of m![]() $^{2}$, similar to the permeability of a porous medium, see table 2.

$^{2}$, similar to the permeability of a porous medium, see table 2.

Table 2. Summary of pressure and velocity fields with the corresponding units.

From the five fundamental problems (FPsx)–(FPpz), we can determine the resistance vectors ![]() $\boldsymbol{f}^{(1)}$ and

$\boldsymbol{f}^{(1)}$ and ![]() $\boldsymbol{f}^{(2)}$ for the pressure condition (3.3). We start with

$\boldsymbol{f}^{(2)}$ for the pressure condition (3.3). We start with ![]() $\boldsymbol{f}^{(2)}$. It generates a pressure jump

$\boldsymbol{f}^{(2)}$. It generates a pressure jump

where ![]() $\tilde{\boldsymbol{f}}^{(2)}=\boldsymbol{f}^{(2)}\boldsymbol{\cdot }\unicode[STIX]{x1D647}$. The pressure field response (3.7) due to the shear is

$\tilde{\boldsymbol{f}}^{(2)}=\boldsymbol{f}^{(2)}\boldsymbol{\cdot }\unicode[STIX]{x1D647}$. The pressure field response (3.7) due to the shear is

Then, we need to relate the effective pressures in porous and free-fluid regions to the linear pressure responses ![]() $\hat{p}^{(\unicode[STIX]{x1D70F}x)}$ and

$\hat{p}^{(\unicode[STIX]{x1D70F}x)}$ and ![]() $\hat{p}^{(\unicode[STIX]{x1D70F}y)}$ in the interface cell. For the velocity, a simple plane average at the interface (2.7) is sufficient. However, for the pressure condition a single pressure value will not provide the necessary information about the pressure jump. Therefore, we define the effective pressure in the interior and free fluid as

$\hat{p}^{(\unicode[STIX]{x1D70F}y)}$ in the interface cell. For the velocity, a simple plane average at the interface (2.7) is sufficient. However, for the pressure condition a single pressure value will not provide the necessary information about the pressure jump. Therefore, we define the effective pressure in the interior and free fluid as

with ![]() $V_{f}$ corresponding to the fluid volume in the integration region. To neglect any transition effects of the pressure field near the interface, these volume averages are taken at the bottom and at the top of the interface cell. In this way, the averaging operation is sufficiently far away from the interface to obtain a representative pressure value for the interior and the free fluid.

$V_{f}$ corresponding to the fluid volume in the integration region. To neglect any transition effects of the pressure field near the interface, these volume averages are taken at the bottom and at the top of the interface cell. In this way, the averaging operation is sufficiently far away from the interface to obtain a representative pressure value for the interior and the free fluid.

Now we insert the pressure field decomposition (3.11) into (3.12) and we take the difference between the interior pressure and the free-fluid pressure,

By comparing the above to (3.10), we obtain

We emphasise that ![]() $\hat{p}^{(\unicode[STIX]{x1D70F}x)}$ and

$\hat{p}^{(\unicode[STIX]{x1D70F}x)}$ and ![]() $\hat{p}^{(\unicode[STIX]{x1D70F}y)}$ are pressure fields in the interface cell generated due to shear stress forcing (figure 8c,d) and can be computed from the fundamental problems (FPsx), (FPsy). Finally, the resistance vector

$\hat{p}^{(\unicode[STIX]{x1D70F}y)}$ are pressure fields in the interface cell generated due to shear stress forcing (figure 8c,d) and can be computed from the fundamental problems (FPsx), (FPsy). Finally, the resistance vector ![]() $\boldsymbol{f}^{(2)}$, appearing in the front of the slip velocity in (3.3), is obtained from

$\boldsymbol{f}^{(2)}$, appearing in the front of the slip velocity in (3.3), is obtained from

The procedure to get this friction coefficient is similar to the one reported by Marciniak-Czochra & Mikelić (Reference Marciniak-Czochra and Mikelić2012) and Carraro et al. (Reference Carraro, Goll, Marciniak-Czochra and Mikelić2013).

Figure 9. A lid-driven cavity with a porous bed. (a) Shows the dimensions of the computational domain. The dashed vertical line indicates the streamwise position where the DNS and the effective models are compared. (b) Depicts an enlarged view of the porous materials showing the microscale geometry of the three test cases considered. The interface is located at a distance of ![]() $0.1\ell$ above the solid structure. (c) Shows the domain for the continuum description.

$0.1\ell$ above the solid structure. (c) Shows the domain for the continuum description.

We turn our attention to the resistance coefficient ![]() $\boldsymbol{f}^{(1)}$. The pressure jump condition (3.3) due to the Darcy velocity is

$\boldsymbol{f}^{(1)}$. The pressure jump condition (3.3) due to the Darcy velocity is

where ![]() $\tilde{\boldsymbol{f}}^{(1)}=-\boldsymbol{f}^{(1)}\boldsymbol{\cdot }\unicode[STIX]{x1D646}$. The pressure field response (3.7), corresponding to the pore pressure gradient forcing, is

$\tilde{\boldsymbol{f}}^{(1)}=-\boldsymbol{f}^{(1)}\boldsymbol{\cdot }\unicode[STIX]{x1D646}$. The pressure field response (3.7), corresponding to the pore pressure gradient forcing, is

Using (3.12), we can express the pressure jump as

$$\begin{eqnarray}\displaystyle p-p^{-} & = & \displaystyle \langle \hat{p}\rangle ^{+}-\langle \hat{p}\rangle ^{-}=\left(\langle \hat{p}^{(px)}\rangle ^{-}-\langle \hat{p}^{(px)}\rangle ^{+}\right)\frac{\unicode[STIX]{x2202}_{x}p^{-}}{\unicode[STIX]{x1D707}}\nonumber\\ \displaystyle & & \displaystyle +\,\left(\langle \hat{p}^{(py)}\rangle ^{-}-\langle \hat{p}^{(py)}\rangle ^{+}\right)\frac{\unicode[STIX]{x2202}_{y}p^{-}}{\unicode[STIX]{x1D707}}+\left(\langle \hat{p}^{(pz)}\rangle ^{-}-\langle \hat{p}^{(pz)}\rangle ^{+}\right)\frac{\unicode[STIX]{x2202}_{z}p^{-}}{\unicode[STIX]{x1D707}}.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle p-p^{-} & = & \displaystyle \langle \hat{p}\rangle ^{+}-\langle \hat{p}\rangle ^{-}=\left(\langle \hat{p}^{(px)}\rangle ^{-}-\langle \hat{p}^{(px)}\rangle ^{+}\right)\frac{\unicode[STIX]{x2202}_{x}p^{-}}{\unicode[STIX]{x1D707}}\nonumber\\ \displaystyle & & \displaystyle +\,\left(\langle \hat{p}^{(py)}\rangle ^{-}-\langle \hat{p}^{(py)}\rangle ^{+}\right)\frac{\unicode[STIX]{x2202}_{y}p^{-}}{\unicode[STIX]{x1D707}}+\left(\langle \hat{p}^{(pz)}\rangle ^{-}-\langle \hat{p}^{(pz)}\rangle ^{+}\right)\frac{\unicode[STIX]{x2202}_{z}p^{-}}{\unicode[STIX]{x1D707}}.\end{eqnarray}$$The comparison of (3.16) and (3.18) yields

We recall that the pressure fields in the interface cell are generated by the pore pressure gradient forcing below the interface (figure 8e–g), and they are computed from fundamental problems (FPpx)–(FPpz). The final form of the friction coefficient is,

This friction coefficient term, which to the best of authors’ knowledge is reported for the first time, is particularly important for capturing the correct pressure jump across the interface for layered problems, as we demonstrate in the next section.

3.3 Validation of the TR model for porous surfaces

We consider the same flow configuration as in § 2.3, but we replace the bottom textured wall with a porous surface, see figure 9(a). The porous medium consists of a periodic distribution of solid inclusions with a characteristic length scale ![]() $\ell$ (see

$\ell$ (see ![]() $\ell \times \ell$ square in figure 9a). The width and the height of the cavity are

$\ell \times \ell$ square in figure 9a). The width and the height of the cavity are ![]() $H$, while the depth of the porous material is

$H$, while the depth of the porous material is ![]() $H/2$. The scale separation parameter is again

$H/2$. The scale separation parameter is again ![]() $\unicode[STIX]{x1D716}=\ell /H=0.1$. The flow reaches the interior seepage velocity quickly (Lācis & Bagheri Reference Lācis and Bagheri2016; Lācis, Zampogna & Bagheri Reference Lācis, Zampogna and Bagheri2017); therefore, a porous material containing only five repeating structures in depth is sufficient for using Darcy’s equation in the interior.

$\unicode[STIX]{x1D716}=\ell /H=0.1$. The flow reaches the interior seepage velocity quickly (Lācis & Bagheri Reference Lācis and Bagheri2016; Lācis, Zampogna & Bagheri Reference Lācis, Zampogna and Bagheri2017); therefore, a porous material containing only five repeating structures in depth is sufficient for using Darcy’s equation in the interior.

To demonstrate the generality of the TR model, we consider three kinds of porous geometries, see figure 9(b). Configuration (i) has circular solid inclusions, which results in an isotropic porous medium. The anisotropic elliptic inclusions considered in configuration (ii) are the same as investigated by Carraro et al. (Reference Carraro, Goll, Marciniak-Czochra and Mikelić2013). The last geometry (iii) has isotropic circular inclusions with the interface layer different from the interior. The porosity and geometrical details of the three configurations are listed in table 3.

We carry out fully resolved DNS. For each configuration, the mean over an ensemble of ![]() $50$ shifted porous beds is computed. The free flow is similar to the flow in the lid-driven cavity with the textured bottom (§ 2.3) except that there are mass fluxes in and out of the porous material. The averaged DNS will be compared to effective representations of the porous bed (figure 9c). Since the flow configuration is similar to the one reported in § 2.3, we will again neglect

$50$ shifted porous beds is computed. The free flow is similar to the flow in the lid-driven cavity with the textured bottom (§ 2.3) except that there are mass fluxes in and out of the porous material. The averaged DNS will be compared to effective representations of the porous bed (figure 9c). Since the flow configuration is similar to the one reported in § 2.3, we will again neglect ![]() $\unicode[STIX]{x2202}_{x}u_{z}$ in the effective simulations. We have checked that

$\unicode[STIX]{x2202}_{x}u_{z}$ in the effective simulations. We have checked that ![]() $\unicode[STIX]{x2202}_{x}u_{z}$ is much smaller than

$\unicode[STIX]{x2202}_{x}u_{z}$ is much smaller than ![]() $\unicode[STIX]{x2202}_{z}u_{x}$. Within the porous domain, we employ Darcy’s law, where the only unknown quantity is the pore pressure

$\unicode[STIX]{x2202}_{z}u_{x}$. Within the porous domain, we employ Darcy’s law, where the only unknown quantity is the pore pressure ![]() $p^{-}$. The interior permeability tensors (